BONFIGLIOLI BN 71, BN 80, BN 90, BN 100, BN 132 Installation, Operation And Maintenance Manual

...

BN-BE-BX-M-ME-MX series

Installation, Operation

and Maintenance Manual

USER

MANUAL

OWNER’S MANUAL FOR ELECTRIC MOTORS SERIES BX, BE, BN, MX, ME, M

Description

1 Field of application

2 General safety info

3 Installation

4 Wiring

5 Start-up

6 Maintenance

7 Disassembly, recycling or disposal

8 Spare parts

2

2

2

6

10

11

15

16

Read carefully

Electrical hazard

Revisions

Refer to page 32 for the catalogue revision index.

Visit www.bonglioli.com to search for catalogues with up-to-date revisions.

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

1 / 32

1 FIELD OF APPLICATION

The following instructions apply to the three-phase asynchronous electric motors manufactured by

BONFIGLIOLI RIDUTTORI S.p.A., series:

- BX, BE, BN

- MX, ME, M

in their standard version, with or without brake.

Special versions as described in the catalogues and/or in offers, or special applications (for example,

power supply from inverter) will require additional information.

2 GENERAL SAFETY INFORMATION

The electric motors described in the following instructions are designed to be used in industrial installations and must be operated by qualied personnel only.

During operation, motors have live or moving parts. Therefore, removal of electrical or mechanical guards, improper use, or inadequate maintenance may cause serious damage to persons or property.

Installation and maintenance on motors must be performed only by qualied personnel who

have thorough knowledge of the instructions and technical data for the product and who have

been authorised to perform such operations by the safety supervisor.

Since the electric motor does not have a dened function for the nal user and is going to be

physically coupled to another machine, it is the responsibility of the installer to guarantee that

all provisions for its safe operation have been taken.

3 INSTALLATION

3.1 Identication

Gearmotors and motors have a nameplate carrying their identication data.

Table shows the plate used for all motor congurations.

On standard voltage electric motors with an FD brake, the nameplate only gives electrical data

for the frequency identied by the motor designation.

2 / 32

On standard voltage electric motors with an FA brake, the nameplate gives electrical data for

50 Hz and 60 Hz.

On non-standard voltage electric motors with a brake, the nameplate only gives electrical data

for the frequency identied by the motor designation.

On motors with the CUS option, the nameplate only gives electrical data for the frequency

identied by the motor designation.

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

IE1

IE2 - IE3

FD

3.2 Reception

Upon receipt of the motor, check that it was not damaged during transportation; if damage is noted,

inform the carrier immediately. In addition, check that the characteristics stated on the plate conform

to those ordered and conrmed by BONFIGLIOLI RIDUTTORI S.p.A.

3.3 Transport and handling

Cartons containing more than one motor are usually attached to wooden boards to facilitate handling

by forklifts or transpallets.

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

CUS CCC

3 / 32

Motors may be handled individually by lifting them with belts or chains (if required due to weight).

Motors of frame sizes BX 100 / MX3, BE 100 / ME3, BN 100 / M3, and larger, are provided with an

eyebolt / lifting point for lifting purposes.

The eyebolts / lifting points are suitable for lifting the motor only.

Make sure that the motor rests in a stable manner and will not roll (in the case of anged motors).

3.4 Storage

Observe the following instructions to ensure correct storage of products:

a) Do not store outdoors, in areas exposed to weather or with excessive humidity.

b) Always place boards in wood or other material between oor and products, to avoid direct contact

with the oor.

c) For storage periods exceeding 60 days, all coupling surfaces such as anges and shafts must be

protected with a suitable anti-oxidation product (Mobilarma 248 or equivalent).

d) For storage periods exceeding 6 months, it is a good rule to turn the rotor every 1-2 months and to

take adequate measures against corrosion and humidity.

3.5 Motor installation

Check that mains assembly and service conditions comply with the information on the plate

and described in the technical documentation.

The following instructions must be observed when installing the motor:

Prior to installing the motor remove from the shaft the plastic guards that are supplied for transportation purposes.

4 / 32

These must be disposed of according to the rules applicable in the Country where the installation

takes place.

If applicable, remove oxidation preventative coating of shaft by means of a suitable solvent, which

afterwards must be disposed of according to the regulations applying locally.

Do not let the solvent be in touch with oilseal lips.

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

Make sure that the motor is well-ventilated, that there is nothing to obstruct the free circulation of air,

and that no situation will arise that could block the regular heat dissipation.

The installation must also allow the performance of ordinary maintenance on the motor and, if supplied, of the brake.

Avoid hitting on the motor shaft: bearings may be damaged.

In outdoor installations, protect the motor from direct sun ratiation and, if possible, from inclement weather.

Prior to tting anged motors onto gear units make sure that the key is retained safely into the key

seat. Coat thoroughly motor shaft with a suitable anti-seize product (Loctite 767 or equivalent) to prevent fretting corrosion and facilitate removal of motor at a later time.

Every 6-12 months it may be recommended to remove the motor from the gear head, clean the shaft

area and re-apply the anti-seize product.

In order to avoid vibration once in operation, make sure the motor is secured tightly to mating gearbox ange. Should the motor need to be painted, screen name plate as well as vented plug (if applicable) and machined parts on beforehand.

After the installation of a brake motor is complete, unscrew and remove the lever that operates the

manual brake release, thus preventing any accidental operation of the same.

3.6 Balancing

The rotor shaft is dynamically balanced with half key tted. Assembly of external transmission unit

must be performed with adeaquate instruments after suitable balancing, avoiding knocks which could

damage the bearings.

Be especially careful not to operate the motor without having properly secured the key not being

used (motors with two shaft ends).

