Bondioli&Pavesi 399USA011-D User Manual [en, de, es, fr, it]

MADE IN ITALY

399USA011/D

ROTATING DRIVE SHAFT

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT-

ALL DRIVELINE GUARDS, TRACTOR

AND EQUIPMENT SHIELDS IN PLACE

DRIVE SHAFT SECURELY

ATTACHED AT BOTH ENDS

DRIVE SHAFT GUARDS THAT TURN

FREELY ON DRIVE SHAFT

READING OPERATOR’S MANUAL

DO NOT USE PTO ADAPTORS

399141000

Cod 399141000

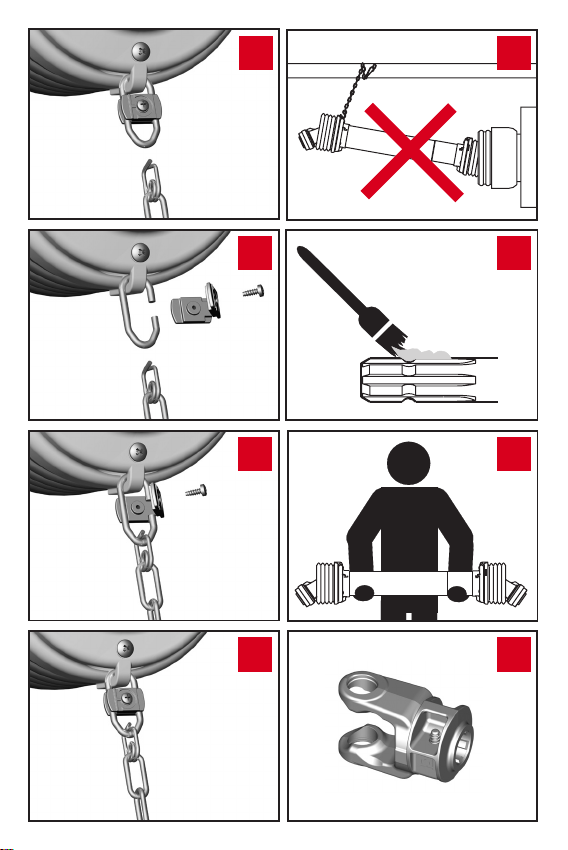

1

1

Cod 399JAP001

2

3

Cod 399CEE051

4

2 87

Cod 399143000

95

6 10

7 11

8 12

3

1713

14 18

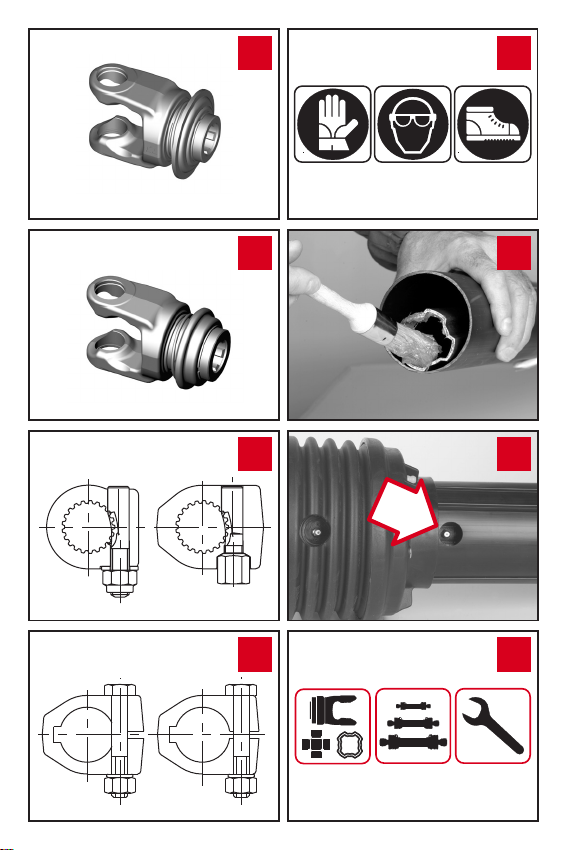

15 19

16 20

4

2521

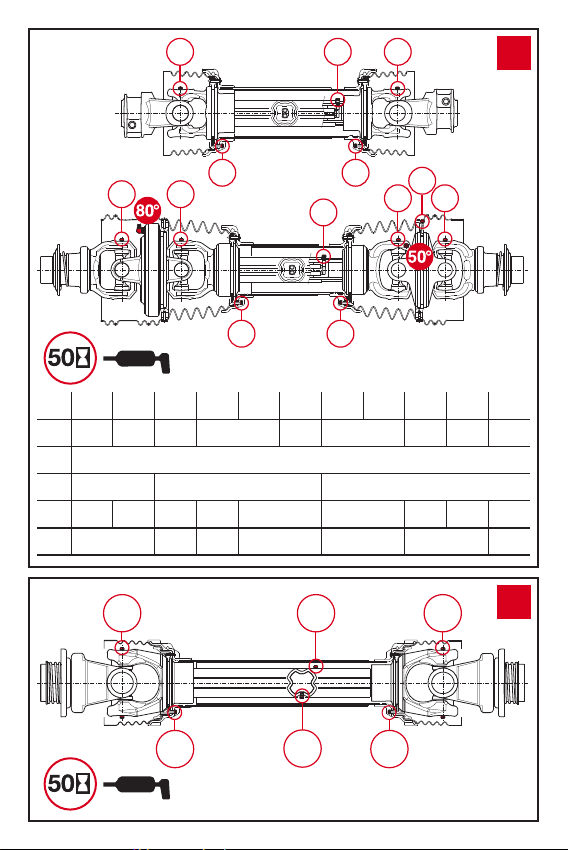

22 26

23

27

24 28

5

29 33

30 34

31 35

32 36

6

T CC

37

S

C

C

S S

1 oz. = 28,3 g

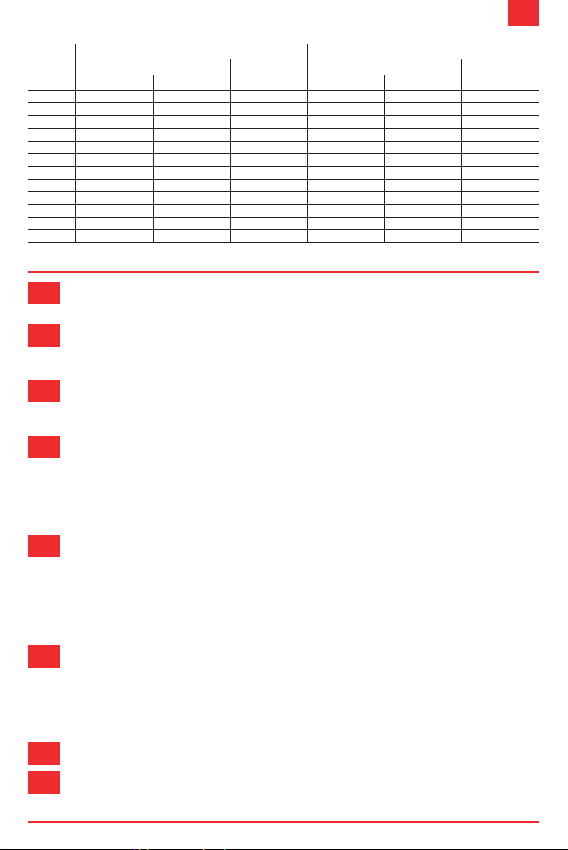

S1 S2 S4 S5 S6 H7 S8 H8 S9 SH S0

4 gr. 7 gr. 10 gr. 13 gr. 18 gr. 22 gr. 26 gr. 28 gr. 30 gr.

