Agile

VABus/TCP

Communication module CM-VABus/TCP

Frequency inverter 230 V / 400 V

CONTENTS

1 GENERAL INFORMATION ABOUT THE DOCUMENTATION 6

1.1 This document 6

1.2 Warranty and liability 7

1.3 Obligation 7

1.4 Copyright 7

1.5 Storage 7

2 GENERAL SAFETY INSTRUCTIONS AND INFORMATION ON USE 8

2.1 Terminology 8

2.2 Designated use 9

2.3 Misuse 9

2.3.1 Explosion protection 9

2.4 Residual risks 10

2.5 Safety and warning signs at frequency inverter 10

2.6 Warning information and symbols used in the user manual 11

2.6.1 Hazard classes 11

2.6.2 Hazard symbols 11

2.6.3 Prohibition signs 11

2.6.4 Personal safety equipment 11

2.6.5 Recycling 12

2.6.6 Grounding symbol 12

2.6.7 ESD symbol 12

2.6.8 Information signs 12

2.6.9 Font style in documentation 12

2.7 Directives and guidelines to be adhered to by the operator 12

2.8 Operator's general plant documentation 12

2.9 Operator's/operating staff's responsibilities 13

2.9.1 Selection and qualification of staff 13

2.9.2 General work safety 13

2.10 Organizational measures 13

2.10.1 General 13

2.10.2 Use in combination with third-party products 13

2.10.3 Transport and Storage 14

2.10.4 Handling and installation 14

2.10.5 Electrical connections 14

2.10.6 Safe operation 14

2.10.7 Maintenance and service/troubleshooting 15

2.10.8 Final decommissioning 16

12/13

Agile

VABus/TCP 3

3 INTRODUCTION 17

3.1 Supported configurations 20

3.2 Initialization time 20

4 FIRST COMMISSIONING 20

5 COMMUNICATION OPTIONS 21

5.1 Control software VPlus: 21

6 ASSEMBLY/DISASSEMBLY OF COMMUNICATION MODULE 22

6.1 Assembly 22

6.2 Disassembly 23

7 VABUS/TCP INTERFACE 24

7.1 Communication modules 25

7.1.1 Installation instructions 25

7.2 Setup 26

7.3 TCP/IP address & subnet 26

7.3.1 Network without DHCP server: 26

7.3.2 Network with DHCP server: 26

7.4 TCP/IP configuration 27

7.4.1 TCP configurations tool 27

7.4.2 Parameter settings with VPlus 31

7.5 Operating behavior in the case of a communication error 33

8 PROTOCOL 34

8.1 Telegram types 35

8.1.1 Data types 35

8.1.2 Send Request / Enquiry Telegram 36

8.1.3 Setting Request / Select Telegram 37

8.1.4 System bus Node-ID 38

8.2 Telegram check 40

8.3 Timeout control 41

8.4 Resetting errors 41

9 PARAMETER ACCESS 42

9.1 Handling of datasets / cyclic writing of parameters 42

9.2 Handling index parameters / cyclic writing 43

9.2.1 Example: Writing of index parameters 43

9.2.2 Example: Reading of index parameters 44

4

Agile

VABus/TCP 12/13

10 EXAMPLE MESSA GES VA BUS/TCP 45

10.1 Reading parameters 45

10.2 Writing parameters 46

11 CONTROL OF FREQUENCY INVERTER 49

11.1 Control via contacts/remote contacts 50

11.1.1 Device state machine 52

11.2 Control via state machine 53

11.2.1 Statemachine diagram 55

11.3 Behavior in the case of a quick stop 57

11.3.1 Behavior in the case of transition 5 (disable operation) 58

11.3.2 Reference value/actual value 59

11.3.3 Example sequence 60

12 ACTUAL VALUES 61

13 PARAMETER LIST 62

13.1 Actual values (Menu “Actual ”) 62

13.2 Parameters (Menu “Para”) 63

14 APPENDIX 64

14.1 List of control words 64

14.2 List of status words 64

14.3 Warning messages 65

14.4 Application warning messages 66

14.5 Error messages 67

14.6 Conversions 67

14.6.1 Speed [1/min] into frequency [Hz] 67

14.6.2 Frequency [Hz] into speed [1/min] 67

14.7 ASCII table (0x00 – 0x7F) 68

INDEX 69

12/13

Agile

VABus/TCP 5

1 General Information about the Documentation

Compliance with the documentation is required to ensure safe operation of the frequency inverter. BONFIGLIOLI VECTRON GmbH shall not be held liable for any damage

In case any problems occur which are not covered by the documentation sufficiently,

please contact the manufacturer.

For better clarity, the documentation of the frequency inverter is structured according to the customer-specific requirements.

The present manual was created in the German language. The German manual is the original version.

Other language versions are translations.

Quick Start Guide

The “Quick Start Guide” describes the basic steps required for mec hanical and electrical installa tion of

the frequency i nverte r. The guide d comm issi oning s up ports yo u in t he s electi on o f nece ssary para meters and the configuration of the software of the frequency inverter.

User manual

The user manual documents the complete functionality of the frequency inverter. The parameters

required for special purposes, for adj ustment to the application and the numerous a dditional functio ns

are described in detail.

Separate user manuals are supplied for optio nal components for the frequency inverter. These manuals complement the operating instructions and the “Quick Start Guide” for the frequency inverter.

Application manual

The application manual complements the documentation to ensure goal-directed installation and

commissioning of the frequency inverter. Information on various t opics in connection with the use of

the frequency inverter is described in context with the specific application.

1.1 This document

This document descr ibes the communicat ion via the VABus/TCP protocol wit h frequency inverters of

Agile

the

inverters can be customized to meet the customer' s specific requirements, including applications requiring high functionality and dynamism.

series of devices. Thanks to the modular hardware and software structure, the frequency

WARNING

caused by any non-compliance with the documentation.

6

Agile

VABus/TCP 12/13

1.2 Warranty and liability

BONFIGLIOLI VECTRON GmbH would like to point out that the contents of this user manual do not

form part of any previous or existing agreement, assurance or legal relationship. Neither are they

intended to supplement or replace such agreements, a ssurances or le gal re lations hips. Any obligations

of the manufacturer shall solely be based on the relevant purchase agreement which also includes the

complete and solely valid warranty stipulations. These contractual warranty provisions are neither

extended nor limited by the specifications contained in this documentation.

The manufacturer reserves the right to correct or am end the specificat ions, product informa tion and

omissions in these operating instructions w ithout notice. The manufacturer s hall not be liable for any

damage, injuries or costs which may be caused for the aforementioned reasons.

Furthermore, BONFIGLIOLI VECTRON GmbH excludes any warranty/liability claims for any personal

and/or material damage if such damage is due to one or more of the following causes:

• inappropriate use of the frequency inverter,

• non-compliance with the instructions, warnings and prohibitions contained in the documentation,

• unauthorized modifications of the frequency inverter,

• insufficient monitoring of parts of the machine/plant which are subject to wear,

• repair work at the machine/plant not carried out properly or in time,

• catastrophes by external impact and force majeure.

1.3 Obligation

This user manual must be read before commissioning and complied with. Anybody entrusted with

tasks in connection with the

• transport,

• assembly,

• installation of the frequency inverter and

• operation of the frequency inverter

must have read a nd unde rstood the user man ual and, i n parti cular, the safet y instr uctions i n order to

prevent personal and material losses.

1.4 Copyright

In accordance with applicable law a gainst unfair competition, this user manual is a certificate. Any

copyrights relating to it shall remain with

BONFIGLIOLI VECTRON GmbH

Europark Fichtenhain B6

47807 Krefeld

Germany

This user manual is intended for the operator of the frequency inverter. Any disclosure or copying of

this document, exploitation and communication of its contents (as hardcopy or electronically) shall be

forbidden, unless permitted expressly.

Any non-compliance will constitute an offense against the copyright law dated 09 September 1965,

the law against unfair compe tition and the Civil Code and may result in claims for damages. All ri ghts

relating to patent, utility model or design registration reserved.

1.5 Storage

The documentati on form an integral part of the frequency inverter. It must be stored such that it is

accessible to operating staff at all times. If the frequency inverter is sold o n to other users, then this

user manual must also be handed over.

12/13

Agile

VABus/TCP 7

2 General safety instructions and information on use

The chapter "Ge neral safet y instructions and informat ion on use" co ntains gener al safety inst ructions

for the Operator and the Operating Staff. At the beginning of certain main chapters, some safety instructions are included whi ch appl y to all w ork de scrib ed in t he rele vant c hapter. Special wor k-specific

safety instructions are provided before each safety-relevant work ste p.

