ACTIVE

Brief manual

Frequency Inverter 230 V / 400 V

0.55 kW ... 30.0 kW

06/05 1

General Information about the Documentation

The present documentation refers to the frequency inverters ACT 201 and ACT 401

series. With their factory settings, both series of devices are suited for a wide range

of applications. The modular hardware and software structure enables customerspecific adaptation of the frequency inverters. Applications with high functionality and

dynamism requirements can be realized easily.

In order to make it as easy as possible for the user to find his/her way through the

documentation, it is structured according to the customer-specific demands made of

the frequency inverter.

Brief Instructions

The Brief Instructions describe the basic steps required for mechanical and electrical

installation of the frequency inverter. The guided commissioning supports you in the

selection of necessary parameters and the configuration of the frequency inverter by

the software.

Operating Instructions

The Operating Instructions describe and document all functions of the frequency

inverter. The parameters required for adapting the frequency inverter to specific

applications as well as the wide range of additional functions are described in detail.

Application Manual

The Application Manual contains additional information facilitating the installation and

commissioning of the frequency inverter, i.e. information on the different issues

relating to the specific application realized by the frequency inverter.

Installation Instructions

Complementing the Brief Instructions and the Operating Instructions, the Installation

Instructions provide information on how to install and use the additional/optional

components.

If you need a copy of the documentation or additional information, contact your

representative of BONFIGLIOLI.

The following pictograms and signal words are used in the documentation:

Danger!

Danger refers to an immediate threat. Non-compliance with the precaution described

will result in death, serious injury or material damage.

Warning!

Warning refers to a possible threat. Non-compliance with the warning may result in

death, serious injury or material damage.

Caution!

Caution refers to an immediate hazard. Non-compliance may result in personal or

material damage.

Attention!

Attention and the related text refer to a possible behavior or an undesired condition

which can occur during operation.

Note

Note and the related text provide useful information which supplements the corresponding part of the documentation.

06/052

TABLE OF CONTENTS

TABLE OF CONTENTS............................................................................................................ 2

1 General Safety Instructions and Information on Use.................................................... 4

1.1 General Information ................................................................................................ 4

1.2 Purpose of the Frequency Inverters ........................................................................ 5

1.3 Transport and Storage ............................................................................................. 5

1.4 Handling and Installation ........................................................................................ 5

1.5 Electrical Connection ............................................................................................... 6

1.6 Information on Use.................................................................................................. 6

1.7 Maintenance and Service......................................................................................... 6

2 Scope of Supply.............................................................................................................. 7

2.1 Frequency Inverter (0.55 to 4.0 kW)....................................................................... 7

2.2 Frequency Inverter (5.5 to 15 kW).......................................................................... 8

2.3 Frequency Inverter (18.5 to 30 kW)........................................................................ 9

3 Technical Data.............................................................................................................. 10

3.1 Frequency Inverter 230 V (0.55 to 3.0 kW) .......................................................... 10

3.2 Frequency Inverter 400 V (0.55 to 4.0 kW) .......................................................... 11

3.3 Frequency Inverter 400 V (5.5 to 15.0 kW) .......................................................... 12

3.4 Frequency Inverter 400 V (18.5 up to 30 kW) ...................................................... 13

3.5 Operation diagrams ............................................................................................... 14

4 Mechanical Installation................................................................................................ 15

4.1 Frequency Inverter (0.55 to 4.0 kW)..................................................................... 16

4.2 Frequency Inverter (5.5 to 15 kW)........................................................................ 17

4.3 Frequency Inverter (18.5 to 30 kW)...................................................................... 18

5 Electrical Installation ................................................................................................... 19

5.1 EMC Information.................................................................................................... 20

5.2 Block diagram ........................................................................................................ 21

5.3 Mains Connection .................................................................................................. 22

5.3.1 Frequency Inverter (0.55 to 4.0 kW) ....................................................................... 22

5.3.2 Frequency Inverter (5.5 to 15.0 kW) ....................................................................... 23

5.3.3 Frequency Inverter (18.5 to 30 kW) ........................................................................ 24

5.4 Motor Connection .................................................................................................. 24

5.4.1 Frequency Inverter (0.55 to 4.0 kW) ....................................................................... 25

5.4.2 Frequency Inverter (5.5 to 15 kW) .......................................................................... 26

5.4.3 Frequency Inverter (18.5 to 30 kW) ........................................................................ 27

5.5 Connection of a Brake Resistor ............................................................................. 28

5.5.1 Frequency Inverter (0.55 to 4.0 kW) ....................................................................... 28

5.5.2 Frequency Inverter (5.5 to 15 kW) .......................................................................... 28

5.5.3 Frequency Inverter (18.5 to 30 kW) ........................................................................ 29

06/05 3

TABLE OF CONTENTS

5.6 Control Terminals .................................................................................................. 29

5.6.1 Relay Output......................................................................................................... 30

5.6.2 Control Terminals – Terminal Diagram..................................................................... 31

5.6.2.1 Configuration 110 – Sensorless Control ............................................................. 31

5.6.2.2 Configuration 410 – Sensorless Field-Oriented Control........................................ 32

5.7 Optional Components ............................................................................................ 33

6 Control Unit KP500 ...................................................................................................... 34

6.1 Actual Value Menu (VAL) ....................................................................................... 35

6.2 Parameter Menu (PARA)........................................................................................ 36

6.3 Controlling the Motor via the Control Unit ............................................................ 37

7 Commissioning of the Frequency Inverter................................................................... 39

7.1 Switching on Mains Voltage .................................................................................. 39

7.2 Setup Using the Control Unit ................................................................................. 39

7.2.1 Configuration ........................................................................................................40

7.2.2 Data Set ............................................................................................................... 40

7.2.3 Motor Type ........................................................................................................... 40

7.2.4 Machine Data ........................................................................................................ 41

7.2.5 Plausibility check ................................................................................................... 41

7.2.6 Parameter identification ......................................................................................... 43

7.2.7 Application data..................................................................................................... 45

7.2.7.1 Acceleration and deceleration........................................................................... 45

7.2.7.2 Set points at multi-functional input ................................................................... 45

7.2.8 Selection of an actual value for display .................................................................... 46

7.3 Check direction of rotation .................................................................................... 46

8 Basic parameters.......................................................................................................... 47

8.1 Menu branch PARA ................................................................................................ 47

8.2 Menu branch VAL ................................................................................................... 50

9 Operational and error diagnosis .................................................................................. 51

9.1 Status message...................................................................................................... 51

9.2 Warning message .................................................................................................. 51

9.3 Fault message ........................................................................................................ 52

06/054

1 General Safety Instructions and Information on Use

Warning! The specifications and instructions contained in the documentation must

be complied with strictly during installation and commissioning. Only

qualified staff who has read the documentation and, in particular, the

safety instructions carefully is allowed to carry out installation or

commissioning work or to operate the frequency inverters. The term

„Qualified Staff“ refers to anybody who is familiar with the installation,

assembly, commissioning and operation of the frequency inverter and

has the proper qualification for the job.

The present documentation was prepared with great care and it was subjected to

extensive and repeated reviews. For reasons of clarity, it was not possible to include

all details of all the different types of the product in the documentation. Neither was

it possible to consider all conceivable installation, operation or maintenance

situations. If you require further information or if you meet with specific problems

which are not dealt with in sufficient detail in the documentation, contact your local

BONFIGLIOLI agent.

We would also like to point out that the contents of this documentation do not form

part of any previous or existing agreement, assurance or legal relationship. Neither

are they intended to supplement or replace such agreements, assurances or legal

relationships. The manufacturer's obligations are exclusively specified in the relevant

purchase contract. This contract also contains all and any warranty regulations which

may apply to the relevant scope of supply. These contractual warranty provisions are

neither extended nor limited by the specifications contained in this documentation.

The manufacturer reserves the right to correct or amend the specifications, product

information and omissions in these operating instructions without notice. The

manufacturer shall not be liable for any damage, injuries or costs which may be

caused by the aforementioned reasons.

1.1 General Information

Warning! The DC-link circuit of the frequency inverter is charged during operation,

i.e. there is always the risk of contact with high voltage. Frequency

inverters are used for driving moving parts and they may become hot at

the surface during operation.

Any unauthorized removal of the necessary covers, improper use, wrong

installation or operation may result in serious injuries or material

damage.

In order to avoid such injuries or damage, only qualified staff may carry

out the transport, installation, setup or maintenance work required. The

standards EN 50178, IEC 60364 (Cenelec HD 384 or DIN VDE 0100),

IEC 60664-1 (Cenelec HD 625 or VDE 0110-1), BGV A2 (VBG 4) as well

as the applicable national regulations must be complied with. The term

„Qualified Staff“ refers to anybody who is familiar with the installation,

assembly, commissioning and operation of the frequency inverter as well

as the possible hazards and has the proper qualification for the job.

