Page 1

STOCK NUMBER

93-7122.0

MODEl. NUMBER

MTO1122B09

FACTORY NUMBER

130..61OF098

Thank you tol' purchasing an Amel'lcan-built product.

Page 2

Slope Gauge Safe Operation Practices

Assembly Instructions. .

Controls.. "

Operation. Adjustments lubrication Maintenance Off-Season Storage.

Western Auto Supply Company warrants to the original retail purchaser that this Wizard product

is free from defects in material and workmanship and agrees to repair any product free of charge

within these time periods from date of purchase:

One year, if the product is used for personal, family, or household use;

90 days, if the product is used for any other purpose such as commercial or rental use.

A battery which proves defective within ninety (90) days will be replaced without charge. After

90 days but within one year from the date of purchase. Western Auto will replace the defective

battery for a charge of 1/12 of the current retail price of the battery for each full 30 day period

between the date of purchase and the date of return.

The company manufacturing the engine furnishes their own two year warranty and provides service through their authorized field service facilities. For additional information, see the warranty

covering the engine. Repair service arrangements may be handfed through any participating

Western Auto Store.

Excluded from this warranty are: normal wear and maintenance, and mechanical adjustments which

are not due to defects in material or workmanship. For assistance in making such adjustments,

consult your owner's manual. Any unit which has been altered, misused, abused, or repaired by

other than a Western Auto authorized service facility is also excluded.

For repair service return unit with proof of purchase date to any participating Western Auto Store.

If difficulty is encountered in having this warranty honored, contact: Western Auto Supply Company, Consumer Affairs Section, General Service Department, 2107 Grand Avenue, Kansas City,

Missouri 64108. This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

.3

.5

.6

Engine Operating and Maintenance

Instructions. Trouble Shooting Chart. Illustrated Parts for Lawn Tractor. .

10

Electrical System. Illustrated Parts for Transaxle Illustrated Parts for Engine. Partslnformation

12

14

15

18

MTD7122BO9

LIMITED WARRANTY

19-23

,.. .24.25

26-33

..., ...29

34,35

36-39

Back Cover

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any unim-

proved forest-covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with

a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available

through participating Western Auto Stores.

2

Page 3

E~ 't: .-

0;o.~-u <

a.-C

~c: -c

>~

cE.

.

> u

41 ~

41 c:

...

4I.c

-I/)

.

.

-I/)

.

.

.

.

.

.

.

.

41 -

41 41

-Q.

-:. .-=

-

< .~

.

.

.

.

.

.

.

.

~N ...>

.! 0 .

"".

Q.:

-~ GI ...

o.

('II ~ .:. .

.../'

>OC: ~

Cf):

m"iOl ~"U

GlE~ Q.

E c: .2 ~

00)1/) ~~

Q.-9c: 00

-'- 0)

';-c:J ~

a. oX'- _"a

"x .c 0) ~ C

0>:;: Om

0)~3 GlQ.

~OII/) ~:J

c", "~.: ~ --GI

Z ~GI=-O)

Z -~.GI>

a: GlQ.1/) ~c:

< ~°"U ~rh

In

0

0 .

>- OI=:- eGi

-

-c .0 ~ 0

~ GI ~uQ.

>1.) -

0 GI-

o,S>~O

Ln~~"'~

~"U CO)

~~c C~

~ ~

"'- --J

EO) 0)0)

~ GI'-

Eo~a::~

001 ~~

- E --

cc~ "-:; GI 0)

o~x a.Q.

0 .~ GI 0 0

~

r7

c81.) ~..:.,

0 ~ ZoA.

~:Jc :J

.~ a. 0

.c c:"jU ~ ~

c3--= EUJ

~O) E ... 00» 41

,

.-:J m

u-c- O~

.: 0 0 ~ ~

,

,

,

,

-~

I/)~c: -I.)

I/)o~ ~~

GI .-GI -

CO)O ~

O):J- ~O

~~OI Q.GI

GI ~.S ~ £

\

.

0 I.) ~ I.)

a.~... 0"-

"- ~ 0 C ~

~c>-U1/)

--uo"am

II ..

~I ..i I

I

.~

i >

I ..J

I W

, u.

c:(

U')

I W

I ..-

I c:(

I a:

j

, ,

, '

I'",

, I ~ j

I~

..

.

.

.

.

.

1 , .

I ..-

I ..

I .

I ..

I.. ,

I W

I W

I: b Y)

I U')

I -

I :I:

I U')

+ i~~!ff ;~)1 ~

W

U')

I

I :J

I

I :I:

I ..-

I

I

I

I

.

---

I .,

:

I «

I

W tn.

W -.'

w '" .

ct ct Q.:

ct ~ a.. ~:

[I: ~ -.

(.) 0 UJ J ~ ::! (.) $.:

~ C/) '..

-J ~ 0 c.

[I: => Z

UJ ID ",,'

> ~ cr'

< ~ ",,'

I 0 ~ tt::

z I -.

~ a: .'

3 UJ I ~:

-J a:, .../.

~ LIJ 0 I fi1:

T J (/) Cl. I 0:

T . C/) .

I .

I I .

I :--

-J <:> ct

-CI: c.

w .OJ U I J... :

~ w I ~: "> I c;..

0 :> I o.

Z I I :

-J 0 I C:

0 Cl. .../.

::I: .~ I 0:

Q I L4.:.

<-' I I :

< I I :

I- I I .

:I: I I :

I I .

-I

r': ~'; '

I I :

I I .

cn

10

I ..-

: Z

I >

I «

I ~

I

I =>

10

I >

I UJ

I a:

I UJ

~ :s:

41

I :I:

.S U')

-J W

.~ Q.

oC 0

~-.. ..J

c:t W

I a:

:J -

-Z

Y ~

I C

10

I ..-

I

I W

I C

I -

I w

I t-

I UJ

I =>

I cn

I "

I «

I w

I Q.

10

Page 4

I

I

I

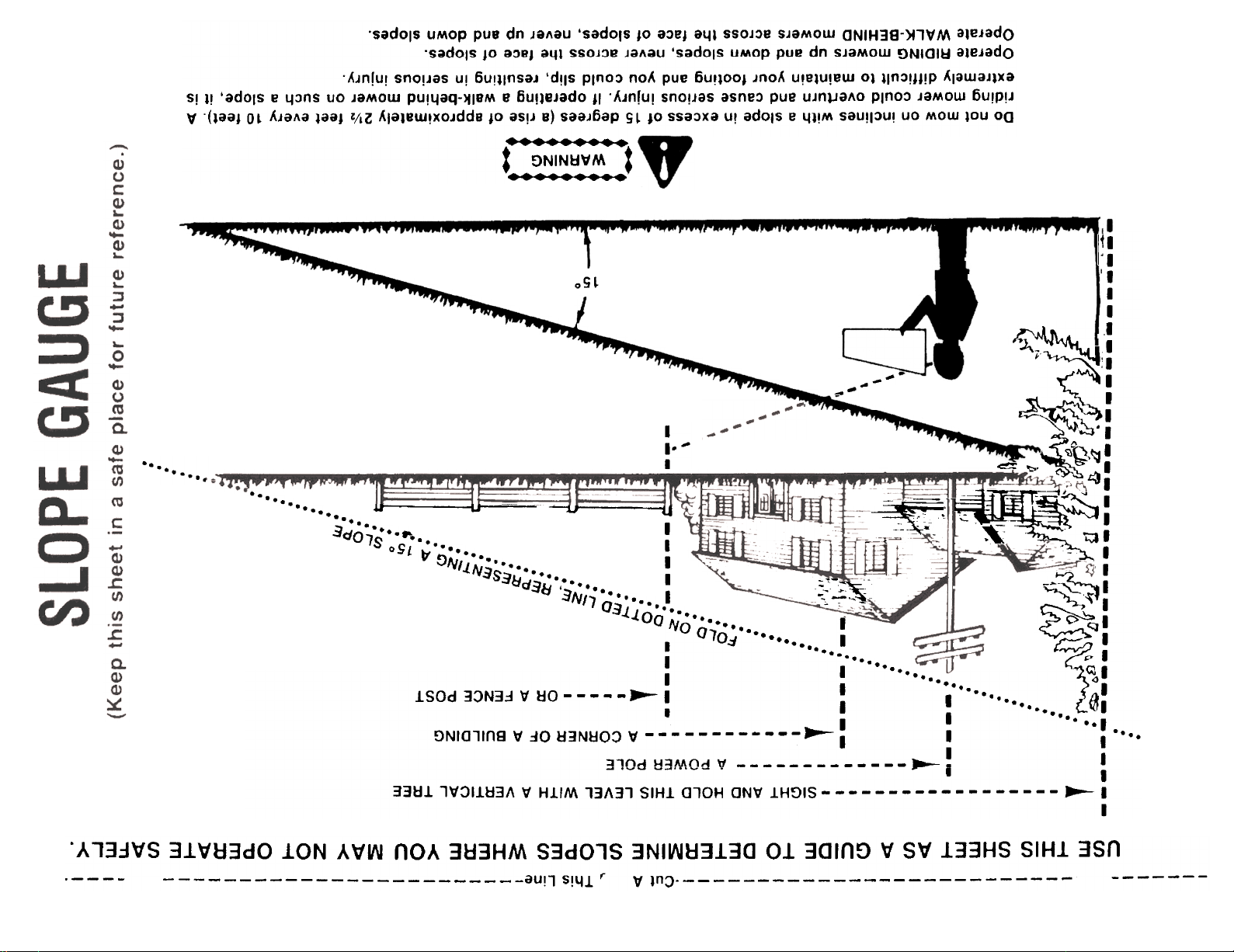

Remove this sheet from your owner's manual and lay the hardware on the illustration for identification purposes.

After assembly, keep the Slope Gauge which is on the reverse side of this sheet for future use.

(Hardware pack may contain extra items which are not used on your unit.)

INST ALLING THE SA TTERY Cable

Tie

rf§:!;~--- + ~~

A TT ACHING THE STEERING WHEEL

Hex Lock Nut

5/16-24 c

Hex Bolt

1/4-20 x

.Long

Hex

@ ~ Lock

Nut

1/4-20

Thread

I

I

I

I

I

I

CO)

c

-

:!:

2

Bellow

Screws 3/8-16 x

3/4" Long

Steering Wheel

1m IGNITION KEYS

(May Be

Attached to

Tractor)

Cap

~

in"

!::

~

CD

I

I

I

I

I

I

I

I

I

I I I I

0

I«;tES

I

2

I

3

4

Page 5

RULES FOR SAFE OPERA liON

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWEO COULD ENDANGER THE PERSONAL SAFETY

AND/OR PROPERlY OF YOURSELF AND OTHERS READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING

TO OPERATE YOUR UNIT FAILURE TO COMPl Y WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY WHEN YOU SEE

SYMBOl- A HEED ITS WARNING.

1 READ THIS OWNER'S MANUAL carefully in Its entirety before at-

temptIng to assemble or operate this unit. Keep this manual In

a safe place for future and regular reference and for ordering

replacement par1s.

2. This unit is a precision piece of power equipment. not a plaything.

Therefore exercise extreme caution at all times

3 Know the ccntrols and how to stop the machine QuIckly

4 Do not allow children to operate vehicle. Do not allow adults to

operate it without proper Instruction. Only persons well acquainted

with these rules of safe operation should be allowed to use your

mower

5. Wear sturdy, rough-soled work shoes and close-fitting slacks and

shirts to avoid entanglement in the moving pans. Never operate

a unit in bar~ feet, sandals, or sneakers.

6. To prevent inJury, do not carry passengers or give rides. Keep

children, pet~i and bystanders out of the area while mowing. Only

the operator should ride on the unit and only ride in the seat

7 Check overhead clearanc~ c-arefully before driving under power

lines. guy wires, brIdges or low hanging tree branches, before

entering or leaving buildings. or in any other situation where the

operator may be struck or pulled from the unit, which could result

in serious injury

8. To maintain control of the unit and reduce the possibility of upset

or collision. cperate the tractor smoothly Avoid erratic operation

and excessive speed.

9. Keep the area of operation clear of all persons, particularly sl:1all

children and pets Stop engine when they are in the vicinity of

your mower Although the area of operation should be completely cleared of foreign objects, a small obJect may have been

overlooked and could be accidently thrown by the mower in any

direction and cause inJury to you or a bystander.

10. Always wear ~~afety glasses or eye shields during operation or while

performing art adlustment or repair. to protect eyes from foreign

objects that rnay be thrown from the machine in any direction

11. Stop the blaOe(s) when crossing gravel drives, walks or roads

12. Disengage all attachment clutches and shift into neutral before

attempting to start engine.

13. Before leaving the operator's position. disengage blade(sj, place

shift lever in leutral, engage parking brake. shut engine off and

remove key.

14 Do not put hands or feet near or under rotating parts. Keep clear

of (he discharge opening at all times as the rotating blade(s) can

calise Inlury.

