Page 1

ACTIVE and

ACTIVE Cube

Modbus communication

with CM-232/CM-485/CM-485T

Frequency Inverter 230 V / 400 V

Page 2

Page 3

General Information about the Documentation

The present supplement of the operating instructions refers to the frequency inverters

of the ACT and ACU line. It contains necessary information for installation and use of

the communication modules CM-232 and CM-485.

In order to make it as easy as possible for the user to find his/her way through the

documentation, it is structured according to the customer-specific demands made of

the frequency inverter.

Brief Instructions

The Brief Instructions describe the basic steps required for mechanical and electrical

installation of the frequency inverter. The

guided commissioning supports you in the

selection of necessary parameters and the configuration of the frequency inverter by

the software.

Operating Instructions

The Operating Instructions describe and document all functions of the frequency in-

verter. The parameters required for adapting the frequency inverter to specific applications as well as the wide range of additional functions are described in detail.

Application Manual

The Application Manual contains additional information facilitating the installation and

commissioning of the frequency inverter, i.e. information on the different issues relating to the specific application realized by the frequency inverter.

Installation Instructions

Complementing the Brief Instructions and the Operating Instructions, the Installation

Instructions provide information on how to install and use the additional/optional

components.

If you need a copy of the documentation or additional information, contact your local

representative of BONFIGLIOLI.

The following pictograms and signal words are used in the documentation:

Danger!

Danger refers to an immediate threat. Non-compliance with the precaution described

will result in death, serious injury or material damage.

Warning!

Warning refers to a possible threat. Non-compliance with the warning may result in

death, serious injury or material damage.

Caution!

Caution refers to an immediate hazard. Non-compliance may result in personal or

material damage.

Attention!

Attention and the related text refer to a possible behavior or an undesired condition

which can occur during operation.

Note

Note and the related text provide useful information which supplements the corresponding part of the documentation.

Modbus Instruction manual 105/08

Page 4

Warning! The specifications and instructions contained in the documentation must

be complied with strictly during installation and commissioning. Only

qualified staff who has read the documentation and, in particular, the

safety instructions carefully is allowed to carry out installation or commissioning work or to operate the frequency inverters. The term „Qualified

Staff“ refers to anybody who is familiar with the installation, assembly,

commissionin

g and operation of the frequency inverter and has the

proper qualification for the job.

Modbus Instruction manual 05/082

Page 5

TABLE OF CONTENTS

1 General Safety Instructions and Information on Use.................................................... 5

1.1 General Information ................................................................................................ 5

1.2 Purpose of the Frequency Inverters ........................................................................ 5

1.3 Transport and Storage ............................................................................................. 6

1.4 Handling and Installation ........................................................................................ 6

1.5 Electrical Connection ............................................................................................... 6

1.6 Information on Use.................................................................................................. 7

1.7 Maintenance and Service......................................................................................... 7

2 Introduction ................................................................................................................... 8

3 Installation/Disassembly of the communication module.............................................. 9

3.1 Installation .............................................................................................................. 9

3.2 Disassembly ........................................................................................................... 10

4 Plug Assignment/Bus Termination/Cable ................................................................... 11

4.1 RS232 module CM-232 .......................................................................................... 11

4.2 RS485 module........................................................................................................ 12

4.2.1 RS485 module CM-485 DB9.................................................................................... 12

4.2.2 RS485 module CM-485 T........................................................................................ 12

4.2.3 Bus termination ..................................................................................................... 13

5 Startup ......................................................................................................................... 14

5.1 General Information on configuration .................................................................. 14

5.2 RS232 Module CM-232 .......................................................................................... 16

5.2.1 Setting the Modbus Baud Rate and Parity ................................................................ 16

5.2.2 Setting the Modbus Address ................................................................................... 16

5.3 RS485 Module CM-485 .......................................................................................... 17

5.3.1 Setting the Modbus Baud Rate and Parity ................................................................ 17

5.3.2 Setting the Modbus Node Address........................................................................... 17

6 Modbus over Serial Line Protocol................................................................................. 18

6.1 Master/Slaves Protocol Principle .......................................................................... 18

6.2 Addressing Rules ................................................................................................... 19

6.3 Message Description .............................................................................................. 19

6.4 Supported Function Codes..................................................................................... 20

6.4.1 Function Code 3, Read 16-bit Parameter.................................................................. 20

6.4.2 Function Code 6, Write 16-bit Parameter ................................................................. 22

6.4.3 Function Code 100, Read 32-bit Parameter ..............................................................23

6.4.4 Function Code 101, Write 32-bit Parameter.............................................................. 24

6.4.5 Function Code 8, Diagnostics.................................................................................. 25

6.5 Exception Responses ............................................................................................. 27

6.6 Exception Codes .................................................................................................... 27

6.7 The two serial Transmission Modes....................................................................... 29

6.7.1 RTU Transmission.................................................................................................. 29

6.7.1.1 Character Format ............................................................................................ 29

6.7.1.2 Frame Description ........................................................................................... 29

Modbus Instruction manual 305/08

Page 6

6.7.1.3 Modbus Message RTU Framing......................................................................... 30

6.7.1.4 CRC Checking .................................................................................................30

6.7.2 ASCII Transmission................................................................................................ 33

6.7.2.1 Character Format ............................................................................................ 33

6.7.2.2 Modbus Message ASCII Framing....................................................................... 33

6.7.2.3 LRC Checking.................................................................................................. 34

6.8 Monitoring Timing Function .................................................................................. 35

6.9 Watchdog............................................................................................................... 35

7 Handling of Data Sets/Cyclic Writing .......................................................................... 36

8 Modbus Message Examples.......................................................................................... 38

8.1 Modbus RTU-Message Examples ........................................................................... 38

8.1.1 Function Code 3, Read 16-bit Parameter.................................................................. 38

8.1.2 Function Code 6, Write 16-bit Parameter ................................................................. 39

8.1.3 Function Code 100, Read 32-bit Parameter ..............................................................40

8.1.4 Function Code 101, Write 32-bit Parameter.............................................................. 41

8.1.5 Function Code 8, Diagnostics.................................................................................. 42

8.2 Modbus ASCII-Message Examples ........................................................................ 43

8.2.1 Function Code 3, Read 16-bit Parameter.................................................................. 43

8.2.2 Function Code 6, Write 16-bit Parameter ................................................................. 44

8.2.3 Function Code 100, Read 32-bit Parameter ..............................................................45

8.2.4 Function Code 101, Write 32-bit Parameter.............................................................. 46

8.2.5 Function Code 8, Diagnostics.................................................................................. 47

9 ACT Inverter Control/Reference Value........................................................................ 48

9.1 Control ................................................................................................................... 50

9.1.1 Control via Contacts............................................................................................... 50

9.1.2 Control via Control Word of Statemachine................................................................ 53

9.1.2.1 Behavior in Case of Quick Stop......................................................................... 58

9.1.2.2 Behavior in state-transition 5............................................................................ 59

9.1.3 Control via Remote Contacts................................................................................... 60

9.2 Reference Value..................................................................................................... 63

9.2.1 Reference Frequency ............................................................................................. 63

9.2.2 Reference Percentage ............................................................................................ 65

10 ACU Inverter Control/Reference Value........................................................................ 66

10.1 Control via contacts/remote contacts................................................................ 68

10.2 Control via state machine................................................................................... 71

10.2.1 Behavior in quick stop............................................................................................ 74

10.2.2 Behavior in transition 5 .......................................................................................... 75

10.2.3 Reference value/actual value .................................................................................. 76

11 Parameter List.............................................................................................................. 78

11.1 Actual Value Menu (VAL).................................................................................... 78

11.2 Parameter Menu (PARA) .................................................................................... 78

12 Annex ........................................................................................................................... 80

12.1 Warning Messages.............................................................................................. 80

12.2 Error Messages ................................................................................................... 81

12.3 ASCII Tabelle (0x00 – 0x7F) .............................................................................. 83

Modbus Instruction manual 05/084

Page 7

1 General Safety Instructions and Information on Use

The present documentation was prepared with great care and it was subjected to

extensive and repeated reviews. For reasons of clarity, it was not possible to include

all details of all types of the product in the documentation. Neither was it possible to

consider all conceivable installation, operation or maintenance situations. If you require further information or if you meet with specific problems which are not dealt

with in sufficient detail in the documentation, contact your local BONFIGLIOLI a

We would also like to point out that the contents of this documentation do not form

part of any previous or existin

are they intended to supplement or replace such agreements, assurances or legal

relationships. The manufacturer's obligations are exclusively specified in the relevant

purchase contract. This contract also contains all and any warranty regulations which

may apply to the relevant scope of supply. These contractual warranty provisions are

neither extended nor limited by the specifications contained in this documentation.

The manufacturer reserves the right to correct or amend the specifications, product

information and omissions in these operating instructions without notice. The manufacturer shall not be liable for any damage, injuries or costs which may be caused by

the aforementioned reasons.

1.1 General Information

gent.

g agreement, assurance or legal relationship. Neither

Warning!

The DC-link circuit of the frequency inverter is charged during operation,

i.e. there is always the risk of contact with high voltage. Frequency inverters are used for drivin

surface during operation.

Any unauthorized removal of the necessary covers, improper use, wron

installation or operation may result in serious injuries or material damage.

In order to avoid such in

out the transport, installation, setup or maintenance work required. The

standards EN 50178, IEC 60364 (Cenelec HD 384 or DIN VDE 0100), IEC

60664-1 (Cenelec HD 625 or VDE 0110-1), BGV A2 (VBG 4) as well as the

applicable national regulations must be complied with. The term „Qualified Staff“ refers to anybody who is familiar with the installation, assembly, commissionin

possible hazards and has the proper qualification for the job.

1.2 Purpose of the Frequency Inverters

Warning!

The frequency inverters are electrical drive components intended for installation in industrial plants or machines. Commissioning and start of

operation is not allowed until it has been verified that the machine meets

the requirements of the EC Machinery Directive 98/37/EEC and EN 60204.

In accordance with the CE markin

comply with the Low Voltage Directive 72/23/EEC as well as EN 50178 /

DIN VDE 0160 and EN 61800-2. The user shall be responsible for making

sure that the requirements of the EMC Directive 89/336/EEC are met.

Frequency inverters are only available at specialized dealers and are exclusively intended for professional use as per EN 61000-3-2.

The frequency inverters are also marked with the UL label according to

UL508c, which proves that they also meet the requirements of the CSA

Standard C22.2-No. 14-95.

The technical data, connection specifications and information on ambient

conditions are indicated on the name plate and in the documentation and

must be complied with in any case. Anyone involved in any kind of work

at the device must have read the instructions carefully and understood

them before starting the work.

g moving parts and they may become hot at the

g

juries or damage, only qualified staff may carry

g and operation of the frequency inverter as well as the

g requirements, the frequency inverters

Modbus Instruction manual 505/08

Page 8

1.3 Transport and Storage

The frequency inverters must be transported and stored in an appropriate way. During

transport and storage the devices must remain in their original packaging. The units

may only be stored in dry rooms which are protected against dust and moisture and

are exposed to little temperature deviations only. Observe the climatic conditions according to EN 50178 and the markin

for more than one year without connecting them to the rated mains voltage.

1.4 Handling and Installation

Warning!

The frequency inverters are to be used in accordance with the documentation as well

as the applicable directives and standards. They must be handled carefully and protected against mechanical stress. Do not bend any components or chan

distances. Do not touch electronic components or contacts. The devices are equipped

with components which are sensitive to electrostatic energy and can easily be damaged if handled improperly. Any use of dama

considered as a non-compliance with the applicable standards. Do not remove any

warning signs from the device.

Damaged or destroyed components must not be put into operation because they may be a health hazard.

1.5 Electrical Connection

Warning!

When workin

A2 (VBG 4), VDE 0100 and other national directives. Comply with the electrical installation instructions given in the documentation as well as the relevant directives. Responsibility for compliance with and examination of the limit values of the EMC product norm EN 61800-3 for variable-speed electrical drive mechanisms is with the manufacturer of the industrial plant or machine.

