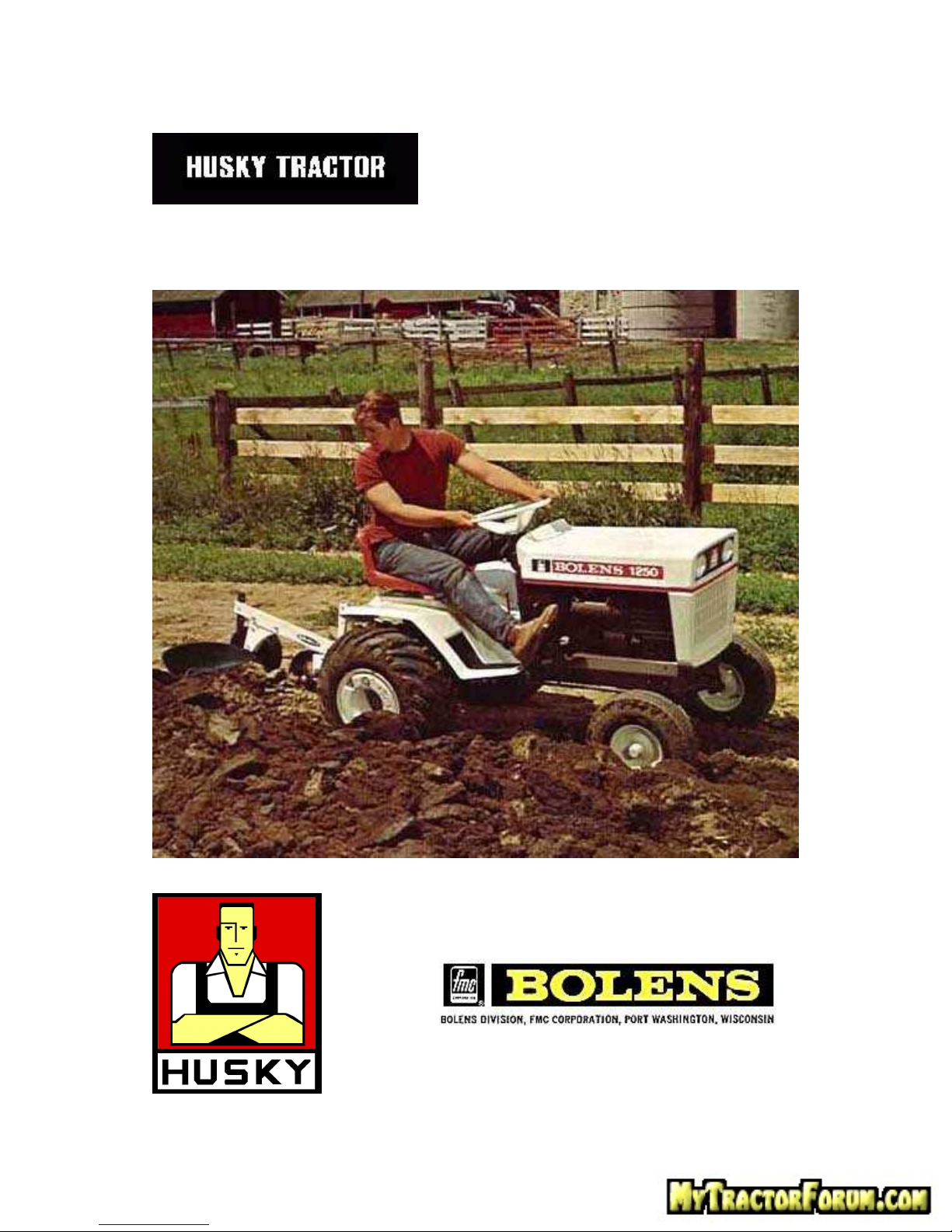

Bolens nolens 1250, Husky 1250 Operator And Maintenance Manual

1250 Large Frame

Operator’s and

Maintenance

Manual

197-01

Husky 1250, Operator's and Maintenance Manual

SAFE OPERATING PRACTICES

Serious accidents can be prevented. Every

operator should approach the following safety

practices with serious intentions of conforming

to them. An accident prevention program can be

successful only with wholehearted co-operation.