15. Disengage poller to attachment(s) and stop engine before making any repairs or adjustments Disconnect the spark plug wire

and keep the wire away from the plug to prevent accidental starting.

16. Before atteml:,ting to unclog the mower or discharge chute, stop

the engine. The mower blade(s) may continue to rotate for a few

seconds after ~he engine is shut off. Therefore, be sure the blade(s)

ha~e stopped I~ompletely. [)sconnect the spark plug wire and keep

the wire away from the plug to prevent accidental starting

17 Disengage power to attachment(s) when transporting or not In use

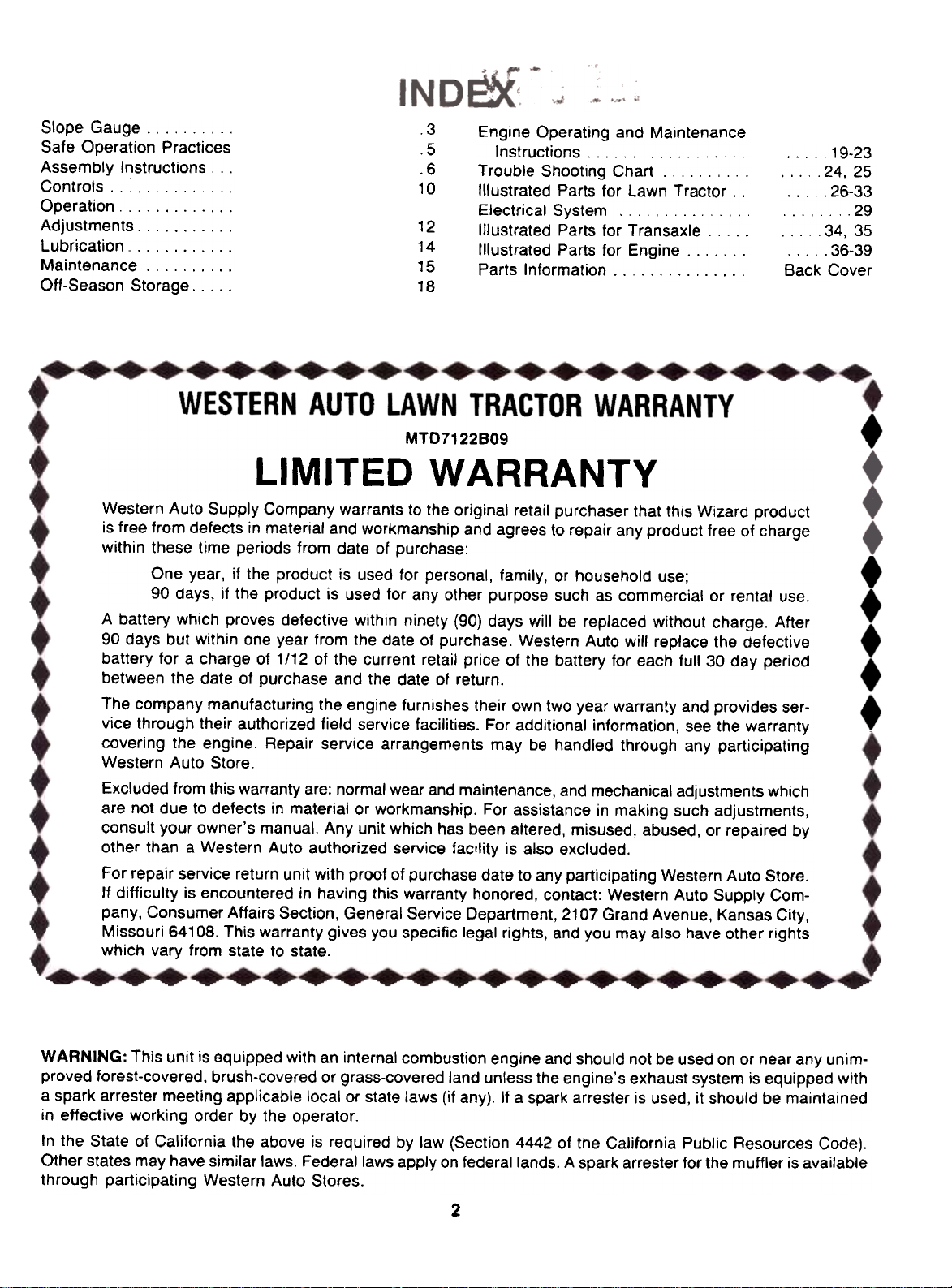

18. For your safety, use the slope gau~ Included as part of thiS manual

to measure slopes before operating this unit on a sloped or hilly

area. If the slope is greater than 150 as shown on the slope gauge.

do not operate this unit on that area or serious injury could result.

19. Do not stop or start suddenly when going uphill or downhill. Mow

up and down face of steep slopes; never across the face Use

extreme caution if it IS necessary to drive the tractor up an incline

or back the tractor down an Incline because ttle front of the trac-

tor could lift and rapidly flip over backward which could cause

serious injury

20. Reduce speed on slopes and in sharp turns 10 prevent tipping or

loss of control. Always keep the tractor in low gear when gOing

down steep hills to take advantage of engine braking action Choose

a low enough gear so that you will not have to stop or shift while

on the slope

21. Stay aler1 for roles in terrain and other hidden hazards which may

cause the unit to tip over

22 Use care when pulling loads or uSing heavy equipment.

A Use only approved drawbar hitch points.

B Limit loads to those you can safely control.

C. Do not turn sharply. Use care when backing.

0 Use counterweight(s) or wheel weights when suggested in

owner's manual.

23. Watch out for traffic when crossing or near roadways.

24. When using any attachments, never direct discharge of material

toward bystanders nor allow anyone near vehlc~ while In operation.

25 Handle gasoline with care It is highly flammable

A Use approved gasoline container

B. Never remove cap or add gasoline to a running or hot engine

or fill fuel tank indoors Wipe up spilled gasoline Always use

original type vented cap.

C Open doors if engine is run in garage. Exhaust fumes are

dangerous Do not run engine indoors

26. Never store the machine with fuel in the fuel tank inside a building

where ignition sources are present. such as hot water and space

heaters. clothes dryers, and the like. Allow the engine to cool before

storing in any enclosure.

27 To reduce fire hazard, keep engine and cutting deck free of grass,

leaves or excessive grease

28 Keep the vehicle and atlCM:hments in good ~erating condition.

and keep safety devices in place. Use guards as instructed In

operator's manual.

29 Keep all nuts, bolts. and screws tight to be sure the eQuipment

is in safe working condition.

30. The vehicle and attachments should be stopped and inspected for

damage after striking a foreign object. The damage should be

repaired before restarting and operating the eQuipment

31. Do not change the engine governor settings or overspeed the

engine.

5

,

~

Page 6

32. When using the vehicle with roower, proceed as follows: 34. Look behind to make sure the area IS clear before placing the

(1) Mow only in daylight or in good artificial light transmission in reverse and continue lookIng behInd while back-

(2) Never make a cutting heIght a~ustment while engine IS running ing up Disengage blades before shifting into reverse and backing

if operator must dismount to do so up.

(3) Shut the engine off and walt until the blade comes to a complete 35. This unit should not be driven up a ramp onto a trailer or truck

stop before removing the grass catcher. under power. because the unit could tip over, causIng serious per-

(4) Check blade roounting bolts for proper tightness at frequent in- sonal injury. The unit must be pushed manually to load properly

tervals. 36. Check brake operation frequently. Adjust and service according

33. Check grass catcher bags frequently for wear or deterioration. For to brake adjustment "structions in this manual

safety protection. replace ooly with new bag m~ting original equipment specifications.

ASSEMBLY

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL; however, a small amount of oil

may be present from the factory. Do not overfill.

After assembly, service engine with gasoline and

oil as instructed in the engine section of this

manual.

NOTE: Reference to right or left hand side of the

unit is observed from the driver's seat, facing

forward.

UNPACKING

1. Remove the lawn tractor from the carton as follows.

Open the top flaps. Remove all loose parts and carton inserts. Cut the front corners of the carton.

Make certain brake is released. and push the unit

out of the carton.

2. Remove page four from this manual and lay the

contents of the hardware pack on the illustration

for identification.

BATTERY INFORMATION

A WARNING

A. Battery acid must be handled with great care as

contact with it can burn and blister the skin. It is also

advisable to wear protective clothing (goggles, rub-

ber gloves and apron) when working with it..

B. Should battery acid accidentally splatter into the

eyes or onto the face, rinse the affected area im-

mediately with clean cold water. If there is any

further discomfort, seek prompt medical attention.

C. If acid spills on clothing, first dilute it with clean

water, then neutralize with a solution of ammonia}

water or baking soda/water.

D. Since battery acid is corrosive, do not pour it into

any sink or drain. Before discarding empty elec-

trolyte containers. rinse them with a neutralizing

solution.

E. NEVER connect or disconnect charger clips to bat-

tery while charger is turned on as it can cause

sparks.

F. Keep all lighted materials (cigarettes, matches,

lighters) away from the battery as the hydrogen gas

generated during charging can be combustible.

G. As a further precaution, only charge the battery in

a well-ventilated area.

.Always shield eyes, protect skin and clothing

when working near batteries.

6

Page 7

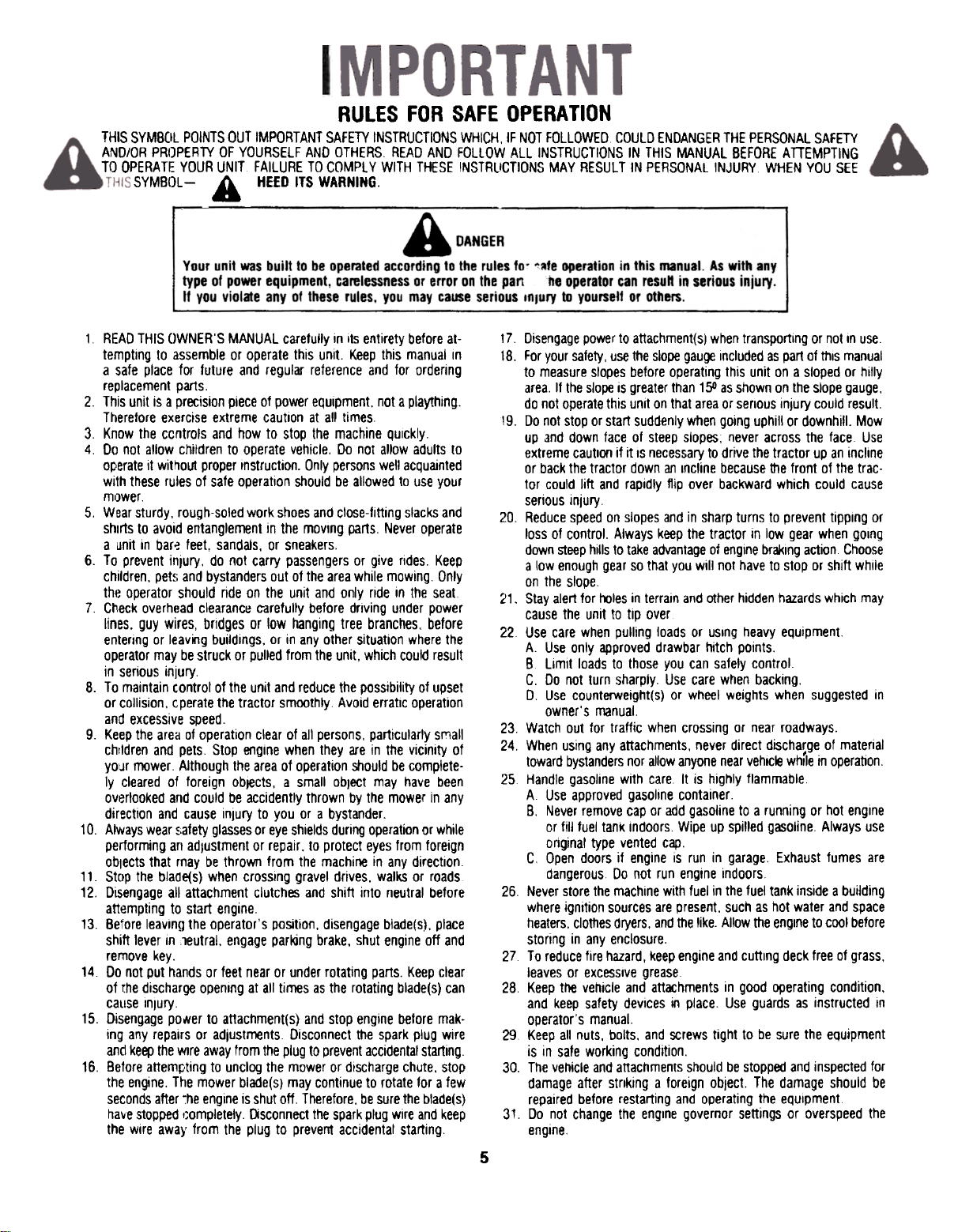

FIGURE 1,

FIGURE 2.

