Page 1

21" Self-Propelled Rotary Mower

Operating Manual

Model No. TMO-37478A

Montgomeiy Ward

Page 2

INDEX

Slope Gauge.................................................................3

Contents of Hardware Pack..........................................4

Rules for Safe Operation..............................................5

Assembly

Controls.......................................................................10

Operation....................................................................11

Adjustments................................................................13

Lubrication..................................................................14

Maintenance...............................................................14

Off-Season Storage....................................................17

Illustrated Parts.....................................................18, 21

Repair Parts Lists

Trouble Shooting Chart

Parts Information

NOTICE: A data plate with the model number and serial numbers of your unit is located on the top rear

of the deck. Record these numbers in the spaces provided on the back cover of this guide.

......................................................................

................................................

.............................................

.........................................

19-21

Back Cover

6

22

Dear Customer,

So often throughout the year we are all in a

rush to meet our daily obligations.

However, we at Montgomery Ward are tak

ing a quick moment out to sa/. , ,

"Thank you for your business."

Sincerely,

MONTGOMERY WARD

INSTRUCTIONS GIVEN WITH THIS SYM

BOL ARE FOR PERSONAL SAFETY. BE

A

SURE TO FOLLOW THEM.

BEFORE YOU CALL SERVICE

Check Spark Plug Wire

• Firmly attached?

• Wire terminal clean?

Check Crankcase Oil Level

• Overfilled/underfilled?

Check Fuel Tank

• Fuel in tank?

• Fuel dirty or stale?

• Fuel shut-off valve closed?

• If tank has been empty for a tong period,

fill tank completely.

Check Air Cleaner

• Clean?

• Choke plate stuck?

• Governor spring free to move?

Check under Blade Housing (Disconnect Spark Plug First)

• Blade obstructed or bent?

Check Starting Instructions

• Read instruction manuals and labels for specific

instructions.

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with

a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available

through your nearest engine authorized service center.

Page 3

-------------------------------------------------------------------------------------------Cut Along This Line--------------------------------------------------------------------------------------------------

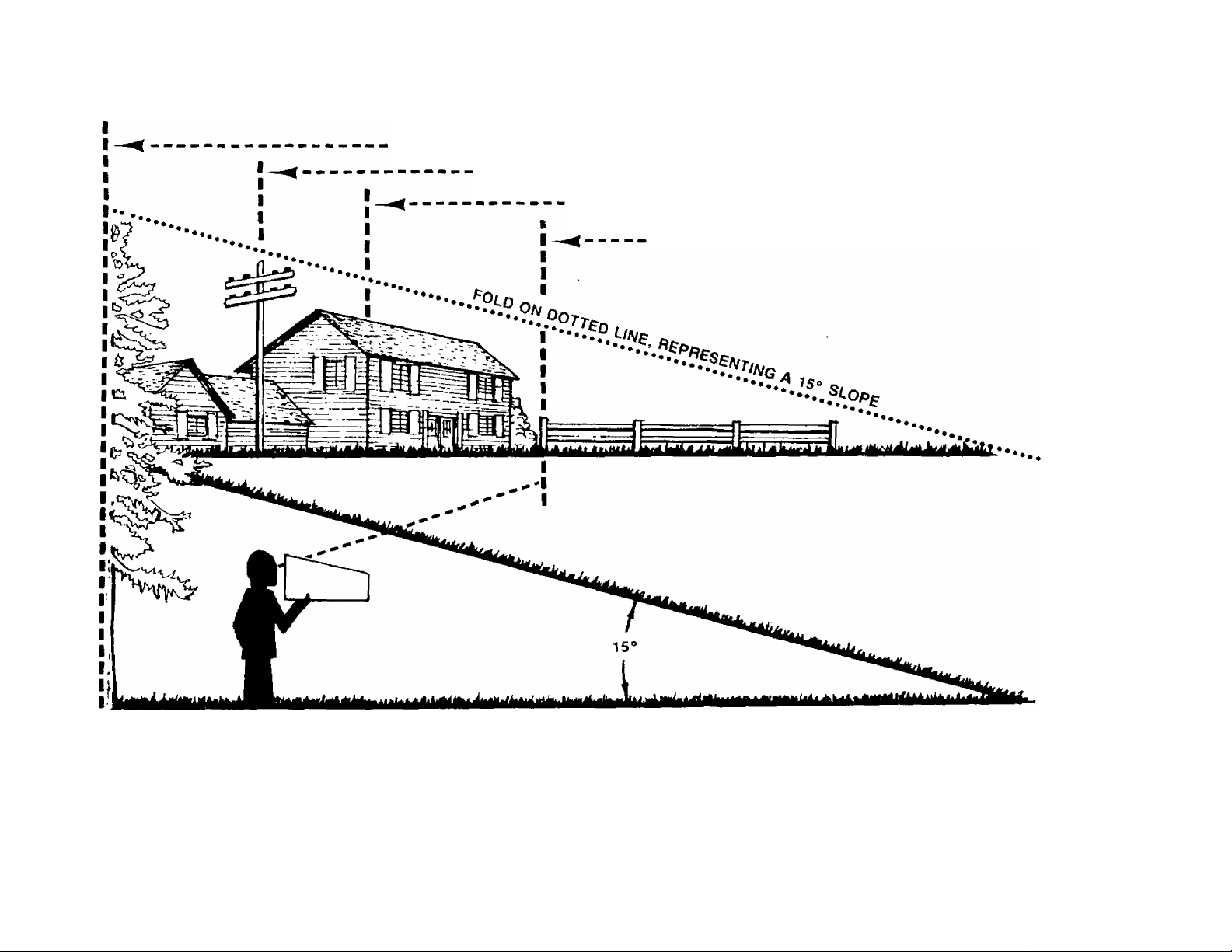

USE THIS SHEET AS A GUIDE TO DETERMINE SLOPES WHERE YOU MAY NOT OPERATE SAFELY.

SIGHT AND HOLD THIS LEVEL WITH A VERTICAL TREE

A POWER POLE

A CORNER OF A BUILDING

7s

*o

5’

tu

c/>

D)

CD

■o

0)

o

(b

(0

d)

CP

ar

<D

CO

n

OR A FENCE POST

AC WARNING ^

Do not mow on inclines with a slope in excess of 15 degrees (a rise of approximately 2Vz feet every 10 feet). A

riding mower could overturn and cause serious in|ury. If operating a walk-behind mower on such a slope, it is

extremely difficult to maintain your footing and you could slip, resulting in serious injury.

Operate RIDING mowers up and down slopes, never across the face of slopes.

Operate WALK-BEHIND mowers across the face of slopes, never up and down slopes.

c

c

(t)

