ACTIVE CUBE

Profibus-DP

Communication module CM-PDPV1

Frequency Inverter 230V / 400V

T

T

A

g

General points on the documentation

The present supplement of the documentation is valid for frequency inverters of the

device series ACU 201/401. The information necessary for the assembly and application of the Profibus-DP communication module CM-PDPV1 is documented in this guid-

For better clarity, the user documentation is structured according to the customer-

ance.

specific demands made on the frequency inverter.

Brief instructions

The brief instructions manual “Quick Start Guide” describes the fundamental steps for

mechanical and electrical installation of the frequency inverter. The guided commissioning supports you in the selection of necessary parameters and the software configuration of the frequency inverter.

Operating instructions

The operating instructions document the complete functionality of the frequency in-

verter. The parameters necessary for specific applications for adaptation to the application and the extensive additional functions are described in detail.

Application manual

he application manual supplements the documentation for purposeful installation and

commissioning of the frequency inverter. Information on various subjects connected

with the use of the frequency inverter are described specific to the application.

Installation instructions

As a complement to the brief instructions and the operating instructions, the installation instructions describe the installation and use of devices.

The documentation and additional information can be requested via your local repre-

sentation of the firm of BONFIGLIOLI.

he following pictograms and signal words are used for the purposes of the present

documentation:

Danger!

Danger refers to an immediate threat. Non-compliance with the precaution described

will result in death, serious injury or material damage.

Warning!

Warning refers to a possible threat. Non-compliance with the warning may result in

death, serious injury or material damage.

Caution!

Caution refers to an immediate hazard. Non-compliance may result in personal or

material damage.

Attention!

ttention and the related text refer to a possible behavior or an undesired condition

which can occur during operation.

Note

marks information that facilitates handlin

for you and supplements the corresponding

part of the documentation.

CM-PDPV1 108/08

Warning! In installation and commissioning, comply with the information in the

documentation. You as a qualified person must read the documentation

carefully before the start of the activity and obey the safety instructions.

For the purposes of the instructions, "qualified person" designates a person acquainted with the installation, assembly, commissioning and operation of the frequency inverters and possessing the qualification corresponding to the activity.

CM-PDPV1 08/082

Contents

1 General safety and application information .................................................................. 5

1.1 General information ................................................................................................. 5

1.2 Proper use ................................................................................................................ 5

1.3 Transport and storage ............................................................................................. 6

1.4 Handling and installation ......................................................................................... 6

1.5 Electrical connection ................................................................................................ 6

1.6 Operating information ............................................................................................. 7

1.7 Maintenance and servicing ...................................................................................... 7

2 Introduction ................................................................................................................... 8

3

Installation/Disassembly of the communication module .............................................. 9

3.1 Installation .............................................................................................................. 9

3.2 Disassembly ........................................................................................................... 10

4 Socket connection/bus termination/line ..................................................................... 11

5 Baud rate setting/line length ....................................................................................... 12

6 Setting the station address .......................................................................................... 12

7 LED indicators .............................................................................................................. 13

8 Status Parameters ........................................................................................................ 14

9 Error Behaviour ............................................................................................................ 14

10 Setting PPO structure .................................................................................................. 15

10.1 Configuration process on the DP master ............................................................ 16

11 Commands SYNC/FREEZE ............................................................................................ 18

12 Available objects/scanning times ................................................................................ 18

13 Handling of the objects ................................................................................................ 21

13.1 Parameter access via communication channel PKW .......................................... 21

13.1.1 Request identification ............................................................................................. 22

13.1.2 Reply identification ................................................................................................ 22

13.1.3 Fault messages ...................................................................................................... 22

13.1.4 Parameters, data set selection and cyclic writing ...................................................... 23

13.1.5 Sequence of communication ................................................................................... 24

13.1.6 Examples of communication ................................................................................... 25

13.2 Parameter access via the DP-V1 channel ........................................................... 27

13.2.1 Standard Mode ...................................................................................................... 28

13.2.2 S7-compatible Mode .............................................................................................. 29

13.3 Process data channel .......................................................................................... 30

13.3.1 Data types of OUT/IN-objects ................................................................................. 30

13.3.2 Profibus output sources (OUT-PZD x) ...................................................................... 32

13.3.3 Profibus input parameters (IN-PZD x) ...................................................................... 33

CM-PDPV1 308/08

13.4 Frequency conversion PDP word Å Æ inverter internal notation ...................... 35

13.4.1 PZD1, control word/state word ............................................................................... 36

13.4.2 Control via contacts ............................................................................................... 37

13.4.3 Control via state machine ....................................................................................... 38

13.4.3.1 Behaviour in quick stop .................................................................................... 42

13.4.3.2 Behaviour in transition 5 .................................................................................. 43

13.4.4 Control via remote contacts .................................................................................... 44

13.4.5 PZD2, reference value/actual value ......................................................................... 47

13.5 Actual value display of Profibus data ................................................................. 49

14 Parameter list ............................................................................................................... 52

14.1 Actual values ...................................................................................................... 52

14.2 Parameters ......................................................................................................... 53

15 Annex ........................................................................................................................... 54

15.1 Warning messages ............................................................................................. 54

15.2 Fault messages ................................................................................................... 54

15.3 GSD File – BV__0B2C.GSD .................................................................................. 55

CM-PDPV1 08/084

1 General safety and application information

T

T

f

g

g

his documentation has been produced with the greatest of care and extensively and

repeatedly checked. For reasons of clarity, not all the detailed information on all types

of the product and also not every imaginable case of installation, operation or maintenance has been taken into account. If you require further information or if specific

problems which are not dealt with extensively enou

can request the necessary information via the local representation of the company

BONFIGLIOLI.

We would also point out that the contents of this documentation are not part of a

previous or existin

to amend the same. All obligations of the manufacturer result from the underlying

purchase contract, which also contains the complete and solely valid warranty regulation. These contractual warranty provisions are neither extended nor limited by the

production of this documentation.

he manufacturer reserves the right to correct or amend the contents and the product

information as well as omissions without prior notification and assumes no kind o

liability for damage, injuries or expenditure to be put down to the aforementioned

reasons.

1.1 General information

Warning! BONFIGLIOLI VECTRON frequency inverters have high voltage levels dur-

1.2 Proper use

Warning! The frequency inverters are electrical drive components intended for in-

ing operation, depending on their protection class, drive moving parts and

have hot surfaces.

In the event of inadmissible removal of the necessary covers, improper

use, wron

persons or property.

To avoid any dama

installation, setup or maintenance work required. Comply with the standards EN 50178, IEC 60364 (Cenelec HD 384 or DIN VDE 0100), IEC

60664-1 (Cenelec HD 625 or VDE 0110-1), BGV A2 (VBG 4) and national

provisions. Qualified persons within the meanin

information are people acquainted with the installation, fitting, commissionin

in possession of qualifications matching their activities.

stallation in industrial plants or machines. Commissioning and start of

intended operation are not allowed until it has been established that the

machine corresponds to the provisions of the EC machine directive

98/37/EEC and EN 60204. According to the CE sign, the frequency inverters additionally fulfill the requirements of the low-volta

2006/95/EC and standards EN 50178/DIN VDE 0160 and EN 61800-2.

Responsibility for compliance with the EMC directive 89/336/EEC is with

the user. Frequency inverters are available in a limited way and as components exclusively intended for professional use within the meanin

the EN 61000-3-2.

With the issue of the UL accordin

CSA Standard C22.2-No. 14-95 have also been fulfilled.

The technical data and the information on connection and ambient conditions the rating plate and the documentation be complied with. The instructions must be read and fully understood before starting work on the

device.

gh in the documentation exist, you

g agreement, assurance or legal relationship and are not intended

g installation or operation, there is the risk of serious damage to

e, only qualified staff may carry out the transport,

g of this principal safety

g and operating of frequency inverters and the possible hazards and

e directive

g of

g to UL508c, the requirements of the

CM-PDPV1 508/08

T

g

1.3 Transport and storage

Transport and storage are to be carried out in an adequate way in the original packag-

ing. Storage shall be in dry rooms protected against dust and moisture with slight

temperature fluctuations. Please observe the climatic conditions according to EN

50178 and the marking on the packaging. The duration of storage without connection

to the admissible reference voltage may not exceed one year.