Adopt adequate measures to avoid accidental contact with exposed live or moving parts.

Avoid contact with the motor case, since the temperature under normal operating conditions

may exceed 50 °C.

3.7 Insulation test

Before start-up, or after long storage (or idle) periods, check insulation resistance to mass with

Megger at 500V DC.

The value measured at 25 °C for new windings in good condition should exceed 10 MΩ.

If this value is not reached, oven drying will be required to eliminate excess humidity.

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

5 / 32

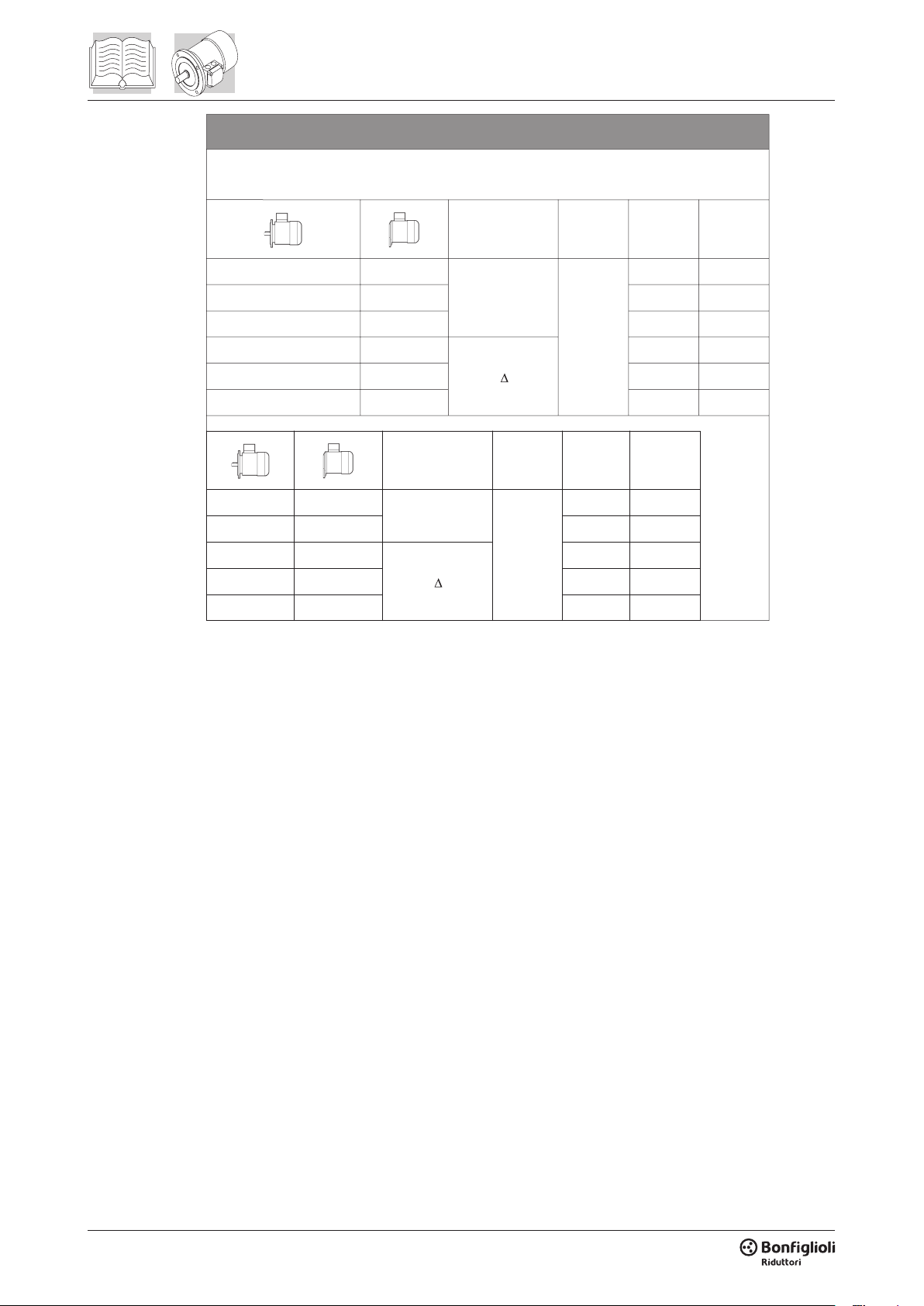

4 WIRING

U1

V a.c.±10% Hz P [W] I [A]

BN 71 M1

1~230

50/60

22 0.12

BN 80 M2

22 0.12

BN 90 —

40 0.30

BN 100 M3

50 0.25

BN 112 —

3 ~ 230 / 400Y

50 0.26/0.15

BN 132 ... BN 160MR M4

110 0.38 / 0.22

BN 160M ... BN 180M M5

50

180 1.25 / 0.72

BN 180L ... BN200L —

250 1.51 / 0.87

V a.c. ± 10% Hz P [W] I [A]

BX 80 - BE 80 MX2 - ME2

1 ~ 230

50 / 60

22 0.12

BX 90 - BE 90 —

40 0.30

BX 100 - BE 100 MX3 - ME3

50 0.25

BX 112 - BE 112 —

3 ~ 230 / 400Y

50 0.26 / 0.15

BX 132 - BE 132 MX4 - ME4

110 0.38 / 0.22

BX 160 - BE 160 MX5 - ME5

50

180 1.25/0.72

BX 180 - BE 180 —

250 1.51/0.87

Fan wiring terminals are housed in a separate terminal box

4.1 Norms applicable to all motors

Use cables with suitable section for the rated current and for installation conditions, avoiding excessive heating and/or voltage drops. Connection at the terminal board must be performed according to

the diagrams shown in chart below or according to the instructions supplied in the terminal box, using

the appropriate plates, nuts and washers. Earth according to current norms before connecting to the

mains.

