Bondioli&Pavesi 399USBR15 User Manual [en, es, fr]

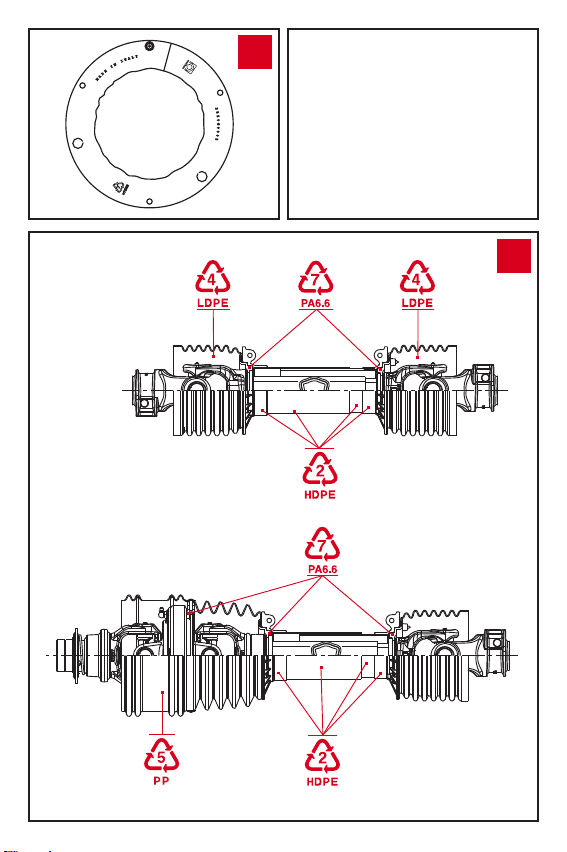

MADE IN BRAZIL

399USBR015

Cod 399FXBR05

1

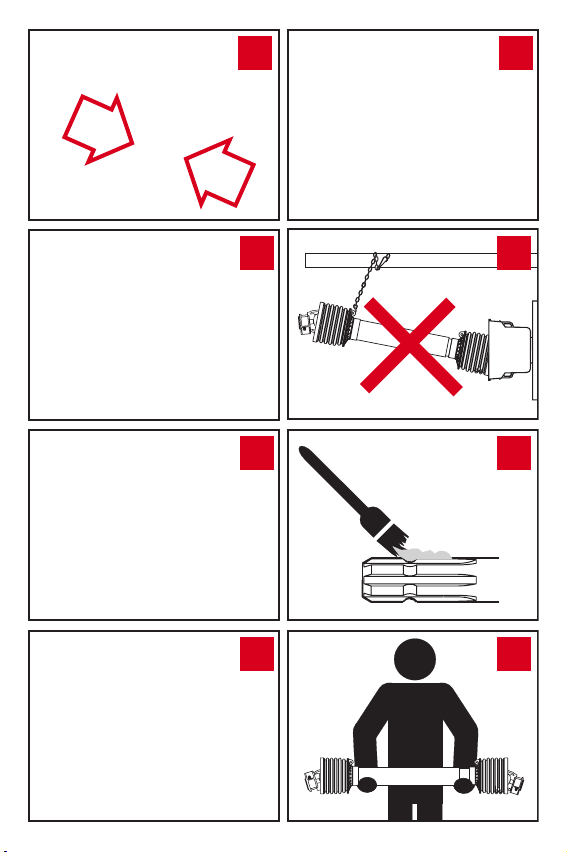

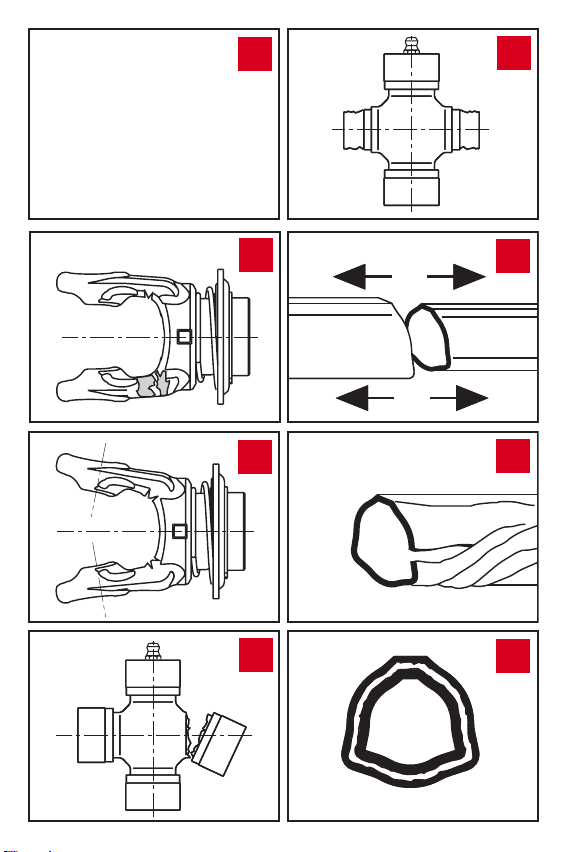

ROTATING DRIVE SHAFT

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT-

ALL DRIVELINE GUARDS, TRACTOR

AND EQUIPMENT SHIELDS IN PLACE

DRIVE SHAFT SECURELY

ATTACHED AT BOTH ENDS

DRIVE SHAFT GUARDS THAT TURN

FREELY ON DRIVE SHAFT

READING OPERATOR’S MANUAL

DO NOT USE PTO ADAPTORS

399141000

Cod 399141000

33

BP COMPONENTES HIDRÁULICOS E MECÂNICOS

CAXIAS DO SUL - RS

MADE IN BRAZIL

G1 G2 G4 G5 G7

2013 2014 2015 2016

399CEBR05

Cod 399CEBR05

2 51

BP COMPONENTES HIDRÁULICOS E MECÂNICOS

CAXIAS DO SUL - RS

MADE IN BRAZIL

G1 G2 G4 G5 G7

2013 2014 2015 2016

399FXBR05

Cod 399USR05

4

8

5

6

L

1/2 L

L

7

9

10

11

3

12

16

13

14

15

4

17

18

19

20

24

21

22

23

25

26

27

5

28

32

29

30

31

6

33

34

35

80

36

37

T

80

T

7

38

42

39

40

41

8

43

44

45

46

50

47

48

49

51

52

53

9

54

58

10

55

56

57

59

60

61

62

66

63

64

65

67

68

69

11

7470

12

71

72

73

75

76

77

78

82

79

80

81

83

84

85

13

86

87

14

TRANSLATION OF THE

ENGLISH

SAFETY LABELS

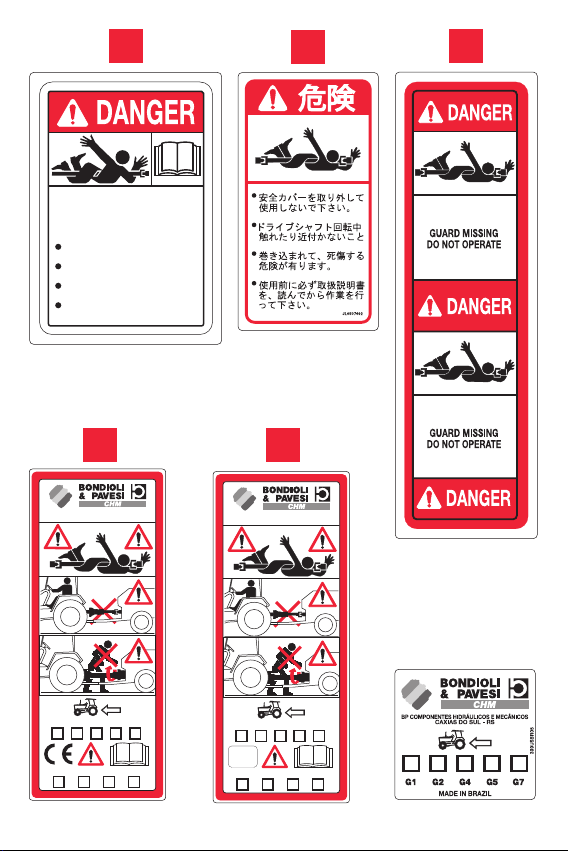

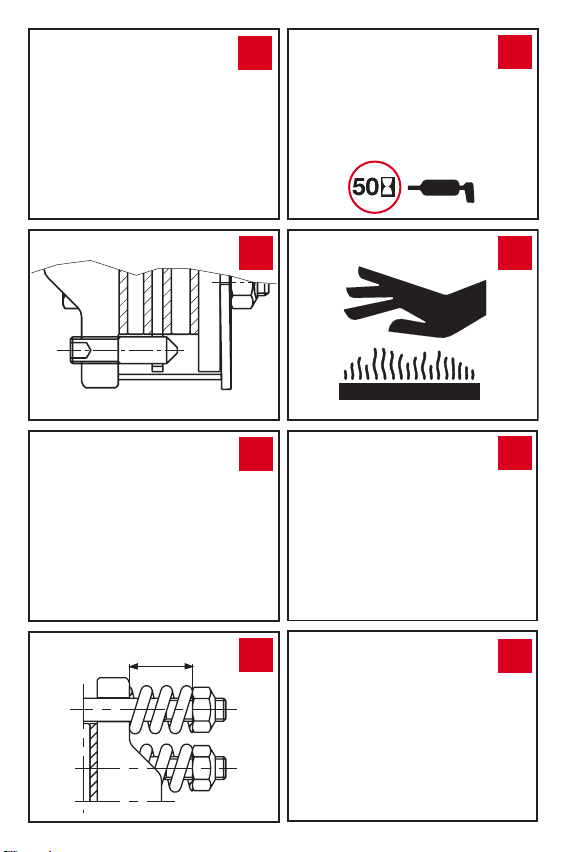

