Bolton Tools ZX32G, ZX32GP Operating Manual

MILLING & DRILLING MACHINE

OPERATING MANUAL

Model ZX32G

Model ZX32GP

1

Please read this manual carefully before using your machine.

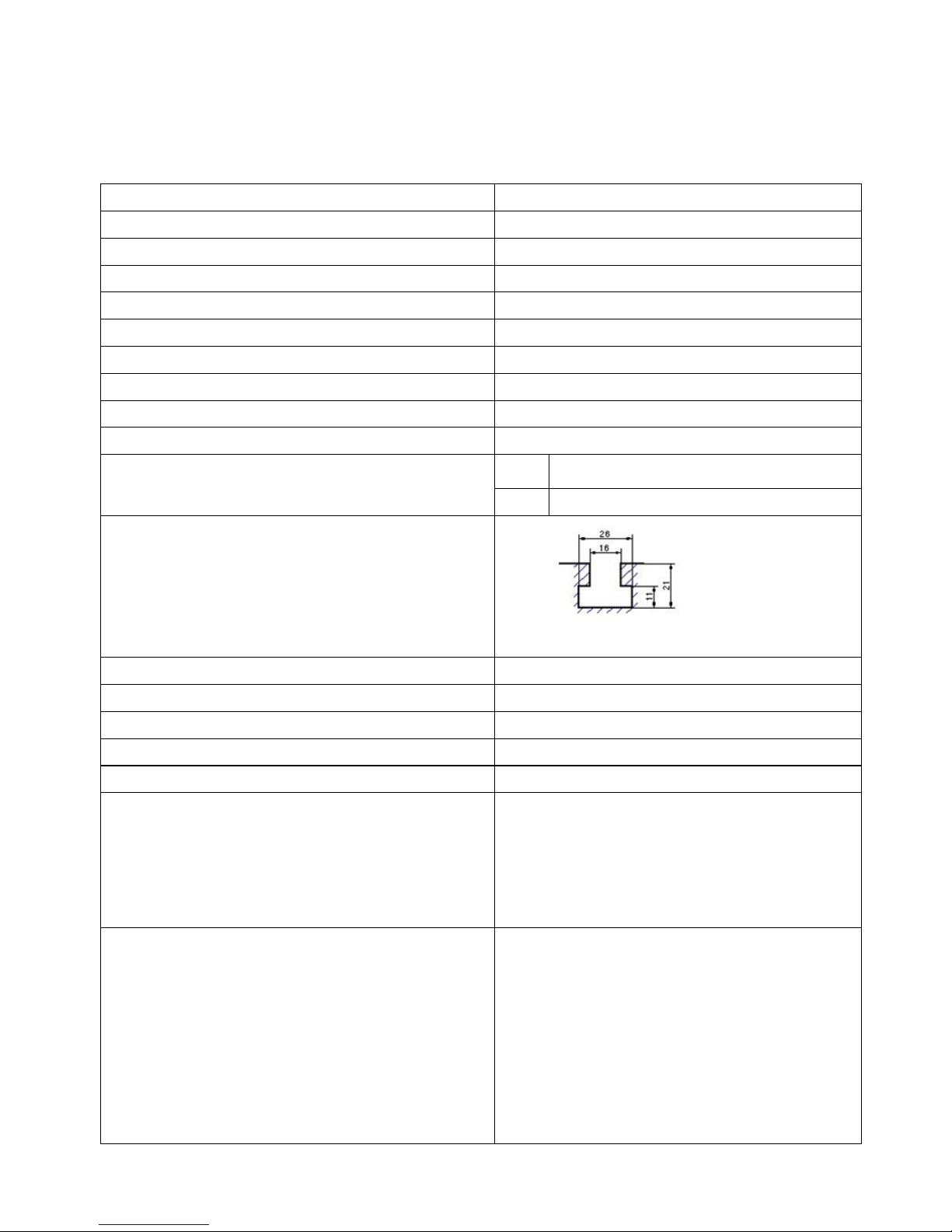

1. SPECIFICATION

Model

Specification

Max. Drilling capacity

1 1/4"