C

S

12 gr. 20 gr. 32 gr.

T

80°

50°

20 gr. 30 gr. 60 gr. 80 gr.

5 gr. 6 gr. 7 gr. 8 gr.

36g 16g

6 gr.

S

T

CSC

100 gr. 160 gr.

SK

6g 6g

16g

36g

37

1 oz. = 28,3 g

7

38

42

39

43

40 44

41 45

8

46

50

47

49

51

5248

53

9

54

58

10

55

59

56 60

57 61

621270

66

63

64

65

67

68

69

11

74

71

72

73

75

76

77

78

82

79

80

81

83

84

85

13

86 87

88

89

14

TRANSLATION OF THE

ENGLISH

SAFETY LABELS

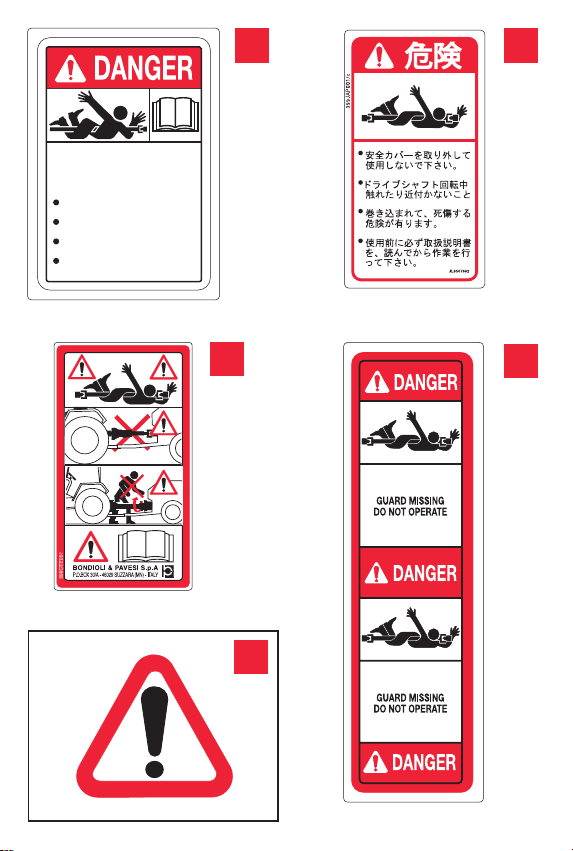

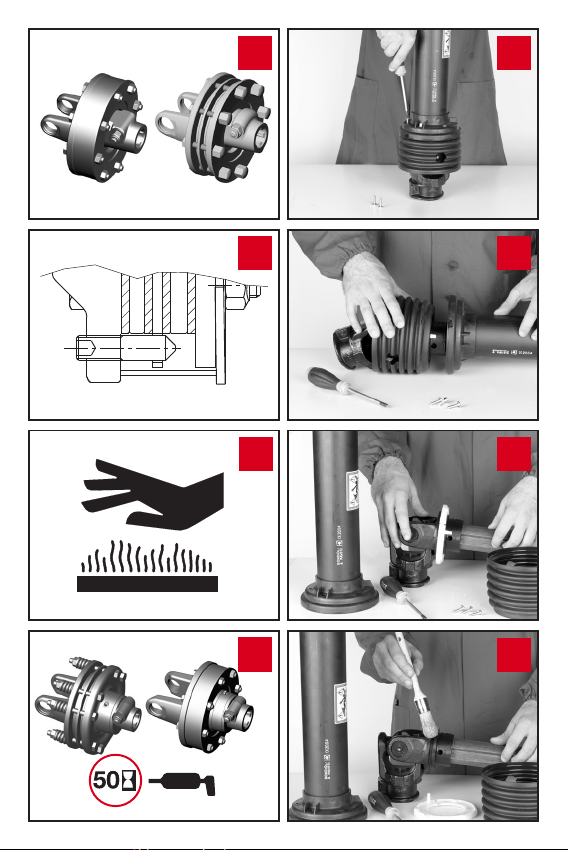

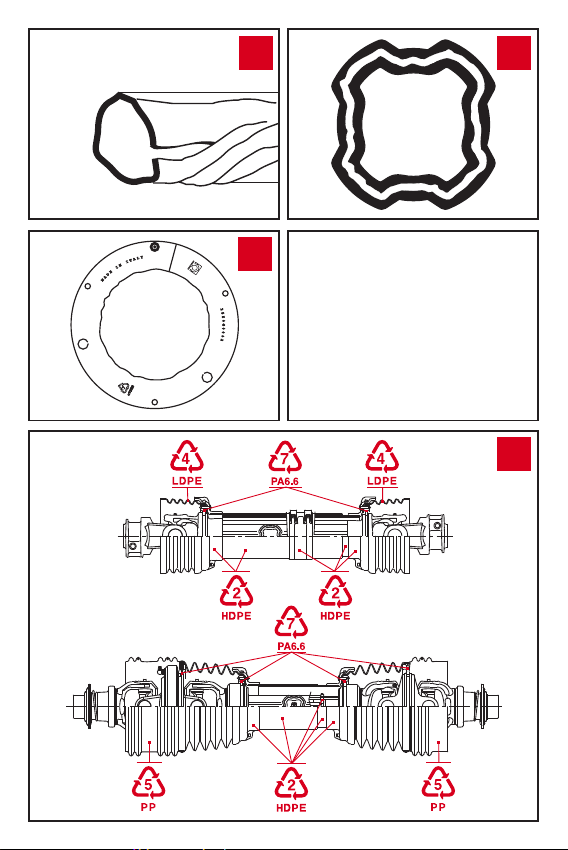

SHIELD TUBE LABEL COD. 399141000

1

SHIELD TUBE LABEL COD. 399JAP001

The operator must obey all labels and must maintain the proper shielding.

A high percentage of driveline injuries occur when safety shielding is missing or

not functioning properly.

For export reasons it may be displayed together with label 399CEE051 but this is

not necessary for the purpose of obtaining .

