INDUSTRY PROCESS

AND AUTOMATION SOLUTIONS

Expansion

Module EM-ABS-01

Frequency Inverter 230 V / 400 V

ACTIVE Cube

GB

TABLE OF CONTENTS

1 General Information about the Documentation ........................................................................ 7

1.1 Instructions ............................................................................................................. 7

1.2 Pictograms and signal words used .......................................................................... 8

1.3 Copyright ................................................................................................................. 8

2 General Safety Instructions and Information on Use ................................................................ 9

2.1 General Information ................................................................................................ 9

2.2 Designated use ........................................................................................................ 9

2.3 Transport and Storage ........................................................................................... 10

2.4 Handling and installation ....................................................................................... 10

2.5 Electrical Installation ............................................................................................. 10

2.6 Information on Use ................................................................................................ 11

2.6.1 Operation with products from other manufacturers ................................................... 11

2.7 Maintenance and service ....................................................................................... 11

2.8 Disposal ................................................................................................................. 11

3 Introduction ....................................................................................................................... 12

3.1 Restrictions for operation of standard functions .................................................. 13

3.2 Range of applications of encoders ......................................................................... 14

3.2.1 Asynchronous motor .............................................................................................. 14

3.2.2 Synchronous motor ................................................................................................ 14

4 Technical data .................................................................................................................... 15

5 Installation ......................................................................................................................... 17

5.1 General .................................................................................................................. 17

5.2 Mechanical Installation ......................................................................................... 17

5.3 Electrical Installation ............................................................................................. 19

5.3.1 Block diagram ....................................................................................................... 19

5.3.2 Control terminals ................................................................................................... 21

5.3.2.1 Cable assembly SinCos .................................................................................... 23

5.3.2.2 Cable assembly EnDat 2.1 ................................................................................ 24

5.3.2.3 Cable assembly Hiperface ................................................................................ 25

5.3.3 Power supply ......................................................................................................... 26

5.3.3.1 Internal power supply ...................................................................................... 26

5.3.3.2 Looping via terminals X410A ............................................................................ 27

5.3.3.3 Direct connection of external power supply to the encoder ................................. 28

6 Commissioning the encoder ................................................................................................ 29

6.1 General Information .............................................................................................. 29

6.1.1 Information on use ................................................................................................ 30

6.2 SinCos encoders ..................................................................................................... 31

6.3 Hiperface encoders ................................................................................................ 32

6.4 EnDat 2.1 encoders ................................................................................................ 33

6.5 SSI encoders .......................................................................................................... 34

6.6 Commissioning of linear encoders ......................................................................... 36

6.6.1 Checking the settings ............................................................................................. 41

6.6.2 Initialize counting direction ..................................................................................... 43

6.6.3 Initializing home position ........................................................................................ 43

03/12 EM-ABS-01 for ACU 3

7 System bus interface ........................................................................................................... 44

7.1 Bus termination ..................................................................................................... 44

7.2 Cables .................................................................................................................... 45

7.3 Control terminal X410B ......................................................................................... 45

7.4 Baud rate setting/line lengths .............................................................................. 46

7.5 Setting the node address ....................................................................................... 46

7.6 Functional overview .............................................................................................. 47

7.7 Network management ........................................................................................... 47

7.7.1 SDO channels (parameter data) .............................................................................. 48

7.7.2 PDO channels (process data) .................................................................................. 48

7.8 Master functionality ............................................................................................... 49

7.8.1 Control boot-up sequence, network management ..................................................... 49

7.8.2 SYNC telegram, generation ..................................................................................... 51

7.8.3 Emergency message, reaction ................................................................................. 52

7.8.4 Client SDO (system bus master) .............................................................................. 53

7.9 Slave functionality ................................................................................................. 54

7.9.1 Implement boot-up sequence, network management ................................................ 54

7.9.1.1 Boot-up message ............................................................................................ 54

7.9.1.2 Position control ............................................................................................... 54

7.9.2 Process SYNC telegram .......................................................................................... 55

7.9.3 Selecting the synchronization source ....................................................................... 55

7.9.3.1 Settings for electronic gear in configuration x40 ................................................. 57

7.9.3.2 Scope sources ................................................................................................. 57

7.9.4 Emergency-Message, fault shutdown ....................................................................... 58

7.9.5 Server-SDO1/SDO2 ................................................................................................ 59

7.10 Communication channels, SDO1/SDO2 .............................................................. 61

7.10.1 SDO telegram (SDO1/SDO2) ................................................................................... 61

7.10.2 Communication via field bus actuation (SDO1) ......................................................... 63

7.10.2.1 Profibus-DP .................................................................................................... 63

7.10.2.2 RS232/RS485 with VECTRON bus protocol ........................................................ 63

7.11 Process data channels, PDO ............................................................................... 65

7.11.1 Identifier assignment process data channel .............................................................. 65

7.11.2 Operation modes process data channel .................................................................... 66

7.11.3 Timeout monitoring process data channel ................................................................ 67

7.11.4 Communication relationships of the process data channels ........................................ 68

7.11.5 Virtual links ........................................................................................................... 69

7.11.5.1 Input parameters of the TxPDOs for data to be transmitted ................................ 72

7.11.5.2 Source numbers of the RxPDOs for received data .............................................. 74

7.11.5.3 Examples of virtual links .................................................................................. 75

7.12 Control parameters............................................................................................. 76

7.13 Handling of the parameters of the system bus .................................................. 77

7.14 Ancillaries ........................................................................................................... 79

7.14.1 Definition of the communication relationships ........................................................... 80

7.14.2 Production of the virtual links .................................................................................. 81

7.14.3 Capacity planning of the system bus........................................................................ 82

8 Control inputs and outputs .................................................................................................. 84

8.1 Analog input EM S1INA ......................................................................................... 84

8.1.1 General ................................................................................................................. 84

8.1.2 Characteristic ........................................................................................................ 84

8.1.3 Operation modes ................................................................................................... 85

8.1.3.1 Examples ........................................................................................................ 85

4 EM-ABS-01 for ACU 03/12

Scaling .................................................................................................................. 88

8.1.4

8.1.5 Tolerance Band and Hysteresis ............................................................................... 89

8.1.6 Error and warning behavior .................................................................................... 90

8.1.7 Adjustment ........................................................................................................... 91

8.1.8 Filter time constant ................................................................................................ 91

8.2 Digital outputs EM-S1OUTD and EM-S2OUTD ....................................................... 92

8.2.1 General ................................................................................................................. 92

8.2.2 Operation modes ................................................................................................... 92

8.2.3 Repetition frequency output via EM-S1OUTD and EM-S2OUTD................................... 92

8.3 Digital inputs EM-SxIND ........................................................................................ 93

8.3.1 Fixed reference value and fixed value change-over ................................................... 93

8.4 Encoder input EM-ABS-01 ...................................................................................... 94

8.4.1 Division marks ....................................................................................................... 94

8.4.2 Tracks/Protocol ..................................................................................................... 95

8.4.3 Power supply ......................................................................................................... 98

8.4.4 Supply voltage ..................................................................................................... 101

8.4.5 Speed filter ......................................................................................................... 102

8.4.6 Offset ................................................................................................................. 102

8.4.7 Bits/Turn ............................................................................................................. 104

8.4.8 Bits Multiturn ....................................................................................................... 105

8.4.9 SSI: error/additional bits ...................................................................................... 106

8.4.9.1 Example 1 .................................................................................................... 107

8.4.9.2 Example 2 .................................................................................................... 107

8.4.9.3 Example 3 .................................................................................................... 107

8.4.9.4 Example 4 .................................................................................................... 107

8.4.10 SSI: Sampling interval .......................................................................................... 108

8.4.11 Gear factor speed sensor 2 ................................................................................... 108

8.4.11.1 Example ....................................................................................................... 109

8.4.12 Instructions on speed-controlled configurations (“Not x40”) .................................... 109

8.4.13 Instructions on positioning (configuration x40) ....................................................... 110

8.4.13.1 Example ....................................................................................................... 111

8.4.13.2 Homing ........................................................................................................ 112

8.4.14 Warning Dig. Encoder .......................................................................................... 112

8.4.15 Act. speed source ................................................................................................ 113

8.4.16 Actual position source .......................................................................................... 113

8.5 Reference frequency and percentage value channel .......................................... 114

8.6 Actual value display ............................................................................................. 114

8.6.1 Absolute value encoder - raw data ........................................................................ 115

8.6.2 Actual position ..................................................................................................... 115

8.7 Status of digital signals ....................................................................................... 116

8.8 Motor temperature .............................................................................................. 117

9 List of parameters ............................................................................................................. 118

9.1 Actual value menu (VAL) ..................................................................................... 118

9.2 Parameter menu (PARA) ..................................................................................... 118

10 Annex .............................................................................................................................. 121

10.1 Recommended encoder settings ...................................................................... 121

10.1.1 SinCos encoders: ................................................................................................. 121

10.1.2 Hiperface encoders: ............................................................................................. 122

10.1.3 EnDat2.1 encoders: ............................................................................................. 122

10.1.4 SSI encoders, rotary: ........................................................................................... 123

10.1.5 SSI encoders, linear encoders: .............................................................................. 123

10.2 Compatibility list .............................................................................................. 124

03/12 EM-ABS-01 for ACU 5

Module Firmware 1.0.1.0 ...................................................................................... 124

10.2.1

10.2.2 Module-Firmware 2.0.1.0 ...................................................................................... 124

10.3 Error messages ................................................................................................. 125

Index ..................................................................................................................................... 128

6 EM-ABS-01 for ACU 03/12

1 General Information about the Documentation

The present supplement to the operating instructions is valid for the frequency inverters of the ACU

series of devices. The information necessary for the assembly and application of the EM-ABS-01 extension module is documented in this guidance.

