Bond PBB 2 x 2, PBB 4 x 4 Adjusting Instructions And Illustrated Parts List

ADJUSTING INSTRUCTIONS AND

ILLUSTRATED PARTS LIST

Introducing our latest creation...

All New Model PBB Portable Bobbinless Binder!

PBB 2 x 2 & 4 x 4 MODELS

4511 WAYNE AVE PHILADELPHIA PA 19144

TOLL FREE PHONE 888-800-BOND (2663)

TOLL FREE FAX 800-582-9643

LOCAL PHONE 215-842-0200

EMAIL: sales@bondproducts.com

WEB: www.bondproducts.com

BOND

PRODUCTS INC

LOCAL FAX 215-844-7175

Rev. August 2018

WELCOME...

..........to Carpet Binding 101. The bond team has been serving the carpet trade

for 61 years. This is your one-stop source for everything you need to finish and

bind carpet. In addition, we have many specialty products that are custom

designed to meet the needs of carpet mechanics, workrooms and Do-It-Yourself

customers.

Ou

r experienced staff will assist you in selecting the right products for your job:

Cutting and binding machines, carpet binding tapes in a wide variety of styles

and colors, and serging tape for use with our binding machines. Also, carving

machines for sculpted area rugs, sundry tools and products necessary for

completion of your tasks.

k to Bond for all your carpet-related needs!

Loo

Carpet Bind ing 101

troducing

In

BOND’S PORTABLE BOBBINLESS CARPET BINDER

PBB-4x4 and PBB-2x2

This instruction manual has been prepared and written to guide you in the usage of your PORTABLE

BOBBINLESS BINDER. In order to obtain maximum efficiency from this machine, we urge you to

read this entire manual thoroughly before using the machine for the first time.

Although this machine has been carefully assembled, inspected and tested, should it ever need factory

service, we recommend it be shipped in its original carton. If the original carton is no longer available,

you may use a sturdy carton with ample room to allow packing material (i.e. foam, carpeting, etc.) to

surround the entire machine, (especially the bottom) to prevent it from shifting inside while in transit.

Send or address all inquiries or returns to:

Service Manager

BOND PRODUCTS INC

4511 Wayne Avenue

Philadelphia PA 19144- 3639 USA

Call Toll Free (888-800-2663) or

Fax Toll Free (800-582-9643)

When ordering replacement parts or supplies identify the model and serial number of the machine. We

recommend shipping the machine for repairs via UPS, FedEx, or Parcel Post. Be sure to insure its value

in case of damage during transit.

BOND MANAGEMENT

Limited 90 Day Warranty

Bond Products, Inc. makes every effort to assure that its products meet high quality and durability standards and warrants, to the original

purchaser, that this product is free from defects in materials and workmanship for a period of 90 days from date of purchase. This warranty

does not apply to damage due, directly or indirectly, to misuse, abuse, negl igence, repairs or alterations outside our facilities, or lack of

maintenance.

We shall in no event be liable for death or injuries to persons or property, or for incidental, contingent, special, or consequential damages

arising from the use of our products. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

To take advantage of this warranty, the product or part must be returned to us with transportation charges prepaid. Proof of purchase and

an explanation of the complaint must accompany the merchandise. If our inspection verifies the defect, we will eith er repair or replace the

product at our election, or we may elect to refund the purchase price if we cannot readily and quickly provide you with a replacement. The

repaired product will be returned to you via the most economical route, and you will be charged for the cost of transportation.

This warranty gives you specific legal rights. You may also have other rights which var y from state to state.

WARNING

PERSONAL INJURY MAY RESULT IF THE

FOLLOWING SAFETY PRECAUTIONS ARE

NOT OBSERVED.

1. BE SURE THE AREA SURROUNDING MACHINE

IS FREE OF ALL HAZARDS SUCH AS FIRE, WATER,

OIL, RUBBISH OR ANYTHING THAT CAN CAUSE

INJURY.

2. DO NOT OPERATE MACHINE IN AN EXPLOSIVE

AREA OR UNDER WET CONDITIONS. THE MACHINE

IS NOT AN EXPLOSION PROOF TYPE, NOR WATERPROOF TYPE.

3. DO NOT OPERATE MACHINE BEFORE READING

INSTRUCTION MANUAL.

4. DO NOT OPERATE MACHINE ON VOLTAGES

OTHER THAN SPECIFIED FOR THE MACHINE.