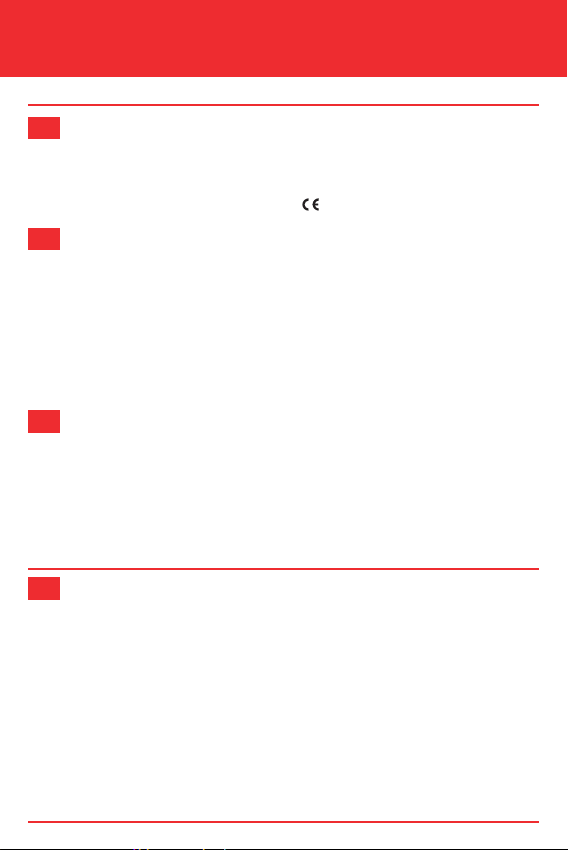

SHIELD TUBE LABEL COD. 399CEE051

2

Rotating driveline – contact can cause death. Keep away! Do not wear

loose clothing, jewelry, or hair that could become entangled with the driveline.

Do not operate without all driveline, tractor and implement shields in place. Damaged or missing parts must be repaired or replaced before using the driveline.

Driveline must be securely attached at both ends. Driveline shields must turn freely

on driveline.

Disconnect PTO clutch, shut off tractor engine, and remove key before approaching

the implement. Keep all bystanders away from the implement while in operation.

Read this manual, and the operator’s manual for the implement, before using the

machine.

YOUR SAFETY DEPENDS UPON THIS INFORMATION.

DRIVE TUBE LABEL COD. 399143000

3

DANGER! Do not wear loose clothing, jewelry, or hair that could become

entangled with the driveline.

Contact with rotating parts could cause serious injury or death.

GUARD MISSING DO NOT OPERATE.

Do not operate without all driveline, tractor and implement shields in place.

Damaged or missing parts must be repaired or replaced before using the driveline.

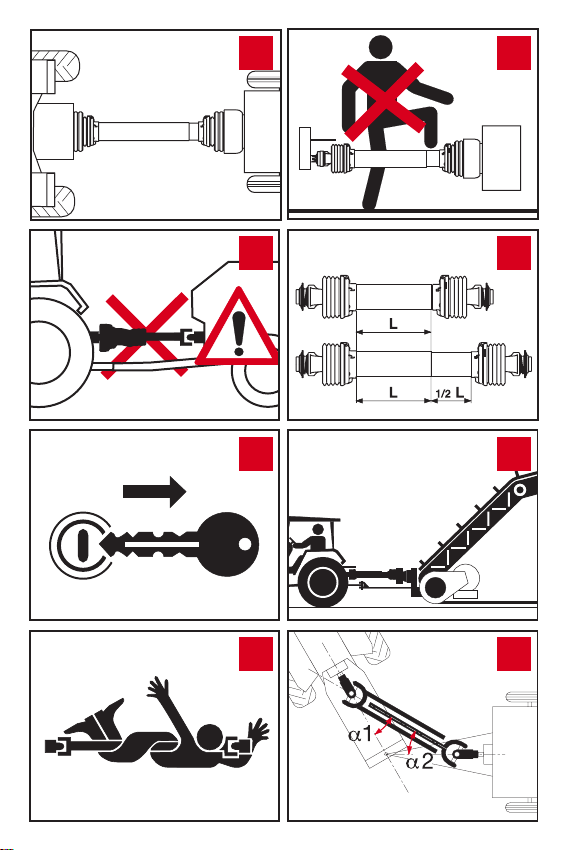

SAFETY AND WORKING CONDITIONS

When using the implement and the driveline, do not exceed the speed or

4

power limits given by the operator’s manual.

Do not overload the implement or suddenly engage the PTO clutch.

Any torque limiter or clutch must be installed on the implement end of the driveline.

Use the implement only with the original driveline, which is compatible in length,

power capacity, torque limiters or overrunning clutches and shielding.

The driveline and its torque limiter or overrunning clutch are designed specically

for the implement, and should be used exclusively for this purpose.

Verify in the implement instruction handbook if the driveline requires a torque limiting or overrunning clutch. Standard drivelines, torque limiters and overrunning

clutches are designed for speeds up to 1000 min –1.

Check that the driveline can operete freely without interfering with the tractor or

implement. Contact with parts of the tractor (drawbar, tires, three point linkage)

damage the shield on the driveline.

Do not use tractors or implement hitching systems that interfere with the driveline

when the joint angles change. Do not use adapters or other components not approved by the implement manufacturer.

ORIGINAL INSTRUCTIONS

ENG

15

ENG

All rotating parts must be guarded. Contact with a rotating driveline can

5

cause death or serious injury. The tractor master shield, the driveline guards,

and the implement input connection shield form an interactive guarding system.

Ensure that all driveline, tractor, and implement shields are functional and

6

in place before operation. Damaged or missing parts must be replaced with

original equipment spare parts, correctly installed, before using the driveline.

Disengage the PTO, turn off the tractor engine, remove the key, and check

7

that all rotating parts have come to a standstill before approaching the implement or performing maintenance work.

Do not approach, nor allow bystanders to come near the work zone or rota-

8

ting parts. Do not wear loose clothing, jewelry, hair, or anything which could

get caught in the machine.

Contact with rotating parts could cause serious injury or death.

Do not stand, lean, or otherwise come in contact with the driveline. Do not

9

step over or go under the driveline.

Telescoping tubes should overlap by 1/2 of their length in normal operation

10

and they must overlap by at least 1/3 of their length in any operating condition. If greater telescoping capability is required, contact the implement dealer or

manufacturer. During maneuvers, when the driveline is not rotating, the telescoping

tubes must have a suitable overlap to maintain the tubes aligned and allow then to

slide propely.

Always hitch the tractor to STATIONARY MACHINERY (pumps, hoists, ge-

11

nerators, dryers, etc.) so that the prole tubes are not over-extended, and

chock the tractor wheels to prevent rolling.

SINGLE CARDAN JOINTS

12

When operating, ensure that the joint angles are small and as equal as possible. The joint angles may vary widely during turns, but must never exceed 35°

under power or 45° during rotation. Disengage the PTO when the angle of the

joints becomes excessive or too unequal.

CONSTANT VELOCITY JOINTS

13

Constant velocity joints can allow large joint angles - up to 50°, 75° (SH

dimension) or 80° depending upon the type. These joint angles should only be

allowed for brief periods, for example during turning.

For drivelines with a constant velocity joint on the tractor side and a single cardan

joint on the implement side, the maximum recommended angles of the single joint

are 16° at 540 min –1 and 9° at 1000 min –1 to prevent irregular motion.

