Bondioli&Pavesi 399USA010-C User Manual [en, de, es, fr, it]

MADE IN ITALY

399USA010/C

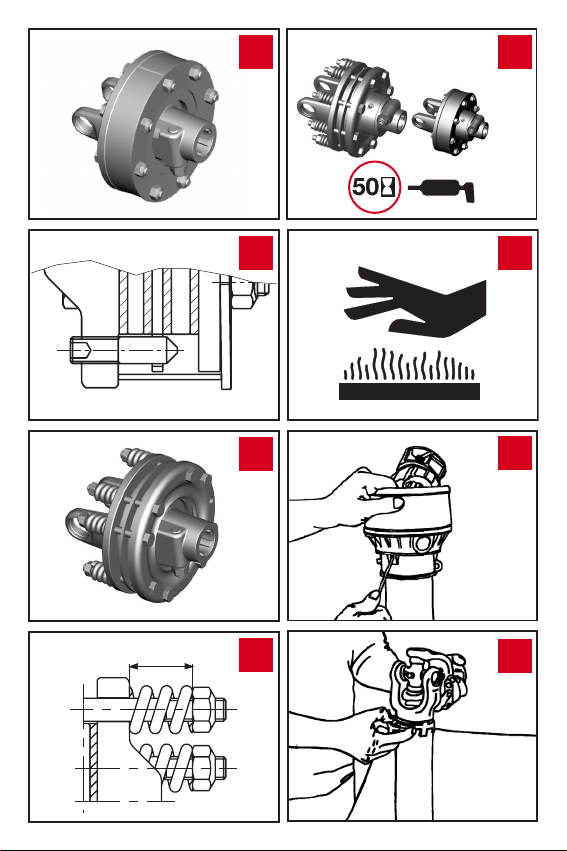

1

ROTATING DRIVE SHAFT

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT-

ALL DRIVELINE GUARDS, TRACTOR

AND EQUIPMENT SHIELDS IN PLACE

DRIVE SHAFT SECURELY

ATTACHED AT BOTH ENDS

DRIVE SHAFT GUARDS THAT TURN

FREELY ON DRIVE SHAFT

READING OPERATOR’S MANUAL

DO NOT USE PTO ADAPTORS

399141000

1

2

3

4

2 79

5 9

6 10

7 11

8 12

3

13 17

14 18

15 19

2016

4

21 25

22 26

23 27

24 28

5

29

33737

30

34

3531

32

6

36

38

42

39

40

41

8

43

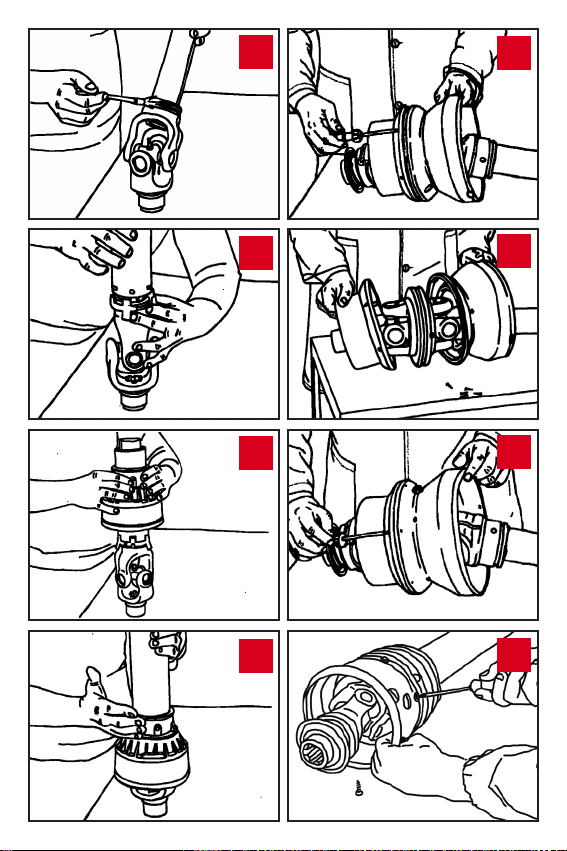

44

45

46

50

47

48

49

51

52

53

9

54

58

10

55

56

57

59

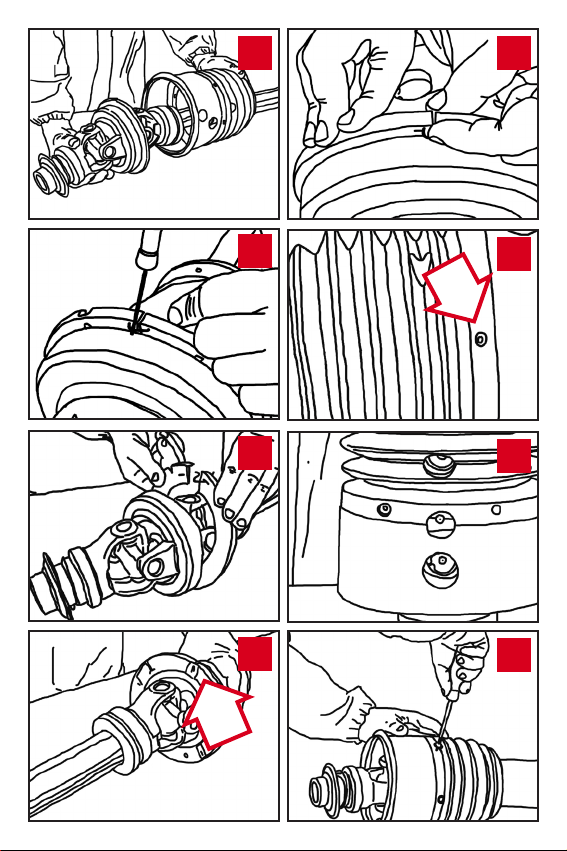

60

61

62

66

63

64

65

67

68

69

11

7470

12

71

72

73

75

76

77

78

81

02

HDPE

7

PA66

82

83

84

5

PP

13

79

80

07

O

04

LDPE

02

HDPE

7

PA66

5

PP

7

PA6

2

HDPE

ENG

ENGLISH

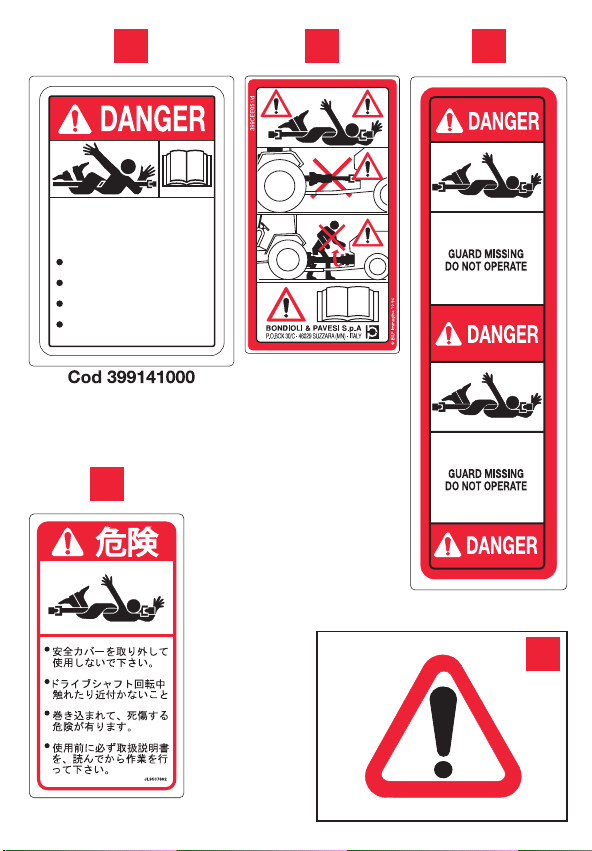

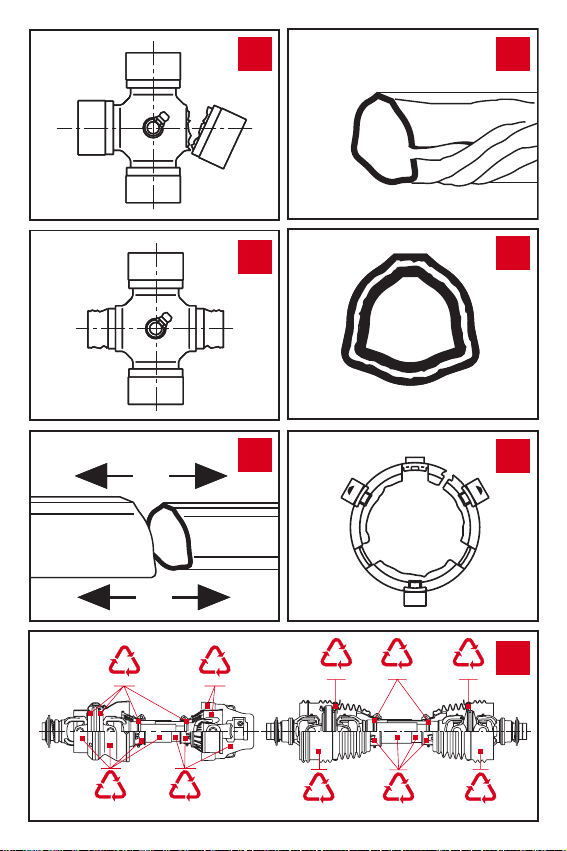

SAFETY LABELS

SHIELD TUBE LABEL Code 399141000

1

SHIELD TUBE LABEL Code 399JAP001

The operator must obey all labels and must maintain the proper shielding. A large

percentage of accidents caused by PTO drive shafts occur when the shielding is

not present or is not functioning correctly.

For export reasons it may be displayed together with label 399CEE051 but this is

not necessary for the purpose of obtaining .

SHIELD TUBE LABEL Code 399CEE051

2