The documentation contains information on EMC-conformin

connected to the frequency inverters may not be subjected to high-voltage insulation

tests unless appropriate circuitry measures are taken before. Otherwise the unit may

be damaged.

Before any assembly or connection work, discharge the frequency inverter. Verify that the frequency inverter is discharged.

Do not touch the terminals because the capacitors may still be charged.

Comply with the information

frequency inverter label.

g at the frequency inverters, comply with the applicable standards BGV

g on the packaging. The units must not be stored

ge the isolating

ged or destroyed components shall be

given in the operating instructions and on the

g installation. The cables

Modbus Instruction manual 05/086

Page 9

1.6 Information on Use

Warning!

The frequency inverter may be connected to power supply every 60 s.

Consider this for a jog operation of a mains contactor. For commissioning

or after an emergency stop, a non-recurrent, direct restart is permissible.

After a failure and restoration of the power supply, the motor may star

unexpectedly if the AutoStart function is activated. Install protective

equipment if personal injury or material damage is possible.

Before commissioning and start of the operation fix all covers and chec

the terminals. Check the additional monitoring and protective devices accordin

Machines Act, Accident Prevention Directives etc.).

No connection work may be performed, while the system is in operation.

1.7 Maintenance and Service

Warning!

Unauthorized opening and improper interventions can lead to personal

injury or material damage. Repairs on the frequency inverters may only be

carried out by the manufacturer or persons authorized by the manufacturer. Check protective equipment regularly.

g to EN 60204 and applicable the safety directives (e.g. Working

t

k

Modbus Instruction manual 705/08

Page 10

2 Introduction

This document describes the Modbus protocol of the communication modules CM-232

with RS232 port and CM-485 with RS485 port. This protocol can be used alternatively

to the VABus via the same hardware (CM-232/CM-485). Both protocols can not be

operated at the same time. The Modbus operation modes RTU and ASCII are available.

For the RS232 connection, the frequency inverter must be equipped with the RS232

communication module CM-232.

For the RS485 connection, the frequency inverter must be equipped with the RS485

communication module CM-485.

The communication modules CM-232 and CM-485 are separate components and must

be mounted to the frequency inverter by the user. This is described in detail in chapter "Assembly".

Note: This document only describes the communication modules CM-232 and

Note: In some chapters of these instructions, setting and display options via the

Attention! Via the RS232 port at CM-232 or the RS485 port at CM-485, a controller

RS485 connection:

Frequency inverters can be connected to a bus system by extension with CM-485

communication modules. The bus structure is linear and designed as a 2-wire line. Via

a bus master, up to 247 frequency inverters can be addressed.

The frequency inverters can be parameterized and controlled easily. Additionally, frequency inverter data can be polled and positionin

during operation via the bus system by means of a PC or a PLC.

RS232 connection:

The RS232 connection enables a peer-to-peer connection between two clients.

CM-485. It does not provide basic information on the serial interfaces

RS232 and RS485. Neither does it contain any basic information on the

operation of the frequency inverters.

Basic knowled

ge of the methods and function of the RS232 and RS485

serial interfaces and Modbus protocol is required in order to understand

and use the instructions contained in this document.

PC software VPlus are described as an alternative to the KP500 control

unit. In this case, VPlus communicates with the frequency inverter

− via the module CM-232 or CM-485 or

− via the interface adapter KP232.

If the serial interface of the module CM-232/CM-485 is connected to a

PLC, for example, VPlus cannot access the frequency inverter via this

interface directly.

In this case, the PC must be connected via the optional interface adapter

KP232.

can access all parameters of the frequency inverter.

Any chan

ge of parameters, the meaning of which is unknown to the user,

may result in the frequency inverter becoming inoperative.

g commands can be transmitted

Modbus Instruction manual 05/088

Page 11

3 Installation/Disassembly of the communication module

The communication module is pre-assembled in a case. Additionally, a PE spring is

3.1 Installation

enclosed for PE connection (shield).

Caution! The frequency inverter must be disconnected from power supply before

installation of the communication module.

Assembly under voltage is not permissible and will destroy the frequency

inverter and/or the communication module.

Do not touch the PCB visible on the back of the module, otherwise com-

Work steps:

ponents may be damaged.

• Disconnect the frequency inverter from mains voltage and protect it against being

energized unintentionally.

• Remove covers (1) and (2) of the frequency inverter. Slot B (4) for the commu-

nication module is now accessible.

• Mount the supplied PE spring (5) using the M4 screw (6) in the unit. The spring

must be aligned centrally.

• Insert the communication module in slot B (4) until it engages audibly.

• Fix the communication module by screwing the M2 screw (7) of the module to the

PE spring (5).

8

5

7

(M2)

6

(M4)

• In the upper cover (1), break out the pre-punched cutout (3) for the plug X310

(8).

• Mount the two covers (1) and (2).

Modbus Instruction manual 905/08

Page 12

3.2 Disassembly

• Disconnect the frequency inverter from mains voltage and protect it against being

energized unintentionally.

• Remove covers (1) and (2) of the frequency inverter.

• Loosen the M2 screw (7) at the communication module

9

7

• Unplug the communication module from Slot B (4) by unlocking the locking hooks

(9) on the right and left side of the module from the case of the frequency in-

verter using a small screwdriver.

The looking hooks (9) are located at the place where the looking hooks (10) for

the upper cover (1) project from the case of the frequency inverter.

To do this, insert the screwdriver in the gap between the case of the module

•

and the frequency inverter carefully and push the locking hook inwards in the

direction of the arrow (

Õ). As soon as the right side is unlocked, pull out the

module a bit on the right side and hold it.

• Hold the module on the ri

side in the same way (

ght side while unlocking the locking hook on the left

Ö).

• Pull the module out of the slot by gently pulling on the right and left side al-

ternately.

• Disassemble the PE spring (5).

• Mount the two covers (1) and (2).

Modbus Instruction manual 05/0810

Page 13

4 Plug Assignment/Bus Termination/Cable

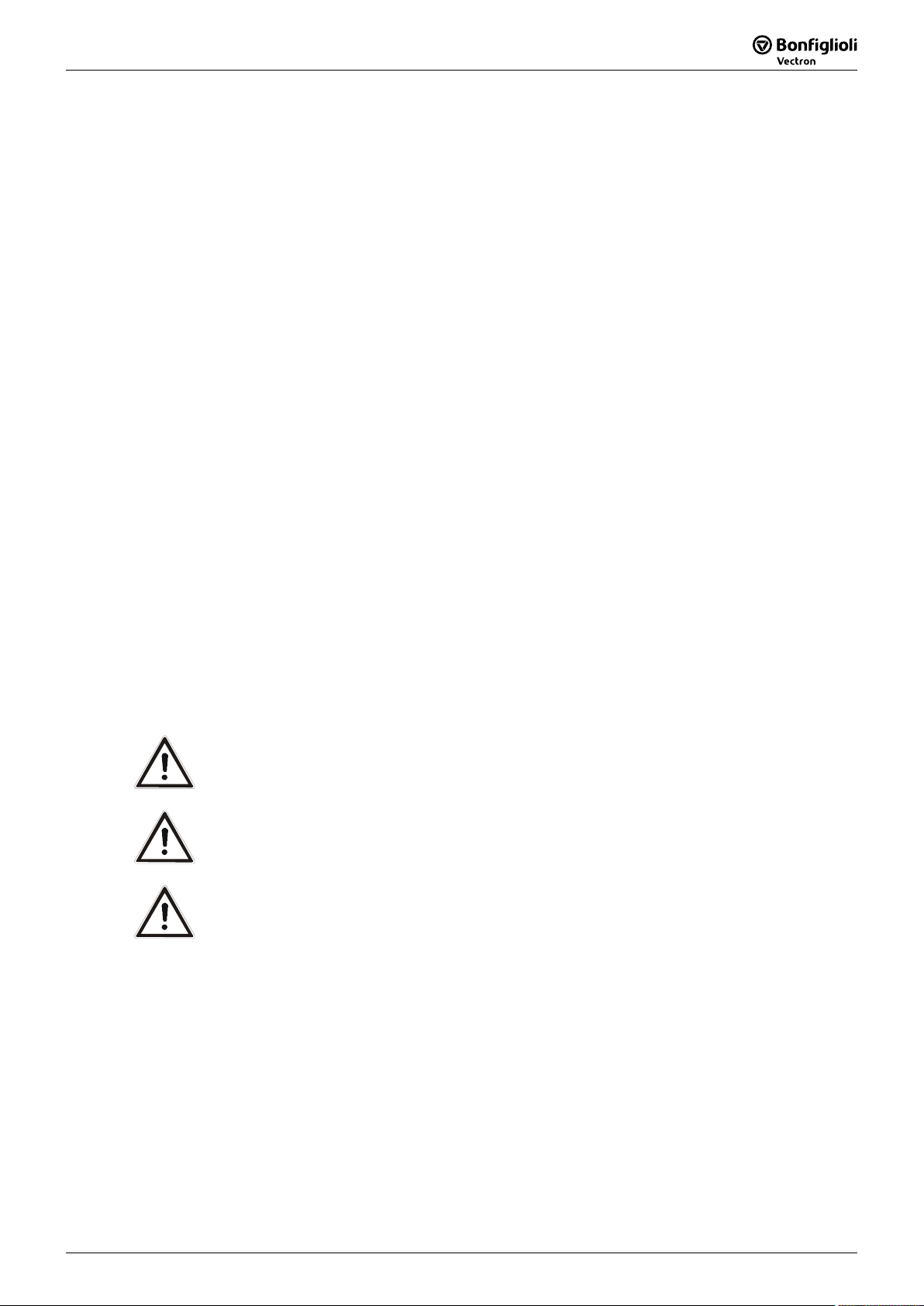

Bus Connector X310 CM-232 (9p Sub-D)

• If no pre-assembled connection cable is used for the RS232 connection, a twisted

4.1 RS232 module CM-232

The RS232 interface is connected to a PC or a

Part. no.

179 675-100

pin name function

Housing Shield connected with PE

1

2

3

4

5

6

7

8

9

– n. c.

RxD receive Data (input)

TxD transmit Data (output)

– n. c.

0 V Ground

– n. c.

– n. c.

– n. c.

– n. c.

and shielded cable is to be used

• 1:1 assignment of the pin contacts

• The shield must be a harness shield (not a foil shield)

• The shield is to be connected to PE properly on both sides

controller via the 9-pin D-Sub socket X310. The

gnment complies with the standard, thus a

assi

RS232 connection cable (1:1) is required for connection only.