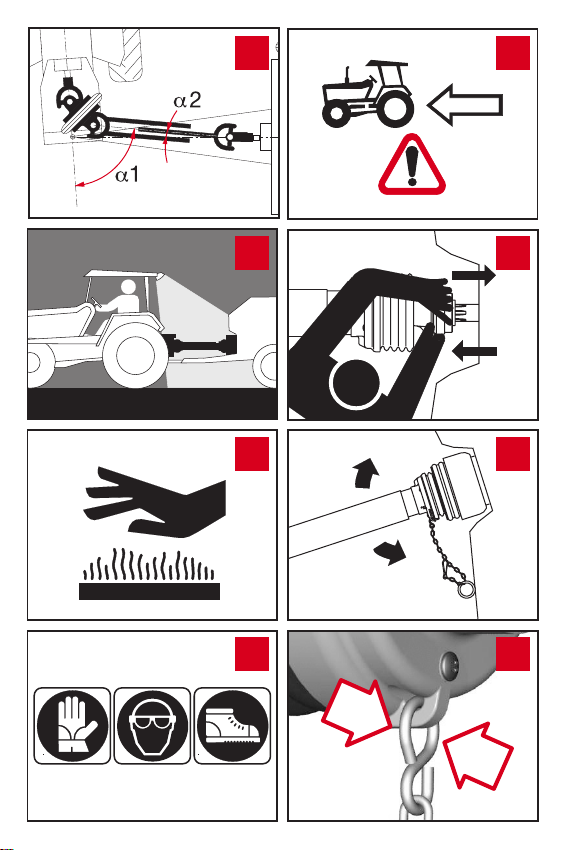

When used at night or in poor visibility, illuminate the driveline operating area.

14

Friction clutches may become hot during use. Do not touch!

15

Keep the area around the friction clutch clear of any material which could

catch re and avoid prolonged slipping.

16

RATED POWER Pn and RATED TORQUE Mn

Pn Mn Pn Mn

S1 13 18 234 20 27 190

S2 21 28 364 31 42 295

S4 28 38 494 42 57 400

S5 37 50 651 55 75 527

S6 40 55 716 61 83 583

H7 51 70 911 78 106 745

S8 66 90 1171 100 136 956

H8 66 90 1171 100 136 956

S9 81 110 1431 122 166 1166

SH 97 132 1717 147 200 1405

S0 124 169 2199 187 254 1785

SK 180 254 3183 284 386 2712

INSTALLATION

16

17

end.

18

Check that all bolts or nuts are properly torqued.

19

Best results are achieved when the chains are attached nearly perpindicular to the

driveline guard. Adjust the length to allow articulation of the driveline in working or

transport postions, but avoid excessive slack that may wrap around the driveline.

20

and the chain will disconnect from the shield.

In this case, replace the chain.

The “S” hook of the new chain must be inserted in the eyelet of the base cone and

must be closed to prevent it slipping and maintain its form.

21

and the chain will disconnect from the shield.

The chain may be easily reconnected as described in the following procedure.

22

23

24

25

kW CV-HP-PS N∙m kW CV-HP-PS N∙m

Always wear adequate safety equipment when performing any maintenance

or repair work.

The tractor symbol on the shield indicates the tractor end of the driveline.

Torque limiters or overrunning clutches must be mounted at the implement

Ensure that the driveline is securely attached to the tractor and the implement before operating.

Attach the shield restraint chains, allowing sufcient slack for the driveline to

move during turns and operation.

If the length of the chain is not adjusted correctly and tension is excessive,

for example during machine maneuvers, the “S” connection hook will open

If the length of chain is not adjusted correctly and tension is excessive, for

example during machine maneuvers, the “Spring Link” connection will open

Open the locking ring by loosening the screw and removing the plate.

Insert the chain in the locking ring and reposition the plate.

Close the plate by means of the screw.

Never use the shield restraint chains to support the driveline for storage.

Always use the support on the implement.

540 min

-1

1000 min

-1

ENG

17

ENG

Clean and grease the tractor PTO and implement input connection shaft to

26

facilitate installation of the driveline.

Keep the driveline horizontal during handling to prevent the halves from sli-

27

ding apart, which could cause injury or damage the shielding. Use suitable

means to transport heavy drivelines.

PUSH - PIN

28

Push the pin and slide the yoke onto the PTO shaft so that the pin engages

the groove on the PTO. Make sure that the pin returns to its initial position after

attachment to the shaft.

BALL COLLAR

29

Align the yoke on the PTO. Push or pull the collar to the open position. Slide

the yoke onto the splined shaft. Release the collar and pull or push the yoke along

the shaft until the balls engage the groove and the collar returns to its original

(closed) position. Make sure the collar returns to its initial (closed) position and the

yoke is properly attached to the shaft.

AUTOMATIC BALL COLLAR

30

Pull the collar back until it locks in the open position. Use both hands to slide

the yoke onto the shaft - the collar will automatically unlock. Push or pull the yoke

along the shaft until the balls engage the groove and the collar returns to its original

(closed) position. Make sure the collar returns to its initial (closed) position and the

yoke is properly attached to the shaft.

TAPER PIN

31

Ensure correct tightening of the nut before use.

Slide the yoke onto the PTO and insert the pin so that the tapered prole ts into

the groove on the shaft. Recommended tightening torque:

150 Nm (110 ft lbs) for 1 3/8” Z6 or Z21 proles.

220 Nm (160 ft lbs) for 1 3/4” Z6 or Z20 proles.

Use only Bondioli & Pavesi taper pins for replacement.

CLAMP BOLT

32

Ensure correct tightening of the bolt before use.

Recommended tightening torque:

91 Nm (67 ft lbs) for M12 bolts. 144 Nm (106 ft lbs) for M14 bolts.

LUBRICATION

Always wear adequate safety equipment when performing any maintenance

33

or repair work.

LUBRICATION OF TELESCOPING TUBES

34

If grease ttings are not provided, separate the two halves of the driveline,

and manually lubricate the telescoping tubes.

GREASING SYSTEM

35

If the driveline is equipped with the Greasing System the telescoping tubes

may be lubricated via the grease tting located next to the tube yoke.

The Greasing System enables rapid lubrication of telescoping tubes at any driveline position, without removal from either the tractor or implement.

18

Replace worn or damaged components with genuine Bondioli & Pavesi spa-

36

re parts. Do not modify or tamper with any part of the driveline. For any

operations not explained in this instruction manual, consult your local Bondioli &

Pavesi representative.

Check that all components are in good condition and properly lubricated

37

before using the driveline. Clean and re-lubricate the driveline before seasonal storage.

Lubricate each part after the number of hours shown in chart.

Heavy duty applications in aggressive environments may require more

frequent lubrication intervals.

The quantitiv of grease specied in the manual is recommended for intervals of

50 hours.

Quantities specied in grams (g). 1 ounce (oz.) = 28.3 g (grams).

Inject grease into the cross kit until it purges from each bearing cap.

Pump progressively and avoid high pressures from the grease gun

Recommended grease NLGI 2.

Following seasonal use, it is recommended to clean out any grease inside the CV

shield.