Rotating driveline – contact can cause death. Keep away. Do not wear loose

clothing, jewelry, or hair that could become entangled with the driveline.

Do not operate without all driveline, tractor and implement shields in place.

Damaged or missing parts must be replaced and installed correctly before using

the driveline. Disconnect PTO clutch, shut off tractor engine, and remove key

before approaching the implement. Keep all bystanders away from the implement

while in operation. Read this manual, and the operator’s manual for the implement,

before using the machine.

YOUR SAFETY DEPENDS UPON THIS INFORMATION.

DRIVE TUBE LABEL Code 399143000 - DANGER!

3

Keep clear of the work area and rotating parts.

Do not wear loose clothing, jewelry, or hair that could become entangled with the

driveline.

Contact with rotating parts can cause serious injury or death.

GUARD MISSING, DO NOT OPERATE.

Do not operate without all driveline, tractor and implement shields in place.

Damaged or missing parts must be repaired or replaced before using the

driveline.

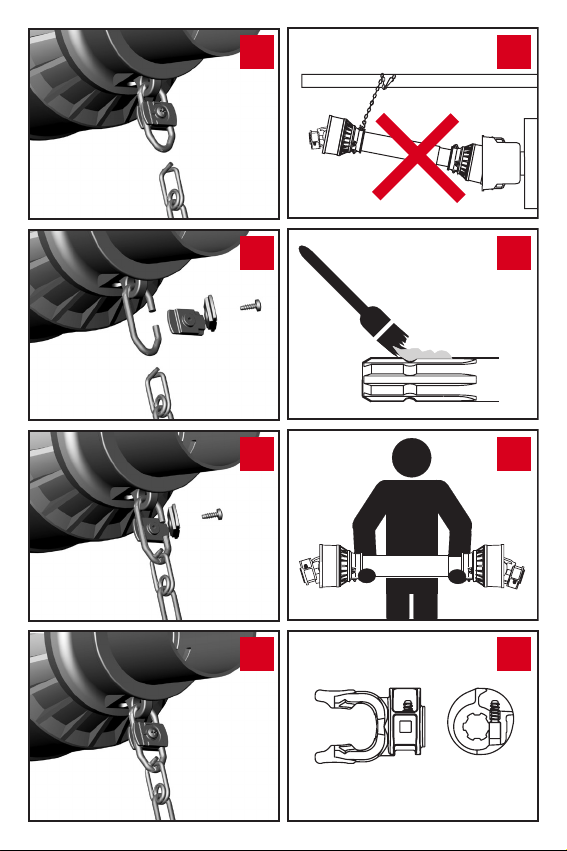

SAFETY AND WORKING CONDITIONS

When using the implement and the driveline, do not exceed the speed

4

or power limits specified in the operator’s manual. Do not overload the

implement or suddenly engage the PTO clutch. Any torque limiter or clutch must

be installed on the implement end of the driveline. Use the implement only with

the original driveline, which is fit for the purpose in terms of length, dimensions,

devices and shields.