5. BE SURE MACHINE IS CO NN ECTED TO

BUILDING ELECTRICAL SAFETY GROUND (EARTH).

6. BE SURE POWER (AND AIR SUPPLY) IS OFF

BEFORE PERFORMING MACHINE MAINTENANCE,

PARTS REPLACEMENT, ADJUSTMENTS OR

CLEANING.

Identifying and Ordering Parts

Where the construction permits, each part is

stamped with its part number. On all orders,

please include part number, part name and

model name of machine.

(SAMPLE: PBB203081 Looper)

Safety Rules

To prevent personal injury:

• All power sources to the machine must be

turned off before threading, oiling, adjusting

or replacing parts.

• All cover and guards must be in position

before operating machine.

• Do not tamper with safety cover, guards,

etc., while machine is in operation.

Cautions When Using the Machine

Safety Precautions

1) Always turn power off before threading,

oiling, and adjusting the machine or

replacing parts.

2) Wear safety glasses.

7. DO NOT OPERATE MACHINE WITH GUARDS

AND COVERS REMOVED.

8. DO NOT TOUCH KNIFE, NEEDLE, PULLEY, BELT

AND MOVING PARTS WHEN MACHINE IS IN

OPERATION.

9. BE SURE MACHINE IS PLACED ON A SMOOTH

(LEVEL) SURFACE WHEN PERFORMING

MAINTENANCE, PARTS REPLACEMENT,

ADJUSTMENTS, CLEANING OR STORAGE.

10. BE SURE THE MATERIAL TO BE SEWN OR

CLOSED COMPLIES WITH THE MACHINE

SPECIFICATIONS.

11. DO NOT USE SPARE PARTS OTHER THAN

“BOND” GENUINE PARTS.

3) Make sure before starting the machine that

all covers and shields are in place and

closed.

Maintenance

• Please keep in mind to handle the machine

carefully and to maintain the machine in

good condition.

• Thread fuzz or dust must be cleaned with air

or brush on throat plate, in the groove of

feed dog or around looper after the day’s

work.

• Wipe the area easy to rust with oil cloth.

• Check the machine for loose screws and

tighten them, if any, once a month.

• Good maintenance will prolong the machine

life.

i.

CONTENTS

___________________________________________________________________

1. SPECIFICATIONS.......................................................................................... 1

2. THE POINTS BEFORE OPERATION..................... ................... .. .................. 1

3. THREADING.............. ................... .................................................................. 4

4. OILING............................................................................................................ 5

5. OPERATION................................................................................................... 5

6. ADJUSTING................................................................................................... 6

6-1 Needle and Looper....................................................................................................... 6

6-2 Needle Height............................................................................................................... 6

6-3 Gap between Looper and Needle................................................................................. 7

6-4 Feed Dog Height.......................................................................................................... 7

6-5 Needle Guard Adjustment............................................................................................ 8

PARTS LIST......................................................................................................... 9

NUMERICAL INDEX OF PARTS....................... ................... ................... ..........21, 22

DIAGRAM OF SCREW, NUT & WASHER..... ..................................................... 23

PARTS ASSEMBLIES DIAGRAMS...................................................................24-44

Frame 1- Puller Assembly............................................................................................ 24

Frame 2- Puller Wheel Assembly.............................. ..... ...... .......... .............................. 25

Frame 3- PBB 2x2 Clutch Assembly........................................................................... 26

Frame 4- PBB 4x4 Puller Assembly............................................................................ 27

Frame 5- PBB 4x4 Clutch Assembly............................................................................ 28

Frame 6- PBB 4x4 Rear Puller Assembly.................................................................... 29

Frame 7- Puller Lifting Lever Assembly....................................................................... 30

Frame 8- PBB 4x4 Back Puller Lower Assembly......................................................... 31

Frame 9- Caster Brackets Assembly............................................................................ 32

Frame 10- Thread Bracket Assembly............................................................................ 33

Frame 11- Handle Bracket Assembly............................................................................ 34

Frame 12- Caster Brackets Assembly........................................................................... 35

Frame 13- Belt Cover Assembly.................................................................................... 36

Frame 14- Handle Assembly.......................................................................................... 37

Frame 15- Handle & Thread Base Support Bracket Assembly...................................... 38

Frame 16- Binding Bracket Assembly............................................................................ 39

Frame 17- Assorted Threads for Needle & Looper......................................................... 40

Frame 18- Assorted Tools & Accessories.......................................................................41

Frame 19- Cove Base Binding Guide Assembly.............................................................42

Frame 20- Assorted Tape Folders & Bracket Assemblies...............................................43

Frame 21- Light Assembly...............................................................................................44

___________________________________________________________________

ii.