2.1 Terminology

According to the documentation, different activities must be performed by certain persons with certa in

qualifications.

The groups of persons with the required qualification are defined as follows:

Operator

This is the entre preneur/company w ho/which operate s the frequency inve rter and uses it a s per the

specifications or has it operated by qualified and instructed staff.

Operating staff

The term Operating Staff covers persons instructed by the Operator of the frequency inverter and

assigned the task of operating the frequency inverter.

Skilled Personnel

The term Skilled Personnel covers staff that are assigned specia l tasks by the Operator of the frequency inverter, e .g. install ation, maint enance and s ervice/re pair and tro ubleshoo ting. Based o n their

qualification and/or know-how, Skilled Personnel must be capable of identifying defects and assessing functions.

Qualified electrician

The term Qualified Electrician covers qualified and tra ined staff that have special technical know-how

and experience with electrical installations . In addition , Qualified Electri cians must be familiar with the

applicable standards and regulations, they must be able to assess the assigned tasks properly and

identify and eliminate potential hazards.

Instructed person

The term Instru cted Person covers sta ff that are instructed and trained about/in the assig ned tasks

and the potential hazards that might result from inappropria te behavior. In addition, instructed persons must have been instructed in the required protection provisions, protective m easures, the applicable directives, accident prevention regulations as well as the operating conditions and have their

qualification verified.

Expert

The term Expert covers qualified and trained staff that have special te chnical know-how and experience relating to the frequency inverter. Experts must be familiar with the applicable government work

safety directives, accident prevention regulations, gui delines and genera lly accepted rules of tech nology in order to assess the operationally safe condition of the frequency inverter.

8

Agile

VABus/TCP 12/13

2.2 Designated use

The frequency inverter is designed according to the state of the art and recognized safety regulations.

The frequency inverters are electrical drive comp onents intended for installa tion in industrial plants or

machines. Commissioning and start of operation is not allowed until it has be en verified that the machine meets the requirements of the EC Machinery Directive 2006/42/EC and DIN EN 60204-1.

The frequency inverters meet the requirements of the low voltage directive 2006/95/EEC and DIN

EN 61800-5-1. CE-labeling is based on these standards. Responsibility for comp liance with the EMC

Directive 2004/108/EC lies with the operator. Frequency inverters are only available at specialized

dealers and are exclusively intended for commercial use as per EN 61000-3-2.

No capacitive loads may be connected to the frequency inverter.

The technical dat a, connection sp ecifications a nd informati on on ambient co nditions are ind icated on

the rating plate and in the documentation and must be complied with at all times.

2.3 Misuse

Any use other than that described in "Designated use" shall not be permissible and shall be considered as misuse.

For, example, the machine/plant must not be operated

• by uninstructed staff,

• while it is not in perfect condition,

• without protection enclosur e (e.g. covers),

• without safety equipment or with safety equipment deactivated.

The manufacturer shall not be he ld liab le for any d am age r esulting fr om suc h misuse . The p lant ope rator shall bear the sole risk.

2.3.1 Explosion protection

The frequency inverter is an IP 20 protection class de vice. For this reason, use of the device in explosive atmospheres is not permitted.

12/13

Agile

VABus/TCP 9

2.4 Residual risks

Residual risks are special hazards involved in handli ng of the freque ncy in verter w hich can not be eliminated despite the safety-compliant design of the device. R emaining hazards are not obvious and can

be a source of possible injury or health damage.

Typical residual hazards include:

Electrical hazard

Danger of contact with energized components due to a defect, opened covers or enclosures or im-

proper working on electrical equipment.

Danger of contact wi th energized components in fre quency inverter if no external d isconnection de-

vice was installed by the operator.

Electrostatic charging

Touching electronic components bears the risk of electrostatic discharg es.

Thermal hazards

Risk of accidents by hot machine/plant surfaces, e.g. heat sink, transformer, fuse or sine filter.

Charged capacitors in DC link

The DC link may have dangerous voltage levels even up to three minutes after shutdown.

Danger of equipment falling down/over, e.g. during transport

Center of gravity is not the middle of the electric cabinet modules.

2.5 Safety and warning signs at frequency inverter

Comply with all safety instructions and danger informa tion provided on the frequency inverter.

• Safety information and warnings on the frequency inverter must not be removed.

10

Agile

VABus/TCP 12/13

risk of death or serious injury if not

risk of death or serious in jury if

risk of minor or moderate physical

Symbol

Meaning

Symbol

Meaning

Symbol

Meaning

Symbol

Meaning

2.6 Warning information and symbols used in the user manual

2.6.1 Hazard classes

The following hazard identifications and symbols are used to mark particularly important information:

DANGER

Identification of immediate threat holding a high

avoided.

WARNING

Identification of immediate threat holding a medium

not avoided.

CAUTION

Identification of immediate threat holding a low

injury if not avoided.

NOTE

Identification of a threat holding a risk of material damage if not avoided.

2.6.2 Hazard symbols

General hazard

Electrical voltage

2.6.3 Prohibition signs

No switching; it is forbidden to switch the machine/plant, assembly on

Suspended load

Hot surfaces

2.6.4 Personal safety equipment

Wear body protection

12/13

Agile

VABus/TCP 11

2.6.5 Recycling

Symbol

Meaning

to avoid waste, collect all materia ls for

Symbol

Meaning

Symbol

Meaning

Symbol

Meaning

Example

Font style

Use

1234

bold

Representation of parameter numbers

Parameter

italic, Font

Times New Roman

Representation of parameter names

P.1234

bold

Representation of parameter numbers without name, e.g. in

formulas

Q.1234

bold

Representation of source numbers

Recycling,

reuse

2.6.6 Grounding symbol

Ground connection

2.6.7 ESD symbol

ESD: Electrostatic Discharge (can damage components and assemblies)

2.6.8 Information signs

Tips and informat ion making using the frequency

inverter easier.

2.6.9 Font style in documentation

2.7 Directives and guidelines to be adhered to by the operator

The operator must follow the following directives and regulations:

• Ensure that the applicable workplace-related accident prevention regulations as well as other appli-

cable national regulation are accessible to the staff.

• An authorized person must ensure, before using the frequency inverter, that the devi ce is used in

compliance with its designated use and that all safety requirements are met.

• Additionally, comply with the applicable laws, re gulations and directives of the country in whic h the

frequency inverter is used.

Any additional guidelines and directives that ma y be required additionally shall be de fined by the operator of the machine/plant considering the operating environment.

2.8 Operator's general plant documentation

• In addit ion to the user manual, the operator should issue separate internal operating instructions

for the frequency inverter. The user manual of the frequency inverter must be included in the user

manual of the whole plant.

12

Agile

VABus/TCP 12/13

2.9 Operator's/operating staff's responsibilities

2.9.1 Selection and qualification of staff

• Any work on the frequency inverter may only be carried o ut by qualified technical sta ff. The staff

must not be under the influence of any drugs. Note the minimum age required by law. Define the

staff's responsibility in connection with all work on the frequency inverter clearly.

• Work on the electri cal components may only be performed by a qualified electrician according to

the applicable rules of electrical engineering.

• The operating staff must be trained for the relevant work to be performed.

2.9.2 General work safety

In addition to the user manual of the machine/plant, any applicable legal or other regulations

relating to accident prevention and environmental protection must be complied with. The staff

must be instructed accordingly.

Such regulations and/or requirements may include, for example, handl ing of hazardous media and

materials or provision/use of personal protective e quipment.

In addition to this user manual, issue any additional directives that may be required to meet spe-

cific operating requirements, including supervision and reporting requirements, e.g . dir ectives relating to work organization, workflow and employed sta ff.

Unless approved of expressly by the manufacturer, do not modify the frequency inverter in any

way, including addition of attachments or retrofits.

Only use the frequency inverter if the rated connection and setup values specified by the manu-

facturer are met.

• Provide appropriate tools as may be required for performing all work on the frequency inverter

properly.

2.10 Organizational measures

2.10.1 General

Train your staff in the handling and use of the frequency inverter and the machine/plant as well

as the risks involved.

Use of any individual parts or components of the frequency inverter in other p arts of the opera-

tor's machine/plant is prohibited.

• Optional components for the frequency inverter must be used in accordance with their designated

use and in compliance with the rele vant documentation.

2.10.2 Use in combination with third-party products

• Ple ase note that BONFIGLIOLI V ECTRON GmbH will not accept any responsibility for com patibility

with third-party products (e.g. motors, cables or filters).