TORQUE LIMITER AND OVERRUNNING CLUTCH

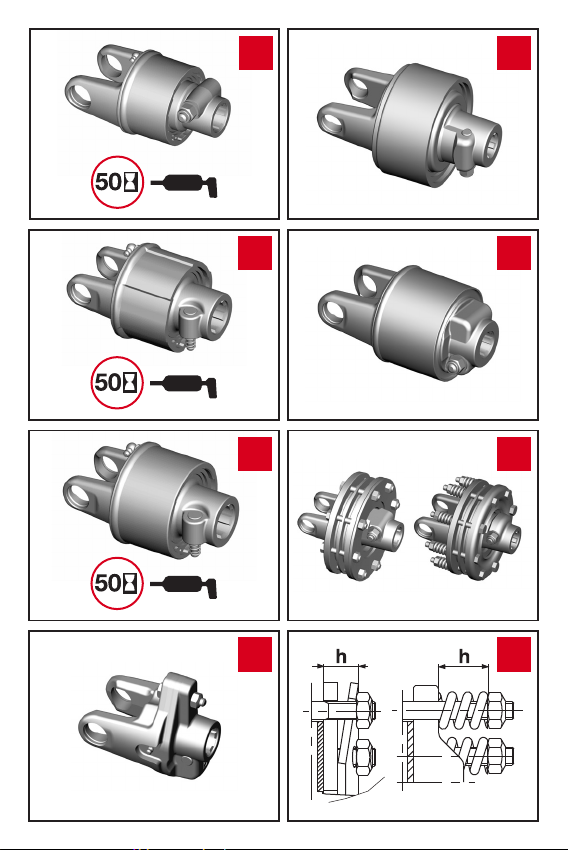

RA - RL OVERRUNNING CLUTCHES

38

This device prevents transmission of inertial loads from implement to the

tractor during deceleration or stopping of the PTO.

Lubricate every 50 hours of use and after storage.

The RL overrunning clutches do not require lubrication and are not equipped

with grease ttings.

Keep clear of the machine until all parts have stopped moving.

SA - LC RATCHET TORQUE LIMITERS

39

This device interrupts the transmission of power when the torque exceeds

the setting.

Immediately disengage the PTO when ratcheting sounds are heard.

Lubricate every 50 hours of use and after storage.

The LC limiters are tted with seal rings and require lubricaion only once each

season.

LN - LT SYMMETRICAL RATCHET TORQUE LIMITERS

40

This device interrupts the transmission of power when the torque exceeds

the setting.

Immediately disengage the PTO when ratcheting sounds are heard.

Lubricate every 50 hours of use and after storage.

The LT limiters are tted with seal rings and require lubricaion only once each

season.

LB – SHEAR BOLT TORQUE LIMITER

41

This device interrupts the transmission of power by shearing a bolt when the

torque exceeds the setting.

Replace the sheared bolt with the same diameter, length and grade as the original.

Lubricate the LB limiters with grease ttings at least once every season and after

long periods of storage.

ENG

19

ENG

LR – AUTOMATIC TORQUE LIMITER

42

This device interrupts the transmission of power when the torque exceeds

the setting. To automatically re-engage the device, slow down or stop the PTO.

This device is sealed - no additional lubrication is required.

GE – SHOCK ABSORBING CLUTCH

43

Absorbs shock loads and vibrations, and smoothes transmission of an alternating or pulsating load.

No maintenance is required.

FRICTION TORQUE LIMITERS

Check the condition of the friction linings when installing the clutch or after periods

of storage.

• If the edges of the clutch plates are exposed (see g. 44) the clutch is either type

FV with Belleville spring or FFV with helicoil springs. Measure and record the spring

height as shown in gure 45. If the clutch plates are covered by a metal band (see

gure 46) the clutch is type FT.

If the clutch discs are exposed and the bolts have cap nuts, the clutch is of

the FK type.

Following seasonal use, relieve the spring pressure and keep the clutch in a dry

place. Check the condition of friction disks and restore spring pressure before

using the clutch. If the clutch overheats due to frequent or prolonged slipping,

consult your equipment dealer or manufacturer, or your local Bondioli & Pavesi

representative.

FV - FFV FRICTION TORQUE LIMITER

44

The torque transmitted to the machine is limited by allowing the clutch plates

to slip relative to each other.

Torque peaks or short duration overloads are limited when the clutch is used and

adjusted properly.

It can be used as an overload clutch, or to help start implements with high inertial loads.

The setting can be adjusted by modifying the working height of the springs.

The torque setting of friction torque limiters FV and FFV is adjusted by incre-

45

asing or decreasing the height “h” of the spring.

To increase / reduce the torque setting, screw / unscrew each of the eight nuts

by 1/4 of turn and check for proper operation. Repeat the procedure if necessary.

Avoid excessive tightening of the bolts - implement, tractor, or driveline damage

may occur.

FT - FK FRICTION TORQUE LIMITERS

46

The torque transmitted to the machine is limited by allowing the clutch plates

to slip relative to each other. Torque peaks or short duration overloads are limited

when the clutch is used and adjusted properly. It can be used as an overload

clutch, or to help start implements with high inertial loads. The FT has a metal

band around its circumference. The bolts should be tightened until the metal band

around the circumference of the clutch touches the spring, then loosen each nut

by 1/4 turn. Avoid excessive tightening of the bolts - implement, tractor, or driveline

damage may occur.

The FK clutch has bolts with cap nuts. The spring compression is correct

when the nuts are fully screwed on. Use only special B&P bolts and nuts.

20

If the clutch has four socket head set screws in addition to the eight hex

47

head bolts on the ange yoke, it is equipped with the Spring Release system.

Spring pressure is relieved when these four set screws are screwed into the ange

yoke. See the instruction leaet enclosed with clutches with the Spring Release

system installed.

The Spring Release System enables checking of the condition of the friction clutch

and reduces spring pressure on the disks during storage.

Friction clutches equipped with the Spring Release System are supplied with

an additional instruction sheet. Read this information for proper use of the

Spring Release System.

Friction clutches may become hot during use. Do not touch!

48

Keep the area around the friction clutch clear of any material which could

cause a re and avoid prolonged slipping of the clutch.

FNV - FFNV - FNT - FNK COMBINATION FRICTION AND OVERRUNNING CLUTCH

49

A clutch which combines the functional characteristics of friction clutch and

an overrunning clutch.

Used on machines with high inertial loads.

Lubricate every 50 hours of use and after storage.

Keep clear of the machine until all parts have stopped moving.