The driveline and its torque limiter or overrunning clutch are designed specifically

for the implement, and should be used exclusively for this purpose. Check the

implement instruction handbook to ascertain whether the driveline must be

equipped with a torque limiting or overrunning clutch. Standard drivelines, torque

limiters and overrunning clutches are designed for speeds of up to 1000 min –1.

Ensure that the driveline can perform all operations without interfering with the

tractor or the machine. Contact with parts of the tractor, hooks, drive pins, tires,

drawbar, hammerstrap, or 3-point hitch, will damage the guard. Never use tractors,

(or systems for connection to the implement) that interfere with the driveline during operation. Do not use adapters or components not offered by the implement

manufacturer.

TRANSLATION OF THE

ORIGINAL INSTRUCTIONS

14

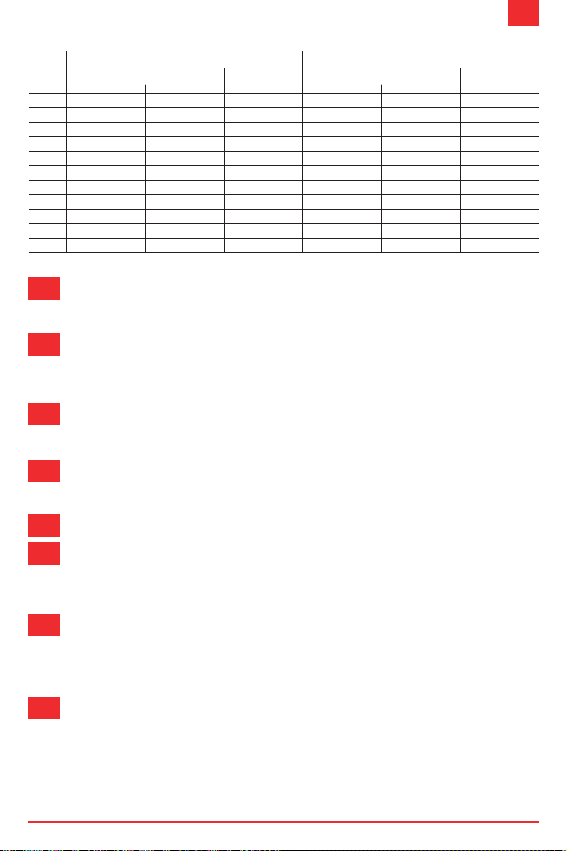

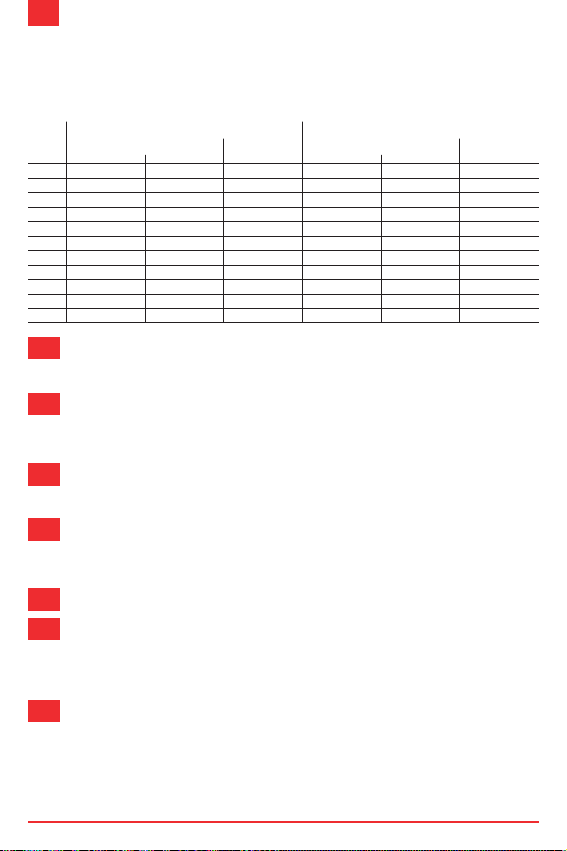

NOMINAL POWER Pn and NOMINAL TORQUE Mn

540 min

Pn Mn Pn Mn

kw CV-HP PS N•m kw CV-HP PS N•m

1 12 16 210 18 25 172

2 15 21 270 23 31 220

3 22 30 390 35 47 330

43 26 35 460 40 55 380

4 26 35 460 40 55 380

5 35 47 620 54 74 520

6 47 64 830 74 100 710

7 55 75 970 87 118 830

8 70 95 1240 110 150 1050

9 88 120 1560 140 190 1340

10 106 145 1890 170 230 1630

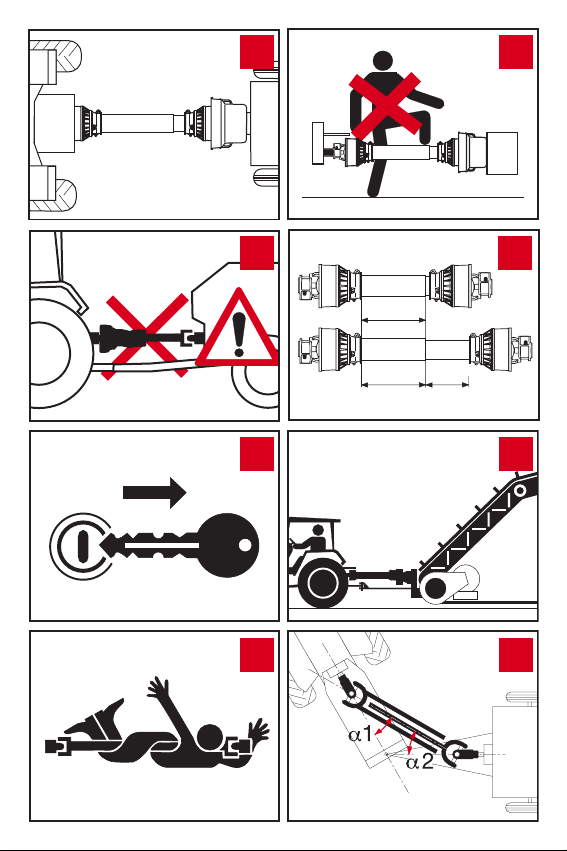

All rotating parts must be shielded.