Max. Face milling capacity

2 1/2"

Max. End milling capacity

13/16"

Swivel angle of head-stock at perpendicular direction

±90°

Swivel angle of head-stock at level direction

360°

Spindle travel

3 3/8"

Max. Distance between spindle nose and table

17 5/16"

Distance between spindle axis and surface of column

7 3/8"

Spindle taper

MT3

Spindle speed (1400r/min motor)

50Hz

95、180、270、500、930、1420 r/min

60Hz

115、220、320、600、1120、1700 r/min

T-solt

Forward and backward travel of table

5 1/2"

Left and right travel of table

16 1/8"

Table size

27 9/16" x 7 1/16"

Motor

0.75KW

Net weight

232kg

Special accessories

Milling cutter holder Ø63

Vice 90mm

end mill cutter 2-20mm

drill 1-20mm

machine stand

Standard accessories

Double-head wrench 19mm×22mm 1pc

Allen wrench 5mm,6mm 1pc each

Screw driver(-) 150mm 1pc

Drill stock MT3 1pc

Drill chuck 1-13mm 1pc

Wedge

Drawbar 1pc

Drawbar washer 1pc

2

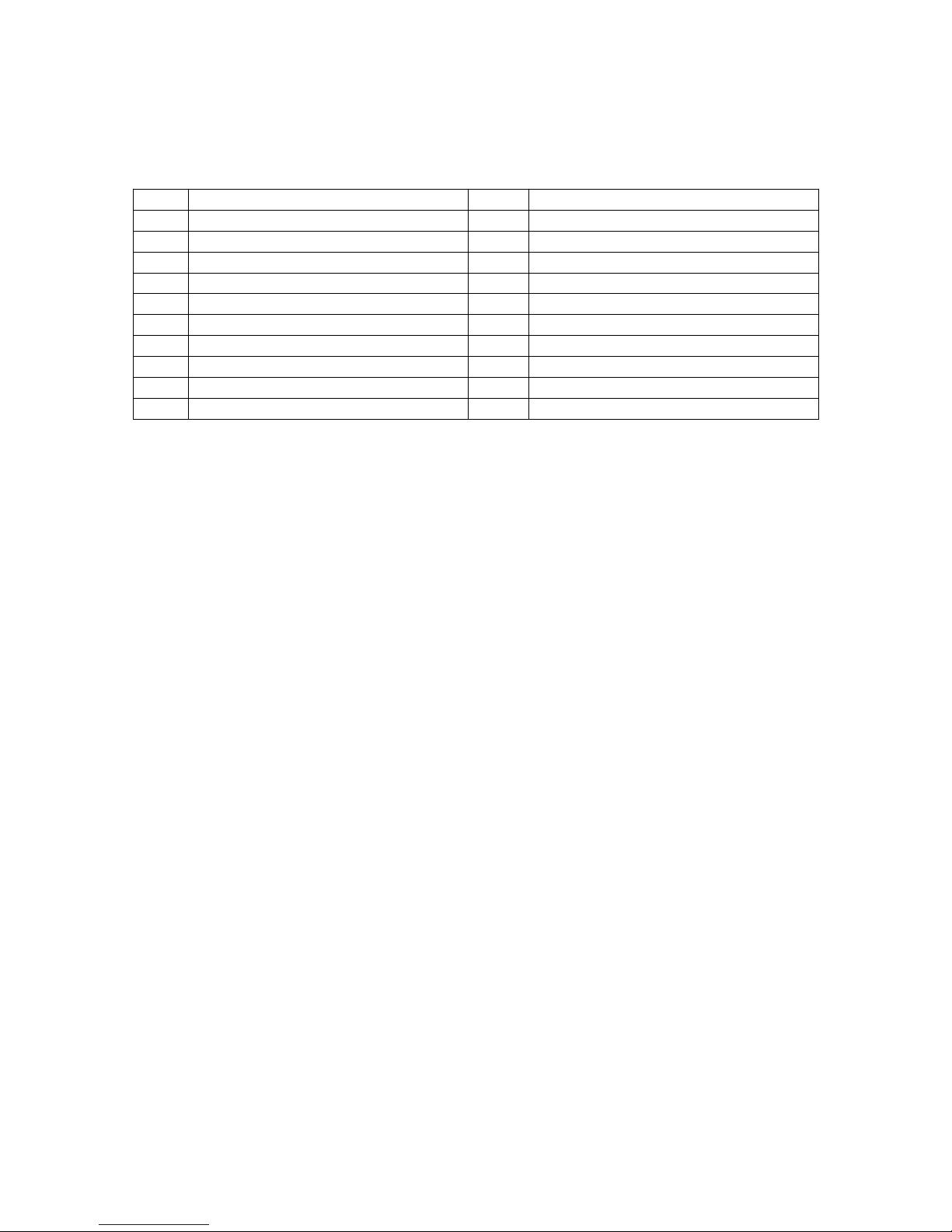

No.

Description

No.

Description

1

bolt11Scale

2

Head handle

12

Adjustable lock screw

3

nut13Longitudinal table feed handle wheel

4

Combined switch

14

Micro feed handle wheel

5

Speed handle

15

Operate bar

6

Gauge bar

16

Head body

7

Plexiglass protective cover

17

Oil filler plug

8

Longitudinal table feed handle wheel

18

To raise and lower body

9

Stop block

19

Arbor bolt cover

10

Cross table feed handle wheel

20

Column

2.USES AND FEATURES

2.1This machine has several functions: milling, drilling, boring, grinding,

working face and tapping etc.

2.2It’s suitable for cutting, processing and repairing single or small

batches parts of all professions. It is of high quality, good function, easy

operation, and not limited to skill operator.

2.3Operating drilling and milling by two ways:

(1) Manual operation for rapid drilling;

(2) Worm feed operation for slow milling.

2.4Bronze adjustable nut, which adjust the thread clearance, reduce the

wear, and also make screws rotated smoothly and increase the thread

accuracy.

2.5Whole-piece cast iron column make this machine strong and stable,