1.4 Handling and installation

Warning! Damaged or destroyed components may not be put into operation be-

cause they may be a health hazard.

he frequency inverters are to be used according to the documentation, the directives

and the standards. Handle carefully and avoid mechanical overload. Do not bend the

components or chan

ge the isolation distances. Do not touch electronic components or

contacts. The devices contain electrostatic sensitive components which can easily be

ged by improper handling. Any use of damaged or destroyed components shall

dama

be considered as a non-compliance with the applicable standards. Do not remove any

warning signs from the device.

1.5 Electrical connection

Warning! Before any assembly or connection work, de-energize the frequency in-

verter. Make sure that the frequency inverter is de-energized.

Do not touch the sockets, because the capacitors may still be charged.

Comply with the information

iven in the operating instructions and on

the frequency inverter label.

While working on the frequency inverters, obey the applicable standards BGV A2

(VBG 4), VDE 0100 and other national directives. Comply with the information in the

documentation on electrical installation and the relevant directives. Responsibility for

compliance with and examination of the limit values of the EMC product standard EN

61800-3 for variable-speed electrical drive mechanisms is with the manufacturer o

the industrial plant or machine.

The documentation contains information on installation correct for EMC. The cables

connected to the frequency inverters may not be subjected to an isolation test with a

high test voltage without previous circuit measures.

f

CM-PDPV1 08/086

08/08 CM-PDPV1 7

g

1.6 Operating information

Warning! The frequency inverter may be connected to power supply every 60 s.

Consider this for a jog operation of a mains contactor. For commissioning

or after an emergency stop, a non-recurrent, direct restart is permissible.

After a failure and restoration of the power supply, the motor may start

unexpectedly if the AutoStart function is activated. Install protective

equipment if personal injury or material damage is possible.

Before commissioning and the start of the intended operation, attach all

the covers and check the sockets. Check additional monitoring and protective devices pursuant to EN 60204 and the safety directives applicable

in each case (e.

etc.).

No connection work may be performed, while the system is in operation.

1.7 Maintenance and servicing

Warning! Unauthorized opening and improper interventions can lead to physical

injury or damage to property. Repairs on the frequency inverters may

only be carried out by the manufacturer or persons authorized by the

latter. Check protective equipment regularly.

. Working Machines Act, Accident Prevention Directives

CM-PDPV1 708/08

2 Introduction

This document describes the features of the Profibus-DP communication module CM-

PDPV1 for frequency inverters of the ACU series.

For the Profibus-DP connection, the frequency inverter must be equipped with the

Profibus-DP communication module CM-PDPV1. The Profibus component CM-PDPV1 is

enclosed with the inverter as a separate part and must be fitted by the user. This is

described in the chapter "Installation".

Note: These instructions are not to be understood as fundamental information

The Profibus component CM-PDPV1 has the ident number 0x0B2C (hexadecimal).

The device's data set file has the designation BV__0B2C.GSD and is attached to the

appendix of this documentation. The identification number and desi

file have been assigned by the Profibus user organization in Karlsruhe Germany.

Attention! With the help of the Profibus-DP communication module CM-PDPV1 it is

on the Profibus-DP. They presuppose underlying knowledge of the methods and modes of effect of the Profibus-DP on the part of the user.

In some points, setting and display possibilities are described alternatively to the control unit KP500 via the VPlus PC program. Operation of a PC

with the VPlus program on the frequency inverter with use of the Profibus component CM-PDPV1 is only possible via an optional interface

adapter KP232 on the slot of the control unit KP500.

gnation of the GSD

possible to access ALL parameters of the frequency inverter from the

external control unit. Control of the access via the Control Level (Parameter 28) as with the control unit KP500 or the VPlus PC software does

not exist. A change of parameters with an unknown meaning to user can

lead to the inoperability of the frequency inverter.

CM-PDPV1 08/088

g

3

Installation/Disassembly of the communication module

3.1 Installation

The communication module is pre-assembled in a case. Additionally, a PE spring is

enclosed for PE connection (shield).

Caution! The frequency inverter must be disconnected from the power supply be-

fore installation of the communication module.

Assembly under voltage is not permissible and will destroy the frequency

inverter and/or the communication module.

Do not touch the PCB visible on the back of the module, otherwise com-

Work steps:

• Disconnect the frequency inverter from the mains voltage and protect it against

ponents may be damaged.

being energized unintentionally.

• Remove covers (1) and (2) of the frequency inverter. Slot B (4) for the commu-

nication module is now accessible.

• Mount the supplied PE spring (5) using the M4 screw (6) in the unit. The spring

must be aligned centrally.

• Insert the communication module in slot B (4) until it engages audibly.

• Fix the communication module by screwing the M2 screw (7) of the module to the

PE spring (5).

• In the upper cover (1), break out the pre-punched cutout (3) for the plu

(8).

• Mount the two covers (1) and (2).

8

5

7

(M2)

6

(M4)

X310

CM-PDPV1 908/08

g

3.2 Disassembly

• Disconnect the frequency inverter from mains voltage and protect it against bein

energized unintentionally.

• Remove covers (1) and (2) of the frequency inverter.

• Loosen the M2 screw (7) on the communication module

• Unplug the communication module from Slot B (4) by unlocking the locking hooks

(9) on the right and left hand side of the module from the case of the frequency

inverter using a small screwdriver.

The looking hooks (9) are located at the place where the looking hooks (10) for

the upper cover (1) project from the case of the frequency inverter.

• To do this, carefully insert the screwdriver in the

module and the frequency inverter and push the locking hook inwards in the

direction of the arrow (

the module out a bit on the right hand side and hold it.

• Hold the module on the right hand side while unlockin

the left hand side in the same way (

• Pull the module out of the slot by gently pulling on the right and left hand side

alternately.

• Disassemble the PE spring (5).

• Mount the two covers (1) and (2).

9

7

gap between the case of the

Õ). As soon as the right hand side is unlocked, pull

g the locking hook on

Ö).

CM-PDPV1 08/0810

4 Socket connection/bus termination/line

X

The bus socket X310 (9-pole Sub-D) is connected according to the Profibus DP standard

EN50170.

Please take the details for the pin allocation

of the bus plug from the following table.

310

The bus termination necessary on the bus line in the physically first and last subscrib-

er can be activated via corresponding circuits in the bus connection sockets (e.g. built

by Siemens).

Attention! The device(s) will only communicate with the master if

− The master is connected to the mains (or powered by DC 24V)

− The unit is connected to the mains (or powered by DC 24V)

− The first and the last subscriber on the connected branch have a

correctly set bus termination

− All other devices in between have no bus termination or a deactivated

bus termination.

Bus plug X310

Pin Name Function

housing screen connected with PE

1 PE PE

2 not used 3 RxD/TxD-P positive signal RxD/TxD-P, corresponding to RS485 B-Line

4 CNTR-P control signal for repeater

5 DGND isolated ground for bus connection

6 VP isolated 5V for bus connection

7 not used 8 RxD/TxD-N negative signal RxD/TxD-N, corresponding to RS485 A-Line

9 not used -

Only admissible types are to be used for the bus socket. They must all be suited for

the 12 MBaud transmission rate.

This is, for example, type Profibus connector 12 MBAUD (6ES7 972-0BA11-0XA0)

from Siemens.

Only admissible types are to be used as a line for the Profibus (line type A).

This is, for example, type UNITRONIC-BUS L2/F.I.P. 1x2x0,64 from Lappkabel.

Attention! The line screen is to be connected to ground (PE) on both sides with

good conductivity.

CM-PDPV1 1108/08

5 Baud rate setting/line length

A

g

P

The baud rate is not explicitly set. The Profibus component supports the Auto_Baud

function and independently determines the baud rate set on the bus.

The maximum line length recommended by the PNO correlates to the Baud rate.