1. SPECIFICATIONS

BOND PRODUCTS INC

4511 WAYNE AVENUE

PHILADELPHIA PA 19144-3639

TOLL FREE PHONE 888-800-BOND (2663)

TOLL FREE FAX 800-582-9643

LOCAL PHONE 215-842-0200

LOCAL FAX 215-844-7175

EMAIL: sales@bondproducts.com

WEB: www.bondproducts.com

Stitch type.......................................................double thread chain stitch

Stitch length................................................... 8.5mm / 21/64 inches or

Speed.............................................................. up to 30 feet per minute

Needle............................................................ UY143GS / DNX1-25/080

Threads: .........................................................Needle = #75 Mono/clear H.D.

Drive motor....................................................110/125, 220/230/240V (AC)

2. THE POINTS BEFORE OPERATION

• Oil the area through which thread passes, the tension disc, the thread guide, looper, etc.

(Note: An anticorrosive agent is applied to the machines at the factory, in order to prevent rusting. It

is necessary to use oil to remove this agent or it may prevent the thread from passing smoothly.)

3 stitches per inch

adjustable variable speed

Looper = #69 Bonded Nylon; #138 Bonded Nylon

12/24V (DC) 50/60Hz, Single phase

• Confirm that the machine has been threaded as per the instructions 3. in the manual.

• Confirm that the machine has been lubricated as per the instructions 4. in the manual.

- 1 -

3. NEEDLE & LOOPER THREADING

- 2 -

NEEDLE THREADING

To simplify the threading of the needle, just tie off

both thread ends with a knot, continue pulling the

thread through all the guides. Cut off the knot and

continue threading through the needle eye. Leave a

six inch plus tail beyond the needle eye, or...

1. Remove the dome from the old thread canister by

twisting it counter-clockwise (Fig. 1A)

2. Turn the black knob on the top of the canister

counter-clockwise.

3. Replace the empty canister with the new canister

by aligning the threaded rod through the center

holes of the canister.

4. Screw the black knob clockwise to the threaded

rod. Tighten knob snuggly.

5. Install the clear dome over the canister making

sure that the thread is clear and won’t get pinched

as yo u twist the clear dome clockwise onto the

canister base. (Fig. 1B)

6. Pull the thread from the top of the dome and

follow the thread eyelets threading sequence: 1

through 6. (Fig. 1C)

- 3 -

LOOPER THREADING

To simplify the threading of the looper, just tie off

both thread ends with a knot, and then continue

pulling the thread through the thread rod eye and

the tensioner. Continue pulling the thread end

through all eyelets and through both looper eyes.

Leave a six inch tail past the looper, or...

1. Remove the black knob from the empty spool by

twisting it counter-clockwise.

2. Replace the empty spool with the new spool.

(Fig. 1B)

3. Screw the black knob clockwise to the threaded

rod, tighten knob snuggly.

4. Put thread end through the eye of the thread rod

above the spool. (Fig. 1A)

5. Continue threading through the thread tensioner,

then through the eyelet below it.

6. Remove the tape guide bracket by loosening the

two allen screws with the 5/32 allen wrench two

full turns only. (Fig. 1D)

7. Lift up on the folder bracket and set it aside. Put

the thread through the front casting eyelet and

through the take up eyelet, then through the

looper eyes.

8. Leave a 6 inch tail past the looper.

9. Replace the tape folder bracket and tighten

screws snuggly.

You are now ready to bind.

- 4 -

4. OILING

Oiling of all moving parts is imperative before each operation of this machine. The oiling points are

marked in red, spray lube the looper area after blowing off debris from the looper chamber. Use Bond spray

lube, stock# 21325.

5. OPERATION

1. Hold the machine at the handle with your right hand.

2. Support the carpet with your left hand.

3. To start binding the carpet, align one corner of the carpet into the tape folder guide mouth, pull the

trigger switch and slowly feed the carpet through the folder mouth. Let the machine move towards you

without helping it pull through the carpet.

4. When you get to the other end of the carpet, continue binding on the tape until the carpet has passed the

rear feed rollers/pullers. Cut off the tape ½” past the corner.