1. Always place transmission lever in PARK

prior to starting tractor.

2. Always place transmission lever in PARK

whenever vehicle is to be left unattended.

Ground all attachments.

3. Attachments must be GROUNDED when

storing tractor.

4. Do not tow vehicle over eight miles per hour.

5. When towing or moving the vehicle, place

transmission lever in NEUTRAL.

6. Keep hands clear of transmission cooling fan.

7. Do not mount or leave vehicle while it is in

motion or in actual operation, nor leave vehicle

unattended while engine is running.

8. Do not carry passengers.

9. Do not start or operate vehicle in an enclosed

area unless steps have been taken for sufficient

ventilation.

10. Keep tractor and attachments free of excess

grease and oil.

11. Engine must be stopped, and P.T.O.

disengaged when cleaning, servicing, adjusting,

repairing, or installing attachments on tractor.

12. Always disconnect ground (-) battery cable

from battery before doing any work on the

electrical system.

13. Study your manual. Know your tractor

before operating it. Take time to operate the unit

in the safest manner.

14. Always follow manufacturer's operational

suggestions.

15. Do not allow minors to operate vehicle

without proper instruction and adult supervision.

16. Do not allow adults to operate vehicle

without proper instruction.

17. Do not fill gasoline tank when engine is

running or hot.

18. When adding weight to rear wheels to

improve traction, do not use more than 3 wheel

weights per wheel. Wheel weights are 40 lbs.

each, 120 lbs. total for each wheel.

Back

INTRODUCTION

In 1919, Bolens engineered, manufactured, and introduced the first garden tractor . . . your new HUSKY

tractor represents years of research, engineering, and manufacturing skills. For this reason, we have

dedicated this manual to assist you in obtaining trouble free performance and to know the advantages

and features of your HUSKY tractor.

Your Bolens dealer has been carefully chosen to service your equipment for top performance through all

the years you use it. Take your HUSKY to him at regular intervals for inspection and servicing. Feel free

to contact him for answers to questions which you can not find in this manual.

Table of Contents

Safe Operating Practices Inside Front

Serial Number 2

Specifications 2

Break-In Period 3

Controls 3

Pre-Operational Checks 4

Starting the Engine 4

Run-In Period 5

Operation 5

Stopping the Engine 7

Preventative Maintenance

Page

Cover

7

Maintenance Guide 10

Lubrication 10

Lubrication Chart 10

Power Take-Off (P.T.O.) 12

Minor Trouble Shooting

Guide

Wiring Diagram 13

Optional Equipment 14

Storing Your Husky

Tractor

Warranty

Adjustments 9

Page

13

15

Cover

This is an operational and general maintenance manual only and does not cover major repair. All major

repair work must be performed by an authorized BOLENS DEALER or the factory warranty is . void.

Bolens equipment is carefully engineered to give trouble-free performance if properly operated and

maintained. Keep your equipment clean and lubricate it as prescribed in this manual. Periodically inspect

your unit and perform any upkeep maintenance necessary.

Your dealer is obligated by the factory to completely assemble and service new equipment prior to

delivery, and thoroughly explain and demonstrate its operation. He will repair or replace any parts which

fail due to defective material and/or workmanship during the warranty period, and also provide future

repair service and supply genuine factory repair parts.

TO THE OWNER

PAGE 1

Figure 1 Figure 3

SERIAL NUMBER

To ensure prompt service when repairs or adjustments are

required, your Bolens Dealer must have the following

information:

1. Model number of unit.

2. Serial number of unit.

3. Model number of engine.

4. Serial and Spec. number of engine.

Your Bolens dealer has available a master Parts List for

your unit. He can identify any parts you may require and

furnish genuine factory replacements.