In addition to the main terminals, the conduit box may contain thermal protection, anti-condensation

heaters, and brake connections.

Wire any device according to the diagrams contained in the conduit box.

Single-speed motors Two-speed motors

Delta connection

Star connection

During rest time voltage may still apply to terminals of the heaters and/or the brake.

When installing, repairing or maintaining the motor double check that all connections to the

mains have been cut.

Furthermore, always prevent uncontrolled restarting of the motor as this may be extremely

hazardous for the operator.

At the end of the wiring operations, place the gasket on its site and close the cover. Carefully tighten

the cable gland and close all the openings that are not used.

Single winding (Dahlander)

Low

speed

High

speed

Two separate winding

Low

speed

High

speed

4.2 Anti-condensate heaters

6 / 32

Power to the anti-condensate heaters must be supplied separately and it must always be disconnected while the motor is operating.

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

4.3 Ventilation

BX 180 - BE 180 —

Motors are cooled through outer air blow (IC 411 according to CEI EN 60034-6) and are equipped

with a plastic radial fan, which operates in both directions.

Ensure that fan cover is installed at a suitable distance from the closest wall so to allow air circulation

and servicing of motor and brake, if tted.

On request, all BX/MX, BE/ME motors and BN/M motors, starting from BN 71 or M1 size, can be supplied with independently power-supplied forced ventilation system.

Motor is cooled by an axial fan with independent power supply and tted on the fan cover (IC 416

cooling system).

Brake motors of BN_BA type and all motors with rear shaft projection (PS option) are excluded.

4.4 Ratings of separate supply fan units

Fan wiring terminals are housed in a separate terminal box

BN 71 M1

BN 80 M2

BN 90 —

BN 100 M3

BN 112 —

BN 132 ... BN 160MR M4

BN 160M ... BN 180M M5

BN 180L ... BN200L —

BX 80 - BE 80 MX2 - ME2

BX 90 - BE 90 —

BX 100 - BE 100 MX3 - ME3

BX 112 - BE 112 —

BX 132 - BE 132 MX4 - ME4

BX 160 - BE 160 MX5 - ME5

U1

V a.c.±10% Hz P [W] I [A]

22 0.12

1~230

50/60

3 ~ 230

V a.c. ± 10% Hz P [W] I [A]

3 ~ 230

/ 400Y

50

1 ~ 230

50 / 60

/ 400Y

50

22 0.12

40 0.30

50 0.25

50 0.26/0.15

110 0.38 / 0.22

180 1.25 / 0.72

250 1.51 / 0.87

22 0.12

40 0.30

50 0.25

50 0.26 / 0.15

110 0.38 / 0.22

180 1.25/0.72

250 1.51/0.87

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

7 / 32

(A) (B) (C) (D)

Start

coil coil coil coil

Start Start StartStop Stop Stop Stop

U2

Delta

connection

Star connection

Motor terminal board Brake

Fan terminals are wired in the motor terminal box

V a.c.±10% Hz P [W] I [A]

BN 71 M1

BN 80 M2

BN 90 —

BN 100 M3

BN 112 —

BN 132 ... BN 160MR M4

BE 80 ME2

BE 90 —

BE 100 ME3

BE 112 —

BE 132 ME4

4.5 Direction of rotation

1~230

50/60

3 ~ 230

V a.c. ± 10% Hz P [W] I [A]

1 ~ 230

3 ~ 230

/ 400Y

/ 400Y

50 / 60

22 0.12

40 0.30

40 0.12 / 0.09

50 0.26 / 0.15

110 0.38 / 0.22

22 0.12

22 0.12

40 0.30

40 0.12 / 0.09

50 0.26 / 0.15

110 0.38 / 0.22

If the mains with phase sequence L1, L2, L3 is connected to terminals U, V, W, the direction of rotation of the motor will be clockwise as seen from the drive end.

If any two terminals are switched, the direction of rotation will be counter-clockwise.

For unidirectional motors, a plate will be provided indicating the direction of rotation and the phase

sequence to be applied (e.g., U, V, W).

This indication is present only when the motor, as a function of project characteristics, requires only

one direction of rotation (for example, anti run-back device installed).

Pay special attention when single direction status is imposed by machine or plant specications.

4.6 FD brake connections

On standard single-pole motors, the rectier is connected to the motor terminal board at the factory.

For switch-pole motors and where a separate brake power supply is required, connection to rectier

must comply with brake voltage VB stated in motor name plate.

Because the load is of the inductive type, brake control and DC line interruption must use

contacts from the usage class AC-3 to IEC 60947-4-1.

8 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

Scheme (A) - Brake power supply from motor terminals and a.c. line disconnection. Delayed stop

time t2 and function of motor time constants. Mandatory when soft-start/stops are required.

Scheme (B) - Separate supply of brake coil and a.c. line disconnect. Regular stopping time, independent on time constants of motor.

Scheme (C) - Brake coil power supply from motor terminals and AC/DC line disconnection.

Scheme (D) - Brake coil with separate power supply and AC/DC line disconnection.

(A) (B) (C) (D)

coil coil coil coil

Start

Start Start StartStop Stop Stop Stop

4.7 FA and BA brake connections

The diagram below shows the wiring when brake is connected directly to same power supply of the motor:

Delta

connection

Star connection

Motor terminal board Brake

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

9 / 32

Switch-pole motors, nine pin motors (motors with voltage in ratio 2) and, at request, single-pole motors with separate power supply are equipped with an auxiliary terminal board with 6 terminals for

brake connection.

