Bolens 750, 550 User Manual

OPERATOR’S MANUAL

SNOW

THROWER

MODELS

Snow Boss 550

Snow Boss 750

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-9722.

WHITE OUTDOOR PRODUCTS COMPANY P.O. BOX 361131 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

FORM NO.

770-10014B.fm

(6/00)

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices...................................................................3

Assembling Your Snow Thrower........................................................................5

Know Your Snow Thrower .................................................................................7

Operating Your Snow Thrower...........................................................................8

Making Adjustments ..........................................................................................10

Maintaining Your Snow Thrower........................................................................12

Service...............................................................................................................13

Troubleshooting.................................................................................................16

Parts List............................................................................................................17

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new Snow Thrower. It will help you assemble, prepare

and maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on

the model plate is very important if you need help from our Customer Support Department or

an authorized dealer.

• You can locat e the model numb er by l ookin g at the l ower fr ame co ver in the rear of your snow

thrower. A sample model plate is explained below. For future reference, please copy the model

number and the serial number of the equipment in the space below.

(Model Number)

(Serial Number)

WHITE OUTDOOR

PRODUCTS COMPANY

P.O. BOX 361131

CLEVELAND, OHIO 44136

Copy the model number here:

Copy the serial number here:

CALLING WARRANTY SERVICE

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call the Customer Dealer Referral Line.

Call 1- (800)-949-4483 to reach the Customer Dealer Referral Line. Please have your unit’s

model number and serial number ready when you call. See previous section to locate this

information.

For more details about your unit, visit our website at www.whiteoutdoor.com

2

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could

endanger the personal safety and/or property of yourself and others. Read and follow all instructions in

this manual before attempting to operate this machine. Failure to comply with these instructions may

result in personal injury. When you see this symbol - heed its warning.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State of California to cause cancer

and birth defects or other reproductiv e harm.

DANGER

: This machine was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

Training

1. Read, understand, a nd follow all in struction s on the

machine and in the manual(s ) before a ttempting to

assemble and o perate. Keep this ma nual in a safe pl ace

for future and regular re ference a nd for orde ring

replacement parts.

2. Be familiar with all controls and their prope r operation.

Know how to stop the mach ine and d isengage them

quickly.

3. Never allow childre n under 14 y ears old to operate this

machine. Children 14 years old and over should rea d and

understand the op eration in struction s and sa fety rules i n

this manual and should be trained and sup ervised b y a

parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Thrown objects can cause seriou s personal injury . Plan

your snow throwin g pattern to avoid di scharge of mat erial

toward roads, bystanders and the like.

6. Keep bystanders, hel pers, pets and chi ldren at l east 75

feet from the machin e while it is in operatio n. Stop

machine if anyo ne enters the area.

7. Exercise caution to avoid s lipping o r falli ng, espe cially

when operating in reverse.

Preparation

1. Thoroughly inspect the area wh ere the eq uipment i s to

be used. Remove all door mat s, newspa pers, sle ds,

boards, wires and o ther foreig n object s which c ould be

tripped over or throw n by the auger/imp eller.

2. Always wear safet y glasses or eye s hields d uring

operation and while performing an adjustment or repair to

protect your eyes. T hrown ob jects whi ch ricochet can

cause serious inj ury to the eyes.

3. Do not operate wit hout wearing adequate winter outer

garments. Do not wear jewelry, long scarves or other

loose clothing which cou ld becom e entang led in m oving

parts. Wear footwear w hich wi ll improve footing on

slippery surfaces.

4. Use a grounded three wire ex tension cord and receptac le

for all units with electric start engi nes.

5. Adjust collector housing height to clear gravel or crus hed

rock surfaces.

6. Disengage all cl utch levers before st arting the engin e.

7. Never attempt to m ake any adjustme nts while engine i s

running, except where spec ifically recomm ended in the

operator’s manual.

8. Let engine and m achine adju st to outd oor tem perature

before starting to clear snow.

9. To avoid personal injury or pro perty damage use extre me

care in handling gasolin e. Gasol ine is e xtremely

flammable and the v apors are explosiv e. Serious

personal injury c an occur w hen gas oline is spilled o n

yourself or your c lothes which c an ignit e. Wash y our skin

and change clot hes immedi ately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cig ars, pipes and other

sources of ignition.

c. Never fuel machine indoo rs.

d. Never remove gas cap or add fue l whil e the

engine is hot or running.

e. Allow engine to cool at leas t two minu tes before

refueling.

f. Never over fill fuel tank. Fil l tank to no more tha n

½ inch below bottom of fill er neck to provide space

for fuel expansi on.

g. Replace gasoli ne cap an d tighten secu rely.

h. If gasoline is sp illed, wip e it off th e engine and

equipment. Move machine to another area . Wait 5

minutes before start ing the e ngine.

i. Never store the machine or fuel containe r inside

where there is an o pen flam e, spark or pilot l ight

(e.g. furnace, water heater, space heate r, clothes

dryer etc.).

j. Allow machine to cool at least 5 mi nutes bef ore

storing.