5. Continue binding the next side of the carpet.

6. Let the machine pull itself. If you pull the machine faster than its speed, the binder will mis-stitch or

break the needle.

7. This machine has variable speed trigger switch. For more speed, squeeze the switch more; for slower

speed, squeeze less. Turn and adjust speed control knob located at the trigger switch until the desired

speed is found.

- 5 –

6. ADJUSTMENT

The machine has been properly adjusted before shipment fro m

the factory. But if it needs re-adjustment for repair or

replacement parts, proceed as follows; When adjusting, make

sure that the electric wiring plug is removed from the consent.

6-1 Ne

Check the distance between needle center and looper edge.

Turn the pulley by hand unt il the looper reaches its r ight

furthest position, while keeping the clearance of 5mm between

needle center and looper edge.

edle and Looper

6-2 Ne

When the looper moves left and right t o turn pulle y by hand,

the looper and the needle shall be adjusted in such a way that

the bottom of both holes will be entirely corresponded as

shown in Fig. 3.

edle Height

1) Che

2) Mak

ck to make sure the needle is set in the needle bar

as deep as it will go by loosening the needle bar

clamping nut.

e sure of setting a needle with its concave part

facing correctly toward the looper when the needle is

just going up from the lowest po sitio n.

nfirm whether or not the distance between centers

1) Co

of ball joint (A) is being kept 87mm. Also pay

special attention to the strict distance of 87mm, and if

not, it will prevent you to adjust every part correctly.

2) Tur

Make sure that the nuts (b) has left-handed thread.

n the pulley again by hand until looper reaches its

left furthest position, while keeping the clearance of

5mm between needle center and looper edge to loose

nuts (a) and (b) of joint rod (B). Fig. 2

In case the distance between centers is more than

5mm, turn joint rod (B) to “S” direction to decrease

it.

In case the distance between centers is less than

5mm, turn joint rod (B) to “L” direction to increase

it. Fig. 2

3) Should it be necessary to change needle height, first

remove the upper face plate.

raise the needle bar....

To

Loosen the screw (a), lower the needle bar

connectio n to obtain proper distance required and

tighten it. Then, loosen the screw (b), raise the

needle bar until the needle bar connection touches the

needle bar connecting st ud and tighten it.

To lower the needle bar....

Loosen the screw (b), lower the needle bar to obtain

proper di s tance require d and tighten it. Then, loosen

the screw (a), fix the needle bar connection at the

place where it touches the needle bar connecting stud

and tighten it.

heck once again if the direction of concave part of

4) C

needle is correct or not.

- 6 -

6-3 Gap between Looper and Needle

Turn pulley by hand and fix eccentric cam so that

the screw (a) may be horizontal position as shown

in Fig. 5, while the looper is passing behind needle

and the sharp point of looper is corresponded with

needle center.

Afterwards, adjust the gap to be 0.05-0.1mm

between looper and needle to confirm they do not

clash with each other when the sharp point of looper

is passing behind needle.

The adjustment of the gap shall be done by

loosening screw (b) of looper oscillating arm.

6-4 Feed Dog Height (Fig. 7)

Adjust the height of feed dog to loosen screw (a) in

order to obtain the most appropriate protrusion of

1.0- 1.2mm above the upper surface of throat plate

after regulating the screw (b).

- 7 -

6-5 Needle Guard Adjustment

Adjust the clearance between needle guard and

needle to zero when the needle is just coming up

from its lowest position as shown in Fig. 8 and

tighten the screw (a).

PBB 4 x 4 only

When binding oval or round shaped carpets, please

disengage the rear upper puller.

[NOTES ON CARRYING AND STORAGE]

1. Carry the machine in a storage box.

2. After using of the machine, unplug,

clean the dirt, oil all parts and then put it into a

storage box. We suggest you to use a soft brush

to clean the machine.

- 8 –

ORDERING PARTS

1. Description of each part and its stamp number is described in this parts list. Screws and nuts for parts are

shown adjacent to the relevant parts. When ordering parts, describe clearly stamp number with its name of

part.

2. The parts which have no Ref. Number can not be delivered independently; always order it as an assembly.

3. A set of assembled parts is represented by the stamp number of its main parts.

4. The last figure on the parts stamp number advances on each improvement of the parts.

5. Parts No. described in [ ] of Remarks means old parts No.

* The parts list is subject to change without prior notice.

When ordering parts for this binder, always start with PBB then the part number(s).