X310

Modbus Instruction manual 1105/08

Page 14

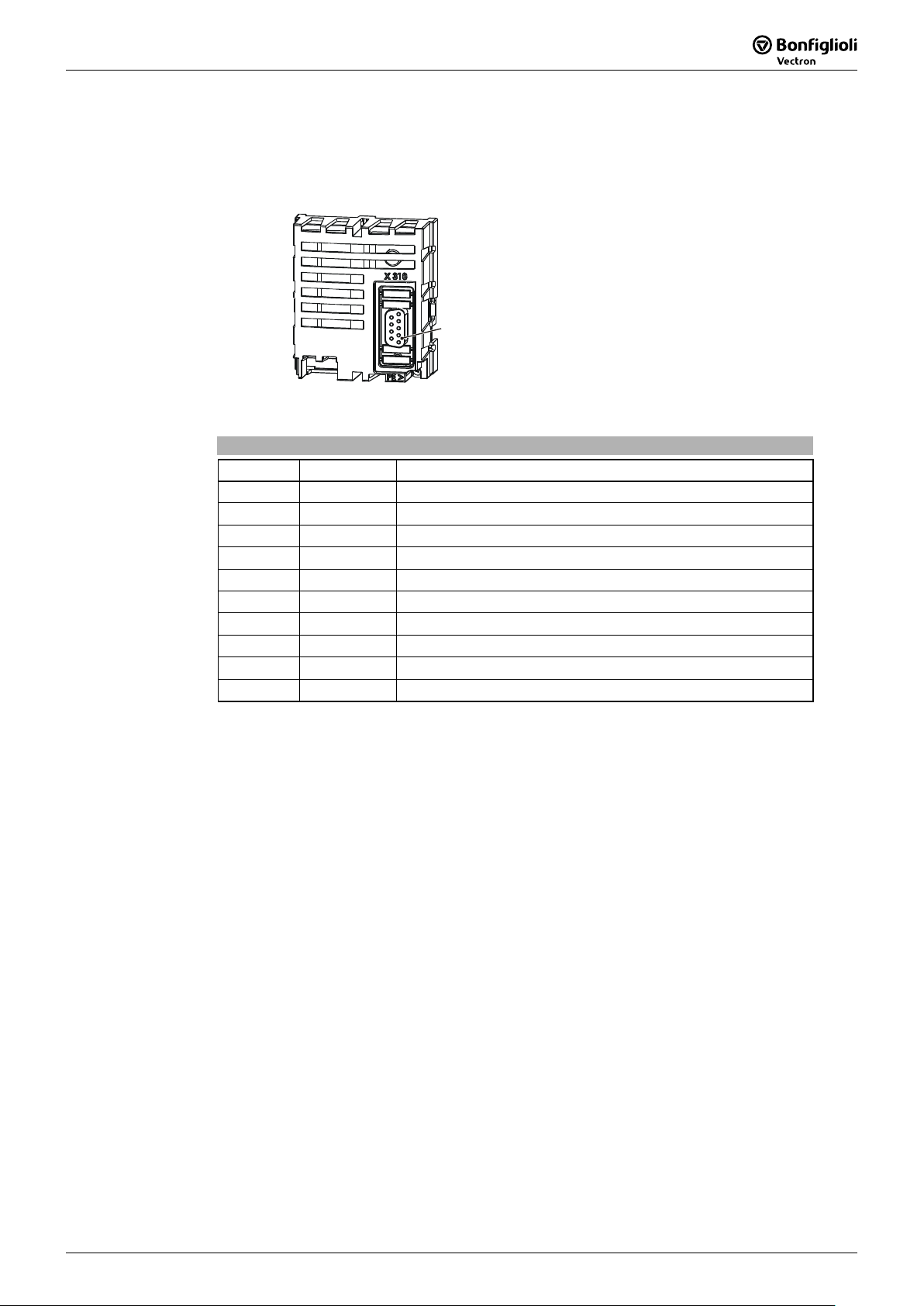

4.2 RS485 module

• For the bus cable RS485, the twisted and shielded line is to be used

• The shield must be a harness shield (not a foil shield)

• The shield is to be connected to PE properly on both sides.

The pin assignment of the RS485 cable is different from that of the RS232 cable;

•

if you use the wrong cable, no communication is possible

4.2.1 RS485 module CM-485 DB9

The RS485 interface is connected via the 9-pin

D-Sub socket X310.

For details on the pin assi

following table.

S1

Part. No.

179 675-110

O

N

Å

X310

Bus Connector X310 CM-485 DB9

pin name function

Housing Shield connected with PE

1

2

3

4

5

6

7

8

9

Data Line B short-circuit proof and functionally insulated; max. current 60 mA

Data Line B’ same as pin 1 – for cable network

0 V GND/earth

– n. c.

+5 V Supply voltage interface converter +5 V

– n. c.

Data Line A short-circuit proof and functionally insulated; max. current 60 mA

Data Line A’ same as pin 7 – for cable network

– n. c.

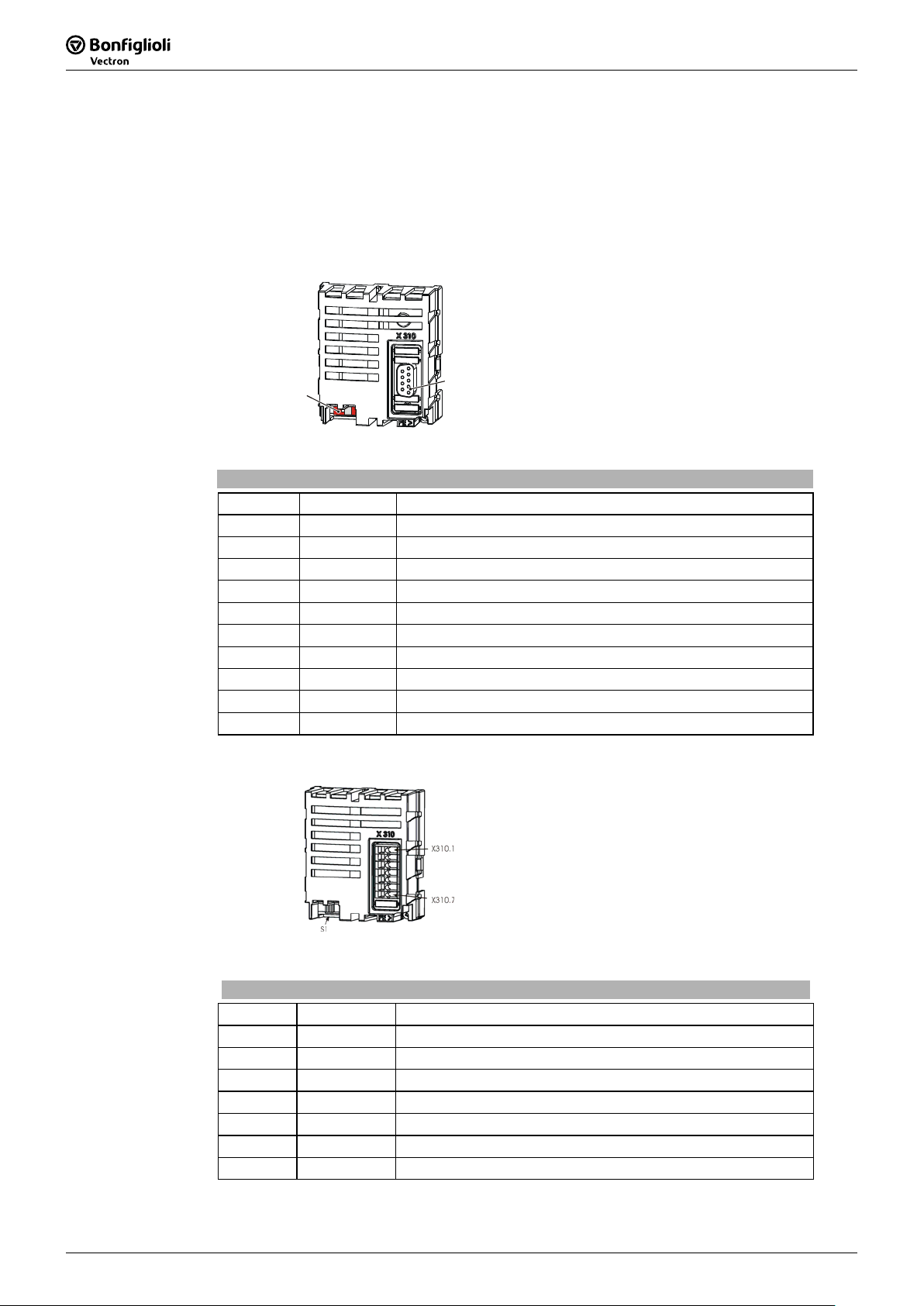

4.2.2 RS485 module CM-485 T

The RS485 interface is connected via the 7-pin

terminal socket X310

For details on the pin assignment, refer to the

following table.

gnment, refer to the

Part. no.

179 675-111

Busstecker X310 CM-485T (7p terminal)

terminal name function

1 Data Line A short-circuit proof and functionally insulated; max. current 60 mA

2 Data Line A’ same as terminal 1 – for cable network

3 Data Line B short-circuit proof and functionally insulated; max. current 60 mA

4 Data Line B’ same as terminal 3 – for cable network

5 +5 V Supply voltage interface converter +5 V

6 0 V GND/ earth

7 PE Shield/PE

Modbus Instruction manual 05/0812

Page 15

4.2.3 Bus termination

Attention! The passive bus termination (connection of a termination resistor) is

required at the physically first and last client. It can be activated by the

DIP Switch S1 of the CM-232 and CM-485.

By default, the bus termination is set to OFF.

It is important to realize the correct termination. If not, no communication is possible

by the RS485 interface!

As an alternative the active bus termination is possible via corresponding circuit:

The active termination is only allowed once each branch. The bus termination via an

external circuit and via DIP switch at the same time is not allowed.

Take care for the ground wiring; this will protect the communication bus for a high

noise level.

For easy wiring the signal terminals A and B have parallel contacts.

Example of wiring with different CM-485 modules:

max. 1200 - 2400m

12 78 3

BA

GND

BA

9pin D-Sub

GND

Inverter 1 Inverter (last)Master (PC)

termination OFF termination ONtermination ON

BA

7pin terminal

1234 6

GND

Modbus Instruction manual 1305/08

Page 16

5 Startup

By default, the parameters of the communication modules CM-232 and CM-485 are

set as follows:

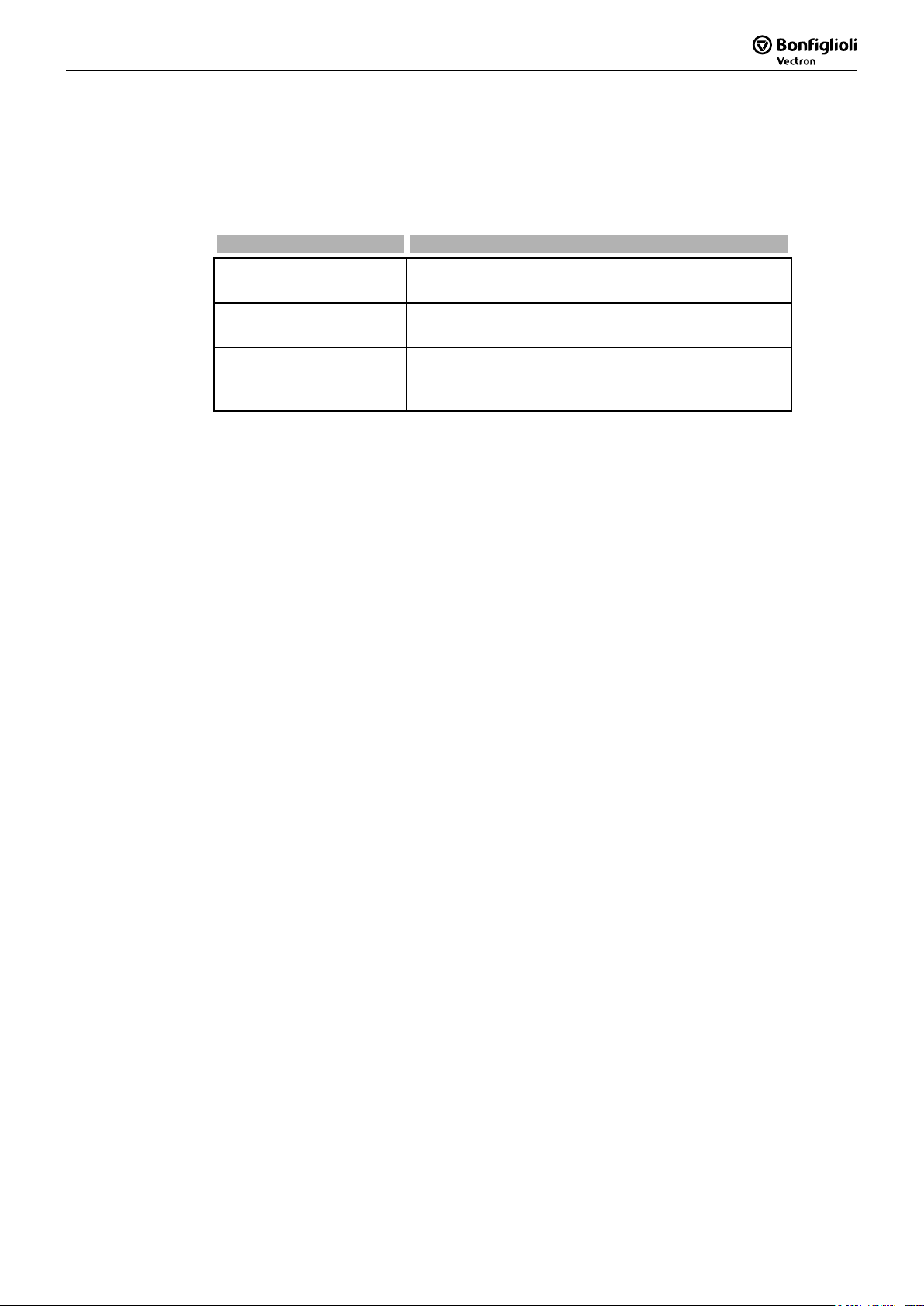

No. Description Factory setting

395 Protocol Type 0 - VCB bus protocol

413 Watchdog Timer 0

No. Description Factory setting

10 Baud Rate 4 - 19200

1375 Modbus Parity 0 – EVEN

1376 Modbus Address 1

5.1 General Information on configuration

The CM-232 / CM-485 communication modules can be configured in different ways:

− Direct connection CM-232 to PC / PLC

Direct connection between the 9-pin Sub-D socket (X310) of the

− Direct connection CM-485 to PC / PLC

Direct connection between the 9-pin Sub-D socket (X310) of the

Attention! For connection of the CM-485 to the RS232 interface of the PC /

− Connection of interface adapter KP232 to PC

Connection of the interface adapter KP232 at slot A of the fre-

− Configuration via Control Unit KP500

Configuration via the pluggable control unit KP500 at slot A of the

Parameter Settings

Parameter Settings

CM-232 and the serial interface of a PC / PLC.