—T

"♦l

o

3

o

(D

o

Page 4

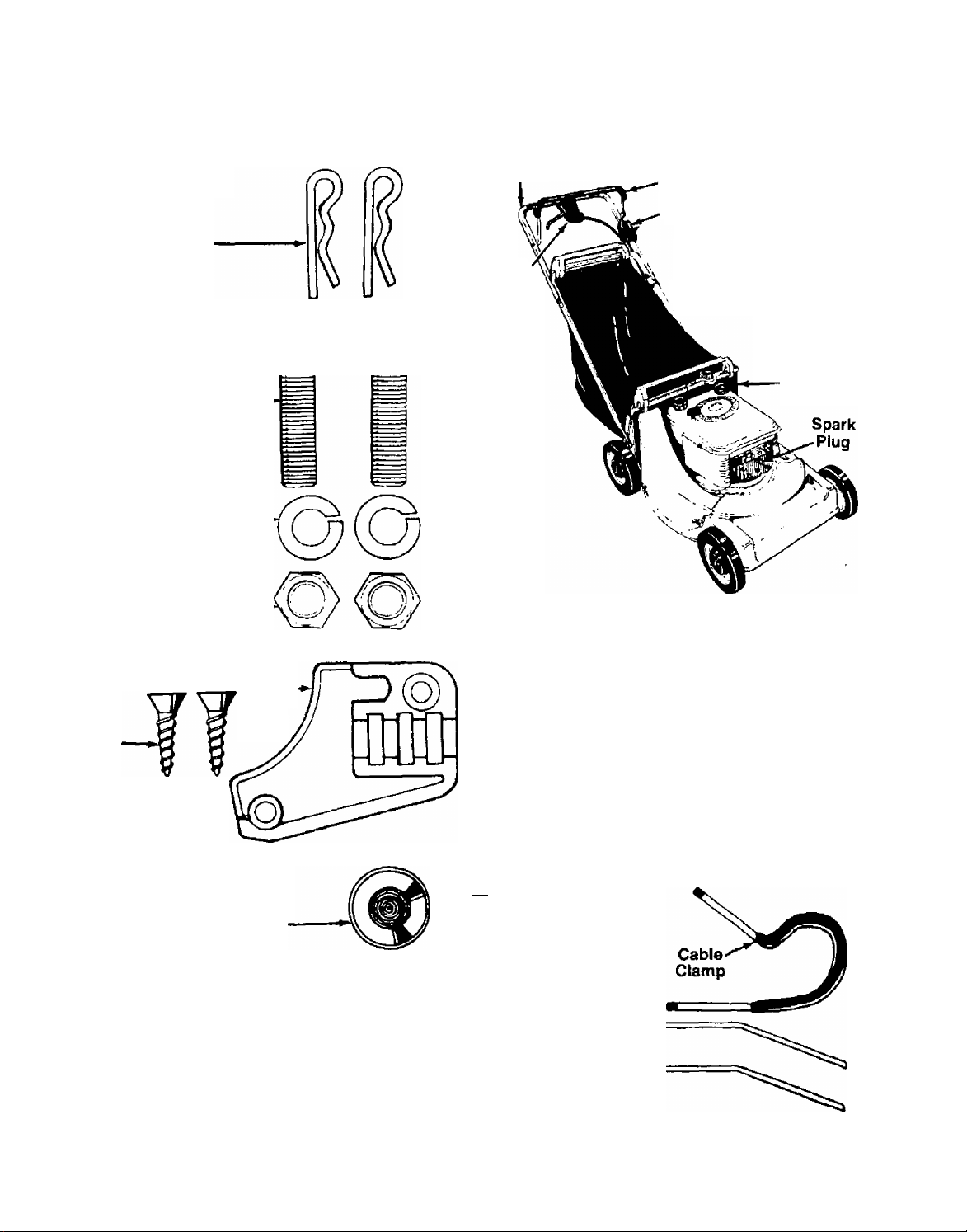

CONTENTS OF HARDWARE PACK

Remove this sheet from your owner’s manual and lay the hardware on the illustration for identification purposes.

After assembly, keep the Slope Gauge which is on the reverse side of this sheet for future use.

(Hardware pack may contain extra items which are not used on your unit.)

ATTACHfNG THE

LOWER HANDLE

Hairpin

Clips

ATTACHING THE

UPPER HANDLE

Curved Head-

Bolts

Split Washers-

5/16" I.D.

Hex Nuts

5/16-18 Thread.

ATTACHING THE DRIVE CLUTCH CONTROL

CABLE

Plastic-

Phillips

Head

Screws

Cap

Upper

Handle

Drive

Clutch

Housing

PARTS INFORMATION

ASSEMBLY OF GRASS CATCHER

(Upper Bag Support

Is Not Shown)

Blade Brake/Clutch

Control Handle

-Throttle Control

^_^Lower Handle

Housing

Catcher

Panel

o

c

>

o

3

(Q

W

ATTACHING THE BLADE

BRAKE/CLUTCH CABLE

SECURING THE CABLES

r

u

M

I I i I I I I

0

INCHES

I I

Push Cap

Truss Machine-

Self-Tapping Screws

Q[ FINAL

ASSEMBLY

Hub Caps are

Not Shown

Cable Ties

I i I I I I I

Page 5

▲

IMPORTANT

RULES FOR SAFE OPERATION

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY

ANO/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING

TO OPERATE YOUR LAWN MOWER, FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY, WHEN

YOU SEE THIS SYMBOL-

A HEED ITS WARNING.

A

A

A

Ai

Your lawn mower was built to be operated according to the rules for sate operation in this manual. As

with any type of power equipment, carelessness or error on the part of the operator can result in serious

injury. t( you violate any of these rules, you may cause serious injury Id yourself or others.

TRAINING

1. Read this owner's manual carefully in its entirety before attempt

ing to assemble or operate this machine. Be completely familiar

with the controls and the proper use of this machine before

operatirrg li. Keep this manual in a safe place lor future and regular

reference and for ordering repiacement parts.

2. Your rotary mower is a precision piece of power equipment, nrrt

a plaything. Therefore, exercise extreme caution at ail times.

3. Never allow cnildren to operate a power mower. Only persons well

acquainted with these rules of safe operation should be allowed

to use your mower,

4. Keep the area of operation clear of all persons, particularly small

children and pets. Stop engine when they are in the vicinity of

your mower to help prevent blade contact or thrown object in

jury. Although the area of operation should be completely cleared

of loreign objects, an object may have been overlooked and could

be accidently thrown by the mower in any direction and cause

serious personal injury to the operator or any others allowed in

the area.

PREPARATION

1. Thoroughly inspect the area where the equipment is to be used.

Remove all stones, sticks, wire, bones and other foreign obiects

which could be picked up and thrown by the mower in any direc

tion and cause serious personal injury to the operator or any others

allowed in ihc-area.

2. Always wear safety glasses or eye shields during operation or while

performing an adjustment or repair, to protect eyes from foreign

objects that may be thrown from the machine m any direction.

3. Wear sturdy, rough-soled work shoes and close-fitting slacks and

shirts to avoid entanglement in the moving pans. Never operate

a unit in bare feet, sandals, or sneakers.

4. Check the fuel before starting the engine. Gasoline is an extreme

ly flammable fuel. Do not fill the gasoline tank indoors, while the

engine is running, or until engine has been allowed to cool for

two minutes after running. Replace gasoline cap securely and wipe

ofi any spilled gasoline before starting the engine as it may cause

a fire or explosion.

5. Disengage the self-propelled mechanism or drive clutch on units

so equipped before starting the engine.

6. The blade control handle is a safety device. Never attempt to bypass

its operation. Doing so makes the safety device inoperative and

may result in personal injury through contact with the rotating

blade. The blade control handle must operate easily in both

directions.

7. Never attempt to make a wheel or cutting height adjustment while

the engine is running.

8. Never operate the equipment in wet grass. Always be sure of your

footing, A slip and fall can cause serious personal injury. Keep

a firm hold on the handle and walk, never run. Mow only in daylight

or in good artificia! light.

DANGER

9. For your safety, use the slope gauge included as part of this manual

to measure sfopes before operating this unit on a sloped or hilly

area. If the slope is greater than IS*’ as shown on the slope gauge,

do not operate this unit on that area or serious injury could result.

OPERATION

1. Do not change the engine governor settings or overspeed the

A

A

engine. Excessive engine speeds are dangerous.

2. Do not put hands or leet near or under rotating parts. Keep clear

of the discharge opening at all times as the rotating blade can

cause injury.

3. Stop the blade when crossing gravel drives, walks or roads.

4. After striking a foreign object, stop the engine, remove the wire

from the spark plug, and thoroughly inspect the mower for any

damage. Repair the damage before restarting and operating the

mower.

5. It the equipment should start to vibrate abnormally, stop the engine

and check immediately for the cause. Vibration is generally a warn

ing of trouble.

Shut the engine off and wait until the blade comes to a complete

6.

stop before removing the grass catcher or unctogging the chute.

I he cutting blade continues to rotate for a few seconds after the

engine is shut off. Never place any part of the body in the blade

area until you are sure the blade has stopped rotating.

Before cleaning, repairing or inspecting, таке certain the blade

and all moving parts have stopped. Disconnect the spark plug wire,

and keep the wire away from the spark plug to prevent accidental

starting.

Do not run the engine indoors.

Mow across the face of slopes, never up-and-down. Exercise ex

treme caution when changing direction on slopes. Do not mow

excessively steep slopes. Always be sure of your footing. A slip

and fall can cause serious personal injury.

Never operate mower without proper guards, plates or other safety

10

protective devices in place

11. Do not operate this mower with the chute door open, unless the

complete grass catcher is properly mounted on the mower.

MAINTENANCE AND STORAGE

1. Check the blade and engine mounting bolts at frequent intervals

for proper tightness

2. Keep all nuts, bolts, and screws tight to be sure the equipment

is in safe working condition.

3. Never store the equipment with gasoline in the tank inside of a

building where fumes may reach an open flame or spark. Allow

the engine to cool before storing in any enclosure.

4. To reduce fire hazard, keep the engine free of grass, leaves, or

excessive grease,

5 Check the grass catcher bag frequently for wear or deterioration.

For safety protection, replace only with new bag meeting original

equipment specifications.

Page 6

Rules for Safe Operation (Continued)

BLADE BRAKE/CLUTCH MAINTENANCE

NOTE:

Any required repair work on the blade brake/clutch should be

performed by an authorized service dealer. If you cannot locate an

authorized service dealer, contact the manufacturer.

1. The blade brake/clutch hand control is a safety device. Never

attempt to bypass its operation.

inoperative and may result in personal injury through contact with

the rotating blade. This hand control must operate freely in both

directions.

2.

Striking a solid object can cause damage to the blade brake/clutch

or to the engine crankshaft. Extensive vibration of the mower during

operation is an indication of damage and the unit should be

promptly inspected and repaired.