ACTIVATING THE BATTERY

Do not activate battery (fill with battery acid) until

Caps

"

~

battery is actually placed in service. Be certain to

read previous warnings before activating the

battery.

1. Open the battery pack. Be careful not to puncture

the box. It contains the battery with a long plastic

tube attached, battery fluid (acid) in a plastic container, one short plastic tube and one hardware

pack (two hex bolts and nuts).

2. Place the battery on a table or workbench. Make

certain the long plastic drain tube is in place on

the vent elbow.

3. Remove the six fill caps from the top of the battery with a screwdriver. Be careful not to damage

4 the fill caps. See figure 1.

4. Place the battery fluid container on the table or

workbench. Carefully cut off tip of the spout and

attach the short plastic tube provided. Do not

squeeze the container when cutting tip.

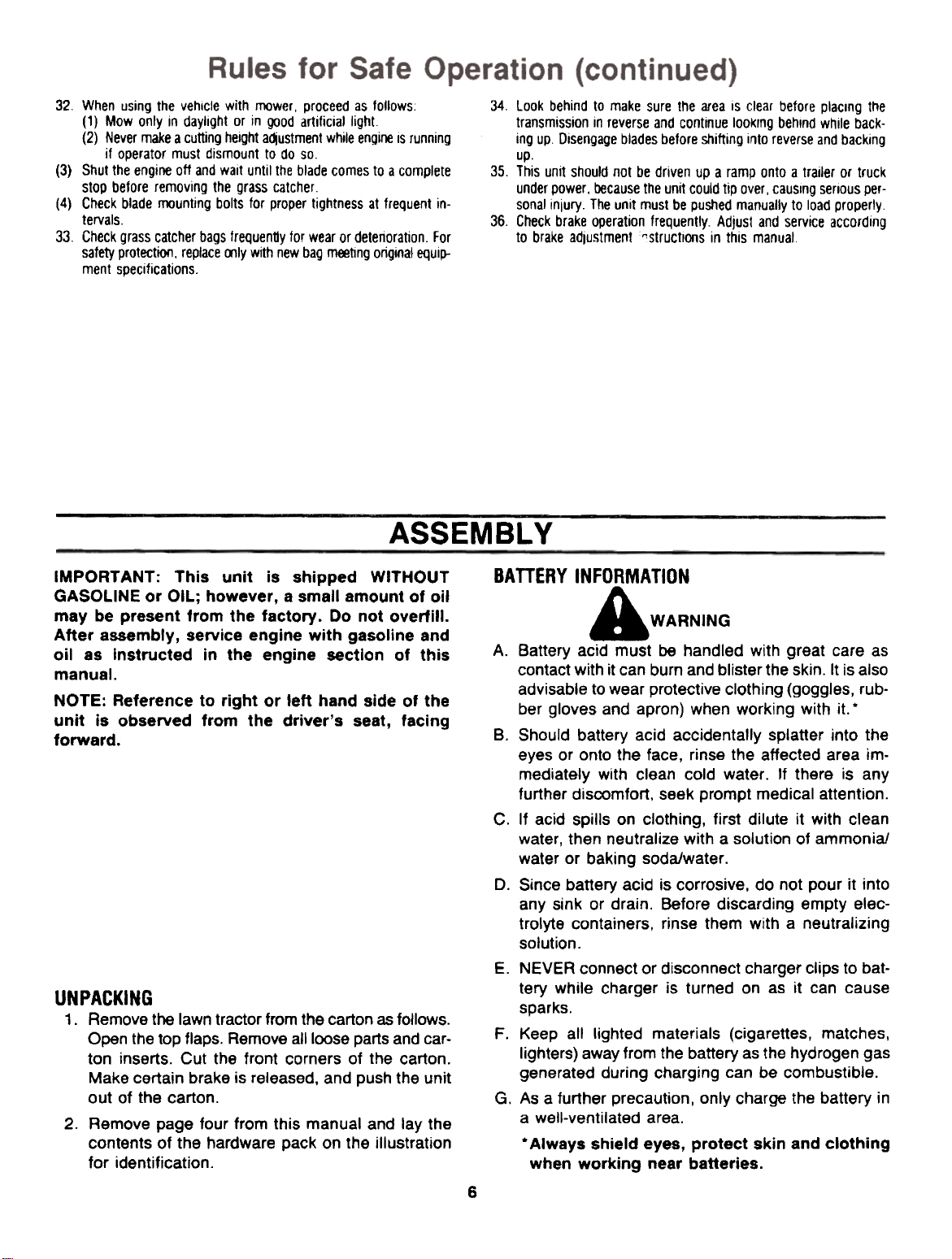

5. Fill each battery cell slowly and carefully to the UP.

.PER LEVEL line marked on battery. See figure 2.

Use caution as the acid level will rise rapidly after

the bottom of the cell is filled.

6. Allow battery to stand for 30 minutes with the fill

caps removed, while the plates absorb acid.

7. If acid level has fallen after the 30 minute standing

period, refill each cell with battery acid to the UP-

PER LEVEL line on battery. Replace the fill caps.

8. Before discarding the empty container, neutralize

any residue with baking soda and rinse container

with water. Puncture container several times

before discarding.

9. Charge the battery after the 30 minute standing

period. SLOW CHARGE THE BATTERY (DO NOT

FAST CHARGE) at a maximum bench rate of 1.4

amperes until the specific gravity reading is

1.260-1.280. Charge for a minimum of 2 hours and

a maximum of 8 hours.

,f.

~

NOTE: This engine is equipped with an alternator. The

current for the battery charger alternator is unregulated.

During normal operation, it is only necessary to charge

the battery:

1. When it is activated for the first time.

2. Before winter storage.

3. Before using the lawn tractor after winter storage.

NOTE: Charging rate after battery has been put into

operation-the battery is to be charged for a period of

14-16 hours. NO LONGER THAN 30 HOURS.

After battery has been charged, add only distilled

water. Do not add acid.

7

Page 8

Battery

~Drain

Tube

FIGURE 3.

,I

I~

=~~~

..! r- --.,,-

\y Terminal

~

-'- --

Black Box Red

(Negative) (Positive)

Cable Cable

Battery -\

Negative

/ Positive

\'9

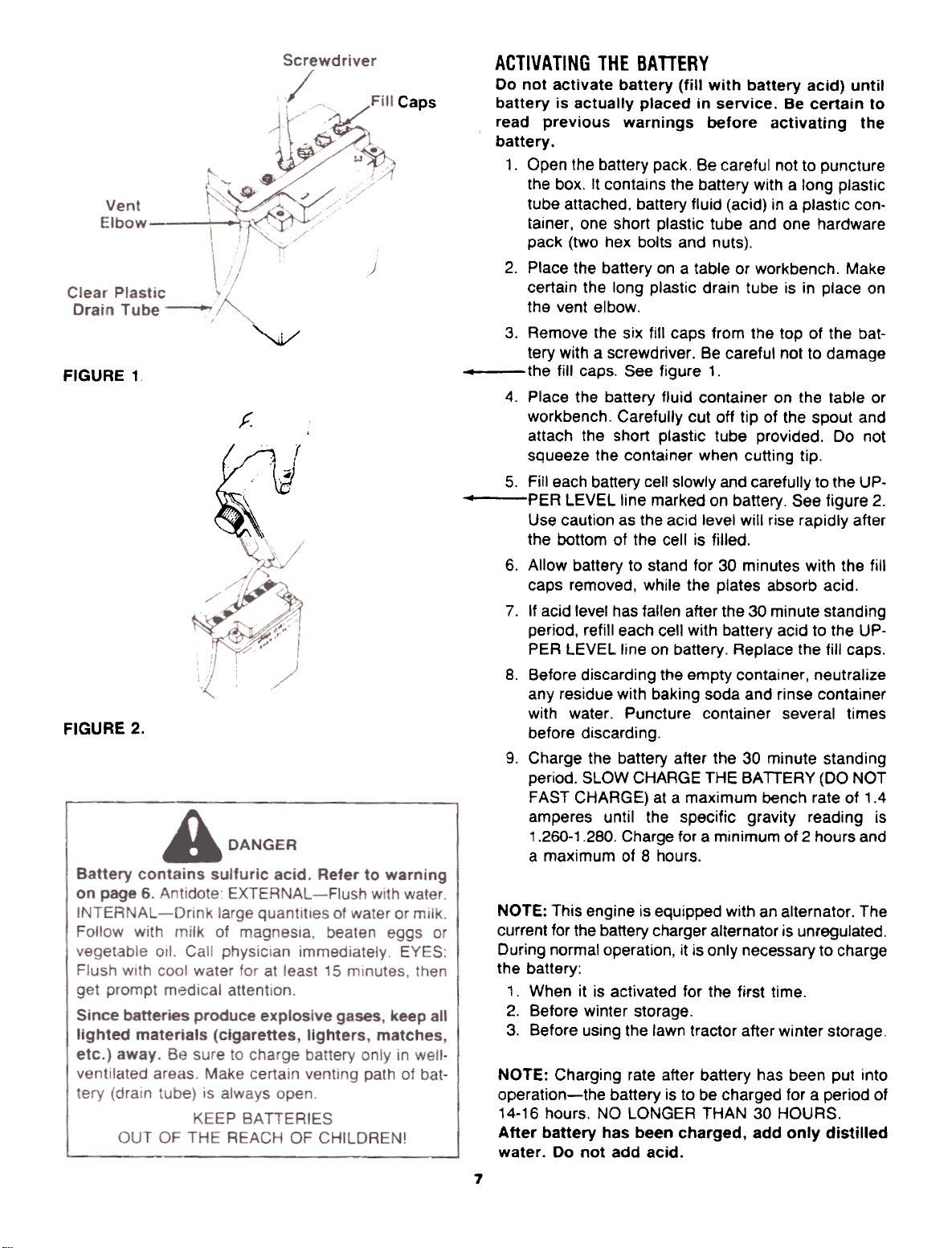

INSTALLING THE BATTERY (Hardware A)

1. Raise the seat bracket (on top of the fenders).

2. Make certain the positive cable (heavy red wire)

extends through the retainer on the front of the battery box. The negative cable (heavy black wire)

should be routed up along the back of the battery

box.

3. Place the battery inside the battery box so that the

positive terminal is toward the front of the unit. See

figure 3. Route the battery drain tube down beside

the battery box.

4". Slide the hex nut (provided with battery hardware)

into the positive (+) terminal. Place the positive

cable on the positive terminal. Secure with bolt pro--'vided.

See figure 3.

5. Slide the hex nut (provided with battery hardware)

into the negative (-) terminal. Place the negative

cable on the negative terminal. Secure with bolt

provided.

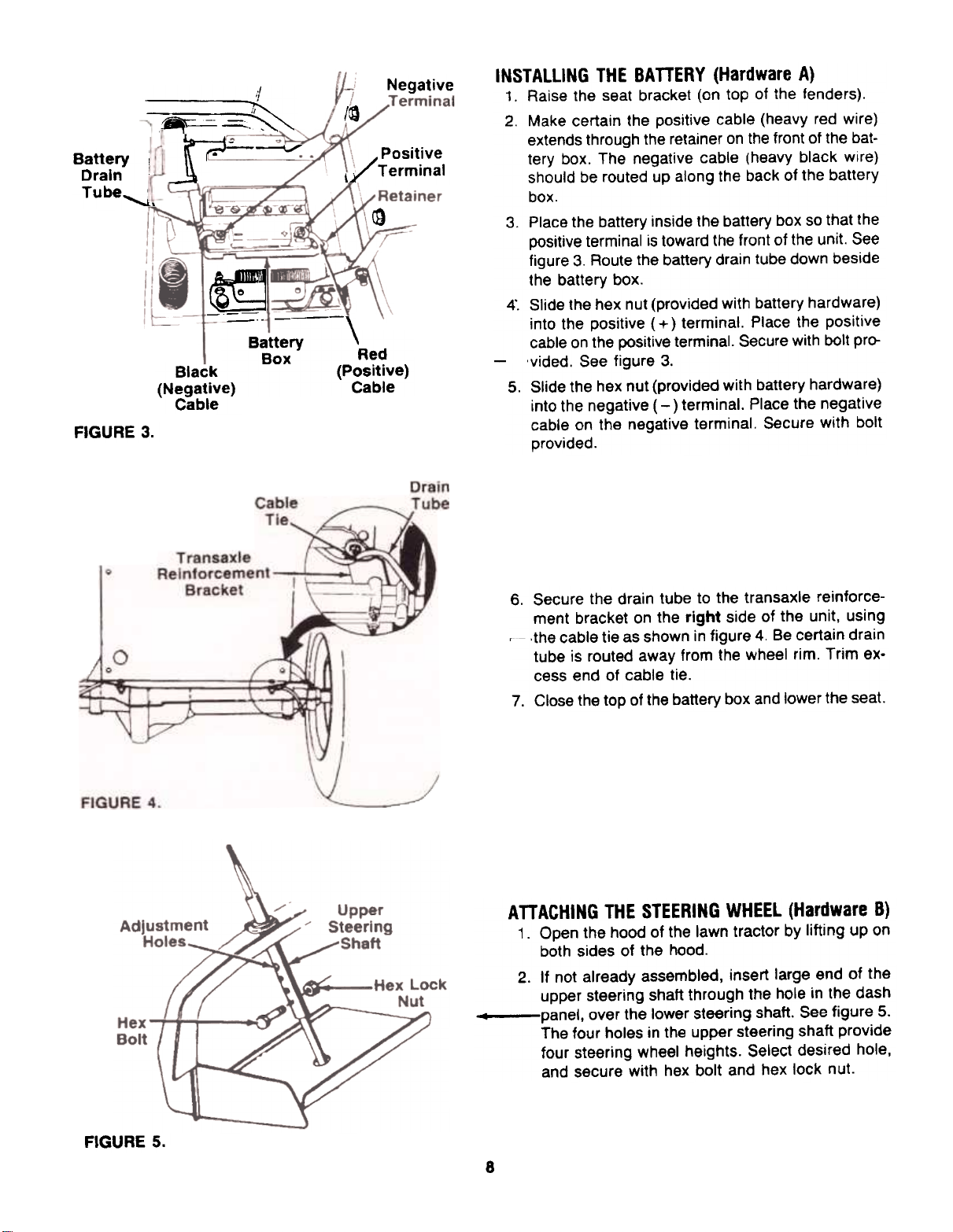

6. Secure the drain tube to the transaxle reinforcement bracket on the right side of the unit, using

~ .the cable tie as shown in figure 4. Be certain drain

tube is routed away from the wheel rim. Trim excess end of cable tie.