06/05 5

1.2 Purpose of the Frequency Inverters

Warning! The frequency inverters are electrical drive components intended for

installation in industrial plants or machines. Commissioning and start of

operation is not allowed until it has been verified that the machine meets

the requirements of the EC Machinery Directive 98/37/EEC and

EN 60204. In accordance with the CE marking requirements, the

frequency inverters comply with the Low Voltage Directive 72/23/EEC as

well as EN 50178 / DIN VDE 0160 and EN 61800-2. The user shall be

responsible for making sure that the requirements of the EMC Directive

89/336/EEC are met. Frequency inverters are only available at specialized

dealers and are exclusively intended for professional use as per EN

61000-3-2.

The frequency inverters are also marked with the UL label according to

UL508c, which proves that they also meet the requirements of the CSA

Standard C22.2-No. 14-95.

The technical data, connection specifications and information on ambient

conditions are indicated on the name plate and in the documentation and

must be complied with in any case. Anyone involved in any kind of work

at the device must have read the instructions carefully and understood

them before starting the work.

1.3 Transport and Storage

The frequency inverters must be transported and stored in an appropriate way.

During transport and storage the devices must remain in their original packaging.

The units may only be stored in dry rooms which are protected against dust and

moisture and are exposed to small temperature deviations only. Observe the climatic

conditions according to EN 50178 and the marking on the packaging. The units must

not be stored for more than one year without connecting them to the rated mains

voltage.

1.4 Handling and Installation

Warning! Damaged or destroyed components must not be put into operation

because they may be a health hazard.

The frequency inverters are to be used in accordance with the documentation as well

as the applicable directives and standards. They must be handled carefully and

protected against mechanical stress. Do not bend any components or change the

isolating distances. Do not touch electronic components or contacts. The devices are

equipped with components which are sensitive to electrostatic energy and can easily

be damaged if handled improperly. Any use of damaged or destroyed components

shall be considered as a non-compliance with the applicable standards. Do not

remove any warning signs from the device.

06/056

1.5 Electrical Connection

Warning! Before any assembly or connection work, discharge the frequency

inverter. Verify that the frequency inverter is discharged.

Do not touch the terminals because the capacitors may still be charged.

Comply with the information given in the operating instructions and on

the frequency inverter label.

When working at the frequency inverters, comply with the applicable standards BGV

A2 (VBG 4), VDE 0100 and other national directives. Comply with the electrical

installation instructions given in the documentation as well as the relevant directives.

Responsibility for compliance with and examination of the limit values of the EMC

product norm EN 61800-3 for variable-speed electrical drive mechanisms is with the

manufacturer of the industrial plant or machine.

The documentation contains information on EMC-conforming installation. The cables

connected to the frequency inverters may not be subjected to high-voltage insulation

tests unless appropriate circuitry measures are taken before. Otherwise the

frequency inverter may be damaged.

1.6 Information on Use

Warning! The frequency inverter may be connected to power supply every 60 s

only. Otherwise the unit may be damaged. For this reason, a jog

operation of a mains contactor is not permissible. For commissioning or

after an emergency stop, a non-recurrent, direct restart is permissible.

After a failure and restoration of the power supply, the motor may start

unexpectedly if the Auto-Start function is activated.

Before commissioning and the start of the operation fix all covers and

check the terminals. Check the additional monitoring and protective

devices according to EN 60204 and applicable the safety directives (e.g.

Working Machines Act, Accident Prevention Directives etc.).

No connection work may be performed, while the system is in operation.

1.7 Maintenance and Service

Warning! Unauthorized opening and improper interventions can lead to personal

injury or material damage. Repairs on the frequency inverters may only

be carried out by the manufacturer or persons authorized by the

manufacturer. Check protective equipment regularly.

06/05 7

2 Scope of Supply

Thanks to the modular hardware components, the frequency inverters can be

integrated in the automation concept easily. The scope of delivery described can be

supplemented by optional components and adapted to the customer-specific

requirements. The plug-in type connection terminals enable a safe function and an

economical assembly.

2.1 Frequency Inverter (0.55 to 4.0 kW)

ACT 201 (230 V) and ACT 401 (400 V)

Power range 0.55 kW to 4.0 kW

Scope of Supply

A

Frequency inverter

B

Terminal strip X1 (Phoenix ZEC 1,5/ST7,5)

Plug-in terminals for mains connection and DC linking

C

Terminal strip X10 (Phoenix ZEC 1.5/3ST5.0)

Plug-in terminals for the relay output

D

Standard fixtures for vertical assembly

E

Brief Instructions and manuals on CD

F

Terminal strip X2 (Phoenix ZEC 1,5/ST7,5)

Plug-in terminal for brake resistor and motor connection

G

Control terminals X210A / X210B (Wieland DST85 / RM3.5)

Plug-in terminal for connection of the control signals

Note: Please check incoming goods for quality, quantity and nature without

delay. Obvious defects such as exterior damage of the packing and/or

the unit must be notified to the sender within seven days for insurance

reasons.

06/058

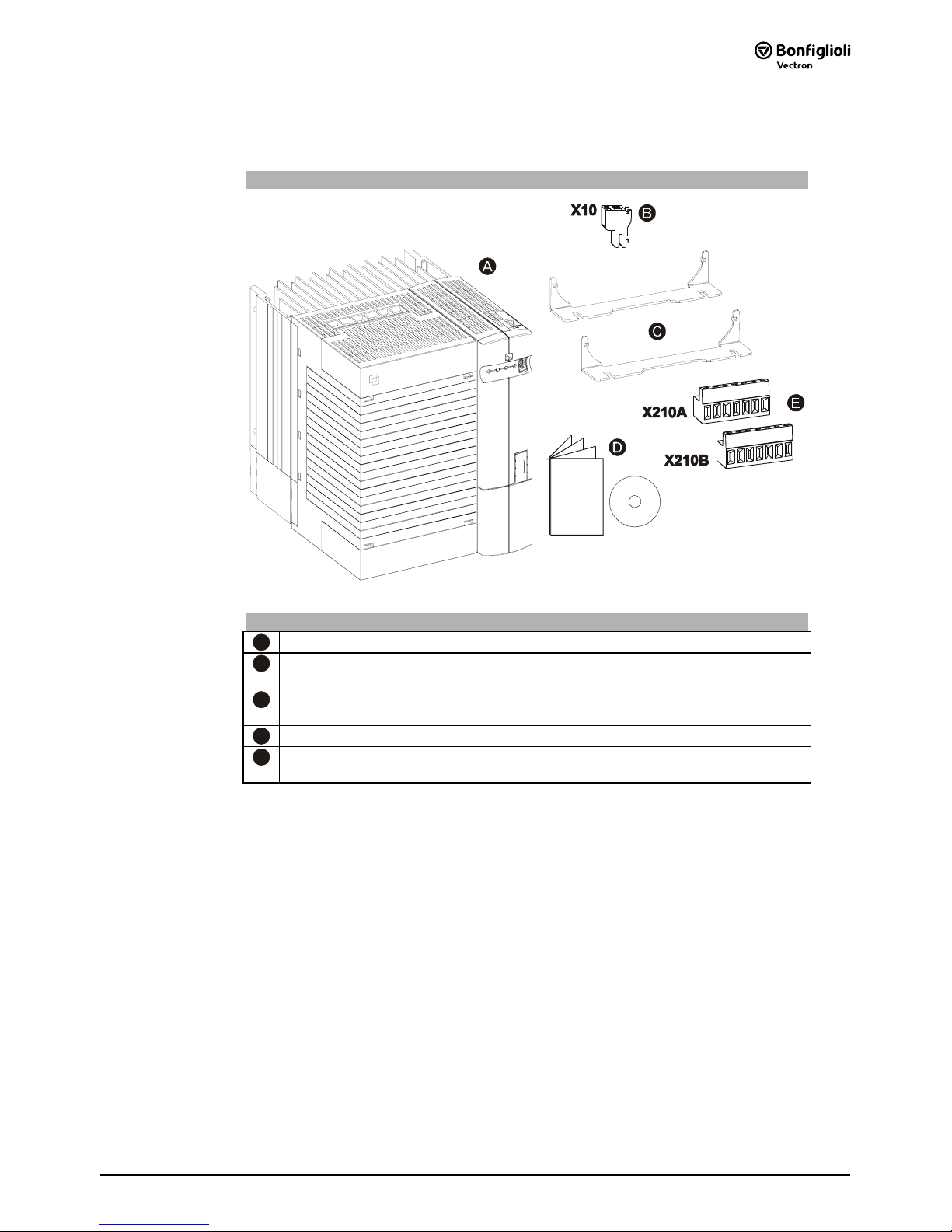

2.2 Frequency Inverter (5.5 to 15.0 kW)

ACT 401 (400 V)

Power range 5.5 kW to 15 kW

Scope of Supply

A

Frequency inverter

B

Terminal strip X10 (Phoenix ZEC 1.5/3ST5.0)

Plug-in terminals for the relay output

C

Standard fixtures with fixing bolts (M4x20, M4x60)

for vertical assembly

D

Brief Instructions and manuals on CD

E

Control terminals X210A / X210B (Wieland DST85 / RM3.5)

Plug-in terminal for connection of the control signals

Note: Please check incoming goods for quality, quantity and nature without

delay. Obvious defects such as exterior damage of the packing and/or the

unit must be notified to the sender within seven days for insurance

reasons.