In this version, motors feature a larger terminal box.

See diagram:

Auxiliary terminal board

Motor terminal board

Brake

Wire the brake according to voltage and type of connection as shown on motor name plate.

Delta

connection

Star

connection

5 START-UP

Perform the following operations and checks before start-up:

1) check that all safety measures have been applied;

2) power up the motor unloaded at rated voltage;

3) check that the sepate fan cooling (if any) is operating;

4) check that operation is smooth and vibration-free;

5) If the brake is tted, verify that it operates regularly;

6) if operation is satisfactory, apply the load to the motor while checking on values of absorbed current, power and voltage.

Abnormal operations such as over current, overheating, noise, or vibrations, may cause serious damage or hazardous conditions. In these cases, cut power and notify maintenance personnel immediately.

10 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

6 MAINTENANCE

Before any intervention, the motor, auxiliary circuits and/or accessories must be disconnected from

the mains.

In particular:

- check disconnection from the electrical mains,

- provide suitable protections from exposed live parts,

- duble check that accidental restarts are not possible under any circumstances.

It is recommended that periodical checks of motor operating conditions are scheduled as a routine

maintenance practice.

Check particularly on the following:

1) check that operation is smooth and absorbed current within rated value;

2) On brakemotors, check condition of the brake, gauge the air gap “T” and play “X” of the manual

brake release device;when provided

3) keep motor clean and fan cowl unobstructed by accumulation of dust or foreign particles;

4) check that seal rings are in good condition;

5) check that lead-in wires and all wirings are safely and tightly secured;

6) If condensate draining holes are provided, remove periodically the screws that close the holes and

allow the condensate to drain. On installing the motor make sure that the drain hole is located at the

lowest point.

7) standard bearings are grease packed for life and in general no periodical maintenance is required; it is good practice however to check their condition and eventually replace them after approx.

3 years.

The motor does not have to be removed for normal inspections unless the bearings need to be replaced. In this case, the operations should be performed by specialised personnel and with appropriate tools.

6.1 Adjustment of air gap on motors with d.c. brake (FD) or a.c. brake (FA).

Loosen nut ref. 2

Depending on motor frame size adjust the air gap and set dimension T to the min. value indicated in

diagram through either socket head screws ref. (1) or nut ref. (3).

Then after hold rmly screw ref. (1) and lock it by tightening nut ref.(2).

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

11 / 32

Check the air gap periodically and re-adjust it if dimension T is found exceeding the min/max values

FA 02 3.5

FA 03 7.5

FA 04 15

FA 14 15

FA 05 40

FA 15 40

FA 06S 60

FA 06 75

FA 07 150

FA 08 250

BRAKE Max. brake torque

indicated in diagram.

Particularly, brake may become noisier if gap is wider than the max value. In extreme cases releasing

of the brake might also be affected.

If the brake disengagement device is tted, too wide a gap may lead the braking torque to

drop signicantly as a consequence of the reduced play in the release mechanism.

Distance “X” must mandatorily be equal to or greater than the value listed in the chart.

Thickness of disc lining must always be greater than 1.5 mm.

FD

FA

T

X

T (mm) = Air gap

Min 0.2

Max

BRAKE TYPE

FD 02 FD 03

FA 02 FA 03 FA 04

0.5

0.8

FD 53

0.2

0.5

0.8

FD 04

FD 14

FA 14

0.3

0.6

1.0

BN 71 ... BN 100 - BE 80 ... BE 100 - BX 80 ... BX 100

FD 05

FD 15

FD 55

FA 05

FA 15

0.3

0.6

1.0

M1 ... M3 - ME2, ME3 - MX2, MX3

FD 06S FD 06

FA 06S FA 06 FA 07 FA 08

0.35

0.7

1.1

FD 56

0.35

0.7

1.1

FD 07 FD 08

0.4

0.8

1.2

FD 09

0.5

1.0

1.5

12 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

6.2 Brake torque setting on motors with a.c. brake (FA)

Brake torque can be adjusted steplessly by changing the preload of springs (3).

WARNING: For safety reasons, brake torque will not be set lower than 30% of rated value, even at

springs fully unloaded.

BRAKE Max. brake torque

FA 02 3.5

FA 03 7.5

FA 04 15

FA 14 15

FA 05 40

FA 15 40

FA 06S 60

FA 06 75

FA 07 150

FA 08 250

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

13 / 32

6.3 Brake torque setting on motors with a.c. brake (BA)

Max 0.7 0.7 0.7 0.7 0.7 0.7 0.8

Loosen locking nut (2). Through nut (1) adjust the air gap and restore distance “T” to its minimum

value, as listed in the chart Repeat the operation symmetrically on each stud bolt holding the brake.

When setting is complete tighten nuts (1) and (2) on each stud bolt.

Too wide an air gap may result into noise and vibrations in operation and, in extreme cases,

even prevent the motor from braking.

BRAKE TYPE

BA

T

T (mm) = Air gap

Min 0.3 0.3 0.3 0.3 0.3 0.3 0.4

BA 60 BA 70 BA 80 BA 90 BA 100 BA 110 BA 140

6.4 Brake torque setting on motors with a.c. brake (BA)

Brake torque can be adjusted steplessly by changing the preload of springs (4) acting on nuts (3).

Braking torque will increase proportionally to the compression of springs (4).

Repeat the operation symmetrically on each stud bolt holding the brake.

BRAKE Max. brake torque

BA 60 5

BA 70 8

BA 80 18

BA 90 35

BA 100 50

BA 110 75

BA 140 150

14 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

7 DISASSEMBLY, RECYCLING OR DISPOSAL

The electrical motors are mainly made by ferrous, non - ferrous, plastic materials and electric / electronic devices.