7. Close the top of the battery box and lower the seat.

ATTACHING THE STEERING WHEEL (Hardware B)

1. Open the hood of the lawn tractor by lifting up on

both sides of the hood.

2. If not already assembled, insert large end of the

upper steering shaft through the hole in the dash

.panel, over the lower steering shaft. See figure 5.

The four holes in the upper steering shaft provide

four steering wheel heights. Select desired hole,

and secure with hex bolt and hex lock nut.

FIGURE 5.

8

Page 9

Steeri

FIGURE 6.

~~~HeX Lock Wheel ,~ Nut

,

..,r"

:--- Cupped

Washer

-"'l\

.J\

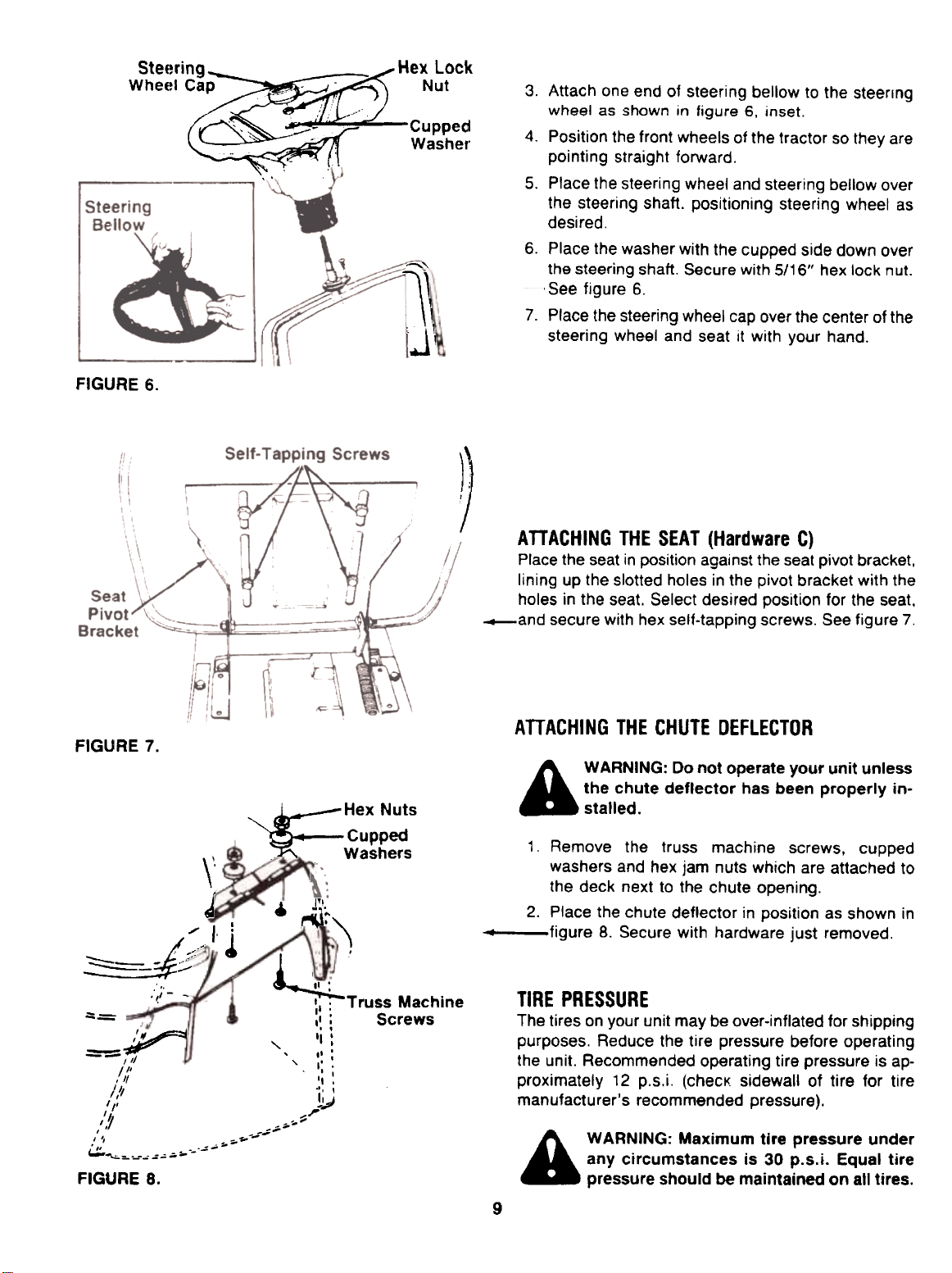

3. Attach one end of steering bellow to the steering

wheel as shown in figure 6, inset.

4. Position the front wheels of the tractor so they are

pointing straight forward.

5. Place the steering wheel and steering bellow over

the steering shaft. positioning steering wheel as

desired.

6. Place the washer with the cupped side down over

the steering shaft. Secure with 5/16" hex lock nut.

~ See figure 6.

7. Place the steering wheel cap over the center of the

steering wheel and seat it with your hand.

ATTACHING THE SEAT (Hardware C)

Place the seat in position against the seat pivot bracket,

lining up the slotted holes in the pivot bracket with the

holes in the seat. Select desired position for the seat,

_and secure with hex self-tapping screws. See figure 7.

FIGURE 7.

\"

J

/, i

/- .:.-

k .. II '

----

--= ' ,.'

-III " ,':

/. ~ '

, --

, " -..~

c:.::.~:,,-," =-, ;';"

FIGURE 8.

:~I .:-~

~,=.. ~ I

, "I

1/1 I ,

, /1 'I ,

1/1 do ,

/, II -1

/" ,..,

7 -,,--

, --

-..;--

Hex Nuts

Cupped

.Washers

r\l~)

:1; Truss Machine

,I : Screws

I':

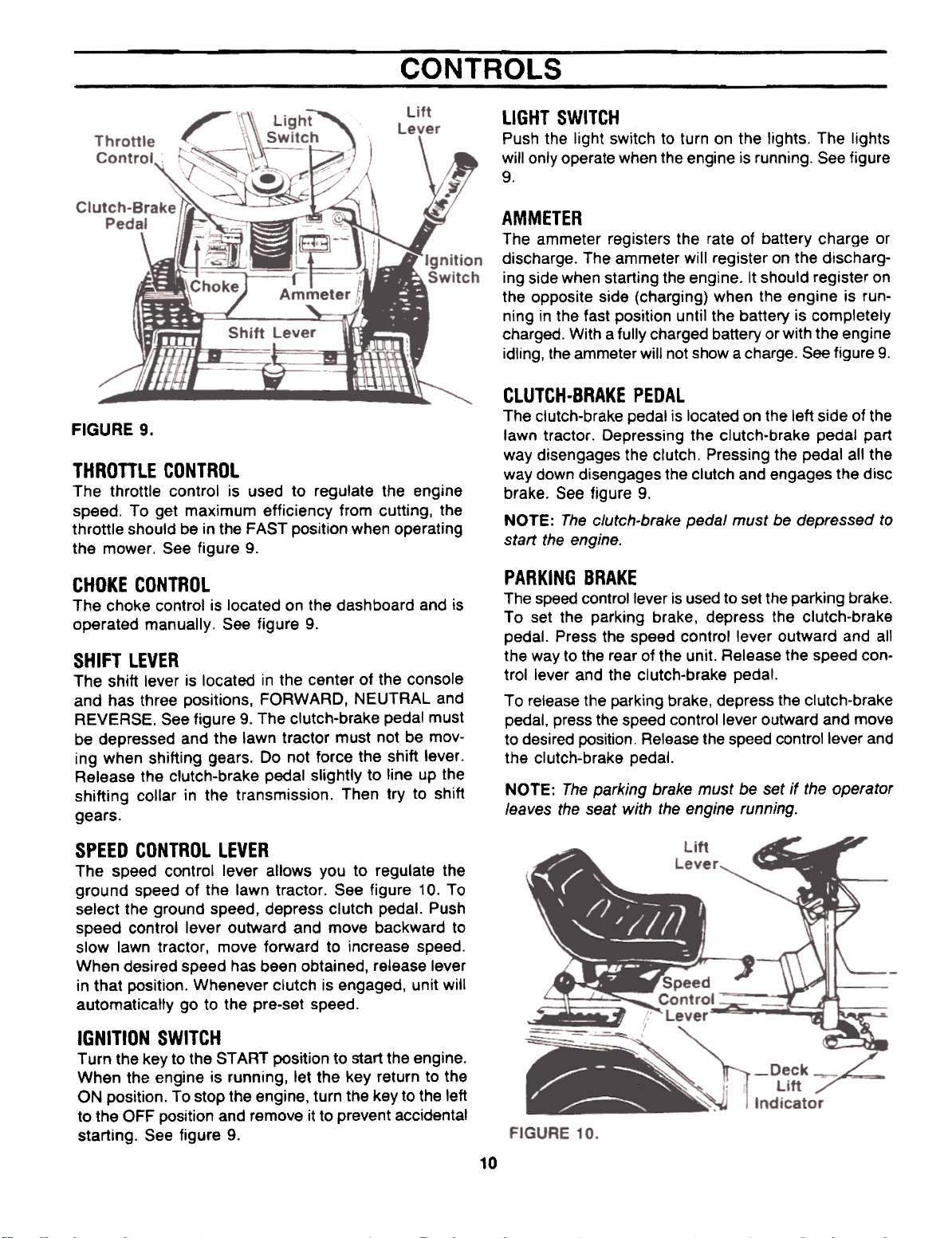

AnACHING THE CHUTE DEFLECTOR

A WARNING: Do not operate your unit unless

the chute deflector has been properly installed.

1. Remove the truss machine screws. cupped

washers and hex jam nuts which are attached to

the deck next to the chute opening.

2. Place the chute deflector in position as shown in

~ figure 8. Secure with hardware just removed.

TIRE PRESSURE

The tires on your unit may be over-inflated for shipping

purposes. Reduce the tire pressure before operating

the unit. Recommended operating tire pressure is ap-

proximately 12 p.s.i. (checK sidewall of tire for tire

manufacturer's recommended pressure).

A WARNING: Maximum tire pressure under

any circumstances is 30 p.s.i. Equal tire

pressure should be maintained on all tires.

~

~

.

~~

9

Page 10

CONTROLS

FIGURE 9.

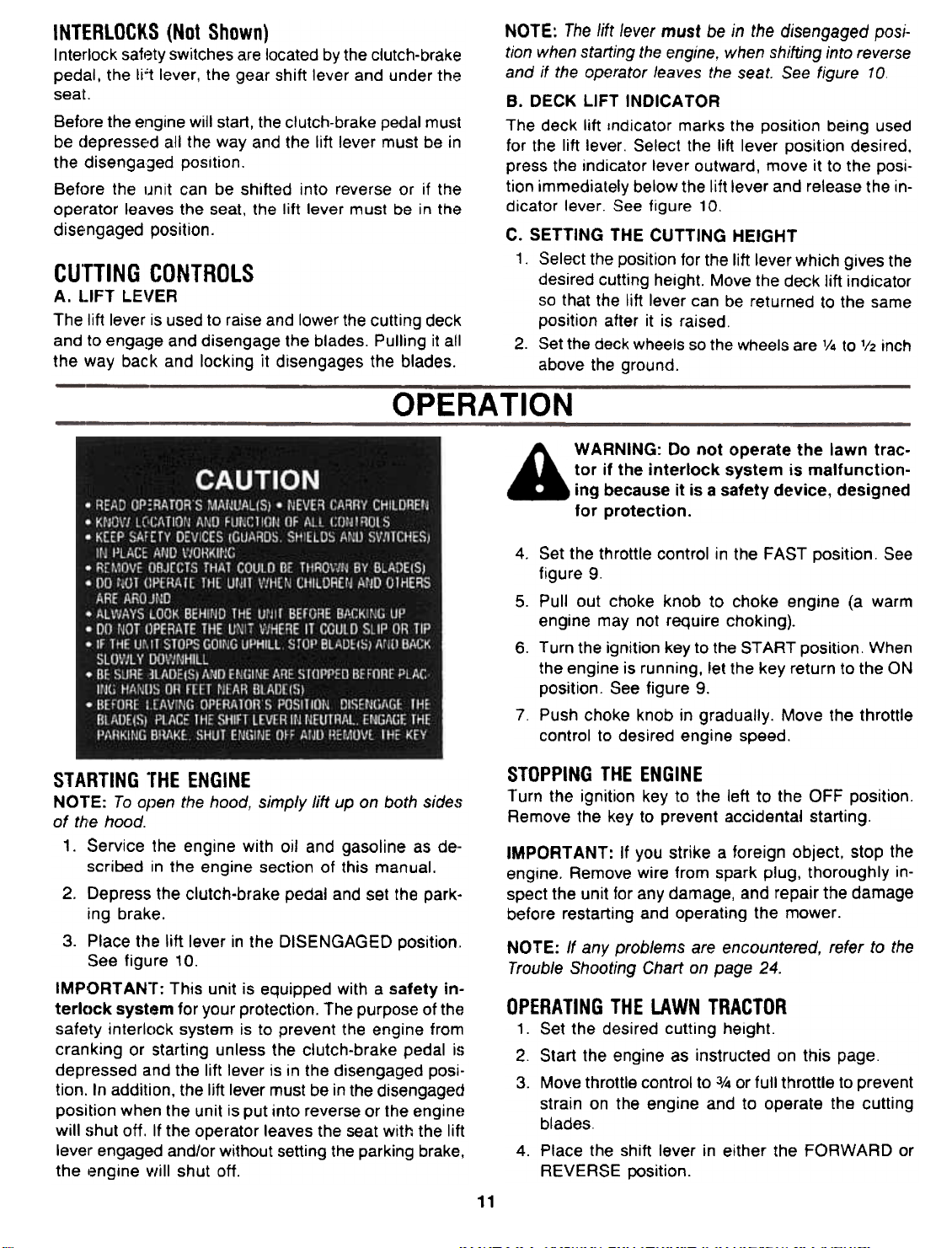

THROTTLE CONTROL

The throttle control is used to regulate the engine

speed. To get maximum efficiency from cutting, the

throttle should be in the FAST position when operating

the mower. See figure 9.

LIGHT SWITCH

Push the light switch to turn on the lights. The lights

will only operate when the engine is running. See figure

9.

AMMETER

The ammeter registers the rate of battery charge or

discharge. The ammeter will register on the discharg-

ing side when starting the engine. It should register on

the opposite side (charging) when the engine is run-

ning in the fast position until the battery is completely

charged. With a fully charged battery or with the engine

idling, the ammeter will not show a charge. See figure 9.

CLUTCH-BRAKE PEDAL

The clutch-brake pedal is located on the left side of the

lawn tractor. Depressing the clutch-brake pedal part

way disengages the clutch. Pressing the pedal all the

way down disengages the clutch and engages the disc

brake. See figure 9.

NOTE: The clutch-brake pedal must be depressed to

start the engine.

CHOKE CONTROL

The choke control is located on the dashboard and is

operated manually. See figure 9.

SHIFT LEVER

The shift lever is located in the center of the console

and has three positions, FORWARD, NEUTRAL and

REVERSE. See figure 9. The clutch-brake pedal must

be depressed and the lawn tractor must not be mov-

ing when shifting gears. Do not force the shift lever.

Release the clutch-brake pedal slightly to line up the

shifting collar in the transmission. Then try to shift

gears.

SPEED CONTROL LEVER

The speed control lever allows you to regulate the

ground speed of the lawn tractor. See figure 10. To

select the ground speed, depress clutch pedal. Push

speed control lever outward and move backward to

slow lawn tractor, move forward to increase speed.

When desired speed has been obtained, release lever

in that position. Whenever clutch is engaged, unit will

automatically go to the pre-set speed.

IGNITION SWITCH

Turn the key to the START position to start the engine.

When the engine is running, let the key return to the

ON position. To stop the engine, turn the key to the left

to the OFF position and remove it to prevent accidental

starting. See figure 9.

PARKING BRAKE

The speed control lever is used to set the parking brake.

To set the parking brake, depress the clutch-brake

pedal. Press the speed control lever outward and all

the way to the rear of the unit. Release the speed control lever and the clutch-brake pedal.

To release the parking brake, depress the clutch-brake

pedal. press the speed control lever outward and move

to desired position. Release the speed control lever and

the clutch-brake pedal.

NOTE: The parking brake must be set if the operator

leaves the seat with the engine running.

10

Page 11

INTERLOCKS (Not Shown)

Interlock safety switches are located by the clutch-brake

pedal. the li"t lever, the gear shift lever and under the

seat.

Before the engine will start, the clutch-brake pedal must

be (jepressed all the way and the lift lever must be in

the disengaged position.

Before the IJnit can be shifted into reverse or if the

operator leaves the seat, the lift lever must be in the

disengaged position.

CUTTING CONTROLS

A. LIFT LE"ER

The lift lever is used to raise and lower the cutting deck

and to engage and disengage the blades. Pulling it all

the way back and locking it disengages the blades.

OPERA TION

NOTE: The lift lever must be in the disengaged posi-

tion when starting the engine, when shifting into reverse

and if the operator leaves the seat. See figure 10

B. DECK LIFT INDICA TOR

The deck lift ,ndicator marks the position being used

for the lift lever. Select the lift lever position desired.

press the indicator lever outward, move it to the position immediately below the lift lever and release the in-

dicator lever. See figure 10.

C. SETTING THE CUTTING HEIGHT

1. Select the position for the lift lever which gives the

desired cutting height. Move the deck lift indicator

so that the lift lever can be returned to the same

position after it is raised.

2. Set the deck wheels so the wheels are '/4 to '/2 inch

above the ground.

WARNING: Do not operate the lawn tractor if the interlock system is malfunctioning because it is a safety device, designed

for protection.

STARTING "rHE ENGINE

NOTE: To open the hood, simply lift up on both s;de~;

of th'e hood.

1. Service the engine with oil and gasoline as de..

scribed in the engine section of this manual.

2. Depress the clutch-brake pedal and set the parking brake.

3. Place the lift lever in the DISENGAGED position..

See figure 10.

IMPORTANT: This unit is equipped with a safety in-

terlock system for your protection. The purpose of the

safety interlock system is to prevent the engine from

cranking or starting unless the clutch-brake pedal is

depressed and the lift lever is in the disengaged position. In addition, the lift lever must be in the disengaged

position when the unit is put into reverse or the engine

will ~)hut off. If the operator leaves the seat with the lift

lever engaged and/or without setting the parking brake.

the engine viii I shut off.

Set the throttle control in the FAST position. See

figure 9.

5. Pullout choke knob to choke engine (a warm

engine may not require choking).6.

Turn the ignition key to the START position. When

the engine is running, let the key return to the ON

position. See figure 9.

7 Push choke knob in gradually. Move the throttle

control to desired engine speed.

STOPPING THE ENGINE

Turn the ignition key to the left to the OFF position.

Remove the key to prevent accidental starting.

IMPORT ANT: If you strike a foreign object, stop theengine.

Remove wire from spark plug, thoroughly in-

spect the unit for any damage, and repair the damage

before restarting and operating the mower.

NOTE: If any problems are encountered, refer to the

Trouble Shooting Chart on page 24.

OPERATING THE LAWN TRACTOR

1. Set the desired cutting height.

2. Start the engine as instructed on this page.

3. Move throttle control to 3/4 or full throttle to prevent

strain on the engine and to operate the cutting

blades.

4. Place the shift lever in either the FORWARD or

REVERSE position.

4.

11

Page 12

WARNING: Look to the rear before back-

ing up.

5. Release the parking brake by depressing the

clutch-brake pedal, pressing outward on the speed

control lever and moving to desired position. Use

first speed position when operating the lawn trac-

tor for the first time.

6. Release clutch-brake pedal slowly to put unit into

motion.

7. The lawn tractor is brought to a stop by depressing the clutch-brake pedal.

NOTE: When operating the unit initially, there will be little

difference between the highest two speeds until after

the belts have seated themselves i~to the pulleys during the break.in period.

Move the lift lever into the DISENGAGED position to

raise the deck and disengage the blades.

GRASS CATCHER Stock Number 95-1136-1 (Factory

No. 190-064) is available as optional equipment.

A WARNING: The mower should not be

operated without the entire grass catcher

or chute deflector in place.

NOTE: Under normal usage bag material is subject to

wear, and should be checked periodically. Be sure any

replacement bag complies with the mower manufacturer's recommendations.

For replacement bags, use only factory authorized

replacement bag.

Be sure that the lawn is clear of stones, sticks, wire,

or other objects which could damage lawn mower or

engine. For best results and to insure more even grass

distribution, do not mow when lawn is excessively wet.

A WARNING: Before leaving the operator's

position for any reason, disengage the

blades, place the shift lever in neutral,

engage the parking brake, shut engine off

and remove the key.

When stopping the unit to empty a grass bag, etc.,

follow the instructions above. This procedure will also

eliminate "browning" the grass, which is caused by hot

exhaust gases from a running engine.

If unit stalls with speed control in high speed, or if unitwill

not operate with speed control lever in a low speedposition,

proceed as follows.

1. Place shift lever in NEUTRAL.

2. Restart engine.

3. Place speed control lever in high speed position.

4. Release clutch-brake pedal fully.

5. Depress clutch-brake pedal.

6. Place speed control lever in desired position.

7. Place shift lever in either FORWARD or

REVERSE, and follow normal operating pro-

cedures.

SEAT ADJUSTMENT

The seat may be adjusted to different positions. Refer

to seat installation section of assembly instructions.

STEERING WHEEL ADJUSTMENT

There are four height positions for the steering wheel.

To adjust the height of the steering wheel, remove the

hex bolt and hex lock nut on the steering shaft. Place

the steering wheel in the position desired and secure

with hex bolt and hex lock nut. Refer to figure 5.

NOTE: When raising the height of the steering wheel,stretch

the steering bellow to cover the steering shaft.