Operation

1. Do not put hands o r feet near rotating p arts, in the a uger/

impeller housing o r disc harge chu te. Cont act wit h the

rotating parts can am putate ha nds and feet.

2. The auger/impelle r clutch lev er is a safety de vice. Nev er

bypass its operati on. Doing so, makes the ma chine

unsafe and may cause p ersonal i njury.

3

3. The clutch leve rs must o perate easily in both d irections

and automaticall y return to the disengaged pos ition when

released.

4. Never operate with a missing or da maged di scharge

chute. Keep all safe ty devic es in pl ace and working.

5. Never run an engine indoors or in a poorly vent ilated

area. Engine exhaust contains carbon monoxide , an

odorless and dea dly gas .

6. Do not operate mac hine while under the influenc e of

alcohol or drugs.

7. Muffler and engine beco me hot and can cause a burn. Do

not touch.

8. Exercise extreme ca ution when operating on or cro ssing

gravel surfaces. Stay alert for hidden hazards or traffic.

9. Exercise caution w hen changi ng directi on and w hile

operating on slop es.

10. Plan your snow t hrowing pat tern to av oid disc harge

towards windows, wa lls, cars e tc. To avoid prope rty

damage or personal injury caus ed by a ricochet.

11. Never direct disc harge at c hildren, b ystander s and pet s

or allow anyone in front of t he machi ne.

12. Do not overload machine capa city by attemptin g to clear

snow at too fast of a rate.

13. Never operate this machine without good vi sibility or

light. Always be s ure of yo ur footing and keep a firm hold

on the handles. W alk, never r un.

14. Disengage power to t he aug er/impeller w hen

transporting or not in use.

15. Never operate mach ine at hi gh transp ort speeds on

slippery surfaces. Look down and b ehind an d use ca re

when in reverse.

16. If the machine sh ould start to vi brate abnormally , stop the

engine, disconnect the spark plug an d grou nd it agai nst

the engine. Inspect thoroughly for dam age. Repair any

damage before starting and ope rating.

17. Disengage all cl utch lev ers and st op engin e before y ou

leave the operating position (be hind the handles). Wai t

until the auger/im peller come s to a complete stop befo re

unclogging the d ischarge chute, m aking an y

adjustments, or inspecti ons.

18. Never put your hand in the d ischarge or colle ctor

openings. Always use a cl earing to ol to unc log the

discharge opening.

19. Use only attach ments a nd acce ssories approved by the

manufacturer (e.g. wheel weigh ts, tire c hains, cabs etc.) .

20. If situations occur which are not covered in this manua l,

use care and good judgment. Cont act your dealer or

telephone 1-800-94 9-4483 for assista nce and the name

of your nearest s ervicing de aler.

Maintenance And Storage

1. Never tamper with sa fety devic es. Check their prop er

operation regularly.

2. Disengage all cl utch lev ers and stop engine. Wait u ntil

the auger/impelle r come to a complet e stop . Disconn ect

the spark plug wir e and ground aga inst the engine to

prevent unintended s tarting before cleaning, r epairing, or

inspecting.

3. Check bolts, and sc rews for pro per tightn ess at fre quent

intervals to keep the machine in sa fe working conditio n.

Also, visually inspect mach ine for an y damage .

4. Do not change the engine governo r setting or over-speed

the engine. The g overnor co ntrols th e maxim um safe

operating speed o f the engi ne.

5. Snow thrower shave plate s and skid shoe s are subjec t to

wear and damage. F or your sa fety prote ction, fre quently

check all compon ents a nd replace with orig inal

equipment manuf acturer’s (O.E.M. ) parts on ly. “Us e of

parts which do not meet the original equipment

specifications ma y lead t o imprope r performan ce and

compromise safety!”

6. Check clutch controls periodically to verify they engage

and disengage proper ly and adjust, if necessary. Re fer to

the adjustment sec tion in th is opera tor’s manual for

instructions.

7. Maintain or replace safety and instruction labels, as

necessary.

8. Observe proper disp osal laws and regu lations for gas,

oil, etc. to protect t he enviro nment.

9. Prior to storing, run machine a few minutes to clear snow

from machine an d prevent freeze up of auger/i mpeller.

10. Never store the machine or fuel cont ainer inside whe re

there is an open flame, s park or pilot light such as a water

heater, furnace ,cloth es dryer etc.

11. Always refer to the o perator’s manual f or proper

instructions on off-sea son storage.