Bonglioli recommends and encourages the end of life motor dismantling and the differentiation and

recycling of the components.

The differentiated disposal of the motor components shall be performed with respect to the local regulations for the environment protection.

For dismantled motors disposal, the European Waste Code (EWC) provides the following classication:

• 16 02 14 discarded equipment other than those mentioned in 16 02 09 to 16 02 13

• 16 02 16 components removed from discarded equipment other than those mentioned in 16 02 15

where:

• 16 02 09* transformers and capacitors containing PCBs

• 16 02 10* discarded equipment containing or contaminated by PCBs other than those mentioned in

16 02 09

• 16 02 11* discarded equipment containing chlorouorocarbons, HCFC, HFC

• 16 02 12* discarded equipment containing free asbestos

• 16 02 13* discarded equipment containing hazardous components other than those mentioned in

16 02 09 to 16 02 12

• 16 02 15* hazardous components removed from discarded equipment

* = concerning hazardous components - hazardous components are not present in Bonglioli electric motors.

NOTE: The above classication is referred to Bonglioli electric motors as per their factory initial conditions. Bonglioli is not responsible for any particular or inappropriate usage or modications applied

to the electric motors, which might require a different EWC classication.

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

15 / 32

8 SPARE PARTS

6440 1030

1010 (6030) (6050)

1080 1290

(6320)

(6310)

1030

(6020)

1

(1230)

(1200)

(1240)

6250

(1220) 6234 1390 6444

1328

(1370)

1320 1360

1180

1150

(6290)

6300

(6080)

1310

(1325)

1300

M05 FD

kit ref. Description

M05

M05 FD

M05 FA

1 Motor ange

1010 Stator

1030 Rotor

1150 Fan

1180 Fan cowl

KSM

(1200) Terminal box

(1230) Terminal box gasket

KSA

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6310) Circlip

(6320) Circlip

6234 Blank plug

6250 Terminal board

6440 Flange bolt

6444 NDE shield bolt

M05

1070 Rear shield

KSA (6080) V-ring

kit ref. Description

M05 FD

M05 FA

1080 Shield for brake motor

1290 Spacer ring

1310 Brake disc

1320 Brake springs

KTF

(1325) Brake hub

(6290) Key (brake hub)

(6300) Circlip

1328 Stainless steel disc

KPF

(1370) Water/dust guard (IP55)

(6080 Brake seal ring/V-ring (IP55)

M05 FD

KSM

(1220) Terminal box lid

(1240) Terminal box lid gasket

1300 d.c. brake type FD

1360 Brake release

1390 ac/dc recti er

M05 FA

1350 a.c. brake type FA

1380 Brake release

(####) Only available as a complete kit

M05

M05

M05 FA

16 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

M05

6440 1030

(6020)

(1220) 6234 1390 6444

M05 FD

1

1030

(6310)

(6320)

(1240)

(1200)

(1230)

6250

1010 (6030) (6050)

1328

(1370)

1080 1290

1320 1360

1180

1150

(6290)

6300

(6080)

1300

(1325)

1310

M05

M05 FD

M05 FA

M05

kit ref. Description

1 Motor ange

1010 Stator

1030 Rotor

1150 Fan

1180 Fan cowl

(1200) Terminal box

KSM

(1230) Terminal box gasket

(6020) Bearing

(6030) Bearing

KSA

(6050) Compensation ring

(6310) Circlip

(6320) Circlip

6234 Blank plug

6250 Terminal board

6440 Flange bolt

6444 NDE shield bolt

1070 Rear shield

KSA (6080) V-ring

M05 FD

M05 FA

M05 FD

M05 FA

kit ref. Description

1080 Shield for brake motor

1290 Spacer ring

1310 Brake disc

1320 Brake springs

(1325) Brake hub

KTF

(6290) Key (brake hub)

(6300) Circlip

1328 Stainless steel disc

(1370) Water/dust guard (IP55)

KPF

(6080 Brake seal ring/V-ring (IP55)

(1220) Terminal box lid

KSM

(1240) Terminal box lid gasket

1300 d.c. brake type FD

1360 Brake release

1390 ac/dc recti er

1350 a.c. brake type FA

1380 Brake release

(####) Only available as a complete kit

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

17 / 32

ME2 ... ME4 MX2 ... MX4M1 ... M4

1328

M/ME

MX

M_ FA ME_ FA MX_ FA

kit ref. Description

M_

M_ FD

M_ FA

ME_

ME_ FD

ME_ FA

MX_

MX_ FD

MX_ FA

1 Motor ange

1010 Stator

1030 Rotor

1100 Tie-rods

1150 Fan

1180 Fan cowl

KSM

(1200) Terminal box

(1230) Terminal box gasket

1340 Motor ange for W gearbox

KSA

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6310) Circlip

(6320) Circlip

6234 Blank plug

6250 Terminal board

6385 Kit bushing for W gearbox

M_ / ME_

MX_

1070 Rear shield

KSA (6080) V-ring

kit ref. Description

M_ FD

M_ FA

ME_ FD

ME_ FA

MX_ FD

MX_ FA

1080 Shield for brake motor

1290 Spacer ring

1310 Brake disc

1320 Brake springs

KTF

(1325) Brake hub

(6290) Key (brake hub)

(6300) Circlip

KPF

(1370) Water/dust guard (IP55)

(6080) Brake seal ring/V-ring (IP55)