06/05 9

2.3 Frequency Inverter (18.5 to 30.0 kW)

ACT 401 (400 V)

Power range 18.5 kW to 30 kW

Scope of Supply

A

Frequency inverter

B

Terminal strip X10 (Phoenix ZEC 1.5/3ST5.0)

Plug-in terminals for the relay output

C

Standard fixtures with fixing bolts (M4x20, M4x70)

for vertical assembly

D

Brief Instructions and manuals on CD

E

Control terminals X210A / X210B (Wieland DST85 / RM3.5)

Plug-in terminal for connection of the control signals

Note: Please check incoming goods for quality, quantity and nature without

delay. Obvious defects such as exterior damage of the packing and/or the

unit must be notified to the sender within seven days for insurance

reasons.

06/0510

3 Technical Data

3.1 Frequency Inverter 230 V (0.55 to 3.0 kW)

Type

ACT 201 -05 -07 -09 -11 -13 -15

Output, motor side

Recommended shaft output P kW 0.55 0.75 1.1 1.5 2.2 3.0 4)

Output current I A 3.0 4.0 5.4 5) 7.0 9.5 12.5

4) 5)

Overload current (60 s) I A 4.5 6.0 7.3 10.5 14.3 16.2

Overload current (1 s) I A 6.0 8.0 8.0 14.0 19.0 19.0

Output voltage U V 3 x 0 ... mains voltage

Protection - - Short circuit / earth fault proof

Rotary field frequency f Hz 0 ... 1000, depending on switching frequency

Switching frequency f kHz 2, 4, 8 (nom. operat. point), 12, 16

Output, brake resistor

min. brake resistor (U

dBC

= 385 V) R Ω 230 160 115 75 55 37

Input, mains side

Mains current 3) , 3ph/PE

1ph/N/PE ; 2ph/PE

I A

3.0

5.4

4.0

7.2

5.5

1)

9.5 2)

7.0

13.2

9.5

16.5 2)

10.5

1)

16.5

2) 4)

Mains voltage U V 184 ... 264

Mains frequency f Hz 45 ... 66

Fuse 3ph/PE

1ph/N/PE ; 2ph/PE

I A

6

10

10

16

16

20

16

20

UL type 250 VAC RK5, 3ph/PE

1ph/N/PE; 2ph/PE

I A

6

10

10

15

15

20

15

20

Mechanics

Dimensions: HxWxD mm 190x60x175 250x60x175

Weight (approx.) m kg 1.2 1.6

Degree of protection - - IP20 (EN60529)

Terminals A

mm

2

0.2 ... 1.5

Form of assembly - - vertical

Ambient conditions

Energy dissipation

(2 kHz switching frequency)

P W 43 53 73 84 115 170

Coolant temperature

T

n

°C 0 ... 40 (3K3 DIN IEC 721-3-3)

Storage temperature

T

L

°C -25 ... 55

Transport temperature

T

T

°C -25 ... 70

Rel. air humidity - % 15 ... 85; not condensing

If required by the customer, the switching frequency may be increased if the output current is

reduced at the same time. Comply with the applicable standards and regulations for this operating

point.

Output current

Switching frequency

Frequency inverter nominal power

2 kHz 4 kHz 8 kHz 12 kHz 16 kHz

0.55 kW 3.0 A 3.0 A 3.0 A 2.5 A 2.0 A

0.75 kW 4.0 A 4.0 A 4.0 A 3.4 A 2.7 A

1.1 kW 5.5 A 2) 5.5 A

2) 5)

5.4 A

2) 5)

4.5 A

2) 5)

3.7 A 5)

1.5 kW 7.0 A 7.0 A 7.0 A 5.9 A 4.8 A

2.2 kW 9.5 A 2) 9.5 A 2) 9.5 A 2) 8.0 A 2) 6.5 A

3.0 kW

2) 4)

12.5 A

1)

12.5 A

1) 5)

12.5 A

1) 5)

10.5 A

1) 5)

8.5 A 5)

1) Three-phase connection requires a commutating choke.

2)

One- and two-phase connection requires a commutating choke.

3)

Mains current with relative mains impedance 1% (see chapter„Electrical installation“)

4)

Maximum output current is 9.5 A for one- and two-phase connection.

5)’

Switching frequency is reduced in thermal limit range

06/05 11

3.2 Frequency Inverter 400 V (0.55 to 4.0 kW)

Type

ACT 401 -05 -07 -09 -11 -12 -13 -15 -18

Output, motor side

Recommended shaft output P kW 0.55 0.75 1.1 1.5 1.85 2.2 3.0 4.0

Output current I A 1.8 2.4 3.2 3.8 3) 4.2 5.8 7.8 9.0

3)

Overload current (60 s) I A 2.7 3.6 4.8 5.7 6.3 8.7 11.7 13.5

Overload current (1 s) I A 3.6 4.8 6.4 7.6 8.4 11.6 15.6 18.0

Output voltage U V 3 x 0 ... mains voltage

Protection - - Short circuit / earth fault proof

Rotary field frequency f Hz 0 ... 1000, depending on switching frequency

Switching frequency f kHz 2, 4, 8 (nom. operat. point), 12, 16

Output, brake resistor

Min. brake resistor (U

dBC

= 770 V) R Ω 930 634 462 300 300 220 148 106

Input, mains side

Mains current 2) 3ph/PE I A 1.8 2.4 2.8 1)3.3 1) 4.2 5.8 6.8 1) 7.8 1)

Mains voltage U V 320 ... 528

Mains frequency f Hz 45 ... 66

Fuses 3ph/PE I A 6 10

UL type 600 VAC RK5, 3ph/PE I A 6 10

Mechanics

Dimensions: HxWxD mm 190x60x175 250x60x175

Weight (approx.) m kg 1.2 1.6

Degree of protection - - IP20 (EN60529)

Terminals A

mm

2

0.2 ... 1.5

Form of assembly - - vertical

Ambient conditions

Energy dissipation

(2 kHz switching frequency)

P W 40 46 58 68 68 87 115 130

Coolant temperature

T

n

°C 0 ... 40 (3K3 DIN IEC 721-3-3)

Storage temperature

T

L

°C -25 ... 55

Transport temperature

T

T

°C -25 ... 70

Rel. air humidity - % 15 ... 85, not condensing

If required by the customer, the switching frequency may be increased if the output current is

reduced at the same time. Comply with the applicable standards and regulations for this operating

point.

Output current

Switching frequency

Frequency inverter nominal power

2 kHz 4 kHz 8 kHz 12 kHz 16 kHz

0.55 kW 1.8 A 1.8 A 1.8 A 1.5 A 1.2 A

0.75 kW 2.4 A 2.4 A 2.4 A 2.0 A 1.6 A

1.1 kW 3.2 A 1) 3.2 A 1) 3.2 A 1) 2.7 A 1) 2.2 A

1.5 kW 1) 3.8 A 3.8 A 3) 3.8 A 3) 3.2 A 3) 2.6 A 3)

1.85 kW 4.2 A 4.2 A 4.2 A 3.5 A 2.9 A

2.2 kW 5.8 A 5.8 A 5.8 A 4.9 A 3.9 A

3.0 kW 7.8 A 1) 7.8 A 1) 7.8 A 1) 6.6 A 1) 5.3 A

4.0 kW 9.0 A 1) 9.0 A

1) 3)

9.0 A

1) 3)

7.6 A

1) 3)

6.1 A

3)

1) Three-phase connection requires a commutating choke.

2)

Mains current with relative mains impedance 1% (see chapter„Electrical installation“)

3)

Switching frequency is reduced in thermal limit range

06/0512

3.3 Frequency Inverter 400 V (5.5 to 15.0 kW)

Type

ACT 401 -19 -21 -22 -23 -25

Output, motor side

Recommended shaft output P kW 5.5 7.5 9.2 11.0 15.0

Output current I A 14 18 22 3) 25 32

Overload current (60 s) I A 21.0 26.3 30.3 37.5 44.5

Overload current (1 s) I A 28.0 33.0 33.0 50.0 64.0

Output voltage U V 3 x 0 ... mains voltage

Protection - - Short circuit / earth fault proof

Rotary field frequency f Hz 0 ... 1000, depending on switching frequency

Switching frequency f kHz 2, 4, 8 (nom. operat. point), 12, 16

Output, brake resistor

Min. brake resistor (U

dBC

= 770 V) R Ω 80 58 48 48 32

Input, mains side

Mains current 2) 3ph/PE I A 14.2 15.8 1) 20.0 1) 26.0 28.2 1)

Mains voltage U V 320 ... 528

Mains frequency f Hz 45 ... 66

Fuses 3ph/PE I A 16 25 35

UL type 600 VAC RK5, 3ph/PE I A 20 30 40

Mechanics

Dimensions HxWxD mm 250x100x200 250x125x200

Weight (approx.) m kg 3.0 3.7

Degree of protection - - IP20 (EN60529)

Terminals A mm

2

0.2 ... 6 0.2 ... 16

Form of assembly - - vertical

Ambient conditions

Energy dissipation

(2 kHz switching frequency)

P W 145 200 225 240 310

Coolant temperature Tn °C 0 ... 40 (3K3 DIN IEC 721-3-3)

Storage temperature TL °C -25 ... 55

Transport temperature TT °C -25 ... 70

Rel. air humidity - % 15 ... 85, not condensing

If required by the customer, the switching frequency may be increased if the output current is

reduced at the same time. Comply with the applicable standards and regulations for this operating

point.