IMPORTANT: This unit is shipped WITHOUT GASOLINE or OIL. After assembly, service engine with

NOTE: Reference to right or left hand side of the mower is observed from the operating posi

Doing so makes the safety device

gasoline and oil as instructed in the separate engine manual packed with your unit.

tion. Refer to parts identification illustration on page 4 for location of parts when assem

bling the mower.

ASSEMBLY INSTRUCTIONS

3. A leak in the lower engine crankshaft oil seal could expose the

blade brake/clutch friction pads to excess oil resulting in blade

or brake slippage, which could increase the stopping time of the

blade. Oil collection on the floor beneath the mower dunng storage

may be an indication of an oil seal leak. The unit should be checked

by an authorized service dealer.

4, Periodically inspect the inner control cable in the area where it

attaches to the hand control. If the cable becomes frayed, it could

cause the blade brake/clutch to operate improperly. Also, be careful

to avoid pinching the blade brake/clutch control cable when stor

ing the handle.

Tools Required for Assembly

(1) Pair of Pliers

(1) Phillips Head Screwdriver

(1) 1/2" Wrench*

(1) 5/16" Wrench or Nutdriver*

(1) 7/16" Wrench*

*Or one 6" Adjustable Wrench.

UNPACKING

1. Remove the lawn mower from the carton by open

ing the top flaps and lifting the unit out. Be careful

of the staples. Make certain all parts and literature

have been removed from the carton before the car

ton is discarded.

2. Disconnect and ground the spark plug wire against

the engine. Check beneath the deck for any card

board packaging. Remove if present.

3. Stretch out all control cables and place on the floor.

Be careful not to bend or kink the cables at any

time during assembly.

4. Remove page four from this manual and lay the

contents of the hardware pack on the illustration

for identification.

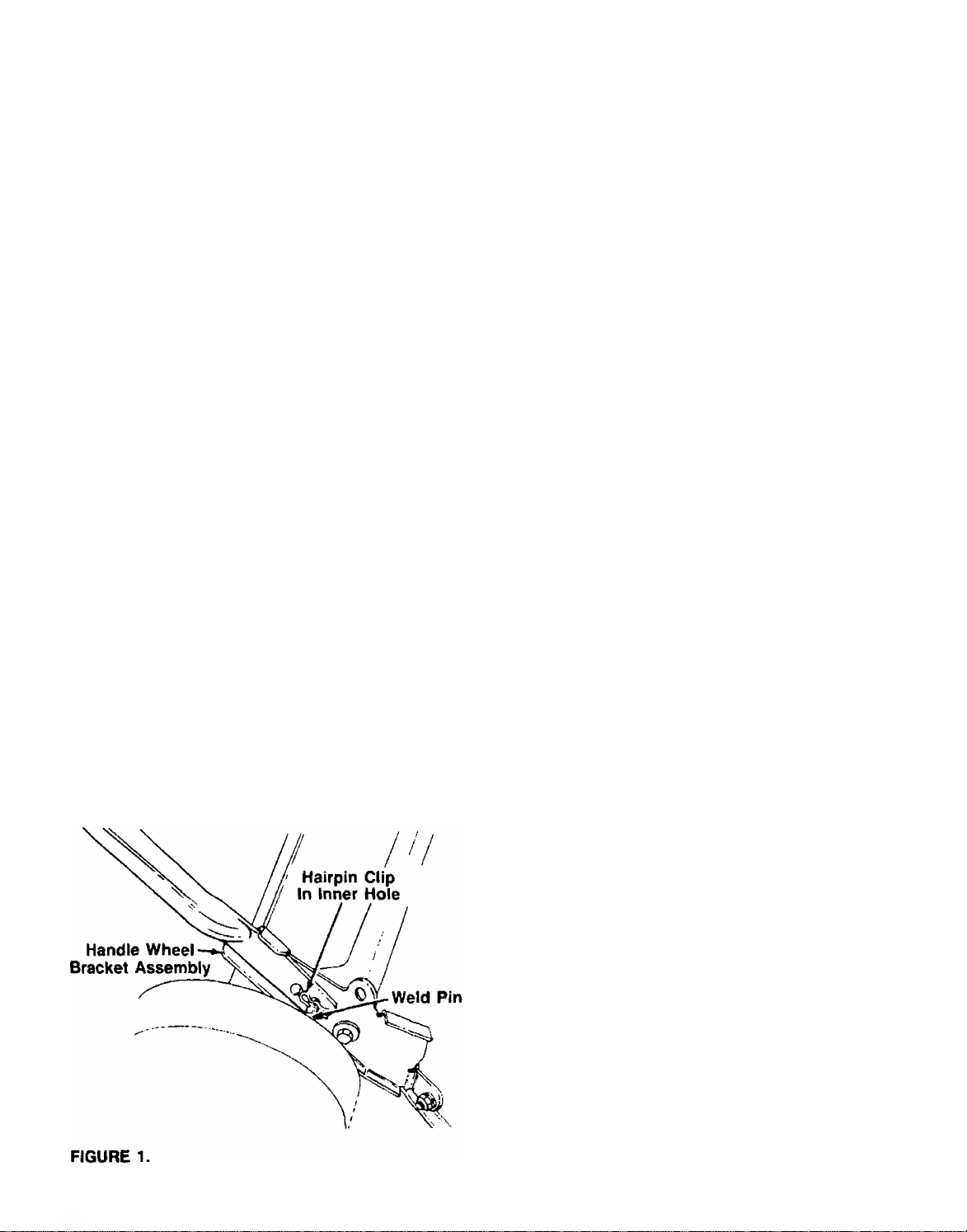

ATTACHING THE LOWER HANDLE (Hardware A)

1. For shipping purposes your mower is set with the

wheels in the lowest cutting height position. Raise

the mower to the highest setting for assembly of

lower handle.

2. Attach the lower handle by placing the bottom

holes in the lower handle over the weld pins on the

handle wheel bracket assemblies on the rear of the

deck. Make certain the instruction label on the

lower handle can be read from the operating

position.

—3. Using a pair of pliers, squeeze one leg of the lower

handle against the handle wheel bracket assembly.

Insert the hairpin clip into the inner hole on the

weld pin. See figure 1. Repeat on other side.

Page 7

split Washer

Hex Nut

FIGURE 2.

FIGURE 3.

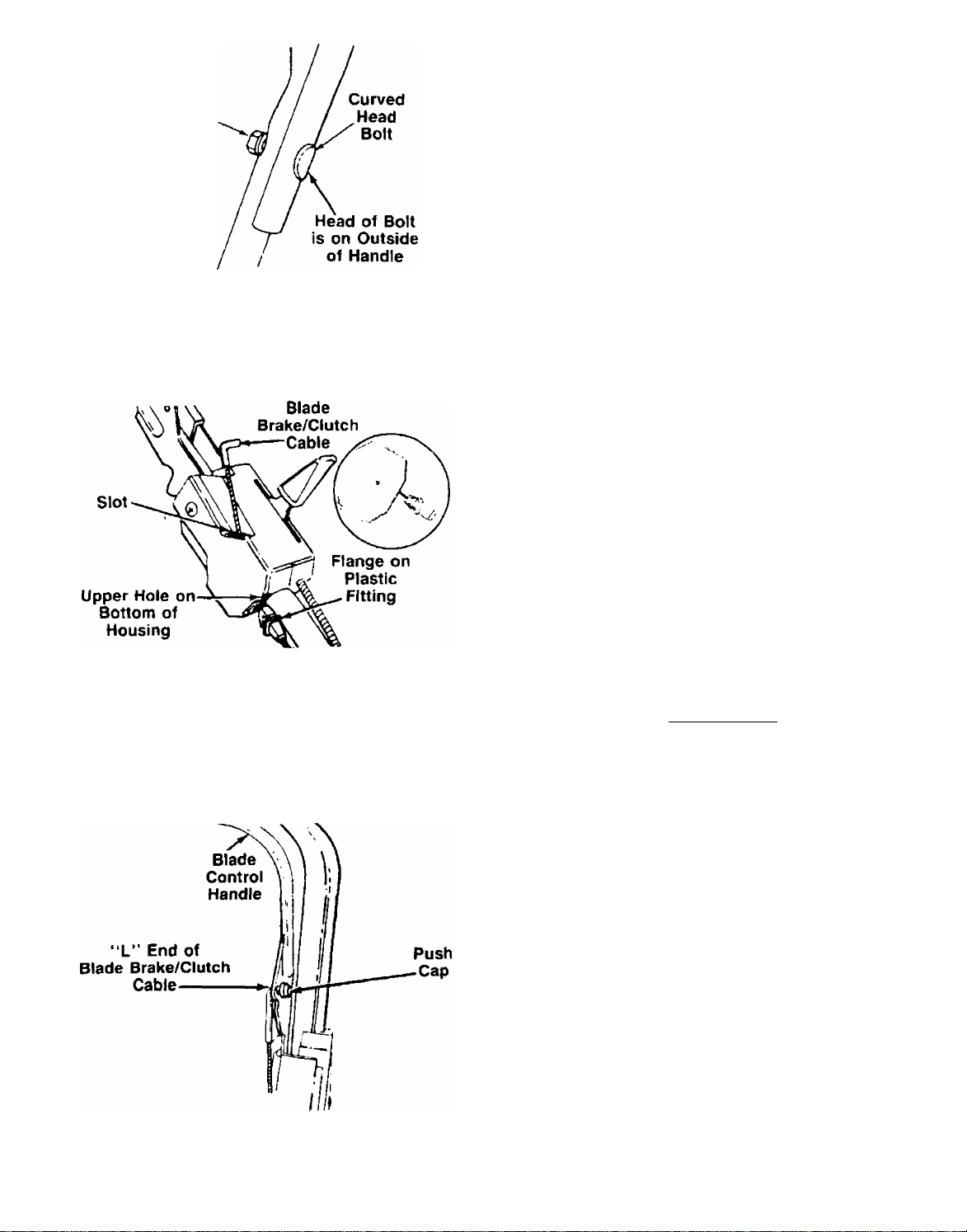

ATTACHING THE UPPER HANDLE (Hardware B)

