Bombardier 462-532-582UL Repair Manual

Repair

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

Manual

for engine type

462 - 532 - 582 UL

Edition: 10 1994

Bombardier-Rotax GmbH

4623 GUNSKIRCHEN Telefon: (0)7246/271-0*

Welser Strasse 32 Telefax: (0)7246/370

recommended ATS 900,-price:

WITHOUT COMMITMENT TO ADVISE MODIFICATIONS.

FOR INFORMATION ONLY.

Part no: 899 081

Table of contents

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

1) Introduction:.................................................................................................................. 6

1.1) Engine number: .............................................................................................................................6

1.2) General notes: ...............................................................................................................................7

2) Technical data: .............................................................................................................8

2.1) Technical data ROTAX engine type 462 UL: ..............................................................................8

2.2) Technical data ROTAX engine type 532 UL: ............................................................................10

2.3) Technical data ROTAX engine type 582 UL: ............................................................................12

3) Tools and supplementary means: ........................................................................... 15

3.1) Standard tools: ............................................................................................................................15

3.2) Special service tools for the engine: ........................................................................................16

3.3) Special service tools and gasket set for reduction gearbox "A" and "B": ...........................19

3.4) Special service tools and gasket set for the reduction gearbox "C": ...................................20

3.5) Lubricating-, securing- and sealing agents: ............................................................................21

4) Powerplant in aircraft: ............................................................................................... 22

4.1) Removal of engine from the aircraft: ........................................................................................22

4.2) Re-installation of engine into aircraft: ......................................................................................22

5) Disassembly of engine:.............................................................................................23

5.1) Removal of reduction gearbox „A“: ..........................................................................................23

5.2) Removal of reduction gearbox „B“: ..........................................................................................24

5.3) Disassembly of reduction gearbox „C“:...................................................................................25

5.4) Removal of rewind starter:.........................................................................................................27

5.5) Dismantling of electric starter: ..................................................................................................27

5.6) Removal of exhaust manifold: ...................................................................................................28

5.7) Removal of ignition coils support plate and disassembly of rotary disk: ...........................28

5.7.1) Engine type 462 UL: .......................................................................................................28

5.7.2) Engine type 532 and 582 UL: .........................................................................................29

5.8) Disassembly of water pump: .....................................................................................................31

5.9) Disassembly of rotary valve shaft:............................................................................................31

5.10) Disassembly of BOSCH ignition unit:.......................................................................................32

5.11) Disassembly of DUCATI ignition unit: ......................................................................................33

5.12) Removal of cylinder head (type 462): .......................................................................................34

5.13) Removal of cylinder head (type 532 and 582): .........................................................................35

5.14) Disassembly of cylinders and pistons: ....................................................................................35

5.15) Disassembly of crankcase: ........................................................................................................37

6) Cleaning of engine components:............................................................................. 38

7) Inspection and judgement of components: ........................................................... 39

7.1) Crankcase: ...................................................................................................................................39

7.1.1) Measuring of crankcase:.................................................................................................39

7.2) Crankshaft:...................................................................................................................................41

7.2.1) Removal and inspection of crankshaft bearings:............................................................41

7.2.2) Checking of crankshaft alignment:..................................................................................42

7.2.3) Radial- and axial clearance of conrod: ...........................................................................43

7.3) Cylinder: .......................................................................................................................................45

7.3.1) Inspection of the cylinder: ...............................................................................................45

7.3.2) Cylinder bore:..................................................................................................................46

7.4) Piston: ..........................................................................................................................................47

7.4.1) Piston-to-wall clearance:.................................................................................................47

7.4.2) Piston rings: ....................................................................................................................48

7.4.3) Piston pin: .......................................................................................................................49

7.4.4) Piston pin bearing: ..........................................................................................................49

7.5) Cylinder head: .............................................................................................................................50

7.6) Thermostat:..................................................................................................................................50

- 2 - of 170

Rm. 462-532-582 UL10-1994

7.7) Rotary valve shaft: ......................................................................................................................51

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

7.7.1) Disassembly of rotary valve shaft: ..................................................................................51

7.7.2) Inspection of the single components: .............................................................................52

7.7.3) Sealing of rotary valve shaft: ..........................................................................................52

7.7.4) Reassembly of rotary valve shaft:...................................................................................53

7.8) Contact breaker ignition unit: ....................................................................................................54

7.8.1) BOSCH magneto generator SCP2 on ROTAX 462 UL and 532 UL: .............................54

7.8.2) Stator plate:.....................................................................................................................54

7.8.3) Wiring diagram: ...............................................................................................................55

7.8.4) Flywheel: .........................................................................................................................55

7.8.5) Ignition damping box:......................................................................................................56

7.8.6) Adjusting of ignition timing: .............................................................................................57

7.8.7) Pole shoe breakaway gap:..............................................................................................58

7.9) ROTAX 582 UL with breakerless DUCATI dual ignition unit (DCDI): .....................................59

7.9.1) Brief description: .............................................................................................................59

7.9.2) Operation of the ignition unit:..........................................................................................59

7.9.3) Ignition switches:.............................................................................................................59

7.9.4) Magneto flywheel: ...........................................................................................................60

7.9.5) Electronic box:.................................................................................................................60

7.9.6) Wiring diagram of electronic box: ...................................................................................61

7.9.7) Wiring diagram: ...............................................................................................................62

7.9.8) Stator repair kit:...............................................................................................................63

7.9.9) Trouble shooting: ............................................................................................................63

7.9.10) Fault-tracing schedule:....................................................................................................64

7.9.11) Resistance values of DUCATI ignition unit: ....................................................................64

7.9.12) Sundry data of DUCATI ignition system: ........................................................................64

7.10) Spark plugs:.................................................................................................................................65

7.11) Spark plug connector: ................................................................................................................67

7.12) Hydro-damper:.............................................................................................................................67

7.13) Rewind starter: ............................................................................................................................68

7.13.1) Disassembly of rewind starter:........................................................................................68

7.13.2) Reassembly of rewind starter: ........................................................................................69

7.14) Electric starter: ............................................................................................................................71

7.14.1) Pinion starter on P.T.O. side: ..........................................................................................71

7.14.2) Pinion starter on magneto side: ......................................................................................71

7.14.3) Check of electric starter: .................................................................................................72

7.15) Carburetor:...................................................................................................................................74

7.15.1) Attachment: .....................................................................................................................75

7.15.2) Fuel intake control:..........................................................................................................75

7.15.3) Main regulating system: ..................................................................................................76

7.15.4) Sectional view of Bing-double float carburetor: ..............................................................77

7.15.5) Idling system: ..................................................................................................................79

7.15.6) Starting aid (starting carburator): ....................................................................................80

7.15.7) Check list for carburetor: .................................................................................................80

7.16) Pneumatic synchronization of a 2-carb installation:...............................................................81

7.16.1) Mechanical synchronization: ...........................................................................................82

7.17) Matching of the carburetor to specific climatic conditions: ..................................................82

7.18) Rubber carburetor-adaptor: .......................................................................................................83

7.19) Air filter:........................................................................................................................................84

7.19.1) Application of new air filters: ...........................................................................................84