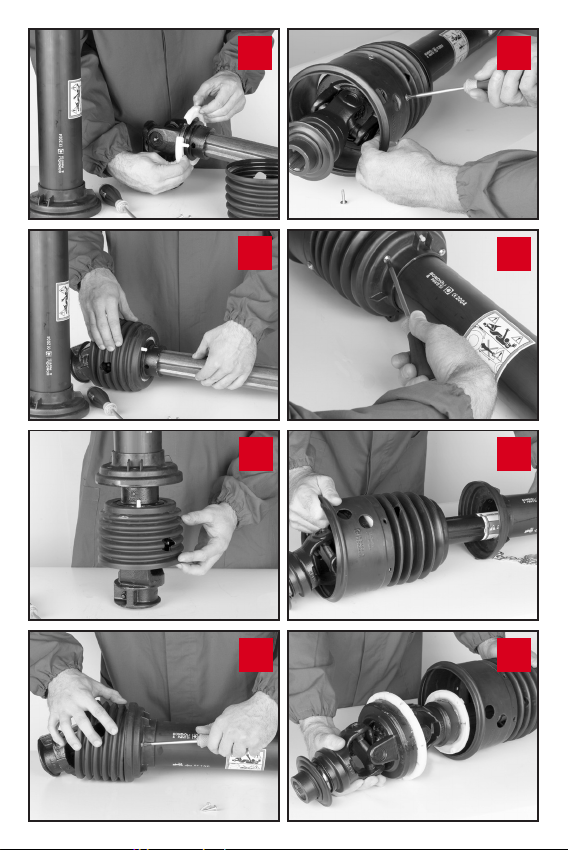

SHIELD DISASSEMBLY

Remove the Philips head screws.

50

Remove the base cone and the shield tube.

51

Remove the outer cone and the bearing ring.

52

SHIELD ASSEMBLY

Grease the bearing groove on inner yokes.

53

Fit the bearing ring into the yoke groove with the grease tting facing the

54

drive tube.

Install the outer cone, inserting the grease tting through the proper hole.

55

Install the base cone and shield tube.

56

Tighten the Philips head screws.

57

Use of electric powered screwdrivers is not recommended.

ENG

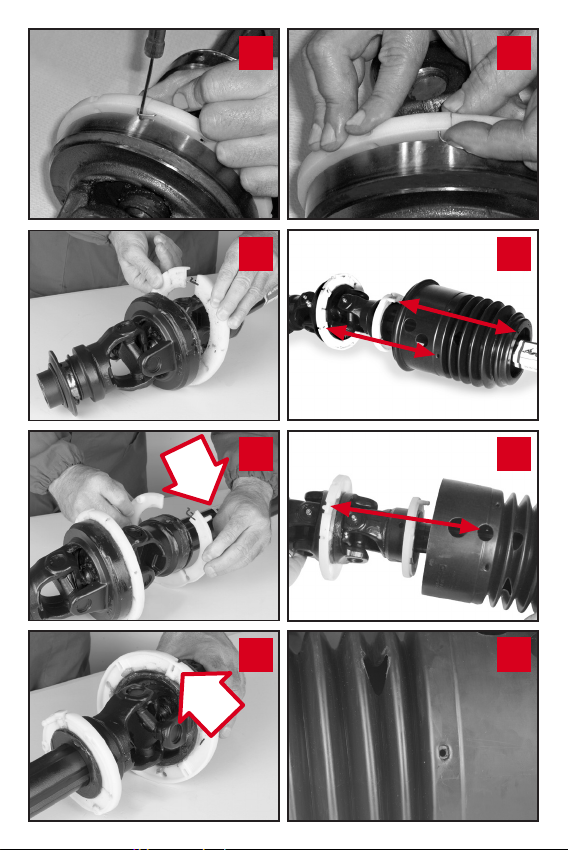

CV JOINT SHIELD DISASSEMBLY

Remove the screws arranged radially around the circumference of the CV

58

cone.

Remove the screws from the base cone.

59

Remove the base cone and the shield tube.

60

21

ENG

Remove the CV cone.

61

Disengage the retaining spring, leaving it inserted in one of the two holes of

62

the bearing ring to avoid losing it.

Spread the bearing rings and remove from their groove.

63

CV JOINT SHIELD ASSEMBLY

Grease the bearing grooves.

64

Fit the bearing ring into the yoke groove with the grease tting facing the

drive tube.

Install the bearing ring on the CV body with the reference pins facing the

65

inner yoke. The bearing ring is equipped with a grease tting, used only for

50° CV joints. This grease tting is not used with 80° CV joints.

Connect the retaining spring to the two edges of the bearing ring.

66

Slide the CV cone onto the CV body and align the radial holes with the be-

67

aring ring reference pins. Align the hole at the base of the CV cone with the

grease tting on the smaller bearing ring.

In the case of 50° CV joints only: insert the shield strip, aligning with the

68

elements specied in point 66, and also the additional hole of the shield strip

with the grease tting of the large ring.

Ensure that the radial holes of the CV cone are aligned with the holes on the

69

reference pins of the bearing ring.

In the case of 50° CV joints only: Ensure that the radial holes of the shield

70

strip are aligned with the holes on the reference pins of the bearing ring

and that the access hole on the CV cone is aligned with the grease tting of the

bearing ring.

Tighten the 6 flange head screws of the protection strip. The use of an elec-

71

tric screwdriver is not recommended.

Fit the base cone and tube, inserting the grease tting in the hole on the

72

base cone.

Tighten the 3 screws. Use of electric powered screwdrivers is not recommended.

73

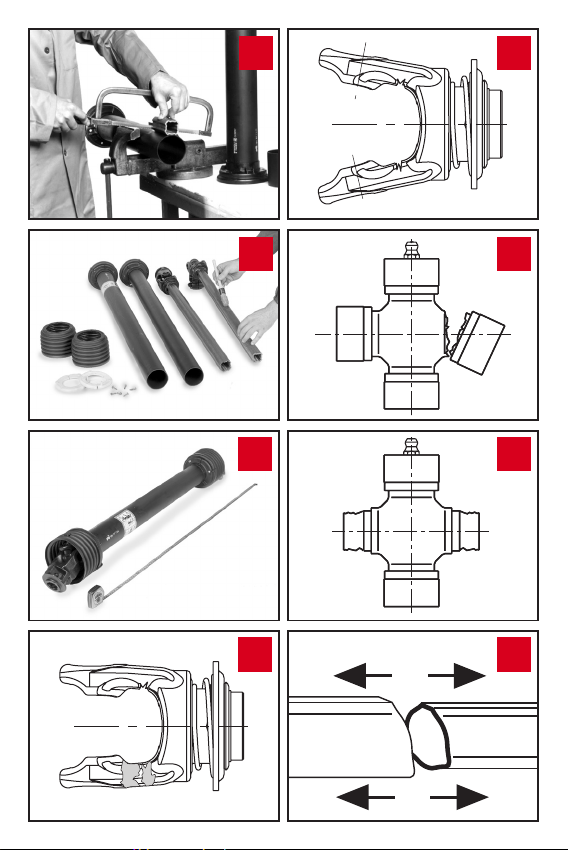

SHORTENING THE DRIVELINE

Bondioli & Pavesi does not recommend modications to its products.

74

If the driveline needs to be shortened, proceed as described below.

If you are unsure of the procedure, or need additional assistance, please contact

your local implement dealer or qualied service center.

Remove shielding.

75

22

Shorten drive tubes by the required length. In normal conditions, telesco-

76

ping tubes must always overlap by at least a 1/2 of their length. During manoeuvres, when the driveline is not rotating, the telescoping tubes must have a

suitable overlap to maintain the tubes aligned and allow then to slide properly. If

the driveline is tted with a single chain restraint system (splined inner tube), the

tubes can be shortened by a limited amount (normally no more than 70 mm) to

avoid eliminating the splined ring connecting the two shield tubes. If the driveline

is tted with a greasing system incorporated in the inner drive tube, the tubes

can be shortened by a limited amount to avoid damage to the lubrication system.