For better clarity, the documentation is structured according to the customer-specific requirements

made on the frequency inverter.

1.1 Instructions

For better clarity, the documentation is structured according to the customer-specific requirements

made on the frequency inverter.

Quick Start Guide

The Quick Start Guide describes the basic steps required for mechanical and electrical installation of

the frequency inverter. The guided commissioning supports you in the selection of necessary parameters and the configuration of the frequency inverter by the software.

User manual

The Operating Instructions describe and document all functions of the frequency inverter. The parameters required for adapting the frequency inverter to specific applications as well as the wide range

of additional functions are described in detail.

Application Manual

The application manual supplements the documentation for purposeful installation and commissioning

of the frequency inverter. Information on various subjects connected with the use of the frequency

inverter are described specific to the application.

If you need a copy of the documentation or additional information, contact your local representative

of BONFIGLIOLI.

The present documentation was prepared with great care and it was subjected to extensive and repeated reviews. For reasons of clarity, it was not possible to include all details of all types of the product in the documentation. Neither was it possible to consider all conceivable installation, operation or

maintenance situations. If you require further information or if you meet with specific problems which

are not dealt with in sufficient detail in the documentation, contact your local BONFIGLIOLI agent.

We would also like to point out that the contents of this documentation do not form part of any previous or existing agreement, assurance or legal relationship. Neither are they intended to supplement

or replace such agreements, assurances or legal relationships. Any obligations of the manufacturer

shall solely be based on the relevant purchase agreement which also includes the complete and solely

valid warranty stipulations. These contractual warranty provisions are neither extended nor limited by

the specifications contained in this documentation.

The manufacturer reserves the right to correct or amend the specifications, product information and

omissions in these operating instructions without notice. The manufacturer shall not be liable for any

damage, injuries or costs which may be caused by the aforementioned reasons.

The present instructions were issued in German language. Other language versions are translations of

the German document.

03/12 EM-ABS-01 for ACU 7

1.2 Pictograms and signal words used

The following pictograms and signal words are used in the documentation:

Danger!

Danger refers to an immediate threat. Non-compliance with the precaution described may

result in death, serious injury or material damage.

Warning!

Warning refers to a possible threat. Non-compliance with the warning may result in death,

serious injury or material damage.

Caution!

Caution refers to an indirect threat. Non-compliance may result in personal or material

damage.

Attention!

Attention refers to a possible operational behavior or an undesired condition that can occur in accordance with the reference text.

Note

Note marks information that facilitates handling for you and supplements the corresponding part of

the documentation.

1.3 Copyright

This user manual is protected by copyright. It is solely intended for use by operating staff and must

not be copied nor disclosed to third parties.

8 EM-ABS-01 for ACU 03/12

2 General Safety Instructions and Information on Use

Warning!

The specifications and instructions contained in the documentation must be complied with

strictly during installation and commissioning. Before starting the relevant activity, read the

documentation carefully and comply with the safety instructions. The term “Qualified Staff”

refers to anybody who is familiar with the installation, assembly, commissioning and operation of the frequency inverter and has the proper qualification for the job.

2.1 General Information

Warning!

The DC-link circuit of the frequency inverter is charged during operation, i.e. there is always the risk of contact with high voltage. Frequency inverters are used for driving moving

parts and they may become hot at the surface during operation.

Any unauthorized removal of the necessary covers, improper use, wrong installation or operation may result in serious injuries or material damage.

In order to avoid such injuries or damage, only qualified technical staff may carry out the

transport, installation, commissioning, setup or maintenance work required. The standards

DIN EN 50178, IEC 60364 (Cenelec HD 384 or DIN VDE 0100), IEC 60664-1 (Cenelec HD

625 or VDE 0110-1), BGV A2 (VBG 4) as well as the applicable national regulations must

be complied with. The term „Qualified Staff“ refers to anybody who is familiar with the installation, assembly, commissioning and operation of the frequency inverter as well as the

possible hazards and has the proper qualification for the job.

Persons not familiar with the operation of the frequency inverter or children must not have

access to the device.

2.2 Designated use

Warning!

The frequency inverters are electrical drive components intended for installation in industrial plants or machines. Commissioning and start of operation is not allowed until it has

been verified that the machine meets the requirements of the EC Machinery Directive

2006/42/EEC and DIN EN 60204. In accordance with the CE marking requirements, the

frequency inverters comply with the Low Voltage Directive 2006/95/EEC as well as DIN

EN 61800-5-1. The user shall be responsible for making sure that the requirements of the

EMC Directive 2004/108/EEC are met. Frequency inverters are only available at specialized

dealers and are exclusively intended for professional use as per DIN EN 61000-3-2.

Any use other than the use described above, will be considered as not in accordance with

the specified purpose and may result in the warranty becoming null and void.

The frequency inverters are also marked with the UL label according to UL508c, which

proves that they also meet the requirements of the CSA Standard C22.2-No. 14-95.

The technical data, connection specifications and information on ambient conditions are

indicated on the rating plate and in the documentation and must be complied with in any

case. Anyone involved in any kind of work at the device must have read the instructions

carefully and understood them before starting the work.

03/12 EM-ABS-01 for ACU 9

2.3 Transport and Storage

The frequency inverters must be transported and stored in an appropriate way. During transport and

storage the devices must remain in their original packaging.

The units may only be stored in dry rooms which are protected against dust and moisture and are

exposed to little temperature deviations only. Observe the conditions as per DIN EN 60721-3-1 for

storage, DIN EN 60721-3-2 for transport and the labeling on the packaging.

The duration of storage without connection to the permissible nominal voltage may not exceed one

year.

2.4 Handling and installation

Warning!

Damaged or destroyed components must not be put into operation because they may be a

health hazard.

The frequency inverters are to be used in accordance with the documentation as well as the applicable directives and standards.

It must be handled carefully and protected against mechanical stress.

Do not bend any components or change the isolating distances.

Do not touch electronic components or contacts. The devices are equipped with components which

are sensitive to electrostatic energy and can be damaged if handled improperly. Any use of damaged

or destroyed components shall be considered as a non-compliance with the applicable standards.

Removal of seals from the housing can result in invalidation of warranty.

Do not remove any warning signs from the device.

2.5 Electrical Installation

Warning!

Before any assembly or connection work, discharge the frequency inverter. Verify safe isolation from power supply.

Do not touch the terminals because the capacitors may still be charged.

Comply with the information given in the operating instructions and on the frequency in-

verter label.

Follow the safety rules applying to work on electrical equipment.

Follow the safety rules applying to work on electrical equipment:

• Isolate: Isolate the installation from all possible sources of electrical power.

• Secure against reconnection. Only the persons working on the installation may re-commission the

relevant part of the installation.

• Verify there is no electrical power: Using a measuring instrument or voltage tester, ensure there is

no voltage against ground on the relevant plant component.

• Ground and short-circuit: Starting from the ground terminal, connect all conductors to one anoth-

1)

er.

• Cover und shield neighboring live parts: By covering, shielding or isolation of energized plant com-

ponents contact with such parts is to be prevented.

1)

Deviations from this are possible in certain circumstances.

When working at the frequency inverters, comply with the relevant accident prevention regulations,

the applicable standards BGV A2 (VBG 4), VDE 0100, standards governing work on systems with dangerous voltages (e.g. DIN EN 50178) and other national directives.