When ordering engine component parts, consult the

Engine Manufacturer's Manual.

For your own personal reference, fill in the spaces

provided below.

Model Number of Unit _______________________

Serial Number of Unit _______________________

Engine Model Number _______________________

Engine Serial Number _______________________

Engine Spec. Number _______________________

PAGE 2

SPECIFICATIONS

(Specifications subject to change without notice)

NOTE

Bolens reserves the right to make changes or

improvements to its products without obligation to install

same on products previously manufactured.

Engine 28.86 cu. inch Wisconsin

Type

Fuel capacity 5.3 gallons

Engine oil capacity 2 quarts

Transmission oil capacity

Air cleaner Dry type

Drive Hydrostatic transmission

Speed. Infinitely variable.

Power to attachments

Tires

Height 45 inches

Width 38 inches

Length 72 inches

Wheelbase 49 inches

Turning radius 54 inches

Ground clearance 8-1/2 inches

Shipping weight 975 lbs.

4 cycle, single cylinder, air

cooled

10 quarts

Forward: approx. 0-8 mph

Reverse: approx. 0-4 mph

Triple belt drive (P.T.O.), with

universal joints and splined

shaft.

Front: 5.70/5.00-8

Rear: See optional equipment

section, page 14.

Standard equipment. . P.T.O., splined shaft to drive

front, center or rear attachments, hydraulic lift system

with visual depth gauging, electric starting, head lights

and tail lights, full fenders, adjustable all angle seatspring suspension with foam-padded adjustable seat

(easily removable for weather protection), 45 amp

battery, selector level for drive-neutral-park, tapered

roller bearing front wheels and replaceable spindle

bushings, automotive type muffler, compression

release for easy starting, coil ignition, three-unit

regulator (automotive type), ammeter, extra heavy

channel frame, tilting hood for access to engine.

Location of tractor model and serial number . . . . . . .

Top left side of heat shield

Location of engine model and serial number . . . . . . . . .

Front of engine cowling

BREAK-IN PERIOD Figure 3

As with a new car, your new HUSKY Tractor should

receive special attention. During the first few hours of

operation, it is best to vary the engine speed (see

inside front cover of engine manual) . . . . . . avoid full-

throttle driving . . . . and avoid quick starts and stops

until you have become well acquainted with your

tractor. IMPORTANT: THE TRACTOR IS SHIPPED

FROM THE FACTORY WITH OIL IN THE ENGINE

CRANKCASE. CHECK THE CRANKCASE AND THE

HYDROSTATIC TRANSMISSION OIL RESERVOIR

FOR PROPER OIL LEVEL BEFORE ATTEMPTING TO

START YOUR UNIT. BECOME FAMILIAR WITH THE

LOCATION OF EACH CONTROL. BE SURE

TRANSMISSION LEVER IS IN "PARK" POSITION.

Both the tractor and engine have been fully tested by

the factory and your dealer to assure your complete

satisfaction. Keep this manual available at all times,

read it carefully, if you have any questions that are not

answered in the manual, consult your Bolens dealer.

CONTROLS

Before operating the tractor, the operator should

become familiar with the function and location of each

control to ensure proper and efficient operation.

The following listed numbers and accompanying

information correspond to those numbers assigned to

the controls indicated in Figure 4.

1. Choke. Pull choke knob out to operate choke.

2. Ammeter. Indicates level of charge or discharge to or

from battery.

3. Light Switch. Pull light switch knob out to turn on

lights . . . . push in to turn lights off.

NOTE

Ignition-starter switch (4) must be ON to turn on head

and tail lights.

4. Ignition-Starter switch. Turn ignition switch against spring

tension to actuate starter. Release when engine starts.

5. Throttle. Pull throttle knob out one-half way for starting.

More or less throttle may be required due to grade of fuel and

temperature variations. Allow engine to warm up, then adjust

throttle to full engine R.P.M. while operating under load.