Carefully measure and shorten each drive tube equally.

Carefully deburr the ends of the tubes with a le and remove any chippings

77

from the tubes.

Shorten shield tubes one at time by cutting the same length that was cut

78

from the drive tubes. If the driveline is equipped with Single Chain Restraint

System, shortening the driveline will involve removal of the plastic ring which connects the shield tubes. If it is necessary to remove this collar, ADD A RETAINING

CHAIN TO THE TRACTOR SIDE OF THE DRIVELINE SHIELD.

Grease the internal drive tube.

79

Reassemble the shielding on the driveshaft.

Check the length of the drive shaft at the minimum and maximum positions

80

of the machine.

Telescoping tubes must always overlap by at least a 1/2 of their length.

During manoeuvres, when the driveline is not rotating, the telescoping tubes must

have a suitable overlap to maintain the tubes aligned and allow then to slide properly.

TROUBLESHOOTING

WEAR OF YOKE EARS

81

EXCESSIVE WORKING ANGLE

• Reduce the working angle.

• Disengage PTO when joint angle exceeds 45°.

DEFORMATION OF YOKES

82

EXCESSIVE TORQUE PEAK OR SHOCK LOAD

• Avoid overloading or engaging PTO when under load.

• Check function of torque limiter.

CROSS ARM BROKEN

83

EXCESSIVE TORQUE PEAK OR SHOCK LOAD

• Avoid overloading or engaging PTO when under load.

• Check function of torque limiter.

ACCELERATED WEAR OF CROSS ARMS

84

EXCESSIVE LOAD

• Do not exceed the speed or power limits indicated in the instruction manual.

INSUFFICIENT LUBRICATION

• Follow instructions in point 37.

ENG

23

ENG

SEPARATION OF TELESCOPING TUBES

85

EXCESSIVE EXTENSION OF DRIVELINE

• Do not extend driveline to the point that the tubes separate.

• For stationary machinery, position the tractor so the telescoping tubes overlap as

illustrated in point 10.

TWISTING OR BENDING OF TELESCOPING TUBES

86

EXCESSIVE TORQUE PEAK OR SHOCK LOAD

• Avoid overloading or engaging PTO when under load

• Check function of torque limiter.

• Check that driveline does not come into contact with tractor or implement components during movement.

ACCELERATED WEAR OF TELESCOPING TUBES

87

INSUFFICIENT LUBRICATION

• Follow instructions from point 33 to point 37.

INSUFFICIENT TUBE OVERLAP

• Follow instructions in point 10.

ACCELERATED WEAR OF SHIELD BEARING

88

INSUFFICIENT LUBRICATION

• Follow instructions in point 37.

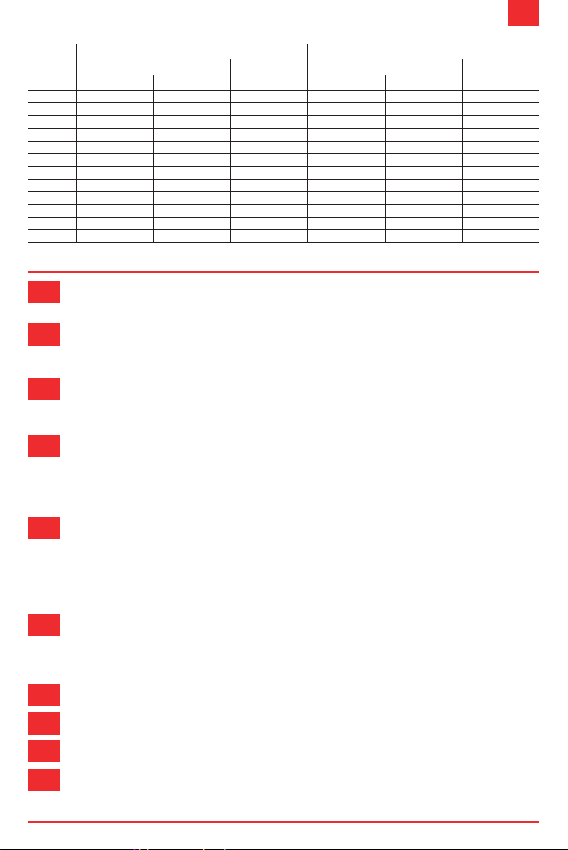

Plastic parts of the Bondioli & Pavesi drivelines are completely recyclable.

89

For a cleaner environment, collect and dispose properly at the time of replacement.

24

TRADUCTION DES

FRANÇAIS

ÉTIQUETTES DE SÉCURITÉ

ÉTIQUETTE POUR TUBE PROTECTEUR Code 399141000

1

ÉTIQUETTE POUR TUBE PROTECTEUR Code 399JAP001

L’opérateur doit respecter les indications gurant sur les décalcomanies de

sécurité et doit maintenir le protecteur efcace. Un grand nombre d’accidents

provoqués par les transmissions à cardan se produisent lorsque le protecteur n’est

pas monté ou n’est pas efcace.

Pour cause d’exportation, elle peut appliquée avec l’étiquette de sécurité

399CEE051, mais elle n’est pas nécessaire pour l’homologation .

ÉTIQUETTE POUR TUBE PROTECTEUR Code 399CEE051

2

Ne pas s’approcher de la transmission à cardan lorsqu’elle est en service.

Le contact avec une pièce en rotation peut provoquer des accidents graves. Ne

pas porter de vêtements de travail ou ceintures avec pans ottants, des écharpes,

etc. Avant d’utiliser la machine, s’assurer que tous les protecteurs du tracteur et

de la machine ont été installés et qu’ils fonctionnent correctement. Remplacer les

composants détériorés ou manquants et les monter correctement avant d’utiliser

la transmission. Arrêter le moteur du tracteur et retirer la clé de contact avant toute

intervention de maintenance sur la machine. Lire attentivement le présent manuel

ainsi que le manuel de la machine avant de l’utiliser.

CES INDICATIONS CONCERNENT VOTRE SÉCURITÉ.

ÉTIQUETTE POUR TUBE TRANSMISSION Code 399143000

3

DANGER! Ne pas s’approcher de la zone de travail ou des composants en

rotation. Éviter de porter des vêtements de travail ou ceintures avec pans ottants,

des écharpes, etc…. Le contact avec une pièce en rotation peut provoquer des

accidents graves. PROTECTION ABSENTE, NE PAS UTILISER.

Ne pas utiliser la transmission à cardan sans protecteur. S’assurer que tous les

protecteurs sont bien en place et efcaces avant de se servir de la machine. Les

pièces ou parties manquantes ou détériorées doivent être réparées ou remplacées

avant d’utiliser la transmission à cardan.