3

and also keeps high accuracy.

2.6The tough cast headstock ensures its accuracy lasting enduring

through the treatment of precise boring, honing, and relieving internal

stress.

2.7The machine gears are ground for steady precision.

2.8 Easy to change speed.

3.PRESERVING MANUAL

Please preserve the manual because it gives you such operation,

maintenance, fixing breakdown, parts subsidiary form, circuit diagram;

Meanwhile, please reverse your invoice of purchasing machine.

Please write your invoice number on the called of manual, store up

the invoice and manual in safe, dry place in order to be consulted.

4.Warning

The warning of our manual couldn’t include all situations happening

on all condition and circumstances. Operator must understand that he

only could operate and couldn’t repair by himself.

5.General safe rule

Warning! You should look up manual to know basic safe preventive

measures in order to reducing the danger of fire and electricity shocking

before operating, processing or saving.

4

5.1 Keep the product circumstance clean. The confusion circumstance is

easy to bring danger.

5.2 Idea work condition. Don’t make the power source drenched by the

rain; don’t make the power source equipment on damp place.

5.3 Don’t allow child nearby workshop, and not allow child or visitor to

touch the machine (or subsidiary equipment). They should far from the

work place.

5.4 Store up idle tool. You should put it on dry, high or locked place, and

not allow child to hold when you don’t use it.

5.5Don’t make the machine overload. You should draw up quota load for

safety.

5.6Using tool right. Don’t make small tool and subsidiary equipment

overload or excess function (For example: Don’t use round saw to cut the

pipe feed or wood.)

5.7 Proper dress. Don’t wear oversized clothes or jewelry. You should

wear rubber gloves, anti-slippery shoes and cover long hair as carrying

parts outdoor.

5.8 Wearing protective glasses. Operator usually should wear protective

glasses on the dusty circumstance.