7.19.2) Cleaning of used air filters: .............................................................................................85

7.20) Intake silencer: ............................................................................................................................85

7.21) Fuel pressure testing:.................................................................................................................87

7.21.1) Fitting the fuel pressure tester: .......................................................................................87

7.21.2) Test procedure: ...............................................................................................................88

7.21.3) Fault finding:....................................................................................................................88

Rm. 462-532-582 UL 10-1994

- 3 - of 170

7.22) Cooling system of engine: .........................................................................................................91

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

7.22.1) Venting of the cylinder head: ..........................................................................................91

7.22.2) Operation of radiator cap and overflow bottle:................................................................92

7.22.3) Temperature of coolant: ..................................................................................................92

7.22.4) Checking of the single components: ...............................................................................93

7.22.5) Flowrate of coolant:.........................................................................................................93

7.22.6) Cooling circuit for engine installation with spark plugs up: .............................................94

7.22.7) Cooling circuit for engine installation with spark plugs down: ........................................95

7.23) Oil circuit for rotary valve- and water pump drive:..................................................................96

7.23.1) Oil circuit for engine installation with spark plugs “up”: ..................................................97

7.23.2) Oil circuit for engine installation with spark plugs “down":..............................................97

7.24) Oil pump for fresh oil engine lubrication (ROTAX 582 DCDI): ...............................................98

7.24.1) Description: .....................................................................................................................98

7.24.2) Technical data, characteristics: ......................................................................................98

7.24.3) Installation: ......................................................................................................................98

7.24.4) Disassembly of oil pump: ................................................................................................99

7.24.5) Adjustment on oil pump installation: .............................................................................100

7.24.6) Maintenance:.................................................................................................................100

7.24.7) Directions for installation: ..............................................................................................101

7.25) Exhaust system:........................................................................................................................102

7.25.1) Installation of the exhaust system:................................................................................103

7.25.2) After-muffler system: .....................................................................................................103

7.26) Propeller reduction gears type “A” and “B”: .........................................................................104

7.26.1) General information: .....................................................................................................104

7.26.2) Moment of inertia: .........................................................................................................104

7.26.3) Fitting position of powerplant: .......................................................................................105

7.26.4) Reduction gear type “A”: ...............................................................................................106

7.26.5) Reduction gear type “B”: ...............................................................................................107

7.26.6) Disassembly and judgement (reduction gears “A” and “B”): .......................................108

7.26.7) Reassembly of propeller reduction gear (type “A” and “B”): .........................................109

7.26.8) Determination of the proper preload setting of the springs (type “A” and “B”): ............110

7.26.9) Fitting of gear to engine (type “A” and “B”): ..................................................................111

7.27) Reduction gear type “C”: ............................................................................................................113

7.27.1) General information: .....................................................................................................113

7.27.2) Disassembly of gear cover:...........................................................................................113

7.27.3) Reassembly of gear cover: ...........................................................................................114

7.27.4) Inspection of gear housing and reassembly: ................................................................115

7.27.5) Adjusting axial clearance on reduction gear “C”: ..........................................................116

7.27.6) Assembly of reduction gear Type “C”: ..........................................................................117

7.28) General notes and maintenance of reduction gear:..............................................................119

8) Assembly of the engine: .......................................................................................... 120

8.1) Crankshaft:.................................................................................................................................120

8.2) Crankcase: .................................................................................................................................123

8.3) Assembly of the rotary valve shaft: ........................................................................................126

8.4) Assembly of the water pump: ..................................................................................................127

8.5) Fitting of the pistons:................................................................................................................127

8.5.1) Assembly of piston on Type 532 and 582 UL:..............................................................129

8.6) Re-assembly of the cylinders: .................................................................................................130

8.7) Assembly of the cylinder head: ...............................................................................................132

8.8) Fitting and setting of rotary valve: ..........................................................................................134

8.8.1) Rotary valve timing: ......................................................................................................135

8.7.2) Fitting of the rotary valve cover:....................................................................................135

- 4 - of 170

Rm. 462-532-582 UL10-1994

8.9) Installation of the ignition unit:................................................................................................136

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

8.9.1) Fitting of stator plate assembly on engines 462 UL and 532 UL:.................................136

8.9.2) Ignition timing: ...............................................................................................................136

8.9.3) Adjustment of ignition timing:........................................................................................136

8.9.4) Break-away gap: ...........................................................................................................136

8.9.5) Fitting of the stator plate assembly on Type 582 UL: ...................................................137

8.9.6) Adjustment of trigger gap:.............................................................................................138

8.9.7) Setting of the ignition timing..........................................................................................139

8.10) Fitting of the rewind starter: ....................................................................................................140

8.11) Fitting of the electric starter: ...................................................................................................140

8.11.1) Electric starter on p.t.o. side: ........................................................................................140

8.11.2) Electric starter on magneto side: ..................................................................................141

8.11.3) Power supply to electric starter:....................................................................................141

8.12) Installation of the thermostat:..................................................................................................141

8.13) Fitting and assembly of ignition components supporting plate:.........................................142

8.14) Installation of the oil tank:........................................................................................................144

8.15) Installation of propeller reduction gear: .................................................................................144

8.16) Fitting of the exhaust manifold:...............................................................................................144

8.17) Fitting of the carburetors: ........................................................................................................145

8.17.1) Carburetor air intake: ....................................................................................................146

9) Trouble shooting:.....................................................................................................147

10) Extract from an article about power plants of UL aircraft by an expert:.........150

10.1) Carburetor icing: .......................................................................................................................150

10.2) Fuel systems: ............................................................................................................................151

10.2.1) Check the spark plug(s): ...............................................................................................151

10.2.2) Check engine for seizure: .............................................................................................152

10.2.3) Inspection of the fuel system: .......................................................................................152

10.2.4) Examination of fuel line between tank and fuel pump: .................................................152

10.2.5) Elimination of air leaks in the fuel line: .........................................................................154

10.2.6) Fuel supply to float chamber:........................................................................................154

10.2.7) Float chamber and main jet: .........................................................................................155

10.2.8) Problems related to fuel supply: ...................................................................................155

10.2.9) Various effects on formation of the air/fuel mixture: .....................................................156

10.3) Ignition problems: .....................................................................................................................157

10.4) Propeller matching:...................................................................................................................157

10.5) Prevention is better than cure: ................................................................................................158

11) Epilogue:....................................................................................................................158

12) Maintenance plan .....................................................................................................159

13) Essential tightening torques for engine types 462 - 532 - 582 UL: ..................160

14) Table of wear limits:................................................................................................. 162

15) Operational limits:....................................................................................................164

16) Operating liquids: ..................................................................................................... 164

17) AUTHORIZED DISTRIBUTORS and SERVICE CENTERS................................165

18) Modifications: ........................................................................................................... 169

Rm. 462-532-582 UL 10-1994

- 5 - of 170

1) Introduction:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

This Repair Manual covers the ROTAX 2-cycle-, 2-cylinder-, water-cooled ULTRALIGHT

AIRCRAFT ENGINES, Type 462, 532 and 582 UL. The manual has been prepared as a guide

to help to service and repair these engines correctly. It is supplemented by the corresponding

Operator’s Manual and a current Spare Parts List.