Output current

Switching frequency

Frequency inverter nominal power

2 kHz 4 kHz 8 kHz 12 kHz 16 kHz

5.5 kW 14.0 A 14.0 A 14.0 A 11.8 A 9.5 A

7.5 kW 18.0 A 1) 18.0 A 1) 18.0 A 1) 15.1 A 1) 12.2 A

9.2 kW 1) 23.0 A 22.7 A

3)

22.0 A

3)

18.5 A 3) 15.0 A

3)

11 kW 25.0 A 25.0 A 25.0 A 21.0 A 17.0 A

15 kW 32.0 A 1) 32.0 A 1) 32.0 A 1) 26.9 A 1) 21.8 A

1) Three-phase connection requires a commutating choke.

2)

Mains current with relative mains impedance 1% (see chapter„Electrical installation“)

3)

Switching frequency is reduced in thermal limit range

06/05 13

3.4 Frequency Inverter 400 V (18.5 up to 30 kW)

Type

ACT 401 -27 -29 -31

Motor-side output

Recommended motor shaft output P kW 18.5 22 30

Output current I A 40.0 45.0 60.0

Overload current (60 s) I A 60.0 67.5 90.0

Overload current (1 s) I A 80.0 90.0 120.0

Output voltage U V 3 x 0 ... mains voltage

Protection - - Short circuit / earth fault proof

Rotary field frequency f Hz 0 ... 1000, depending on switching frequency

Switching frequency f kHz 2, 4, 8 (nom. operat. point)

Brake resistor output

Min. brake resistor (U

dBC

= 770 V) R Ω 24 16

Mains-side input

Mains current 2) 3ph/PE I A 42.0 50.0 58.0 1)

Mains voltage U V 320 ... 528

Mains frequency f Hz 45 ... 66

Fuses 3ph/PE I A 50 50 63

UL type 600 VAC RK5, 3ph/PE I A 40 50 60

Mechanical

Dimensions HxWxD mm 250x200x290

Weight (approx.) m kg 8

Degree of protection - - IP20 (EN60529)

Terminals A mm

2

up to 25

Form of assembly - - vertical

Environmental conditions

Energy dissipation

(2 kHz switching frequency)

P W 420 470 750

Coolant temperature T

n

°C 0 ... 40 (3K3 DIN IEC 721-3-3)

Storage temperature TL °C -25 ... 55

Transport temperature TT °C -25 ... 70

Rel. air humidity - % 15 ... 85, not condensing

Depending on the customer-specific requirements, an increase of the switching frequency is

permissible if the output current is reduced. Comply with the applicable standards and regulations

for this operating point.

Output current

Switching frequency

Frequency inverter nominal power

2 kHz 4 kHz 8 kHz

18.5 kW 40.0 A 40.0 A 40.0 A

22 kW 45.0 A 45.0 A 45.0 A

30 kW 60.0 A 1) 60.0 A 1) 60.0 A 1)

1) Three-phase connection requires a commutating choke.

2)

Mains current with relative mains impedance 1% (see chapter "Electrical installation")

06/0514

3.5 Operation diagrams

The technical data of the frequency inverters refer to the nominal point which was

selected to enable a wide range of applications. A functionally and efficient

dimensioning (derating) of the frequency inverters is possible based on the following

diagrams.

Site altitude

100

85

60

40

20

55

45

3000

1000

2000 4000

3000

1000

2000

4000

Power reduction (Derating),

5%/1000 m above sea level,

h = 4000 m

max

max. coolant temperature,

3.3 °C/1000 m above sea level,

Mounting altitude in m above sea level Mounting altitude in m above sea level

Output current in %

Coolant temperature in °C

Coolant temperature

100

80

63

40

20

0 10

20

30

40 50 55

Power reduction (Derating)

2.5%/K upper 40 °C, T = 55 °C

max

Output current in

%

Coolant temperature in °C

Mains voltage

100

83

63

40

20

0 400

420

440

460

480

reduction of output current at constant power (Derating

)

0.22%/ V upper 400 V, U = 480 V

max

O

utput current in

%

Mains voltage in V

06/05 15

4 Mechanical Installation

The frequency inverters of degree of protection IP20 are designed, as a standard, for

installation in electrical cabinets.

• During installation, both the installation and the safety instructions as well as the

device specifications must be complied with.

Warning! To avoid serious physical injuries or major material damage, only

qualified persons are allowed to work on the devices.

Warning! During assembly, make sure that no foreign particles (e.g. filings, dust,

wires, screws, tools) can get inside the frequency inverter. Otherwise

there is the risk of short circuits and fire.

The frequency inverters comply with protection class IP20 only if the

covers and terminals are mounted properly.

The units may only be used if these requirements are met.

Caution! Mount the devices with sufficient clearance to other components so that

the cooling air can circulate freely. Avoid soiling by grease and air

pollution by dust, aggressive gases, etc.

06/0516

4.1 Frequency Inverter (0.55 to 4.0 kW)

The frequency inverter is mounted in a vertical position on the assembly panel by

means of the standard fittings.

The following illustration shows the different mounting possibilities.

Standard installation

b

b1

a1

a a2

c

c1

x

x

x 100 mm

≥

b1

Assembly is effected by inserting the long side of the fixing plate in the heat sink and

screwing it to the mounting plate.

The dimensions of the device and the installation dimensions are those of the

standard device without optional components and are given in millimeters.

Dimensions in mm Installation dimensions in mm

Frequency inverter

a b c a1 a2 b1 c1

0.55 kW ... 1.1 kW

190 60 175 210 ... 230 255 30 130

ACT 201

1.5 kW ... 3.0 kW

250 60 175 270 ... 290 315 30 130

0.55 kW ... 1.5 kW

190 60 175 210 ... 230 255 30 130

ACT 401

1.85 kW ... 4.0 kW

250 60 175 270 ... 290 315 30 130

06/05 17

4.2 Frequency Inverter (5.5 to 15 kW)

The frequency inverter is mounted in a vertical position on the assembly panel by

means of the standard fittings. The following illustration shows the standard fitting.

Standard installation

b

b1

a

a1 a2

c

x

x

c1

x 100 mm

≥

fixing bracket bottom

(fixing with screws )

M4x60

fixing bracket top

(fixing with screws )

M4x20

Assembly is done by screwing the two fixing brackets to the heat sink of the

frequency inverter and the assembly panel.

The frequency inverters are provided with fixing brackets, which are fitted using four

thread-cutting screws.

The dimensions of the device and the installation dimensions are those of the

standard device without optional components and are given in millimeters.

Dimensions in mm Installation dimensions in mm

Frequency inverter

a b c a1 a2 b1 c1

5.5 kW ... 9.2 kW

250 100 200 270 ... 290 315 12 133

11.0 kW ... 15.0 kW

250 125 200 270 ... 290 315 17.5 133

06/0518

4.3 Frequency Inverter (18.5 to 30 kW)

The frequency inverter is mounted in a vertical position on the assembly panel by

means of the standard fittings. The following illustration shows the standard fitting.

Standard installation

c

c1

x 100 mm

≥

x

a

a1

a2

b

b1

x

fixing bracket top

(fixing with screws )

M4x20

fixing bracket bottom

(fixing with screws )

M4x70

Assembly is done by screwing the two fixing brackets to the heat sink of the frequency

inverter and the assembly panel.

The frequency inverters are provided with fixing brackets, which are fitted using four

thread-cutting screws. The dimensions of the device and the installation dimensions

are those of the standard device without optional components and are given in

millimeters.

Dimensions in mm Installation dimensions in mm

Frequency inverter

a b c a1 a2 b1 c1

18.5 kW ... 30 kW

250 200 290 270 … 290 315 20 165

06/05 19

5 Electrical Installation

The electrical installation must be carried out by qualified staff according to the

general and regional safety and installation directives. For a safe operation of the

frequency inverter it is necessary that the documentation and the device

specifications be complied with during installation and commissioning. In the case of

special applications, you may also have to comply with further guidelines and

instructions.

Danger! When the frequency inverter is disconnected from power supply, the

mains, DC-link voltage and motor terminals may still be live for some

time. Wait for some minutes until the DC link capacitors have

discharged before starting to work at the unit.

The connecting cables must be protected externally, considering the maximum

voltage and current values of the fuses. The mains fuses and cable cross-sections are

to be selected according to EN 60204-1 and DIN VDE 0298 Part 4 for the nominal

operating point of the frequency inverter. According to UL/CSA, the frequency

inverter is suitable for operation at a supply network of a maximum of 480 VAC which

delivers a maximum symmetrical current of 5000 A (effective value) if protected by

fuses of class RK5. Only use copper cables with a temperature range of 60/75 °C.