Place upper handle in position over lower handle. The

label on the throttle control housing and the control

lever must be facing up. Secure upper handle with two

curved head bolts, split washers and hex nuts. See

■figure 2.

ATTACHING THE BLADE BRAKE/CLUTCH CABLE

(Hardware O)

The blade brake/clutch cable is the cable which has

an “L” fitting on the loose end. and is attached to the

blade brake/clutch underneath the deck.

1. Route the blade brake/clutch cable to the outside

of the catcher panel and height adjustment lever,

and under the lower handle. Place end of cable into

the upper hole on the bottom of the control hous

ing, and through the slot on the side of the hous

ing as shown. The angle of the plastic flange must

------

be positioned downward as shown in figure 3. Be

careful not to bend or kink the cable at any time,

2. Push the plastic flange until it locks into the con

trol housing.

i WARNjNG ^

A

The cable must be assembled as

shown for proper blade brake/clutch

operation.

FIGURE 4.

3. Insert the “L” end of the blade brake/clutch cable

into the hole in the blade brake/clutch control han

dle, from the inside to the outside as shown in

—figure 4. Hold the end of the cable, and press push

cap on by hand.

Page 8

FIGURE 5.

Rush^^^r Slotv Screw

Control Lever

on Engine

U J I r IJ1

l-i'i, P

ATTACHING THE THROTTLE CABLE

1. Push the throttle control lever on the handle all the

way forward to CHOKE, then back it off two

------

“clicks” (approximately 5/16"). See figure 5.

2. The throttle control cable is attached to the upper

handle. Route the throttle control cable to the out

side of the height adjustment lever and catcher

panel. Hook the ”2” end of the throttle control

cable into the hole in the control lever on the

engine. See figure 5.

3. Using a 5/16" wrench or nutdriver, remove the

screw on the cable clamp shown in figure 5. Slip

the control cable under the clamp. Replace the

screw (cable should be above the screw), but do

not tighten screw (cable must still move freely

beneath the clamp). Make certain the tab on the

cable clamp is seated into the slot on the engine.

4. Push the control lever on the engine as far toward

the outside of the engine as it will go. The edge

of the control lever should be flush with the bracket

on the engine. See figure 5. Hold the control lever

in this position as you tighten the screw on the

cable clamp to secure the throttle cable.

5. Loosen the screw on the clamp on the side of the

engine. Slip the cable casing under the clannp to

secure the cable away from the muffler Be

careful not to bend or kink the cable. Tighten the

screw.

FIGURE 6.

figure 7.

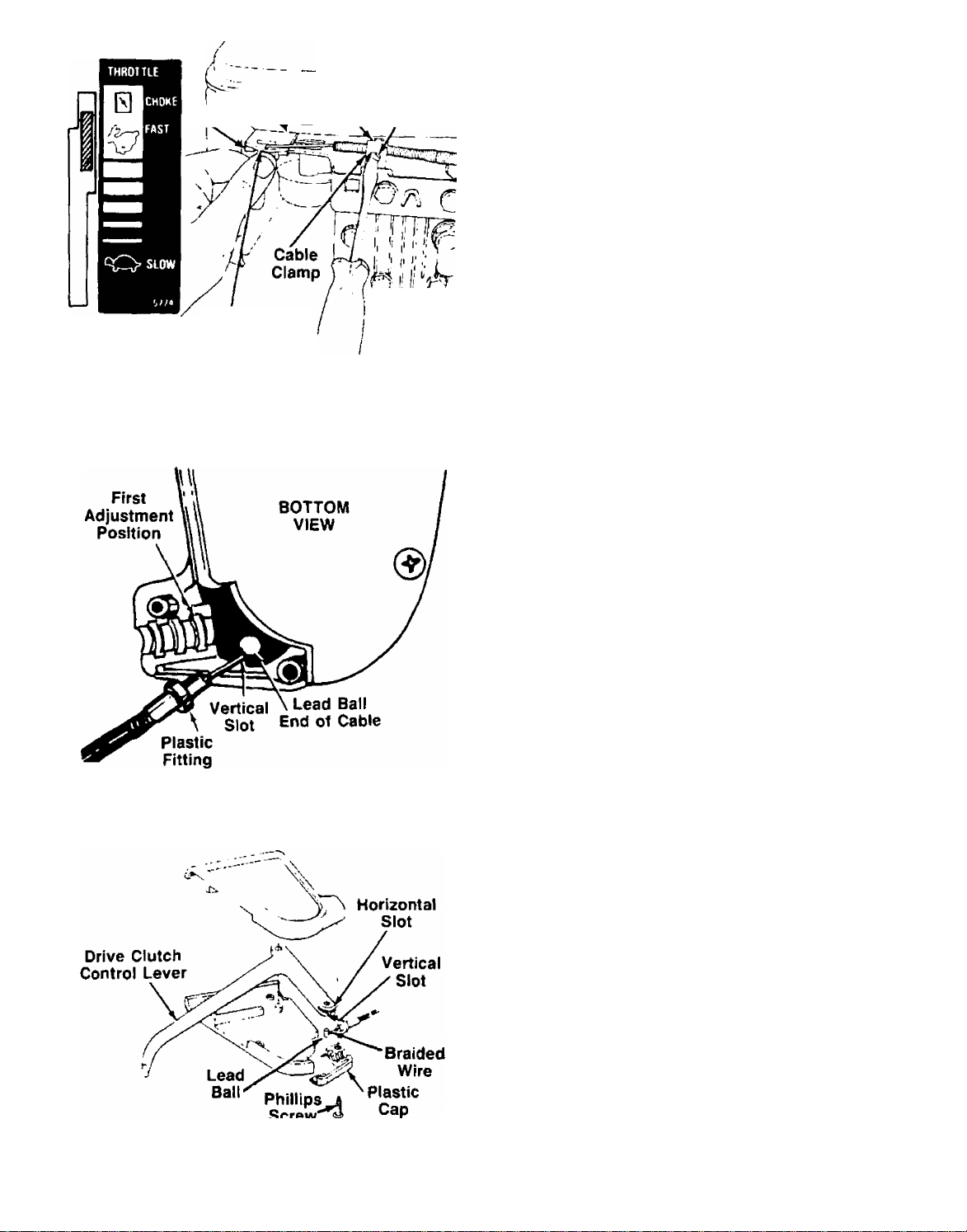

ATTACHING THE DRIVE CLUTCH CONTROL

CABLE (Hardware C)

■The drive clutch control cable is attached to the deck.

Attach the cable to the lever in the clutch control hous

ing, located in the middle of the upper handle, as

follows.

1. Place the lead ball end of the cable into the fitting

provided in the end of the clutch control lever. Slip

the braided wire into the vertical slot as shown in

figure 6.

2. Slide the braided wire around in the horizontal slot.

See figure 7.

3. Place the plastic fitting on the control cable Into

the first adjustment position in the clutch control

housing. See figure 6.

4. Secure the plastic cap to the clutch control hous

ing using the two Phillips head screws. See figure

------

7.

i WARNING 1

A

Drive clutch adjustment must be

checked before the unit is operated,

as described in the operation sec

tion.

Page 9

FIGURE 8.

Grass Catcher

Handle—

Truss Machine

Self-Tapping ,

Screw (

FIGURE 9.

}\

/

Plastic

Channels

■ Upper Bag

Support

Brackets

SECURING THE CABLES (Hardware E)

Secure all cables to the grass catcher panel and lower

handle as toltows.

A. Open the cable clamp provided in your hardware

pack, and slip the cables inside. Remove the up

per hex nut and lock washer from the side of the

catcher panel. Attach cable clamp as shown in

-----

figure 9A. Secure with lock washer and hex nut.