DECK LEVELING ADJUSTMENT

If an uneven cut is obtained, the deck may be leveled

as follows.

With unit on hard, level surface, measure the distance

from the bottom edge of the center of the left side of

deck to the ground. Measure the same distance on the

center of the right side of the deck (just behind the

chute area on side discharge units). Or, place the

blades in a straight line, and measure the distance fromthe

outside edge of the blade tips to the ground.

Adjust the lift link on the left side of the deck asnecessary.

See figure 11. Recheck the adjustment.

OPERATING THE CUTTING BLADES

The cutting blades may be engaged while the fawn tractor is moving or standing still. DO NOT engage the cutting blades abruptly as the sudden belt tension on the

pulley may cause the engine to stall.

WARNING: Keep feet and hands away from

the discharge opening, the blades or any

part of the deck. When the unit is used for

other than mowing operations, the blade

drive should be disengaged.

'-'II~dJU.t.b::::::~:::::~-~

~~-==:~-===="==""~

~/~

FIGURE 11.

12

c~~

-'"-=""

,//

Page 13

SPEED CONTROL ADJUSTMENT (See figure 12)

NOTE: When operating the unit initially or after replac-

ing the belt5. there will be little difference between the

highest two speeds until after the belts have gone

through a break-in period and have seated themselves

into the pull~ys.

First. adjust the speed control lever by pushing the

clutch-brake pedal forwaroj until the stop on the brake

rod is against the frame ..e figure 12. Have another

person hold the pedal in this position as you make the

following adjustment. Place the speed control lever in

parking brake position. Remove the hairpin clip and flat

washer. and adjust the ferrule on the rod so it is against

the back end of the slot. See figure 12. Replace the

flat washer and hairpin clip.

Next. adjust the speed control link as follows to obtain

the correct neutral adjustment.

1. Start the engine.

2. Place the shift lever in Neutral position.

3. Place the speed control lever in high speed

position.

4. Release ~h~ clutch-brake pedal completely, then

slowly depress the pedal all the way (to park posi-

tion). Hold the pedal in this position.

5. Turn the engine off.

6. After engine stops completely, release the clutchbrake pedal.

7. Place speed control lever in first position.

8. Remove the cotter pin and flat washer which

secures the speed control link to the variable speed

torque bracket assembly.

9. Push the clutch-brake pedal backward by hand as

far as it will go using light pressure. Hold it in this

position as you thread the speed control link in or

out of the ferrule until it lines up with the pin on

the variable speed torque bracket assembly.

10. Secure speed control link to variable speed torque

bracket assembly with flat washer and cotter pin.

NEUTRAL ADJUSTMENT

1 Place the transmission in neutral. (The unit will

move freely when pushed forward and backward

with the parking brake released.)

2. Loosen the bolt which secures the shift lever

assembly to the shift lever link. See figure 13.

3. Place the shift lever in the netural slot. See figure

13.

4. Tighten the bolt to 13 foot pounds.

Variable Speed

Torque Bracket

Assembly

",'

.,.,~ -

~

.."""

,~

of Slot

Clip and

Flat Washer

.'.':-. -

i~~- ~.. :;:-

.:r~",- ~ -o i:.:--:-- ~~~"

1 "(~---'- ~~:'-.! ,/ -'~': ,,' ':.;::.. --:-::'. '

,. ,-

/;

"""

.-.,-

~ '~'~ --I '.

-'-- '... -

",

.,., -..~ ;~..

..'.. -

,.' .

~ --.+- ,

"" .~.;.::~ ';,\

Brake

Rod

Speed

Control

Lever

...'-~~~

~

,\

'~

Cotter Pin

and Flat Washer

~-~

~ ,,-",,-~ -'~-::.;:-~~

~- -~+... -

~",,- ,~- 'F".",--

-~:- Speed Control "~"'" "--~_::~ -.~ ~ Rod ""O."--:;""'"' :---~ "-

~Ferrul;"~.~. .-' --,.~(

-~

-'., ~-~ --'~ -.,)

'"'-

J ~

~~

~ --.f;

,- -

---

--'-.

'+..~

",

~ :':"

~

Q~ -~

"", --

-"""""""~

--

,

" -

" r

,; !

...\

' ""

::;;::::--

~

Speed Contro!

/::

)l': ,I "

-::

/

,

Ferrule

'

FIGURE 12.

13

.~~_.~

Page 14

FIGURE 13.

FIGURE 15.

BRAKE ADJUSTMENT (See figure 16)

The brake is located by the right rear whee! inside the

frame. During normal operation of this machine, the

brake is subject to wear and will require periodic

examination and adjustment.

WHEEL ADJUSTMENT

The caster (forward slant of the king pin) and the

camber (tilt of the wheels out at the top) require no ad-

justment. Automotive steering principles have been

used to determine the caster and camber on the trac-

tor. The front wheels should toe-in 1/8 inch.

To adjust the toe-in, follow these steps.

1. Remove the hex nut and lock washer, and drop

the tie rod end from the wheel bracket. See figure

14.

2. Loosen the hex jam nut on tie rod.

3. Adjust the tie rod assembly for correct toe-in.

Tie"

Rod

FIGURE 14.

Dimension "B" should be approximately 1/8" less than

Dimension "A." See figure 15.

A.) To increase Dimension "B," screw tie rod into tie

B.) To decrease Dimension "B," unscrew tie rod from

C.) Reassemble tie rod. Check dimensions. Readjust

Hex,

Nut

Hex Nut

Lock Washer Tie Rod

End

rod end.

tie rod end.

if necessary.

WARNING: Do not have the engine running

when you adjust the brake.To

adjust the brake, remove the cotter pin. Adjust the

castle nut so the brake starts to engage when the brake

lever is V4 II to 5/16" away from the axle housing.

NOTE: Figure 16 is shown with the unit tipped up onrear

wheels for clarity only.

A WARNING: Always stop engine and

disconnect spark plug wire before clean-

ing, lubricating or doing any kind of work

on lawn tractor.

STEERING GEARS

Lubricate teeth of steering gears with automotive multipurpose grease after every 25 hours of operation or

once a season. See figure 17.

14

Page 15

STEERING SHAFT

Lubricate steering shaft at least once a season with light

oil.

ENGINE

Refer to the engine section of Iris manual for all engine

maintenance instructions.

CLEANING ENGINE AND BLADE HOUSING

Any fuel or 011 spilled on the machine should be wiped

off promptly. Grass, leaves, and other dirt must not be

left to accumulate around the cooling fins of the engine

or on any part of the machine

Clean the underside of the blade housing after each

mowing.

CUTTING BLADES

A. Removal for Sharpening or Replacement

-

FIGURE 17.

Steering Gears

VARIABLE SPEED PULLEY

Lubricate needle bearings inside the variable speed

pulley with light oil once a season. Also lubricate the

bearings inside the pulley by putting a small amount

of light oil ort the shaft. Then start the tractor, and with

the shift lever in neutral, move the speed selector forward and backward which will move the center sheave

and distribute the oil on the shaft. Be careful not to get

oil on the sheaves of the pulleys or on the belts. which

could cause the belts to slip.

TRANSAXLE

The transaxle is lubricated at the factory and does not

require che(:king. If disassembled for any reason,

lubricate with 10 oz. of Shell grease, part number

737-0148 (16 oz. package).

The rear axles may be lubricated once a season, us-

ing the access hole on each side of the transaxle housing. See figure 16. A push-type hand grease gun.

equipped with a special flush coupler is required. Use

Shell grease, part number 737-0148 (16 oz. package).

WHEELS

The f, Jnt wheels are provided with grease fittings. The

rear wheels must be removed from the axle for lubrication. Lubricate both front and rear wheels at least once

a season with automotive multi-purpose grease.

PIVOT POINTS

Lubricate all pivot points with light oil at least once a

season.

MAINTENANCE

A WARNING: Disconnect the spark plug wire

and ground against the engine before performing any repairs or maintenance.

TROUBLE SHOOTING

Refer to page 24 of this manual for trouble shooting

information.

A WARNING: Be sure to disconnect and

ground the spark plug wire and remove

ignition key before working on the cutting

blade to prevent accidental engine starting. Protect hands by using heavy gloves

or a rag to grasp the cutting blades.

1. Remove the large bolt and lock washer which holds

the blade and adapter to the blade spindle.

2. Remove the blade and adapter from the spindle.

3. If the blade or blade adapter needs replacing.

remove the two small bolts, lock washers and nuts

which hold the blade to the adapter.

B. Sharpening

Remove the cutting blades by following the directions

of the preceding section.

When sharpening the blades. follow the original angle

of grind as a guide. It is extremely important that each

cutting edge receives an equal amount of grinding to

prevent an unbalanced blade. An unbalanced blade will

cause excessive vibration when rotating at high speeds.

may cause damage to the mower and could break,

causing personal injury.

The blade can be tested for balance by balancing it on

a round shaft screwdriver. Remove metal from the

heavy side until it balances evenly

NOTE: It is recommended that the blade always be

r'emoved from the adapter for the best test of balance.

C. Reassembly

Before reassembling the blade and the blade adapter

to the unit. lubricate the spindle and the inner surface

of the blade adapter with light oil. Lubricating the bolt

holes, bolts and inner surface of the nuts with light oil

is also recommended. A 4 oz. plastic bottle of light oil

lubricant is available. Order part number 737-0170.

Engine oil may also be used.

When replacing blades, be sure to install the blade with

the side of the blade marked "Bottom" (or with part

number) facing the ground when the mower is in the

operating position.

15

Page 16

Blade Mounting Torque

3/8" Dia. Bolt 375 in. Ib, min.. 450 in. Ib, max.

5/16" Dia. Bolt 150 in. Ib, min., 250 in, Ib, max,

To insure safe operation of your unit, ALL nuts and bolts

must be checked periodically for correct tightness.

FUEL FILTER

Your unit is equipped with a replaceable in-line fuel

filter. Replace filter whenever contamination or

discoloration is noticed. Order replacement- filter

through participating Western Auto Stores.

BELT REMOVAL AND REPLACEMENT

WARNING: Disconnect the spark plug wire

and ground it against the engine. Block the

wheels of the unit.

NOTE: Figures 18 and 22 through 24 are shown with

the unit tipped up for clarity. It is not necessary to tip

the unit to remove the belts.

However, if tipping the unit is desired, remove the bat.

tery from the unit. To prevent gasoline leakage, drain

the gasoline, or remove the fuel tank cap, place a thin

piece of plastic over the neck of the fuel tank and screw

on the cap. Be certain to remove the plastic when

finished changing the belts. Block unit securely.

Deck Belt Removal and Replacement

1. Place the lift lever in the disengaged position.

2. Remove the hex bolts (belt keepers) from the

engine pulley belt guard. See figure 18.

NOTE: When reassembling, make certain hex bolts are

assembled in the same locations from which they were

removed. See figure 1 B.

5. Disconnect the spring which is attached to a

bracket on the transaxle. inside the left rear wheel.

Use a spring puller or other suitable tool.

6. Disconnect the six deck links by removing the hairpin clips and flat washers.

7. Disconnect the stabilizer plate from the stabilizer

shaft assembly by removing the hairpin clips and

flat washers and sliding out the rod.

8. Place the lift lever in the disengaged position.

9. Slide the deck from beneath the lawn tractor.

10. Remove the belt guards at each deck pulley by

removing the hex bolts, lock washers and hex nuts.

See figure 19.

Belt Guard

FIGURE 19.

11. Remove and replace the belt, reassemble following the instructions in reverse order.