For installing the engine into the aircraft, consult the Installation Instructions. In the event of

questions or problems, please, contact your local authorized ROTAX distributor or Service

Partner.

This manual was published primarily to be used by qualified mechanics who are already

familiar with ROTAX engines.

The Repair Manual deals with

— Disassembly of engine

— Inspection and judgement of components

— Table of tightening torques

— Table of wear limits

— Chart about carburetor calibration.

The ROTAX design incorporates the latest technical developments. We reserve the right to

make modifications without prior notice in the case of further development. If considered

necessary, modifications will be dealt with Service Informations, consecutively numbered.

This manual emphasizes particular information denoted by the following wording or symbols:

▲ WARNING: Identifies an instruction which, if not followed, could cause personal injury.

■ ATTENTION: Denotes an instruction which, if not followed, could severely damage

engine components.

◆ NOTE: Indicates supplementary information needed to fully complete an instruc-

tion.

Although the mere reading of such information does not eliminate the hazard, compliance

with the given information is strongly advised.

1.1) Engine number:

On inquiries and spare part orders always state engine number, because of possible

running changes. The engine number is located on top half of crankcase, magneto

side.

- 6 - of 170

Rm. 462-532-582 UL10-1994

1.2) General notes:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

▲■ To warrant proper repair, use genuine ROTAX spares only. It is a necessity to

utilize special tools, fixtures and to use service products (see Chapter "Tools and

supplementary means").

▲■ Repair work to be carried out by skilled persons only.

▲■ Use clean screws and nuts only and check face of nuts and thread for damage.

■ Once loosened, always renew self-securing nuts.

■ Meet the specific tightening torque without fail (Chapter "Essential tightening

torques").

■ At the re-assembly renew all sealing rings, gaskets, securing rings, O-rings and

oil-seals.

Rm. 462-532-582 UL 10-1994

- 7 - of 170

2) T echnical data:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

2.1) Technical data ROTAX engine type 462 UL:

DESCRIPTION:

BORE:

STROKE:

DISPLACEMENT:

COMPRESSION RATIO:

POWER OUTPUT:

TORQUE MAX.:

MAX. PERMISSIBLE RPM:

DIRECTION OF ROTATION:

Two-cycle, two-cylinder rotary valve engine, oil-in-fuel

lubrication, liquid-cooled, with integrated water pump

69,5 mm (2,736 in.)

61,0 mm (2,401 in.)

462,8 c.c. (28,242 cu.in.)

theoretical: 11,5

effective: 6,7

28 kW (38 hp) at 5500 rpm (low performance version = extra

silent version), performance sheet Lb. 278

38 kW (52 hp) at 6500 rpm (standard version), performance

sheet Lb. 278

52 Nm (38 ft.lb.) at 5250 rpm, performance sheet Lb. 278

56 Nm (40 ft.lb.) at 6000 rpm, performance sheet Lb. 278

5800 1/min. (low performance version)

6800 1/min. (standard version)

counter-clockwise, viewed towards p.t.o.

(without reduction gear-box)

CYLINDER:

PISTON:

PISTON/CYL. CLEARANCE:

IGNITION SYSTEM:

GENERATOR OUTPUT:

RECTIFIER REGULATOR,

(OPTIONAL):

IGNITION TIMING:

CONTACT BREAKER GAP:

BREAK-AWAY GAP:

SPARK PLUG:

ELECTRODE GAP:

2 light alloy cylinders with cast iron sleeve

Aluminum, cast piston with 2 piston rings

0,08 - 0,10 mm (.00315 - .00394 in.)

flywheel magneto generator SCP2 with contact breakers

AC 12V 110W + 30W

a) 866 080 requires minimum load 12 W (1 A) to regulate

b) 264 870 - no minimum load required

O

1,86 mm ± 0,25 mm = .0732 in. ± .01 in. (18

max. difference between cylinders 0,1 mm (.004 in.)

0,3 mm - 0,4 mm (.012 - .016 in.)

13 - 17 mm (.51 - .67 in.)

14 mm, B8ES

0,5 mm (.02 in.)

) B.T.D.C.

RADIO FREQUENCY INTERFERENCE SUPPRESSION:

- 8 - of 170

optional for AC or DC

Rm. 462-532-582 UL10-1994

ROTARY VALVE:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

cut off section Low performance version: 924 202 117

Standard version: 924 205 147

O

O

ROTARY VALVE TIMING:

LUBRICATION OF ROTARY

VALVE DRIVE:

CARBURETOR:

FUEL PUMP:

FUEL:

LUBRICATION OF ENGINE:

STARTER:

Low performance version: rotary valve opens: 120 OB.T.D.C.

rotary valve closes: 40

Standard version: rotary valve opens: 140

rotary valve closes: 51

O

A.T.D.C.

O

B.T.D.C.

O

A.T.D.C.

referring to inlet port in crankcase, +/- 4° tolerance

oil bath, Super 2-stroke oil as used for engine lubrication

1 x BING 36 mm (1,42 in.), hand lever choke or cable choke

pneumatic fuel pump DF 52

regular gasoline, octane number not below MON 83 or RON 91

(unleaded allowed)

oil-in-fuel SUPER 2-stroke oil, ASTM/CEC standards API-TC speci-

fication) e. g. Castrol TTS, mixing ratio 1:50 (2%)

Rewind starter

optional:

a) rewind starter and electric starter, p.t.o. side (for engine

without reduction gearbox) or

b) electric starter, magneto side, without rewind starter (gear-

box is possible)

REDUCTION GEAR BOX,

(optional):

LUBRICATION OF GEARBOX:

DIRECTION OF PROP. SHAFT:

COOLING SYSTEM:

WEIGHTS:

ADDITIONAL WEIGHTS:

with torsional shock absorber

ratios available: i = 2,0 / 2,24 / 2,58 / 3,0 (i = 3,0 for extra silent

version only and supplied only installed on engine).

Gear oil API-GL5 or GL6, SAE 140 EP or 85W-140 EP

clockwise, viewed towards propeller flange

liquid-cooled

optional: a) 2 radiator kit, integrated 0,6 l =. 160 gal.US

complete cooling system 2,3 l =. 610 gal.US

b) 1 radiator kit 0,8 l = .211 gal.US

Engine without: carburetor, exhaust system, intake silencer,

radiator, fuel pump ........ 26,00 kg (57,3 lb.)

Carburetor with rubber flange and clamps: ........0,90 kg ( 2,0 lb.)

Exhaust system assy. ........................... approx. 3,90 kg ( 8,6 lb.)

Intake silencer with air filter........................ ........ 0,84 kg ( 1,9 lb.)

Integrated radiator kit ............................ approx. 2,10 kg ( 4,6 lb.)

Electric starter kit, p.t.o. side ....................... ...... 3,42 kg ( 7,5 lb.)

Electric starter kit, magneto side .................. ..... 3,50 kg ( 6,6 lb.)

Reduction gearbox "A" , dry ............................... 4,50 kg ( 9,9 lb.)