M_ FD

ME_ FD

MX_ FD

KSM

(1220) Terminal box lid

(1240) Terminal box lid gasket

1300 d.c. brake type FD

1328 Stainless steel disc

1360 Brake release kit

1390 ac/dc recti er

M_ FA

ME_ FA

MX_ FA

1350 a.c. brake type FA

1380 Brake release kit

(####) Only available as a complete kit

M_ ME_ MX_

M/ME

MX

M_ FD ME_ FD MX_ FD

M/ME

MX

1340

6385

1030

(1240)

1390

(1200)

(6020)

1

1030

(6310)

(6320)

1010 1100 (6030) (6050)

1080(1230)62506234(1220)

(1370) 1290

1310

118013601320

1150

(6290)

(6300)

(6080)

(1325)

1300

18 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

ME2 ... ME4 MX2 ... MX4M1 ... M4

M_ FA ME_ FA MX_ FA

M/ME

MX

M_

M_ FD

M_ FA

ME_

ME_ FD

ME_ FA

MX_

MX_ FD

MX_ FA

M_ / ME_

MX_

kit ref. Description

1 Motor ange

1010 Stator

1030 Rotor

1100 Tie-rods

1150 Fan

1180 Fan cowl

(1200) Terminal box

KSM

(1230) Terminal box gasket

1340 Motor ange for W gearbox

(6020) Bearing

(6030) Bearing

KSA

(6050) Compensation ring

(6310) Circlip

(6320) Circlip

6234 Blank plug

6250 Terminal board

6385 Kit bushing for W gearbox

1070 Rear shield

KSA (6080) V-ring

M_ FD

M_ FA

ME_ FD

ME_ FA

MX_ FD

MX_ FA

M_ FD

ME_ FD

MX_ FD

M_ FA

ME_ FA

MX_ FA

kit ref. Description

1080 Shield for brake motor

1290 Spacer ring

1310 Brake disc

1320 Brake springs

(1325) Brake hub

KTF

(6290) Key (brake hub)

(6300) Circlip

(1370) Water/dust guard (IP55)

KPF

(6080) Brake seal ring/V-ring (IP55)

(1220) Terminal box lid

KSM

(1240) Terminal box lid gasket

1300 d.c. brake type FD

1328 Stainless steel disc

1360 Brake release kit

1390 ac/dc recti er

1350 a.c. brake type FA

1380 Brake release kit

(####) Only available as a complete kit

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

19 / 32

M5 ME5 MX5

M5 FA ME5 FA MX5 FA

kit ref. Description

M5

M5 FD

M5 FA

ME5

ME5 FD

ME5 FA

MX5

MX5 FD

MX5 FA

1 Motor ange

1010 Stator

1030 Rotor

1150 Fan

1180 Fan cowl

KSM

(1200) Terminal box

(1220) Terminal box lid

(1230) Terminal box gasket

(1240) Terminal box lid gasket

KSA

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6310) Circlip

(6320) Circlip

6234 Blank plug

6250 Terminal board

6440 Flange bolt

6448 NDE shield bolt

kit ref. Description

M5 / ME5

MX5

1070 Rear shield

KSA (6080) V-ring

M5 FD

M5 FA

ME5 FD

ME5 FA

MX5 FD

MX5 FA

1080 Shield for brake motor

1310 Brake disc

1320 Brake springs

KTF

(1325) Brake hub

(6045) Spacer

(6290) Key (brake hub)

(6300) Circlip

KPF

(1370) Water/dust guard (IP55)

(6080) Brake V-ring (IP55)

M5 FD

ME5 FD

MX5 FD

1300 d.c. brake type FD

1328 Stainless steel disc (IP55)

1360 Brake release

1390 ac/dc recti er

M5 FA

ME5 FA

MX5 FA

1350 a.c. brake type FA

1380 Brake release

(####) Only available as a complete kit

M5 ME5

MX5

M5 FD ME5 FD

MX5 FD

20 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

M5 MX5ME5

M5 FA ME5 FA

MX5 FA

M5

M5 FD

M5 FA

ME5

ME5 FD

ME5 FA

MX5

MX5 FD

MX5 FA

kit ref. Description

1 Motor ange

1010 Stator

1030 Rotor

1150 Fan

1180 Fan cowl

(1200) Terminal box

(1220) Terminal box lid

KSM

(1230) Terminal box gasket

(1240) Terminal box lid gasket

(6020) Bearing

(6030) Bearing

KSA

(6050) Compensation ring

(6310) Circlip

(6320) Circlip

6234 Blank plug

6250 Terminal board

6440 Flange bolt

6448 NDE shield bolt

M5 / ME5

MX5

M5 FD

M5 FA

ME5 FD

ME5 FA

MX5 FD

MX5 FA

M5 FD

ME5 FD

MX5 FD

M5 FA

ME5 FA

MX5 FA

kit ref. Description

1070 Rear shield

KSA (6080) V-ring

1080 Shield for brake motor

1310 Brake disc

1320 Brake springs

(1325) Brake hub

(6045) Spacer

KTF

(6290) Key (brake hub)

(6300) Circlip

(1370) Water/dust guard (IP55)

KPF

(6080) Brake V-ring (IP55)

1300 d.c. brake type FD

1328 Stainless steel disc (IP55)

1360 Brake release

1390 ac/dc recti er

1350 a.c. brake type FA

1380 Brake release

(####) Only available as a complete kit

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

21 / 32

BN 63

kit ref. Description

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (B5/B14)

1070 Rear shield

1100 Tie-rods

1150 Fan

1180 Fan cover

KSM

(1200) Terminal box lid

(1230) Terminal box gasket

kit ref. Description

6234 Blank plug

6250 Terminal board

KSA

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6060) Key

(6070) Seal ring

(6080) V-ring

(####) Only available as a complete kit

kit ref. Description

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (IM B5/IM B14)