Profibus-DP interface

Baud rate/kBaud max. line length/m

9.6 1200

19.2 1200

45.45 1200

93.75 1200

187.5 1000

500 400

1500 200

3000 100

6000 100

12000 100

6 Setting the station address

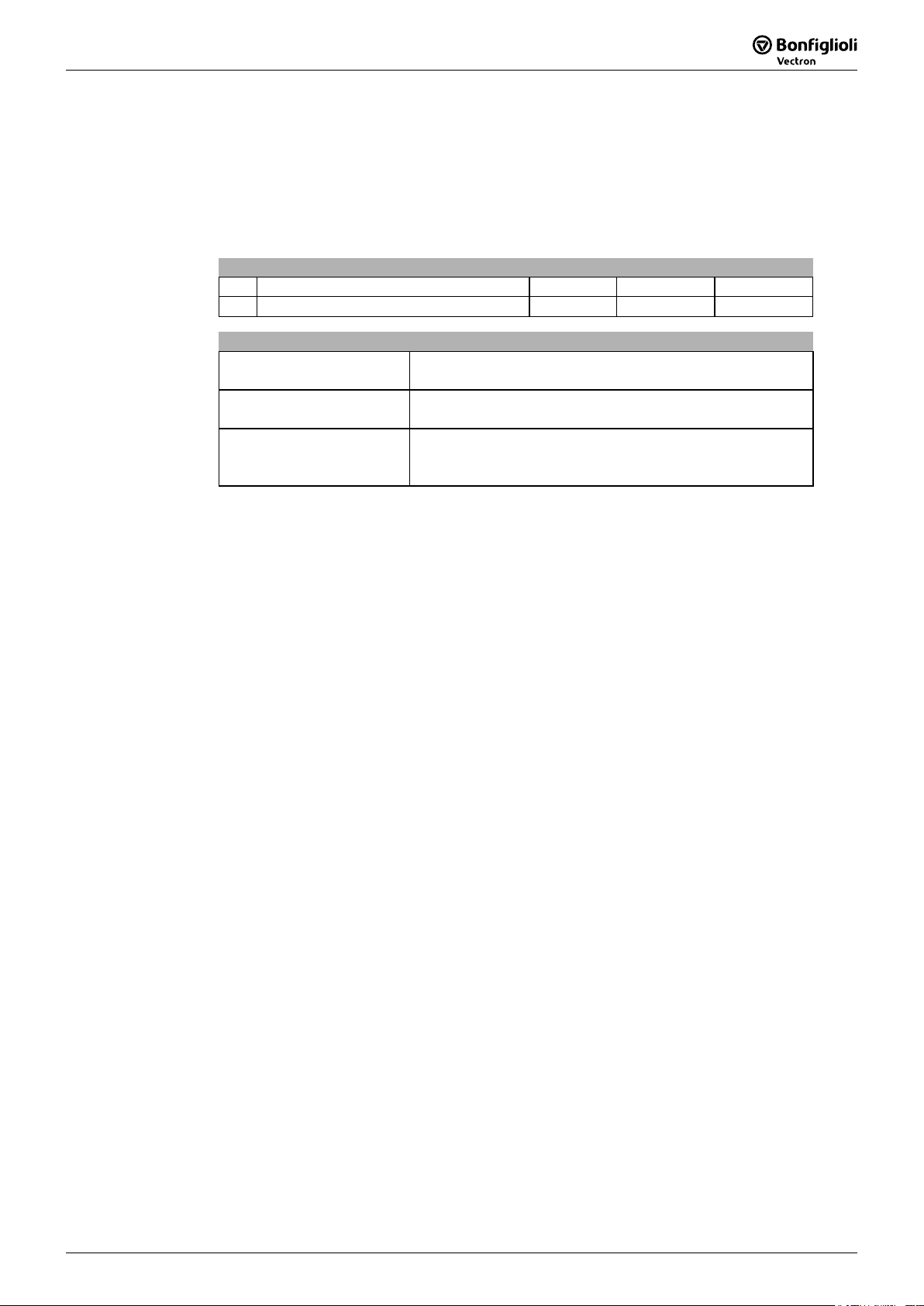

Parameter Setting

No. Description Min. Max. Fact. sett.

391 Profibus Node-ID -1 126 -1

Note:

maximum of 125 slave frequency inverters can be operated on the Profibus-DP.

Each frequency inverter is assigned a node ID for its unambi

uous identification; this

ID may only exist once in the system. The setting of the node ID is carried out via

parameter

Profibus Node-ID 391.

rofibus Node-ID 391= -1 means Profibus function switched off.

CM-PDPV1 08/0812

g

7 LED indicators

The communication module has two bicolor LEDs which display the module status and

the (Profibus) operation mode.

X310

Operation

Status

mode

Operation Mode

state indication

Off not online/no power

Green online, data exchange

Flashing Green online clear

Flashing Red (1 flash) parameterisation error

Flashing Red (2 flashes) configuration error (*)

(*) configuration error

The configuration error indicates an incorrect configuration of the data exchange object. See chapter “Configuration process on the DP master”.

Status

state indication

Off not initialised/no power

Green initialised

Flashing Green initialised, diagnostic event present (*)

Red exception error (**)

(*) diagnostic event

When the inverter enters the error state a diagnostic event is sent from the inverter

controller to the CM-PDPV1. The CM-PDPV1 then sends a dia

gnostic message to the

Profibus master. The Profibus master device is then able to display the inverter error.

The LED stops flashing after the acknowledgement of the inverter error.

Note: Diagnostic events are handled by a S7-CPU with OB82/OB86. If these objects

are NOT loaded the CPU enters the STOP state in the case of a dia

nostic

event.

(**) exception error

An exception error indicates a fatal error on the CM-PDPV1 or communication loss

between CM-PDPV1 and inverter controller. Check the inverter error message (with

KP500 or KP232 and VPlus).

CM-PDPV1 1308/08

8 Status Parameters

Wait_Process_PDP Waiting for connection to Profibus master

Wait_Process2_PDP Waiting for reconnection to Profibus master after

Process_Active_PDP Connection to Profibus master established, Data-

WAIT_PROCESS Waiting for connection to Profibus master

PROCESS_ACTIVE Connection to Profibus master established,

The Profibus module CM-PDPV1 has two actual value parameters which display the

current status of the module itself as well as that of the controlling software in the

inverter.

Status Control 365 displays the software state of the the controlling software in the

inverter.

Status Fieldbus Module 366 displays the module state.

The Status Control 365 and Status Fieldbus Module 366 show the following states

during operation.

Status Control 365

connection loss

Exchange with Profibus master running

Status Fieldbus Module 366

Data-Exchange with Profibus master running

These parameters can show other messages that are usually not of interest. These

messages are of interest for Bonfiglioli Vectron support in the case of problems and

trouble shooting.

Description

Description

9 Error Behaviour

Parameter Setting

No. Description Min. Max. Fact. Sett.

393 Profibus Error Reaction 0 3 1

Operation mode 393 Function

0 - No Reaction Inverter remains in the current state.

1 - Error Inverter enters error state.

2 - Coast to Stop Inverter power stages are switched off and drive stops in

3 - Quick Stop Drive is decelerated with quick stop ramps.

In the event of Profibus errors (e. g. Profibus OFF), the behaviour of the inverter can

be set with

Profibus Error Reaction 393.

free run.

Note: The operation modes “2 - Coast to Stop” and “3 - Quick Stop” are only

available when

Local/Remote 412 is set to “1 - Control via Statemachine”.

CM-PDPV1 08/0814

10 Setting PPO structure

A

g

T

g

Profibus - Objects

Object Objects

PPO 1 12 6

PPO 2 20 10

PPO 3 4 2

PPO 4 12 6

PKW 8 4

PZD 4 2

Note: Further information on the contents of the objects is described in the

s a function of the application in question, various process peripheral objects (PPOs)

with differing lengths and contents are used for data exchange. The CM-PDPV1 offers

a wide ran

e of PPO settings. With the help of a hardware configuration tool the user

is able to construct PPO settings as needed for his application.

Four predefined objects PPO1, PPO2, PPO3 and PPO4 and two additional ob

(communication object PKW, process data object PZD) are available for free configuration.

The required object is to be set on the DP master in the hardware configuration.

There is no setting for the required object on the side of the frequency inverter, it sets

itself automatically to the projected object.

length/Bytes

Objects

length/Words

chapter 13 “Handling of the objects”.

PKW object is used for accessing parameters (read/write) in the in-

The

verter. This object causes additional busload because it sends its contents

with every data exchange cycle, whether it is used or not. As an alternative function without the necessity of the PKW object, the CM-PDPV1

module supports the DP-V1 channel.

his function is explained in chapter

13.2 “Parameter access via the DP-V1 channel”.

Each PZD object has two words of input/output data. The handlin

object is explained in chapter 13.3.1 “Data types of OUT/IN-objects”.

jects

of this

CM-PDPV1 1508/08

10.1 Configuration process on the DP master

The configuration process of the frequency inverter with the Profibus communication

module CM-PDPV1 is shown here using the example of a Siemens STEP7 hardware

gurator. The process is principally valid for other configurations in an equivalent

confi

form.