10 EM-ABS-01 for ACU 03/12

Comply with the electrical installation instructions given in the documentation as well as the relevant

directives.

Responsibility for compliance with and examination of the limit values of the EMC product norm DIN

EN 61800-3 for variable-speed electrical drive mechanisms is with the manufacturer of the industrial

plant or machine. The documentation contains information on EMC-conforming installation.

The cables connected to the frequency inverters may not be subjected to high-voltage insulation tests

unless appropriate circuitry measures are taken before.

Do not connect any capacitive loads.

2.6 Information on Use

Warning!

The frequency inverter may be connected to power supply every 60 s. This must be considered when operating a mains contactor in jog operation mode. For commissioning or after

an emergency stop, a non-recurrent, direct restart is permissible.

After a failure and restoration of the power supply, the motor may start unexpectedly if the

AutoStart function is activated.

If staff is endangered, a restart of the motor must be prevented by means of external circuitry.

Before commissioning and the start of the operation, make sure to fix all covers and check

the terminals. Check the additional monitoring and protective devices according to DIN EN

60204 and applicable the safety directives (e.g. Working Machines Act, Accident Prevention

Directives etc.).

No connection work may be performed, while the system is in operation.

2.6.1 Operation with products from other manufacturers

Please note that Bonfiglioli Vectron will not accept responsibility for compatibility with products from

other manufacturers (e.g. motors, cables, filters, etc.).

In order to achieve optimum system compatibility, Bonfiglioli Vectron offers components which ensure

easy commissioning and are perfectly adjusted to one another in operation.

Use of the device with products from other manufacturers will be at your own risk.

2.7 Maintenance and service

Warning!

Unauthorized opening and improper interventions can lead to personal injury or material

damage. Repairs on the frequency inverters may only be carried out by the manufacturer

or persons authorized by the manufacturer.

Check protective equipment regularly.

Any repair work must be carried out by qualified electricians.

2.8 Disposal

The components of the frequency inverter must be disposed of in accordance with the applicable local

and national laws, regulations and standards.

03/12 EM-ABS-01 for ACU 11

T

A

g

g

g

y

3 Introduction

This document describes the possibilities and the properties of the EM-ABS-01 exten-

sion module for the frequency inverters of the ACU series of devices.

Note:

The EM-ABS-01 extension module is an optional hardware component to extend the

functionality of the frequency inverter. It enables the data exchange within the network and between the components which have been directly connected, for example

control and regulation elements.

n absolute value encoder or a SinCos encoder and an external DC 24 V power source

can be connected to the extension module EM-ABS-01. The connected volta

can power the encoder. To that end, the encoder power supply must be set to “Via

X410A” via a parameter (Parameter

supply). The voltage level for encoder power supply can be set via a parameter (Parameter

can be controlled via a measuring cable (often referred to as “sense” cable).

The EM-ABS-01 extension module extends the functionality of the frequency inverters

of the ACU series of devices by the following functions:

− System bus CAN

(Can interface ISO -DIS 11898, CAN High Speed, max. 1 MBaud).

See chapter 7 “System bus”.

− Analog input

See chapter 8.1 “Analog input EM S1INA”.

− Encoder interface including

Supported encoder types:

See chapter 8.4 “Encoder input EM”.

− Three digital inputs.

See chapt

− Two digital outputs, can

See chapter 8.2 “Digital outputs EM-S1OUTD and EM-S2OUTD”.

− Adjustable voltage ou

See chapter 8.4.3 “Power supply” and 8.4.4 “Supply voltage”.

− DC 24 V voltage input for connecti

connected encoder can be powered.

See chapter 5.3.3 “Power supply” 8.4.3 “Power supply”.

Note: Dependin

Note: The EM-ABS-01 extension module has been enclosed with the frequenc

his document exclusively describes the

EM-ABS-01 extension module. It is not to be understood as fundamental

information for the operation of the frequency inverters of the ACU series

of devices.

e source

Power Supply 1186, see chapter 8.4.3 Power

Supply voltage 1187, see Chapter 8.4.4 “Supply voltage”). The volta

DC -10…+10 V or DC 0…+

PTC evaluation via HD-Sub-D female connector.

o SinCos (optionally with commutation tracks for synchronous motors)

o EnDat 2.1 (encoder type with SinCos track required)

o Hiperface

o Being prepared: SSI encoder (optionally with TTL [RS-422]- or SinCos

track)

er 8.3 “Digital inputs EM-SxIND

also be used as repetition fre

tput for encoder supply.

on the motor and encoder type used there are restrictions as

to usability in applications. See chapter 3.2 “Range of applications of en-

coders”.

inverter as a separate component and must be fitted by the user. This is

described in the chapter 5.2 “Mechanical Installation”.

10 V.

”.

quency output.

on of external power supply. Via this input a

e value

12 EM-ABS-01 for ACU 03/12

T

g

he extension module is assembled simply by plugging on without tools being needed

thanks to the modular set-up of the frequency inverters of the ACU series of devices.

Caution! Carry out the assembly of the extension module before the frequency

inverter is put into operation, and only in a voltage-free state.

The plug-type terminals of the extension module enable economical overall fitting with

a safe function.

Note:

Chapter 10.2 contains a compatibility list of the EM-ABS-01 modules in

combination

with the ACU inverter firmware versions.

3.1 Restrictions for operation of standard functions

Note: If an EM-ABS-01 module is used with an ACU device, the following func-

tions of the basic device can no longer be used:

• Repetition frequency mode via MFO1 of base device.

Instead, repetition frequency mode can be realized via digital outputs of the EM-ABS-01 module.

• Repetition frequency mode (also PWM frequency input) via di

inputs of basic device

Instead, the speed sensor 1 input of the basic device can be used.

ital

03/12 EM-ABS-01 for ACU 13

g

3.2 Range of applications of encoders

Depending on the motor and encoder type used there are restrictions as to usability in

applications. The following sections describe the range of applications.

Note: The EM-ABS-01 module supports, in the case of EnDat 2.1 encoders, a

baud rate of 100 kBit/s. Other baud rates will not be supported.

3.2.1 Asynchronous motor

SinCos,

Hiperface,

EnDat 2.1 with SinCos track,

SSI with incremental track (TTL [RS-422] or SinCos)

can be used on asynchronous motors as:

• Motor encoders for speed feedback (e.g. Configuration 210)

• Motor encoders for speed feedback and parallel position feedback in non-slip

systems (e.g. Configuration 240)

• Application encoder for position feedback with parallel speed feedback either

via motor model (sensorless e.

terminals on ACU basic device e.g. Configuration 240).

SSI encoders without incremental track

can be used on asynchronous motors as:

• Application encoder for position feedback with speed feedback either via mo-

tor model (sensorless e.g. Configuration 440) or via HTL encoder (via terminals on ACU basic device e.g. Configuration 240).

EnDat 2.1 without SinCos track

cannot be used.

. Configuration 440) or via HTL encoder (via

3.2.2 Synchronous motor

SinCos with commutation tracks,

Hiperface,

EnDat 2.1 with SinCos track,

SSI with incremental track (TTL [RS-422] or SinCos)

can be used on synchronous motors as:

• Motor encoders for speed feedback (e.g. Configuration 510).

• Motor encoders for speed feedback and parallel position feedback in non-slip

systems (e.g. Configuration 540).

• Application encoder for position feedback with parallel speed feedback via mo-

tor model (sensorless e.g. Configuration 640) .

SinCos without commutation track,

SSI encoders without incremental track

can be used on synchronous motors as:

• Application encoder for position feedback with parallel speed feedback via mo-

tor model (sensorless e.g. Configuration 640) .

EnDat 2.1 without SinCos track

cannot be used.

14 EM-ABS-01 for ACU 03/12

4 Technical data

When using the EM-ABS-01 extension module, the technical data of the frequency

inverter must be considered.

Control terminal X410A Control terminal X410B

X410A.1 Voltage input DC 24 V X410B.1 Ground

X410A.2 Ground DC 24 V X410B.2 Digital input EM-S1IND1)

X410A.3 Digital output EM-S1OUTD

X410A.4 Digital output EM-S2OUTD

X410A.5 Voltage output DC 5…12 V3) X410B.5 System bus, CAN low

X410A.6 Analog input EM-S1INA1) X410B.6 System bus, CAN high

X410A.7 Ground DC 10 V X410B.7 Ground

1)

The control electronics parameters can be configured as required.

2)

Can be used as repetition frequency output. The repetition frequency output can

withstand external voltage in a range from -5 V to +10 V.

3)

The max. power available is reduced by the other control outputs of the frequency

inverter and extension module.