5

The tractor master shield, the driveline guard, and the implement shield all

work together for your safety.

Do not operate without all driveline, tractor and implement shields in place.

6

Damaged or missing parts must be repaired with original spare parts or

replaced before using the driveline. The driveline must be securely attached at

both ends. Guards must turn freely on the driveline.

Disengage the PTO, turn off the tractor engine, remove the key and ensure

7

that all rotating parts have stopped before approaching the implement or

performing maintenance work.

Keep clear of the work area and rotating parts. Do not wear loose clothing,

8

jewelry, or hair that could become entangled with the driveline. Contact with

rotating parts can cause serious injury or death.

Do not stand on the driveline. Do not step over, or go under, the driveline.

9

Telescoping tubes must always overlap by at least 1/2 of their length in normal

10

operation and at least 1/3 of their length in all working conditions. During

maneuvers, when the driveline is not rotating, the telescoping tubes must have a

suitable overlap to maintain the tubes aligned and allow then to slide freely.

Use STATIONARY MACHINERY (pumps, elevators, generators, dryers, etc.)

11

only when hitched to the tractor.

Brake the tractor, placing blocks under the wheels if necessary. The tractor must

be hitched to the implement and positioned so that the angles of the joints are

minimal and equal.

CARDAN JOINTS

12

When operating, ensure that joint angles are small and equal: a1 = a2.

During turns or other short duration maneuvers, the maximum recommended joint

angle is 45°. Disengage the PTO if the angles are too large or not identical.

-1

1000 min

-1

ENG

15

ENG

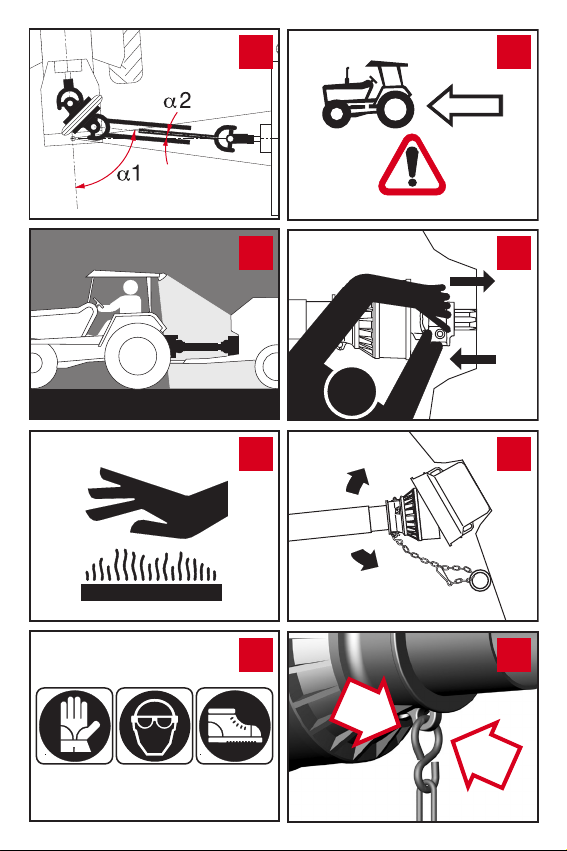

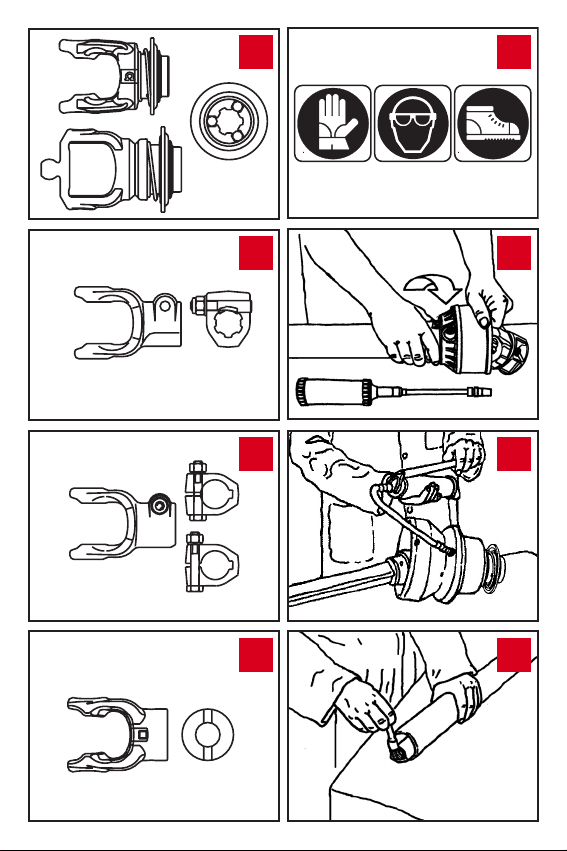

CONSTANT VELOCITY JOINTS

13

For normal operations, it is best to keep the CV joint aligned or with the

smallest joint angle possible. During turns or other short duration maneuvers, the

maximum joint angle is 50°, 70° (Constant Velocity Joint 652) or 80° according to

the design of the CV joint. When the driveline includes a CV joint on the tractor side

and a single U-joint on the implement side, the maximum recommended angles of

the U-joint are 16° at 540-1 and 9° at 1000

When used at night or in poor visibility, illuminate the driveline operating

14

area.

Friction clutches may become hot during use. Do not touch! Keep the area

15

around the friction clutch clear of any material which could cause a fire and

avoid prolonged slipping of the clutch.

INSTALLATION

Always wear adequate safety equipment when performing any maintenance

16

or repair work.

The tractor stamped on the shield indicates the tractor end of the driveline.