Warning! The frequency inverters are to be grounded properly, i.e. large

connection area and with good conductivity. The leakage current of the

frequency inverters may be > 3.5 mA. According to EN 50178 a

permanent connection must be provided. The protective conductor

cross-section required for grounding the fixing plate must be at least 10

mm², or a second protective conductor must be installed electrically

parallel to the first one. In these applications, the cross-section must

correspond to the recommended cross-section of the wire.

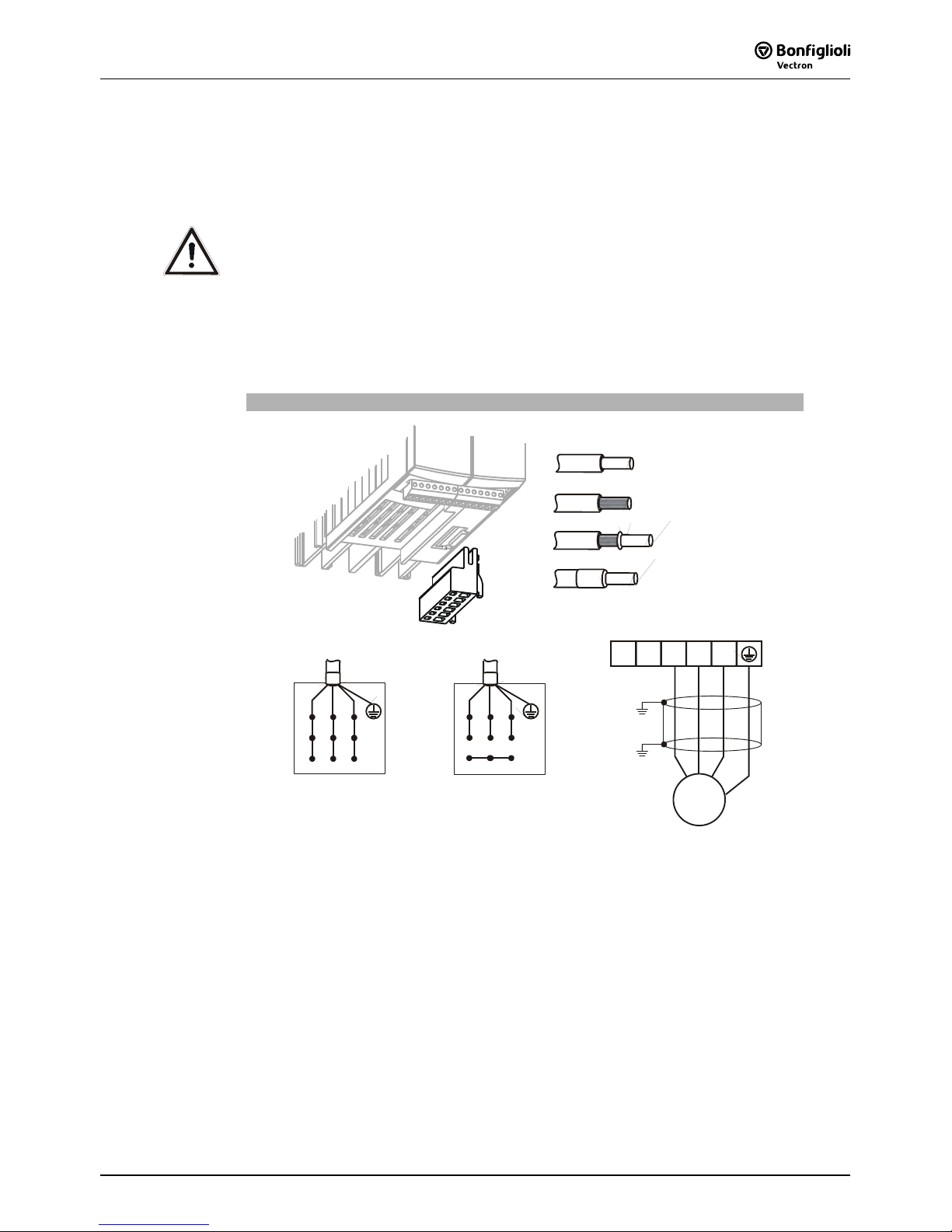

Connection conditions

− The frequency inverter is suited for connection to the public or industrial supply

mains according to the technical data. If the transformer output of the supply

mains is ≤ 500 kVA, the optional mains commutation choke is only necessary for

the frequency inverters identified in the technical data. The other frequency

inverters are suitable for connection without a mains commutating choke with

relative mains impedance ≥ 1%.

− It must be checked, based on the specifications of EN 61000-3-2, if the devices

can be connected to the public supply means without taking additional measures.

The frequency inverters ≤ 9.2 kW with integrated EMC filter comply with the

emission limits of the product standard EN 61800-3 up to a motor cable length of

10 m, without additional measures being required. Increased requirements in

connection with the specific application of the frequency inverter are to be met

by means of optional components. Commutating chokes and EMC filters are

optionally available for the series of devices.

− Operation on unearthed mains (IT mains) is admissible after disconnection of the

Y capacitors in the interior of the device.

− Interference-free operation with residual-current device is guaranteed at a

tripping current ≥ 30 mA if the following points are observed:

− Pulse-current and alternating-current sensitive residual current devices (Type

A to EN 50178) in the case of a connection of frequency inverters with onephase power supply (L1/N)

− All-current sensitive residual current devices (Type B to EN 50178) in the case

of a connection of frequency inverters with two-phase (L1/L2) or three-phase

(L1/L2/L3) power supply.

− Use EMC filters with reduced leakage current or, if possible, do not use EMC

filters at all.

− The length of the shielded motor cable is ≤ 10 m and there are no additional

capacitive components between the mains or motor cables and PE.

06/0520

5.1 EMC Information

The frequency inverters are designed according to the requirements and limit values

of product norm EN 61800-3 with an interference immunity factor (EMI) for operation

in industrial applications. Electromagnetic interference is to be avoided by expert

installation and observation of the specific product information.

Measures

• Install the frequency inverters and commutating chokes on a metal mounting

panel. Ideally, the mounting panel should be galvanized.

• Provide proper equipotential bonding within the system or the plant. Plant

components such as control cabinets, control panels, machine frames, etc. must

be connected by means of PE cables.

• Connect the frequency inverter, the commutating choke, external filters and

other components to an earthing point via short cables.

• Keep the cables as short as possible, make sure that cables are installed properly

using appropriate cable clamps, etc.

• Contactors, relays and solenoids in the electrical cabinet are to be provided with

suitable interference suppression components.

A

Mains connection

The length of the mains supply cable is not

limited. However, it must be installed separate

from the control, data and motor cables.

B

DC link connection

The frequency inverters are to be connected to

the same mains potential or a common direct

voltage source. Cables longer than 300 mm are

to be shielded. The shield must be connected to

the mounting panel on both sides.

C

Control Connection

The control and signal cables must be kept physically separate from the power cables. The shield

of the control cables is to be connected to

ground potential properly, i.e. with good

conductivity, on both sides. Analog signal lines

are to be connected to the shield potential on

one side.

D

Motor and brake resistor

A

B

C

D

The shield of the motor cable is to be connected

to ground potential properly on both sides. On

the motor side use a metal compression gland.

On the frequency inverter side an appropriate

shield clamp is to be used. The signal cable used

for monitoring the motor temperature must be

kept separate from the motor cable. Connect the

shield of this line on both sides. If a brake

resistor is used, the connection cable must also

be shielded, and the shield is to be connected to

earth potential on both sides.

Attention! The frequency inverters meet the requirements of the low-voltage direc-

tive 73/23/EEC and the requirements of the EMC directive 89/336/EEC.

The EMC product standard EN 61800-3 relates to the drive system. The

documentation provides information on how the applicable standards

can be complied if the frequency inverter is a component of the drive

system. The declaration of conformity is to be issued by the supplier of

the drive system.