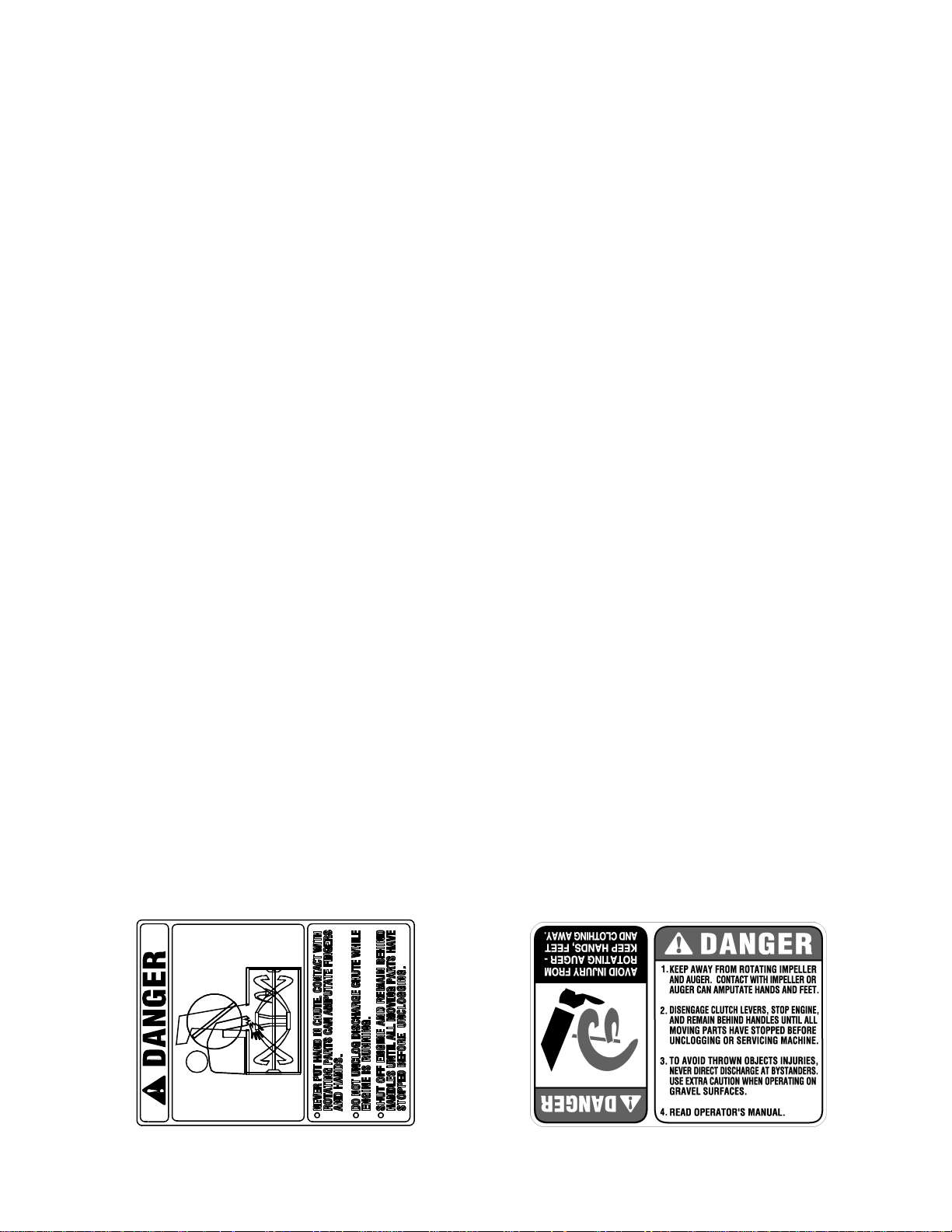

Your Responsibility:

Restrict the use of this power machine to persons who

read, understand and follow the warnings and

instructions in this manual and on the machine. The

safety labels are given below for your reference.

4

SECTION 2: ASSEMBLING YOUR SNOW THROWER

NOTE: Any referen ce in this manual to the left or right

side of the snow thrower is observed from the

operator’s position.

Unpacking

• Remove screws from the top sides and ends of the

shipping crate.

• Set panel aside to avoid tire punctures or personal

injury.

• Remove and discard plastic bag that covers unit.

• Remove any loose parts included with unit (i.e.,

Operator’s Manual, etc).

• Roll unit out of crate.