17

Any torque limiter or overrunning clutch should always be installed on the

implement end.

Ensure that the driveline is securely attached to the tractor and the implement

18

before operating.

Check that all fixing screws are tight.

Attach the driveline guard restraints (chains). Best results are achieved when

19

chains are attached nearly perpendicular to the driveline guard. Adjust the

length of the chains to allow enough slack for full movement of the driveline during

turns, operation, and transport. Avoid excessive slack, which could cause the

chains to roll around the driveline.

If the length of the chain is not adjusted correctly and tension is excessive,

20

for example during implement maneuvers, the “S” hook will detach from the

locking ring and the chain will disconnect from the shield.

In this case, the chain must be replaced.

The “S” hook of the new chain must be inserted in the eye of the base cone and

it must be closed to prevent it from becoming disengaged, maintaining its round

shape.

If the length of the chain with device for separation from the base cone is

21

not adjusted correctly and chain tension increases excessively, for example

during implement maneuvers, the spring hook will detach from the locking ring and

the chain will disconnect from the shield.

In this case, the chain is easily reconnected as described in the following procedure.

Open the retaining ring, unscrewing the screw and moving the plate.

22

Insert the chain in the locking ring and reposition the plate.

23

Close the plate by means of the screw.

24

-1

to avoid drive irregularities.

16

Never use the safety chains to transport or support the driveline when you

25

have finished using it for storage. Always use the support provided on the

implement.

Clean and grease the tractor PTO and implement shaft before installing the

26

driveline.

Keep the driveline horizontal during handling to prevent the halves from

27

sliding apart, which could cause injury or damage the shielding. Use suitable

means to transport heavy drivelines.

PUSH-PIN

28

Push the pin and slide the yoke onto the PTO shaft so that the pin engages

the groove on the PTO. Make sure that the pin returns to its initial position after

attachment to the shaft.

BALL COLLAR

29

Align the yoke on the PTO. Slide the collar to the open position. Slide the

yoke onto the splined shaft. Release the collar and pull or push the yoke along the

shaft until the balls engage the groove and the collar returns to its original (closed)

position. Make sure the collar returns to its initial (closed) position and the yoke is

properly attached to the shaft.

TAPER PIN

30

Slide the yoke onto the PTO and insert the pin so that the tapered profile fits

into the groove on the shaft.

Recommended tightening torque:

- 150 Nm (110 ft lbs) for 1 3/8” Z6 or Z21 spline.

- 220 Nm (160 ft lbs) for 1 3/4” Z6 or Z20 spline.

Use only Bondioli & Pavesi taper pins for replacements.

CLAMP BOLT

31

Slide the yoke onto the PTO and insert the bolt.

Recommended tightening torque: - 90 Nm (65 ft lbs) for M12 bolts;

- 140 Nm (100 ft lbs) for M14 bolts.

SHEAR PINS

32

Use only bolts of the size and class shown in the implement handbook.

Choose the bolt length in such a way as to minimize protrusion.

ENG

LUBRICATION

Always wear adequate safety equipment when performing any maintenance

33

or repair work.

LUBRICATION OF THE UNIVERSAL JOINT

34

Rotate the shielding until opening the access hole. Lubricate, and close the

hole by rotating the shielding.

LUBRICATION OF THE 650 CV JOINT

35

Rotate the shell to expose the grease fitting and inject grease.

LUBRICATION OF TELESCOPING TUBES

36

If grease fittings are not provided, separate the two halves of the driveline,

and manually lubricate the telescoping tubes.

17

ENG

Check that all components are in good condition and properly lubricated

37

before using the driveline. Clean and re-lubricate the driveline before storage

at the end of the season. Lubricate the parts according to the diagram; lubrication

intervals are in expressed in hours.

Lubricate the 650 type 70° CV joint every 8 hours. The lubrication interval for other

parts of the driveline is 50 hours.

Pump grease into the crosses until it purges from the bearing caps.

Inject the grease gradually and avoid pumping the grease gun violently with

resulting high delivery pressure.

Use NLGI grade 2 grease. Before storage at the end of the season remove any

grease that has accumulated inside the CV joint shield.

Replace worn or damaged parts with genuine Bondioli & Pavesi spare parts.

38

Do not modify or tamper with any part of the driveline. For any operations not

explained in this instruction manual, consult your implement dealer or manufacturer,

or your local Bondioli & Pavesi representative.

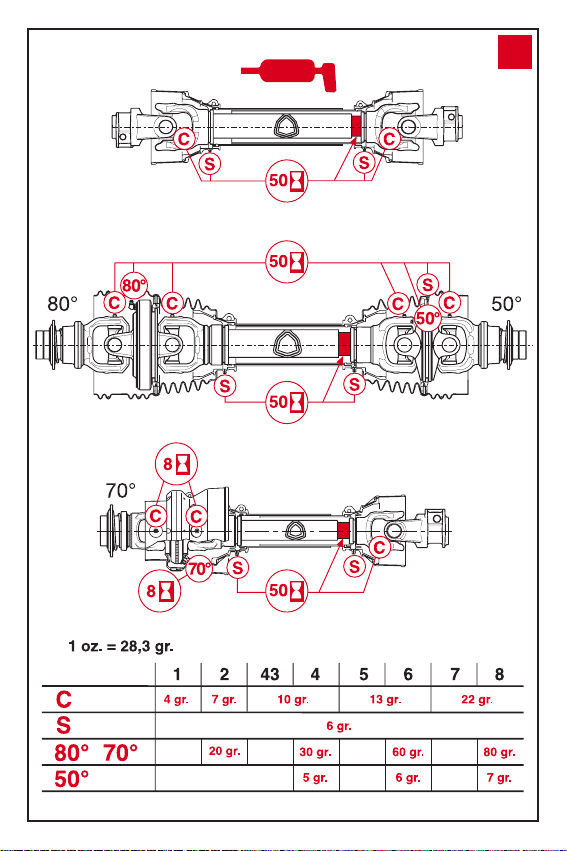

TORQUE LIMITER AND OVERRUNNING CLUTCH

RA - OVERRUNNING CLUTCH.

39

This device prevents transmission of inertial loads from implement to the

tractor during deceleration or stopping of the PTO.