Example: PBB2030 81, Loo per

PARTS LIST CONTENTS

(1) THREAD STAND AND THREAD TENSION PARTS............................................... 10

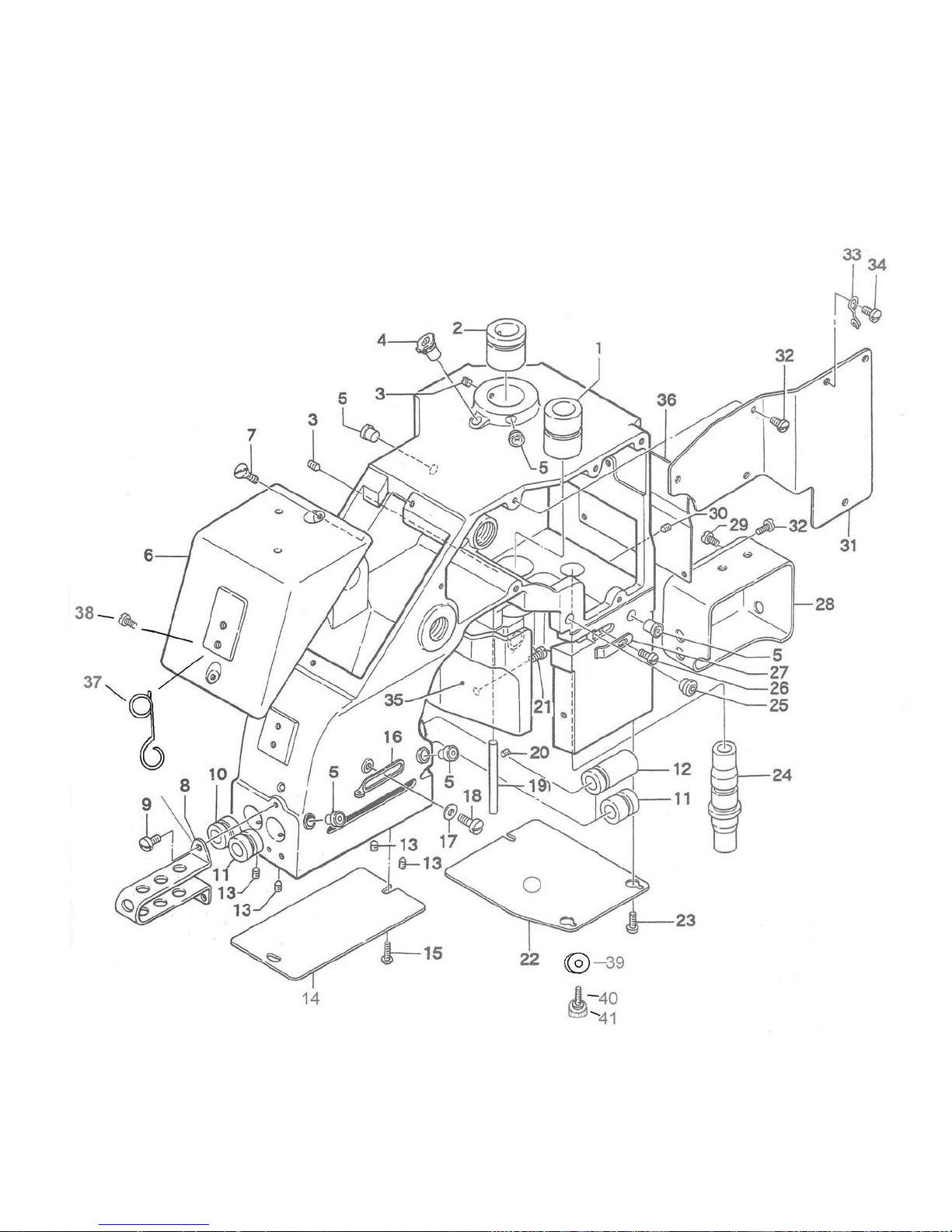

(2) COVERS, BUSHINGS AND OILING PARTS...........................................................11 – 12

(3) NEEDLE BAR, PRESSER BAR AND DRIVING PARTS..........................................13 – 14

(4) LOOPER DRIVING PARTS......................................................................................15 – 16

(5) FEED DRIVING AND THREAD CUTTER PARTS...................................................17 – 18

(6) MOTOR, SWITCH AND HANDLE PARTS