B. Place the height adjustment lever in the lowest posi

tion. Insert posts on cable ties into holes provided

on the left side of lower handle, one near the top

and one near the bottom of the handle. The holes

may be on either the inside or outside of the han

dle. See figure 9B.

C. Secure the cables with the cable ties, making cer

tain to take the slack out of the cables so they do

not contact the wheel. See figure 9C.

D. Trim excess ends of cable ties.

ASSEMBLY OF GRASS CATCHER (Hardware F)

1. Place bag over frame (black plastic side is the bot

tom of bag). Handle on frame goes to the top of

bag. Brackets hook toward the front. See figure 9.

2. Secure bag to frame by slipping plastic channels

-------on bag over frame. See figure 9.

3. Insert the upper bag support into the pocket on the

rear of the bag. Place grass catcher handle on top

of grass catcher support as shown in figure 9. The

handle should hook toward the rear of the bag as

shown in figure 9. Secure with two truss machine

self-tapping screws.

TO ATTACH BAG TO MOWER

FIGURE 10.

A

WARNING

DO NOT operate the mower unless the

complete grass catcher or side chute

deflector is properly mounted on the

mower.

1. Hook the handle on the rear of the grass catcher

over the lower handle of the mower. See figure

—10A.

2. Hold the chute door on the catcher panel open as

shown in figure 10B.

3. Slide the frame of the grass catcher down into the

channels on the catcher panel. The top portion of

the frame goes over the catcher panel.

4. Secure the grass catcher by turning the locking

lever to the locked position as shown in figure IOC.

To remove the grass catcher, turn the locking lever to

the unlocked position, unhook the rear handle and lift

the grass catcher straight up.

Page 10

TO CONVERT MOWER TO SIDE DISCHARGE

To convert your mower to a side discharge unit, remove

only the grass bag and top discharge chute, and

assemble the side chute deflector. It is not necessary

to remove the catcher panel and brackets.

To remove the top discharge chute, proceed as follows.

•See figures 11 and 12.

1. Remove the wing nuts on the side of the deck.

2. Lift up on the front edge of the discharge chute,

then slide it toward the side, removing it from the

bolts in the side ot the deck.

3. Attach the side chute deflector by first placing it

over the rear bolt in the side of the deck, then over

the front bolt and sliding it into position, with

shoulder bolt on deck in notch on deflector. Secure

with wing nuts.

•FINAL ASSEMBLY OF MOWER (Hardware G)

1. Attach hub caps to the wheels by lining up the hub

caps with the wheels. Push to lock in position.

2. Make certain all nuts and bolts are tightened

securely.

CONTROLS

THROTTLE CONTROL

The throttle is located on the left side of handle. It con

trols engine speed. See figure 13.

DRIVE CLUTCH CONTROL

Squeezing the drive clutch control engages the drive

mechanism to the rear wheels. Releasing the clutch

control stops the rear wheels from driving. Release the

drive clutch control to slow down when negotiating an

obstacle, making a turn or stopping. See figure 13.

BLADE BRAKE/CLUTCH CONTROL

WARNING

THIS CONTRCX MECHANISM IS A

SAFETY DEVICE NEVER ATTEMPT

TO BYPASS ITS OPERATIONS

The blade brake/clutch control is located on the upper

handle of the mower. The blade brake/clutch handle

engages and disengages the blade.

To engage the blade, pul! the side release lever away

from the unit. See figure 13. Pull the blade brake/clutch

control handle against the upper handle. Release side

lever.

Release the blade brake/clutch control handle to stop

the blade from turning.

10

Page 11

OPERATION

DO NOT OPERATE MOWER UNLESS

THIS GUARD OR ENTIRE GRASS-

CATCHER IS IN ITS PROPER PLACE.

FIGURE 14.

Keep hands and feet away from the chute area on cut

ting deck. See figure 14.

NOTE

For shipping purposes your mower

is set with the wheels in a low cut

ting height position. For best re

sults raise the cutting position un

til it is determined which height is

best for your lawn. See cutting

height adjustment section.

BEFORE STARTING

Before each use, check for proper drive clutch opera

tion by performing the following before starting the

engine;

With the drive clutch control released, push mower for

ward. tt should move freely. Pull mower backward. It

should move freely.

If it does not and the rear wheels tend to lock up, the

clutch may not be releasing completely. Do not start

the engine until corrections have been made. Check

the control cable for severe bend, kinks and binding,

or grass build-up in the pulley grove. Correct and ad

just as required.

TO START ENGINE

WARNING

A i

When starting the unit for the first

time, face the mower against a solid

object such as a wall, fence, etc.

Start the unit, and if it shows any

signs of motion with the drive clutch

control disengaged, shut the engine

off immediately. Check the position

of the drive clutch control cable.

The plastic fitting must be assem

bled in the first adjustment position

inside the housing, all the way to the

right, as shown in figure 6.

GAS AND OIL FILL-UP

Service the engine with gasoline and oil as instructed

in the separate engine manual packed with your

mower. Read instructions carefully.

NOTE

Your unit has been shipped without oil;

however, a small amount of oil may be

present from the factory. Do not overfill.

A

Never fill fuel tank indoors, with en

gine running or until the engine has

been allowed to cool for at least two

minutes after running.

1. Attach spark plug wire to spark plug. Make certain

the metal loop on the end of the spark plug wire

{inside the rubber boot) is fastened securely over

the metal lip on the spark plug. See figure 15.

Metal Loop

on Spark

Plug Wire

Rubber Boot

FIGURE 15.

2. The fuel shut-off valve is located beneath the fuel

tank. The fuel shut-off valve should be in the open

position. See figure 16. Open fuel shut-off valve

if it is closed. It may be necessary to remove the

discharge chute.

11

Page 12

FIGURE 16.

3. Move throttle control lever to CHOKE position.

NOTE

A warm engine may not require choking.

4. With the blade brake/clutch handle released,

crank engine by pulling recoil starter with a quick

firm pull. Do not pull out so far that rope stops with

a jerk as this will cause rope failure. Do not allow

rope and handle to snap back into place.

5. After engine starts, move throttle control to desired

engine speed.

TO STOP ENGINE

1. Move throttle control lever to STOP position.

2. Disconnect spark plug wire from spark plug and

ground against the engine to prevent accidental

starting while equipment is unattended.

NOTE

If a warm engine falters or stalls when

attempting to engage the blade, refer

to Carburetor Adjustment Section of

this owner’s manual.

3. Release the blade brake/clutch control handle to

stop the blade from turning.

NOTE

Always release the blade brake/clutch control han

dle before stopping the engine. If the engine begins

to stall, release the blade brake/clutch control handle

immediately.

Should the engine stall with the blade brake/clutch con

trol in the operating position (control handle not re

leased), difficulty may be encountered in pulling the

starter rope to restart the engine. Proceed as follows.

1. Disconnect the spark plug wire from the spark

plug.

2. Move the throttle lever to STOP position.

3. Hold the blade brake/clutch control in the engaged

position.

4. While holding the blade brake/clutch control han

dle in this position, pull the starter rope.

5. As the starter rope is being pulled, release the

blade brake/clutch control handle.

The starter rope should now operate correctly. Recon

nect the spark plug wire for normal operation.

NOTE

If any problems are encountered, refer

to the Trouble Shooting Chart on page

22.

i WARNING 1

A

Never operate your unit without

either the side chute deflector or entire

top discharge chute and catcher panel

assembly in place.

TO ENGAGE THE BLADE

1. Start engine as instructed previously. Allow the

engine to warm up for one minute before at

tempting to engage the blade.

2. To engage the blade, pull the side release lever

away from the unit. Pull the blade brake/clutch con

trol handle down against the upper handle.

Release the side lever. See figure 13.

USING YOUR ROTARY MOWER

WARNING

A

DO NOT operate the mower with the

chute door open unless the com

plete grass catcher is properly

mounted on the mower.

Be sure that lawn is clear of stones, sticks, wire, or other

objects which could damage lawn mower or engine.

Such objects could be accidently thrown by the mower

in any direction and cause serious personal injury to

the operator and others.

Operate a new engine at intermediate speeds and light

load for the first few hours as you would a new

automotive engine.

For the best results, do not cut wet grass because it

tends to stick to the underside of the mower, prevent

ing proper discharge of grass clippings, and could

cause you to slip and fall. New grass, thick grass or

wet grass may require a narrower cut. Blade speed

should be adjusted to the condition of the lawn.

12

Page 13

When using the side discharge mower, the best mow

ing pattern is one that allows the clippings to discharge

towards the uncut part of the lawn. This permits recut

ting of the clippings to further pulverize them. When

cutting high weeds, discharge towards cut portion, then

recut at right angles to first direction.

For best results, cut off one-third or less of the total

length of the grass. Lawn should be cut in the fall as

long as there is growth.

This mower is designed to be operated at full throttle

to give you the best cut and do the most effective job

of bagging the cut grass.