First, the GSD file BV__0B2C.GSD is installed in the hardware configuration tool (if not

already existent). This is done with the menu selection Extras\Install new GSD.

Here, you enter the path and the name for the GSD file (BV__0B2C.GSD).

If the GSD file has been installed, the frequency inverter appears under the selection

PROFIBUS-DP \ Further FIELD DEVICES \ Drives \ ACTIVE-DPV1

From this position, a frequency inverter ACTIVE-DPV1 can be connected to the Pro-

fibus by Drag & Drop.

CM-PDPV1 08/0816

The six possible objects PPO1 to PPO4 and PKW, PZD are visible under the menu item

f

ACTIVE-DPV1. The required object is now assigned to the inverter by Drag & Drop.

The screen shot from the STEP7 hardware configuration shows a frequency inverter

with station address 3 and a custom-specific configuration.

The above configuration setting is:

1 PKW object 8 bytes or 4 words, communication object (input/output)

4 PZD objects 16 bytes or 8 words, process data objects (input/output)

Note:

• The data direction IN/input and OUT/output is from the master's point o

view.

• Every single configured PZD object results in two word (4 byte) ob

jects PZDn

PZDn+1 for both input and output.

• The CM-PDPV1 offers four predefined ob

jects (PPO1…4) to be compatible to

the former CM-PDP and two additional objects PKW (communication channel)

and PZD (process data) for application specific configurations.

Restrictions for user defined configuration settings:

• The PKW object is allowed only once as the first object.

• As a minimum one PZD object must be configured.

• The resulting number of all objects must be less than or equal to 36 bytes (18

words).

Note: A restriction violation results in a configuration error message from the PLC

on the Profibus start up cycle. Also the Operation Mode Led on the CMPDPV1 flashes red (2 flashes).

CM-PDPV1 1708/08

11 Commands SYNC/FREEZE

g

g

g

The Profibus component supports the Profibus commands SYNC/UNSYNC and

FREEZE/UNFREEZE. These commands are used to synchronize a number of slaves.

With the FREEZE command, all the slaves keep their input data. They are then read

out in sequence by the bus master. As all the slaves keep their inputs simultaneously

with the FREEZE command, the bus master is

at a defined time. With the UNFREEZE command, this state is cancelled and the slaves

iven a process pattern of all the slaves

update their inputs again.

With the SYNC command, all the slaves retain their current outputs. Subsequently

arriving data are not put throu

h to the outputs, but buffered. The bus master can

ive new commands to the slaves and activate all the slaves simultaneously with the

UNSYNC command. They immediately transfer the buffer data to their outputs with

the UNSYNC command.

12 Available objects/scanning times

If a Profibus slave has been recognized, parameterised and configured by its master

on the bus, there is a cyclic exchange of data with the Profibus DATA_EXCHANGE

service, in which the output data are transmitted from the master to the slave and the

input data from the slave to the master in one cycle. The repetition rate with which

the slaves carry out the exchange of data with the master, the so-called bus rotation

time, is a function of the transmission rate, the number of subscribers and the size o

the objects transmitted. If there are few subscribers, a high transmission rate and

short objects being exchanged, bus rotation times of 1 to 2 ms are possible.

It is therefore sensible to configure the objects to suit the application. Depending on

the application the focus can be transmission speed, number of objects or a combination of both.

The configured data exchange objects have principally two components, which are

either completely, partly or not at all existent with the differing object configurations.

These components are the communication channel and the process data channel.

The communication channel (PKW object) is used for accessing (write/read) para-

meters in the frequency inverter. An exception is formed by the strin

g parameters, to

which there is NO access. The communication proceeds according to a firmly defined

hand-shake process and lasts for a number of DATA_EXCHANGE cycles.

The process data channel (PZD objects) is processed in every cycle. The reference

values are accepted and the actual values forwarded. Therefore a data update takes

place with every DATA_EXCHANGE.

Direction of transmission Master Î

Slave (OUT)

communication channel process data channel

PKW area PZD area

PKE IND PWE PWE PZD 1 PZD 2 PZD x PZD x PZD x PZD x

PWEh PWEl STW HSW Outx Outx Outx Outx

PKW Parameter identification value

PZD Process data channel STW = Control word HSW = Main reference value

Outx = user defined

f

CM-PDPV1 08/0818

g

Direction of transmission Slave Î

Master (IN)

communication channel process data channel

PKW area PZD area

PKE IND PWE PWE PZD 1 PZD 2 PZD x PZD x PZD x PZD x

PWEh PWEl ZSW HIW Inx Inx Inx Inx

PKW Parameter identification value

PZD Process data channel ZSW = State word HIW = Main actual value

Inx = user defined

Consistency area

communication channel process data channel

PKW object PZD objects

PKE IND PWE PWE PZD 1 PZD 2 PZD x PZD x PZD x PZD x

full length word word word word word word

The consistency area describes the parts of the object which must have consistent

contents. The consistency states are encrypted in the configuration data of the GSD

file and have effects on the possible access mechanisms on the part of the DP master.

In this way, the 8 bytes of the communication channel in a PLC of type Siemens S7

can only be reached via the special functions SFC14 (DPRD_DAT) and SFC15

(DPWR_DAT). The words of the process data channel are directly addressable as

periphery input/output words (PEW, PAW).

communication channel process data channel

PKE IND PWEh PWEl PZD1 PZD2 PZD3 PZD4 PZD5 PZD6

PPO1

PPO2

PPO3

PPO4

PPO1 … PPO4 are predefined configurations. With the help of the PZD- and PKWobjects you are able to build your own application specific configuration.

• The communication channel is always treated identically. This is valid for the predefined configurations PPO1/PPO2 and custom specific configuration with communication object PKW.

• The process data channel objects PZD1/PZD2 are firmly defined and its contents

cannot be altered. This definition is also valid for user defined configurations.

• The contents of process data channels PZD3 to PZD 18 (maximum, without communication channel PKW !) is user defined.

Note: In the data transmission, the Motorola format is presupposed for the

position of Low/High byte first, as is also supported by a PLC of the type

Siemens S7. If the DP master supports the Intel format, Low/Hi

h byte

are to be swapped on the master side before transmission and after receipt.

CM-PDPV1 1908/08

Scan time

Scan time defines the data update cycle between the Profibus module CM-PDPV1 and

the inverter's controller which processes the Profibus data. This scan time is independent of the bus rotation time.

Regardless of the transmission speed on the Profibus, the scanning time of the inverter is a function of the configured objects and the resultant object length (number o

bytes).

No. of configured

Scan time

Controller/CM-PDPV1

bytes words [ms]

4 2 2

8 4 2

12 6 2

16 8 2

20 10 2

24 12 2

28 14 2

32 16 2

36 18 4

The scan time is dependent on the number of configured objects.

Inverter ACU

f

CM-PDPV1 08/0820

t

13 Handling of the objects

The communication channel (PKW area) has the following structure:

PKE IND PWE-high PWE-low

Byte No. 0 1 2 3 4 5 6 7

The data is transmitted in the Motorola format as, for example, supported by the S7

Note: The data set is always on the high byte of "Index“ (data set/Byte No. 2).

Structure of the parameter identification (PKE):

PKE High Byte Low Byte

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

AK: Request or reply identification (value range 0 ..15)

SPM: Toggle bit for spontaneous result processing

PNU: Parameter number (value range 1 to 1599)

• The request and reply identifications are stored in the AK area. If no parameter

• With bit 11 (SPM), the readiness for spontaneous report processing can be

• The PNU area transmits the number of the parameter to be processed.

Parameter values (= data) of the type Integer/Unsigned Integer (16 Bit) and Long (32

Note: An Excel file, which is available on request, exists for the necessary infor-

Note: To obtain access to the PKW object on a S7 PLC the functions SFC14/15

13.1 Parameter access via communication channel PKW

Designation

Content

Parameter

identification

High

Byte

Low

Byte

Index Parameter value

High

Byte

data set SB

PLC from Siemens. Thus, the high byte is on the lower byte of the telegram and the

low byte on the higher byte.

If the System bus function is available (EM-module with Systembus) a

Systembus address is set on the low byte of “Index” (SB/Byte No. 3). With

the help of this parameter the access to a Systembus subscriber is possible. For details see the Systembus manual.