06/05 21

5.2 Block diagram

+10 V / 4 mA

MFI1

GND 10 V

6

X210A

+20 V / 180 mA

GND 20 V

S4IND

X210B

5

6

7

1

2

3

S3OUT

X

10

A

D

5

S3IND

4

S2IND

2

S1IND

7

S5IND

3

1

1

S6IND

GND 20 V

2

4

MFO1

S1OUT

3

CPU

+

-

L2 L3L1

X1

V

W

U

Rb1

X2

+

-

Rb2

I

U, I

A

B

C

D

E

F

A

Relay connection S3OUT

Change-over contact, response time approx. 40 ms, 240 V AC / 5 A, 24 V DC / 5 A

(ohmic)

B

Digital input S1IND

Digital signal, controller enable signal, response time approx. 16 ms (on), 10 µs (off),

U

max

= 30 V, 10 mA at 24 V, PLC compatible

C

Digital input S2IND ... S6IND

Digital signal: response time approx. 16 ms, U

max

= 30 V, 10 mA at 24 V, PLC com-

patible, frequency signal: 0...30 V, 10 mA at 24 V, f

max

= 150 kHz

D

Digital output S1OUT

Digital signal, 24 V, I

max

= 40 mA,

PLC compatible, overload and short-circuit proof

E

Multi-function output MFO1

Analog signal: 24 V, I

max

= 40 mA, pulse-width modulated, f

PWM

= 116 Hz

Digital signal: 24 V, I

max

= 40 mA,

frequency signal: 0...24 V, I

max

= 40 mA, f

max

= 150 kHz,

PLC compatible, overload and short-circuit proof

F

Multi-function input MFI1

Analog signal: resolution 12 Bit, 0...10 V (Ri = 70 kΩ), 0...20 mA (Ri = 500 Ω),

digital signal: response time approx. 16 ms, U

max

= 30 V, 4 mA at 24 V,

PLC compatible

06/0522

5.3 Mains Connection

The mains fuses and cable cross-sections are to be selected according to EN 60204-1

and DIN VDE 0298 Part 4 for the nominal operating point of the frequency inverter.

According to UL/CSA, approved Class 1 copper lines with a temperature range of

60/75°C and matching mains fuses are to be used for the power cables. The

electrical installation is to be done according to the device specifications and the

applicable standards and directives.

Caution! The control, mains and motor lines must be kept physically separate from

one another. The cables connected to the frequency inverters may not be

subjected to high-voltage insulation tests unless appropriate circuitry

measures are taken before.

5.3.1 Frequency Inverter (0.55 to 4.0 kW)

The mains connection of the frequency inverter is via plug-in terminal X1. Degree of

protection IP20 (EN60529) is only guaranteed if terminal X1 is plugged in.

Danger! Switch off power supply before connecting or disconnecting the keyed

plug-in terminal X1. Dangerous voltage may be present at the mains

terminals and the DC terminals even after the frequency inverter has been

disconnected safely from power supply. Wait for some minutes until the

DC link capacitors have discharged before starting the work.

• The unit may only be connected with the power supply switched off.

• Make sure that the frequency inverter is discharged.

Mains power connection 0.55 kW to 4.0 kW

X1

1ph / 230V AC

+

-

L1

L2 L3L1

N

PE

3ph / 230V AC

3ph / 400V AC

+

-

L1

L2 L3L1

L2

L3 PE

2ph / 230V AC

+

-

L1 L2 PE

L2

L3

L1

550 W … 1.1 kW

Phoenix ZEC 1,5/ .. ST7,5

0.2 … 1.5 mm

AWG 24 … 16

2

0.2 … 1.5 mm

AWG 24 … 16

2

0.25 … 1.5 mm

AWG 22 … 16

2

0.25 … 1.5 mm

AWG 22 … 16

2

2ph / 230V AC

+

-

L1

L1 L2 L3L1

L2

PE

1ph / 230V AC

+

-

L1

L1 L2

L3

L1

N

PE

1.5 kW … 3.0 kW

3ph / 230V AC

3ph / 400V AC

+

-

L1

L1 L2

L3

L1

L2

L3 PE

1.5 kW … 3.0 kW 1.5 kW … 4.0 kW

1

With a mains current above 10 A, the mains power connection 230 V 1ph/N/PE

and the mains power connection 230 V 2ph/N/PE are to be done on two

terminals.

06/05 23

5.3.2 Frequency Inverter (5.5 to 15.0 kW)

Danger! Switch off power supply before connecting or disconnecting the

mains cable to terminal X1 Dangerous voltage may be present at the

mains terminals and the DC terminals even after the frequency inverter

has been disconnected safely from power supply. Wait for some

minutes until the DC link capacitors have discharged before starting the

work.

• The unit may only be connected with the power supply switched off.

• Make sure that the frequency inverter is discharged.

Mains power connection 5.5 kW to 15.0 kW

0.2 … 6 mm

AWG 24 … 10

2

5.5 kW … 9.2 kW

WAGO Line 745 / 6qmm / RM7,5

0.2 … 6 mm

AWG 24 … 10

2

0.25 … 4 mm

AWG 22 … 12

2

0.25 … 4 mm

AWG 22 … 16

2

+

-

L1

L2 L3L1

L2

L3 PE

3ph / 400V AC

X1

0.2 … 16 mm

AWG 24 … 6

2

11 kW … 15 kW

WAGO Line 745 / 16qmm / RM10+1

5

0.2 … 16 mm

AWG 24 … 6

2

0.25 … 10 mm

AWG 22 … 8

2

0.25 … 10 mm

AWG 22 … 8

2

X1

06/0524

5.3.3 Frequency Inverter (18.5 to 30 kW)

Danger! Switch off power supply before connecting or disconnecting the mains

cable to terminal X1 Dangerous voltage may be present at the mains

terminals and the DC terminals even after the frequency inverter has been

disconnected safely from power supply. Wait for some minutes until the

DC link capacitors have discharged before starting the work.

• The unit may only be connected with the power supply switched off.

• Make sure that the frequency inverter is discharged.

Mains power connection 18.5 kW to 30 kW

0.5 … 35 mm

AWG 20 … 2

2

18.5 kW … 30 kW

PHOENIX MKDSP 25/ 6-15,00-

F

0.5 … 25 mm

AWG 20 … 4

2

1.00 … 25 mm

AWG 18 … 4

2

1.5 … 25 mm

AWG 16

… 4

2

+

-

L1

L2 L3L1

L2

L3 PE

3ph / 400V AC

X1

X1

5.4 Motor Connection

The connection of the motor and the brake resistor to the frequency inverter is to be

done using shielded cables. The shield is to be connected to PE potential properly,

i.e. with good conductivity, on both sides. The control, mains and motor lines must

be kept physically separate from one another. The user must comply with the

applicable limits stipulated in the relevant national and international directives as

regards the application, the length of the motor cable and the switching frequency.

Permissible length of motor cable without output filter

Frequency inverter unshielded cable shielded cable

0.55 kW … 4.0 kW 50 m 25 m

5.5 kW … 15.0 kW 100 m 50 m

18.5 kW … 30.0 kW 150 m 50 m

The specified lengths of the motor cables must not be exceeded if no output filter is

installed. Upon request, we will check if longer motor cables can be used after taking

appropriate technical measures, e.g. use of low-capacitance cables and output filters.

Note: The frequency inverters ≤ 9.2 kW with integrated EMC filter comply with the

emission limits stipulated in EN 61800-3 if the motor cable is not longer than

10 m. Customer-specific requirements can be met by means of an optional

filter.

06/05 25

5.4.1 Frequency Inverter (0.55 to 4.0 kW)

The connection of the motor and the brake resistor to the frequency inverter is to be

done via plug-in terminal X2. Degree of protection IP20 (EN60529) is only

guaranteed if terminal X2 is connected.

Danger! Switch off power supply before connecting or disconnecting the

keyed plug-in terminal X2. Dangerous voltage may be present at the

motor terminals and the terminals of the brake resistor even after the

frequency inverter has been disconnected safely from power supply.

Wait for some minutes until the DC link capacitors have discharged

before starting to work at the unit.

• The unit may only be connected with the power supply switched off.

• Make sure that the frequency inverter is discharged.

Motor power connection 0.55 kW to 4.0 kW

Phoenix ZEC 1,5/ .. ST7,5

0.2 … 1.5 mm

AWG 24 … 16

2

0.2 … 1.5 mm

AWG 24 … 16

2

0.25 … 1.5 mm

AWG 22 … 16

2

0.25 … 1.5 mm

AWG 22 … 16

2

X2

Star connection

V

W

U

Delta connection

V

W

U

V

W

U

Rb2

Rb1

M

3~

06/0526

5.4.2 Frequency Inverter (5.5 to 15 kW)

The connection of the motor to the frequency inverter is to be done via terminal X2.

Danger! Switch off power supply before connecting or disconnecting the

motor cables to terminal X2. Dangerous voltage may be present at the

motor terminals and the terminals of the brake resistor even after the

frequency inverter has been disconnected safely from power supply.

Wait for some minutes until the DC link capacitors have discharged

before starting to work at the unit.

• The unit may only be connected with the power supply switched off.

• Make sure that the frequency inverter is discharged.

Motor power connection 5.5 kW to 15 kW

Star connection

V

W

U

Delta connection

V

W

U

5.5 kW … 9.2 kW

WAGO Line 745 / 6qmm / RM7,5

0.2 … 6 mm

AWG 24 … 10

2

0.2 … 6 mm

AWG 24 … 10

2

0.25 … 4 mm

AWG 22 … 12

2

0.25 … 4 mm

AWG

22 … 1

6

2

11 kW … 15 kW

WAGO Line 745 / 16qmm / RM10+1

5

0.2 … 16 mm

AWG 24 … 6

2

0.2 … 16 mm

AWG 24 … 6

2

0.25 … 10 mm

AWG 22 … 8

2

0.25 … 10 mm

AWG

22 …

8

2

X2

X2

V

W

U

Rb2

Rb1

M

3~

06/05 27

5.4.3 Frequency Inverter (18.5 to 30 kW)

The connection of the motor to the frequency inverter is to be done via terminal X2.