• In order t o enable optimum system compatibility, BONFIGLIOLI VECTRON Gm bH offers compo-

nents facilitating commissioning and providing optimum synchronization of the machine/plant

parts in operation.

• If you use the frequency inverter in combination with third-party products, you do this at your

own risk.

12/13

Agile

VABus/TCP 13

2.10.3 Transport and S torage

• The frequency i nverters m ust be transpo rted and stor ed in an app ropriate wa y. During tr ansport

and storage the devices must remain in their original packaging.

• The unit s ma y o nly be sto r ed in dr y r oom s whi ch a re prot ect ed ag ai nst d us t a nd moi stur e a nd ar e

exposed to small temperature deviations only. The requirements of DIN EN 60721-3-1 for storage,

DIN EN 60721-3-2 for transport and labeling on the packaging must be met.

• The duration of storage without connection to the permissible nominal voltage may not exceed

one year.

2.10.4 Handling and installation

Do not comm i ssion any damaged or de s troyed components.

Prevent any mechanical overloading of t he frequency inver ter. Do not bend any components a nd

never change the isolation distances.

Do not touch any electronic construction elements and cont acts. The frequency inverter i s

equipped with components which are sensitive to electrostatic energy and can be damaged if

handled improperly. Any use of damaged or destroyed components will endanger the machine/plant safety and shall be considered as a non-compliance with the applicable standards.

Only install the frequency inverter in a suitable operating environment. The frequency inverter is

exclusively designed for installat ion in industrial environments.

• If seals are removed from the case, this can result in the warranty becoming null and void.

2.10.5 Electrical connections

The five safety rules must be complied with.

Never touch live terminals. The DC link may have dangerous voltage levels even up to three

minutes after shutdown.

When performing any work on/with the frequency inverter, alwa ys comply with the applicable

national and international regulations/laws on work on electrical equipment/plants of the country

in which the frequency inverter is used.

The cables connected to the frequency inverters may not be subjected to high-voltage insulation

tests unless appropriate circuitry measures are taken before.

• O nly connect the frequency inverter to suitable supply mains.

2.10.5.1 The five safety rules

When working on/in electrical plants, alwa ys follow the five safety rules:

1. Isolate

2. Take appropriate measures to prevent re-connection

3. Check isolation

4. Earth and short-circuit

5. Cover or shield neighboring live parts.

2.10.6 Safe operation

During operation of the frequency inverter, always comply with the applicable national and inter-

national regulations/laws on work on electrical equipment/plants.

Before commissioning and the start of the operation, make sure to fix all covers and check the

terminals. Check the additional monitoring and protective devices according to the applicable national and international safety directives.

During operation, never open the machine/plant

Do not connect/disconnect any components/equipment during operation.

The machine/plant holds high voltage levels during operation, is equipped with rotating parts

(fan) and has hot surfaces. Any unauthorized removal of covers, improper use, wrong installation

or operation may result in serious injuries or material damage.

14

Agile

VABus/TCP 12/13

Some components, e.g. the heat sink or brake resistor, may be hot even some time after the ma-

chine/plant was shut down. Don't touch any surfaces directly after shutdown. Wear safety gloves

where necessary.

The frequency inverter may hold dangerous voltage lev els until the capacitor in the DC link is dis-

charged. Wait for at least 3 minutes after shutdown before starting electrical or mechanical work

on the frequency inverter. Even after this waiting time, make sure that the equipment is deenergized in accordance with the safety rules before starting the work.

In order to avoid accidents or damage, only qualified staff and electricians may carr y out the work

such as installation, commissioning or setup.

In the case of a defect of terminals and/or cables, immediately disconnect the frequency inverter

from mains supply.

Persons not familiar with the operation of frequency inverte rs must not have access to the fre-

quency inverter. Do not bypass nor decommission any protective facilities.

The frequency inverter may be connected to power supply every 60 s. This must be considered

when operating a mains contactor in jog operation mode. For commissioning or after an emergency stop, a non-recurrent, direct restart is permissible.

After a failure and restoration of the power supply, the motor may start unexpectedly if the Auto-

Start function is activated.

If staff are endangered, a restart of the motor must be prevented by means of external circuitry.

Before commissioning and the start of the operation, make sure to fix all covers and check the

terminals. Check the additional monitoring and protective devices according to EN 602 04 and applicable safety directives (e.g. Working Machines Act or Accident Prevention Directives).

2.10.7 Maintenance and service/troubleshooting

Visually inspect the frequency inverter when carrying out the required maintenance work and

inspections at the machine/plant.

Perform the maintenance work and inspections prescribed for the machine carefully, including the

specifications on parts/equipment replacement.

Work on the electrical components may only be performed by a qualified electrician according to

the applicable rules of electrical engineering. Only use original spare parts.

Unauthorized opening and improper interventions in th e machine/plant can lead to personal injury

or material damage. Repairs on the frequency inverters may only be carried out by the manufacturer or persons authorized by the manufacturer. Check protective equipment regularly.

• Before performing any maintenance work, the machine/plant must be disconnected from mains

supply and secured against restarting. The five safety rules must be complied with.

12/13

Agile

VABus/TCP 15

2.10.8 Final decommissioning

Electric scrap, electronic components, lubricants and other utility materials must be

mentally compatible disposal of the frequency inverter. For more details, contact the

Unless separate return or disposal agreements were made, recycle the disassembled frequency inverter components:

• Scrap metal materials

• Recycle plastic elements

• Sort and dispose of other component materials

treated as special waste and may only be disposed of by specialized companies.

Always comply with any applicable national disp osal regulations as regards environcompetent local authorities.

16

Agile

VABus/TCP 12/13

This manual only describes the CM-VABus/TCP and CM-VABus/TCP-2P communication

tions provided by this document.

In some chapters of these instructions, setting and display options via the PC software

for communication with the frequency inverter.

The module enables using VABus/TCP via a PLC and VPlus via the VABus/TCP protocol