Caution! The input for external DC 24 V voltage supply can withstand external vol-

tage up to DC 30 V. Avoid higher voltage levels. Higher voltages may destroy the module.

Caution! The power output on terminal X410A.1 may be loaded with a maximum

power of 2 W. Higher power levels can damage components of the module.

Encoder and PTC input X412 (HD-Sub-D)

Encoder input: PTC input

Internal resistance <100 Ω Trigger resistance = 2.4 kΩ according

A/B and C/D track:

sine-shaped differential signal 0.6…1.2 Vss

1), 2)

X410B.3 Digital input EM-S2IND1)

1), 2)

X410B.4 Digital input EM-S3IND1)

to

DIN 44081

Hysteresis = 1.3 kΩ

PTC or bimetal temperature sensor

R-track:

(NC)

Differential signal 0.2…1.7 Vss

Clock and data (alternative to C/D track)

Signal: V =DC 2.5 V ±0.5 V

Power supply encoder:

track: Supply DC 5…12 V

V

ENC

V

ENC,Sense

track: encoder sensor cable

Warning! The PTC input is not insulated. Only PTCs which feature a safe isolation

from the motor winding as per EN61800-5-1 may be connected.

Note: BONFIGLIOLI servo motors of types BCR and BTD are provided with

safe isolation to the motor winding.

Note: BONFIGLIOLI VECTRON recommends connecting an external power

supply to the voltage input of the control terminal. This auxiliary voltage

enables powering an encoder via the voltage output of the control terminal. Note the manufacturer's input power specifications of the encoder.

03/12 EM-ABS-01 for ACU 15

Digital inputs (X410B.2) … (X210B.4):

Technical data of control terminals

Low Signal: DC 0 V …3 V, High Signal: DC 12 V … 30 V, input resistance: 2.3 kΩ, PLC

compatible

Sample Times: 1 ms in configurations x40 (“Positioning”)

4 ms in all other configurations

Frequency signal: DC 0 to 30 V, 10 mA at DC 24 V, f

Digital outputs (X410A.3), (X410A.4):

Low signal: DC 0 V to 3 V,

High signal: DC 12 V to 30 V, output current: 40 mA, PLC compatible,

Repetition frequency output: frequency signal , F

circuit proof, I

= ±60 mA at min. permissible line termination 150 Ω, according to

max

specification EIA485

Analog input (X410A.6):

Analog signal: Input voltage: DC -10 V to 10 V / DC 0 V to 10 V (R

Resolution 13 Bit

Voltage output DC 5 to 12 V for encoder supply (X410A.5):

= 2 W. Depending on the load on the digital outputs of the frequency inverter

P

max

and extension module, this value may be lower.

Voltage input DC 24 V for external power supply (X410A.1)

Input voltage range DC 24 V ±10%, U

= DC 30 V,

max

Rated input current: max. DC 1.0 A (typical DC 0.45 A),

Peak inrush current: typical: < DC 20 A,

External fuse: standard fuse elements for rated current, characteristic: slow,

Safety: Safety extra low voltage (SELV) according to EN 61800-5-1

Conductor cross-section:

The control terminals are suitable for the following cable sizes:

with ferrule: 0.25 … 1.0 mm²

without ferrule: 0.14 … 1.5 mm²

= 150 kHz

max

= 150 kHz, overload and short-

max

= 100 kΩ),

i

16 EM-ABS-01 for ACU 03/12

g

g

T

g

A

g

j

g

5 Installation

5.1 General

The mechanical and electrical installation of the EM-ABS-01 extension module must be

carried out by qualified personnel accordin

installation directives. For a safe operation of the frequency inverter it is necessary

that the documentation and the device specifications be complied with during installation and commissionin

. In the case of special applications, you may also have to

comply with further guidelines and instructions.

he frequency inverters are designed according to the requirements and limit values

of product norm EN 61800-3 with an interference immunity factor (EMI) for operation

in industrial applications. The electroma

installation and observation of the specific product information.

For further information, refer to the chapter "Electrical Installation" of the frequency

inverter operating instructions.

Warning!

ll connection terminals where dangerous voltage levels may be present

(e.g. motor connection terminals, mains terminals, fuse connection terminals, etc.), must be protected against direct contact.

to the general and regional safety and

netic interference is to be avoided by expert

5.2 Mechanical Installation

Danger! If the followin

with the possible consequences of death or severe in

• Before assembly or disassembly of the EM-ABS-01 extension module, the frequen-

cy inverter must be de-energized. Take appropriate measures to make sure it is

not energized unintentionally.

• Make sure that the frequency inverter is discharged.

Danger! When the frequency inverter is disconnected from power supply, the

current. Further, failure to comply can lead to destruction of the frequency

inverter and/or of the extension module.

mains, DC-link volta

time. Wait for at least three minutes until the DC link capacitors have

discharged before starting to work at the unit.

instructions are not complied with, there is direct danger

ury by electrical

e and motor terminals may still be live for some

03/12 EM-ABS-01 for ACU 17

g

g

2

The EM-ABS-01 extension module is supplied in a housing for assembly on the lower

slot of the frequency inverter.

• Remove the lower cover (1) of the frequency inverter.

The slot for the EM-ABS-01 extension module becomes accessible.

1

Caution! The EM-ABS-01 (2) extension module is pre-fitted in a housin

visible on the back may not be touched, as modules can be dama

this.

• Plug the EM-ABS-01 (2) extension module onto the slot (3).

. The PCB

ed by

3

• Re-install the lower cover (1).

Assembly is complete.

When the supply voltage of the frequency inverter is switched on, the EM-ABS-01

ex-tension module is ready for operation.

1

18 EM-ABS-01 for ACU 03/12

g

r

y

g

T

g

5.3 Electrical Installation

Danger! If the followin

with the possible consequences of death or severe injury by electrical

current. Further, failure to comply can lead to destruction of the frequenc

inverter and/or of the extension module.

• Before electrical installation of the EM-ABS-01 extension module, the frequency

inverter must be de-energized. Take appropriate measures to make sure it is not

energized unintentionally.

• Make sure that the frequency inverter is discharged.

Danger! When the frequency inverter is disconnected from power supply, the

mains, DC-link volta

time. Wait for at least three minutes until the DC link capacitors have

discharged before starting to work at the unit.

5.3.1 Block diagram

instructions are not complied with, there is direct dange

e and motor terminals may still be live for some

Caution!

he digital inputs and the DC 24 V terminal of the electronic control

equipment can withstand external volta

e up to DC 30 V. Avoid higher

voltage levels. Higher voltages may destroy the module.

03/12 EM-ABS-01 for ACU 19

V

V

A

k

A

j

g

A

oltage input, connection for external power supply of encoder

Input voltage range DC 24 V ±10%, U

Rated input current: max. DC 1.0 A (typical DC 0.45 A),

Peak inrush current: typical: < DC 20 A,

External fuse: standard fuse elements for rated current, characteristic: slow,

Safety: Safety extra low voltage (SELV) according to EN 61800-5-1

B

Digital outputs EM-S1OUTD, EM-S2OUTD

Digital signal, DC 24 V, I

C

oltage output for encoder supply

DC 5 V … 12 V, according to configuration of parameter Supply voltage 1187 (factory

setting DC 5.0 V), P

Caution! The power output on terminal X410A.1 may be loaded with a maximum

power of 2 W. Higher power levels can damage components of the mod-

D

nalog signal, resolution 13 bit, U

E

Digital signal, response time 1 ms in configurations x40 (“Positioning”), 4 ms in all

ule.

Analog input EM-S1INA

Digital inputs EM-S1IND … EM-S3IND

other configurations, U

PLC-compatible,

frequency signal, DC 0 ... 30 V, 10 mA at DC 24 V

F

Communication interface system bus

CAN-connection of system bus according to ISO-DIS 11898 (CAN High Speed), bus

termination can be activated via switch

G

Inputs for SinCos encoders and PTC (15-pin female connector HD-SubD)

The encoder interface is designed for connection of standard commercial SinCos (optionally with commutation tracks for synchronous motors), EnDat 2.1 (SinCoS trac

required), Hiperface and SSI encoders (optionally with TTL [RS-422] or SinCos track).

Depending on the encoder type, different signals are evaluated. The following signals

can be evaluated:

- A/B tracks and/or Sin/Cos tracks

- C/D tracks (commutation tracks) or Data/Clock tracks (absolute value encoders)

- R tracks (reference track)

- Measuring line for monitoring and control of encoder supply voltage

Input: sinusoidal incremental signals, internal resistance of source <100 Ω,

/B and C/D tracks: Direct portion V =DC 2.5 V ±0.5 V, peak value: 0.6 V,

R-track: Direct portion V

The encoder supply voltage at contacts X412.6 (V

usted throu

h parameter Supply voltage 1187 in between DC 5.0 … 12 V. See chap-

ter 8.4.4 “Supply voltage”. Max. load: 2 W.