Rear Drive Belt

1. Place shift lever in neutral position. Unscrew the

shift knob. Remove the two truss head screws

which secure the transmission cover. See figure

20A.

2. Lift the transmission cover. Unplug the safety wire

from beneath the transmission cover. See figure

208. Remove transmission cover.

{/~

3.

Unhook the deck belt from the engine pulley.4.

Place the lift lever in the engaged (all the way forward) position.

rAI/ ,-j IBI [

'7 /;/ .~ I

\\

\\

FIGURE 20.

16

Page 17

3 Push the idler pulley toward the right side of the

unit. Lift the belt over the idler pulley. See figure 21 .

4 Remo\'e the belt from the variable speed pulley.

5. Remo'v.e the two bolts which hold the shift lever

bracket to the frame on the left side of the unit.

Swing ~he bracket toward the right so the belt can

be removed from the transmIssion pulley. See

figure ;~1.

6. Replace belt, and reassemble in reverse order

FIGURE 21.

Front Drive Belt

1. To remol/e the front drive belt. first remove the rear

drive belt from the idler pulley and variable speed

pulley.

2. Place the lift lever in the disengaged position.

3. Remove the three hex bolts (belt keepers) from the

engine pulley belt guard. Refer to figure 18.

NOTE: MakE~ certain hex bolts are reassembled as

shown in figure 18.

4. Unhook the deck belt from the engine pulley.

5. Remove the two bolts. lock washers and nuts on

each side of the frame which hold the engine pulley

belt guard to the frame. See figure 22.

6. Remove the engine pulley belt guard by slipping

it back and to the right. See figure 23.

FIGURE 23.

7. Place the clutch-brake pedal in park position.

8. Push forward on the variable speed pulley I and lift

the belt off the engine and remove the belt from

the engine pulley

9. Release the clutch-brake pedal. Using the pedal

to move the variable speed pulley as necessary,

lift the belt up and off the variable speed pulley.

NOTE: When reassembling, make certain belt is inside

the pins. See figure 24.

FIGURE 22.

FIGURE 24.

10. Reassemble with a new belt. following instructions

in reverse order.

17

Page 18

BATTERY REMOVAL OR INSTALlATION

A WARNING: When removing the battery,

follow this order of disassembly to prevent

the screwdriver from shorting against the

frame.

1. Remove the Negative cable.

2. Remove the Positive cable.

To install a battery:

1. Attach the Positive cable.

2. Attach the Negative cable.

JUMP STARTING

1. Attach the first jumper cable from the Positive terminal of the good battery to the Positive terminal

of the dead battery.

2. Attach the second jumper cable from the Negative

terminal of the good battery to the FRAME OF THE

UNIT WITH THE DEAD BATTERY.

COMMON CAUSES FOR BATTERY FAILURE ARE:

1. Overcharging

2. Undercharging

3. Lack of water

4. Loose holds downs and/or corroded connections

5. Excessiv~ loads

6. Battery :':trolyte substitutes

7. Freezing of electrolyte

NOTE: THESE FAILURES DO NOT CONSTITUTE

WARRANTY.

TIRES

Recommended operating tire pressure is approximately

12 p.s.i. (check sidewall of tire for tire manufacturer's

recommended pressure). Maximum tire pressure under

any circumstances is 30 p.s.i. Equat tire pressure

should be maintained on all tires.

When installing a tire to the rim, be certain rim is clean

and free of rust. Lubricate both the tire and rim

generously. Never inflate to over 30 p.s.i. to seat beads.

A WARNING: Failure to use this starting pro-

cedure could cause sparking, and the gas

in either battery could explode.

BATTERY MAINTENANCE

1. Check periodically (every two weeks or before and

after charging) to be sure electrolyte level is above

the lowest line on battery. Add only distilled water

or a good quality drinking water. NEVER add additional acid or other chemicals to battery after in-

itial activation.

2. The battery should be checked with a hydrometer

after every 25 hours of operation. If the specific

gravity is less than 1.225. remove battery and

recharge.

3. Coat the terminals and exposed wiring with a thin

coat of grease or petroleum jelly for longer service

and protection against electrolyte corrosion,

4. The battery should be kept clean. Any deposits of

acid should be neutralized with soda and water.

Be careful not to get this solution in the cells.

BATTERY STORAGE

1. Charge battery using normal methods. NEVER

store discharged battery as it will not recover.

2. When storing battery for extended periods, disconnect battery cables. Removing battery from unit is

recommended.

3. Store in cold, dry place.

4. Recharge battery whenever the specific gravity is

less than 1.225, before returning to service, or

every two months, whichever occurs first.

A WARNING: Excessive pressure (over 30

p.s.i.) when seating beads may cause

tire/rim assembly to burst with force suffi-

cient to cause serious injury.

STORAGE

If the machine is to be inoperative for a period longer

than 30 days, prepare for storage as follows.

1. Clean the engine and the entire unit thoroughly.

2. Lubricate all lubrication points. Wipe the entire

machine with an oiled rag to protect the surfaces.

3. Refer to the engine section of this manual for correct engine storage instructions. The engine must

be completely drained of fuel to prevent gum

deposits from forming on essential carburetor

parts, fuel lines and fuel tanks.

4. Refer to battery storage instructions on this page.

5. Store unit in a clean, dry area.

NOTE: When storing any type of power equipment in

an unventilated or metal storage shed, care should be

taken to rustproof the equipment. Using a light oil or

silicone, coat the equipment, especially any chains,

springs, bearings and cables.

OFF-SEASON

18

Page 19

FOR ENGINE MODEL 281707-0411-01

IMPORT ANT: Do not start the engine before reading

the following section of this manual.

A WARNING: Do not operate engine in an

enclosed area. Exhaust gases contain carbon monoxide, an odorless and deadly

poison.

AI'Nays remove ignition key and disconnect

spark plug wire from spark plug before performing any repairs or maintenance.

SECTION "1

BEFORE STARTING

Fill Sump With Oil-Use a high quality detergent oil

classified "~or Service SF, SE. SD or SC." Nothing

should be added to the recommended oil.

Place engirle level. Clean area around oil fill before

removing oil dipstick.

Remove oil dipstick. Fill to full mark on dipstick. Pnur

slowly. Capacity approximately 3 pints; however, a

small amou'1t of oil may be present from the factory.

When checking oil level, screw dipstick assembly firmly

but slowly until cap bottoms on tube. Do not overfill

or excessive smoking may occur when engine is run-

ning. Dipstick assembly must be securely assembled

to tube at all times when engine is operating.

NOTE: Be ,:ertain to fill only to the full mark on the

dipstick. Do not overfill.

Fill Fuel Tank-The engine will operate satisiactorily

on any gasoline intended for automotive use. DO NOT

MIX OIL WITH GASOLINE.

The use of clean, fresh, lead.free gasoline IS recom-

mended. Leaded gasoline may be used if lead-free is

not available. A minimum of 77 octane i.c reCOrTtmended. The use of lead-free gasoline results in fewer

combustion deposits and longer valve life.

Do not fill fuel tank to point of overflowing. Allow tank

space for fuel expansion

Recommended SAE Viscosity Grades

19

Page 20

SECTION 2

STARTING

A WARNING: ALWAYS KEEP HANDS AND

FEET CLEAR OF MOWER BLADE OR

OTHER ROTATING PARTS.

~ "'\

'. ~~ \~ -.,'~~:-

~", -, --

,~- .~':(~::~l~~~'~~':

))

Lift

To Start Engine

1. Depress the clutch-brake pedal and set the parking brake.

2. Place the lift lever in the DISENGAGED position.

3. Set the throttle control in the FAST position.

4. Pull choke knob out to choke engine.

NOTE: A warm engine requires less choking than a

cold engine.

5. Turn the ignition key to the START position. When

the engine is running, let the key return to the ON

position.

NOTE: The best starter life is provided by using short

starting cycles of several seconds. Prolonged cranking can damage the starter motor if cranked more than

15 seconds per minute.

6. Push choke knob in gradually. Move the throttle

control to desired engine speed.

To Stop Engine-Turn ignition key to OFF position.

CAUTION: Always remove key from switch when leav-

ing equipment unattended or when equipment is not

in use.

SECTION 3

REGULAR MAINTENANCE

A WARNING: TO PREVENT ACCIDENTAL

STARTING when performing any /' .

maintenance or repairs, always disconnect

spark plug wire from spark plug and ground

against the engine.

SURE PROPER OIL LEVEL IS MAINTAINED.

Change Oil after first five hours of operation. Thereafter

change engine oil every 50 hours, under normal

operating conditions. Change engine oil every 25 hours

of operation if the engine is operated under heavy load,

or in high ambient temperatures. Change oil while

engine is warm. Oil may be drained through oil drain

plug on side of engine.

Air Cleaner

Service air cleaner at three month intervals or every

25 hours, whichever occurs first.

NOTE: Service air cleaner more often under dusty con-

ditions.

To Service Air Cleaner:

1. Remove two cover knobs and remove air cleaner

cover.

-'--

Throttle

Clutch-

Brake

Pedal'

/"

Cold Weather Starting Tips

1. Be sure to use the proper oil for the temperature

expected.

2. Declutch all possible external loads.

3. Set throttle control at part-throttle position.

4. A slightly richer fuel mixture, obtained by turning

carburetor needle valve 1/8 turn counterclockwise,

will usually improve cold starting.

5. A warm battery has much more starting capacity

than a cold battery.

6. Use fresh winter grade fuel. (Winter grade gasoline

has higher volatility to improve starting. Do not use

gasoline left over from summer.)

I\UJ

~"

'-1

\Check Oil Level after each five hours of operation. BE

Q:9 "-'

Oil Drain Plug

~

11"'0

I

-.d-- Cover~

.~~ Knobs "'~#' .

To Remove

, Cover

~

~/ ../ Cartridge

~ Nuts

.Fiber

~~:~~ Washer

-~ .Foam

'r::::;--- Pre-Cleaner

Air Cleaner

Base

~~

J'

20

Page 21

2 Remove foam pre-cleaner. Spark Plug-Clean and reset gap at .030" every 1 00

a. Wash pre-cleaner in liquid detergent and warm hours of operation.

water to remove dirt. NOTE: Do not blast clean spark plug. Spack plug

b. WrElp pre-cleaner in cloth and squeeze dry. should be cleaned by scraping or wire brushing and

c. Saturate foam in engine 011. Squeeze to

remove excess oil. Caution: Sparking can occur if wire terminal does not

3. Remove two nuts rom top 0 cartrl ge.

4. Remove cartridge and clean air cleaner body is equipped with spark arrester screen assembly,

carefully to prevent dirt from entering carburetor. remove every 50 hours for cleaning and inspection.

Brush ,jirt from lower air cleaner body Into duct. Replace if damaged.

5. Clean cartridge by tapping ~ently on flat ~urface Fuel Filter-Replace in-line fuel filter every season.

a. If very dirty, replace cartridge or wash In a low

or non-sudsing detergent and warm water

solution.

b. Rinse thoroughly from inside out until water is

clear.

c. Cartridge must be allowed to stand and air ry

thoroughly before using.

6. Reassemble air cleaner. f

Caution: Petroleum solvents, such as kerosene, are

not to be used to clean cartridge. They may cause

deterioration of the cartridge. Do not oil cartridge. Do

not use pressurized air to clean or dry cartridge. (

f f .d fit firmly on spark plug. Reform terminal if necessary.

.Spark Arrester Equipped Muffler-If engine muffler

.washing with a commercial solvent.

~ \

I IIn-Line

.

d I

Filter