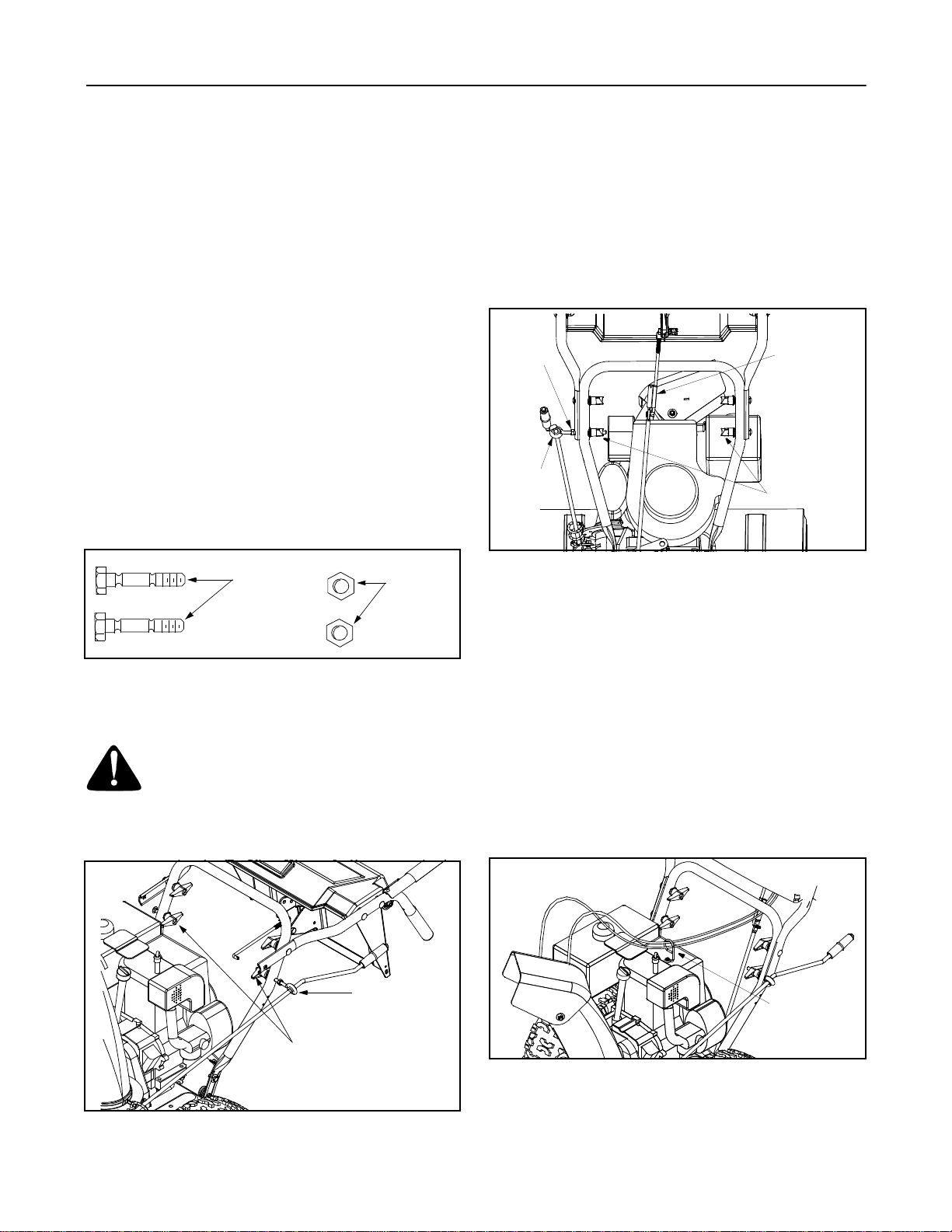

Loose Parts

The augers are secured to the auger shaft with two

shear bolts and hex lock nuts. If you hit a foreign object

or ice jam, the snow thrower is designed so that the

bolts may shear. Two replacement shear bolts and nuts

are provided for your convenience. Store in a safe

place until needed. See Figure 1.