1070 Rear shield

1150 Fan

1180 Fan cover

(1200) Terminal box lid

KSM

(1230) Terminal box gasket

6234 Blank plug

(####) Only available as a complete kit

22 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

kit ref. Description

6250 Terminal board

6440 Flange bolt

6444 NDE shield bolt

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

KSA

(6060) Key

(6070) Seal ring

(6080) V-ring

BX 80 ... BX 132

BN 71 ... BN 160MR BE 80 ... BE 132

kit ref. Description

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (B5/B14)

1070 Rear shield

1100 Tie-rods

1150 Fan

1180 Fan cover

(1200) Terminal box lid

KSM

(1230) Terminal box gasket

(####) Only available as a complete kit

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

kit ref. Description

6234 Blank plug

6250 Terminal board

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

KSA

(6060) Key

(6070) Seal ring

(6080) V-ring

23 / 32

kit ref. Description

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (B5/B14)

1080 Rear shield

1150 Fan

1180 Fan cover

KSM

(1200) Terminal box

(1220) Terminal box lid

(1230) Terminal box gasket

(1240) Lid gasket

1290 Spacer ring

1300 d.c. brake type FD

1310 Brake disc

1320 Brake springs

KTF

(1325) Brake hub

(6290) Key (brake hub)

(6300) Circlip

kit ref. Description

1328 Stainless steel disc (IP55)

1360 Hand release lever

KPF

(1370) Grommet (IP55)

(6080) V-ring (IP55)

1390 ac/dc recti er

KSA

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6060) Key

(6070) Seal ring

6234 Blank plug

6250 Terminal board

6440 Flange bolt

6444 NDE shield bolts

(####) Only available as a complete kit

BX 160 , BX 180

BN 160M ... BN 200 BE 160 , BE 180

kit ref. Description

KSM

(####) Only available as a complete kit

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (IM B5)

1070 Rear shield

1150 Fan

1180 Fan cover

(1200) Terminal box

(1220) Terminal box lid

(1230) Terminal box gasket

(1240) Lid gasket

kit ref. Description

KSA

6234 Blank plug

6250 Terminal board

6440 DE ange bolts

6448 NDE shield bolts

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6060) Key

(6070) Seal ring

(6080) V-ring

24 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

BN 63 FD

kit ref. Description

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (B5/B14)

1080 Rear shield

1150 Fan

1180 Fan cover

(1200) Terminal box

KSM

KTF

(####) Only available as a complete kit

(1220) Terminal box lid

(1230) Terminal box gasket

(1240) Lid gasket

1290 Spacer ring

1300 d.c. brake type FD

1310 Brake disc

1320 Brake springs

(1325) Brake hub

(6290) Key (brake hub)

(6300) Circlip

kit ref. Description

1328 Stainless steel disc (IP55)

1360 Hand release lever

KPF

KSA

(1370) Grommet (IP55)

(6080) V-ring (IP55)

1390 ac/dc recti er

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6060) Key

(6070) Seal ring

6234 Blank plug

6250 Terminal board

6440 Flange bolt

6444 NDE shield bolts

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

25 / 32

BN 71 FD ... BN 160MR FD

kit ref. Description

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (IM B5)

1080 Rear shield (NDE)

1150 Fan

1180 Fan cover

KSM

(1200) Terminal box

(1220) Terminal box lid

(1230) Terminal box gasket

(1240) Lid gasket

1300 d.c. brake type FD

1310 Brake disc

1320 Brake springs

KTF

(1325) Brake hub

(6290) Key (brake hub)

(6300) Circlip

kit ref. Description

1328 Stainless steel disc (IP55)

1360 Hand release lever

KPF

(1370) Grommet (IP55)

(6080) V-ring (IP55)

1390 ac/dc recti er

KSA

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6060) Key

(6070) Seal ring

6234 Blank plug

6250 Terminal board

6310 Circlip

6440 Bolts DE

6448 Bolts NDE

(####) Only available as a complete kit

BX 80 FD ... BX 132 FDBE 80 FD ... BE 132 FD

kit ref. Description

KSM

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (B5/B14)

1080 Rear shield

1100 Tie-rods

1150 Fan

1180 Fan cover

(1200) Terminal box

(1220) Terminal box lid

(1230) Terminal box gasket

(1240) Lid gasket

1290 Spacer ring

1300 d.c. brake type FD

1310 Brake disc

1320 Brake springs

kit ref. Description

KTF

KPF

KSA

(1325) Brake hub

(6290) Key (brake hub)

(6300) Circlip

1328 Stainless steel disc (IP55)

1360 Hand release lever

(1370) Grommet (IP55)

(6080) V-ring (IP55)

1390 ac/dc recti er

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6060) Key

(6070) Seal ring

6234 Blank plug

6250 Terminal board

(####) Only available as a complete kit

26 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

BN 160 FD ... BN 200L FD

BE 160 FD , BE 180 FD BX 160 FD , BX 180 FD

kit ref. Description

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (IM B5)

1080 Rear shield (NDE)

1150 Fan

1180 Fan cover

(1200) Terminal box

KSM

KTF

(1220) Terminal box lid

(1230) Terminal box gasket

(1240) Lid gasket

1300 d.c. brake type FD

1310 Brake disc

1320 Brake springs

(1325) Brake hub

(6290) Key (brake hub)

(6300) Circlip

kit ref. Description

1328 Stainless steel disc (IP55)

1360 Hand release lever

KPF

KSA

(1370) Grommet (IP55)

(6080) V-ring (IP55)

1390 ac/dc recti er

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6060) Key

(6070) Seal ring

6234 Blank plug

6250 Terminal board

6310 Circlip

6440 Bolts DE

6448 Bolts NDE

(####) Only available as a complete kit

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

27 / 32

BN 63 FA

kit ref. Description

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (B5/B14)