Configuration of the installed communication module via the control

software VPlus or the control unit KP500.

In the case of the CM-232 the connection to a PC / PLC is realized

via a RS232 connection cable (1:1).

CM-485 and the serial interface of a PC via an interface converter.

PLC, an appropriate interface converter must be installed in the signal line.

Configuration of the installed communication module via the control

software VPlus or the control unit KP500.

quency inverter. Connection to PC via a RS232 connection cable

(1:1). Configuration of the installed communication module via the

control software VPlus.

frequency inverter.

Modbus Instruction manual 05/0814

Page 17

Attention! The transmitter and receiver must be set to the same transmission rate

(Baud rate).

The setting of the Baud rate effects the communication of the modules CM-232 and

CM-485. The KP232 interface adapter adjusts the Baud rate automatically to the PC

or control transmission rate.

Work steps:

• Install module CM-232/CM-485 on the frequency inverter.

• In the case of module CM-232:

Connect CM-232 and PC/PLC via RS232 cable.

• In the case of module CM-485:

Connect CM-485 via RS485 cable with interface converter.

Connect the RS232 port of the interface converter with the PC/PLC.

• Plug in control unit KP500 or interface adapter KP232 to slot A of the frequency

inverter.

• In the case of KP232: Connect interface adapter KP232 to PC via a serial cable.

Protocol type settings

By default, the communication modules CM-232/CM-485 are set to the BONFIGLIOLI

VECTRON standard protocol (VCB-Bus). Communication with the VPlus control software is only possible with this protocol type.

Attention! If another protocol type or a wrong setting is selected, no communica-

tion is possible via CM-232/CM-485.

In this case, correct the protocol type using the control unit KP500.

For detailed information, see chapter

6 “Modbus over Serial Line Proto-

col”.

Note: The interface adapter KP232 operates with the BONFIGLIOLI VECTRON

standard protocol VCB-Bus independent of the communication module

CM-232 or CM-485 and can communicate with VPlus at any time.

Modbus Instruction manual 1505/08

Page 18

The transmission speed and parity of the CM-232 are set via parameters

5.2 RS232 Module CM-232

5.2.1 Setting the Modbus Baud Rate and Parity

Baud Rate 10 and Modbus Parity

1375.

The transmission speed of the CM-232 depends on various application-specific pa-

rameters. For example, the cable length limits the transmission speed due to signal

propagation delays.

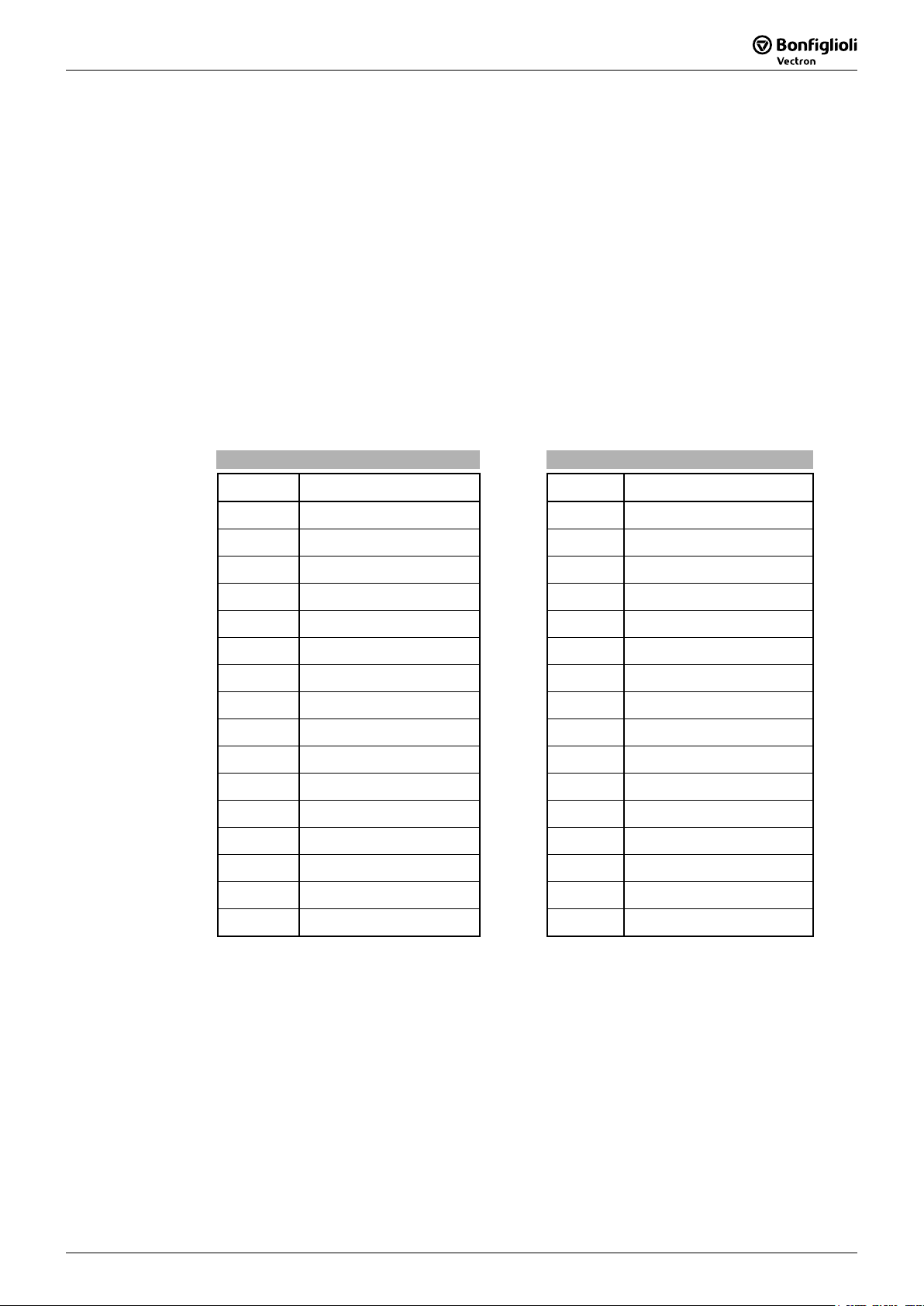

Baud Rate 10 Function max. cable length

1 – 2400 Baud Transmission rate 2400 Baud 30 m

2 – 4800 Baud Transmission rate 4800 Baud 30 m

3 – 9600 Baud Transmission rate 9600 Baud 30 m

4 – 19200 Baud Transmission rate 19200 Baud 30 m

5 – 57600 Baud Transmission rate 57600 Baud 10 m

6 – 115200 Baud Transmission rate 115200 Baud 10 m

1)

The indicated cable lengths are recommended maximum values which depend,

1)

among other things, on the quality of the cable.

Modbus Parity 1375 Function

0 – EVEN EVEN Parity is used in transmission

1 – ODD ODD Parity is used in transmission

2 – None No Parity is used in transmission

Attention! Baud rate and parity changes are only active after a reset of the fre-

quency inverter via the software or Mains Off/On.

In the case of the software reset, proceed as follows:

• Via the control unit KP500 or the control software VPlus open parameter

Program(ming) 34.

• Set parameter value "123".

• Confirm by pressing "ENT".

After the reset, the frequency inverter is initialized and is ready for operation after a few seconds.

5.2.2 Setting the Modbus Address

The address of the CM-232 can be set via parameter Modbus Address 1376.

No. Description Min. Max. Fact. sett.

1376 Modbus Address 1 247 1

Parameter Settings

Note: Normally, it is not necessary to change the default setting (Address 1).

In the case of special operating conditions, the address can be adjusted.

Attention! An address change is effective immediately, i.e. without a restart of

the frequency inverter.

For details on addressing, see chapter 6.2 “Addressing Rules”.

Modbus Instruction manual 05/0816

Page 19

The transmission speed and parity of the CM-485 are set via parameters

5.3 RS485 Module CM-485

5.3.1 Setting the Modbus Baud Rate and Parity

Baud Rate 10 and Modbus Parity

1375.

The transmission speed of the CM-485 depends on various application-specific pa-

rameters. For example, the cable length limits the transmission speed due to signal

propagation delays. In case of using very long cables, it is possible to take RS485

repeater units.

Baud Rates 10 Function max. line length

1 – 2400 Baud Transmission rate 2400 Baud 2400 m

2 – 4800 Baud Transmission rate 4800 Baud 2400 m

3 – 9600 Baud Transmission rate 9600 Baud 1200 m

4 – 19200 Baud Transmission rate 19200 Baud 1200 m

5 – 57600 Baud Transmission rate 57600 Baud 600 m

6 – 115200 Baud Transmission rate 115200 Baud 300 m

Attention! • All bus clients must be set to the same baud rate.

• Baud rate changes are only active after a reset of the frequency

inverter via the software or Mains Off/On.

In the case of the software reset, proceed as follows:

• Via the control unit KP500 or the control software VPlus open

parameter

Program(ming) 34.

• Set parameter value "123".

• Confirm by pressing "ENT".

After the reset, the frequency inverter is initialized and is ready for

operation after a few seconds.

Modbus Parity 1375 Function

0 – EVEN EVEN Parity is used in transmission

1 – ODD ODD Parity is used in transmission

2 – None No Parity is used in transmission

5.3.2 Setting the Modbus Node Address

The node address of the CM-485 is set via parameter Modbus Address 1376. Up to

247 frequency inverters can be used on the RS485 bus. The frequency inverters are

assigned unambiguous addresses in the range from 1 to 247.

No. Description Min. Max. Fact. sett.

1376 Modbus Address 1 247 1

Parameter Settings

Attention! − For operation with the CM-485 module, each client must be as-

signed an address.

− Bus addresses may only be assigned once, i.e. no double assignments.

− An address change is effective immediately, i.e. without a restart of

the frequency inverter.

For details on addressing, see 6.2.

Modbus Instruction manual 1705/08

Page 20

6 Modbus over Serial Line Protocol

The Modbus protocol described in the following has been incorporated into the stan-

dard ACT/ACU software of BONFIGLIOLI VECTRON. It defines and describes the

communication via the serial interfaces RS232/RS485 using the Modbus RTU and

ASCII transmission modes.

By default, the frequency inverters are set to the standard VCB bus protocol. The

Modbus protocol type can be set via parameter

Protocol 395 Function

0 - VCB Bus

1 - P-Bus

2 - Modbus RTU

3 - Modbus ASCII

Note

Attention ! − Changes of the parameter Protocol 395 are effective immedi-

The Modbus protocol enables the operation as a pure Master/Slave system. A PC, a

PLC or any type of computer system is the bus master.