parameters of the

3 Introduction

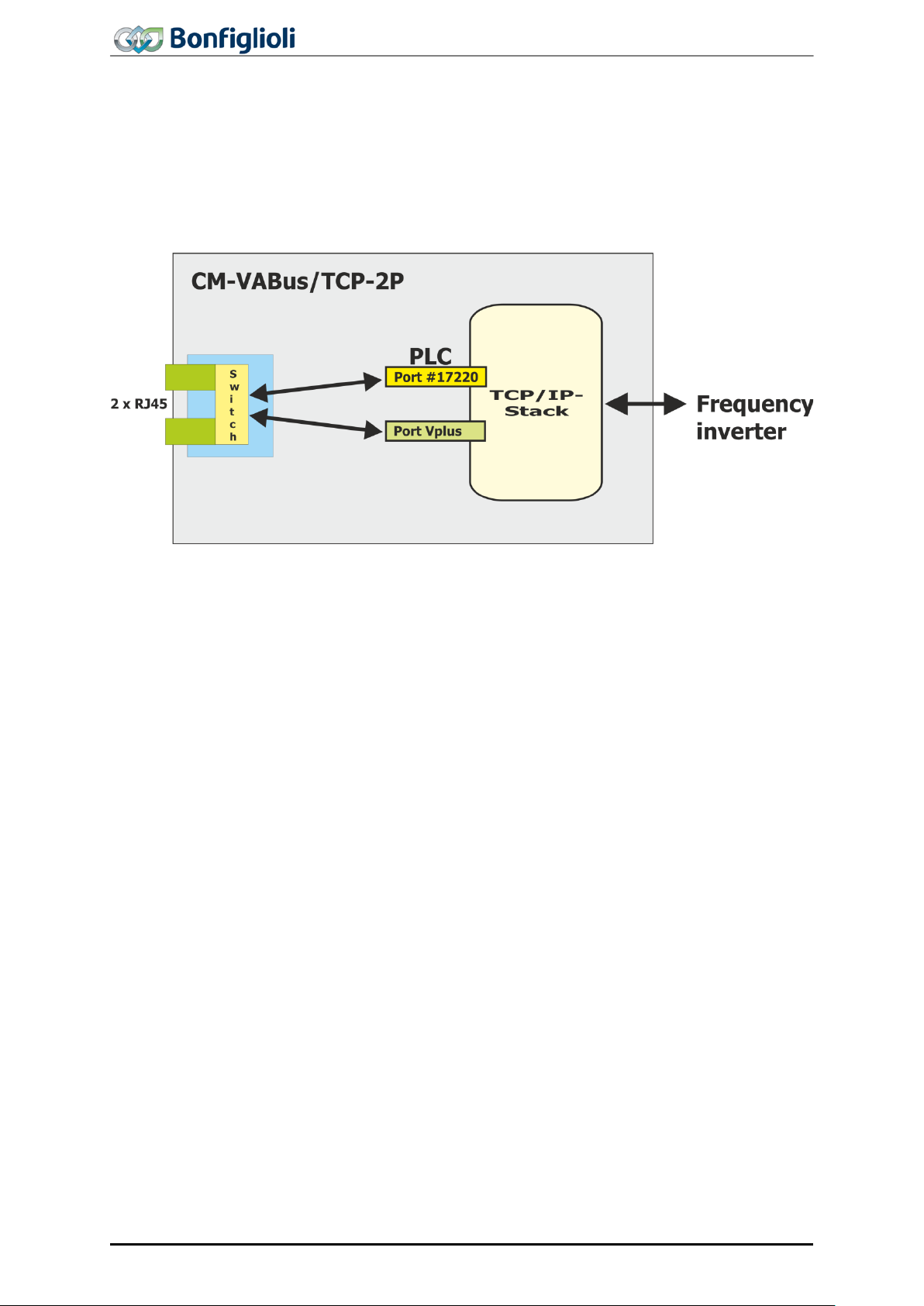

The present document describes the VABus/TCP protocol for the CM-VABus/TCP and

CM-VABus/TCP-2P (switch function integrated) communication modules. After connecting VABus/TCP

to the PLC, you can use an a dditional logic connect ion from VA Bus/TCP to t he VPlus softwa re running

on a terminal connected via an Ethernet network.

For VABus/TCP co nnection, the frequency inverter must be equipped with the CM-VABus/TCP or CMVABus/TCP-2P communicatio n module.

The CM-VABus/TCP and CM-VABus/TCP-2P communication modules are separate components and

must be attached to the frequency inverter. This is described in chapter 6.1 “Assembly”.

VABus/TCP communication (as described in this manual) requires software version 6.1.0 or higher.

modules. This manual is not to be understood as p r oviding general/basic information on

Ethernet interfaces or frequency inverters.

General/basic knowledge of the m ethods and function of VABus/TCP interfaces and

VABus/TCP protocol are a prerequisite for understanding and implementing the instruc-

VPlus are described as an alternative to the control unit. In this case, VPlus can use

− CM-VABus/TCP or CM-VABus/TCP-2P module or

− the serial interface

at the same time.

WARNING

With CM-VABus/TCP or CM-VABus/TCP-2P, controll ers ca n acces s all

frequency inverter.

Changing parame ters the function of whic h is unkn own can re sult in ma lfuncti on of th e

frequency inverter and dangerous situations in the plant.

Ethernet properties:

• 10/100 MB (10Base-T/100Base-T)

• Automatic identification (Autonegotiation)

• MDI/MDIX

12/13

Agile

VABus/TCP 17

Ports:

The module supports two logic TCP/IP ports for VABus/TCP communication. Each port can be used for

establishing one logic connection:

• Port #17220: Connection for PLC communication

• Port VPlus: Connection for VPlus

When a PLC starts communicating with a frequency inverter, it creates a TCP/IP source port to send

data to target port #17220 of the frequency inverter. The response of the frequency inverter is sent

by 17220 to this port of the PLC.

VPlus is the software for co nfiguration and ma intenance of BO NFIGLIOLI VEC TRON frequency in verters. It can conne ct wit h a f re que nc y i nvert er whil e it is com mu nica ting with a PLC . VP lus ca n est ab lis h

connections to any type of industrial Ethernet CM modules.

Module variants:

There are two VABus/TCP variants.

CM-VABus/TCP provides a physical inte rface for communication via VABus/TCP. A sta r-type network

topology can be used. An external switch is the star point.

CM-VABus/TCP-2P provides two physical interfaces for communi cation via VABus/TCP. The foll owing

network topologies are pos s i ble:

• Star-type (like in CM-VABus/TCP)

• Line

18

Agile

VABus/TCP 12/13

[1] PLC

[2] PC for commissioning or diagnosis (connecte d temporarily or permanently)

[3] AGL with CM-VABus/TCP or CM-VABus/TCP-2P (2nd port not connected)

[4] AGL with CM-VABus/TCP-2P

12/13

Agile

VABus/TCP 19

3.1 Supported configurations

Wait until the initialization phase is complete before s tarting the communication (RUN

For first commissioning, you should be familiar with the followings steps and the described functions:

• Installation of module

Chapter

6.1

• Selection of device control Local/Remote 412

Chapter

11

• Commissioning of device functions via PLC

o Fault Reaction

Chapter

7.5

Fault reset

Chapter

8.4 • Setting reference values:

o Reference Frequency

Chapter

11.3.2

• Diagnosis:

Chapter

13.1 and 14.1

Agile

frequency inverters support various types of control and reference point input:

• Contacts or remote contacts

• St ate machine

Contacts or remote contacts

Required settings:

Control (start, stop, frequency changeover, etc.) is typically performed through

o digital contacts.

o Remote contacts via field bus.

Reference values depend on the selected function. Typical:

o Reference speed/reference frequency:

Analog input.

Fixed values from parameters.

o Reference percentage for technology controller or torque control

Analog input.

Fixed values from parameters.

See Chapter 11 “Control of frequency inverter”.

State machine:

Required settings:

Control (start, stop, change of mode, etc.) is performed via

Reference values depend on the selected function. Typical:

o Reference speed/reference frequency:

Analog input.

Fixed values from parameters.

o Reference percentage for technology controller or torque control

Analog input.

Fixed values from parameters.

Local/Remote 412 = (remote) contacts

Local/Remote 412 = 1 – State machine

Control word

410.

3.2 Initialization time

When the frequency inve rter is turned on, the com m u nica tio n mod ul e m ust be ini t ia lize d in a dd iti on to

the frequency inverter. The initialization can take up to 20 seconds.

LED).

4 First commissioning

20

Agile

VABus/TCP 12/13

Interface

See

CAN connection control terminals

Instructions on Systembus or CANopen®.

CM-CAN

Communication interface X21

Instructions on VABus or Modbus.

CM-232

Instructions on VABus or Modbus.

CM-485

Instructions on VABus or Modbus.

CM-PDPV1

Instructions on Profibus DP-V1.

CM-DEV

Instructions on Device Net .

CM-VABus/TCP

Instructions on VABus/TCP.

CM-EtherCAT

Instructions on Et herCAT®.

CM-EtherNet/IP

Instructions on Et herNet/IP.

CM-Modbus/TCP

Instructions on Modbus TCP.

CM-PROFINET

Instructions on PROFINET.

Optional communication module (CM)

Frequency inverter

terminals X12.5 and X12.6

CANopen®

and (at the same time)

Systembus

Systembus

and (at the same time)

CANopen®

Via an optional USB adapter, you can connect an U SB interface of a PC to the X21

communication interface. This enables configuration and monitoring using the PC

software VPlus.

X21 (RJ45)

VPlus

USB

RJ45

Adapter

5 Communication options

Combinations of Systembus and CANopen

®

communication at the two interfaces:

5.1 Control software VPlus:

12/13

Agile

VABus/TCP 21

6 Assembly/disassembly of communication module

The CM-VABus/TCP and CM-VABus/TCP-2P communication modules are pre-

spring is supplied

for PE-connection (shield).

Danger of destruction of frequency inverter and/or communication module

Before installation of the communication module, the frequency inverter must

permissible while the

nents may be damaged.

Work steps:

1

2

3

6.1 Assembly

assembled in a case and are ready for insta llation. In addition, a PE -

CAUTION

•

be disconnected from power suppl y. Installation is not

• Dis connect the frequency inverter from mains voltage and protect it aga inst being

• Remove the cover of the module slot.

• Fix the PE-spring (1). Use the screw provided at the frequency inverter.

unit is energized.

• Do not touch the PCB visible on the back of the module, otherwise compo-

energized unintentionally.

• Insert the communication module.

• Fix the communication module (2) at the frequency inverter using the scr ew (3).

• Break out the pre-punched cut-out from the cover.

• Fix the cover again.

22

Agile

VABus/TCP 12/13

6.2 Disassembly

• Dis connect the frequency inverter from power supply and protect it against being

energized unintentionally.

• Remove the cover of the module slot.

• Loos en the screw (3) at the communication module.

• Using a small screwdriver, unlock the hooks (4) (first right then left).

• P ull communication module out of slot.

• Unscrew PE-spring.

• Fix the cover on the fr eq ue ncy i n ver te r.

12/13

Agile

VABus/TCP 23

7 VABus/TCP interface

This document does not provide basic information about Ethernet interfaces. Basic

required. This document describes the special properties of

parameters of the frequency

The frequency inverter can be controlled by a PLC or another master device via an Ethernet interface

using the VABus/TCP protocol.