PTC input:

Trigger resistance = 2.4 kΩ (PTC) as per DIN 44081,

PTC or bimetal temperature sensor (NC)

Use PTC resistors with safe isolation from motor winding according to EN 61800-5-1.

= DC 30 V,

max

= 40 mA, PLC compatible, overload and short-circuit proof

max

= 2 W

max

= DC ±10 V (Ri = 100 kΩ)

max

= DC 30 V, 10 mA at DC 24 V,

max

=DC 2.5 V ±0.5 V, differential voltage: 1.8 V.

) and X412.15 (0VL) can be ad-

Enc

20 EM-ABS-01 for ACU 03/12

g

g

g

5.3.2 Control terminals

The control and software functionality can be configured as required to ensure a reli-

able and economical operation.

Extension module EM-ABS-01

0.2 … 0.3 Nm

1.8 … 2.7 lb-in

Caution! Switch off power supply before connectin

inputs and outputs.

Atten-

tion!

In order to minimize electroma

nal quality, the shield of the cable is to be connected to ground on a

si

netic interference and to obtain a good

plane at both ends.

Control terminal X410A

Terminal Description

1 DC 24 V voltage input

2 Ground (GND) DC 24 V

3 Digital output EM-S1OUTD1)

4 Digital output EM-S21OUTD1)

5 DC 5 … 12 V voltage output2)

6 Analog input EM-S1INA1)

7 Ground DC 10 V

Wieland DST85 / RM3,5

0.14 … 1.5 mm

AWG 30 … 16

0.14 … 1.5 mm

AWG 30 … 16

0.25 … 1.0 mm

AWG 22 … 18

0.25 … 0.75 mm

AWG 22 … 20

or disconnecting the control

2

2

2

2

Control terminal X410B

Terminal Description

1 Ground (GND)

2 Digital input EM-S1IND1)

3 Digital input EM-S2IND1)

4 Digital input EM-S3IND1)

5 System bus, CAN low

6 System bus, CAN high

7 Ground (GND)

1)

The control electronics parameters can be configured as required.

2)

The max. power available is reduced by the other used control outputs of the frequency

inverter and extension module. For sufficient power, connect an external power source to

the DC 24 V voltage input.

The voltage value can be adjusted via parameter

Supply voltage 1187.

Caution! The input for external DC 24 V voltage supply can withstand external vol-

tage up to DC 30 V. Avoid higher voltage levels. Higher voltages may destroy the module.

Caution! The power output on terminal X410A.1 may be loaded with a maximum

power of 2 W. Higher power levels can damage components of the module.

03/12 EM-ABS-01 for ACU 21

A

V

V

“

V

P

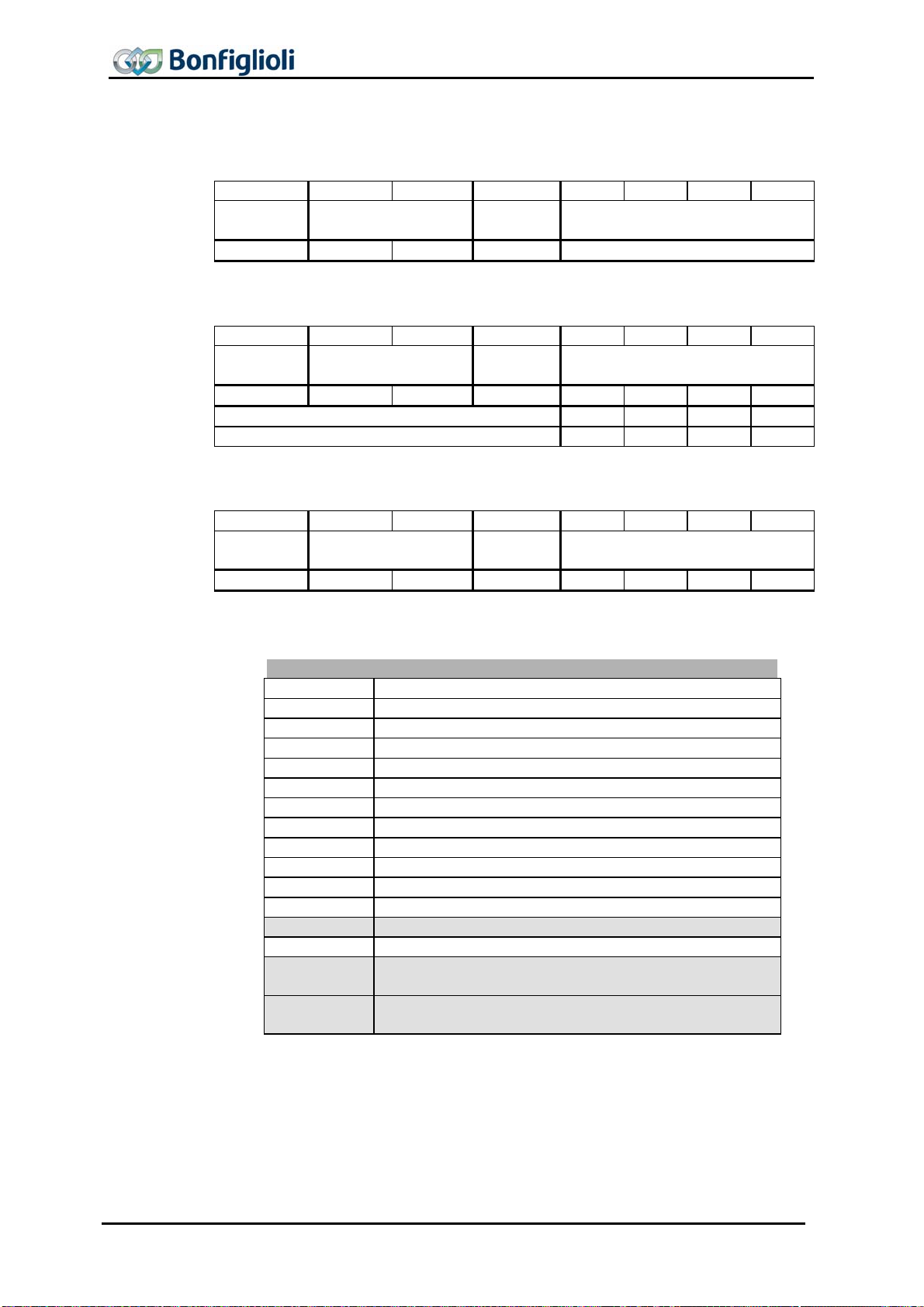

Female connector X412

Encoder and PTC input X412 (female connector HD-Sub-D)

Sin/Cos Hiperface EnDat 2.1 SSI

Contact

Function

Housing PE PE PE PE

1 D- Clock- Clock 2 D+ Clock+ Clock+

3 Cos- Cos- B- / Cos- (optionally B- / Cos-)

4 Cos+ Cos+ B+ / Cos+ (optionally B- / Cos-)

5 TM

6 V

– TM

PTC

V

Enc

Enc

– TM

PTC

V

– TM

PTC

V

Enc

Enc

PTC

–

7 R-

8 C- Data- Data- Data 9 Sin- Sin- A- / Sin- (optionally A- / Sin-)

10 TM

11 V

+ TM

PTC

V

Enc,Sense

PTC

+ TM

+ TM

PTC

Enc,Sense

PTC

V

Enc,Sense

+

12 R+

13 C+ Data+ Data+ Data+

14

Sin+ Sin+ A+ / Sin+ (optionally A+ /

Sin+)

15 GND GND GND GND

Function and signal

Function Signal

Housing Shield connected with PE

+/A- Sin+/SinB+/B- Cos+/CosC+/CD+/D-

0.6 V … 1.2 Vss incremental signal

In the case of SSI encoders, the A+/A- and B+/B- tracks can be

used, as an option, for TTL [RS-422] or SinCos signals.

R+/R- DC 0.2 … 1.7 V analog signal

Clock+/Clock- Clock signal

Data+/Data- Data signal

TM

+

PTC

–

TM

PTC

Enc

GND

Measuring line for monitoring of V

EncS

1)

The voltage value can be adjusted via parameter Supply voltage 1187. See chapter 8.4.4

Supply voltage”.