AK SPM PNU

processing is to be carried out, the “no request” type of function is to be set.

switched on and off (0 = OFF, 1 = ON, in the present application, the spontaneous report processing is not supported, so SPM is always 0).

Bit) can be written and read. The data type is specificied in the request identification.

In data set change-over capable parameters (array), the required data set is stated in

the Index Byte (Byte 2).

mation on the parameters with regards to the data type and data se

change-over capability.

must be used.

PKW Area

Low

Byte

High-Word

High

Byte

Low

Byte

Parameter value

Low-Word

High

Byte

Low

Byte

CM-PDPV1 2108/08

g

g

13.1.1 Request identification

Structure of the request identification AK (output data set, Master Î Slave)

Request identifica-

Data type Function

tion AK

0 - no request

1 int/uint , long read parameter value

2 int/uint write parameter value int/uint

3 long write parameter value long

6 int/uint , long Array read parameter value Array

7 int/uint Array write parameter value int/uint Array

8 long Array write parameter value long Array

Array: Applies to data set change-over capable parameters; the required data must

13.1.2 Reply identification

Reply identification AKData type Function

be specified in data set/INDEX. Otherwise, data set/INDEX = 0.

Structure of the reply identification AK (input data set, Slave Î Master)

0 - no request

1 int/uint transmit parameter value int/uint

2 long transmit parameter value long

4 int/uint Array transmit parameter value int/uint Array

5 long Array transmit parameter value long Array

7 - request cannot be implemented

8 - no control sovereignty for PKW interface

• If the reply identification = 7 (request cannot be implemented), an error code is

inserted in PWE low (Byte 6/7).

• If the reply identification = 8 (no control soverei

right to the slave.

13.1.3 Fault messages

nty), the master has no writin

Coding of the fault messages in the reply data set PWE Low/Low Byte at

Byte 7 (Slave Î

Fault No. (dec.) acc.

Master):

Meaning

to PROFIDRIVE

0 Inadmissible parameter number PNU

1 Parameter value cannot be altered

2 Lower or upper parameter value limit exceeded

3 Faulty data set

4 No data set change-over capable parameter

5 Wrong data type

18 Other fault

Extension Meaning

101

103

104

105

106

Parameter cannot be read

Fault occurred in reading the EEPROM

Fault occurred in writing the EPROM

Check sum fault in EEPROM occurred

Parameter may not be written in operation

107 Values of the data sets differ

108 Unknown request

CM-PDPV1 08/0822

g

13.1.4 Parameters, data set selection and cyclic writing

Parameters to be set can be taken from the parameter list referring to the configura-

tion of the standard operating instructions. In the parameter list, state whether a parameter is data set change-over capable (data set/INDEX = 1 to 4) or only exists once

(data set/INDEX = 0).

The parameter list also provides information on the display format of a parameter and

its type (int/uint/lon

). String parameters cannot be transmitted due to the possible

number of bytes.

The values transmitted are always integer values. For values with decimal places, the

decimal point is not transmitted.

The word IND passes on the required data set of the parameter. In the present appli-

cation, the data set number 0 is assi

gned to existing parameters; a selection from

multiple (data set change-over capable) existing parameters is carried out by inserting

a number from 1 to 4.

The actual parameter value is transmitted in the PWE area; as a 16 Bit value (int/uint)

it occupies PWEl, as a 32 Bit value (long) PWE high and PWE low, with the high word

located in PWE high.

If parameters with four data values are set via data set = 0, all four data sets are set

to the same transmitted value. A read access with data set = 0 to such parameters is

only successful if all four data sets are set to the same value. If this is not the case an

error is reported.

Caution! The values are entered automatically into the EEPROM on the controller.

If values are to be written cyclically with a high repetition rate, there must

be no entry into the EEPROM, as it only has a limited number of admissible writin

g cycles (about 1 million cycles). If the number of admissible

writing cycles is exceeded, the EEPROM is destroyed.

To avoid this, cyclically written data should be transmitted into the RAM (only without

a writing cycle onto the EEPROM). Then the data are not stored secure against zero

voltage and must be written again after a Power off/on.

This mechanism is activated by the target data set being increased by five in the specification of the data set (IND).

Entry only into the RAM:

EEPROM RAM

Entry into data set 0 Data set (IND) = 5

Entry into data set 1 Data set (IND) = 6

Entry into data set 2 Data set (IND) = 7

Entry into data set 3 Data set (IND) = 8

Entry into data set 4 Data set (IND) = 9

Writing access to data set change-over capable parameters is to be considered as a

further special point. If the values of a data set change-over capable parameter are to

be set to the same value in all data sets, the parameter can be written via the data

set (IND) 0.

CM-PDPV1 2308/08

A

g

13.1.5 Sequence of communication

request from the master is always answered with a reply from the slave. Each PPO

can only accept one request or one reply at a time. In this way, a defined hand-shake

procedure between master and slave must be complied with.

In the initial situation, the request and reply identification must = 0. The master sets

its request identification and waits for the slave to change the reply identification from

0 to ≠ 0. Now, the reply from the slave is available and can be evaluated. Thereupon,

the master sets its request identification = 0 and waits for the slave to chan

e the

reply identification from ≠ 0 to 0. With this, the communication cycle is completed and

a new one can start.

Attention! The slave only replies to new requests if it has reacted to the request

identification = 0 with the reply identification = 0.

Idle

request identification Master= 0

reply identification Slave = 0

Master set data

+ order identification

reply

identification

of the slave

unequal 0 ?

evulate reply data of the slave

set order identification = 0

a request can

be started

False

Tru e

False

Tru e

CM-PDPV1 08/0824

A

A

13.1.6 Examples of communication

Parameter Setting

No. Description Type Write /

Read

400 Switching frequency P-W S/L x 1 8 2

480 Fixed frequency 1 P[I]-D S/L xxxx.xx Hz -999.00 999.00 5.00

Parameter 400 is one word (P-W), int, not data set switch-over capable and is to be

Format Min. Max. Fact.

Sett.

read.

Request from Master:

K = 1 (request identification = read parameter value)

PNU = 400 (= 0x190)

IND = 0

PWEh = 0

PWEl = 0

PKW area

Designation PKE IND PWE high PWE low

Content Parameter

identification

High

Byte

Low

Byte

Index Parameter value

High Word

High

Byte

Low

Byte

High

Byte

Low

Byte

Parameter value

Low Word

High

Byte

Low

Byte

0x11 0x90 0 0 0 0 0 0

Byte No. 0 1 2 3 4 5 6 7

Reply from Slave:

K = 1 (reply identification = transmit parameter value int/uint)

PNU = 400 (= 0x190)

IND = 0

PWEh = 0

PWEl = value

PKW area

Designation PKE IND PWE high PWE low

Content Parameter

identification

High

Byte

Low

Byte

Index Parameter value

High Word

High

Byte

Low

Byte

High

Byte

Low

Byte

Parameter value

Low Word

High

Byte

Low

Byte

0x11 0x90 0 0 0 0 0 Wert

Byte No. 0 1 2 3 4 5 6 7

CM-PDPV1 2508/08

Parameter 480 is a double word (P[I]-D), long, data set change-over capable, and is

to be written. The target data set is data set 3.

Reference value = -300.00 Hz (-30000 is transmitted)

The negative value is portrayed as follows in accordance with integer arithmetic:

0xFFFF8AD0

Request from Master:

AK = 8 (request identification = write parameter value long Array)

PNU = 480 (= 0x1E0)

IND = 3

PWEh = 0xFFFF

PWEl = 0x8AD0

PKW area

Designation PKE IND PWE high PWE low

Content Parameter

identification

High

Byte

Low

Byte

Index Parameter value

High Word

High

Byte

Low

Byte

High

Byte

Low

Byte

Parameter value

Low Word

High

Byte

Low

Byte

0x81 0xE0 3 0 0xFF 0xFF 0x8A 0xD0

Byte No. 0 1 2 3 4 5 6 7

Reply from Slave:

AK = 5 (reply identification = transmit parameter value long Array)

PNU = 480 (= 0x1E0)

IND = 3

PWEh = 0xFFFF

PWEl = 0x8AD0

PKW area

Designation PKE IND PWE high PWE low

Content Parameter

identification

High

Byte

Low

Byte

Index Parameter value

High Word

High

Byte

Low

Byte

High

Byte

Low

Byte

Parameter value

Low Word

High

Byte

Low

Byte

0x51 0xE0 3 0 0xFF 0xFF 0x8A 0xD0

Byte No. 0 1 2 3 4 5 6 7

CM-PDPV1 08/0826

T

t

A

x

13.2 Parameter access via the DP-V1 channel

The Profibus communication module CM-PDPV1 provides the possibility to use the

Profibus V1-channel. This is an alternative to the usage of the communication object

PKW in the data exchange object. The PKW object is always sent on the bus,

whether it is used or not, and therefore causes needless busload.

he V1 telegrams for parameter access are special Profibus telegrams that are sen

only when a parameter access is necessary. Contrary to the usage of the PKW object, the V1 telegrams can access all types of parameters including string parameters.