Danger! Switch off power supply before connecting or disconnecting the

motor cables to terminal X2. Dangerous voltage may be present at the

motor terminals and the terminals of the brake resistor even after the

frequency inverter has been disconnected safely from power supply.

Wait for some minutes until the DC link capacitors have discharged

before starting to work at the unit.

• The unit may only be connected with the power supply switched off.

• Make sure that the frequency inverter is discharged.

Motor power connection 18.5 kW to 30 kW

V

W

U

Delta connection

V

W

U

0.5 … 35 mm

AWG 20 … 2

2

18.5 kW … 30 kW

PHOENIX MKDSP 25/ 6-15,00-F

0.5 … 25 mm

AWG 20 … 4

2

1.00 … 25 mm

AWG 18 … 4

2

1.5 … 25 mm

AWG 16

… 4

2

X

2

V

W

U

Rb2

Rb1

M

3~

X

2

06/0528

5.5 Connection of a Brake Resistor

Connection of a brake resistor is done via terminal X2.

Danger! Switch off power supply before connecting or disconnecting the brake

resistor cables to terminal X2. Dangerous voltage may be present at the

motor terminals and the terminals of the brake resistor even after the

frequency inverter has been disconnected safely from power supply. Wait

for some minutes until the DC link capacitors have discharged before

starting to work at the unit.

• The unit may only be connected with the power supply switched off.

• Make sure that the frequency inverter is discharged.

Caution! The brake resistor must be equipped with a temperature switch. The

temperature switch must disconnect the frequency inverter from mains

supply if the brake resistor is overloaded.

5.5.1 Frequency Inverter (0.55 to 4.0 kW)

Degree of protection IP20 (EN60529) is only guaranteed if terminal X2 is connected.

Connection of brake resistor with temperature switch

X2

V WU

Rb2Rb1

R

b

T1

Rb1 Rb2

T2

X

2

5.5.2 Frequency Inverter (5.5 to 15 kW)

Connection of brake resistor with temperature switch

X2

R

b

T1

Rb1 Rb2

T2

V WU

Rb2Rb1

X

2

06/05 29

5.5.3 Frequency Inverter (18.5 to 30 kW)

Connection of brake resistor with temperature switch

R

b

T1

Rb1 Rb2

T2

V WU

Rb2Rb1

X2

X

2

5.6 Control Terminals

The control and software functionality can be freely configured to ensure a reliable

and economical operation. The operating instructions describe the factory settings of

the standard connections in the relevant

Configuration 30 as well as the software

parameters to be set up.

Caution! Switch off power supply before connecting or disconnecting the keyed

control inputs and outputs. Otherwise, components may be damaged.

• The unit may only be connected with the power supply switched off.

• Make sure that the frequency inverter is discharged.

Control Terminals

0.14 … 1.5 mm

AWG 30 … 16

2

Wieland DST85 / RM3,5

0.14 … 1.5 mm

AWG 30 … 16

2

0.25 … 1.0 mm

AWG 22 … 18

2

0.25 … 0.75 mm

AWG 22 … 20

2

0.2 … 0.3 Nm

1.8 … 2.7 lb-in

06/0530

Control terminal X210A

Ter. Description

1 Voltage output 20 V, I

max

=180 mA 1)

2 Ground / GND 20 V

3 Digital input S1IND, U

max

=30 V, 10 mA at 24 V, PLC compatible,

response time approx. 16ms (on), 10 µs (off)

4 Digital input EM-S2IND, U

max

=30 V, 10 mA at 24 V, PLC compatible,

response time approx. 16 ms

5 Digital input EM-S3IND, U

max

=30 V, 10 mA at 24 V, PLC compatible,

response time approx. 16 ms

6 Digital input S4IND, U

max

= 30 V, 10 mA at 24 V, PLC compatible,

frequency signal: 0...30 V, 10 mA at 24 V, f

max

= 150 kHz

7 Digital input S5IND, U

max

= 30 V, 10 mA at 24 V, PLC compatible,

frequency signal: 0...30 V, 10 mA at 24 V, f

max

= 150 kHz

Control terminal X210B

Ter. Description

1 Digital input S6IND, U

max

=30 V, 10 mA at 24 V, PLC compatible,

response time approx. 16 ms

2 Ground / GND 20 V

3 Digital output S1OUT, U=24 V, I

max

=40 mA, overload and short-circuit proof

4 Multi-function output MFO1,

analog signal: U=24 V, I

max

=40 mA, pulse-width modulated, f

PWM

=116 Hz

digital signal: U=24 V, I

max

=40 mA, overload and short-circuit proof,

frequency signal: 0...24 V, I

max

=40 mA, f

max

=150 kHz

5 Reference output 10 V, I

max

=4 mA

6 Multi-function input MFI1,

analog signal: resolution 12 Bit, 0...+10 V (Ri = 70 kΩ), 0...20 mA (Ri = 500 Ω),

digital signal: response time approx. 16 ms, U

max

= 30 V, 4 mA at 24 V,

PLC compatible

7 Ground / GND 10 V

1)

The power supply at terminal X210A.1 may be loaded with a maximum current

of I

max

= 180 mA. The maximum current available is reduced by the digital

output S1OUT and multifunctional output MFO1.

5.6.1 Relay Output

By default, the freely programmable relay output is linked to the monitoring function

(factory setting). The logic link to various functions can be freely configured via the

software parameters. Connection of the relay output is not absolutely necessary for

the function of the frequency inverter.

Relay Output

1

2

3

0.2 … 1.5 mm

AWG 24 … 16

2

Phoenix ZEC 1,5/3ST5,0

0.2 … 1.5 mm

AWG 24 … 16

2

0.25 … 1.5 mm

AWG 22 … 16

2

0.25 … 1.5 mm

A

WG 22 … 16

2

S3OUT

X10

X10

Control terminal X10

Ter. Description

1 ... 3 Relay output, floating change-over contact, response time approx. 40 ms,

max. contact load, make contact 5 A / 240 V AC, 5 A (ohmic) / 24 V DC

max. contact load, break contact 3 A / 240 V AC, 1 A (ohmic) / 24 V DC

06/05 31

5.6.2 Control Terminals – Terminal Diagram

The control hardware and the software of the frequency inverter are freely

configurable to a great extent. Certain functions can be assigned to the control

terminals, and the internal logic of the software modules can be freely selected.

In these brief instructions, the sensor-less control and the sensor-less field oriented

control are described in Configuration 110 and Configuration 410, respectively

5.6.2.1 Configuration 110 – Sensorless Control

Configuration 110 contains the functions for variable-speed control of a 3-phase

machine in a wide range of standard applications. The motor speed is set according

to the selected ratio of the reference frequency to the necessary voltage.

Control terminal X210A

X210A.1 Supply voltage +20V

X210A.2 Ground 20 V

X210A.3 Controller release / error acknowl-

edgment

X210A.4 Start of clockwise operation

X210A.5 Start of anticlockwise operation

X210A.6 Data set change-over 1

X210A.7 Data set change-over 2

Control terminal X210B

X210B.1 Motor thermal contact

X210B.2 Ground 20 V

X210B.3 Operating message

X210B.4 Analog signal of actual frequency

X210B.5 Supply voltage +10V

Reference value potentiometer

X210B.6 Reference speed 0 ...+10 V

GND 20 V

S1OUT

MFO1A

+10 V/ 4 mA

MFI1A

GND 10 V

1

2

3

4

5

6

7

X210A

+20 V/180 mA

GND 20 V

S1IND

S2IND

S3IND

S4IND

S5IND

S6IND

X210B

1

2

3

4

5

6

7

M

V

+

+

-

X210B.7 Ground 10 V

06/0532

5.6.2.2 Configuration 410 –

Sensorless Field-Oriented Control

Configuration 410 contains the functions for sensorless, field-oriented control of a 3-

phase machine. The current motor speed is determined from the present currents

and voltages in combination with the machine parameters. Separate control of torque

and flux-forming current enables high drive dynamism at a high load moment.

Control terminal X210A

X210A.1 Supply voltage +20V

X210A.2 Ground 20 V

X210A.3 Controller release / error acknowl-

edgment

X210A.4 Start of clockwise operation

X210A.5 Start of anticlockwise operation

X210A.6 Data set change-over 1

X210A.7 Data set change-over 2

Control terminal X210B

X210B.1 Motor thermal contact

X210B.2 Ground 20 V

X210B.3 Operating message

X210B.4 Analog signal of actual frequency

X210B.5 Supply voltage +10V

Reference value potentiometer

X210B.6 Reference speed 0 ...+10 V

GND 20 V

S1OUT

MFO1A

+10 V/4 mA

MFI1A

GND 10 V

1

2

3

4

5

6

7

X210A

+20 V/180 mA

GND 20 V

S1IND

S2IND

S3IND

S4IND

S5IND

S6IND

X210B

1

2

3

4

5

6

7

M

V

+

+

-

X210B.7 Ground 10 V

06/05 33

5.7 Optional Components

Thanks to the modular hardware components, the frequency inverters can be

integrated in the automation concept easily. The standard and optional modules are

recognized during the initialization, and the controller functionality is adjusted

automatically. For the information required for installation and handling of the

optional modules, refer to the corresponding documentation.