1080 Rear shield

1100 Tie-rods

1150 Fan

1180 Fan cowl

KSM

(1200) Terminal box

(1230) Terminal box gasket

1290 Spacer ring

1310 Brake disc

1320 Brake springs

KTF

(1325) Brake hub

(6290) Key (brake hub)

(6300) Circlip

kit ref. Description

1350 a.c. brake type FA

KPF

(1370) Brake seal kit (IP55)

(6080) V-ring (IP55)

1380 Hand release lever

KSA

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6060) Key

(6070) Seal ring

6234 Blank plug

6250 Terminal board

(####) Only available as a complete kit

kit ref. Description

KSM

KTF

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (B5/B14)

1080 Rear shield

1150 Fan

1180 Fan cover

(1200) Terminal box

(1230) Terminal box gasket

1290 Spacer ring

1310 Brake disc

1320 Brake springs

(1325) Brake hub

(6290) Key (brake hub)

(6300) Circlip

kit ref. Description

KPF

KSA

1328 Stainless steel disc (IP55)

1350 a.c. brake type FA

(1370) Grommet (IP55)

(6080) V-ring (IP55)

1380 Hand release lever

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6060) Key

(6070) Seal ring

6234 Blank plug

6250 Terminal board

6440 Flange bolt

6444 NDE shield bolts

(####) Only available as a complete kit

28 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

BN 71 FA ... BN 160MR FA

BX 80 FA ... BX 132 FABE 80 FA ... BE 132 FA

kit ref. Description

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (B5/B14)

1080 Rear shield

1100 Tie-rods

1150 Fan

1180 Fan cowl

KSM

KTF

(1200) Terminal box

(1230) Terminal box gasket

1290 Spacer ring

1310 Brake disc

1320 Brake springs

(1325) Brake hub

(6290) Key (brake hub)

(6300) Circlip

kit ref. Description

1350 a.c. brake type FA

KPF

KSA

(1370) Brake seal kit (IP55)

(6080) V-ring (IP55)

1380 Hand release lever

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6060) Key

(6070) Seal ring

6234 Blank plug

6250 Terminal board

(####) Only available as a complete kit

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

29 / 32

kit ref. Description

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (B5/B14)

1080 Rear shield

1100 Tie rods

1110 Fan cowling

KSF

(1120) Brake holding plate

(6130) Bolts

1150 Fan

1190 Brake guard

KSM

(1200) Terminal box

(1230) Terminal box gasket

1310 Brake disc

kit ref. Description

1312 Armature plate

1315 a.c. brake type BA

1460 Brake release

KSA

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

(6060) Key

(6070) Seal ring

(6080) V-ring

6190 Nut screw

6234 Blank plug

6250 Terminal board

(####) Only available as a complete kit

BN 160 FA ... BN 180M FA

BE 160 FA , BE 180 FA BX 160 FA , BX 180 FA

kit ref. Description

KSM

KTF

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (IM B5)

1080 Rear shield

1150 Fan

1180 Fan cowl

(1200) Terminal box

(1220) Terminal box lid

(1230) Terminal box gasket

(1240) Terminal box lid gasket

1310 Brake disc

1320 Brake springs

(1325) Brake hub

(6290) Key (brake hub)

(6300) Circlip

kit ref. Description

KPF

KSA

1350 a.c. brake type FA

(1370) Brake seal kit (IP55)

(6080) V-ring (IP55)

1380 Hand release lever

(6020) Bearing

(6030) Bearing

(6050) Elastic ring

(6060) Key

(6070) Seal ring

6234 Blank plug

6250 Terminal board

6310 Circlip

6440 Bolt DE

6448 Bolt NDE

(####) Only available as a complete kit

30 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

BN 63 BA ... BN 132 BA

kit ref. Description

1010 Stator winding complete

1030 Rotor shaft

1050 Mounting ange (B5/B14)

1080 Rear shield

1100 Tie rods

1110 Fan cowling

(1120) Brake holding plate

KSF

(6130) Bolts

1150 Fan

1190 Brake guard

(1200) Terminal box

KSM

(1230) Terminal box gasket

1310 Brake disc

(####) Only available as a complete kit

kit ref. Description

1312 Armature plate

1315 a.c. brake type BA

1460 Brake release

(6020) Bearing

(6030) Bearing

(6050) Compensation ring

KSA

(6060) Key

(6070) Seal ring

(6080) V-ring

6190 Nut screw

6234 Blank plug

6250 Terminal board

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

31 / 32

INDEX OF REVISIONS (R)

BR_IOM_BX-BE-BN-MX-ME-M_STD_ENG_R02_0

Description

… Removed information on brakes type AFD

… Added information on BX, MX motors

15 Added new chapter "Disassembly, recycling or disposal"

This publication supersedes and replaces any previous edition and revision. We reserve the right to

implement modications without notice. This catalogue cannot be reproduced, even partially, without prior

consent.

32 / 32

IOM BX-BE-BN-MX-ME-M_eng - Translation of original instructions in Italian - Rev 02_0 - 30/09/16

We have a relentless commitment to excellence, innovation &

sustainability. Our team creates, distributes and services worldclass power transmission & drive solutions to keep the world in

motion.

HEADQUARTERS

Bonfiglioli Riduttori S.p.A.

Via Giovanni XXIII, 7/A

40012 Lippo di Calderara di Reno

Bologna (Italy)

tel: +39 051 647 3111

fax: +39 051 647 3126

bonfiglioli@bonfiglioli.com

www.bonfiglioli.com

Loading...

Loading...