5.9 Don’t abuse power line. Don’t take out power line from conduct, and

5

make it far from scorching hot, grease dirt place and the sharp edge of

knife.

5.10 Do not work the overlong work-piece. The length of the work-piece

should be in the standard scope and keep balance in the process of

working.

5.11 Keep the tools under careful maintenance. To keep the edge of knife

clean, and make it has good safe function. You should keep tool

accessories and tools clean and dry as changing and storing up, and also

should be coated with antirust grease, check the extend of power line

regularly, exchange it if you find damage.

5.12 Taking away keys and wrench for adjustment. As usual, Operator

should take away the keys and wrench which be used to adjust and lock

work-piece to avoid danger before start the machine.

5.13 Avoiding unconscious starting. Don’t allow the finger touch the

switch turning on in order to ensuring safe when cutting off the power

source.

5.14 Keeping vigilance. Don’t start machine to operate when the operator

feel tired.

5.15 Don’t start machine after drinking wine or taking medicine.

5.16 Check on damaged part. In order to get normal function, you should

6

check on and determine if the protection board and others parts are

damaged as usual before using the machine again. Check on and calibrate

the running condition of sliding parts, to repair or change it if you find it

damaged. If the switch can’t work (the damage except manual rule), you

can ask service center for changing.

5.17 Exchanging parts or accessories. You should replace the part of tool

by the same parts as repairing, and have right reasons to change any part.

5.18 Operate machine rightly. Don’t use small machine as big machine,

because it should be used in a regular scope. Don’t repair machine and do

something out of its duty.

5.19 The user should know the maintenance of power machine and

should ask profession for maintenance, which is the necessary term

ensuring the machine accuracy and safety.

6.Special warning.

Please take attention on special danger as operating, and protect those

safe protective equipments beside you.

6.1 Electricity danger, Do not operate the machine on electrified and wet

place; Do not use extend of power source or power line wrongly. Make

sure the power source of the machine is ground wired.

6.2 The danger of splashing things. Before using machine, you should

7

avoid the danger of metal splashing things because its speed is very fast

as running, and wear protective glasses; Don’t make the machine

overload; You should stand on one side of the machine in avoid the hurt

of metal things; Don’t allow visitor nearby the machine when it’s

running.

6.3 The danger of tangled body (things). Carry out protective measures to

protect those easy moving parts of the machine. Don’t wear oversized

clothes, jewelry, and keep long hair when operating machine because it

could touch machine or work-piece; you should stop the machine as soon

as it touch the machine.

7.Mounting and carrying.

7.1Don’t install the machine at the sunshine place to avoid the

deformation of machine and loss of accuracy.

7.2 Mount machine to a sturdy table or base. It is advisable that the table

you choose be well constructed to avoid any vibration during operation.

7.3Four holes are provided on the machine base for mounting the

machine. The size is 390mm×240mm. Four holes are provided on the

machine base for mounting. Before tightening bolts make sure the

working table on the machine is level lengthwise and crosswise. Use

shims if necessary.

8

7.4 The hoisting should be fit for the net weight of machine with good

hoist. The load - bearing of hoist should exceed the weight of machine in

order to protect machine and personal safety.

8.Cleaning and lubricating

8.1 The machine has been coated with antirust grease before packing.

You should clean the grease and lubricating it before operating it.

8.2 Before starting machine. Please lubricate all bright work and guide

surface as the lubricate manual (fig 2). The level of oil should keep the

middle of oil gauge.

8.3 Take off the oil filler plug, fill the lubricant in such as SAE68 oil in

level to the gear box until the oil level reach the middle of oil fluid level

indicator, then lock the plug.

9.Protecting for accuracy

Make sure the balance of level of table surface of machine in the length

and breath before operating machine. As milling or drilling, it can’t

guarantee the processing accuracy if it don’t keep on the level purely.

10.Using and Maintenance.

10.1Main parts of machine

(1) To raise and lower the head by head handle (2).

(2) Choose the forward, reverse and stop of changing-direction

Loading...

Loading...