To be compatible to different types of Profibus master devices there are two different methods included for the V1-channel. The behaviour of the CM-PDPV1 concerning the different methods is set with

Parameter Setting

No. Description Min. Max. Fact. Sett.

329 DP-V1 Mode 1 2 2

Operation mode Function

1 - Standard Standard usage of V1 channel

2 - S7 compatible S7 PLC usage of V1 channel

Note: To get access to the V1-channel on a S7 PLC the functions SFC52/53

must be used.

The two different modes are necessary because V1 telegrams are handled differently

on the various Profibus master implementations.

The standard telegram addresses a device by its Profibus node ID and selects the

parameters by two 8 bit objects named

supports the direct setting of the Profibus node ID,

must be set to “1 – Standard” and the handling described for this setting must be

used.

S7 PLC uses two special functions SFC52/53 for the V1-channel. These functions

do not offer an independent setting for node ID,

accomplished by the diagnostic address (with

be accessed. The only available and variable object for the PLC application is

(8 bit). If the Profibus master device does not support the setting of Profibus node

slot

ID,

and

handling described for this setting is to be used.

For both types of DP-V1 Mode the parameter data to be read or written uses the

Motorola format. The number of bytes depends on the parameter data type.

Byte 0 1 2 3 4 5 … …. max. 98

data type

content high byte low byte

data type

content high byte low

data type

content first char.

Parameter data types and byte order

uint/int

uint/int = 2 bytes

long = 4 bytes

string = 1 … 99 bytes

DP-V1 Mode 329.

slot

and

index

. If the Profibus master device

slot

and

index

DP-V1 Mode 329

slot

and

index

. The addressing is

slot

always set to 0) of the device to

inde

index

DP-V1 Mode 329 must be set to “2 – S7 compatible” and the

long

byte

string

CM-PDPV1 2708/08

13.2.1 Standard Mode

A parameter is accessed by its parameter number and data set number. The valid

range for parameter number is 0 … 1599, the range of data set number is 0 … 9.

Note: For the handling of data set selection see chapter “13.1.4 “Parameters, data

set selection and cyclic writing”.

The standard mode uses the direct setting of Profibus node ID,

slot

and

index

the setting of the two 8 bit objects

the selection of parameter number

slot

and

index

. With

and data set number for read/write is done. The number of bytes to be transferred

(read/write) depends on the parameter's data type. In the case of a write cycle and

an invalid number of bytes the CM-PDPV1 protocol reacts with an error message.

Calculation of slot and index:

Calculate an application data index ADI as a 16 bit unsigned integer with

ADI = (parameter number + 1) + (2000 * (data set number + 1))

Calculate the value of

slot

and

index

with

slot = (ADI – 1) / 255

index = (ADI – 1) modulo 255

Example:

parameter number = 480

data set number = 3

ADI = (480 + 1) + (2000 * (3 + 1)) = 8481

slot = (8481 - 1) / 255 = 33

index = (8481 - 1) modulo 255 = 65

The parameter data structure is explained above.

Access to Systembus:

The Standard Mode also offers a special functionality to obtain access to additional

inverters via the Systembus. For example, there exists one inverter with CM-PDPV1

and several additional inverters coupled to the first one via the Systembus.

This function can be implemented with CM-PDPV1 via the virtual parameter 1600.

After power on/reset this virtual parameter 1600 is set to zero. With 1600 = 0 all

parameter accesses by V1 channel are allocated to the inverter with CM-PDPV1 itself.

CM-PDPV1 08/0828

g

Profibus master

(PLC)

Profibus

Parameter =

01

1600

x

CM-PDPV1

Systembus

master

Systembus

Node-ID = 0 Node-ID = 1 Node-ID = x

Systembus

Systembus

slave

Systembus

Systembus

slave

Systembus

To obtain access to parameters of inverters via the Systembus, parameter 1600 is

written to the desired Systembus node ID.

The data type of parameter 1600 is unsigned integer with a valid data range =

0 … 63.

Parameter 1600 can be read and written.

13.2.2 S7-compatible Mode

A parameter is accessed by its parameter number and data set number. The valid

range for parameter number is 0 … 1599, the range of data set number is 0 … 9.

Note: For the handling of data set selection see chapter 13.1.4 “Parameters, data

set selection and cyclic writing”.

The S7-compatible Mode only allows the setting of the object

index

. There are two

steps necessary for reading/writing one parameter. The number of bytes to be transferred (read/write) depends on the parameter's data type. In the case of a write cycle

and an invalid number of bytes the CM-PDPV1 protocol reacts with an error message.

Step 1:

In the first step the desired parameter number, data set number and Systembus node

index

ID are written. This message is sent with

set to 1. The object to be sent has 4

bytes with the following structure:

data structure for index = 1:

Byte 0 1 2 3

content parameter number

high byte low byte

data set

number

System bus

address

Parameter number = 0 …. 1599

Data set = 0 …. 9

System bus address = 0 …. 63

Step 2:

The desired parameter data can now be read or written by sendin

index

request with

set to 2.

The parameter data structure is explained above.

a read or write

CM-PDPV1 2908/08

r

In this chapter the handling of the PZDs is described. The mandatory process data

13.3 Process data channel

objects PZD1/2 are described in chapters 13.4.1 “PZD1, control word/state word” and

13.4.5 “PZD2, reference value/actual value”.

The PZD 3

… 18 objects can be used in an application specific way. Inside the inverte

these objects are represented as sources for PZD Out objects (data received from

Profibus master) and input parameters for sources (data to be sent to the Profibus

master).

Note: Input/output are defined from the Profibus master point of view.

13.3.1 Data types of OUT/IN-objects

Boolean data type

The valid value for boolean is FALSE/0x0000 and TRUE/0xFFFF.

boolean

OUT/IN-PZDn Boolean FALSE 0x0000

OUT/IN-PZDn Boolean TRUE 0xFFFF

data type – Boolean

data content

value

hexadecimal

n = 3 … 18

Word data type

The Word data type can be used for percentage, current and torque variables. Current

and torque are possible in applications with field-orientation. The scalings in question

are described below.

Word data type – Percentage

The value range for percentage values is -300.00 to +300.00%. The values in OUT/IN-

PZDn are displayed with a multiplication factor of 100.

data content

OUT/IN-PZDn Word 0x8AD0 - 30000 - 300.00 %

OUT/IN-PZDn Word 0x0000 0 0.00 %

OUT/IN-PZDn Word 0x7530 + 30000 + 300.00 %

Word data type – Percent

data content

hexadecimal

decimal

logical

interpretation

n = 3 … 18

Word data type – Current

For the current, calculation must be done in the device-internal scaling.

The scaling is:

Reference value = (Reference current[A] / scaling current[A]) · 213

2

13

= 8192 (decimal) = 0x2000 (hexadecimal)

CM-PDPV1 08/0830

Word data type – Torque

For the torque specification, the calculation must be done in the device-internal scal-

ing. The scaling for a torque value is identical to the specification of the reference

current (see Current). If the machine is operated with nominal flux, a reference torque corresponds to a reference current.

Note: The equation stated for current (torque) applies for operation with no-

minal flux. If a machine is operated in the field weakening area, this is to

be considered in the specification values.

If the current or torque variables are used, please take into account the

device-specific scaling.

Long data type

The Long data type can be used for the frequency and position variables.