SÉCURITÉ ET CONDITIONS D’UTILISATION

Lorsque la machine - donc la transmission à cardan est en service, ne pas

4

dépasser les limites de vitesse et de puissance indiquées dans le manuel

de la machine. Éviter les surcharges et les démarrages sous charge de la prise

de force. Utiliser le limiteur de couple et la roue libre sur le côté machine de la

transmission. N’utiliser la machine qu’avec une transmission à cardan Bondioli

& Pavesi présentant longueur, dimensions, dispositifs de sécurité et protecteurs

adéquates. Utiliser la transmission à cardan, les limiteurs de couple et les roues

libres uniquement pour les fonctions auxquelles ils sont destinés.

Vérier dans le livret d’instructions de la machine si la transmission à cardan

doit être équipée d’un limiteur de couple ou d’une roue libre. L’utilisation des

transmissions à cardan, des limiteurs de couples et des roues libres gurant au

catalogue est prévue pour une vitesse ne dépassant pas 1000 min-1.

Vérier que la transmission à cardan puisse réaliser toutes les mises en articulation

prévues sans interférence avec le tracteur ou la machine. Le contact avec des

parties du tracteur, des crochets ou chevilles d’attelage des attelages 3-points

endommage le protecteur de la transmission à cardan.

INSTRUCTIONS D’ORIGINE

F

25

F

Ne pas utiliser de tracteurs ou de systèmes d’accouplement à la machine qui

interfèrent avec l’arbre à cardan au travail. Ne pas utiliser d’adaptateurs ou de

composants qui ne sont pas prévus par le constructeur de la machine.

Toutes les pièces en rotation doivent être protégées.

5

Les protecteurs du tracteur et de la machine doivent former un système

complet et intégré avec le protecteur de la transmission à cardan.

Avant d’utiliser la machine, s’assurer que tous les protecteurs du tracteur

6

et de la machine sont en place et efcaces. Remplacer les composants

détériorés ou manquants par des pièces d’origine Bondioli & Pavesi et les monter

correctement avant d’utiliser la transmission.

Arrêter le moteur du tracteur, retirer la clé de contact et s’assurer que toutes

7

les pièces ou parties en rotation sont arrêtées avant toute intervention de

maintenance sur la machine.

Ne pas s’approcher de la zone de travail ou de composants en rotation.

8

Éviter de porter des vêtements de travail ou ceintures avec pans ottants,

des écharpes, etc. Le contact avec une pièce en rotation peut provoquer des

accidents graves.

Ne pas utiliser la transmission comme barre d’appui ou marchepied.

9

Les tubes télescopiques doivent garantir à la fois un recouvrement d’au

10

moins 1/2 de leur longueur dans les conditions normales de travail et d’au

moins 1/3 de leur longueur en toutes conditions de travail. Et même lorsque la

transmission n’est pas en rotation, il faut conserver un recouvrement sufsant pour

éviter tout problème d’arc-boutement.

Utiliser les MACHINES EN POSTE FIXE (pompes, élévateurs, générateurs,

11

séchoirs, etc.) uniquement si elles sont attelées au tracteur. Immobiliser le

tracteur, avec des cales de roues si nécessaire. Le tracteur doit avoir la machine

attelée et doit être placé de manière que les angles des joints soient limités et

égaux entre eux.

JOINTS DE CARDAN SIMPLES

12

Travailler avec des angles limités et identiques α1 = α2. Pour des périodes

très courtes (braquage), il est recommandé de ne pas dépasser des angles de

fonctionnement de 45°. Débrayer la prise de force du tracteur si les angles sont

trop grands ou inégaux.

JOINTS HOMOCINÉTIQUES

13

Il est recommandé d’utiliser le joint homocinétique normalement aligné ou

avec de petits angles d’inclinaison. Pour des périodes très courtes (braquage),

les angles peuvent être grands mais ne doivent pas dépasser 50°, 75° (dimension

SH) ou 80° selon le type de joint homocinétique. Si la transmission comprend

un joint homocinétique côté tracteur et un joint de cardan côté machine, il est

recommandé de ne pas dépasser des angles de travail en continu du joint simple

de 16° à 540 min-1 et 9° à 1000 min-1 an d’éviter des irrégularités de rotation.

Éclairer la zone d’action de la transmission pendant les opérations d’attelage

14

et de travail nocturne ou en cas de mauvaise visibilité.

Les limiteurs peuvent atteindre des températures de fonctionnement élevées.

15

Ne pas toucher! Pour éviter tout risque d’incendie, éliminer toutes matières

inammables à proximité du limiteur et éviter tous glissements prolongés de celui-ci.

26

PUISSANCE NOMINALE Pn et COUPLE NOMINAL Mn

Pn Mn Pn Mn

S1 13 18 234 20 27 190

S2 21 28 364 31 42 295

S4 28 38 494 42 57 400

S5 37 50 651 55 75 527

S6 40 55 716 61 83 583

H7 51 70 911 78 106 745

S8 66 90 1171 100 136 956

H8 66 90 1171 100 136 956

S9 81 110 1431 122 166 1166

SH 97 132 1717 147 200 1405

S0 124 169 2199 187 254 1785

SK 180 254 3183 284 386 2712

INSTALLATION

16

17

installé du côté de la machine.

18

Contrôler le serrage d’éventuels boulons de xation.

19

rapport à la transmission. Régler la longueur des chaînettes de façon à permettre

la mise en articulation dans toutes les conditions de travail, de transport et de

manoeuvre. Éviter que les chaînettes s’enroulent autour de la transmission à cause

de leur longueur excessive.

20

le crochet en “S” de raccordement s’ouvrira et la chaînette se décrochera du

protecteur. Dans ce cas, remplacer la chaînette.

Le crochet en “S” de la chaînette neuve doit être engagé dans l’orice pratiqué

sur le bol protecteur de base et doit être fermé, an d’éviter son dégagement, en

maintenant sa forme arrondie.

21

excessive, pendant les manoeuvres de la machine par exemple, le crochet et le

ressort se séparent du protecteur.

Dans ce cas, la chaînette peut être facilement raccrochée comme indiqué dans la

procédure ci-après.

22

23

kW CV-HP-PS N∙m kW CV-HP-PS N∙m

Toutes les opérations de maintenance et de réparation doivent être

effectuées avec des outils appropriés et pièces de remplacement d’origine.

Le tracteur imprimé sur le protecteur indique le côté tracteur de la

transmission. L’éventuel limiteur de couple ou roue libre doit toujours être

Avant d’utiliser la machine, s’assurer que la transmission à cardan est

correctement verrouillée sur la prise de force du tracteur et de la machine.

Fixer les chaînettes du protecteur. Les meilleures conditions de

fonctionnement sont obtenues avec la chaînette en position radiale par

Si la longueur de la chaînette n’a pas été réglée correctement et sa tension

devient excessive pendant les manoeuvres de la machine par exemple,

Si la longueur de la chaînette munie du dispositif de décrochage du cône

protecteur de base n’a pas été réglée correctement et sa tension devient

Ouvrir la bague de xation en dévissant la vis et en déplaçant la plaquette.

Introduire la chaînette dans la bague de xation et replacer la plaquette.

540 min

-1

1000 min

-1

F

27

Loading...

Loading...