CUTTING HEIGHT ADJUSTMENT

The height adjustment handle is located on the left side

of the deck. The handle may be placed in one of nine

cutting height positions. Push the handle to the left and

then either forward to lower the cutting height or

backward to raise the cutting height. See figure 18.

For rough or uneven lawns, move the height adjustment

handle to a position which will give a higher cutting

height.

IMPORTANT

If you strike a foreign object, stop

the engine. Remove wire from spark

plug, thoroughly inspect the mower

for any damage, and repair the

damage before restarting and

operating the mower.

Striking a solid object can cause

damage to the blade brake/clutch or

to the engine crankshaft. Extensive

vibration of the mower during opera

tion is an indication of damage. The

unit should be promptly inspected

and repaired.

ADJUSTMENTS

Ac WARNING \

Do not at any time make any adjust

ment to lawn mower without first

stopping engine and disconnecting

spark plug wire,

Height

Adjustment

Handle

FIGURE 18.

THROTTLE

The throttle control wire assembly can be adjusted if

necessary. Loosen the screw on the cable clamp shown

in figure 5. Adjust as instructed in steps 1 and 4 of “At

taching the Throttle Control Cable’’ in Assembly In

structions.

CARBURETOR ADJUSTMENTS

DRIVE CLUTCH CONTROL ADJUSTMENT

If the unit does not self-propel with the drive clutch con

trol engaged, remove the plastic cap from beneath the

drive clutch control housing. Move the plastic fitting on

the control cable to the next adjustment position on the

left. Reassemble the plastic cap and retest. See figure

17.

II warning \

A

If any adjustments are made to the

engine white the engine is running

{e.g. carburetor), disengage all

clutches and blades. Keep clear of

alt moving parts. Be careful of

heated surfaces and muffler.

Minor carburetor adjustments may be required to

compensate for differences in fuel, temperature,

altitude and load. Refer to the separate engine manual

packed with your mower.

NOTE

If a warm engine falters or stalls

when attempting to engage the blade,

the carburetor mixture should be adjusted

1/8 turn richer (counterclockwise). See

figure 19.

13

Page 14

The carburetor should be adjusted with the air cleaner

in place and the blade control handle in the blade

disengaged position.

NOTE

A dirty air cleaner will cause an engine

to run rough. Be certain air cleaner is

clean before adjusting carburetor. Refer

to the separate engine manual.

Idle Speed

Adjusting Screw

Idle Mixture

Valve

FIGURE 19.

Discharge Chute Door Mechanism—The torsion

spring and pivot point should be lubricated periodical

ly with light oil to prevent any rust or binding. Door must

work freely.

Wheels—Lubricate the wheel bearings at least once

a season with light oil. Also, if the wheels are removed

for any reason, lubricate the surface of the axle bolt

and the inner surface of the wheel with light oil. A 4

oz. plastic bottle of light oil lubricant is available. Order

part number 737-0170. Engine oil may also be used.

Engine—Follow engine manual for lubrication in

structions.

Throttle—Periodically lubricate throttle control lever

and throttle wire assembly with a few drops of light oil

for ease of operation.

Transmission—The transmission is pre-lubricated and

sealed at the factory. It does not require checking. If

disassembled for any reason, fill with 2 ounces of

Alvania grease, part number 737-0168.

LUBRICATION

Always stop engine and disconnect

spark plug wire before cleaning,

lubricating or doing any kind of

work on lawn mower.

Blade Brake/Clutch—Lubricate the pivot points on the

blade brake/clutch handle and the cable at least once

a season with light oil. The control must operate freely

in both directions. See figure 20.

FIGURE 20.

MAINTENANCE

Ac warnÌn?

Be sure to disconnect and ground the

spark plug wire before performing any

repairs or maintenance.

NOTE

When tipping the unit, empty the fuel

tank and keep engine spark plug side

up.

TROUBLE SHOOTING

Refer to page 22 of this manual for trouble shooting

information.

CUTTING BLADE

To remove the cutting blade for sharpening or replace

ment, remove the two hex nuts and lock washers which

hold the blade to the blade brake/clutch. Protect hands

by using heavy gloves or a rag to grasp the cutting

blade. See figure 21.

14

Page 15

FIGURE 21.

When sharpening the blade, follow the original angle

of grind as a guide. It is extremely important that each

cutting edge receives an equal amount of grinding to

prevent an unbalanced blade. An unbalanced blade will

cause excessive vibration when rotating at high speeds,

may cause damage to the mower and could break,

causing personal injury.

The blade can be tested for balance by balancing it on

a round shaft screwdriver. Remove metal from the

heavy side until it balances evenly.

When replacing the blade, be sure to install the blade

with the side of the blade marked “Bottom" {or with

part number) facing the ground when the mower is in

the operating position.

Blade Mounting Torque

Make certain that the center bolt which secures the

blade brake/clutch and the two hex nuts which secure

the blade are tightened to between 350 inch pounds

(minimum) and 600 inch pounds (maximum).

To insure safe operation of your unit, all nuts and bolts

must be checked periodically for correct tightness.

DECK

The underside of mower deck should be cleaned after

each period of use as grass clippings, leaves, dirt and

other matter will accumulate. This accumulation of

grass clippings, etc., is undesirable as it will invite rust

and corrosion and may cause an uneven discharge of

grass clippings at the next cutting.

The deck may be cleaned by tilting the mower and

scraping clean with a suitable tool or by washing with

a stream of water from a garden hose.

NOTE

Do not direct the stream of water at a

hot engine as damage to the engine

may result.

ENGINE

Refer to the separate engine manual for all engine

maintenance instructions.

Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service air cleaner every 25 hours under norma! con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should be ser

viced. To service the air cleaner, refer to the separate

engine manual packed with your unit.

The spark plug should be cleaned and the gap reset

once a season. Spark plug replacement is recom

mended at the start of each mowing season; check

engine manual for correct plug type and gap specifi

cations.

Clean the engine regularly with a cloth or brush. Keep

the cooling system (blower housing area) clean to per

mit proper air circulation which is essential to engine

performance and life. Be certain to remove all grass,

dirt and combustible debris from muffler area.

BLADE BRAKE/CLUTCH

This unit is equipped with a blade brake/clutch. If for

some reason the blade brake/clutch becomes in

operative, it is suggested that all repair work on the

blade brake/clutch should be performed by an author

ized service dealer. The unit should be inspected by

an authorized service dealer if any of the following con

ditions are noticed.

1. Frayed clutch control cable.

2. Leaking oil seal (oil collection on the floor during

mower storage).

3. Extensive vibration of the unit.

BELT REMOVAL AND REPLACEMENT

1. Disconnect the spark plug wire and ground it

against the engine.

2. Drain the fuel tank or place a piece of plastic

beneath the cap to prevent gasoline leakage.

3. First remove the grass bag, discharge chute and

catcher panel.

4. Remove the transmission belt cover by removing

three bolts. Loosen the transmission belt auard

See figure 22.

15

Page 16

Screwdriver

in Slot

FIGURE 22.

5. Tip the mower on its side, and block securely.

6. Remove the blade by removing two hex nuts and

lock washers. Refer to figure 21.

NOTE

When reassembling, tighten hex nuts to

between 350 and 600 in. lbs.

7.

Remove the inside belt guard by removing two self

tapping screws. A 3/8" wrench is required. See

figure 23.

8. Remove the center bolt as follows.

a. Insert a screwdriver into the slot provided in the

blade brake/clutch housing where the control

cable enters the housing. See figure 23.

b. Place a 5/8" wrench on the center bolt. Turn

the wrench slowly until the screwdriver catches

in a groove provided inside the clutch. The

screwdriver will now keep the clutch from turn

ing, and the center bolt and cupped washer

may be removed. Lift off lower housing.

FIGURE 23.

9. Remove belt from the engine pulley half. Remove

the belt from between the idler pulley and the belt

guard on the idler pulley bracket. See figure 24.

FIGURE 24.

IMPORTANT

Upon reassembly, be certain to tighten

center bolt to between 350 and 600 in.

lbs.

10. Push the idler to the left and remove the belt from

the transmission pulley. See figure 25.

16

Page 17

FIGURE 25.

11. Reassemble the new belt, following instructions in

reverse order.

NOTE

When reassembling the ..transmission

belt cover, be certain the transmission

belt guard is approximately 1/8" away

from the belt. Make certain to tighten

all nuts and bolts securely. If plastic

was placed under the gas cap, be

certain to remove it.

OFF-SEASON STORAGE

The following steps should be taken to prepare lawn

mower for storage.

1. Clean and lubricate mower thoroughly as de

scribed in the lubrication instructions.

2. Refer to engine manual for correct engine storage

instructions.

3. Coat mower’s cutting blade with chassis grease

to prevent rusting.