SHIELD TUBE LABEL Code 399141000

1

SHIELD TUBE LABEL Code 399JAP001

The operator must obey all labels and must maintain the proper shielding. A large

percentage of accidents caused by PTO drive shafts occur when the shielding is

not present or is not functioning correctly.

DRIVE TUBE LABEL Code 399143000

2

DRIVE TUBE LABEL Code 399USR05

DANGER! Keep clear of the work area and rotating parts.

Do not wear loose clothing, jewelry, or hair that could become entangled with the

driveline.

Contact with rotating parts can cause serious injury or death.

GUARD MISSING, DO NOT OPERATE.

Do not operate without all driveline, tractor and implement shields in place.

Damaged or missing parts must be repaired or replaced before using the driveline.

SHIELD TUBE LABEL Code 399CEBR05

3

SHIELD TUBE LABEL Code 399FXBR05

Rotating driveline – contact can cause death. Keep away. Do not wear loose

clothing, jewelry, or hair that could become entangled with the driveline.

Do not operate without all driveline, tractor and implement shields in place.

Damaged or missing parts must be replaced and installed correctly before using

the driveline. Disconnect PTO clutch, shut off tractor engine, and remove key

before approaching the implement. Keep all bystanders away from the implement

while in operation. Read this manual, and the operator’s manual for the implement,

before using the machine.

YOUR SAFETY DEPENDS UPON THIS INFORMATION.

SAFETY AND WORKING CONDITIONS

When using the implement and the driveline, do not exceed the speed

4

or power limits specified in the operator’s manual. Do not overload the

implement or suddenly engage the PTO clutch. Any torque limiter or clutch must

be installed on the implement end of the driveline. Use the implement only with

the original driveline, which is fit for the purpose in terms of length, dimensions,

devices and shields.

The driveline and its torque limiter or overrunning clutch are designed specifically

for the implement, and should be used exclusively for this purpose. Check the

implement instruction handbook to ascertain whether the driveline must be

equipped with a torque limiting or overrunning clutch. Standard drivelines, torque

limiters and overrunning clutches are designed for speeds of up to 1000 min –1.

Ensure that the driveline can perform all operations without interfering with the

tractor or the machine. Contact with parts of the tractor, hooks, drive pins, tires,

drawbar, hammerstrap, or 3-point hitch, will damage the guard. Never use tractors,

(or systems for connection to the implement) that interfere with the driveline during operation. Do not use adapters or components not offered by the implement

manufacturer.