6.1 Master/Slaves Protocol Principle

The Modbus Serial Line protocol is a Master-Slaves protocol. Only one master (at the

same time) is connected to the bus, and one or several (maximum 247) slave nodes

are also connected to the same serial bus. A Modbus communication is always initiated by the master. The slave nodes will never transmit data without receiving a

request from the master node. The slave nodes will never communicate with each

other. The master node initiates only one Modbus transaction at a time.

The master node issues a Modbus request to the slave nodes in two modes:

Protocol 395:

BONFIGLIOLI VECTRON standard protocol (default setting)

1)

Application-specific bus protocol

Modbus over serial line (with RTU Transmission Mode)

Modbus over serial line (with ASCII Transmission Mode)

1)

This bus protocol is only used for special applications. It cannot be

used for standard applications.

For more detailed information, refer to the application-specific instructions.

ately, i.e. without a restart of the frequency inverter.

− If the wrong protocol is selected, communication via CM-232/CM-

485 is not possible.

In this case, correct the protocol type using the control unit KP500

or KP232 and VPlus.

− In unicast mode, the master addresses an individual slave. After receiving and

processing the request, the slave returns a message (a 'response') to the master. In this mode, a Modbus transaction consists of 2 messages: a request from

the master, and a response from the slave. Each slave must have a unique address (from 1 to 247) so that it can be addressed independently from other

nodes.

− In broadcast mode, the master can send a request to all slaves. No response

is returned to broadcast requests sent by the master. The broadcast requests

are necessarily writing commands. All devices must accept the broadcast

for writing function. Address 0 is reserved to identify a broadcast exchange.

Modbus Instruction manual 05/0818

Page 21

6.2 Addressing Rules

Up to 247 frequency inverters can be used on a Modbus. These are assigned the

addresses 1…247. By address 0, all clients can be addressed simultaneously. Address

0 is also referred to as the Broadcast Address.

A Modbus over serial line message is made up of the following fields:

6.3 Message Description

Address Function Code Data

CRC (or LRC)

• On MODBUS Serial Line, the Address Field only contains the slave address.

Valid slave node addresses are in the range of 0 – 247 decimal. The individual

slave devices are assigned addresses in the range of 1 – 247. A master addresses a slave by placing the slave address in the address field of the message.

When the slave returns its response, it places its own address in the response

address field to let the master know which slave is responding.

• The

Function Code

function code can be followed by a

indicates to the inverter what kind of action to perform. The

Data

field that contains request parameters

(or, in the case of the inverter's response, the response parameters).

If no error occurs related to a correctly received Modbus request then the data

field contains the data requested. If an error occurs then the field contains an

Exception Code to indicate to the master that the request was unsuccessful. Exception Responses and Codes are described in detail in chapter

6.5.

If a request is not received correctly (communication error, checksum error)

then no response is sent. The inverter waits for the next request.

• The Error Checking Field is the result of a "Redundancy Checking" calculation

that is performed on the message contents. Two kinds of calculation methods

are used depending on the transmission mode that is being used (RTU or ASCII)

- see chapter

6.7, "The two serial Transmission Modes".

Modbus Instruction manual 1905/08

Page 22

Modbus definitions for reading/writing data in a device do not fit directly to parame-

6.4 Supported Function Codes

ter access of inverters (independent of inverter manufacturer). Modbus is defined for

reading/writing bits and registers in a different way. Furthermore, data access is

limited to 16 bit wide data.

To fulfill the Modbus requirements the data access to parameters in the devices (inverters) will use the following defined function codes:

- Function Code 3 Read ONE 16 bit wide data

- Function Code 6 Write ONE 16 bit wide data

(Read Holding Register)

(Write Single Register)

For data access to 32 bit wide data two new inverter specific function codes are

defined:

- Function Code 100 Read ONE 32 bit wide data

- Function Code 101 Write ONE 32 bit wide data

With the help of these two new functions (which are not defined by the Modbus

descriptions), data access to 32-bit “long” variables/parameters inside the inverters

is made possible.

For diagnostic purposes the Modbus function code "8" (

Diagnostics

) is also sup-

ported.

These function codes and their corresponding data fields are described in detail in

the following chapters.

Remark: In all data fields with more than one byte, the highest order byte is

transmitted first.

Message examples for all supported function codes in both RTU and ASCII transmis-

sion modes can be found in chapters

8.

6.4.1 Function Code 3, Read 16-bit Parameter

This function code is used to read the value of integer or unsigned integer parame-

ters in the inverter.

Request:

Function Code 1 Byte 0x03

Start Address (Data Set / Para-No.) 2 Bytes 0x0000 – 0x963F

No. of Registers 2 Bytes 0x0001 (always)

Response:

Function Code 1 Byte 0x03

Byte Count 1 Byte 0x02 (always)

Register Value (Parameter Value) 2 Bytes 0 – 0xFFFF

Exception Response:

Error Code 1 Byte 0x83

Exception code 1 Byte 2, 3 or 4

Modbus Instruction manual 05/0820

Page 23

Start Address

This field is used to store the parameter number and data set number. The parameter number ranges from 0 - 1599 and is stored in the lower 12bits; the data set

number ranges from 0 – 9 and is stored in the upper 4 bits.

Example: Parameter 372 (hex. 0x174), data set 2 (hex. 0x2) is stored as hex.

Start address

Data set Parameter number

0x2174

Bits 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

For the example above:

Hex. 0 0 1 0 0 0 0 1 0 1 1 1 0 1 0 0

Bin. 2 1 7 4

No. of Registers

This field is used to store the no. of parameters to be written. The value must always

be 1 as it is only possible to write one parameter at a time.

Byte Count

This field must be set to 2 as the parameter value always contains two bytes.

Register Value

This field is used to store the 16-bit parameter value.

Note:

Parameter Values

with decimal places are transferred without the decimal

point. Depending on the number of decimal places, the values are multiplied by 10, 100 or 1000.

Example:

A current value of 10.3A is to be transmitted. The numerical value actually transmit-

ted is 103, which corresponds to 0x67 in HEX format.

Exception Code

The following exception codes can occur:

2 ILLEGAL DATA ADDRESS • No. of Registers field not equal to 1.

• Parameter unknown

3 ILLEGAL DATA VALUE

4 SLAVE DEVICE FAILURE • Error on reading the parameter

• No. of bytes in the data field too small or too large

Exception Codes are described in detail in Chapter 6.6

Modbus Instruction manual 2105/08

Page 24

This function code is used to write the value of an integer or unsigned integer pa-

6.4.2 Function Code 6, Write 16-bit Parameter

rameter in the inverter.

Request:

Function Code 1 Byte 0x06

Start Address (Data Set / Para-No.) 2 Bytes 0x0000 – 0x963F

Register Value (Parameter Value) 2 Bytes 0 – 0xFFFF

Response:

Function Code 1 Byte 0x06

Start Address (Data Set / Para-No.) 2 Bytes 0x0000 – 0x963F

Register Value (Parameter Value) 2 Bytes 0 – 0xFFFF

Exception Response:

Error Code 1 Byte 0x86

Exception code 1 Byte 2, 3 or 4

Start Address

This field is used to store the parameter number and data set number. The parameter number ranges from 0 – 1599 and is stored in the lower 12 bits; the data set

number ranges from 0 – 9 and is stored in the upper 4 bits.

e.g.: Parameter 372 (hex. 0x174), data set 2 (hex. 0x2) is stored as hex. 0x2174

Start address

Data set Parameter number

Bits 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Register Value

This field is used to store the 16-bit parameter value.

Note:

Parameter Values

with decimal places are transferred without the decimal point. Depending on the number of decimal places, the values are

multiplied by 10, 100 or 1000.

Example:

A curent value of 10.3A is to be transmitted. The numerical value actually transmit-

ted is 103, which corresponds to 0x67 in HEX format.

Exception Code

The following exception codes can occur:

2 ILLEGAL DATA ADDRESS

3 ILLEGAL DATA VALUE

4 SLAVE DEVICE FAILURE • Error on writing the parameter

• Parameter unknown

• No. of bytes in the data field too small or too large

Exception Codes are described in detail in Chapter 6.6

Modbus Instruction manual 05/0822

Page 25

6.4.3 Function Code 100, Read 32-bit Parameter

Request:

Function Code 1 Byte 0x64

Start Address (Data Set / Para-No) 2 Bytes 0x0000 – 0x963F

Response:

Function Code 1 Byte 0x64

Register Value (Parameter Value) 4 Bytes 0 – 0x FFFF FFFF

Exception Response:

Error Code 1 Byte 0xE4

Exception code 1 Byte 2, 3 or 4

Start Address

This field is used to store the parameter number and data set number. The parameter number ranges from 0 – 1599 and is stored in the lower 12 bits; the data set

number ranges from 0 – 9 and is stored in the upper 4 bits.

e.g.: Parameter 372 (hex. 0x174), data set 2 (hex. 0x2) is stored as hex. 0x2174

Start address

Data set Parameter number

Bits 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Register Value

This field is used to store the 32-bit parameter value.

Note:

Parameter Values

with decimal places are transferred without the decimal point. Depending on the number of decimal places, the values are

multiplied by 10, 100 or 1000.

Example:

A frequency value of 100.25 Hz is to be transmitted. The numerical value actually

transmitted is 10025, which corresponds to 0x2729 in HEX format.

Exception Code

The following exception codes can occur:

2 ILLEGAL DATA ADDRESS

3 ILLEGAL DATA VALUE

4 SLAVE DEVICE FAILURE • Error on reading the parameter

• Parameter unknown

• No. of bytes in the data field too small or too large

Exception Codes are described in detail in Chapter 6.6

Modbus Instruction manual 2305/08

Page 26

6.4.4 Function Code 101, Write 32-bit Parameter

Request:

Function Code 1 Byte 0x65

Start Address (Data Set / Para-No) 2 Bytes 0x0000 – 0x963F

Register Value (Parameter Value) 4 Bytes 0 – 0xFFFF FFFF

Response:

Function Code 1 Byte 0x65

Start Address (Data Set / Para-No) 2 Bytes 0x0000 – 0x963F

Register Value (Parameter Value) 4 Bytes 0 – 0xFFFF FFFF

Exception Response:

Error Code 1 Byte 0xE5

Exception code 1 Byte 2, 3 or 4

Start Address

This field is used to store the parameter number and data set number. The parameter number ranges from 0 – 1599 and is stored in the lower 12 bits; the data set

number ranges from 0 – 9 and is stored in the upper 4 bits.

e.g.: Parameter 372 (hex. 0x174), data set 2 (hex. 0x2) is stored as hex. 0x2174

Start address

Data set Parameter number

Bits 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Register Value

This field is used to store the 32-bit parameter value.

Note:

Parameter Values

with decimal places are transferred without the decimal point. Depending on the number of decimal places, the values are

multiplied by 10, 100 or 1000.

Example:

Frequency Value:

A frequency value of 100.25 Hz is to be transmitted. The numerical value actually

transmitted is 10025, which corresponds to 0x2729 in HEX format.

Exception Code

The following exception codes can occur:

2 ILLEGAL DATA ADDRESS

3 ILLEGAL DATA VALUE

4 SLAVE DEVICE FAILURE • Error on writing the parameter

• Parameter unknown

• No. of bytes in the data field too small or too large

Exception Codes are described in detail in Chapter 6.6

Modbus Instruction manual 05/0824

Page 27

6.4.5 Function Code 8, Diagnostics

This function code is used to access the modbus diagnostic counters that are supported by the inverter. Each counter can be obtained by a sub function code bound

to the counter number. All of the counters can be cleared using the hexadecimal

sub-function code 0x0A.

The following sub function codes are supported:

Sub function Name Comments

0x0A Clear all counters Sets all counters to zero

0x0B Return Bus Message Count No. of valid messages received

0x0C Return Bus Communication Error Count No. of messages with CRC or Par-

0x0D Return Bus Exception Error Count No. of Exception Responses sent

0x0E Return Slave Message Count No. of messages received

0x0F Return Slave No Response Count No. of Broadcast messages received

0x10 Return Slave NAK Count not used, return value is always 0

0x11 Return Slave Busy Count not used, return value is always 0

0x12 Return Bus Character Overrun Count No. of messages with Overrun error

Request (Sub function 0x0A, Clear all Counters):

(with all addresses)

ity/Framing/Overrun error.