4. Store mower in a dry, clean area.

__

^ NOTE

When storing any type of power

equipment in an unventilated or

metal storage shed, care should be

taken to rustproof the equipment.

Using a light oil or silicone, coat the

equipment, especially cables and all

moving parts.

NOTE

The use of any accessory on this Rotary Mower other

than those manufactured by the mower manufacturer

is not recommended.

WARNING 1

DO NOT operate the mower with the chute door open unless the complete

A

grass catcher is properly mounted on the mower.

DO NOT operate the mower without the protective shield on the rear of

2.

the deck in place.

Under norma! usage bag material is subject to wear and should be checked

periodically. Be sure any replacement bag complies with the mower manufac

turer’s recommendations.

For replacement bags, use only factory authorized replacement bag No.

764-0216.

I

NOTE

17

Page 18

TMO-37478A

18

Page 19

TMO-37478A

PARTS LIST FOR MODEL TMO-37478A

REF.

NO.

I

1

! 54

L!i.

PART NEW nPF 1

NO.

1

720-0225 Grip (2 Req’d.) N

2 16739

3

731-0734

4

710-0796 Truss Mach. Scr. #12 x

Control Handle Ass’y,—L.H. N

Top Discharge Chute Ass’y-

DESCRIPTION

1.50" Lg.

5

732-0401

6

720-0190

7

731-0817

8 731-0524

9

731-0816 Clutch Panel Half

10

731-0528 Throttle Control Lever

11

731-0975 Hub Cap N

12

731-0607

13 714-0507

14

749-0437

15

16129 Panel Support Brkt.

16 17196

17

17095

18

710-0429

19

732-0483

Lockout Spring

Spring Lever Knob

Control Panel Half

Control Disc Pin

Lock Pin .314" Dia X 1.75"

Cotter Pin 3/32" Dia. x .75" * 66

Upper Handle—Chrome

Top Catcher Panel Ass'y.

Top Discharge Door

Hex B-Tap Scr. #10 x ,38"

Torsion Spring 70

20 747-0514 Pivot Pin

21

710-0134 Carriage Bolt ’/4-20 x .62"* 72 732-0481

22

710-0286

Truss Mach. Scr. ’/4-20 x

.5" Lg.

23

24

710-0289

738-0704

Hex Bolt ’/4-20 X .50" Lg.*

Shoulder Bolt .312" Dia. x

.18" Lg. Special

25 710-0258

Hex Bolt ’/4-20 X .62" Lg.*

26 712-0287 Hex Nut ’/4-20 Thd.*

27

736-0270

28 736-0329

29 16702

731-0802

30

31

731-0619

32

735-0639

33

712-0388

34

746-0672

35

749-0505

36 4 H.P.

764-0216 21" Top Discharge Grass Bag

38

39

14835

41 736-0204

42

17055

43 710-0352

Bell-Wash. ’/4" I.D. 78 777-5815

L-Wash. ’/4" I.D.* 79 777-5811

Front Grass Catcher Frame [

Grass Catcher Handle 1

S.P. Control Cover

Spark Plug Insulator

Wing Nut N 83

Throttle Control Wire 58" Lg.

Lower Handle—Chrome

Engine B&S 110702-0212-03

Retaining Strip 88

FI-Wash. .344" I.D. X .62"

Chain—Axle Ass’y.

Hex B-Tap Scr. ’/4" x .38" 91

Lg.

44

741-0180

Flange Ball Bearing ’/2" I.D, 93

45 710-0776 Hex AB-Tap Scr. ’A x .62"

46 747-0526

47

712-0296

48

713-0353

Upper Bag Support 1

Hex Patch L-Nut 3/8-24 Thd.

#48 Chain .500" Pitch x 30

Links

49

712-0346

50 731-0564

51 731-0672

52

726-0240 Cable Tie

53

712-0328

710-0969

Hex L-Nut ’/2-20 Thd.

Plug

Rear Flap 3.75" x 17.30" Lg. 100

Hex Nut 3/8-24 Thd. (Gr. 8)

Hex AB-Tap Scr. #12 x 1.0"

Lg.

742-0306

21" Blade

4 H.P. 21" ROTARY MOWER

part! no. 1

PART

NO.

58 1 736-0412

j

59

747-0510

60 1

710-1002

61

748-0190

62

736-0169

63

736-0119

64

16136

65

16137

710-0260 Carriage Bolt 5/16-18 x .62"*

67

710-0603

N 68 710-1007 Hex Wash. Hd. TT-Tap Scr.

N

69 712-0267 Hex Nut 5/16-18 Thd.*

720-0223

71

732-0473

1

73 736-0242 Bell-Wash. 5/16" I.D.

74 750-0526

750-0624

75

77 726-0233 Bolt Retainer Va x .50" O.D.

738-0137

80

81 748-0188

82 734-1510

712-0189

N 84 741-0486 Sleeve Bearing ’/2" I.D.

728-0171

85

14924

86

87 720-0224

722-0134

731-0883

89

N 90

736-0271

710-0875

14300

92

741-0124

94 732-0396

746-0650

95

754-0343

96

97 14304

12894

98

99 731-0520 Ball Block

710-0436

101

751-0463 Casing Clamp

102

17075CC621

103 741-0326

104 14305

N

105 10662

19

DESCRIPTtON

Beli-Wash. .46" I.D. x .88"

O.D.

Height Adj. Rod 19.42" Lg.

Hex Bolt 7/16-20 X 2.0" Lg,

(Grade 5)

Spacer .513" I.D. x .703" i

O.D. X .69" Lg.

L-Wash. 3/8" I.D.*

L-Wash. 5/16" I.D,*

R.H. Handle Wheel Brkt.

Ass’y.

L.H. Handle Wheel Brkt.

Ass’y.

Hex Wash. Hd. B-Tap Scr.

5/16-18 X .5" Lg.

3/8-16 x 1.5" Lg.

Grip

Height Adj. Lever

Extension Spring .50" O.D.

x 3.80" Lg,

Spacer .385" I.D. x .502"

O.D. x .270" Lg.

Shid. Spacer .500" Dia. x

.100"

Instruction Label

Control Label

ShId. Scr. .342" Dia. x .268"

Pawl

Wheel Ass’y. Comp.—Rear

8 x 2.0"

Flat Weld Nut ’/4-20 Thd.

Pop Rivet .156" Dia. x .379"

Cable Bracket

Grass Catcher Locking Knob

Foam Strip 1" Lg.

Panel Clip

Spring Wash. .32" I.D.

Hex Tap Scr. ’/a-20 x .75" Lg.

Clutch Blade Housing Ass'y.

Ball Brg. .669" I.D. x 1.574"

Comp. Spring .35" O.D. x

2.0" Lg.

S.P. Cable x 50" Lg.

”V”-Belt

Clutch Cone

Casing Clamp

Hex B-Tap Scr. #10 x .62"

21" Deck Ass’y.

Steel Ball .50" Dia.

Brake Cup Cone

Front Axle Ass’y.

NEW

PART

N

N

N

N

Page 20

TMO-37478A

4 H.P. 21" ROTARY MOWER

PARTS LIST FOR MODEL TMO-37478A (CONTINUED)

REF.

NO.

106

107

108

109

110

111

112

113

114

115

116

117

118

121

122

123

124

125

126

127

128

129

130

131

PART

NO.

DESCRIPTION

711-0313 Sleeve .526" I.D. x .690" 133

O.D, X .880" Lg. 135

732-0397 Ext. Spring 1.75" Lg. 136

714-0104 Intern. Cotter Pin 5/16" Dia. 137

732-0482 Extension Spring .50" O.D, 138

X 3.20" Lg.

14309

736-0221

738-0705

734-1511

Clutch Housing

Intern. L-Wash. 3/8 I.D.'

Shid. Bolt .623" Dia. x .425

Front-Wheel Ass’y. Comp.

7 x 2,0" N

731-0617

731-0618

731-0620

720-0190

710-0841

Self-Propelled Control Cover

Self-Propelled Control Cover

Control Lever

Door Grip

FI-“C’’-Sunk Hd. Tap Scr.

#10 X .75" Lg.

710-0671

Curved Carr. Bolt 5/16-18 x

1.38" Lg.

756-0504

736-0409

756-0503

736-0408

710-0618

Fixed Pulley Adapter

Serrated Washer 1.0" t.D.

Serrated Pulley Half

Wave Washer 1.005" t.D.

Flat HD Tap Scr. V4-20 x

.625" Lg.

748-0319

748-0320

746-0406

748-0318

714-0115

Flywheel

Flywheel Adapter

Control Cable—49" Lg.

Ratchet Wheel 1.62" O.D.

Cotter Pin 1/8" Dia. x 1.00"

f-g.’

NEW

PART

—

REF.

NO.

140

142

PART

NO.

16559CC621

753-0431

10622

17176

17053

710-0599

736-0326

Side Chute Deflector Ass'y.