Shear Bolts

Figure 1

Hex Lock

Nuts

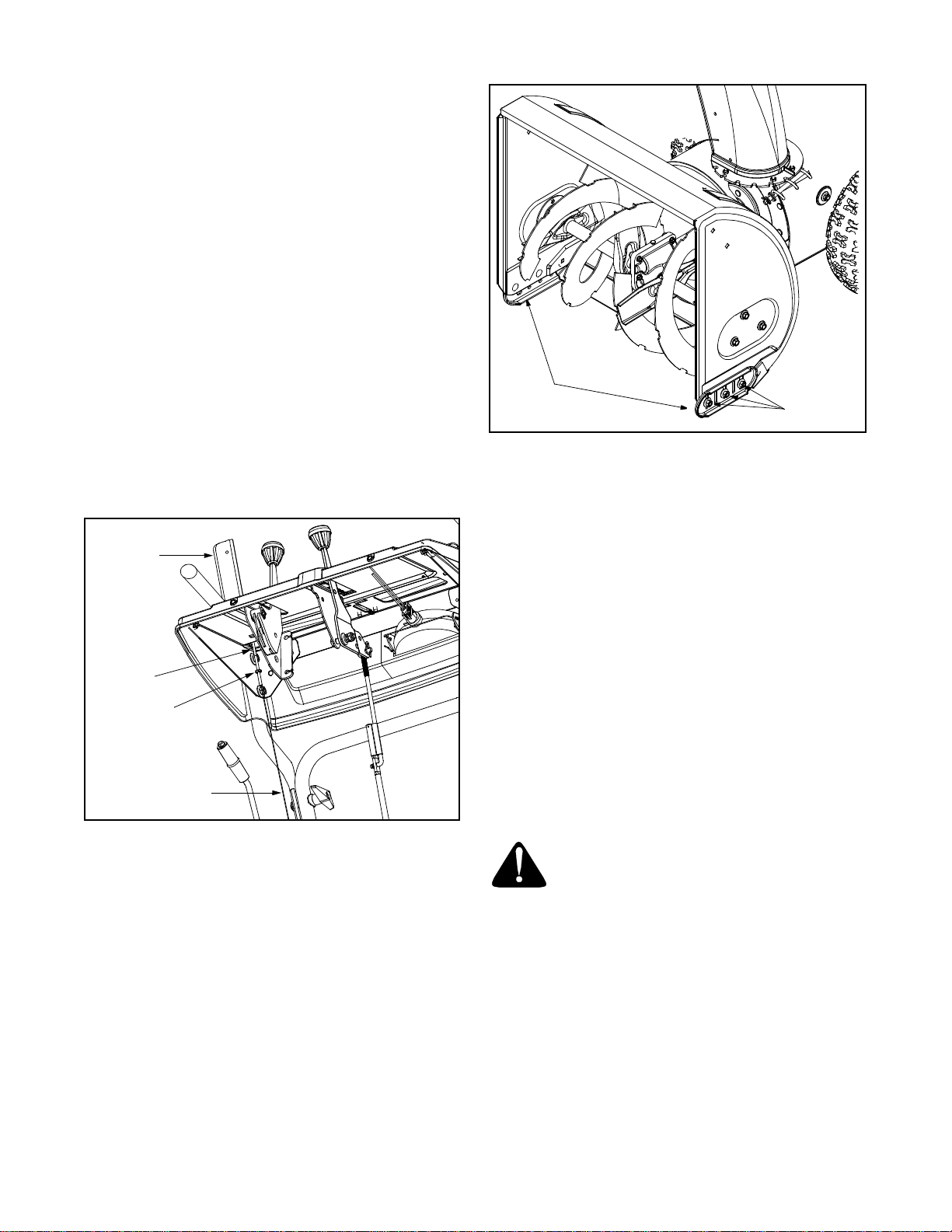

Assembly

• Raise the upper handle assembly until it locks over

the lower handle.

• Look at the lower rear of snow thrower frame to be

sure both cables are aligned with cable roller

guides.

• Secure the upper handle and lower handle with the

two plastic wing knobs, cupped washers and

carriage bolt (eyebolt on the left side) previously

removed. See Figure 3.

Hex Nut

Eyebolt

Figure 3

• Adjust the eyebolt on the chute directional control

so the rod does nut come into contact with the

engine by moving the hex nut against the handle (if

necessary). Retighten the wing nut to secure the

directional control in this position.

• Slide the shift rod connector down over the end of

the lower shift rod. Tap the connector until it locks

on the lower shift rod. See Figure 3.

Connector

Wing Knobs

WARNING: Disconnect the spark plug

wire and ground it against the engine to

prevent unintended starting.

• Remove the lower two plastic wing knobs, cupped

washers and carriage bolt (eyebolt on the left side)

from the lower handle. See Figure 2.

Eyebolt

Wing Knobs, Washers,

& Bolts

Figure 2

NOTE: If the conn ector is not prop erly assemb led, the

shift rod will pivot and y ou will not be able to change

speeds or change directions.

• If not already attached, slip the cables that run from

the handle panel to the chute into the cable guide

located on top of the engine. See Figure 4.

Cable Guide

Figure 4

• Unwrap the headlight wire, which is attached to the

headlight beneath the handle panel.

5

• Wind the headlight wire around the right handle

until excess slack i s remo ved.

• Plug the wire from the headlight into the wire lead

coming from the right side of the engine, beneath

the fuel tank.

Final Adjustments

Auger Control Adjustment

Check the adjustment of the auger control as follows:

• Push forward on the auger control until the small

rubber bumper contacts the upper handle. There

should be slack in the cable. See Figure 5.

• Release the auger control. The cable should be

straight. Make certain you can depress the auger

control against the left handle completely.

If adjustment is necessary, proceed as follows:

• Loosen the jam nut and thread the cable in (for less

slack) or out (for more slack) as necessary. See

Figure 5.

• Recheck th e adjustm ent bef ore reti ghtenin g the

jam nut against the cable.

Auger

Control

Skid

Shoes

Hex Nuts

Figure 6

Adjust skid shoes as follows:

• Loosen, but do NOT remove, the three hex nuts

which fasten the skid shoe to the auger housing.

• Raise or lower the skid shoe to desired position.