SUBJECT TO MODIFICATION WITHOUT NOTICE

Rm. 462-532-582 UL 10-1994

- 9 - of 170

2.2) Technical data ROTAX engine type 532 UL:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

DESCRIPTION:

BORE:

STROKE:

DISPLACEMENT:

COMPRESSION RATIO:

POWER OUTPUT:

TORQUE MAX.:

MAX. PERMISSIBLE RPM:

DIRECTION OF ROTATION:

CYLINDER:

PISTON:

PISTON/CYLINDER

Two-cycle, two-cylinder rotary valve engine, oil-in-fuel lubrication,

liquid-cooled, with integrated water pump

72 mm (2,835 in.)

64 mm (2,52 in.)

521,2 c.c. (31,806 cu.in.)

theoretical: 11,5 - effective: 6,3

47 kW (64 hp) at 6600 rpm, performance sheet Lb. 267

71 Nm (60 ft.lb.) at 6200 rpm, performance sheet Lb. 267

6800 rpm

counter-clockwise, viewed towards p.t.o. (without reduct. gear-box)

2 light alloy cylinders with cast iron sleeve

Aluminum, cast piston with 2 piston rings

0,07 - 0,09 mm (.00276 - .00354 in.)

IGNITION SYSTEM:

GENERATOR OUTPUT:

RECTIFIER REGULATOR

IGNITION TIMING:

CONTACT BREAKER GAP:

BREAK-AWAY GAP:

SPARK PLUG:

ELECTRODE GAP:

RADIO FREQU. INTERFERENCE

SUPPRESSION:

ROTARY VALVE:

flywheel magneto generator with contact

breakers

AC 12V 110W + 30W

a) 866 080 requires minimum load 12 W (1 Amp.) to regulate

b) 264 870 - no minimum load required

O

1,96 mm ± 0,25 mm = .077 in. ± .01 in. (18

) B.T.D.C.

difference between cylinders 0,1 mm (.004 in.)

0,3 mm - 0,4 mm (.012 - .016 in.)

13 - 17 mm (.51 - .67 in.)

14 mm, B8ES

0,5 mm (.02 in.)

optional for AC or DC

924 504, cut off section angle 132

O

ROTARY VALVE TIMING:

opens: 132 O B.T.D.C. closes: 52 O A.T.D.C.

O

referring to inlet port in crankcase, +/- 4

tolerance

LUBRICATION OF ROTARY

VALVE DRIVE:

- 10 - of 170

oil bath, Super 2-stroke oil as used for engine lubrication

Rm. 462-532-582 UL10-1994

CARBURETOR:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

1 x BING 36, hand lever or cable choke

2 x BING 36, hand lever or cable choke

FUEL PUMP:

FUEL:

LUBRICATION OF ENGINE:

STARTER:

REDUCTION GEARBOX, optional:

LUBRICATION OF GEARBOX:

DIRECTION OF PROP. SHAFT:

COOLING:

pneumatic fuel pump DF 52

Premium gasoline, octane number not below MON 87 or RON 96,

leaded or unleaded

oil-in-fuel SUPER 2-stroke oil (for high performance air cooled 2-

cycle engines, proposed ASTM/CEC standard API-TC specifica-

tion) e. g. Castrol TTS, mixing ratio 1:50 (2%)

Rewind starter

optional: a) Rewind starter with electric starter, p.t.o. side (for

engine without reduction gearbox) or

b) electric starter, magneto side, without rewind starter

(gear-box is possible).

with torsional shock absorber, ratios available: i = 2,0 / 2,24 / 2,58

Gear oil, API-GL5 or GL6

SAE 140 EP or 85 W-140 EP

clockwise, viewed towards propeller flange

liquid-cooled

optional: a) 2 radiator kit, integrated 0,6 l. = 0,16 gal US

complete cooling system 2,4 l. = 0,62 gal US

b) 1 radiator kit 0,8 l. = 0,21 gal US

WEIGHTS:

ADDITIONAL WEIGHT:

Engine without carburetors, air filters, fuel pump,

exhaust system, radiator .................................. 28,4 kg (62,6 lb.)

1 Carburetors with rubber flange and clamps:.... 0,9 kg ( 2,0 lb.)

2 Carburetors with rubber flange and clamps:.... 1,8 kg ( 4,0 lb.)

Exhaust system ass´y. .......................... approx. 5,1 kg (11,2 lb.)

1 air filter ............................................................ 0,2 kg ( 0 ,3 lb.)

2 air filters ........................................................ . 0,3 kg ( 0,6 lb.)

1 double air filter ................................................. 0,5 kg ( 1,1 lb.)

Integrated 2-radiator kit, ...................... . approx. 2,1 kg ( 4,6 lb.)

Electric starter kit, p.t.o. side ........................ ..... 3,4 kg ( 7,5 lb.)

Electric starter kit, magneto side .................. .... 3,5 kg ( 7,7 lb.)

Reduction gearbox “B”, dry................................. 4,5 kg ( 9,9 lb.)

Reduction gearbox “C”, dry................................. 8,0 kg (17,6 lb.)

SUBJECT TO MODIFICATION WITHOUT NOTICE.

Rm. 462-532-582 UL 10-1994

- 11 - of 170

2.3) Technical data ROTAX engine type 582 UL:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

DESCRIPTION:

ENGINE CONFIGURATIONS:

BORE:

STROKE:

DISPLACEMENT:

COMPRESSION RATIO:

POWER OUTPUT:

TORQUE:

Two-cycle, two-cylinder-, rotary valve engine, oil-in-fuel lubrication

or by oil pump, liquid cooled, with integrated water pump.

a) 582 b) 582/40 c) 582/32

dual ignition, 1-carburator no no yes

dual ignition, 2-carburators yes yes no

dual ignition, 2-carburators

with oil pump yes no no

76,0 mm (2,99 in.)

64,0 mm (2.52 in.)

3

580,7 cm

(35,44 cu.in.)

theoretical: 11,5 - effective: 5,75

a) 48 kW (64,4 hp SAE) at 6500 1/min., perform. sheet Lb. 362

b) 40 kW (53,6 hp SAE) at 6000 1/min., perform. sheet Lb. 363

c) 32,5 kW (43,6 hp SAE) at 5100 1/min., perform. sheet Lb. 364

Match propeller to achieve above indicated full load r.p.m. as per

engine version.

a) 75 Nm (55,3 ft.lb.) at 6000 1/min., perform. sheet Lb. 362

b) 68 Nm (50,1 ft.lb.) at 5500 1/min., perform. sheet Lb. 363

c) 63 Nm (46,5 ft.lb.) at 4700 1/min., perform. sheet Lb. 364

MAX. PERMISSIBLE RPM.:

DIRECTION OF ROTATION:

CYLINDER:

PISTON:

PISTON/CYLINDER CLEARANCE:

IGNITION SYSTEM:

GENERATOR OUTPUT:

IGNITION TIMING:

SPARK PLUG:

a) 6800 1/min.

b) 6400 1/min.

c) 5500 1/min.

counter-clockwise, viewed towards p.t.o.