When a VABus/TCP or VABus/TCP-2P communication module is used, you can also access the frequency inverter using the V Plus software via Ethernet. VP lus can be used in parallel with a P LC with

VABus/TCP communication.

knowledge of Ethernet is

the VABus/TCP protocol.

In some sections, setting and display options via the PC software VPlus are described as

an alternative to the control unit. In this case, VPlus communicate s with the frequency

inverter via a serial interface or a direct Ethernet connection.

WARNING

With VABus/TCP com m uni c at ion, co nt rol ler s can a c cess all

inverter.

Changing parame ters the function of whic h is unk nown can result in malfu nction of the

frequency inverter and dangerous situations in the plant.

24

Agile

VABus/TCP 12/13

made in the EEPROM, as this only allows a limited number of write cycles (approx. 1

ill

CAUTION

When values are to be wri tten cyclically at a high repetition rate, no entries sh all be

million cycles). If the number of permissible write cy cles is exceeded, the EEPROM w

be damaged. See chapter 9.1 “Handling of datasets / cyclic writing of parameters”.

7.1 Communication m odu les

CM-VABus/TCP

The CM-VABus/TCP communicati on module features an active RJ45 port.

CM-VABus/TCP-2P

The CM-VABus/TCP-2P co mmunication module featur es two active RJ45 p orts with integrated swit ching function. This enables ea sy linking (daisy chain) of frequency in verters which are connected to a

PLC.

7.1.1 Installation instructions

The VABus/TCP module is connected to the PLC or other devices using standard CAT cables and RJ45

connectors:

Ethernet standard: IEEE 802.3, 100Base-TX (fast Ethernet)

Cable type: S/FTP (cable with braided shield, (ISO/IEC 11801 or EN 5 0173, CAT5e

Straight Through of Cross Over)

12/13

Agile

VABus/TCP 25

7.2 Setup

Parameters

Settings

Parameters

Settings

No.

Description

Min.

Max.

Factory setting

1432

IP address

0.0.0.0

255.255.255.255

172.22.1.25

1433

Netmask

0.0.0.0

255.255.255.255

255.255.255.0

DHCP Option 1436

Function

Module must be configured manually, no DHCP server is used.

(Factory setting).

1 -

Enabled

The settings are made by a DHCP server.

By default, the parameters of the CM-VABus/TCP and CM-VABus/TCP-2P communication modules are

set up as follows:

No. Description Factory setting

388 Bus Error Behaviour 1

1432 IP-Address 172.22.1.25

1433 Netmask 255.255.255.0

1434 Gateway 0.0.0.0

1435 DNS Server 0.0.0.0

1436 DHCP Option 0

1437 IP Command 1440 Email Function 0

1441 Email Text (Body) -

The parameter settings must be adapted to the actual application.

7.3 TCP/IP address & subnet

For proper identification, each frequency i nvert er is assigned a TCP/IP address which must be unique

in the system.

7.3.1 Network without DHCP server:

The address is set via parameter IP-Address 1432. In addition, the subnet mask-Netmask 1433 must

be entered properly for the local network.

7.3.2 Network with DHCP server:

When a DHCP server i s used, ma nual networ k configur ation is not r equired. Se t DHCP Opti on 1436

to “1-Enabled” if you wish to use the DHCP function.

0 - Disabled

26

Agile

VABus/TCP 12/13

7.4 TCP/IP configurati on

In order to esta blish co nne ction wi th a freq uency i nve rter fe aturing a C M-VABus/TCP mod ule, you will

have to configure IP settings for the CM-VABus/TCP module.

TCP/IP configuration can be perfor med in different ways.

• TCP/IP configuration program, see Chapter 7.4.1 “TCP configurations tool”.

• Parameter settings with VPlus via service port of frequency inverter (KP232), see Chapter 7.4.2.1

“Basic IP settings”.

• Control panel.

7.4.1 TCP configurations tool

There are different ways to start the “TCP configuration tool”:

• In the “Inverter Manger” window click on the “Start TCP configuratio n tool”.

• Double-click on t he desktop ico n “Vectron Net work Configuration” (stand-alone application).

Once the application has started, a window will appear where you can select the Ethernet adapter via

which the frequency inverter is connected:

• Select the Ethernet adapter and click on “Ok”.

Once the Ethernet a dapt er has been selected, the configuration program is rea dy to search for a vailable frequency inverters.

With the “Timeout ” setting, you define how l ong the TCP configuration t ool will wait for responses

from the frequency inverter.

12/13

Agile

VABus/TCP 27

• In the “Timeout” field, enter the required time and click on “Search”.

The search is started. Upon completion of t he search a ll frequency inver ters found w ill be listed in the

left area of the window.

• Click on the frequency inverter to be configured.

28

Agile

VABus/TCP 12/13

Network adapter:

Name of selected network adapter.

IP address:

IP address of network adapter.

Device name:

Device name from frequency inverter parameter User

Device type:

Type of frequency inverter.

CM type:

Type of CM module, i.e.: CM – VABus/TCP.

Module status:

Current status of CM module, e.g. “Connected to PLC”.

MAC address:

MAC address of CM module.

IP address:

Current IP address of device.

Subnet mask:

Current subnet mask.

Standard gateway:

Address of standard gateway.

DNS Server:

Address of current DNS server.

Host Name:

Name of host.

DHCP activated:

Use of DHCP (yes/no).

The right part of the window shows information on the device and input fields for various settings.

Information about network adapter:

Device information:

name 29.

Device settings

• Enter the device settings required for your application. In order to apply the settings to the device, click on “Write IP settings”.

12/13

Agile

VABus/TCP 29

NOTE

Before clicking on “Write IP set tings”, m ake s ure tha t you are conne cted with the rig ht

frequency inverte r. To c hec k thi s, clic k on the “Wink” butt on. The con ne cte d fre q u ency

SMTP server:

smtp.provider.com

“From” address:

inverter.drive1@company.com

User name:

drive1@company.com

Password:

password

Re-enter password

password

“To” address

service.drives@company.com

NOTE

o

For documentation, all settings can b e saved in a file (type = *.eop).

inverter will flash for 10 seconds.

At the frequency i nverter , you can a cti vate a functio n which w ill se nd an e-ma il in case of an erro r. In

addition, a short text can be entered and saved as the e-mail text. The required settings can only be

made via VPlus. VPlus will access the freque ncy invert er via a local se rvice port ( KP232) or an Et hernet connection.

To configure the e-mail function, please refer to Chapte r 7.4.2.2 “Email”.

To send an e-mail message, the frequency inverter needs various information. It must have its own e-

mail address from where the e-mail message is sent. For e-mail transmission, identification by the

SMTP server (user name and password) is required. The recipient of the e-mail message must be

known.

In addition, the local network must be connected to the Internet, i.e. Gateway and DNS server must

be entered correctly. If you have any questions or problems, please contact your local system administrator.

SMTP settings (examples):

SMTP settings saved before can be viewed by clicking on the “Read SMTP settings”. T he password will

not be displayed.

SMTP settings are applied to t he module by clicking on the “Wr ite SMTP settings”. Whe n the SMTP

settings are written, you will be prompte d to enter a password. The two input fie lds “Password” and

“Re-enter passwo rd” must conta in the same char acter seque nce. If no entr y is made or the contents

of the two input fields are different, an error message will be displayed.

• All device settings are saved in the module and in the non-permanent memory

of the frequency inverter. Switching of modules from one frequency inverter to

another does not have an effect on the IP settings of the frequency inverter. A

PLC will remain connected with the right frequency inverter after switching of the

module.

• SMTP settings are saved in the module only. Switching of modules from one

frequency inverter to another will result in malfunction:

o No e-mail messages will be sent in case of an error.

o Wrong recipient.

Wrong e-mail text.

30

Agile

VABus/TCP 12/13

MAC-ID:

unambiguous MAC-ID

Sno:

Serial number

HW:

Hardware version

SW:

Software version

Parameters

7.4.2 Parameter settings wi t h VPlu s

7.4.2.1 Basic IP settings

IP settings can be made via the interface X21 and the USB/Com Port adapter.

Various parameters are available for module information and IP settings.

Parameter

Module Info 1431 shows basic module data:

For IP setting, five parameters are a va ilable.

No. Description

1432

1433

1434

1435

1436

IP address

Netmask

Gateway

DNS Server

DHCP Option

They define the IP settings a nd/or use of DHCP . When the DHCP option is activated, t he IP settings

will be made by the DHCP server when the module is started.