~~~::::~~~ ~

; :-- -,~

1/_-

Clean Engine-Remove dirt and debris with a cloth or

\brush. Clea,1ing with a forceful spray of water is not

recommended as water could contaminate the fuel I

system.

Clean Cooling System-Grass. chaff or dirt may clog ---~-

the rotating s,creen and the air cooling system, especial- Remove Combustion Deposits every 100-300 hours

Iy after prolonged service in cutting tall dry grasses. of operation. Remove cylinder head and cylinder head

Yearly or e'/ery 100 hours, whichever occurs first, shield. Scrape ar,d wire brush the combustion deposits

remove the blower housing and clean the areas shown from cylinder, cylinder head, top of piston and around

to avoid ol/erspeeding, overheating and engine valves. Use a soft brush to remove deposits. Re-

damage. Clean more often if necessary. assemble gasket, cylinder head and cylinder head

WARNING: Periodically clean muffler area to shield. Torque cylinder head screws in a staggered seremove all grass, dirt and combustible debris. quence to 140 inch pounds (15.82 Nm).

SECTION 4

~ADJUSTMENTS.

CARBURETOR ADJUSTMENT

A WARNING: If any adjustments are made to

the engine while the engine is running

(e.g. carburetor), disengage clutches and

bla,des. Keep clear of all moving parts. Be

careful of heated surfaces and muffler.

Minor carburetor adjustment may be required to com-

pensate for differences in fuel. temperature, altitude or

load.

NOTE: The air cleaner must be assembled to carburetor wherl running engine.

To Adjust C;~rburetor-Gently turn valves clockwise

Mixture r ~

i I / =.. \ \ \.

Idle Speed I

Adjusting

Screw I

Throttle

Stop

until they just close. Valves may be damaged by turn-

ing them -roo far.

-

."

Throttle

\..I.J (High Speed)

Out Chaff

and Dirt

y

-'

Needle Valve

:;.?

~

~

Idle

Ijo~

21

Page 22

Now open needle valve 1-1/2 turns counterclockwise

and idle valve one turn. This initial adjustment will per-

mit the engine to be started and warmed up approx-

imately 5 minutes prior to final adjustment.

Final Adjustment-Place speed control lever in FAST

position. Turn needle valve in until engine slows (clockwise-lean mixture). Then turn it out past smooth

operating point (rich mixture). Now turn needle valve

to midpoint between rich and lean. Next, adjust idle

RPM. Rotate throttle counterclockwise and hold against

stop while adjusting idle speed adjusting screw to ob-

tain 1750 RPM. Holding throttle against idle stop, turn

idle valve in (lean) and out (rich). Set at midpoint between rich and lean. Recheck idle RPM. Release throttle. If engine w111 not accelerate properly, the carburetor

should be re-adjusted, usually to a slightly richer

mixture.

CONTROL ADJUSTMENTS

Proper choke and speed control operation is dependent upon proper adjustment of controls on the powered

equipment.

To Check Operation

Move control lever to CHOKE position. The carburetor

choke should be closed.

To Adjust Choke:

Place control lever on equipment in CHOKE position.