(without reduction gearbox)

2 light alloy cylinders with cast iron sleeve

aluminium, cast piston with 2 piston rings

0,06 mm (.00236 in.) - 0,08 mm (.00315 in.) for engine type 582

and 582/40

0,05 mm (.00197 in.) - 0,07 (.00276 in.) for engine type 582/32

breakerless DUCATI capacitor discharge dual ignition with magneto generator

170W AC at 6000 1/min. and 13,5V RMS

O

1,96 mm ± 0,2 mm = .077 in. ± .008 in. (18

) BTDC

14 mm, B8ES

ELECTRODE GAP:

- 12 - of 170

0,5 mm ± 0,05 mm (.02 in. ± .002 in.)

Rm. 462-532-582 UL10-1994

ROTARY VALVE:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

configurationa+b): 924 504, cut-off section132

configuration c): 924 506, cut-off section 117

O

O

ROTARY VALVE TIMING:

CARBURETOR:

FUEL PUMP:

FUEL:

LUBRICATION OF ENGINE:

LUBRICATION OF

REDUCTION GEAR:

DIRECTION OF PROPELLER

SHAFT:

STARTER:

for a+b) opens: 130 O BTDC - closes: 50 O ATDC

for c) opens: 120

referring to inlet port of crankcase, ± 4

O

BTDC - closes: 45 O ATDC

O

tolerance

1 x BING 36, hand lever or cable choke - or

2 x BING 36, hand lever or cable choke

pneumatic fuel pump DF 52

regular gasoline, octane number not below MON 83 or RON 91

(leaded or unleaded)

1) oil-in-fuel SUPER 2-stroke oil, ASTM/CEC standards, API-TC

specification) e. g. Castrol TTS, mixing ratio 1:50 (2%)

2) by oil pump (optional) with the same oil

O

ATTENTION: pour point at least 10

C below ambient temperat.

gear oil, API GL5 or GL6, SAE 140 EP, or 85 W-140 EP

clockwise, viewed towards propeller flange

rewind starter

STANDARD VERSION INCLUDES:

WEIGHTS:

ADDITIONAL WEIGHT:

engine with

— 2 carburators with clamps

— fuel pump

— exhaust system

engine: ...............................................................27,4 kg (60,4 lb.)

(without: exhaust system, carburetor, intake

silencer, fuel pump, radiator)

2 carburators with carburetor flanges and clamps1,8 kg ( 4,0 lb.)

exhaust system ass´y. ............................approx. 5,1 kg (11,2 lb.)

2 air filters ............................................................ 0,3 kg ( 0,6 lb.)

1 double air filter .................................................. 0,5 kg ( 1,1 lb.)

1 intake silencer with filter, for single carb.,......... 0,8 kg ( 1,8 lb.)

1 intake silencer with filter, for dual carb.,............1,1 kg ( 2,4 lb.)

integrated 2-radiators kit ........................approx. 2,1 kg ( 4,6 lb.)

electric starter kit, p.t.o. side ................................3,4 kg ( 7,5 lb.)

electric starter kit, magneto side ..........................3,5 kg ( 7,7 lb.)

reduction gear box „B“ , dry .................................4,5 kg ( 9,9 lb.)

reduction gear box „C“ , dry ................................. 8,0 kg (17,6 lb.)

Rm. 462-532-582 UL 10-1994

- 13 - of 170

OPTIONAL FEATURES:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

Oil pump

lubrication: The engine is lubricated by an oil pump fitted to the

engine. The carburetor is fed with pure gasoline.

Intake

silencer: 1) for 1-carburetor engine version

2) for 2-carburetor engine version

ATTENTION: If engine was supplied without intake

silencer, the carburetor calibration has to be modified

for use with intake silencer.

Aftermuffler: Special after-muffler to be fitted in addition to the ex-

haust muffler.

Air filter: 1) to be fitted directly on carburetor

2) to be fitted in the intake silencer

3) double filter (one filter for both carburetors).

High altitude

compensation:

Automatic high altitude adjustment of carburetor calibration, with modified carburetor and high altitude compensator, HAC, (on request).

Electric

starter: 1) rewind starter and electric starter, p.t.o. side, for

engine without gearbox,

2) electric starter, magneto side, without rewind starter

(gear box is possible),

3) electric starter integrated in reduction gear E.

Rectifierregulator: 1) 866 080 requires minimum load of 12 W (l Amp) to

regulate

2) 264 870 no minimum load is required

Reduction

gearbox: with torsional shock absorber

configuration „B“: ratios available: i= 2,0 / 2,24 / 2,58

configuration „C“: ratios available: i= 2,62 / 3,0 / 3,47 /

4,0

configuration "E": ratios available, I = 2,62 / 3,0 / 3,47 /

4,0

Cooling

system: 1) 2-radiator kit, fitted on engine (with gearbox) 0,6 lt. =

.16 gal US (cooling system 2,35 lt. = .621 gal US)

2) 1-radiator kit, not fitted on engine 0,8 lt. (.21 gal US)

SUBJECT TO MODIFICATION WITHOUT NOTICE.

- 14 - of 170

Rm. 462-532-582 UL10-1994

3) T ools and supplementary means:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

3.1) Standard tools:

The following standard tools are needed:

Open end spanner:............. A/F 8, 9, 13, 17, 19, 22, 24 mm

Ring spanner: ..................... A/F 8, 9, 10, 13, 17, 19, 22, 27 and 30 mm

Sockets:.............................. A/F 8, 10, 11, 13, 17, 19, 27 and 30 mm

Sockets for Allen keys: ....... A/F 4, 5, 6, 8 and 10 mm

Torque wrench 1/2": ...........for torques up to 30 Nm (270 in. lb.)

for torques up to 300 Nm (2650 in. lb.)

Allen key:............................ A/F 4, 5, 6, 8 and 10 mm

Screw driver:.......................size 3, 4, 7 and 9

Phillips screw driver:........... size 3 and 4

Mallet:................................. plastic or wood

Hammer:............................. c. 500 g

Circlip pliers:....................... one each for inside and outside

piston ring pliers: ................ for piston diameter 69 ÷ 76 mm

Apart from these standard tools, the following special service tools, fixtures and service

products are required:

Rm. 462-532-582 UL 10-1994

- 15 - of 170

3.2) Special service tools for the engine:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

Ill. 2

- 16 - of 170

Rm. 462-532-582 UL10-1994

Ill. no Part no. Description Qty.