Each setting comprises four values. Please c ontact your IT administrator for permissible values . The

four values of the parameters are assigned on the display to four datasets (“Data Set 1” to “Data Set

4”). However, they do not depend on changes of the se data sets directly. The dataset s are only provided for clear representation of the values.

• To make IP settings, click on the first entry (e.g. Parameter 1432

IP-Address “Data Set 1”).

• Enter the required value and go to the next input field by pressing the “TAB” button.

12/13

Agile

VABus/TCP 31

The new settings will be saved in a buffer memory, but not transmitted to the module.

On the network side, they will not be active.

NOTE

Before applying the new IP settings to the module, make sure that the “R/W” button is

The module will reject non-perm issible IP settings and will restore t he last permissible

will be

Parameters

No.

Description

1440

Email Function

1441

Email Text (Body)

Reference:

Frequency inverter type, frequency inverter name (from parameter 29 User

E-mail text:

Optional text (max. 40 characters), defined in parameter 1441 Email Text

In the case of incorrect entries, the values can be overwritten. Old values can be restored via parameter 1437

IP-Command = “1 – Reload IP-Settings”.

The “R/W” activates the “Upd ate all parameters in curre nt window regularly” function:

activated.

• Apply the new IP settings to the module via parameter 1437

IP-Command = “0 – Apply”.

settings automatically. After execution of the “Apply” command, all IP settings

reset and the new settings will be overwritte n by the old settings.

7.4.2.2 Email

When an error occur s in the frequen cy inverter, an e-mail message can be sent automatically to report the incident to the Service department, for example. To activate the e-mail function and define

the e-mail text, two parameters are used:

The contents of t he e-mail message is pre-defined. The reference heading is given and cannot be

edited.

name), IP address, error number

(Body).

Example:

Reference: AGL Main Drive machine no. 5, 172.22.5.145, F0400

Please contact Mr. Doe, extension 2121.

32

Agile

VABus/TCP 12/13

Bus Error Behaviour 388

Function

1 -

Error

“Fault” status will be activated immediately. Factory setting.

Control command “Disable voltage” a nd switch to “switch on disabled” status.

Control command “Quick stop” and switch to “switch on disabled”

status.

Control command “Disable operation” and switch to “Error” status

once the drive has been shut down.

Control comma nd “Quick stop ” and switch to “Error” status once

the drive has been shut down.

= 2…5 are evaluated depending on

7.5 Operating behavior in the case of a communication error

The operating behavior in the case of errors in VABus/TCP comm unicatio n can be pa ramete rized. The

required behavior can be set up via

0 - no response Operating point is maintained.

2 - Stop

3 - Quick stop

4 - Shutdown + Error

5 - Quick stop + Erro r

The parameter settings Bus fault behavior 388

parameter Local/Remote 412.

For evaluation of settings 2…5, parameter Local/Remote 412 must be set to value “1 -

Control via statemachine”.

Bus Error Behaviour 388.

12/13

Agile

VABus/TCP 33

8 Protocol

The VABus protocol was originally developed for the serial interface (RS232/RS485 ) and adapted to

the CM

integrated in the data block of the TCP/IP protocol. VABus/TCP and VABus use a similar structure. The

handshake procedures and the data representation are different. VA Bus uses HEX

VABus/TCP uses binary data. The protocol structure of VABus/TCP aims at fast processing and min

mum protocol overhead.

Read/write commands and VABus/TCP data are integrated in the TCP/IP data range.

The VABus and VABus/TCP protocol enable operation as a pure Master/Slave system. A PC, a PLC or

any type of computer system is the bus Master.

Two types of requests are used:

Send request (inquiry telegram) for the request for reading parameters in the frequency inverter by

the bus Master.

Enquiry request (select telegram) for handing over parameter values or parameter settings to the

frequency inverter by the bus Master.

Send/positioning requests and send/positioning responses use defined data structures which are arranged in frames. Ea

information for parameter access.

The header byte is divided in 8 control bits, only bits 6 and 7 are used. Bits 0 to 5 are not used a nd

must have value “0”. If one or more of these bits has/have value “1”, the error message “syntax error

in received telegram” will be returned as the response.

-VABus/TCP module. The VABus/TCP protocol uses the TCP/IP protocol. The VABus data is

-ASCII data, while

i-

ch frame comprises a header byte and different numbers of bytes containing

34

Agile

VABus/TCP 12/13

Data Types Used

Data type abb.

string of characters

Parameter values with decimal places are transferred without decimal point. Depending

on the number of decimal places, the values are multiplied by 10, 100 or 1000.

The number of decimal places for the corresponding parameters is set in the frequency.

In this way it is made sure that the sent parameter values are processed correctly.

8.1 Telegram types

8.1.1 Data types

The number of data bytes depends on the type of the corresponding parameter. A maximum of 99

data bytes can be transferred.

Type Number of data types "w" Value Bit number

uInt

Int Integer 04 -32768 ... +37767 16

Long Long 08 -231 ... +231-1 32

String

unsigned

Integer

04 0 … 65535 16

variable, up to 99 - variable

Example: Frequency value with data type long:

Value to be transferred = 100.25. The numerical value transmitted in the telegram is 10025, which

corresponds to 0x2729 in HEX format. Since the data type is long, 8 data bytes are transferred

("wwwwwwww").

00002729

Example: Current value with data type Int:

The value to be transmitted is 10.3 A. The numerical value transmitted in the telegram is 103, which

corresponds to 0x67 in HEX format. Since the data type is int, 4 data bytes are transferred

("wwww").

0067

12/13

Agile

VABus/TCP 35

Send request PLC frequency inverter:

Byte

0

1 2 3 4 5

Header

NoB

SYS

DS

P.-No.

7 6 5…0 LSB

MSB

R/W 0 0 4 nn

nn

nnnn

Header:

Bit 7 R/W

0 = Send request

NoB:

Byte number

Number of relevant bytes ([Byte 2] – [Byte 5])

NoB will always be “4” for send requests.

SYS:

Addresses frequency inverters which are connected to a TCP/IP module via CAN System

Bus.

SYS = 0 for direct addressing of frequency inverter in Ethernet connection (SYS = 0…63)

DS:

Data set number of parameter (0, 1 … 4)

P. No.:

Parameter number (0 … 1599)

Send response frequency inverter PLC:

Byte

0

1 2 3 4 5 6 7 8 9 … n

Header

NoB

SYS

DS

P.-No.

data

7 6 5…0 LSB

MSB

uint/int data

R/W E 0

nn

nn

nn

nnnn

LSB

MSB

long data

LSB

MSB

string data

first

character

last

character

Header:

Bit 7 R/W

0 = Send response

Bit 6 E

0 = no error

1 = error

if (E == 1)

NoB:

Byte number

Number of relevant bytes

SYS:

returns value SYS from the reques t frame

DS:

returns dataset number from the request frame

P. No.:

returns parameter number from the request frame

data:

requested parameter value, byte number depending on data type

8.1.2 Send Request / Enquiry Telegram

byte 6+7 contains error code ( NoB = 6)

If no response from the frequency inverter is received within a given response time (see chapter 8.3,

"Timeout control"), or if the frequency inverter returns incorrect data, the inquiry telegram is repeated

three times (maximum of three transmissions possible).

NAK signals an error. An error may have different causes. Errors ma y be caused by incorrect data or

an incorrect string.

36

Agile

VABus/TCP 12/13

Positioning request PLC frequency inverter:

Byte

0

1 2 3 4 5 6 7 8 9 … n

Header

NoB

SYS

DS

P.-No.

data

7 6 5…0 LSB

MSB

uint/int data

R/W 0 0

nn

nn

nn

nnnn

LSB

MSB

long data

LSB

MSB

string data

first

character

last

character

Header:

Bit 7 R/W

1 = Setting request

NoB:

Byte number

Number of relevant bytes

([Byte 2] … [Byte 5] + Number of data bytes)

SYS:

Addresses frequency inverters which are connected to a TCP/IP module via CAN System

Bus.