Frequencies use the internal notation of the inverter (xxx Hz / 4000 Hz) * 2

Examples:

50.00 Hz Î (50.00 / 4000.00) * 2

-80.00 Hz Î (-80.00 / 4000.00) * 2

Position information depends on the settings of the motion control system. (Refer to

the manual “Positioning”.)

data content

OUT/IN-PZDx/y Long 0xnnnnmmmm Application-

x/y = 3/4, 5/6, … 17/18

31

= 0x01999999

31

Long data type

hexadecimal

= 0xFD70A3D8

data content

decimal

specific

logical

interpretation

Application-

specific

31

.

CM-PDPV1 3108/08

t

t

13.3.2 Profibus output sources (OUT-PZD x)

The table below lists the available output sources of the PZD Out objects. The conten

of the sources depends on the application. For the different data types the equivalen

sources must be connected to the inverter input parameters.

Note: •

The availability of Out sources depends on the number of configured

PZD objects.

• Every configured PZD object consists of either two Boolean, two

word or one long output object.

• One PZD out object can be used for one data type only (depending

on the application requirements).

• The first configured PZD object (mandatory) represents the PZD1/2

with fixed contents and functions.

no. of configured

PZD objects

Boolean Sources Word Sources Long Sources

name src-no. name src-no. name src-no.

2 Out-PZD3 Boolean 640 Out-PZD3 Word 656 Out-PZD3_4 Long 672

Out-PZD4 Boolean 641 Out-PZD4 Word 657

3 Out-PZD5 Boolean 642 Out-PZD5 Word 658 Out-PZD5_6 Long 673

Out-PZD6 Boolean 643 Out-PZD6 Word 659

4 Out-PZD7 Boolean 644 Out-PZD7 Word 660 Out-PZD7_8 Long 674

Out-PZD8 Boolean 645 Out-PZD8 Word 661

5 Out-PZD9 Boolean 646 Out-PZD9 Word 662 Out-PZD9_10 Long 675

Out-PZD10 Boolean 647 Out-PZD10 Word 663

6 Out-PZD11 Boolean 648 Out-PZD11 Word 664 Out-PZD11_12 Long 676

Out-PZD12 Boolean 649 Out-PZD12 Word 665

7 Out-PZD13 Boolean 650 Out-PZD13 Word 666 Out-PZD13_14 Long 677

Out-PZD14 Boolean 651 Out-PZD14 Word 667

8 Out-PZD15 Boolean 652 Out-PZD15 Word 668 Out-PZD15_16 Long 678

Out-PZD16 Boolean 653 Out-PZD16 Word 669

9 Out-PZD17 Boolean 654 Out-PZD17 Word 670 Out-PZD17_18 Long 679

Out-PZD18 Boolean 655 Out-PZD18 Word 671

Note: • Every source can be connected to an inverter input parameter with

the same data type. This method is the same as used with Systembus receive objects.

• Boolean sources are representatives for Boolean objects

• Word sources are representatives for current or torque objects

• Long sources are representatives for frequency or position objects

CM-PDPV1 08/0832

-no. name p.-no.

I

I

I

I

The table below lists the available input parameters of the PZD In objects. The con-

13.3.3 Profibus input parameters (IN-PZD x)

tent of the sources depends on the application. For the different data types the

equivalent input parameters must be connected to the inverter sources.

Note: • The availability of In parameters depends on the number of confi-

gured PZD objects.

• Every configured PZD object consists of either two Boolean, two

word or one long input parameter.

• One PZD In object can be used for one data type only (depending

on the application requirements).

• The first configured PZD object (mandatory) represents the PZD1/2

with fixed contents and functions.

no. of configured

PZD objects

Parameter Boolean Parameter Word Parameter Long

name p.-no. name p.

2 In-PZD 3 Boolean 1300 In-PZD 3 Word 1302 In-PZD 3/4 Long 1304

In-PZD 4 Boolean 1301 In-PZD 4 Word 1303

3 In-PZD 5 Boolean 1305 In-PZD 5 Word 1307 In-PZD 5/6 Long 1309

In-PZD 6 Boolean 1306 In-PZD 6 Word 1308

4 In-PZD 7 Boolean 1310 In-PZD 7 Word 1312 In-PZD 7/8 Long 1314

In-PZD 8 Boolean 1311 In-PZD 8 Word 1313

5 In-PZD 9 Boolean 1315 In-PZD 9 Word 1317 In-PZD 9/10 Long 1319

In-PZD 10 Boolean 1316 In-PZD 10 Word 1318

6 In-PZD 11 Boolean 1320 In-PZD 11 Word 1322 In-PZD 11/12 Long 1324

In-PZD 12 Boolean 1321 In-PZD 12 Word 1323

7 In-PZD 13 Boolean 1325 In-PZD 13 Word 1327 In-PZD 13/14 Long 1329

In-PZD 14 Boolean 1326 In-PZD 14 Word 1328

8 In-PZD 15 Boolean 1330 In-PZD 15 Word 1332 In-PZD 15/16 Long 1334

In-PZD 16 Boolean 1331 In-PZD 16 Word 1333

9 In-PZD 17 Boolean 1335 In-PZD 17 Word 1337 In-PZD 17/18 Long 1339

In-PZD 18 Boolean 1336 In-PZD 18 Word 1338

The default setting for all input parameters (except parameters

1302/1303/1307/1308) is FALSE or zero.

The default setting for input parameters 1302/1303/1307/1308 is compatible to the

former CM-PDP module with:

n-PZD 3 Word 1302 = 770 PDP absolute current

n-PZD 4 Word 1303 = 771 PDP active current

n-PZD 5 Word 1307 = 772 warning status

n-PZD 6 Word 1308 = 773 error status

Note: • If one object is set to a specific source no., be sure that the corres-

ponding objects for the same location are set to their default values.

This method is the same as used with Systembus transmit objects.

• Boolean inputs are representatives for boolean objects

• Word inputs are representatives for current or torque objects

• Long inputs are representatives for frequency or position objects

CM-PDPV1 3308/08

Note: The displayed "PDP active current" depends on the control system. In

R

t

field-orientation, the torque-forming current is displayed, in applications

with a v/f characteristic control, the active current, which is also a measure for the torque.

The “PDP absolute current” (r.m.s. current) is always positive. Active current and torque-forming current have a sign prefixed.

Positive currents = motor

Negative currents = generator operation.

Current scaling:

Standardization

Reference value Binary Decimal Hexadecimal

+ 100 % + 214 16384 0x4000

The possible range = ±200% = +32768 to -32768 = 0x8000 to 0x7FFF

For the internal scaling, the data set change-over capable parameter

ated curren

371 is used as a reference.

Parameter Setting

No. Description Min. Max. Fact. Sett.

371 Rated current 0.01 · I

10 · I

FIN

I

FIN

FIN

CM-PDPV1 08/0834

13.4 Frequency conversion PDP word Å Æ inverter internal

notation

If the inverter is equipped with the Profibus module CM-PDPV1 or an expansion module with Systembus, the function

verts frequency values in Profibus notation (see chapter 13.4.5 “PZD2, reference value/actual value”) to frequency values in internal notation and vice versa.

Frequency Converter Profibus Notation/Internal Notation

convert PDP/intern

is available. This function con-

In-F-PDP-word1

1370

In-F-PDP-word2

1371

Convert-Reference

1374

xxx.xx Hz

In-F-intern-long1

1372

In-F-intern-long2

1373

The scaling for In_F_PDP_word1/2 and Out_F_PDPconv_word1/2 is:

X

X

XX

/

/

774 - Out-F-PDPconv-long1

775 - Out-F-PDPconv-lon

776 - Out-F-PDPconv-word1

777 - Out-F-PDPconv-word2

g2

Standardization

Reference value Binary Decimal Hexadecimal

+ 100% + 214 16384 0x4000

- 100% - 214 49152 0xC000

The possible range = ±200% = +32768 to -32768 = 0x7FFF to 0x8000

This function uses its own reference value

Convert-Reference

1374 for data conversion. The benefit of this function is the usage of the word data type for frequency

values, instead of long.

Note: The usage of this function and the usage of In-PZD/Out-PZD ob

jects is

shown in the sample project documented with:

− CM_PDPV1_conf.pdf Cluster with one inverter and CM-PDPV1 and three

additional inverters coupled by Systembus

− CM_PDPV1_S7.pdf Functional description

− CC_0B2C.zip Complete STEP7 project including samples for

In/Out-PZD usage and parameter access via PKW

object and V1 channel

− S7-SoftwareOB1.pdf Listing of OB1 from STEP7 project

CM-PDPV1 3508/08

D

A

13.4.1 PZD1, control word/state word

In PZD1, the master gives its control commands (control word) to the frequency inver-

ter in the output data set and receives the information on its state (status word) in the

input data set.