(with slave address)

Function Code 1 Byte 0x08

Sub function 2 Bytes 0x000A

Data 2 Bytes 0x0000

Response:

Function Code 1 Byte 0x08

Sub function 2 Bytes 0x000A

Data 2 Bytes 0x0000

Exception Response:

Error Code 1 Byte 0x88

Exception code 1 Byte 1, 3 or 4

Data

This field is always 0x0000.

Exception Code

1 ILLEGAL FUNCTION CODE

3 ILLEGAL DATA VALUE

4 SLAVE DEVICE FAILURE • Error on carrying out the function

• Sub function not supported

• No. of bytes in the data field too small or too large

• “data field” not equal to 0x0000

Exception Codes are described in detail in Chapter 6.6

Modbus Instruction manual 2505/08

Page 28

Request (Sub function 0x0B – 0x12, Return Counter Value):

Function Code 1 Byte 0x08

Sub function 2 Bytes 0x000B – 0x0012

Data 2 Bytes 0x0000

Response:

Function Code 1 Byte 0x08

Sub function 2 Bytes 0x000B – 0x0012

Data (Counter Value) 2 Bytes 0 – 0xFFFF

Exception Response:

Error Code 1 Byte 0x88

Exception code 1 Byte 1, 3 or 4

Data

This field is always set to 0x0000 in the request and contains the actual counter

value in the response.

Exception Code

The following exception codes can occur:

1 ILLEGAL FUNCTION CODE

3 ILLEGAL DATA VALUE

4 SLAVE DEVICE FAILURE • Error on Reading the Diagnostic Counter

• Sub function not supported

• No. of bytes in the data field too small or too large

• “data field” not equal to 0x0000

Exception Codes are described in detail in Chapter 6.6

Modbus Instruction manual 05/0826

Page 29

When the master device sends a request to the inverter it expects a normal re-

6.5 Exception Responses

sponse. One of four possible events can occur from the master’s query:

- If the inverter receives the request without a communication error and can handle the query normally, it returns a normal response.

- If the inverter does not receive the request due to a communication error, no

response is returned. The master will eventually process a timeout condition for

the request.

- If the inverter receives the request, but detects a communication error (parity,

LRC, CRC, ...), no response is returned. The master will eventually process a

timeout condition for the request.

- If the inverter receives the request without a communication error, but cannot

handle it (for example, if the request is to read an unknown parameter, the inverter will return an exception response informing the client of the nature of the

error.

The exception response message has two fields that differentiate it from a normal

response:

Function Code Field:

In a normal response, the inverter echoes the function code of the original request

in the function code field of the response. All function codes have a most–significant

bit (MSB) of 0 (their values are all below 0x80 hexadecimal). In an exception response, the inverter sets the MSB of the function code to 1. This makes the function

code value in an exception response exactly 0x80 hexadecimal higher than the value

would be for a normal response. With the function code’s MSB set, the master can

recognize the exception response and can examine the data field for the exception

code.

Data Field:

In a normal response, the inverter may return data or statistics in the data field (any

information that was requested in the request). In an exception response, the inverter returns an exception code in the data field. This defines the server condition

that caused the exception.

The Exception Codes generated by the inverter are listed below

6.6 Exception Codes

The following exception codes are generated by the inverter.

Code Modbus Name Cases when generated by the Inverter

1 ILLEGAL FUNCTION

2 ILLEGAL DATA ADDRESS

3 ILLEGAL DATA VALUE

4 SLAVE DEVICE FAILURE

• Function Code unknown

• Subfunction Code unknown (Diagnostics Function)

• No. of Registers field incorrect (must always be 0x01)

• Unknown Parameter or Parameter Data Type mismatch

• Error in dataset of frame

- No. of bytes too small or too large

- Certain fields not set to specific values

• Read or Write Parameter failed

The reason for the error can be obtained by reading out

Parameter

page).

VABus SST Error Register

11

(see next

Modbus Instruction manual 2705/08

Page 30

Error no. Meaning

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

VABus SST Error Register 11

no error

inadmissible parameter value

inadmissible data set

parameter not readable (write-only)

parameter not writable (read-only)

read error EEPROM

write error EEPROM

checksum error EEPROM

parameter cannot be written while the drive is running

values of the data sets differ from one another

wrong parameter type

unknown parameter

checksum error in received telegram

syntax error in received telegram

data type of parameter does not correspond to the number of bytes

in the telegram

unknown error

When the error register VABus SST Error Register 11 is read out, it is automatically

cleared at the same time.

Modbus Instruction manual 05/0828

Page 31

6.7 The two serial Transmission Modes

Two different serial transmission modes are defined: the RTU mode and the ASCII

mode. They define the bit contents of message fields transmitted serially on the

line. They determine how information is packed into the message fields and decoded.

The transmission mode (and serial port parameters) must be the same for all devices on a MODBUS Serial Line.

6.7.1 RTU Transmission

When devices communicate on a MODBUS serial line using the RTU (Remote Terminal Unit) mode, each 8–bit byte in a message contains two 4–bit hexadecimal characters. The main advantage of this mode is that its greater character density allows

better data throughput than ASCII mode for the same baud rate. Each message

must be transmitted in a continuous stream of characters.

6.7.1.1 Character Format

One character consists of 11 bits:

− 1 start bit

− 8 data bits, least significant bit sent first

− 1 parity bit

− 1 stop bit

Note If no parity is used then an extra stop bit is added.

Character format with parity checking:

Start B1 B2 B3 B4 B5 B6 B7 B8 Parity Stop

Character format without parity checking:

Start B1 B2 B3 B4 B5 B6 B7 B8 Stop Stop

6.7.1.2 Frame Description

Slave

Address

1 byte 1 byte 0 up to 252 bytes

The maximum size of a MODBUS RTU frame is 256 bytes.

Function

Code

Data CRC

2 bytes

(CRC-Lo, CRC-Hi)

Modbus Instruction manual 2905/08

Page 32

6.7.1.3 Modbus Message RTU Framing

A MODBUS message is placed by the transmitting device into a frame that has a

known beginning and ending point. This allows devices that receive a new frame to

begin at the start of the message, and to know when the message is completed.

Partial messages must be detected and errors must be set as a result. In RTU mode,

message frames are separated by a silent interval of at least 3.5 character times

MODBUS Message

Start Address

>= 3.5 char 8 bits 8 bits N x 8 bits 16 bits >= 3.5 char

Function Data CRC End

The entire message frame must be transmitted as a contiguous stream of characters.

If a silent interval of more than 1.5 character times occurs between two characters,

the message frame is declared incomplete and is discarded by the inverter.

6.7.1.4 CRC Checking

The RTU mode includes an error–checking field that is based on a Cyclical Redundancy Checking (CRC) method performed on the message contents.

The CRC field checks the contents of the entire message. It is applied regardless of

any parity checking method used for the individual characters of the message.

The CRC field contains a 16–bit value implemented as two 8–bit bytes.

The CRC field is appended to the message as the last field in the message. It is appended in the sequence “low-order byte”, “high-order byte”. The CRC high–order

byte is the last byte to be sent in the message.

The CRC value is calculated by the sending device, which appends the CRC to the

message. The receiving device recalculates a CRC during receipt of the message,

and compares the calculated value to the actual value it received in the CRC field. If

the two values are not equal, an error results.

The CRC calculation is started by first pre-loading a 16–bit register to all 1’s

(0xFFFF). Then a process begins of applying successive bytes of the message to

the current contents of the register.

During generation of the CRC, each 8bit character is ExOR with the register contents. Then the result is shifted in the direction of the least significant bit (LSB), with a

zero filled into the most significant bit (MSB) position. The LSB is extracted and examined. If the LSB was a 1, the register is then ExOR with the fixed value 0xA001. If

the LSB was a 0, no ExOR takes place.

This process is repeated until eight shifts have been performed. After the last (eight)

shift, the next 8bit char is ExOR with the register’s current value, and the process

repeats for eight more shifts as described above. The final content of the register,

after all the bytes of the message have been applied, is the CRC value.

When the CRC is appended to the message, the low-order byte is appended first,

followed by the high-order byte.

Modbus Instruction manual 05/0830

Page 33

Example for CRC calculating for the frame : “0x02 0x07”

MSB LSB

Start CRC 1111 1111 1111 1111 0xFFFF

1.char 0000 0000 0000 0010 0x02

ExOR

CRC 1111 1111 1111 1101

1.shift right

0111 1111 1111 1110 ⇒1 = ExOR

0xA001 1010 0000 0000 0001

ExOR

CRC 1101 1111 1111 1111

2.shift right

0110 1111 1111 1111

0xA001 1010 0000 0000 0001

ExOR

CRC 1100 1111 1111 1110

3.shift right

4.shift right

0110 0111 1111 1111 ⇒0 = no ExOR

0011 0011 1111 1111 ⇒1 = ExOR

0xA001 1010 0000 0000 0001

ExOR

CRC 1001 0011 1111 1110

5.shift right

6.shift right

0100 1001 1111 1111 ⇒0 = no ExOR

0010 0100 1111 1111 ⇒1 = ExOR

0xA001 1010 0000 0000 0001

ExOR

CRC 1000 0100 1111 1110

7.shift right

8.shift right

0100 0010 0111 1111 ⇒0 = no ExOR

0010 0001 0011 1111 ⇒1 = ExOR

0xA001 1010 0000 0000 0001

ExOR

CRC 1000 0001 0011 1110

2.char 0000 0000 0000 0111 0x07

ExOR

CRC 1000 0001 0011 1001

1.shift right

0100 0000 1001 1100 ⇒1 = ExOR

0xA001 1010 0000 0000 0001

ExOR

CRC 1110 0000 1001 1101

2.shift right

0111 0000 0100 1110 ⇒1 = ExOR

0xA001 1010 0000 0000 0001

ExOR

CRC 1101 0000 0100 1111

3.shift right

0110 1000 0010 0111 ⇒1 = ExOR

0xA001 1010 0000 0000 0001

ExOR

CRC 1100 1000 0010 0110

4.shift right

5.shift right

0110 0100 0001 0011 ⇒0 = no ExOR

0011 0010 0000 1001 ⇒1 = ExOR

0xA001 1010 0000 0000 0001

ExOR

CRC 1001 0010 0000 1000

6.shift right

7.shift right

8.shift right

result 1 2 4 1

0100 1001 0000 0100 ⇒0 = no ExOR

0010 0100 1000 0010 ⇒0 = no ExOR

0001 0010 0100 0001 ⇒0 = no ExOR

CRC = 0x41 0x12

Modbus Instruction manual 3105/08

Page 34

Example : program sequence (C#)

private int Modbus_CRC(string frame)

{

int poly = 0xA001; // polynomal

int CRC = 0xFFFF; // start CRC

for (int i = 0; i < (int)(frame.Length); i++) // for each sign

{

CRC ^= Convert.ToInt16(frame[i]); // ExOR

for (int j = 0; j < 8; j++) // eight times

{

if ((CRC & 0x01) == 0x01) // lsb == 1 ?

{

CRC >>= 1; // shift left

CRC ^= poly; // ExOR

}

else

{

CRC >>= 1; // shift left

}

}

}

return CRC;

}

Call the function for the frame : “0x02 0x07”

string temp_s = Convert.ToString((char)(0x2))+ Convert.ToString((char)(0x7));

Console.WriteLine(Modbus_CRC(temp_s));

Result : 4673 = 0x1241

CRC Low Byte = 0x41

CRC High Byte = 0x12

The Modbus CRC sequence is :

CRC Low Byte / High Byte 0x41 0x12

⇒

Modbus Instruction manual 05/0832

Page 35

6.7.2 ASCII Transmission

When devices are setup to communicate on a MODBUS serial line using 7-bit ASCII

(American Standard Code for Information Interchange) mode, each 8 bit character in

a message is sent as two ASCII characters. This mode is used when the physical

communication link or the capabilities of the device does not allow the conformance

with RTU mode requirements regarding timers management.