2)

oltage control via the measuring line can be activated, as an option, through parameter

Motor PTC

Encoder supply (DC 5 … 12 V)

1)

, max. load capacity 2 W

2)

Enc

Vss: peak-peak voltage

ower Supply 1186. See chapter 8.4.3 “Power supply”.

15

11

10

5

1

6

22 EM-ABS-01 for ACU 03/12

g

5.3.2.1 Cable assembly SinCos

Contact assignment BONFIGLIOLI VECTRON assembled cable for connection of SinCos encoders

BONFIGLIOLI VECTRON assembled cable

Encoder cable 8 twisted two-wire lines

Cable size 0.14 mm2

Length 3 m, 5 m or 10 m

Note: The assembled cables for EnDat 2.1 and SinCos encoders are identical. For

better readability of the individual connections, the specific designations for SinCos

and EnDat 2.1 are used.

• Use PTC resistors with safe isolation from motor windin

according to EN 61800-

5-1.

• Use shielded and twisted cables.

• Install encoder cable separate from motor cable.

• Connect the shield of the encoder line properly on both sides.

• BONFIGLIOLI VECTRON recommends using the pre-assembled cables for syn-

chronous motors types BCR and BTD.

03/12 EM-ABS-01 for ACU 23

g

5.3.2.2 Cable assembly EnDat 2.1

Contact assignment BONFIGLIOLI VECTRON assembled cable for connection of EnDat 2.1 encoders

BONFIGLIOLI VECTRON assembled cable

Encoder cable 8 twisted two-wire lines

Cable size 0.14 mm2

Length 3 m, 5 m or 10 m

Note: The assembled cables for EnDat 2.1 and SinCos encoders are identical. For

better readability of the individual connections, the specific designations for SinCos

and EnDat 2.1 are used.

• Use PTC resistors with safe isolation from motor windin

according to EN 61800-

5-1.

• Use shielded and twisted cables.

• Install encoder cable separate from motor cable.

• Connect the shield of the encoder line properly on both sides.

• BONFIGLIOLI VECTRON recommends using the pre-assembled cables for syn-

chronous motors types BCR and BTD.

24 EM-ABS-01 for ACU 03/12

g

5.3.2.3 Cable assembly Hiperface

Contact assignment BONFIGLIOLI VECTRON assembled cable for connection of Hiperface encoders

• Use PTC resistors with safe isolation from motor windin

according to EN 61800-

5-1.

• Use shielded and twisted cables.

• Install encoder cable separate from motor cable.

• Connect the shield of the encoder line properly on both sides.

• BONFIGLIOLI VECTRON recommends using the pre-assembled cables for syn-

chronous motors types BCR and BTD.

03/12 EM-ABS-01 for ACU 25

5.3.3 Power supply

Encoder power supply can be effected in different ways. Depending on the consumers

connected, there are different encoder power supply possibilities or requirements.

Generally, there are three different application types:

• Low power demand (< 0.5 W) and power supply ≤ 12 V:

Î Internal power supply.

• Medium power demand (0.5... 2 W) and power supply ≤ 12 V:

Î Power supply to be looped via X410.

• High power demand (> 2 W) or power supply > 12 V:

Î Connect encoder directly to external power supply.

Encoders with high power demand (> 2 W) or voltage higher than DC 12 V must be

connected to an external power supply directly.

External power supply can be connected via terminals X410A for encoder supply. In

this case, a DC 24 V supply can be controlled down, by the EM-ABS-01 module, to the

frequently needed voltage levels DC 5…12 V.

5.3.3.1 Internal power supply

Encoders with a low power consumption (< 0.5 W) can be supplied, in most cases, by

the internal power supply unit.

Set parameter Power supply 1186 to either “1 - internal” or “5- internal, sense”. See

chapter 8.4.3 “Power supply”.

The voltage level can be

set up via parameter

8.4.4 “Supply voltage”.

The encoder can be powered as follows:

− via control terminals X410A.5 (DC 5 … 12 V) and X410A.7 (GND) or

− via contacts X412.6 (VEnc) and X412.15 (GND) of the female HD-Sub-D connec-

tor.

See chapter 5.3.2 "Control terminals".

Caution! If power supply is done via the internal power supply of the encoders, a

total power of 2 W is available for all consumers connected to digital, analog and encoder interfaces. This includes all interfaces of the ACU basic

device and the EM-ABS-01 module together.

Supply voltage 1187. See chapter

26 EM-ABS-01 for ACU 03/12

A

g

g

g

g

5.3.3.2 Looping via terminals X410A

In some cases, encoder power supply must be supported or effected by an external

power supply. This is a good idea especially in the case of encoders with medium

power demand (0.5…2 W) or when many consumers are connected to the signal terminals.

n external DC 24 V power supply can be connected to terminals X410A.1 (DC 24 V)

and X410A.2 (ground). Via this power supply, a connected encoder can be powered.

BONFIGLIOLI VECTRON recommends connecting an external power supply.

Requirements to be met by external power supply

Input voltage range DC 24 V ±10%

Rated input current Max. DC 1.0 A (typical DC 0.45 A),

Peak inrush current Typically: < DC 20 A

External fuse Standard fuse elements for rated current, characteristic:

slow

Safety Safety extra low voltage (SELV) according to EN 61800-

5-1

Note: Connect the power supply for the encoder to terminals X410A.1 and

X410A.2. Connection via the terminals of the basic device ACU (X210A.1

and X210A.2) is not sufficient for powering the EM-ABS-01 module and the

encoder.

Caution! If the encoder is powered via X410A, 2 W power are available to the en-

coder interface. Another 2 W are available to the interfaces (di

inputs/outputs) of the basic device.

ital/analo

Caution! The inputs for the external power supply can withstand external volta

to DC 30 V. Avoid hi

module.

her voltage levels. Higher voltages may destroy the

Caution! Some encoders (e.g. laser distance meters) need more power than possi-

ble with the power supply described here. If the encoder requires a power

level higher than 2 W or more than DC 12 V, it must be connected to an

external power supply directly

. Non-fulfillment of this requirement may

result in dangerous plant states.

Set parameter Power supply 1186 to either “2 - via X410A” or “6 via X410A, sense”.

See chapter 8.4.3 “Power supply”.

The voltage level can be

set up via parameter

Supply voltage 1187. See chapter

8.4.4 “Supply voltage”.

The encoder can be powered as follows:

− via control terminals X410A.5 (DC 5 … 12 V) and X410A.7 (GND) or

−

via contacts X412.6 (V

) and X412.15 (GND) of the female HD-Sub-D connector.

Enc

See chapter 5.3.2 "Control terminals".