The control of the frequency inverter can be carried out with three different operation

modes. These are set via the data set change-over capable parameter

cal/Remote

412.

Lo-

Parameter Setting

No. Description Min. Max. Fact. sett.

412 Local/Remote 0 44 44

For operation on the Profibus, only the settings 0, 1 and 2 are relevant. The remaining

settings relate to the possibilities of control via the KP500 control unit.

Operation mode Function

0 - Control via contacts

Control via

1 -

state machine

Control via

2 -

remote contacts

The Start and Stop command as well as the statement

of the direction of rotation are set via digital signals.

The Start and Stop command as well as the statement

of the direction of rotation are set via the DRIVECOM

State machine of the communication interface.

The Start and Stop command as well as the statement

of the direction of rotation are set via logic signals by

the communication protocol.

Control word STW and state word ZSW have different contents depending on the

operation mode. In each case, all or only some of the bits in the control word are

relevant and also only certain feedbacks are possible via the status word. These are

explained later in the descriptions of the three possible operation modes.

The control and state words have been created according to DRIVECOM. In this way,

there is compatibility to PROFIDRIVE.

Note:

Parameter

switchin

Local/Remote 412 is data set change-over capable. Thus,

g over between various operation modes via the data set selection

is possible. For example, it is possible to control a frequency inverter via

the bus and to activate a local emer

gency operation if the bus master

breaks down. This switch-over is also visible via the state word (Bit Remote).

Data set change-over can be carried out locally on the frequency inverter via contact

inputs, or via the bus. For data set change-over via the bus, parameter

tion

414 is used.

Data set selec-

Parameter Setting

No. Description Min. Max. Fact. sett.

414 Data set selection 0 4 0

Data set selection 414 = 0, data set switch-over via contact inputs is active. If

With

ata set selection 414 has been set to 1, 2, 3, or 4, then the corresponding data set

has been activated. Data set switch-over via the contact inputs is then deactivated.

Via parameter

Active data set 249, the currently selected data set can be read out.

ctive data set 249 states the activated data set with the value 1, 2, 3 or 4. This is

independent of whether the data set change-over was carried out via control inputs or

via

Data set selection 414.

CM-PDPV1 08/0836

13.4.2 Control via contacts

In the operation mode control via contacts (

inverter is controlled via the contact inputs S2IND to S6IND. The meaning of these

inputs can be taken from the operating instructions. The control word in PZD1 is not

relevant for this operation mode.

Local/Remote 412 = 0), the frequency

State machine: The values displayed in the states are reflected in the status word

(Bit 0 to Bit 6) in PZD1.

Power on

Initialisation

Ready

Quitt fault

0x23

Enable

on

Enable

off

Operation

enabled

0x27

Control word

15

14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Bit

State word

15 14 13 12 11 10 9 876 5 432 1 0 Bit

Fault

0x08

from any state

-

0

Ready to switch on

1

Ready

2

Operation enabled

3

Fault

4

Voltage – inhibited

5

Quick-stop

6

Switch on inhibit

7

Warning

8

-

9

Remote

10

Reference value reached

11

Limit value reached

12 – 14

-

15

Warning 2

CM-PDPV1 3708/08

g

g

A

g

The status word reflects the operation state.

State word

State HEX (*) Bit 6 Bit 5 Bit 3 Bit 2 Bit 1 Bit 0

Ready 0x23 0 1 0 0 1 1

Operation enabled 0x27 0 1 0 1 1 1

Fault 0x08 0 x 1 0 0 0

(*)without considering bits 7 to bit 15

Note: The occurrence of a fault leads to a switch-over to the "Fault" state.

A fault can only be acknowledged 15 seconds after its occurrence, as a

blocking time is active internally.

The Warning bit "Bit No. 7" can be set at any time. It indicates a device-internal

warning message. The evaluation of the present warning is carried out by reading out

the warning status with parameter

Warnings 270.

The Remote bit "Bit No. 9" is always = 0.

The bit Reference value reached "Bit No. 10" is set whenever the specified refer-

ence value has been reached. In the special case of power failure regulation, the bit is

also set if the power failure regulation has reached the frequency 0 Hz (see operating

instructions). For "Reference value reached“ there is a hysteresis (tolerance range),

which can be set via parameter

max. Control deviation 549 (see operating instruc-

tions).

The bit Limit value active "Bit No. 11" indicates that an internal limit is active. This

can, for example, be the present current limit, the torque limit or the over-volta

e

limit. All the functions lead to the reference value being quit or not reached.

The bit Warning 2 "Bit No. 15" indicates a warning which leads to a fault switch-off

of the frequency inverter within a short period of time. This bit is set if there is a

warnin

phase failure.

13.4.3 Control via state machine

In the operation mode control via state machine (

for motor temperature, heat sink/inside temperature, Ixt monitoring or mains

Local/Remote 412 = 1), the fre-

quency inverter is controlled via the control word in PZD1. The possible states are

shown in the diagram. The values on the transition identify these transitions between

the states. The codes shown on the transitions, 0xnn, are the control word needed in

each case (Bit 0 to Bit 7). The codes contained in the states, 0xnn, display the contents of the state word (Bit 0 to Bit 7).

fter mains on (Reset), the frequency inverter is in the state "Switch-on inhibit“

(0x40). With the transitions 4 and 5, there is a chan

e between "Operation enabled“

(0x27, power parts enabled, drive working) and "Ready“ (0x23, power parts blocked).

CM-PDPV1 08/0838

Release (transition 4) is only possible if the hardware release is available via contact

inputs STOA AND STOB AND (S2IND OR S3IND). (S2IND = Start Clockwise, S3IND

= Start Anticlockwise.)

configuration of the digital inputs. If the contact input STOA or STOB is switched off

(or both), the inverter output stage is switched off. The drive coasts down to

standstill. There is a transition to "Ready“ (0x23, power parts blocked). For the function of the inputs STOA and STOB refer to the application manual “Safe Torque Off”.

The behaviour of transition 5 can be set via parameter

They can be firmly wired or firmly connected to On/Off via the

State transition 5 392. Here,

free stopping, shutdown via ramp (reversible) or DC braking (see Chapter 13.4.3.2

State machine:

“Behaviour in transition 5”) can be used.

0

13

Fault reaction

activ

14

Fault

0x08

12

0x00 or

internal

9

0x00

0x06

Switched off

(Initialising)

Switch-on inhibit

0x40

8

0x06

Ready to switch-on

0x21

0x07

Ready

0x23

1

2

0x00

15

0x80

7

10

3

6

0x06

0x00

5

0x07

Operation enabled

(Drive running)

0x27

11

0x02

Quick-stop

0x07

15 14 13 12 11 10 9 876 5 432 1 0 Bit

Control word

0

Switch on

1

Voltage-inhibit

2

Quick stop

3

Operation-enabled

4 – 6

-

7

Reset-fault

8 – 15

-

CM-PDPV1 3908/08

A

Control commands

The device control commands are triggered by the following bit combinations in the

control word:

Control word

Command HEX Bit 7 Bit 3 Bit 2 Bit 1 Bit 0 Transition

Shutdown 0x06 X X 1 1 0 2, 6, 8

Switch-on 0x07 X X 1 1 1 3

Voltage-inhibit 0x00 X X X 0 X 7, 9, 10

Quick-stop 0x02 X X 0 1 X 11

Operation-inhibit 0x07 X 0 1 1 1 5

Operation enabled 0x0F X 1 1 1 1 4

Reset faults 0x80

0 Ö 1

x x x x 15

The shaded commands are the commands relevant for the simplified state machine.

To make operation of the device easier, a simplification has been implemented in the

extension to the state machine defined under DRIVECOM. An additional transition

from "Switch-on inhibit" to "Operation enabled" exists.

Note: The occurrence of a fault leads to a switch-over to the "Fault" state. The

acknowledgement of the fault is carried out by a positive edge on Bit 7.

fault can only be acknowledged 15 seconds after its occurrence, as a

blocking time is active internally.

15 14 13 12 11 10 9 876 5 432 1 0 Bit

State word

0

Ready to switch on

1

Ready

2

Operation enabled

3