NOTE: Make certai n th e en t ir e b as e of bot h skid sh oe s

are against the ground to avoid uneven wear on the

skid shoes. When one side does wear out, the skid

shoes are reversible.

Z-End

Jam Nut

Auger

Control Cable

Figure 5

Skid Shoe Adjustment

The space between the shave plate and the ground can

be adjusted by repositioning the skid shoes found on

either side of the snow throwers auger housing. For

close snow removal, place skid shoes in the low

position. Use middle or high position when area to be

cleared is uneven. See Figure 6.

IMPORT ANT :

thrower be operated on a gravel surface, as loose

stones can be easily picked up and thrown by the

machine. If you must operate on a gravel surface,

ALWAYS adjust the skid shoes into the HIGH position

to allow the shave plate maximum clearance.

It is NOT recommended that this snow

• Retighten the hex nuts loosened earlier.

• Repeat this adjustment on the skid shoe found on

the opposite side of the snow thrower.

Tire Pressure

The tires are overinflated for shipping purposes.

• Check tire pressure, by referring to tire sidewalls for

recommended tire pressure.

NOTE: If the tire pressure is not equal in both tires, the

unit may pull to one side or the other.

WARNING: Maximum tire pressure under

any circumstance is 30 psi. Equal tire

pressure should be maintained at all

times. Excessive pressure (over 30 psi)

when seating beads may cause tire/rim

assembly to burst with forc e sufficient to

cause serious injury.

Traction Control and Shift Lever Adjustment

To check the adjustment of the traction control and shift

lever, proceed as follows:

• Move the shift lever into sixth (6) position.

a. With the traction control (refer to Figure 7)

released, gently push the snow thrower

forward, then pull it back. Disregarding the

overall weight of the snow thrower, the

machine should otherwise move freely.

6

b. Engage the traction control and attempt to

move them machine both forward and

rearward. You should experience resistance

as the wheels should not be turning.

• Move the shift lever into the fast reverse (R2)

position and repeat the previous steps (a & b).

If you experienced resistance either when repositioning

the shift lever from 6 to R2 or when attempting to move

the machine forward or rearward with the traction

control released, your snow thrower’s traction control is

in need of adjustment and you should NOT operate the

• Retighten the jam nut to secure the cable when

correct adjustment is reached.

If the machine can be moved freely both forward and

rearward when the traction control fully depressed,

proceed as follows:

• Loosen the jam nut on the traction drive cable and

THREAD the cable in one full turn.

• Recheck the adjustment and repeat adjustment as

necessary.

• Retighten the jam nut to secure the cable when

correct adjustment is reached.

machine before completing the adjustment as follows:

• Loosen the jam nut on the traction control cable

and UNTHREAD the cable one full turn.

• Recheck t he ad justm ent.

NOTE: If you are uncert ain that you have rea ched the

correct adjustment, refer to Traction Control Adjustment in Making Adjustments Section.