SYS = 0 for direct addressing of frequency inverter in Ethernet connection

DS:

Data set number of parameter (0,1 …, 4, 5, 6 … 9)

P. No.:

Parameter number (0 … 1599)

data:

parameter value to be written, byte number depending on data type

Setting response frequency inverter PLC:

Byte

0

1 2 3 4 5 6 7 8 9 … n

Header

NoB

SYS

DS

P.-No.

data

7 6 5…0 LSB

MSB

uint/int data

R/W E 0

nn

nn

nn

nnnn

LSB

MSB

long data

LSB

MSB

string data

first

last

Header:

Bit 7 R/W

1 = Setting response

Bit 6 E

0 = no error

1 = error

if (E == 1)

NoB:

Byte number

Number of relevant bytes

([Byte 2] … [Byte 5] + number of data bytes)

SYS:

returns value SYS from the reques t frame

DS:

returns dataset number from the request frame

P. No.:

returns parameter number from the request frame

data:

returns written parameter value, byte number depending on data type

8.1.3 Setting Request / Select Telegram

Via the select telegram, the data are sent to the frequency inverter.

character

character

byte 6+7 contains error code ( NoB = 6)

12/13

Agile

VABus/TCP 37

The System Bus Node-ID 900 is required for addressing networked inverters. If there is no System

Bus, or if the System Bus master is addressed, the SYS character is always filled with the zero

character (

Node-ID

Node-ID

900

Function

SYS character

If the Node-ID 900 is not zero, the SYS character is determined as follows:

For example,

Node-ID

900 of 7 will result in character 0x47 = “G”. Refer to System Bus description.

The procedure shown in the illustration will work in the following Field B use s:

•

•

Instead of the PLC, you can use a standard PC with an appropriate interface.

8.1.4 System bus Node-ID

-1

0

1 ... 63

0x30). The

No System Bus at inverter. “-1” = 0xFFFF

The inverter is the System Bus master. “0” = 0x30

The inverter is the System Bus slave with the

specified ID.

900 has values ranging from 0 to 63.

SYS character = (char)(SysNode-ID Nr + 0x40)

0x41 .. 0x7F

VABus

VABus/TCP

38

Agile

VABus/TCP 12/13

The addresses in a System Bus branch m ust be assigned unambiguously. Since several System Bus

branches can opera ted independently due to the different Ethernet clients, identical System Bus addresses are possible in the network. The disti nction is made based on the dif ferent Ethernet addresses.

In the case of VABus, the network address is a serial address ranging from 1 to 127.

In the case of VABus/TCP , the network address is an IP address in t he format aaa.bbb.ccc.ddd, with

each block of n umbers ranging from 0 to 255.

12/13

Agile

VABus/TCP 39

8.2 Telegram check

The frequency inverter and the bus Master check the telegrams for correctness. Depending on the

syntax, address and text part (content, checksum).

In case the telegram contains errors, the frequency inverter either returns NAK or it does not respond at all. The possible causes are listed below:

no response

wrong telegram structure

wrong control character

wrong address

telegram addressed to address 32 (Broadcast); in this case, the frequency

inverter does not reply.

If an error occurs during parameter access, the freq uency inverter will return an error message (Bit

VABus SST-Error-Register 11

type of telegram, the corresponding reaction takes place. The telegrams are checked for correct

E = “1” in read/write response). Bytes 6 and 7 contain the error code.

Error no. Meaning

0 no error

1 Non-permissible parameter value.

2 Non-permissible dataset

3 parameter not readable (write-only)

4 parameter not writable (read-only)

5 EEPROM read error

6 EEPROM write error

7 EEPROM checksum error

8 Parameter cannot be written while drive is running

9 Values of data sets are different

10 not available

11 unknown parame ter

12 not available

13 Syntax error in received telegram

14 data type of parameter does not correspond to the number of bytes in the telegram

15 unknown error

20 selected System Bus node not available

30 Syntax error in received telegram

40

Agile

VABus/TCP 12/13

Bus Error Behaviour 388

Function

1 -

Error

“Fault” status will be activated immediately. Factory setting.

Control command “Disable voltage” and switch to “switch on disabled” status.

Control command “Quick stop” and switch to “switch on disabled”

status.

Control command “Disable operation” and switch to “Error” status

once the drive has been shut down.

Control comma nd “Quick stop ” and switch to “Error” status once

the drive has been shut down.

The parameter settings Bus Error Behaviour 388 = 2…5 are evaluated depending on

parameter

For evaluation of settings 2…5, parameter

-

Control via statemachine”.

Some errors will occur again after an error reset. In such cases, it may be necessary to

8.3 Timeout control

After first data exchange via the PLC Port #17220, a timeout check will be activated. If no data is

exchanged for more than 10 seconds, the frequency will respond in the way set in parameter

Error Behaviour

PLC”.

0 - no response Operating point is maintained.

2 - Stop

3 - Quick stop

4 - Shutdown + Error

5 - Quick stop + Erro r

388. and switch to fault status with error message F2714 “C ommunication Loss to

Bus

Local/Remote 412.

Local/Remote 412 must be set to value “1

8.4 Resetting errors

Depending on the settings and operating state of the device, errors can be reset in different ways:

• In controller via Parameter

Set bit 7

• By pressing the stop button of the control panel:

Resetting by pressing the STOP button is only possib le if Parameter

control via the control panel.

• Via parameter

A reset via a digital signal can only be carried o ut when parameter

or when an input with the ad dition (hardware) is selected in the case of physical inputs.

Control word 410 = 0x8000.

Error acknowledgment 103 which is assigned a logic signal or a digital input

take certain measures (e.g. moving from a limit switch in the non-disabled direction).

Local/Remote 412 = 1 - Statemachine:

Local/Remote 412 permits

Local/Remote 412 permits this

12/13

Agile

VABus/TCP 41

NOTE

sively without a writing cycle on the EEPROM. Such dat a will be lost in the case of a

Writing on virtual dataset in RAM

Parameters

EEPROM

RAM

Dataset 0

0

5

Dataset 1

1

6

Dataset 2

2

7

Dataset 3

3

8

Dataset 4

4

9

9 Parameter access

9.1 Handling of datasets / cyclic writing of parameters

The parameter values are accessed based on the parameter number and the required dataset. There

are parameters the values of which are present once (dataset 0) as well as parameters the values of

which are present four times (dataset 1...4). These are used for dataset switching.

If parameters which are present four times in the datasets are set to Dataset = 0, the four datasets

are set to the same transmitted value. A read access with data set = 0 to such parameters is only

successful if all four data se ts are set to the same value. I f this is not the case, an error w ill be signaled.

The values are entered automatically in the EEPROM of the controller. When values are

to be written cyclically, no entries shall be m ade in the EEPROM, as this only allow s a

limited number of write cycles (approx. 1 milli on cycles). When t he number of pe rmissible write cycles is exceeded, the EEPROM will be destroyed.

In order to avoid this, data which is written cyclicall y can be entered in the RAM exclupower failure and have to be written again after Power off/on.

This mechanism is started when the target dataset is increa sed by five when spe cifying

the dataset.

42

Agile

VABus/TCP 12/13

Function

Parameters

Index range

Indexing parameters

Write

and read

Write

PLC function

1343 FT-Instruction

1352 FT-Commentary

Multiplexer

1252 Mux Input

01);

1…16

171);

18…33

1250 Write

1251 Read

CANopen®

Multiplexer

1422 CANopen Mux Input

01);

1…16

171);

18…33

1420 Write

1421 Read

1) When the indexing parameter = 0, all indexes will be written upon parameter access in EEPROM. 17 or 33 will write all indexes in RAM.

the RAM and not the EEPROM.

In the RAM, the data is not protected against loss of power. Once power supply is

ing the data set (IND).

Typically, index parameters are wr itten during commissioning.

Writing of Parameter 1344 PL C Inp ut 1 (Type int), in Index 34 in RAM ( Inde x 34 for

write access) with parameter value 2380.

Index = 1341 + 0x 2000 = 0x253D, value (int) = 34 = 0x0022

Index = 1344 + 0x2000 = 0x254 0, val ue (int ) = 238 0 = 0x09 4C

If various parameters in an index are to be edited, it will be sufficient to set i ndex access

via

9.2 Handling index parameters / cyclic writing

Index parameters are used for various AGL functions. Here, 16 or 32 indexes are used instead of the

4 data sets. For each function, the individual indexes are addressed separately via an index access

parameter. Via the indexing parameter, you can select if the data is to be written to EEPROM or RAM.

(Function Table)

EEPROM

RAM

1344 FT-Input 1

1345 FT-Input 2

1346 FT-Input 3

1347 FT-Input 4

1348 FT-Parameter 1

01);

1…32

331);

34…65

1341 Write

1342 Read

1349 FT-Parameter 2

1350 FT-Target Output 1

1351 FT-Target Output 2

NOTE

The values are entered automatically in the EEPROM of the controller. However, only

a limited number of write cycles is permissible for the EE PROM (approx. 1 million cycles). When this number is exceeded, the EEPROM will be destroyed.

Values w hich are written cyclically at a high repetition rate should be written to

disrupted, the data must be written again.