ORIGINAL INSTRUCTIONS

ENG

15

ENG

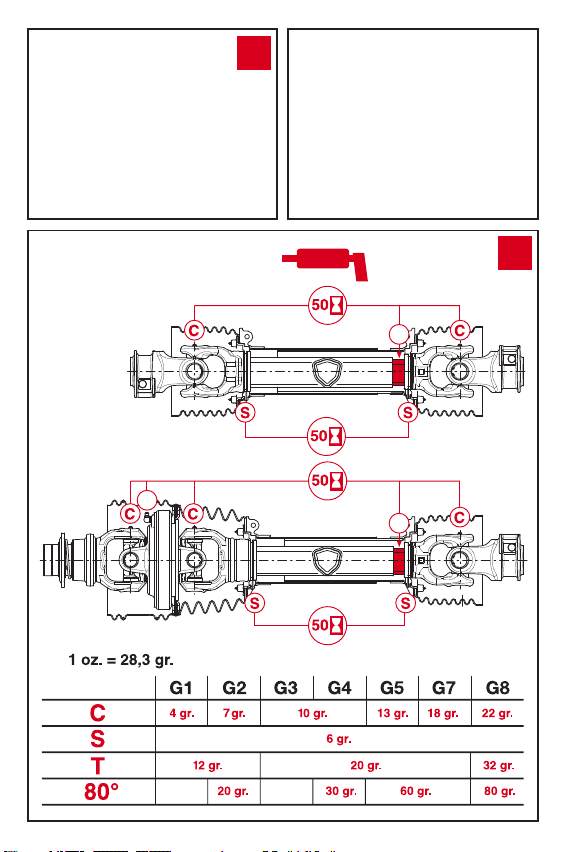

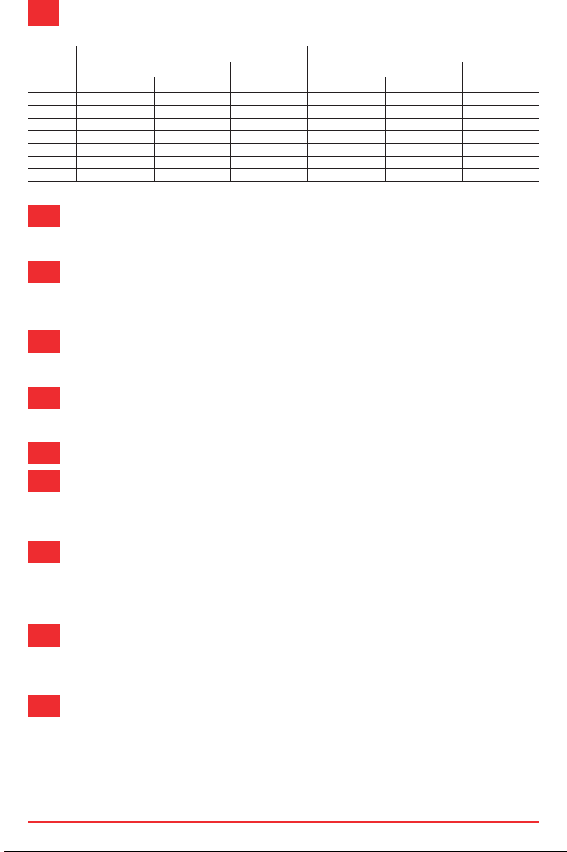

NOMINAL POWER Pn and NOMINAL TORQUE Mn

Pn Mn Pn Mn

G1 12 16 210 18 25 172

G2 15 21 270 23 31 220

G3 26 35 460 40 55 380

G4 26 35 460 40 55 380

G5 35 47 620 54 74 520

G7 47 64 830 74 100 710

G8 61 83 1080 96 130 917

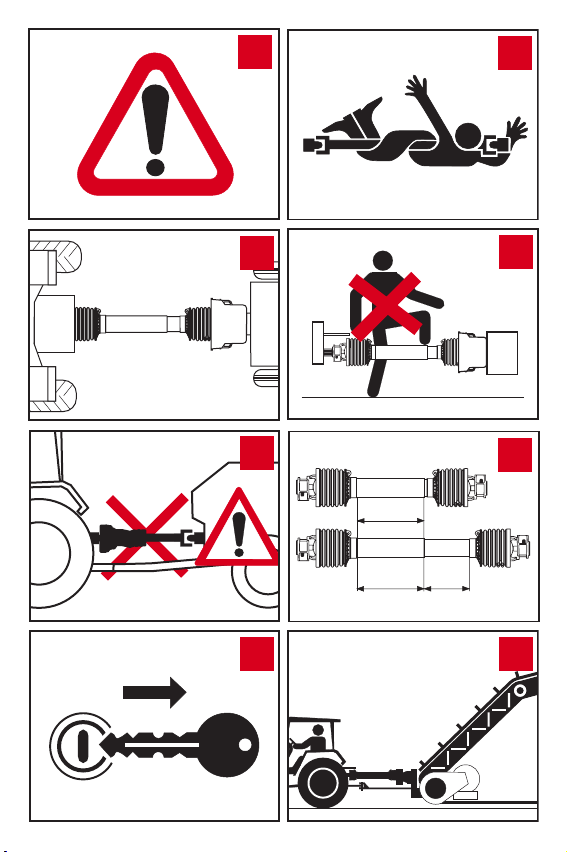

5

work together for your safety.

6