6. Foot Brake. Use when vehicle is being towed or freewheeling; when moving transmission lever (12) from

NEUTRAL or PARK position to DRIVE position.

7. Speed Control. Depress with toe of foot for forward motion.

Depress with heel of foot for reverse motion. Provides instant

braking and speed regulation. (See Figure 7.)

8. Speed Hold. Can be used to hold speed control (7) at a

desired speed setting. Depress with toe of left foot to hold,

and depress with heel of left foot to unlock. See Figure 6 for

operation of speed hold on page 5.

9. Depth Indicator Gauge. Allows operator to locate original

height or depth of attached implement.

10. Hydraulic Lift Lever. Push lever forward to raise and pull

lever back to lower attachments. Pull lift lever all the way back

for FLOAT position.

11. Power Take-Off (P.T.O.) Lever. Engages and disengages

power to attached implements. Lever positions indicated on

etched plate.

12. Transmission Lever. Place transmission lever in :

- NEUTRAL for towing .

- DRIVE for infinitely variable speeds from 0-8 mph forward

to 0-4 mph in reverse .

- PARK for starting and when tractor is At Rest.

CAUTION

Do not place transmission lever into PARK position while

tractor is in motion. Premature shifting into PARK may result

in serious damage to the hydrostatic transmission.

PAGE 3

PRE-OPERATIONAL CHECKS

EMERGENCY STARTING

The operator should become familiar with the following

pre-operational check list prior to starting or operating

the HUSKY.

1. Thoroughly clean area around crankcase oil dipstick,

and check for proper level of engine oil. See Engine

Manufacturer's Manual.

2. Thoroughly clean area around hydrostatic

transmission fill plug area, and check for proper level of

transmission fluid. See Lubrication Chart.

3. Check battery for proper water level.

4. Check gasoline tank for sufficient gas supply.

5. Check that air cleaner screen is free of debris. Check

and clean regularly. Replace if necessary.

6. Clean flywheel screen. Check and clean regularly.

7. Visually check for loose nuts and screws.

8. Check for 6-8 Ibs. tire inflation. TIRE INFLATION

SHOULD NOT BE LESS THAN 6 LBS.

In case of an electrical failure, proceed as follows:

1. Recharge or replace battery.

2. Jumper cables may be used. NOTE: If jumper cables are

used, cables must be connected, Positive (+) to Positive (+)

and Negative (-) to Negative (-).

3. After engine has started, allow it to warm up. Move choke

knob slowly forward, pull out throttle and lock at full speed.

4. Remove battery and have it fully charged as soon as

possible.

5. After the battery is fully charged, reinstall it in the tractor,

being careful to connect ground cable last.

6. Check generator belt for proper tension. Belt should

depress 1/4 inch between pulleys as shown in Figure 5.

Should adjustment be required, loosen generator mounting

screws and generator adjusting screw. Pivot generator

outward from engine until proper tension is obtained.

9. Do not allow ignition switch to remain in the on

position when engine is not running.

STARTING THE ENGINE

ELECTRIC STARTING

1. Be sure power take-off (P.T.O.) safety clutch is in the

OFF position, and the transmission lever is in PARK

position.

2. Pull out choke. Experience will indicate need for

more or less choking due to temperature variations,

grade of fuel, engine heat, etc.

3. Pull out throttle one-half way. More or less throttle

may be required due to grade of fuel and temperature

variations.

4. Turn ignition key against spring tension to actuate

starter. Release key when engine starts.

5. Allow engine to warm up. Move choke slowly

forward; pull out throttle and lock at full speed while

operating.

6. To stop the engine, bring engine back to idle, place

transmission lever in PARK and turn ignition switch off.

Remove the ignition key when the tractor is not in use,

or left unattended.

Figure 5

NOTE

Never pry out generator with a long heavy bar or tool as this

could result in premature bearing failure.

7. Tighten the generator mounting screws and generator

adjusting screw. Make sure all bolts are torqued securely.

PAGE 4

Loading...

Loading...