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

1 - 9 876 932 Repair tools....................................................................... 1

1 876 195 Tool bag ............................................................................1

2 876 640 Crankshaft fixation bolt ..................................................... 1

for crankshaft

3 876 210 Socket wrench (box spanner) 21x26 ................................ 1

4 977 420 Bolt (Tommy bar) 8x130-10 ..............................................1

for socket wrench

5 876 227 socket wrench (box spanner) 10X13 ................................ 1

6 977 425 Bolt (Tommy bar) 6X130-10.............................................. 1

for socket wrench 10x13 MM

7 276 065 Fork wrench (open end spanner) 10X13 .......................... 1

8 876 200 Screw driver......................................................................1

9 852 091 Starter rope 5,5x2110 .......................................................1

10-11 876 740 Trestle assembly............................................................... 1

11 876 746 Mounting plate with detent ................................................ 1

12 876 940 Gauge adapter.................................................................. 1

13 841 771 Set screw M6x8 ................................................................ 1

14 876 950 Precision gauge ................................................................1

15 876 945 Gauge pin ......................................................................... 1

16 277 150 Degree disk....................................................................... 1

for rotary valve timing

17 277 905 Wrench.............................................................................. 1

18 876 080 Puller plate ........................................................................ 1

to hold the magneto flywheel

19 940 591 Hex. screw M8x20 DIN 933 ..............................................3

for magneto flywheel

20 876 065 Puller M42x1,5 assy.,........................................................ 1

for magneto flywheel

21 977 475 Ring half............................................................................ 2

for ball bearing 6207, crankshaft p.t.o. side

22 276 025 Ring half............................................................................ 2

for ball bearing 6206, crankshaft magneto side

23 977 490 Ring................................................................................... 1

for ring halves

24 876 569 Distance ring 72/105/28.................................................... 1

for puller

25 876 552 Protection mushroom........................................................ 1

for crankshaft p.t.o. side

26 876 557 Protection mushroom........................................................ 1

for crankshaft magneto side

27 - 28 876 298 Puller assembly.................................................................1

for ball bearings

Rm. 462-532-582 UL 10-1994

- 17 - of 170

Ill. no Part no. Description ................................................................. Qty.

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

28 940 755 Hex. screw M16x1,5x150.................................................. 1

29 841 201 Hex. screw M8X70............................................................ 4

30 876 572 Aligning tool ......................................................................1

for cylinder

31 876 902 Aligning tool ...................................................................... 1

for cylinder exhaust flange

32 876 612 Extrusion jig ......................................................................1

for rotary valve shaft 937 962, 10 mm

33 876 980 Guide sleeve ..................................................................... 1

for rotary valve shaft 937 962, 10 mm

34 876 500 Insertion jig........................................................................ 1

for ball bearing, rotary valve shaft

35 876 602 insertion jig for oil seal 930

580, .......................................

rotary valve shaft and supporting plate 827 975

36 876 607 Insertion jig........................................................................ 1

for oil seal 930 580, rotary valve shaft

with oil pump drive and supporting plate 827 975.

37 876 512 Insertion jig........................................................................ 1

for inner oil seal 850 710,

rotary valve shaft 10 mm (0,4 in.)

1

38 877 052 Insertion jig........................................................................ 1

for outer oil seal 850 710,

rotary valve shaft 10 mm (0,4 in.)

39 877 030 Rubber protection mat. .....................................................1

for crankcase

40-43 877 090 Piston pin extractor assembly ........................................... 1

41 877 040 Expansion sleeve.............................................................. 2

42 877 155 Extracting nut assembly.................................................... 1

43 877 180 Locating sleeve ................................................................. 2

44-45 877 015 Circlip installation tool assembly ....................................... 1

for fitting of piston pin circlip 18 mm (0,71 in.)

44 877 020 Circlip installation sleeve................................................... 1

45 877 010 Circlip installation pusher .................................................. 1

46 994 428 Gasket set,

46 994 436 Gasket set,

46 886 230 Gasket set,

for the engine 462 UL ....................................

for the engine 532 UL ....................................

for the engine 582 UL ....................................

1

1

1

- 18 - of 170

Rm. 462-532-582 UL10-1994

3.3) Special service tools and gasket set for reduction gearbox "A" and "B":

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

Ill. 3

Ill. no Part no. Description Qty.

1 241 875 Allen screw M6x70/45....................................................1

to remove the gear cover

2 876 880 Mounting bracket

3 276 808 Puller assy. M 28x1.......................................................1

for drive gear, for I=2,00, I=2,24 and I=2,58

4 876 668 Insertion jig assembly ...................................................1

for oil seal 850 055, propeller shaft

5 277 817 Allen key 8 ....................................................................1

6 995 781 Gasket set

for the reduction gearbox..........................................

to compress the dog gear.................

1

1

Rm. 462-532-582 UL 10-1994

- 19 - of 170

3.4) Special service tools and gasket set for the reduction gearbox "C":

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

Ill. 4

Ill. no Part no. Description Qty.

1 877 430 Insertion jig assembly ....................................................... 1

for oil seal 35x47x7 930 715, on propeller-shaft

2 877 432 Insertion jig assembly ....................................................... 1

for oil seal 32X47X7 950 080 in gearbox-housing

3 277 982 Insertion jig assembly ....................................................... 1

for oil seal 35x47x7 930 675 in gearbox-housing

4 877 445 Socket wrench assy. (41 mm)

for hex. nut M30X1,5 842 575 ....................................

5 277 817 Allen key with pilot, 8 mm ................................................. 1

6 877 415 Protection mushroom,

for propeller-shaft..........................

7 - 8 877 375 Puller assembly................................................................. 1

to remove the lay shaft-gear thread 46x1,5

8 940 755 Hex. screw M16X1,5X150 DIN 961 ..................................1

9 876 552 Protection mushroom for

crankshaft p.t.o.-side ................

10 - 11 877 425 Flywheel puller assembly.................................................. 1

11 941 680 Hex. screw M16x1,5x56.................................................... 1

12 851 160 Clamp 90-110 ................................................................... 1

for mounting the rubber coupling 958 960

13 995 775 Gasket set,

for the reduction-gearbox "C" ........................

1

1

1

1

- 20 - of 170

Rm. 462-532-582 UL10-1994

3.5) Lubricating-, securing- and sealing agents:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

Ill. 5

Ill. no Part no. Description Qty.

1 897 511 LOCTITE 380 black .......................................................... 1

20 g., for securing of ignition cable

2 899 785 LOCTITE 221 violet, 10 cc................................................ 1

Low strength bond

3 899 788 LOCTITE 648 green, 5 g...................................................1

High strength bond

4 297 386 SILASTIC 732 RTV, 100 g................................................ 1

5 897 330 LITHIUM-base grease, 250 g............................................ 1

to prevent leakage current

6 897 166 MOLYKOTE 44 medium, 100 g. .......................................1

silicone grease

7 897 241 PERMANENT PLASTIC SEALING COMP., 100 g........... 1

8 297 433 MOLYKOTE G-N, 100 g.

slide paste ....................................................................

9 297 431 LOCTITE Anti-seize 10 g. ................................................. 1

to prevent fretting corrosion

10 899 784 LOCTITE 574 orange, 50 cc............................................. 1

sealing compound

1

Rm. 462-532-582 UL 10-1994

- 21 - of 170

4) Powerplant in aircraft:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

4.1) Removal of engine from the aircraft:

Prior to removing engine from aircraft, carry out the following:

- Cool down engine first

- Disconnect battery

- Drain cooling system, detach coolant hoses if necessary and remove radiator

▲ WARNING: Never drain or refill cooling system when engine is hot!

— If rewind starter is fitted, detach starter rope guides.

— Remove exhaust system along with support.

— Remove throttle control.

— Block fuel line from tank to pump (close fuel tap), pull off fuel line from pump and

carburetor.

— Disconnect oil supply- and oil return line, if oil container for rotary valve drive is not

attached to engine.

— Disconnect oil supply line for engines with fresh oil lubrication (applicable only on

Type 582 UL with fresh-oil lubrication).

— Mark and disconnect electrical wiring, where necessary.