replaced before using the driveline. The driveline must be securely attached at

both ends. Guards must turn freely on the driveline.

7

performing maintenance work.

8

rotating parts can cause serious injury or death.

9

10

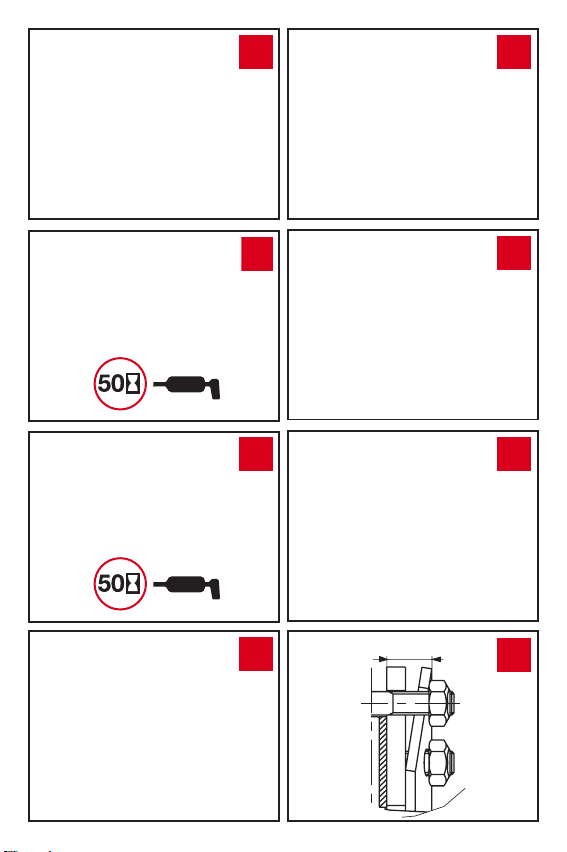

maneuvers, when the driveline is not rotating, the telescoping tubes must have a

suitable overlap to maintain the tubes aligned and allow them to slide freely.