Danger! The hardware modules at slots B and C may only be assembled and

disassembled after the frequency inverter has been disconnected safely

from power supply. Wait for some minutes until the DC link capacitors

have discharged before starting the work.

• The unit may only be connected with the power supply switched off.

• Make sure that the frequency inverter is discharged.

Hardware modules

A

Control Unit KP500

Connection of the optional control unit KP500 or an interface

adapter KP232.

B

Communication module CM

Plug-in section for connection to various communication

protocols:

CM-232: RS232 interface

CM-485: RS485 interface

CM-PDP: Profibus-DP interface

CM-CAN: CANopen interface

C

Extension module EM

A

B

C

Slot for customer-specific adaptation of the control inputs

and outputs to various applications:

EM-ENC: extended speed sensor evaluation

EM-RES: resolver evaluation

EM-IO: analog and digital inputs and outputs

EM-SYS: system bus

(system bus in combination with CM-CAN communication module upon request)

Attention! If two optional components with CAN-Protocol controller are installed,

the system bus interface in the EM extension module is deactivated!

06/0534

6 Control Unit KP500

The optional KP500 control unit is a practical tool for controlling the frequency inverter

and setting and displaying the frequency inverter parameters.

The control unit is not absolutely necessary for the operation of the frequency inverter

and can be plugged on when required.

A

B

C

D

E

F

G

H

I

J

Keys

A

RUN Used for starting the drive and opening the CTRL menu.

Press the RUN key to open the motor potentiometer function.

STOP Used for opening the CTRL menu, stopping the drive and acknowledging

faults

J

� � Used for navigating in the menu structure and selecting parameters.

Increasing/decreasing of parameter values.

ENT Used for opening parameters or switching to another menu within the menu

structure. Confirmation of the selected function or the set parameter.

ESC Used for aborting parameters or switching back to the previous menu within

the menu structure. Canceling the function or resetting the parameter

value.

FUN Used for switching over the key function, access to special functions.

Display

B

Three-digit 7-segment display to show the parameter number

C

One-digit 7-segment display for display of the active data record, direction of

rotation etc.

D

Display of the selected menu branch:

VAL Display actual values

PARA Select parameters and adjust parameter values.

CTRL Select a function for adjustment and/or display via the control unit:

SEtUP guided commissioning

CtrL motor potentiometer and jog function

E

Status and operating messages:

WARN Warning about a critical operating behavior

FAULT Message indicating that the unit was switched off due to a fault

RUN Flashing: signals readiness for operation

Lights up: signals that the unit is operating and the output stage is enabled

REM Active remote control via interface connection

F Function switch-over with the FUN key

F

Five-digit 7-segment display for display of parameter value and sign

G

Physical unit of the parameter value displayed

H

Active acceleration or deceleration ramp

I

Current direction of rotation of the drive

06/05 35

6.1 Actual Value Menu (VAL)

In the VAL menu branch, the control unit displays a variety of actual values,

depending on the configuration selected and the options installed. The parameters

and basic software functions linked to the corresponding actual value are

documented in the operating instructions.

ENT

ESC

ENT

ESC

A

B

C

D

E

A

Use the arrow keys to select the required number from the actual values

displayed in numerical order.

In the current record, the record-related actual value parameters are displayed,

including the corresponding data record number. The seven-segment display

shows data record 0 if the actual values in the four data sets are identical.

Keys

� + � Display the actual value parameter upon switch-on.

FUN , � Display last actual value parameter (highest number).

FUN , � Display first actual value parameter (lowest number).

B

Use the ENT key to select the parameter. The parameter is displayed including

its current value, unit and the active data record.

C

During commissioning, operation and error analysis, it is possible to monitor

each actual value parameter specifically.

Some of the actual value parameters are arranged in the four available data

records. If the parameter values in the four data records are identical, the

actual value is displayed in data record 0. If the actual values in the four data

records are different, diFF is displayed in data record 0.

Keys

� , �

Switch to another of the data set in the case of related actual

values.

FUN , � Determine maximum value and display it permanently.

FUN , � Determine minimum value and display it permanently.

FUN , ENT

Display of mean value of the actual value during the monitoring

period.

D

Use the ENT key to save the selected actual value as a parameter displayed at

switch-on. The message SEt (with parameter number) is displayed for a short

time. When the frequency inverter is switched on the next time, this actual

value will be displayed automatically.

E

After saving the parameter, you can monitor and display the value again. Use

the ESC key to switch to the parameter selection of the VAL menu branch.

06/0536

6.2 Parameter Menu (PARA)

The parameters to be configured during the guided commissioning were selected

from common applications and can be supplemented as required by further settings

in the PARA menu branch. The parameters and basic software functions linked to the

corresponding actual value are documented in the operating instructions.

ENT

ESC

ENT

ESC

A

B

C

D

E

A

Use the arrow keys to select the required number from the parameters

displayed in numerical order. The parameter number is displayed with the

active data set (flashes).

In the current data set, the related parameters are displayed, including the

corresponding data set number. The seven-segment display shows data set 0 if

the parameter values in the four data sets are identical.

Keys

� + � Change to the last parameter edited.

FUN , � Display of last parameter (highest number).

FUN , � Display of first parameter (lowest number).

B

Use the ENT key to select the parameter. The parameter is displayed including

its value, unit and the active data set. If settings are edited in data set 0, the

parameter values are changed in the four data sets.

C

Use the arrow keys to adjust the parameter value or to select an operation

mode. The adjustment possibilities you have depend on the parameter.

Keep the arrow keys pressed for a while to change the displayed values quickly.

If you release the keys again, the speed at which the values change is reduced

again.

If the parameter value starts to flash, the speed at which the values change is

reset to the initial value again.

Keys

� + � Set parameter to factory setting.

FUN , � Set parameter to highest value.

FUN , � Set parameter to smallest value.

FUN , ENT

Change of the data set in the case of data set related

parameters.

D

Use the ENT key to save the parameter. For a short time, the message SEt

including the parameter number and the data set is displayed.

To leave the parameter unchanged, press the ESC key.

Messages

Err1: EEPrO Parameter has not been saved.

Err2: StOP

Parameter can only be read (i.e. not edited) when the unit is in

operation.

Err3: Error Other error

E

After saving the parameter, you can edit the value again or return to the

parameter selection menu by pressing the ESC key.

06/05 37

6.3 Controlling the Motor via the Control Unit

The control unit enables controlling the connected motor in accordance with the

selected operation mode of parameter

Local/Remote 412.

Note: In order to be able to control the drive via the control unit, the digital

controller input S1IND must be connected and set to "High-Signal" in

order to enable the output stage.

Warning! Switch off power supply before connecting and disconnecting control

terminal S1IND.

When the frequency inverter is disconnected from power supply,

dangerous voltage may still be present at the mains, DC link voltage

and motor terminals for some time. Wait for some minutes until the DC

link capacitors have discharged before starting to work at the unit.

• The unit may only be connected with the power supply switched off.

• Verify that the frequency inverter is de-energized.

: When the RUN key was pressed, the drive was in operation already.

The CTRL menu branch can be accessed via the navigation

within the menu structure. The CtrL function contains subfunctions which are displayed according to the operating point

of the frequency inverter.

Press the RUN key at any point in the menu structure to switch

to the motorpoti function Pot or the internal reference value

int if the drive is already in operation.

Motor potentiometer function Pot

Use the arrow keys to adjust the output frequency of the

frequency inverter from the

Minimum Frequency 418 to the

Maximum Frequency 419. The acceleration corresponds to

the factory settings (2 Hz/s) for parameter

Ramp Keypad-

Motorpoti

473. The parameters Acceleration (Clockwise) 420

and

Deceleration (Clockwise) 421 are considered in the case

of low acceleration values.

06/0538

Internal reference value int

The drive is in operation, i.e. output signals are present at the

frequency inverter and the current actual value is displayed.

Press an arrow key to switch to the motor potentiometer

function Pot. The current frequency value is taken over in the

motor potentiometer function Pot.

JOG frequency JOG

This function is useful for manual setup and positioning of a

machine. The frequency of the output signal is set to the

entered value if the FUN key is pressed.

• Press FUN key to switch from the internal reference value

int or the motor potentiometer function Pot to the

JOG-

Frequency

489.

• Keep the FUN key pressed and press the arrow keys to

adjust the required frequency.

(The frequency value last adjusted is saved as the

JOG-

Frequency

489.)

• Release the FUN key to stop the drive.

(The display returns to the previous function Pot or int.)

Key functions

ENT

Reversal of the direction of rotation independent of the control signal on

the terminals Clockwise S2IND or Anticlockwise S3IND.

ESC Cancel function and return to the menu structure.

FUN

Switch from internal set point int or rather motor potentiometer function