— Remove air filter and/or intake silencer.

— Lift out engine from bulkhead.

■ REMEMBER: Sever wire on every wire-secured bolt before removal!

4.2) Re-installation of engine into aircraft:

Generally, reverse removal procedures. However, pay attention to the following:

—Check carburetor Bowden cables for easy movement.

—Check throttle and starting carburetor control.

—Synchronize setting of carburetor pistons.

—Connect and check electrical wiring.

—Check condition and tight connections of oil- and coolant lines.

—Check oil- and coolant level.

—Vent oil- and cooling circuit.

—Check routing of fuel lines.

—Check condition and tightness of fuel lines and connections.

—Check radiator support.

—Ensure tight suspension of engine and exhaust system.

—Trial run or running-in period per operator´s Manual, in case top end of engines or

other parts in need of breaking-in, have been renewed.

■ ATTENTION: Ensure that all the suspension screws are tightened and wire-secured

where applicable. Don’t connect battery before all the installation is

complete and ensure that ignition switch is in „OFF“ position.

- 22 - of 170

Rm. 462-532-582 UL10-1994

5) Disassembly of engine:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

Attach drained and cleaned engine to

trestle by M10 nuts. This trestle enables the engine to be turned and

tilted during engine repair.

Remove carburetor after

marking position as fitted and

slackening of hose clamps.

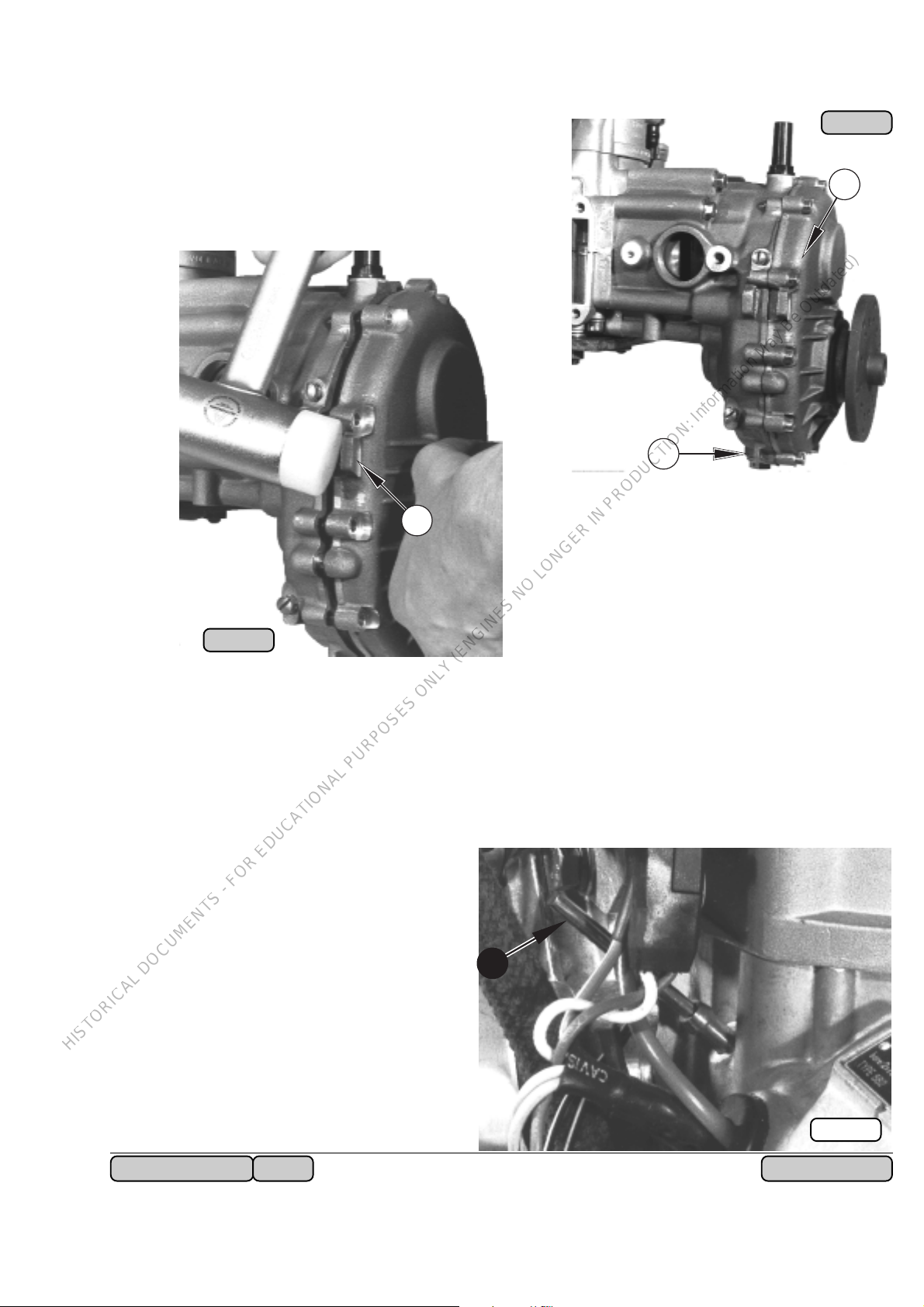

5.1) Removal of reduction gearbox „A“:

Ill. 6

Open drain plug Q and drain gear oil into

suitable tray (0,5 l). Remove the 4 nuts W

M8 holding the gearbox in position on

adaptor.

2

2

Ill. 7

1

3

Carefully pull off gearbox ass'y, take

out O-ring R from groove in adaptor,

undo the 4 Allen screws T M10x45

and remove adaptor Y.Lock crankshaft by locking pin

move hex. hd. screw U 1/2"-20 UNF x

50 along with lock washer and washer,

fit puller ass’y

gear.

◆ NOTE: If required, preheat

276 808

876 640 R.

and pull off drive

Allen screws T locally with hot air gun.

Use Allen key I 277

817.

Re-

The two lower nuts M8 E may remain for

the time being.

8

4

7

6

5

Ill. 8

Rm. 462-532-582 UL 10-1994

- 23 - of 170

5.2) Removal of reduction gearbox „B“:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

Remove drain plug Q and drain

gear oil into suitable tray (0,5 l).

Remove 4 hex. hd. screws W M8

and 2 hex. nuts E M8, or 2 hex.

hd. screws and 4 nuts along with

lock washers. Withdraw gear

cover assembly. If need be, tap

carefully, using a mallet to remove cover.

2

Ill. 9

2

1

3

4

Remove hex. hd. screw 1/2-20

UNF x 50 along with lock

washer and washer. Place protection piece

shaft, fit the puller ass’y T

276 808

◆ NOTE: On a real

876 552

and pull off drive gear.

on crank-

tight fit, facilitate with a

smart blow

of the hammer to the

puller screw.

If necessary

carefully preheat drive pinion by hot air gun.

Ill. 10

■ ATTENTION: If gear housing is attached

with 6 fasteners, remove

gear cover first.

Remove both inside located hex. hd. collar

screws R M8x65 (A/F 11). Take off gear

housing and take out O-ring from groove.