Keep clear of the implement until all parts have stopped moving. Lubricate

every 50 hours of use and after storage.

SA - LN RATCHET TORQUE LIMITER.

40

This device interrupts the transmission of power when the torque exceeds

the setting.

Immediately disengage the PTO when ratcheting sounds are heard.

Lubricate every 50 hours of use and after storage.

LB – SHEAR BOLT TORQUE LIMITER.

41

This device interrupts the transmission of power by shearing a bolt when the

torque exceeds the setting.

Replace the sheared bolt with the same diameter, length and grade as the original.

Lubricate the LB limiters with grease fittings at least once every season and after a

period of disuse.

LR – AUTOMATIC TORQUE LIMITER.

42

This device interrupts the transmission of power when the torque exceeds

the setting.

To automatically re-engage the device, slow down or stop the PTO.

This device is sealed - no additional lubrication is required.

GE – SHOCK ABSORBING CLUTCH

43

Absorbs shock loads and vibrations, and smoothes transmission of an

alternating or pulsating load.

No maintenance is required.

18

FRICTION TORQUE LIMITERS

When installing the device or after a storage period check the operation of the

friction plates:

• release the springs • rotate the clutch while immobilizing the PTO on which is

installed • restore the spring compression to the original value. Following seasonal

use, release the springs and store the clutch in a dry place. Check the condition

of the friction plates and restore spring compression before using the clutch. If the

clutch overheats due to frequent or prolonged slipping, consult your equipment

dealer or your local Bondioli & Pavesi representative.

FV – FRICTION TORQUE LIMITER.

44

The torque transmitted to the implement is limited by allowing the clutch

plates to slip relative to each other.

Torque peaks or short duration overloads are limited when the clutch is used and

adjusted properly.

It can be used as an overload clutch, or to help start implements with high inertial

loads.

The torque setting is adjustable by adjusting the working height of the spring.

The edges of the linings and plates are exposed in an FV clutch.

The torque setting is adjusted by increasing or decreasing the height “h”

45

of the springs. To increase/decrease the torque setting tighten/loosen the

eight nuts by 1/4 of a turn and check for correct operation. Repeat the procedure if

necessary. Avoid excessive tightening of the bolts - implement, tractor, or driveline

damage may occur.

FT – FRICTION TORQUE LIMITER.

46

The torque transmitted to the implement is limited by allowing the clutch

plates to slip relative to each other.

Torque peaks or short duration overloads are limited when the clutch is used and

adjusted properly.

It can be used as an overload clutch, or to help start implements with high inertial

loads.

The FT has a metal band around its circumference.

The bolts should be tightened until the metal band around the circumference of

the clutch barely touches the spring. Avoid excessive tightening of the bolts implement, tractor, or driveline damage may occur.

Clutches supplied with the Spring Release System allow quick and easy

47

checking and maintenance of the clutch without disassembly and make it

possible to minimise spring pressure on the plates during periods of disuse.

Friction clutches equipped with the Spring Release System are supplied with

an additional instruction sheet. Read this information for proper use of the

Spring Release System.

FFV - FRICTION TORQUE LIMITER

48

Limits torque transmission to the setting value. Do not change spring

compression as this will modify the device setting.

FFV - FRICTION TORQUE LIMITER

49

The torque setting is adjusted by increasing or decreasing the height “h”

of the springs. To increase/decrease the torque setting tighten/loosen the eight

nuts by 1/4 of a turn and check for correct operation. Repeat the procedure if

necessary. Avoid excessive tightening of the bolts - implement, tractor, or driveline

damage may occur.

ENG

19

ENG

FNT - FNV - FFNV

50

COMBINATION FRICTION AND OVERRUNNING CLUTCH

Clutch that combines the functional characteristics of a friction clutch and an

overrunning clutch.

Used on machines with high inertial loads.

Keep clear of the implement until all parts have stopped moving.

Lubricate every 50 hours of use and after storage.

Friction clutches may become hot during use. Do not touch! To avoid the

51

risk of fire keep the area around the clutch free of inflammable material and

avoid prolonged slipping of the clutch.

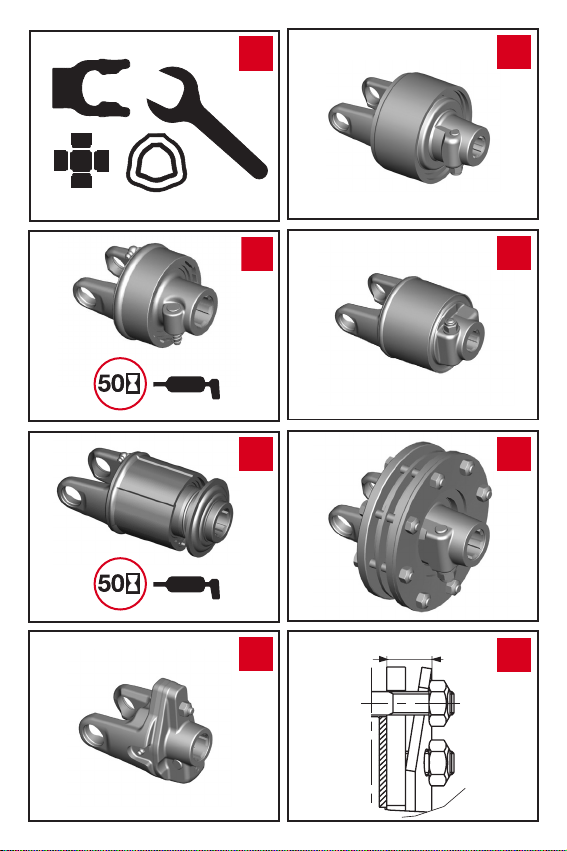

ASSEMBLY AND DISASSEMBLY OF THE SHIELD

DISASSEMBLY OF THE SHIELD

52

Press the cone downwards and disengage the tabs by exerting pressure

with a screwdriver.

Open the ring to completely disengage the shield tube.

53

ASSEMBLY OF THE SHIELD

54

Grease the bearing groove on the inner yokes.

Insert the shield tube, aligning the slots with the protrusions on the bearing.

55

Insert the cone. aligning the grease fitting with the bearing grease boss.