This procedure is started when the target data set is increased by five when specify-

9.2.1 Example: Writing of index parameters

12/13

1341 once first.

Agile

VABus/TCP 43

9.2.2 Example: Reading of index parameters

In order to read an index parameter, you will have to set the indexing parameter to

the relevant index first, then you can read the parameter.

Reading from parameter PLC input 1 1344 type int), in Index 1 with paramete r value

6.

Index = 1342 + 0x2000 = 0x253E, val ue (int ) = 1 = 0x00 01

Index = 1344 + 0x2000 = 0x254 0, val ue (int ) = 6 = 0x0006

If various parameter of an index are to be read, it will be sufficient to set index access

via

1342 once first.

44

Agile

VABus/TCP 12/13

Byte

... 0 1 2 3 4 5

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

> 40

Bytes

7 6 5…0 LSB

MSB 0 0 0 04

00

02

74 01

Byte

... 0 1 2 3 4 5 6 7

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

data

> 40

7 6 5…0 LSB

MSB

uint/int

LSB MSB

0 0 0

06

00

02

74 01

6E

05

Byte

... 0 1 2 3 4 5

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

> 40

Bytes

7 6 5…0 LSB

MSB 0 0 0 04

00

01

E1 01

Byte

... 0 1 2 3 4 5 6 7 8 9

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

data

> 40

7 6 5…0 LSB

MSB

long data

LSB MSB

0 0 0

08

00

01

E1 01

E8

03

00

00

10 Example messages VABus/TCP

This chapter describes some examples of telegrams for VABus/TCP.

10.1 Reading parameters

Example 1:

Reading of parameter

Request: Master frequency inverter

Response: Frequency inverter Master

Rated speed 372 (0x0174) in dataset2.

Bytes

The sent hexadecimal value is 0x056E = Decimal 1390. Parameter

places. Thus, the rated speed is 1390 min

-1

.

Example 2:

Reading of parameter

Fixed frequency 2 481 (0x01E1) in dataset 1.

Request: Master frequency inverter

Response: Frequency inverter Master

Bytes

data

Rated speed 372 has no decimal

The sent hexade cimal value is 0x03E8 = De cimal 1000. Parameter

decimal places. Th us, the frequency is 10.00 Hz.

12/13

Fixed frequency 2 481 has two

Agile

VABus/TCP 45

Example 3:

Byte

... 0 1 2 3 4 5

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

> 40

Bytes

7 6 5…0 LSB

MSB 0 0 0 04

00

00

0c 00

Byte

... 0 1 2 3 4 5 6 7 8 9

10

11

12

13

14

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

data

> 40

Bytes

7 6 5…0 LSB

MSB

String data (hexadecimal and string)

0 0 0

0D

00

00

01 E1

36

2E

32

2E

30

20

53

54

4F

6 . 2 . 0 S T O

Byte

... 0 1 2 3 4 5 6 7

TCP/IP

Header

NoB

SYS

DS

P.-No.

data

> 40

7 6 5…0 LSB

MSB

uint/int data

LSB MSB

1 0 0

06

00

04

78 01

96

00

Byte

... 0 1 2 3 4 5 6 7

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

data

> 40

7 6 5…0 LSB

MSB

uint/int data

LSB MSB

1 0 0

06

00

04

78 01

96

00

Reading of parameter

Inverter software version 12 (0x000c) in dataset 0.

Request: Master frequency inverter

Response: Frequency inverter Master

The sent hexadecimal value is ASCII encoded. In the example, the ASCII string is green. For conversion between hexadecimal and ASCII value, refer to the relevant table in the appendix.

10.2 Writing parameters

Example 1:

Writing of parameter

Rated mech. power 376 (0x0178) in dataset 4.

The rated mechanical power is to be set to 1.50 kW. Parameter

imal places. Thus the value to be sent is 150 = 0x0 0 96.

Request: Master frequency inverter

Bytes

Response: Frequency inverter Master

Bytes

The response is the reflected signal of the request message.

Rated mech. Power 376 has two dec-

46

Agile

VABus/TCP 12/13

Byte

... 0 1 2 3 4 5 6 7

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

data

> 40

7 6 5…0 LSB

MSB

uint/int data

LSB MSB

1 0 0

06

00

04

78 01

00

00

Byte

... 0 1 2 3 4 5 6 7

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

data

> 40

7 6 5…0 LSB

MSB

uint/int data

LSB MSB

1 1 0

06

00

04

78 01

01

00

Byte

... 0 1 2 3 4 5 6 7 8 9

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

data

> 40

7 6 5…0 LSB

MSB

long data

LSB MSB

1 0 0

08

00

09

E2 01

62

11

00

00

Byte

... 0 1 2 3 4 5 6 7 8 9

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

data

> 40

7 6 5…0 LSB

MSB

long data

LSB MSB

1 0 0

08

00

09

E2 01

62

11

00

00

Example 2:

Writing of non-permissible value 0 in parameter

Rated mech. power 376 (0x0178) in dataset 2.

Request: Master frequency inverter

Bytes

Error response: Frequency inverter Master

Bytes

Example 3:

Writing of parameter

Fixed frequency 3 482 (0x01E2) in dataset 9 (= RAM for dataset 4) of frequen-

cy inverter.

The fixed frequency is to be set to 44.50 Hz. Parameter

es. Thus the value to be sent is 4450 = 0x00001162.

Request: Master frequency inverter

Fixed frequency 3 482 has two decimal plac-

Bytes

Response: Frequency inverter Master

Bytes

The response is the reflected signal of the request message.

12/13

Agile

VABus/TCP 47

Byte

... 0 1 2 3 4 5 6 7 8 9

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

data

> 40

7 6 5…0 LSB

MSB

long data

LSB MSB

1 0 0

08

00

09

E2 01

40

0D

03

00

Byte

... 0 1 2 3 4 5 6 7

TCP/IP

Header

Header

NoB

SYS

DS

P.-No.

data

> 40

7 6 5…0 LSB

MSB

uint/int data

LSB

MSB

1 1 0

06

00

09

E2 01

01

00

For explanations of error codes, see 8.2 “Telegram check”.

Example 4:

Writing of parameter

Fixed frequency 3 482 (0x01E2) in dataset 9 (= RAM for dataset 4) of frequen-

cy inverter.

The frequency is t o be set to 2000.00 Hz (non-permissible value). Parameter

has two decimal places. Thus the value to be sent is 20000 = 0x00030D40.

Request: Master frequency inverter

Bytes

Error response: Frequency inverter Master

Bytes

Fixed frequency 3 482

48

Agile

VABus/TCP 12/13

The frequency inverter can generally be controlled via three operation modes. The op-

412.

Parameters

Settings

No.

Description

Min.

Max.

Factory

setting

412

Local/Remote

0

44

44

For operation with a Field bus, only opera tion mode s 0, 1 and 2 are re levant. The other

settings refer to the control option via the control unit.

Operation mode

Function

Control via

(Chapter 11.1)

The Start and Stop commands as well as the direction of

Control via

(Chapters 11.2)

The frequency inverter is controlled via the control word.

Control via

(Chapter 11.1)

The Start and Stop commands as well as the direction of

control word.

Parameter Local/Remote 412 is dataset switchable, i.e. you can switch between the

The data set switching can be effected locally via con trol contacts at the digital inputs

Dataset selection 414 is used.

Parameters

Settings

No.

Description

Min.

Max.

Factory set-

ting

414

Data set selection

0 4 0

With Data set selection 414 = 0, data set switching via contact inputs will be active. If

if the frequency inverter is not enabled.

Via parameter Active data set 249, the currently selected data set can be read. Active

dependent of

Data set selection 414

11 Control of frequency inverter

eration modes can be selected via the data set switchable parameter Local/Remote

0 -

contacts

1 -

state machine

rotation are controlled via digital signals.

2 -

remote contacts

rotation are controlled via virtual digital signals of the

different operation modes by selecting another data set.

of the frequency inverter or via the bus. For data set swit ching via the bus, paramet er

Data set selection 414 is set to 1, 2, 3 or 4, the selected data set is a ctivated a nd data

set switching via the contact inputs is deactivated.

If Data set selection 414 is set to 5, data set switching via contact inputs will be active

data set 249, indicates the active data set (value 1, 2, 3 or 4). This is in

whether the data set switching was done via contact inputs or

.

12/13

Agile

VABus/TCP 49

11.1 Control via

In operation mode “Control via contacts” or “Control via remote contacts” (Parameter

Local/Remote

n-

puts or via the individual bits of the v irtual digital signals in the control

c-