e up

03/12 EM-ABS-01 for ACU 27

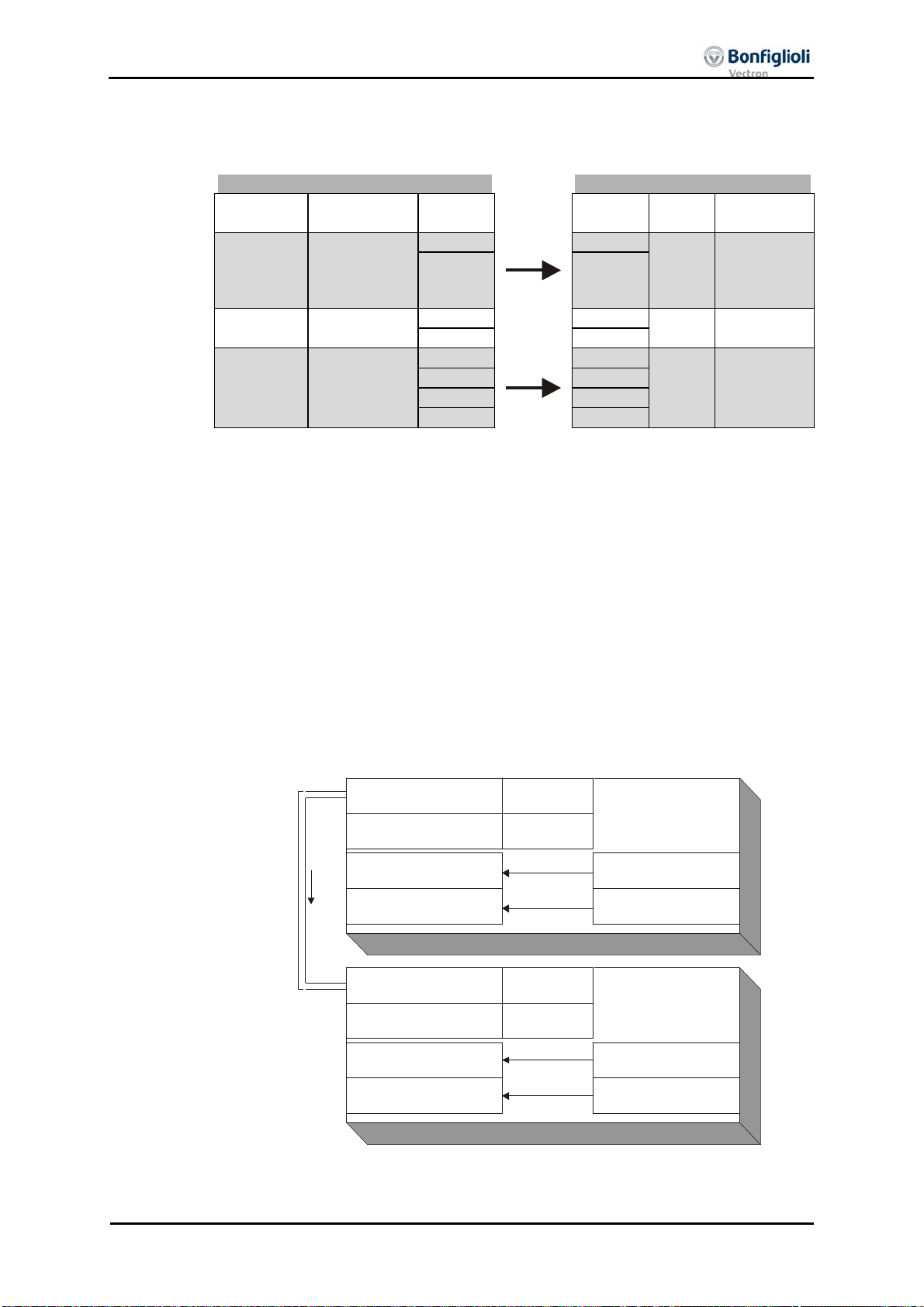

V

oltage input and voltage outputs for encoder power supply

Terminal X410A.1: DC 24 V input

Terminal X410A.2: DC 24 V ground

Terminal X410A.5 and X412.6: DC 5…12 V output

Terminal X410A.5 and X412.15: DC 5…12 V ground

Connect a maximum load of 2 W !

5.3.3.3 Direct connection of external power supply to the encoder

Encoders with high power demand (> 2 W) or voltage higher than DC 12 V must be

connected to an external power supply directly.

Set parameter Power supply 1186 to “1-internal”. See chapter 8.4.3 “Power supply”.

This setting must be used for proper function of the evaluation. However the power

supply terminals do not have to be connected but should remain open.

The voltage level set in

Supply voltage 1187 is irrelevant when the terminal is open.

See chapter 8.4.4 “Supply voltage”.

Note:

In this case, do not set

Power supply 1186 to modes with “sense” line.

This will result in faults and system shutdown

28 EM-ABS-01 for ACU 03/12

T

g

g

g

T

g

g

r

V

g

g

6 Commissioning the encoder

This chapter describes how the different encoder types are commissioned.

6.1 General Information

The EM-ABS-01 supports both Singleturn and Multiturn encoders. Multiturn encoders

must be configured as such in order to avoid unwanted effects.

he internal resolution of encoder information is 32 bits, 16 bits for the position in one

turn and 16 bits for the number of turns. Encoders with other properties will be converted to this format internally.

Note: In the case of motor encoders with a multiturn portion of more than 16

bits, clear identification of the position in the frequency inverter is not

guaranteed.

Note: In the case of motor encoders with a multiturn portion of less than 16 bits,

the free bits are filled up to 16 bits and managed in a fail-safe manner.

Example: An encoder has a multiturn portion of 13 bits. 3 bits are ma-

ed additionally in the inverter, thus 8 (=2³) overflows of the multiturn

na

portion are recognized.

This information may be lost in some situations if the DC link is dischar

ed

very quickly due to external conditions.

In the case of usage in positioning applications (configuration x40), the absolute position of the encoder can be used for the reference system directly in user units [u].

Using gear factors, a

ear transmission between the encoder and the travel distance

can be considered.

Note:

he input data of the encoder is evaluated via the reference systems. The

evaluated parameters (e.

in rev.) are available for dia

. motor frequency, drive speed in rev/s, position

nosis via actual value parameters, see chapte

8.6 “Actual value display”.

Check the power demand of the encoder to be connected. The internal power supply

unit can only supply a maximum total of 2 W for all consumers connected. In the case

of a higher power demand, connect an external DC 24 V supply to X410A.1 (DC 24

e input) and X410A.2 (GND). BONFIGLIOLI VECTRON recommends connecting

volta

an external power supply. Refer to chapter 5.3.3 “Power supply”.

Note: For supply of the encoder via an external power supply unit, always con-

nect it to X410A.1 (DC 24 V volta

e input) and X410A.2 (GND). Connection

at X210A.1 (DC 24 V voltage input of ACU basic device) and X210A.2

(GND) will not be sufficient for external power supply of the encoder.

Install encoder cables separate from motor cables to minimize interference.

Upon first commissioning and during operation, make sure that the encoder and other

electrical components can acclimatize in order to prevent condensation and resulting

malfunction.

03/12 EM-ABS-01 for ACU 29

A

g

g

g

g

g

A

V

6.1.1 Information on use

fter mains on, an initialization may have to be performed depending on the encoder

type. This may take up to 5 seconds, dependin

be eliminated by powerin

DC 24 V supply.

When the encoder or motor (including motor encoder) are replaced, re-calibration will

typically be required for the absolute position. This applies typically to the encoderinternal value (dependin

position angle

rencing

Offset 1188 and carry out a referencin

angle

Offset 1188 and, in positioning applications (configuration x40), refe-

Home-Offset 1131. After encoder replacement, always check the position

applications (configuration x40).

Note: When an absolute value encoder is used, referencing is not required after

encoder or motor replacement to ensure correct function of the ACU

device. Adjustments of

fter encoder or motor replacement, correct function of the system is

achieved by performing a referencing operation or offset adjustment.

The signals provided by the encoder are used in the EM-ABS-01 for various plausibility

checks. This makes the system more fail-safe and less prone to unwanted interference.

During operation, the encoders and communication with the encoder are monitored.

Critical conditions are reported via device errors. Most error evaluations will only be

performed when the power output stage is activated.

Danger! Some absolute value encoder types enable to “zero” or change the posi-

tion transmitted by the encoder. Do not use this function, as this will

change the commutation angle in synchronous motors for

and correct speed control is not guaranteed.

Changing the value while the system is in operation can result in significant failures of the system.

Attention!

ia parameter Change Sense of Rotation 1199, you can change the di-

rection of rotation of the motor system. In the case of absolute value

encoders, a change of

actual value jump. Upon the time of changeover, slave drives in an electronic gear must be switched off.

on the encoder type. This time can

the basic device and the encoder using an external

on the encoder type used, this value cannot be changed),

operation in the case of positionin

Home-Offset 1131 are applied directly.

Offset 1188

Change Sense of Rotation 1199 will result in an

30 EM-ABS-01 for ACU 03/12

g

A

g

g

6.2 SinCos encoders

This chapter describes how SinCos encoders are commissioned.

Note: If a SinCos encoder is used as a motor encoder on a synchronous servo-

motor, the SinCos encoder must also feature, in addition to si

nal tracks

/B, commutation tracks C/D (e.g. Heidenhain ERN 1185).

Step 1: Install the EM-ABS-01 as described in chapter 5.2. Do not connect the encod-

er cable yet.

Step 2: Turn the frequency inverter on for parameter configuration (mains voltage or

DC 24 V).

Step 3: Configure the frequency inverter according to the following parameters.

• Adjust the Division marks 1183 accordin

to the encoder data sheet (see

Chapter 8.4.1), in the case of SinCos encoders, the value is typically 1024

pulses/turn.

• Set

Tracks/Protocol 1184 to value 100, 300, 500 or 700 (please see chapter

8.4.2).

• Adjust the

Supply voltage 1187 accordin

to the encoder data sheet (see

Chapter 8.4.4), in the case of SinCos encoders, the value is typically 5.0V.

• Adjust

Power supply 1186 according to the connections (see chapter 8.4.3).

Bonfiglioli Vectron recommends evaluating the sense line (settings: “5-intern,

Sense” or “6-Via X410A, Sense”), if available and connected.

Attention: Always set the

supply

1186.

Supply voltage 1187 first and then set Power

• If the encoder is used as a motor encoder for a synchronous servomotor, set

Offset 1188 according to chapter 8.4.6. This step is not required in the case

of asynchronous motors or if the encoder is used as an application encoder.