56

Engage the two parts with a forceful maneuver and apply pressure.

Check that the three tabs are perfectly engaged by tapping lightly.

57

DISASSEMBLY OF THE 650 CV JOINT SHIELD

Remove the half-shell fixing screws with a screwdriver.

58

Separate the half-shells and slide them off the joint.

59

Check the components and replace any worn parts.

ASSEMBLY OF THE 650 CV JOINT SHIELD

Lubricate the races on the joint central body.

60

Position the half-shells on the joint and fix them with the relative screws.

DISASSEMBLY OF CV JOINT SHIELD

Unscrew the shield cone screws.

61

Slide off the shield cone. For size 8, the CV shield cone is interlocked with the

62

base cone, must be disengaged before disassembly.

Disengage the retaining spring, leaving it inserted in one of the two holes of

63

the bearing ring to avoid losing it.

Spread apart the shield support rings and remove them from their grooves.

64

20

ASSEMBLY OF CV JOINT SHIELD

Grease the groove and fit the shield bearing ring.

65

Install the bearing ring on the CV body with the bosses facing the inner yoke.

The ring is equipped with a grease fitting, which is utilized only for 50° constant

velocity joints. Disregard the grease fitting of the bearing for 80° joint shields.

Connect the retaining spring to the two edges of the bearing ring.

66

Insert the shield cone, aligning the radial holes with the bearing ring

67

bosses.

Only for 50° constant velocity joints: check that the radial holes of the shield

68

cone are aligned with the holes in the bearing ring bosses and that the additional

hole in the shield cone is aligned with the grease fitting in the bearing ring.

Tighten the 6 flange head screws of the protection strip. Refit the fixing plate

69

for the chain. The use of an electric screwdriver is not recommended.

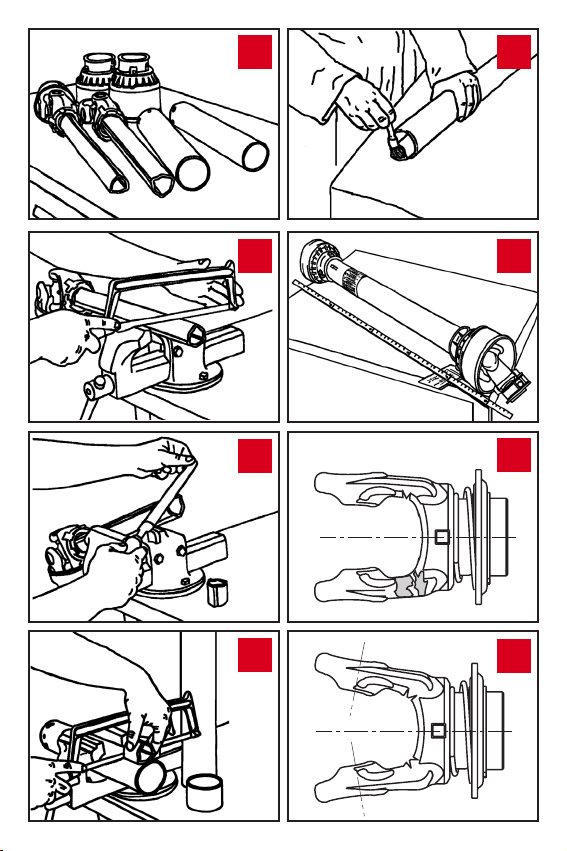

HOW TO SHORTEN THE DRIVE SHAFT

Bondioli & Pavesi advises against altering its products. If modifications are required,

we recommend that you consult your implement dealer or a qualified service center

before proceeding. If the driveline is too long adopt the following procedure.

Remove the shielding.

70

Shorten the drive tubes by the required length.

71

Telescoping tubes must always overlap by at least 1/2 of their length in normal

operation and at least 1/3 of their length in all working conditions.

During maneuvers, when the driveline is not rotating, the telescoping tubes must

have a suitable overlap to maintain the tubes aligned and allow then to slide freely.

Carefully deburr the ends of the tubes with a file and remove all filings from

72

the tubes.

Shorten shield tubes one at time by cutting the same length that was cut

73

from the drive tubes.

Grease the internal drive tube and reassemble the shielding on the

74

driveshaft.

Check the length of the driveshaft at its the minimum and maximum

75

extensions on the implement.

ENG

TROUBLESHOOTING

WEAR OF YOKE EARS

76

EXCESSIVE WORKING ANGLE

• Reduce the working angle.

• Disengage PTO when joint angle exceeds 45°.

21

ENG

DEFORMATION OF YOKES

77

EXCESSIVE TORQUE PEAK OR SHOCK LOAD

• Avoid overloading or engaging PTO when under load.

• Check the efficiency of the torque limiter.

BROKEN CROSS ARMS

78

EXCESSIVE TORQUE PEAKS OR SHOCK LOAD

• Avoid overloading or engaging PTO when under load.

• Check the efficiency of the torque limiter.

ACCELLERATED WEAR OF CROSS ARMS

79

EXCESSIVE LOAD

• Do not exceed the speed or power limits indicated in the instruction manual.

INSUFFICIENT LUBRICATION

• Follow instructions at point 37.

SEPARATION OF TELESCOPING TUBES

80

EXCESSIVE EXTENSION OF DRIVELINE

• Do not extend driveline to the point that the tubes separate.

• For stationary machinery, position the tractor so the telescoping tubes overlap

as illustrated in point 10.

TWISTING OR BENDING OF TELESCOPING TUBES

81

EXCESSIVE TORQUE PEAK OR SHOCK LOAD

• Avoid overloading or engaging PTO when under load

• Check the efficiency of the torque limiter.

• Check that driveline does not come into contact with tractor or implement

components during manoeuvres.

ACCELERATED WEAR OF TELESCOPING TUBES

82

INSUFFICIENT LUBRICATION

• Follow instructions from point 33 to point 37.

INSUFFICIENT TUBE OVERLAP

• Follow instructions at point 10.

ACCELERATED WEAR OF SHIELD BEARINGS

83

INSUFFICIENT LUBRICATION

• Follow instructions at point 37.

All the plastic parts of Bondioli & Pavesi drivelines are totally recyclable.