Remark: this mode is less efficient than RTU since each byte needs two characters.

Example: The byte 0x5B is encoded as two characters: 0x35 and 0x42 ( 0x35 ="5",

and 0x42 ="B" in ASCII ).

6.7.2.1 Character Format

One character consists of 10 bits:

− 1 start bit

− 7 data bits, least significant bit sent first (value = 0x00 .. 0x7F)

− 1 parity bit

− 1 stop bit

Note If no parity is used then an extra stop bit is added.

Character format with parity checking:

Start B1 B2 B3 B4 B5 B6 B7 Parity Stop

Character format without parity checking:

Start B1 B2 B3 B4 B5 B6 B7 Stop Stop

6.7.2.2 Modbus Message ASCII Framing

A MODBUS message is placed by the transmitting device into a frame that has a

known beginning and ending point. This allows devices that receive a new frame to

begin at the start of the message, and to know when the message is completed.

Partial messages must be detected and errors must be set as a result.

The address field of a message frame contains two characters.

In ASCII mode, a message is delimited by specific characters as Start-of-Frame and

End-of-Frame. A message must start with a trigger “colon”- character (“:” = ASCII

0x3A) and ends with a “carriage return/line feed” pair (ASCII 0x0D and 0x0A).

The allowable characters transmitted for all other fields are hexadecimal 0–9, A–F

(ASCII coded). The devices monitor the bus continuously for the colon character.

When this character is received, each device decodes the next character until it detects the End-of-Frame (EoF)-character.

Modbus Instruction manual 3305/08

Page 36

Intervals of up to one second may elapse between characters within the message.

Unless the user has configured a longer timeout, an interval greater than 1 second

means an error has occurred.

A typical message frame is shown below.

SoF Address

1 char : 2 chars 2 chars

Function Data LRC EoF

0 up to 2* 252 chars 2 chars 2 chars

6.7.2.3 LRC Checking

In ASCII mode, messages include an error–checking field that is based on a Longitudinal Redundancy Checking (LRC) calculation that is performed on the message

contents, exclusive of the beginning ‘colon’ and terminating CRLF pair characters. It

is applied regardless of any parity checking method used for the individual characters of the message.

The LRC field is one byte, containing an 8-bit binary value. The LRC value is calculated by the device that emits, which appends the LRC to the message. The device

that receives calculates an LRC during receipt of the message, and compares the

calculated value to the actual value it received in the LRC field. If the two values are

not equal, an error results.

CR, LF

The LRC is calculated by adding together successive each byte of the message and

then two’s complementing the result. It is performed on the ASCII message field

contents excluding the ‘colon’ character that begins the message, and excluding the

CRLF pair at the end of the message. In ASCII mode, the resulting LRC is ASCII

encoded into two bytes and placed at the end of ASCII mode frame prior to the

CRLF.

Example:

Field: SoF

ASCII

Hex

3A 30 31 38 33 30 32 37 41 0D 0A

Adr

: 0 1 8 3 0 2 7 A CR LF

Adr. 0x01 =

Fct.Code 0x83 =

Excep. 0x02 =

----------------------------Sum:

2’comp.

Fct.Code

LCR relevant

1

131

2

-------------- 134

122 = 0x7A

Excep.

Code

LRC

LRC

⇒

EoF

“7” = 0x37

“A” = 0x41

Modbus Instruction manual 05/0834

Page 37

The Modbus protocol defines a pure Master/Slave operation. If a frequency inverter

6.8 Monitoring Timing Function

is addressed by the bus master, other frequency inverters will only be addressed

after the protocol with the first frequency inverter has been completed or the Timeout time has expired.

After a frequency inverter has sent a message, a waiting time of 2 ms must be kept.

This time is needed by the frequency inverter in order to switch off the RS485

transmitter. The bus master may not send a new message before this time has

elapsed.

The frequency inverter replies 10 ms after receipt of a message, at the earliest. This

means that the bus master must have switched off its RS485 transmitter after 10

ms, at the latest.

If the bus master does not receive an answer from the frequency inverter within

500 ms, it can start a new transmission to any frequency inverter.

Attention! If the degree of utilization of the CPU is high (> 90%), the response

time can be more than 500 ms.

Note: The specified times are valid for operation with RS485 and RS232.

6.9 Watchdog

If the frequency inverter is operated via the serial interface (RS232, RS485), it may

be important to monitor the presence of the communication line. For example it may

be that the frequency inverter is switched on/off in Remote Mode, or it only receives

its reference value cyclically via the serial interface. If the communication fails, no or

faulty data are transmitted. This is recognized by the communication watchdog.

The watchdog function monitors the time in which no correct communication takes

place. This time can be adjusted via parameter

RS232/RS485 Watchdog Timer 413.

The adjusted value is the time in seconds (0...10000 seconds) within which at least

one correct exchange of data must have occurred.

If the adjusted monitoring time has elapsed, the frequency inverter signals a fault.

The fault message F2010 Watchdog RS232/RS485 is displayed.

No. Name/Meaning Min. Max. fact. sett.

413 RS232/RS485 Watchdog Timer [sec] 0 10000 0

Parameter Settings

Note: If parameter RS232/RS485 Watchdog Timer 413 is set to 0 (default),

the monitoring function is deactivated.

Modbus Instruction manual 3505/08

Page 38

7 Handling of Data Sets/Cyclic Writing

Access to the parameter values is carried out on the basis of the parameter number

and the required data set.

There are parameters which only have one data value (data set 0) as well as parameters which have four data values (data sets 1...4). These are used for data set

change-over.

If parameters with four data values are set via data set = 0, all four data sets are set

to the same value.

A read access with data set = 0 to such parameters is only successful if all four data

sets are set to the same value. If this is not the case an Exception Response with

exception code 4 "SLAVE DEVICE FAILURE" will be sent and parameter

Bus SST Error Register

another).

In this case, you must read out each data set separately for the relevant parameter.

The values are entered automatically into the EEPROM on the controller. If values

are to be written cyclically at a high repetition rate, there must be no entry into the

EEPROM as it only has a limited number of admissible writing cycles (about 1 million

cycles).

Caution! If the number of admissible writing cycles is exceeded, the EEPROM is

In order to avoid the destruction of the EEPROM, data which are to be written cycli-

Note: The data set for the parameter Control Word 410, Reference Frequency

cally can be entered exclusively into the RAM without a writing cycle to the EEPROM.

In this case, the data are volatile, i.e. they are lost when the supply voltage is

switched off (Mains Off). They must be written into the RAM again after the restart

(Mains On).

The RAM writing operation is activated by increasing the number of the target data

set by five.

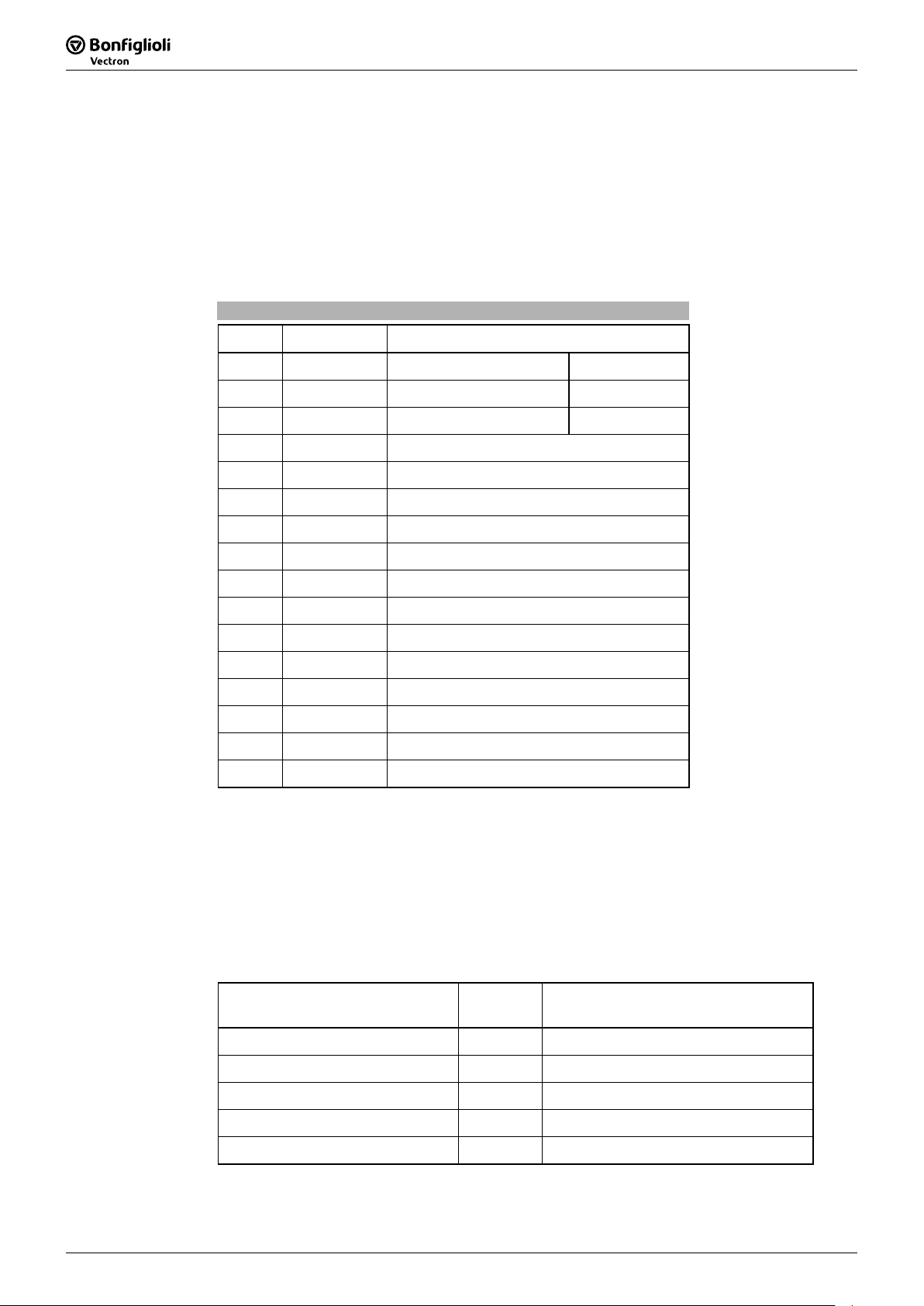

Access to the data sets of the frequency inverter

Parameter EEPROM RAM

Data set 0 0 5

Data set 1 1 6

Data set 2 2 7

Data set 3 3 8

Data set 4 4 9

11 set to the value 9 (values of data sets differ from one

destroyed.

484 and Reference Percentage RAM 524 is always zero. Inter-

RAM

nally they are not written into the EEPROM.