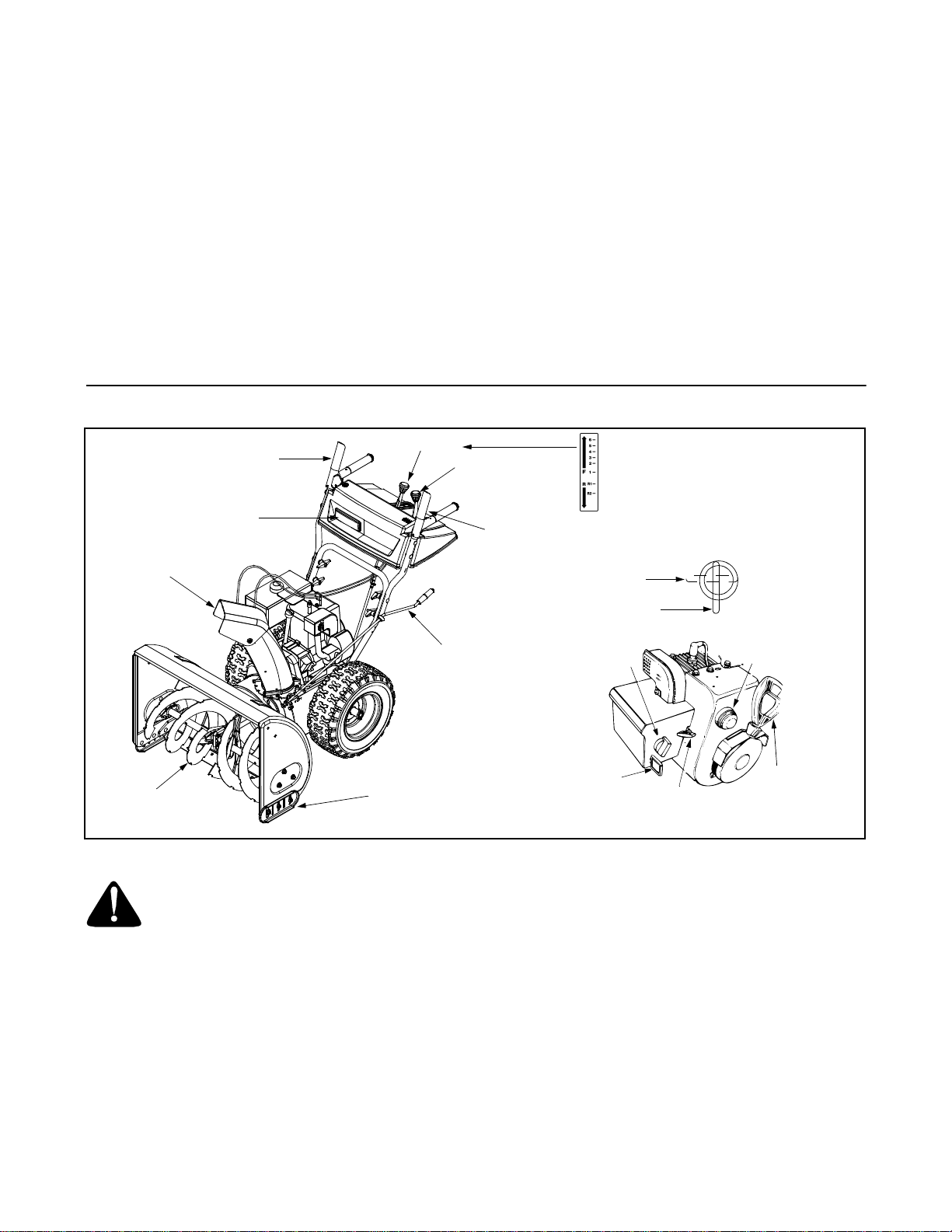

SECTION 3: KNOW YOUR SNOW THROWER

Traction Drive /

Auger Control Lock

Discharge

Chute

Auger

WARNING: Read, understand, and follow

all instructions and warnings on the

machine and in this manual before

operating.

Headlight

Shift Lever

Skid Shoe

Chute Tilt

Control

Auger Drive Control

Chute Directional

Control

Figure 7

operator can release the auger control (on the left

handle) and the auger s will remain engaged. Re lease

the traction control t o stop both the a ugers and wheel

drive (auger control must also be released).

Closed

Choke

Ignition

Key

Open

Throttle

Control

Primer

Rope Starter

Handle

Traction Control / Auger Control Lock

The traction control is located on the right handle.

Squeeze the traction control to engage the wheel drive.

Release to stop. See Figure 7.

This same lever also locks the auger control so you

can turn the chute directional control without

interrupting the snow throwing process. If the auger

control is engaged alo ng with the traction control, the

IMPORT ANT :

Always release tractional control before

changing speeds.

Auger Drive Control

The auger drive control is located on the left handle.

Squeeze the control grip to engage the augers.

Release to stop the snow throwing action. (Traction

control must also be released.) See Figure 7.

7

Shift Lever

The shift lever is located in the center of the handle

panel and is used to determine both ground speed and

direction of travel. It can be moved into any of eight

positions. See Figure 7.

Forward

Your snow thrower has six forward (F) speeds. Position

number one (1) is the slowest. Position number six (6)

is the fastest.

Reverse

Your snow thrower has two reverse (R) s peeds. R1 is

the slower, while R2 is the faster of the two.

IMPORT ANT :

changing speeds.

Always release tractional control before

Chute Directional Contr ol

The chute directional control is located on left side of

the snow thrower. See Figure 7.

To change the direction in which snow is thrown, turn

chute directional control as follows:

• Crank clockwise to discharge to the left.

• Crank counterclockwise to discharge to the right.

Chute Tilt Contro l

The distance snow is thrown can be adjusted by

adjusting the angle of the chute assembly. Move the

chute tilt control forward to decrease the distance and

toward the rear to increase the distance. See Figure 7.

Headlight

The headlight is on whenever the engine is running.

Skid Shoe

The position of the skid shoe is determined by the

condition of the ground from where snow has to be

removed. See Figure 7.

Safety Ignition Key

The ignition key must be inserted in the switch before

the unit will start. Remove the ignition key when snow

thrower is not in use. See Figure 7.

Throttle Control

The throttle control is located on the engine. It regulates

the speed of the engine. See Figure 7.

Fuel Shut-Off Valve (If Equipped)

The fuel shut-off valve, located under fuel tank, control

fuel flow fr om ta nk. S ee F igure 7.

SECTION 4: OPERATING YOUR SNOW THROWER

Before Starting

WARNING: Read, understand, and follow

all instructions and warnings on the

machine and in this manual before

operating.

Gas And Oil Fill-up

Service the engine with gasoline and oil as

instructed in the separate engine manual packed with

your snow thrower. Read instructions carefully.