Step 4: Turn the frequency inverter off.

Step 5: Connect the SinCos Geber to the EM-ABS-01. Bonfiglioli Vectron recommends

the use of pre-assembled cables (see chapter 5.3.2.1).

Step 6: Turn the frequency inverter on.

Step 7: Check the encoder for proper function.

Note: SinCos encoders are no absolute value encoders. In configurations “Posi-

tioning” x40 you will have to carry out a referencing operation with SinCos

encoders after mains on.

03/12 EM-ABS-01 for ACU 31

g

g

”

g

g

g

g

6.3 Hiperface encoders

This chapter describes how Hiperface encoders are commissioned.

Step 1: Install the EM-ABS-01 as described in chapter 5.2. Do not connect the encod-

er cable yet.

Step 2: Turn the frequency inverter on for parameter configuration (mains voltage or

DC 24 V).

Step 3: Configure the frequency inverter according to the following parameters.

• Adjust the Division marks 1183 accordin

Chapter 8.4.1), in the case of Hiperface encoders, the value is typically 1024

amplitudes/turn (in example SRS50/SRM50).

• Set

Tracks/Protocol 1184 according to the encoder data sheet to value 3109,

3119, 3138 or 700 (please see chapter 8.4.2).

Typical values:

Sick SEK37/S

Sick SKS36/SKM36: 9.6 kBaud Æ = value 3109

Sick SRS50/SRM50: 9.6 kBaud Æ = value 3109

• Adjust the

Chapter 8.4.4), in the case of Hiperface encoders, the value is typically 8.0 V.

• Adjust

Power supply 1186 according to the connections to “1-internal” or “2-

Via X410A” (see chapter 8.4.3).

In the case of Hiperface encoders, the sens

or “6-Via X410A, Sense“) is typically not used, as it is not defined in the Hiperface standard Specification. Thus, usin

case of Hiperface encoders.

Attention: Always set the

supply

1186.

• Set the number of Bits/Turn 1271 accordin

chapter 8.4.7).

Typical values:

Sick SEK37/S

Sick SKS36/SKM36: 12 bits/t

Sick SRS50/SRM50: 15 bits/t

• Set the

Bits Multiturn 1272 accordin

8.4.8),

Typical values:

Sick SEL37, S

Note: In the case of sin

will have to set

• If the encoder is used as a motor encoder for a synchronous servomotor, set

Offset 1188 according to chapter 8.4.6. This step is not required in the case

of asynchronous motors or if the encoder is used as an application encoder.

Step 4: Turn the frequency inverter off.

Step 5: Connect the Hiperface Geber to the EM-ABS-01. Bonfiglioli Vectron recommends the use of pre-assembled cables (see chapter 5.3.2.3).

Step 6: Turn the frequency inverter on.

Step 7: Check the encoder for proper function.

Step 8: In configurations “Positioning” x40: Carry out referencing operation once.

to the encoder data sheet (see

EL37 & SEK52/SEL52: 9.6 kBaud Æ value 3109

Supply voltage 1187 accordin

to the encoder data sheet (see

e line (settings “5-intern, Sense

the sense line is not required in the

Supply voltage 1187 first and then set Power

to the encoder data sheet (see

EL37 & SEK52/SEL52: 9 bits/t

to the encoder data sheet (see chapter

EL52, SKM36, SRM50: 12 bits/t

leturn encoders (e.g. Sick SEK37, SKS36, SRS50), you

Bits Multiturn 1272 = 0.

32 EM-ABS-01 for ACU 03/12

g

g

g

g

Note: If the data track cannot be evaluated, error “F1719 Di

error” will be triggered. In this case, check

Tracks/Protocol 1184 setting.

. encoder: Protocol

Note: When the frequency inverter is turned on, the absolute position is read via

the data tracks. Via the incremental tracks, the position is counted up internally and compared to the updated absolute position at regular intervals. This

uarantees a very high positioning and speed accuracy at all

supported transmission rates.

6.4 EnDat 2.1 encoders

This chapter describes how EnDat 2.1 encoders are commissioned.

Note: Only EnDat 2.1 encoders with SinCos tracks can be connected.

Note: The EM-ABS-01 module supports, in the case of EnDat 2.1 encoders, a

baud rate of 100 kBit/s. Other baud rates will not be supported.

Step 1: Install the EM-ABS-01 as described in chapter 5.2. Do not connect the encod-

er cable yet.

Step 2: Turn the frequency inverter on for parameter configuration (mains voltage or

DC 24 V).

Step 3: Configure the frequency inverter according to the following parameters.

• Adjust the Division marks 1183 accordin

to the encoder data sheet (see

Chapter 8.4.1), in the case of EnDat 2.1 encoders, the value is typically 512

amplitudes/turn, (e.g. Heidenhain ECN 1

113, EQN 1125).

• Set

Tracks/Protocol 1184 to value 1101 (please see chapter 8.4.2).

• Adjust the

Supply voltage 1187 accordin

Chapter 8.4.4), in the case of EnDat 2.1 encoders, th

to the encoder data sheet (see

e value is typically 5.0V.

• Adjust

Power supply 1186 according to the connections (see chapter 8.4.3).

Bonfiglioli Vectron recommends evaluating the sense line (settings: “5-intern,

Sense” or “6-Via X410A, Sense”).

Attention: Always set the

supply

1186.

Supply voltage 1187 first and then set Power

• If the encoder is used as a motor encoder for a synchronous servomotor, set

Offset 1188 according to chapter 8.4.6. This step is not required in the case

of asynchronous motors or if the encoder is used as an application encoder.

Note:

Parameters

the case of EnDat 2.1 encoders. The required data is exchanged directly

between the encoder and inverter.

Bits/Turn 1271 and Bits Multiturn 1272 have no function in

03/12 EM-ABS-01 for ACU 33

g

g

T

g

k

g

Step 4: Turn the frequency inverter off.

Step 5: Connect the EnDat 2.1 Geber to the EM-ABS-01. Bonfiglioli Vectron recommends the use of pre-assembled cables (see chapter 5.3.2.1).

Step 6: Turn the frequency inverter on.

Step 7: Check the encoder for proper function.

Step 8: In configurations “Positioning” x40: Carry out referencing operation once.

Note: If the data track cannot be evaluated, error “F1719 Di

Note: When the frequency inverter is turned on, the absolute position is read via

6.5 SSI encoders

This chapter describes how SSI encoders are commissioned. You can connect SSI

encoders with binary evaluation and SSI encoders with Gray code evaluation.

function is being prepared and is currently not supported!

Note: For a correct function of the speed control, an SSI encoder with incremen-

Step 1: Install the EM-ABS-01 as described in chapter 5.2. Do not connect the encod-

er cable yet.

Step 2: Turn the frequency inverter on for parameter configuration (mains voltage or

DC 24 V).

Step 3: Configure the frequency inverter according to the following parameters.

• Set Tracks/Protocol 1184 according to the encoder data sheet (please see

chapter 8.4.2).

SSI operation modes key:

. encoder: Protocol

error” will be triggered. In this case, check

Tracks/Protocol 1184 setting.

the data tracks. Via the incremental tracks, the position is counted up internally and compared to the updated absolute position at regular intervals. This

uarantees a very high positioning and speed accuracy at all

supported transmission rates.

his

tal tracks (TTL [RS-422] level or SinCos tracks) must be used.

If the SSI encoder is used for positionin

(and not for speed feedback),

you can also use a SSI encoder without incremental tracks.

HTL tracks cannot be used as incremental tracks.

Note: If a SSI encoder without incremental trac

(Tracks/Protocol 1184 = 50xx or 60xx) is used for positionin

, the speed

of the data track must be as high as possible for optimum control quality.

The usable transmission rate depends on the length of the encoder cable.

34 EM-ABS-01 for ACU 03/12

g

g

g

g

g

g

g

• Adjust the Division marks 1183 accordin

to the encoder data sheet (see

Chapter 8.4.1), in the case of SSI encoders, the value is typically 512 ampli-

tudes/turn. If

an encoder without incremental tracks is used (settin

Tracks/Protocol 1184), this information is not needed and the settin

via

of this

parameter will be ignored.

• Adjust the Supply voltage 1187 accordin

to the encoder data sheet (see

Chapter 8.4.4), in the case of SSI encoders with TTL [RS-422] or SinCos

track, the valu

e is typically 5.0V.

• Adjust

Power supply 1186 according to the connections (see chapter 8.4.3).

Bonfiglioli Vectron recommends evaluating the sense line (settings: “5-intern,