(FOR TOTALLY ENCLOSED TYPE MOTOR).........................................................19 – 20

- 9 –

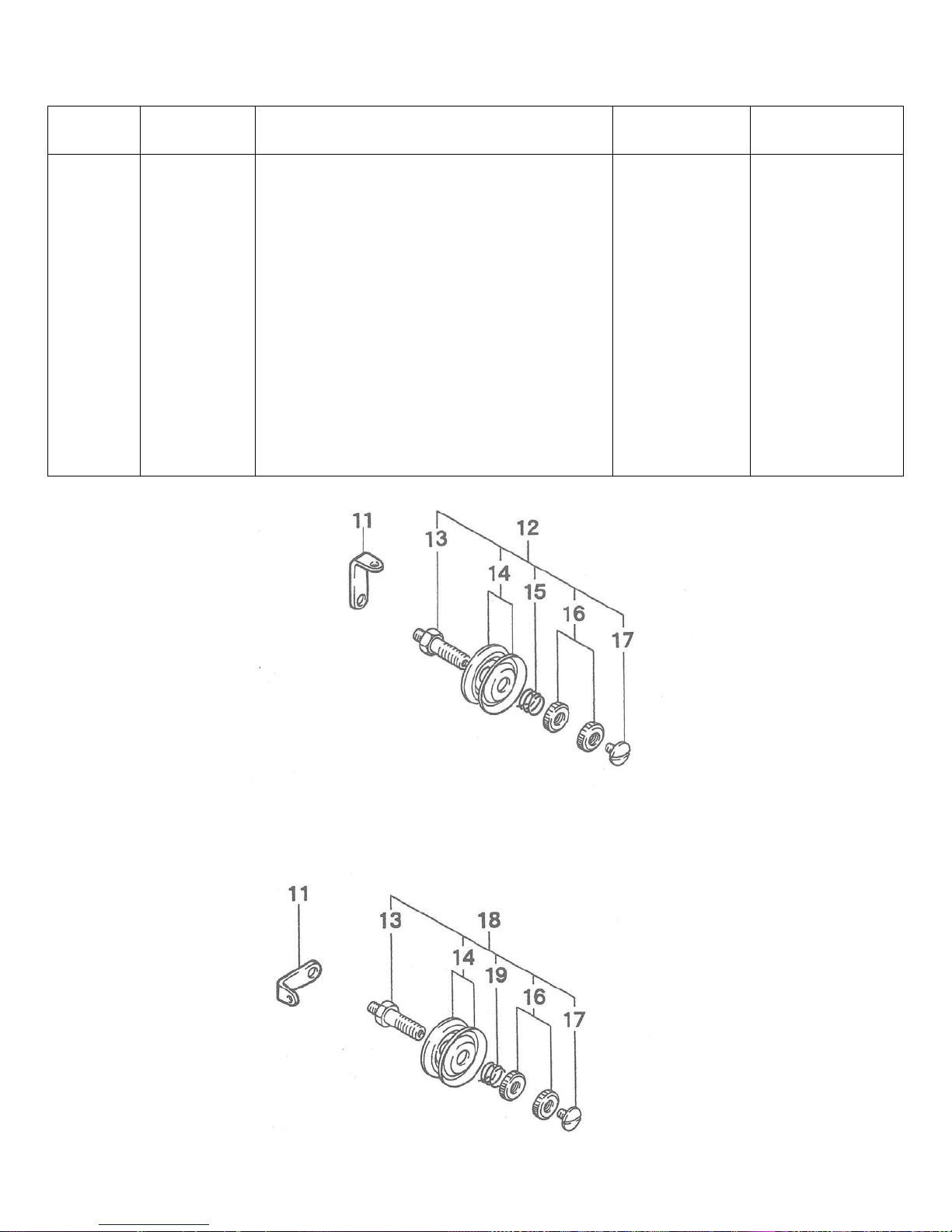

(1) THREAD STAND AND THREAD TENSION PARTS

11

245071

Thread Tension Eyelet

2

Ref. No. Part. No. Description Quantity Remarks

12

13

14

15

16

17

18

19

245081B

245081

065261

205091

245091

9/64S40011

245081A

245101

Thread Tension Assembly for Looper

Tension Post

Tension Disc

Tension Spring

Tension Nut

Screw for 245081

Thread Tension Assembly for Needle

Tension Spring

1

2

4

1

4

2

1

1

(13 – 17)

(13,14,16,17,19)

- 10 –

(2) COVERS, BUSHINGS AND OILING PARTS

- 11 –

Loading...

Loading...