84

Protect the environment by disposing of used plastic parts properly at the

time of replacement.

22

TRADUCTION DES

FRANÇAIS

ÉTIQUETTES DE SÉCURITÉ

ÉTIQUETTE POUR TUBE PROTECTEUR Code 399141000

1

ÉTIQUETTE POUR TUBE PROTECTEUR Code 399JAP001

L’opérateur doit respecter les indications figurant sur les décalcomanies de

sécurité et doit maintenir le protecteur en bon état. Un grand nombre d’accidents

provoqués par les transmissions à cardan se produisent lorsque la protection n’est

pas montée ou n’est pas en bon état.

Pour cause d’exportation, elle peut appliquée avec l’étiquette de sécurité

399CEE051, mais elle n’est pas nécessaire pour l’homologation .

ÉTIQUETTE POUR TUBE PROTECTEUR Code 399CEE051 - Ne pas

2

s’approcher de la transmission à cardan lorsqu’elle est en service. Le

contact avec une pièce en rotation peut provoquer des accidents graves. Ne pas

porter de vêtements de travail ou ceintures avec pans flottants, des écharpes, etc.

Avant d’utiliser la machine, s’assurer que tous les protecteurs du tracteur et de

la machine aient été installés et qu’ils fonctionnent correctement. Remplacer les

composants détériorés ou manquants et les monter correctement avant d’utiliser

la transmission. Arrêter le moteur du tracteur et retirer la clé de contact avant toute

intervention de maintenance sur la machine. Lire attentivement le présent manuel

ainsi que le manuel de la machine avant de l’utiliser.

CES INDICATIONS CONCERNENT VOTRE SÉCURITÉ.

ÉTIQUETTE POUR TUBE TRANSMISSION Code 399143000 - DANGER!

3

Ne pas s’approcher de la zone de travail ou de composants en rotation.

Éviter de porter des vêtements de travail ou ceintures avec pans flottants, des

écharpes, etc…. Le contact avec une pièce en rotation peut provoquer des

accidents graves.

PROTECTION ABSENTE, NE PAS UTILISER.

Ne pas utiliser la transmission à cardan sans protecteurs. S’assurer que tous les

protecteurs sont bien en place et en bon état avant de se servir de la machine.

Les pièces ou parties manquantes ou détériorées doivent être réparées ou

remplacées avant d’utiliser la transmission à cardan.

SÉCURITÉ ET CONDITIONS D’UTILISATION

Lorsque la machine - donc la transmission à cardan est en service, ne pas

4

dépasser les limites de vitesse et de puissance indiquées dans le manuel

de la machine. Éviter les surcharges et les démarrages sous charge de la prise

de force. Utiliser le limiteur de couple et la roue libre sur le côté machine de la

transmission. N’utiliser la machine qu’avec une transmission à cardan Bondioli

& Pavesi présentant longueur, dimensions, dispositifs de sécurité et protecteurs

nécessaires. Utiliser la transmission à cardan, les limiteurs de couple et les roues

libres uniquement pour les fonctions auxquelles ils sont destinés.

Vérifier dans le livret d’instructions de la machine si la transmission à cardan

doit être équipée d’un limiteur de couple ou d’une roue libre. L’utilisation des

transmissions à cardan, des limiteurs de couples et des roues libres figurant au

catalogue est prévue pour une vitesse ne dépassant pas 1000 min-1.

Vérifier que la transmission à cardan puisse accomplir tous les mouvements

d’articulation sans interférence avec le tracteur ou avec la machine attelée.

Le contact avec les parties du tracteur, les crochets ou chapes d’attelage, les

INSTRUCTIONS D’ORIGINE

F

23

F

attelages 3-points endommage la protection de la transmission à cardan. Ne pas

utiliser de tracteurs ou de systèmes de liaison à la machine qui interfèrent avec la

transmission à cardan pendant son mouvement. Ne pas utiliser d’adaptateurs ou

de composants non prévus par le constructeur de la machine.

PUISSANCE NOMINALE Pn et COUPLE NOMINAL Mn

540 min

Pn Mn Pn Mn

kw CV-HP PS N•m kw CV-HP PS N•m

1 12 16 210 18 25 172

2 15 21 270 23 31 220

3 22 30 390 35 47 330

43 26 35 460 40 55 380

4 26 35 460 40 55 380

5 35 47 620 54 74 520

6 47 64 830 74 100 710

7 55 75 970 87 118 830

8 70 95 1240 110 150 1050

9 88 120 1560 140 190 1340

10 106 145 1890 170 230 1630

Toutes les pièces en rotation doivent être protégées.

5

Les protections du tracteur et de la machine doivent former un système

intégré avec le protecteur de la transmission à cardan.

Avant d’utiliser la machine, s’assurer que tous les protecteurs du tracteur

6

et de la machine sont en place et efficaces. Remplacer les composants

détériorés ou manquants par des pièces d’origine Bondioli & Pavesi et les monter

correctement avant d’utiliser la transmission.

Arrêter le moteur du tracteur, retirer la clé de contact et s’assurer que toutes

7

les pièces ou parties en rotation sont arrêtées avant toute intervention de

maintenance sur la machine.

Ne pas s’approcher de la zone de travail ou de composants en rotation.

8

Éviter de porter des vêtements de travail ou ceintures avec pans flottants, des

écharpes, etc. Le contact avec une pièce en rotation peut provoquer des accidents

graves.

Ne pas utiliser la transmission comme barre d’appui ou marchepied.

9

ll faut toujours conserver un recouvrement des tubes télescopiques d’au

10

moins la moitié de leur longueur en conditions normales de travail et d’au

moins un tiers de leur longueur en toutes conditions de travail.

Et même lorsque la transmission n’est pas en rotation, il faut conserver un

recouvrement suffisant pour éviter tout point dur.

Utiliser les MACHINES EN POSTE FIXE (pompes, élévateurs, générateurs,

11

séchoirs, etc.) uniquement si elles sont attelées au tracteur.

Immobiliser le tracteur, avec des cales de roues si nécessaire. Le tracteur doit avoir

la machine attelée et doit être placé de manière que les angles des joints soient

limités et identiques entre eux.

-1

1000 min

-1

24

Loading...

Loading...