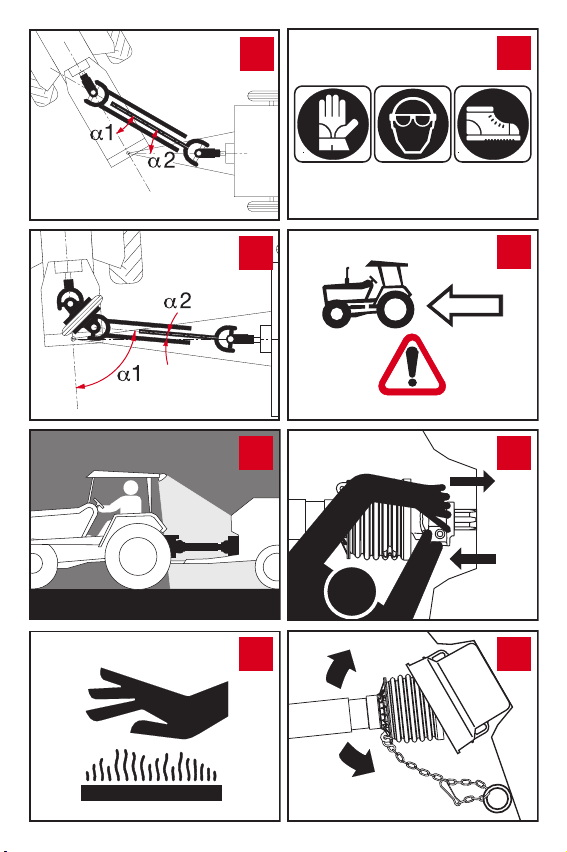

11

Brake the tractor, placing blocks under the wheels if necessary. The tractor must

be hitched to the implement and positioned so that the angles of the joints are

minimal and equal.

12

During turns or other short duration maneuvers, the maximum recommended joint

angle is 45°. Disengage the PTO if the angles are too large or not identical.

13

smallest joint angle possible. During turns or other short duration maneuvers, the

maximum joint angle is 50°, 70° (Constant Velocity Joint 652) or 80° according to

the design of the CV joint. When the driveline includes a CV joint on the tractor side

and a single U-joint on the implement side, the maximum recommended angles of

the U-joint are 16° at 540 min-1 and 9° at 1000 min-1 to avoid drive irregularities.

kW CV-HP-PS N∙m kW CV-HP-PS N∙m

All rotating parts must be shielded.

The tractor master shield, the driveline guard, and the implement shield all

Do not operate without all driveline, tractor and implement shields in place.

Damaged or missing parts must be repaired with original spare parts or

Disengage the PTO, turn off the tractor engine, remove the key and ensure

that all rotating parts have stopped before approaching the implement or

Keep clear of the work area and rotating parts. Do not wear loose clothing,

jewelry, or hair that could become entangled with the driveline. Contact with

Do not stand on the driveline. Do not step over, or go under, the driveline.

Telescoping tubes must always overlap by at least 1/2 of their length in normal

operation and at least 1/3 of their length in all working conditions. During

Use STATIONARY MACHINERY (pumps, elevators, generators, dryers, etc.)

only when hitched to the tractor.

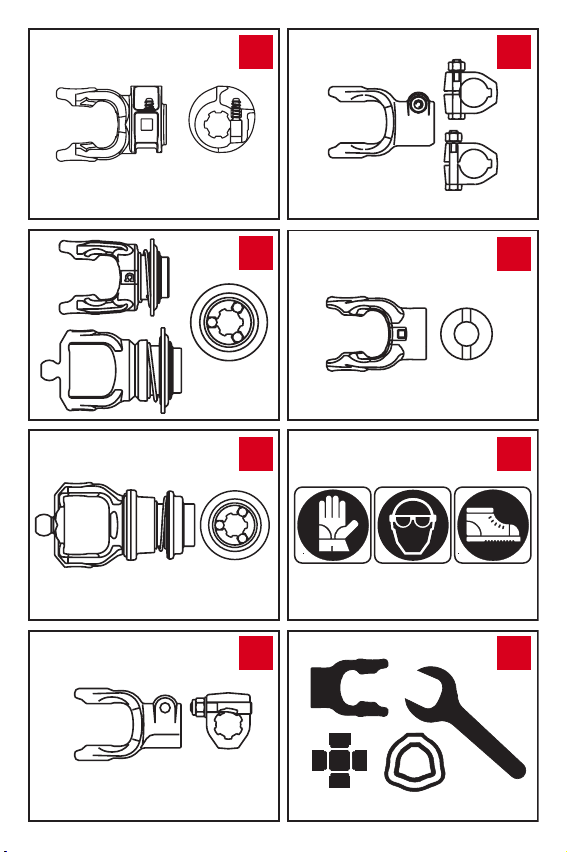

CARDAN JOINTS

When operating, ensure that joint angles are small and equal: a1 = a2.

CONSTANT VELOCITY JOINTS

For normal operations, it is best to keep the CV joint aligned or with the

540 min

-1

1000 min

-1

16

Loading...

Loading...