VA-

Modbus Instruction manual 05/0836

Page 39

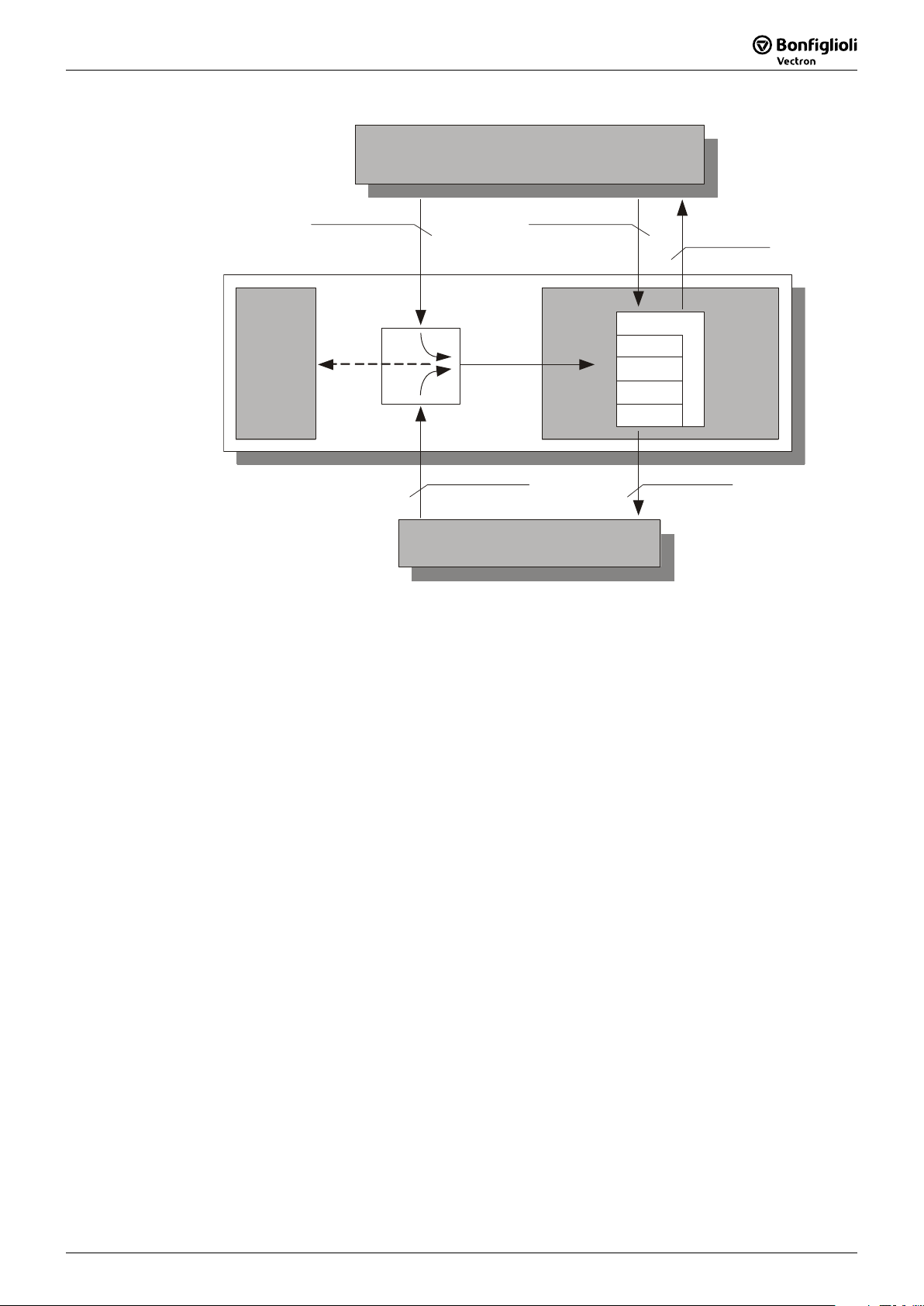

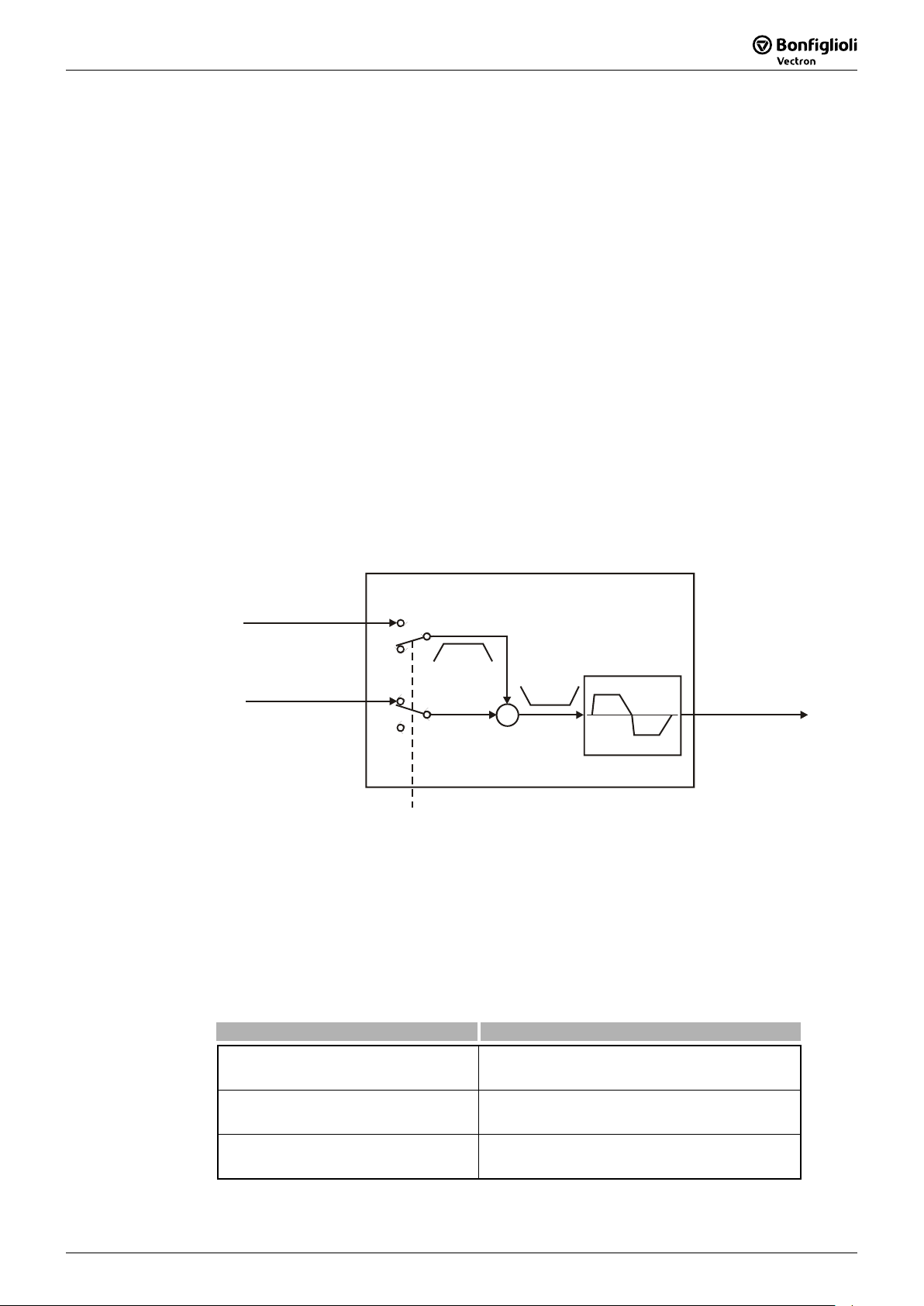

NVRam RAM

fieldbus : RS232 / 485, SystemBus ...

inverter

0 - 4 write

5 - 9 read

CPU function

dataset 1

save copy

dataset 2

dataset 3

dataset 4

0 - 4 write

VPlus + KP500

0 - 4 write

dataset 0

0 - 4 read

Modbus Instruction manual 3705/08

Page 40

8 Modbus Message Examples

8.1 Modbus RTU-Message Examples

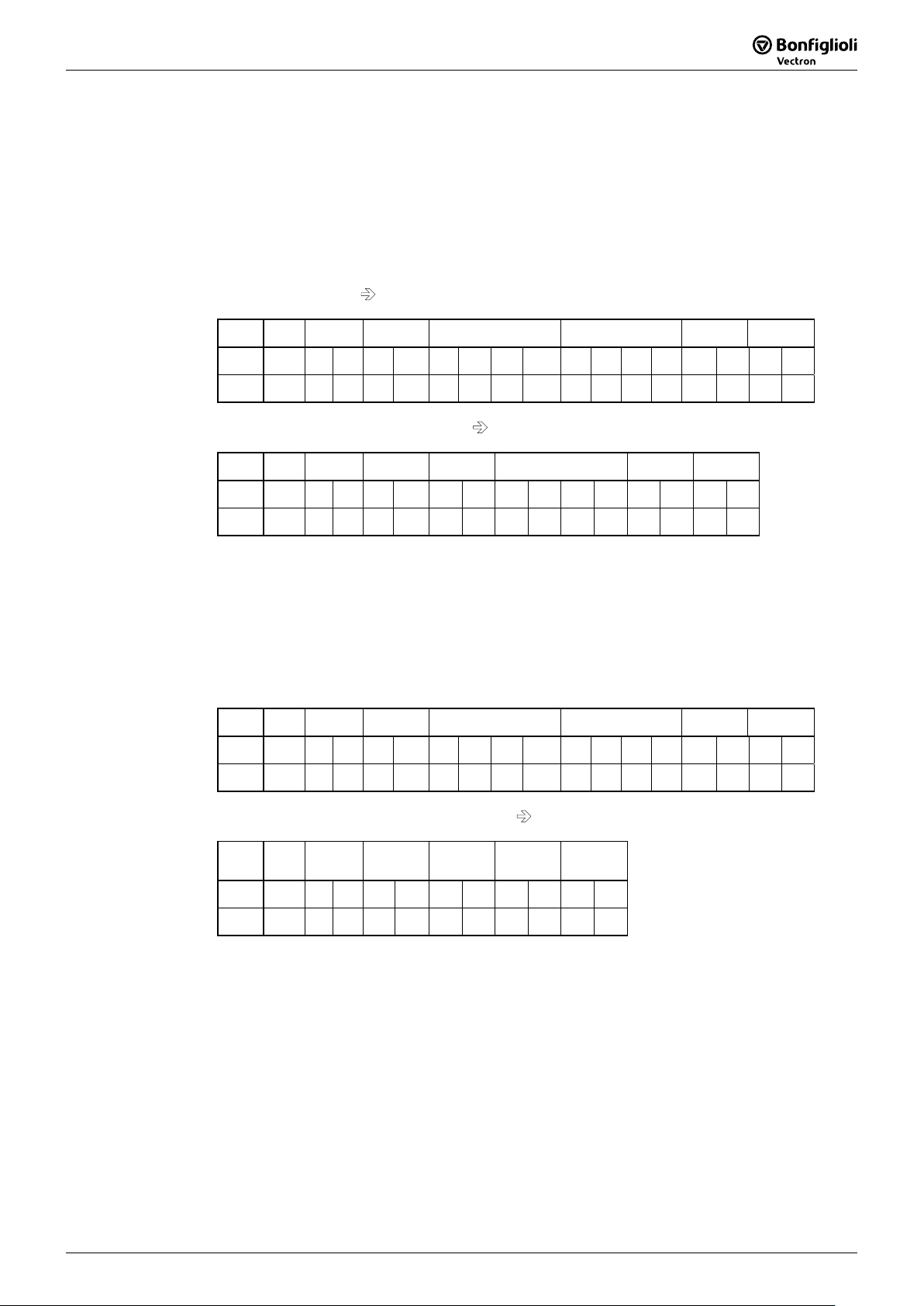

8.1.1 Function Code 3, Read 16-bit Parameter

Example 1:

Reading parameter Rated Speed 372 (0x0174) in data set 2 from the frequency

inverter with address 1

Request: Master Î Frequency Inverter

Field: Addr. Func. DSet/Par-No. No. of Regs CRC

Hex

01 03 21 74 00 01 CE 2C

Response: Frequency Inverter Î Master

Field: Addr. Func. No.Bytes Par-Value CRC

Hex

The hexadecimal value sent is 0x056E = 1390. Parameter

decimal places.

Therefore, the rated speed is 1390 min

01 03 02 05 6E 3A F8

Rated Speed 372 has no

-1

.

Example 2:

Reading parameter Rated Speed 372 (0x0174) in data set 0 from the frequency

inverter with address 1 and No. of Regs field set to 2 (invalid value)

Request: Master Î Frequency Inverter

Field: Addr. Func. DSet/Par-No. No. of Regs CRC

Hex

01 03 01 74 00 02 85 ED

Error Response: Frequency Inverter Î Master

Field: Addr. Func. Except. CRC

Hex

01 83 02 C0 F1

The exception code sent is hexadecimal value 0x02 = ILLEGAL DATA ADDRESS.

Modbus Instruction manual 05/0838

Page 41

8.1.2 Function Code 6, Write 16-bit Parameter

Example 1:

Writing parameter Rated Mech. Power 376 (0x0178) in data set 4 to the frequency