Loosen casing clamp screw. Move casing and wire until

choke is completely closed. Tighten casing clampscrew.

- ~~~:;qll~~~

~- ~ ~

J

~ °!8-C~'ok~ .

Casing

Clamp

Screw

Fast Position

~' E

I '

\~' ,,\

F

Throttle Control Adjustment

Place speed control lever on equipment in FAST (high

speed) position. Loosen casing clamp screw "C," Move

casing "A" and wire until lever "E" touches link at "F,"

Tighten casing clamp screw "C." Move control to

STOP position. Lever must make good contact with

stop switch.

SECTION 5

GENERAL INFORMATION

ENGINE DESIGN

This engine is single cylinder L-head. air-cooled type.

MODEL SERIES 281707

Bore 3-7/16"(87.31 mm)

Stroke 3-1/16" (77.78mm)

Displacement. 28.42 cu. in. (465.7 cc)

Horsepower Max. '."'..' ' .12 @ 3600 APM

Torque (Ft.-Lbs.) Max. 20.5 @ 2400 APM

The horsepower ratings listed are established in

accordance with the Society of Automotive Engineers

Test Code-J607. For practical operation, the

horsepower loading should not exceed 85% of these

ratings. Engine power will decrease 31/2% for each

1,000 feet above sea level and 1 % for each 100 above

600 F.

In some areas, local law requires the use of a resistor

spark plug so as to suppress ignition signals. If an

engine was originally equipped with a resistor spark

plug, be sure to use the same type of spark plug for

replacement.

Major engine repairs should not be attempted unless

you have the proper tools and a thorough knowledge

of internal combustion engines.

TUNE-UP SPECIFICATIONS

Spark Plug Type Champion Autolite

~. Short Plug CJ-8 235

Long Plug J-8 295

Resistor Short Plug RCJ-8 245

Resistor Long Plug RJ-8 306

Spark Plug Gap 030"

Intake Valve Clearance. 005"-.007"

Exhaust Valve Clearance. 009"-.011"

22

"---T~

Page 23

STORAGE INSTRUCTIONS

Engines to be stored over 30 days should be completely

drained of fuel to prevent gum deposits forming on

essential carburetor parts, fuel filter and tank.

NOTE: The use of a fuel additive. such as STABIL, or

an equivalent. will mil'limize the formation of fuel gum

deposits during storage. Such an additive may be

added to the gasoline in the fuel tank of the engine.

or to the gasoline in a storage container8.

All fuel should be removed from the tank. Run the

engine until it stops from lack of fuel.

b. While engine is s1ill warm, drain oil from crankcase

Refill with fresh oil,

c. Remove spark plug, pour approximately '/2 ounce

(15 cc) of engine oil into cylinder and crank slowly

to distribute oil. Replace spark plug.

d. Clean dirt and chaff from cylinder, cylinder head

fins, blower housing, static guard and muffler areas.

e. Store in a clean, dry area.f.

Charge battery and store as recommended on page

18.

23

Page 24

TROUBLE SHOOTING CHART FOR ELECTRIC START MODELS

TROUBLE

Engine will not

crank

LOOK FOR

Battery installed Incor.

rectly

Blown fuse or CirCUli

breaker

Battery is dead or weak

-REMEDY- ---:J

The battery must be instatled with the negative terminal, identified at t'le terminal post by (Neg. N

or -). grounded The positive terminal (Pos, P or ..) attaches to the large cable from the solenOid

The small red wire from the fuse holder or cirCUit breaker IS also attached to the positive termInal

Replace fuse with 7'/2 amp fuse 'I. x 1 '1." Ig CircUit breaker WIll reset Itself when it cools off Fuses

or circuit breakers seldom open or fail without a reason The problem must be corrected Check for

loose connections In the fuse holder Replace fuse holder if necessary A dead shon may be In the

cranking or charging Circuit where the Insulation may have rubbed through and exposed the bare

wire Replace the wIre or repair with electrician's tape if the wire strancs have not been damaged

Note: Look for a wire pinched between body panels. burned by the exhaust pipe or muffler or rubbed

Use a hydrometer to check the condition of 1he battery The SpecIfic GravIty (sg) should be 1 265

at 80°F (1.215 sg minimum needed for cranking engine) 'he reason for the batter,. failing must

be determined (1) Defective battery Battery will not accept or hold a full charge (2) Short circuIt.

Check for grounded wire (3) Charging system not working

The charging system IS an alternator located under the flywheel It IS unregulated and rated 3 amp

at 3600 r.pm A diode (rectifier) IS located In the output lead just befort! the wIre harness plug on

the engine side

Red

Wire

To Alternator <) ~ ~ ~

Diode

--.'

--~

t,:.;';';;;;"D._~

I--'

s

Black

Wire

Polarized

Plug

Iagainst a movIng pan

The diode changes AC to DC to charge the battery A bad diode can either fall to charge the bat.

tery or discharge the battery If the alternator IS shorted as well as the diode To test: (1) Disconnect

charger lead from the battery (small red wire) (2) Connect 12 V small test lamp between the 3 amp

DC charge lead and the positive terminal of the battery. (3) With the engine off, the lamp should

not lIght If It does. the diode and possibly the alternator should be replaced (4) Stan the engine

The lamp should light. If it does not, the alternator (stator) or lead wIre IS bad and should be replaced

Mechanical failure

(Wires and swItches)

Engine cranks

but will nol star1

., I Replace il it does not J

Throttle or choke not in

starting poSition

No spark to spark plug Spark plug lead disconnected Connect lead Hold spark plug lead away from engine block about

The interlock system Includes two mechanical activated switches which are wired in series in the

circuit used to energize the starter solenoid While testing the InterlocK system, you will make the

mower temporarily unsafe by permit1ing the engine to be started wIth the blade and clutch engaged

WARNING While testing, disengage the clutch, shut off the blade control, set the parking brake and

place the gear shift lever in neutral. Attach a wire (minimum 18 gauge) to the positive terminal of the

battery and touch the other end to the small terminal on the solenoid If the engine does not crank: (1)

There is a loose connection or poor ground (2) The solenoid may be bad The solenoid can be checked

by using a heavy wire (*8 gauge minimum) and Jumping between the two large terminals If the engine

cranks, the solenoid is bad. (3) If the engine does not crank when you jump the solenoid, have the

starter motor tested by an authorized engine dealer If the engine does crank. the problem is with

one of the safety switches. Ignition switch or the wire between the fuse holder (or circuit breaker) and

the small terminal on the solenoid. Note: Look for a poor connection at the switches or a defective

swItch Replace if necessary

Check owner's guide for correct position for throttle control and choke for starting

1/8" Crank engine. There should be a spark II not. have engine repaired at local Western Auto Ser-

vice Center.

Faulty spark plug To test. remove spark plug. Attach spark plug lead to sparl\ plug. Ground the spark

plug body against the engine block. Crank the engine. The spark plug should fire at the electrode.

24

Page 25

ILLUSTRATED PARTS FOR MODEL

MT[)7122BO9 LAWN TRACTOR

PARTS LIST FOR MODEL MTD7122BO9 LAWN TRACTOR

~~j NO.

1

710-0924

2

1 16195 3 720-0218

4 16192

5 ' 736-0192

6 711-0198

7 738-0155

I ~! ~~~~~~~~J~

I 9 i 714-0507

Truss Mach. Scr. '/4-20 x j

.75" Lg. i

5-Speed Selector Plate !

Shift Knob

Speed Selector Cam Ass'y.

Flat Washer .53" 1.0. x .93"

Ferrule 3/8-24 x .37" Dia.

Shoulder Bolt

Speed Control Link

Cotter Pin 3/32" Dia. x .75".

DESCRIPTION

,

I REF.-+-~PART

NO.

10 736-0226

11 736-0119

12 712-0267

13 714-0507

14 732-0303

17 736-0140

18 726-0235

19 736-0329

20 1712-0287

""-

l-Wash. 5/16" I.D.*

Hex Nut 5/16-18 Thd.*

Cotter Pin 3/32" Dia. x .75" *

Spring .38" C.D. x 3.18" Lg.

FI-Wash. .385" I.D. x .62"

Speed ClipL-Wash.

Hex Nut 1/4-20 Thd.*

DESCRIPTION

.469" I.D. x .88"

1/4" 1.0. *

~T-Pm-

FI-Wash.

25

Page 26

~

~~8

~

'"

21. '.

41

17

~

11-;-\((

15-i \ \

~'

1.Q .

5 ..

6

1.2./

.

..r

L;,

1

"

I.

6

\ ~'5

w/

17

3

~

"

6$

,

36,~

'~'..~' -~'- ~.. .

~~:;~ .,'

-.~

~\.~.

35

21

31

z: .

r'--

":)

,~

~

/1"~\

I

10

Page 27

Il.LUSTRATED PARTS FOR MODEL

MTD7122BO9 LAWN TRACTOR

""':~

""""

~ ~ ~ 1

---QI 55 '

:.-~-:-~ ~ 58,' ,'26 t

~;;--o:;;;~~~>... ',.f ! I 51

~

~<...y 16 a.1.8

~

-.', ~ rZ ~ I

i

6

To Battery ~

.-""",- 32 ! \'.. ,. ,~~\\ ~..,~""',.,~- i 51' .~ ,~- 52

5'

:5 m '

i

2 z .

;;

,26":

33

/

I :'

--I

-;..;,.;.

60~ oiI.,~ ~ .,.~-"'-;:;:~'c-. !' ,.~.. .:--.

51~ ...~""= .

-'---~i=~ ,~."" ..2fI ~p:'833 C~-

~~y--- 52" ' fl

IJ-.'\:':-:~:'::'--:- ---:--- 117 ~I_/...~~

'4--:: <~;~-"--:-'-'

-'-, A ~ ---'~ c --2

!~~ '.' .A~ 51-- / '---c-., -~~~

T

33 U-~~~~~ 29 --, ~2 59 13/ 30 57

17

N--,"'" ~ =?~;;~- II ~

7-- 61

~-'y--w

"'~i

~

44

/

I

1-'3

'5

~"':~~. ;--8

-..r ~ 9

j ,

~-

or

SP

I

/

~~""'zz-4:- -"';

""-'

~

1.6, t .~

,...~~~::~

~- "II 3' '47

~:~:~~~:-::~- 21.

: ,!

..?""" --.

/1" -., -,-,;' w

~

"

.-:::::--

61

4

4,15 I

£.-:\ I ~

1. .y

t :.~--

-~.-;;;./..

29

NO. NO.

I 1 736-0159-'

I 2 1710-0817

I 3 738-0155

i 4 738-0145

I 5 736-0141

I 6,156070

I 7 i 723-3071

I 8 i 751-0553

I 9 i 726-0209

10 .751-0535-15

11 726-0205

13 712-0287

14 736-0329

16 732-0588

171 723-0360

21 738-0526

22 1710-0227

23 726-0139

24 17621

25 710-0623

26 I 710-0726

1 28 1 710-0134

29 17770

30 1 761-0168

133 710-0323

-. t1EF. PART

PARTS LIST FOR MODEL MTD7122BO9 LAWN TRACTOR

I DESC~IPTIO~ 'REF.

\ FI-Wash. .344" 1.0. x .875"

Hex Wash. Hd. Tap Scr.

\ 5/16-18 x 1.25" Lg.

Shld. Bolt .437" Dia. x .162"

Shld. Bolt .50" Dia. x .84"

I Spr-Wash. .445" 1.0. x .75

I Seat Pivot Bracket

\ Fuel Cap w/o Gasket

Fuel Tank

Tie Strap

Fuel Line

I Hose Clamp

Hex Nut '/4-20 Thd.-

\ L-Wash. V4" 1.0.

Compression Spring

t-

! 34 17620 Lower Frame

1 35 736-0169 I L-Wash. 3/8" 1.0.*

I 38 710-0118 Hex Bolt 5/16-18 x .75" Lg.*

! 39 17622 Upper Frame-A.H. ,

I 41 712-0798 Hex Nut 3/8-16 Thd.' i

1 42 732-0581 Extension Spring 5.31 " Lg. I

Foot Pad-.

IRunning Board Rod

Hex Wash. Hd. AB-Tap Scr.

#8 x .50" Lg.

I Speed Nut #10Z

I Front Pivot Brkt

Hex Tap Scr. 3/8-16 x .75"

I Hex Wash. Hd. AB-Tap Scr.

\ 5/16 x .75" Lg.

II Carriage Bolt '/4-20 x .62" .

Running Board (R.H. & L.H.)

, Blade Brake Ass'y.

I ;:;~ss Mach. Scr. 5/16-18 x

J .75" Lg.-

-

: 54 757-0345 Seat

I 55 17702 Seat Pivot Brkt. Support-A.H.

I 56 738-0296 Shld. Bolt .437" Dia. x .268" I

i 57 725-1303 Spring Switch I

I 58 722-0160 Bushing i

I. 59 710-0971 , Truss Hd. Scr. 5/16-18 x 1.0" Lg. .

I

' 60 736-0607 i External L-Wash. 5/16" 1.0.

I ~726-0222 Insulator Nut Plate

I 63 725-1439 Safety Switch (Seat)

: I

I

27

: iT -I. "'.'0' c:.,,~~CRIPTION- --!RT I DESCRIPTION J I DESCR NO. NO.

36 726-0278 i Insulator Center Plate

43 731-0871 A Battery Box w/Cover

44 725-0514A 12- V Battery

45 17623 Upper Frame-L.H.

46 17286 Shift Cover

47 725-0759 Reverse Safety Switch ;

48 726-0279 Insulator End Plate

50 17225A Hitch Plate

52 736-0119 L-Wash. 5/16" 1.0. *

53 17239A Seat Lift Brkt.

61 723-3003

I! 49 17701 Seat Pivot Brkt. Support-L.H.

I1 51 712-0267 Hex Nut 5/16-18 Thd.*

I Fuel Cap Gasket

~t

"

,10

.;-.

~

~

Page 28

Page 29

rAEFT- PART---

~-:-i !!:.O-.:.-- ---

: 1 i 731-0220

2 \ 712-0237

3 736-0242

I 4 i 731-0805

I 51731-0954

, 6'16512

I 71741-0356

I 8 1712-0324

9117198

I 10 1738-0141

11 ;710-0152

1516

-4

Seat

IREF1

[NO-.:J

1 I 725-0514A

2 ,725-1426

3 ' 725-0459

4 725-0634

5 725-,0925