WARNING: Use extreme care when

handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

Never fuel machine indoors or while the

engine is hot or running. Extinguish

cigarettes, cigars, pip es an o th er s our ces

of ignition.

• A plastic cup is provided inside the fuel fill opening

on the fuel tank. Remove and discard this cup

before filling up the tank. Use the separate fuel tank

cap to close after fill-up.

To Start Engine

NOTE: If unit shows any sign of motion (drive or

augers) with the clutch g rips disengaged, shut engine

off immediately. Readjust as instructed in the Final

Adjustments in the Assembly Section.

• Attach spark plug wire to spark plug. Make certain

the metal loop on end of the spark plug wire (inside

the boot) is fastened securely over the metal tip on

the spark plug.

• Make certain the fuel cutoff valve is in the OPEN

(vertical position). See Figure 7.

• Make certain the auger and drive clutch levers are

in the disengaged (released) position.

• Move throttle control up to FAST position. Insert

ignition key into slot. See Figure 7. Be certain it

snaps into place. Do not turn key.

NOTE: Engine will not start unless ignition key is

inserted into ignition slot in carburetor cover.

8

Electric Starter (If Equipped)

WARNING: The electric starter is

equipped with a grounded three-wire

power cord and plug and is designed to

operate on 120 volt AC household

current. It must be used with a properly

grounded three-prong receptacle at all

times to avoid the possibility of electric

shock. Follow all instructions carefully

prior to operating the electric starter.

• Determine that your house wiring is a three-wire

grounded system. Ask a licensed electrician if you

are not certain.

• If your house wiring system is not a three-wire

grounded system, do not use this electric starter

under any condi tions.

• If your home electrical system is grounded, but a

three-hole receptacle is not available, one should

be installed by a licensed electrician before using

the electr ic start er.

• If you have a grounded three-prong receptacle,

proceed as follows:

• Rotate choke knob to OFF position and do not

prime engine.

• Connect power cord to switch box on engine. Plug

the other end of power cord into a three-hole,

grounded 120 volt AC receptacle.

• Push starter button on top of the engine to crank

engine. As you crank the engine, move choke knob

to FULL choke position.

• When engine starts, release starter button, and

move choke gradually to OFF. If engine falters,

move choke immediately to FULL and then

gradually to OFF.

• When disconnecting the power cord, always unplug

from the three-prong receptacle first and then from

the snow thrower.

Recoil Starter

• Rotate choke knob to FULL choke position (cold

engine start). If engine is warm, place choke in OFF

position instead of FULL.

• Push primer button two or three times. If engine is

warm, pus h prim er but ton on ce on ly.

To Stop Engine

• Run engine for a few minutes before stopping to

help dry off any moisture on the engine.

• To help prevent possible freeze-up of starter,

proceed as follows.

Electric Starter:

• Connect power cord to switch box on engine, then

to 120 volt AC receptacle. With the engine running,

push starter button and spin the starter for several

seconds. The unusual sound made by spinning the

starter will not harm engine or starter. Disconnect

the power cord from receptacle first, and then from

switch box.

Recoil Starter

• With engine running, pull starter rope with a rapid,

continuous full arm stroke three or four times.

Pulling the starter rope will produce a loud clattering

sound, which is not harmful to the engine or starter.

• Move throttle control to “stop” or “off” position.

• Remove ignition key. Do not turn key. Disconnect

the spark plug wire from the spark plug to prevent

accidental starting while equipment is unattended.

NOTE: Keep it in a safe place. Engine will not start

without ignition key.

• Wipe all snow and moisture from the carburetor

cover in the area of the control levers. Also, move

control levers back and forth several times.

To Engage Drive

• With the engine running near top speed, move shift

lever into one of the six FORWARD positions or two

REVERSE positions. Select a speed appropriate

for the snow conditions that exist.

NOTE: Use slower speeds until you are familiar with

the operation of the snow thrower.

• Squeeze the traction control against the right

handle and the snow thrower will move. Release it

and the drive motion will stop.

IMPORT ANT :

releasing the traction control. Doing so will cause

premature wear to drive system’s friction wheel rubber.

NEVER move shift lever without first

NOTE: Always cover vent hole in primer button when

pushing. Additional prim ing may be necessary for firs t

start if temperature is below 15°F.

• Grasp starter handle and pull rope out slowly, until

it pulls slightly harder. Let rope rewind slowly.

• Pull starter handle rapidly. Do not allow handle to

snap back. Allow it to rewind slowly while keeping a

firm hold on the starter handle.

• Repeat the previous steps until engine starts.

To Engage Augers

To engage the augers and start the snow throwing

action, squeeze the auger control against the left

handle.

To disengage power to the augers, release both the

auger control and the traction control, if engaged.

Tire Chains (If Equipped)

Tire chains should be used whenever extra traction is

needed.

9

Loading...

Loading...