Lock crankshaft by inserting locking pin

876 640

crankshaft until pin engages in crank blade

recess.

into pulse hose nipple and turning

5

Ill. 11

- 24 - of 170

Rm. 462-532-582 UL10-1994

5.3) Disassembly of reduction gearbox „C“:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

Undo drain plug Q and drain gear oil, c. 0,2

l. Remove 11 Allen screws W M6x30 attach-

ing gear cover to the gear housing.

3

Remove gear cover by tapping cover on the

lugs E, using a mallet. Gear cover is kept in

position by 2 dowel pins.

Ill. 12

2

1

Ill. 13

Lock crankshaft by inserting locking pin 876 640 R into pulse hose nipple and turning

crankshaft until pin engages in crank blade recess. With crankshaft locked in this

manner, all attachment nuts and screws can be slackened or tightened.

■ ATTENTION: Use genuine

locking pin

only, to prevent

any damage to

crankcase.

4

Ill. 14

Rm. 462-532-582 UL 10-1994

- 25 - of 170

Remove Allen screw M8 x 35 and

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

withdraw pinion shaft Q.

◆ NOTE: Placed on the back-

side of the pinion

are the shims for

proper axial distance of pinion

shaft.

Remove the 8 hex. collar screws W,

4 of them inside the gearbox housing,

using socket spanner 11 A/F and pull

off gearbox housing.

1

1

2

Ill. 15

Fit worm-thread hose clamp

3

4

7

6

Remove coupling flange Y together with the rubber coupling U and afterwards hex.

hd. screw 1/2-20 UNF x 30 along with washer. Slightly grease mushroom shaped

protection piece

onto crankshaft and fit fly wheel

puller I

screws M10x45 and pull off flywheel O by turning-in hex. hd.

screw M16.

5

877 415

877 425

using hex.

851 160

Ill. 16

, place it

E tight around rubber coupling and remove 3

Allen screws M10 x 45 R using

Allen key 8.

◆ NOTE: To prevent any damage

to rubber coupling U,

hold washer with flats

T in position, using open

end spanner 17 A/F.

9

8

◆ NOTE: If need be, facili-

tate with a smart

blow of the hammer to screw P.

Put aside flywheel and protection

piece.

- 26 - of 170

Rm. 462-532-582 UL10-1994

10

Ill. 17

5.4) Removal of rewind starter:

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

Note position of rewind starter. Remove 4 hex. hd. screws M6 x 14 along

with lock washer and take off rewind

starter ass’y. Detach the starter pulley Q by removal of the 3 hex. hd.

screws M8x16 together with lock

washer.

◆ NOTE: Crankshaft still locked!

Ill. 18

On engine type 582 UL, starting

2

1

with engine no. 4,015.239 a hydraulic damper W is fitted between

magneto housing and starter pulley Q, to suppress bending- and

torsional vibration of crankshaft.

Remove this damper if fitted.

Ill. 19

5.5) Dismantling of electric starter:

Before removing electric starter, record

its position. Take off starter after removal of 4 hex. hd. screws M6 x 40

along with lock washer.

Ill. 20

Rm. 462-532-582 UL 10-1994

- 27 - of 170

Ill. 21

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

1

Loosen 3 hex. hd. screws M8 x

40 and remove starter gear Q

and starter adaptor placed behind.

On engine type 582 UL, starting

with engine no.

draulic damper is fitted between

magneto housing and starter gear

adapter, to suppress bendingand torsional vibration of crankshaft. Remove this damper if fitted.

4,015.239

a hy-

5.6) Removal of exhaust

manifold:

Note position of exhaust manifold.

Undo Allen screws M8x30 and

remove manifold along with

gaskets. No screw fitted in

position W .

2

Ill. 22

5.7) Removal of ignition coils support plate and disassembly of rotary valve:

5.7.1) Engine type 462 UL:

Undo hex. hd. screw M8 x 25, common for support tie E and rotary valve cover.

Mark wiring from charging coil

Ill. 23

to ignition coils prior to opening

of connection and take off resistor-spark plug connectors, or

shielded spark plug connectors.

Remove the 3 hex. hd. screws

M6 x 22 and take off support

plate ass’y with ignition coils

and ignition damping box.

3

- 28 - of 170

4

◆ NOTE: Take care of the

spacers R behind

the support plate.

Rm. 462-532-582 UL10-1994

Slacken clamp and remove oil supply hose.

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

◆ NOTE: Drain oil of rotary valve drive into suitable container.

Take off water outlet socket or water outlet bend by removing the 2 M6 hex. nuts

along with lock washers and washers.

◆ NOTE: A thermostat might be fitted between water outlet piece and

cylinder head (see Ill. 27).

Remove all 4 hex. hd. screws and washers attaching rotary valve cover on

crankcase.

Remove all spark plugs and crankshaft locking pin Q and turn crankshaft into

T.D.C. position of magneto side piston. Mark position of rotary valve as

depicted and take off rotary valve.

■ ATTENTION:

While removing rotary valve

cover, hold rotary valve with a

pencil for instance, in position

ensuring it will remain on shaft,

thus enabling to check if rotary

valve timing was correct.

◆ NOTE: If locking pin is used on engine type 462 UL, position

magneto side piston on T.D.C. On Engine type 532 UL and

582 UL, set piston to T.D.C on power take off side.

5.7.2) Engine type 532 and 582 UL:

Slacken hose clamp W and remove oil supply line to rotary valve drive.

◆ NOTE: Drain oil of rotary valve drive (c. 0,3 l) into

Ill. 24

1

suitable container.

2

Ill. 25

Rm. 462-532-582 UL 10-1994

- 29 - of 170

Ill. 26

HISTORICAL DOCUMENTS - FOR EDUCATIONAL PURPOSES ONLY (ENGINES NO LONGER IN PRODUCTION: Information May Be Outdated)

4

1

3

2

tors, tilt ignition coils support assembly forward, slacken hose clamps and

remove electronic boxes assembly

together with oil tank and hoses.

Remove water outlet socket or

water outlet bend E along with

gaskets from cylinder head.

It is advisable to detach

supporting plate of ignition coils prior to the removal of oil hoses. For

that undo the 2 nuts Q

M6 and both hex. hd.

screws W M8x25 along

with washers.

Sever all tie straps on oil

lines and cables and

open all wiring connections to electronic boxes

or ignition coils. Take off

all 4 spark plug connec-

Ill. 27

5

◆ NOTE: A thermostat T

might be fitted

between water

outlet piece R

and cylinder.

Remove the last 2 hex. hd. screws U and washers attaching rotary valve cover

on crankcase.

Remove all spark plugs and crankshaft locking pin. Turn crankshaft into T.D.C.

position of magneto side piston, mark position of rotary valve as shown on

illustration 24 and take off rotary valve.

Ill. 28

6

6

■ ATTENTION: At removal of rotary valve cover

hold rotary valve Y in positionwith

a appropriate tool, thus ensuring

that valve will stay on shaft enabling to check if rotary valve timing was correct.

▲ WARNING: "Do not " use finger to apply pres-

sure on rotary valve, as injury

may result.

7

- 30 - of 170

Rm. 462-532-582 UL10-1994

Loading...

Loading...