Kit—Control Housing Comp.

Spring—Nylon

Engine Mounting Plate Cover

Chain Cover

Hex Wash. S-Tap Scr. V4-20

X .50" Lg.

FI-Wash. .510" I.D. x 1.0"

O.D.

741-0522

143

144

736-0300

Hex Flange Brg. .506" t.D.

FI-Wash. .385" I.D. x .87"

O.D.

147

148

738-0719

741-0324

Rear Shaft Ass’y, 21.94" Lg.

Hex Flange Bearing .506"

I.D. Plastic

149

736-0160 FI-Wash. .531" I.D. x .930"

O.D.

150

736-0179

FI-Wash. .531" I.D. x 1.25"

O.D,

151

741-0491 Flanged Nyliner Brg.

152

710-0751

Hex Bolt 1/4-20 x .62" Lg.

(Grade 5)

153

717-0417

Transmission Comp.

(See Breakdown)

154

16500 Hex Bearing Cup

726-0245

155

156

157

726-0135

717-0845

Push Cap

Push Cap

Blade Brake Clutch Ass’y.

Comp.

DESCRIPTION

--------

NEW

PART

N

i

'Common Hardware—May be purchased locally.

IMPORTANT; DO NOT order parts by reference

number (Ref. No.).

Part No.

8176B088-8

788-0621

777-7002

770-6474C

NOTE; Specifications subject to change without notice

or obligation.

Description

Hardware Pack

Brilliant Fire Mist Spray Paint

Montgomery Ward Plastic Logo

Operating Manual

20

Page 21

TNIO-37478A

94-

—«.M

53-

s_- ^

3Q^

29 5.

"V \ ¿,-8 ’

\,rv j ;-‘-< ,:i> . 4i-

26.

y

i"^'

6—■.>

il'rV.’""

--------

V^.5'

J \

9

« iS> \,(,

"11

'"12

25. ^

\

I

H 35

-.-.4k

23-

22-

21

20

-F ' i'"

\

19

Id V"

4 H.P. 21" ROTARY MOWER

PARTS LIST FOR MODEL TMO-37478A

REF.

NO.

PART

NO.

1

710-0106

736-0329 L-Wash. 1/4" I.D.* 23 736-0270

2

717-0418 Upper Hsg. Half 24 17052

3

713-0400

4

Hex Bolt 1/4-20 X 1.25" Lg.’ i

#48 Sprocket 7 Tooth x '/2

DESCRIPTION

NEW

PART

REF.

NO.

22

PART

NO.

741-0482

25 712-0138

Needle Brg. .375" x .31|

Bell-Wash. .265" I.D. x .75"!

Idler Brk't. Ass'y !

Hex Patch L-Nut V4-28 Thd.!

Pitch ' 26 732-0357 Extension Spring 1.12" Lg.!

736-0336

5

741-0413

6

16500 Hex Bearing Cup

7

736-0314

8

741-0479 Thrust Bearing .375" I.D. x 32 738-0607 Gear Sprocket Shaft

9

715-0152

10

717-0420

11

748-0208 Flange Bearing

12

721-0212

13

738-0708

14

15

756-0330

736-0270

16

712-0351

17

738-0440 iShId. Spacer .375" Dia. x i 42 736-0270

18

736-0344

19

738-0691

20

756-0447

Li'

Ft-Wash. 5/8" I.D. x .030

Hex Flange Brg. .631" I.D.

Thrust Wash. .382" I.D. x 1

.70" O.D.

.812" O.D.

Spring Pin Spir. 1/8" x .62"

Heavy 1 35

11 Tooth Helical Gear

Oil Seal 38

Pulley-Transmission Shaft

27 717-0419 Lower Hsg. Half

28 741-0415 Flange Bearing .566 Dia.

29

717-0422 33 Tooth Helical Gear

30 741-0414

31

721-0213

Flange Bearing .629 Dia.

Oil Seal .625 Dia.

33 736-0722 ' L-Wash. #10 I.D.

34

710-0436

736-0410

36

17058

37

17065

710-0352

39 710-0599

Hex B-Tap Scr. #10 x .62"

' Hex Washer .26" x .88"t

1 Transmission Belt Guard!

Belt Covert

, Hex B-Tap Scr. V4 x .38" Lg.f

! Hex AB-Tap Scr. Va x .50"

Fl-Pulley 5.06" O.D.t Lg.t

Bell-Wash. .265" I.D. x ,75"t

Hex L-Nut 1/4-28 Thd.f 41

40 710-0896

712-0287

Hex B-Tap Scr. V4 x .62" Lg.

Hex Nut V4-20 Thd.’!

Bell-Wash. .265" I.D. x .75"!

! -170t

! FI-Wash. .390" I.D. x 1.0"t

Shid. Bolt .375" Dia. x ,40"t

Fl-ldler Plastic 1.50" Dia.t

! 43 736-0329 i L-Wash. 1/4" I.D.*!

1 44

746-06501 S.P. Cable—50" Lg.!

; 45

! —

747-0549 :

717-04171

S.P. Belt Guard!

Transmission Comp.

----

——

tNot Part of Transmission Complete

DESCRIPTION

-------------------

— _

NEW

PART

______________

21

Page 22

Trouble Shooting Chart

Problem

1 Engine fails to start A Check fuel tank for gas

2 Hard starting or

loss of power

3 Operation erratic

Cause Remedy

B Fuel shut-off valve closed

C Spark plug lead wire discon

nected

D Throttle control lever not in

the starting position

E Faulty spark plug

F Carburetor improperly ad

justed, engine flooded

G Old stale gasoline

A Spark plug wire loose

B Carburetor improperly

adjusted

C Dirty air cleaner

A Dirt in gas tank

B Dirty air cleaner

C Water in fuel supply

D Vent in gas cap plugged

E Carburetor improperly

adjusted

A Fill tank if empty.

B Open fuel shut-off valve.

C Connect lead wire.

D Move throttle lever to start

position.

E Clean, adjust gap or replace.

F Remove spark plug, dry the

plug, crank engine with plug

removed, and throttle in off po

sition. Replace spark plug and

lead wire and resume starting

procedures.

G Drain and refill with fresh

gasoline.

A Connect and tighten spark

plug wire.

B Adjust carburetor. See separate

engine manual.

C Clean air cleaner as described

in separate engine manual.

A Remove the dirt and fill tank

with fresh gas.

B Clean air cleaner as described

in separate engine manual.

C Drain contaminated fuel and

fill tank with fresh gas.

D Clear vent or replace gas cap.

E Adjust carburetor. See

separate engine manual.

4 Occasional skip

(hesitates) at high

speed

5 Idles poorly

6 Engine overheats

7 Excessive vibration

Note: For repairs beyond the minor adjustments listed above, contact your local service dealer.

A Carburetor idle speed too

slow

B Spark plug gap too close

C Carburetor idle mixture ad

justment improperly set

A Spark plug fouled, faulty, or

gap too wide

B Carburetor improperly

adjusted

C Dirty air cleaner

A Carburetor not adjusted

properly

B Air flow restricted

C Engine oil level low

A Cutting blade loose or

unbalanced

B Bent blade

A Adjust carburetor. See

separate engine manual.

B Adjust to .030".

C Adjust carburetor. See

separate engine manual.

A Reset gap to .030" or replace

spark plug.

B Adjust carburetor. See

separate engine manual.

C Clean air cleaner as described

in separate engine manual.

A Adjust carburetor. See

separate engine manual.

B Remove blower housing and

clean as described in separate

engine manual.

C Fill crankcase with the proper oil.

A Tighten blade. Balance blade.

B Replace blade.

22

Page 23

Page 24

SERVICE NATIONWIDE

Montgomeiy Ward

HOW TO OBTAIN

REPLACEMENT PARTS AND SERVICE

The morchandise you have purchased from us has been carefully

engineered and manufactured under Montgomery Ward’s rigid quali

ty standards and should give you satisfactory and dependable opera

tion. However, like all mechanical merchandise, it may occasionally

require adjustment, replacement parts or maintenance.

Toll Free Parts Sales Center

When you need a replacement part or accessory for a major ap

pliance, home electronic item or lawn and garden product that is

not under warranty or covered by a service contract or if you need

the location of the nearest service facility, call our Parts Sales Center

toll free 1-800-323-1965.

Provide the following;

1. Model, serial number and all of the other data shown on the model

plate.

2. Also give the part number or numbers as shown in the parts list

that came with the product.

Replacement Parts wilt be made available at current prices. If re

quested, prices will be quoted in advance when not listed.

If you order parts by mail, you will pay the transportation charges

from the shipping point.

UNIT MODEL NO.

UNIT SERIAL NO.

ENGINE MODEL NO.

TYPE NO

CODE NO.

PART NO. 770-6474C (R880322)

128-176B088

___________________________________

_________

_______

PRINTED IN U.S.A.

Loading...

Loading...