Bolens 41AD250G163 Owner’s Manual

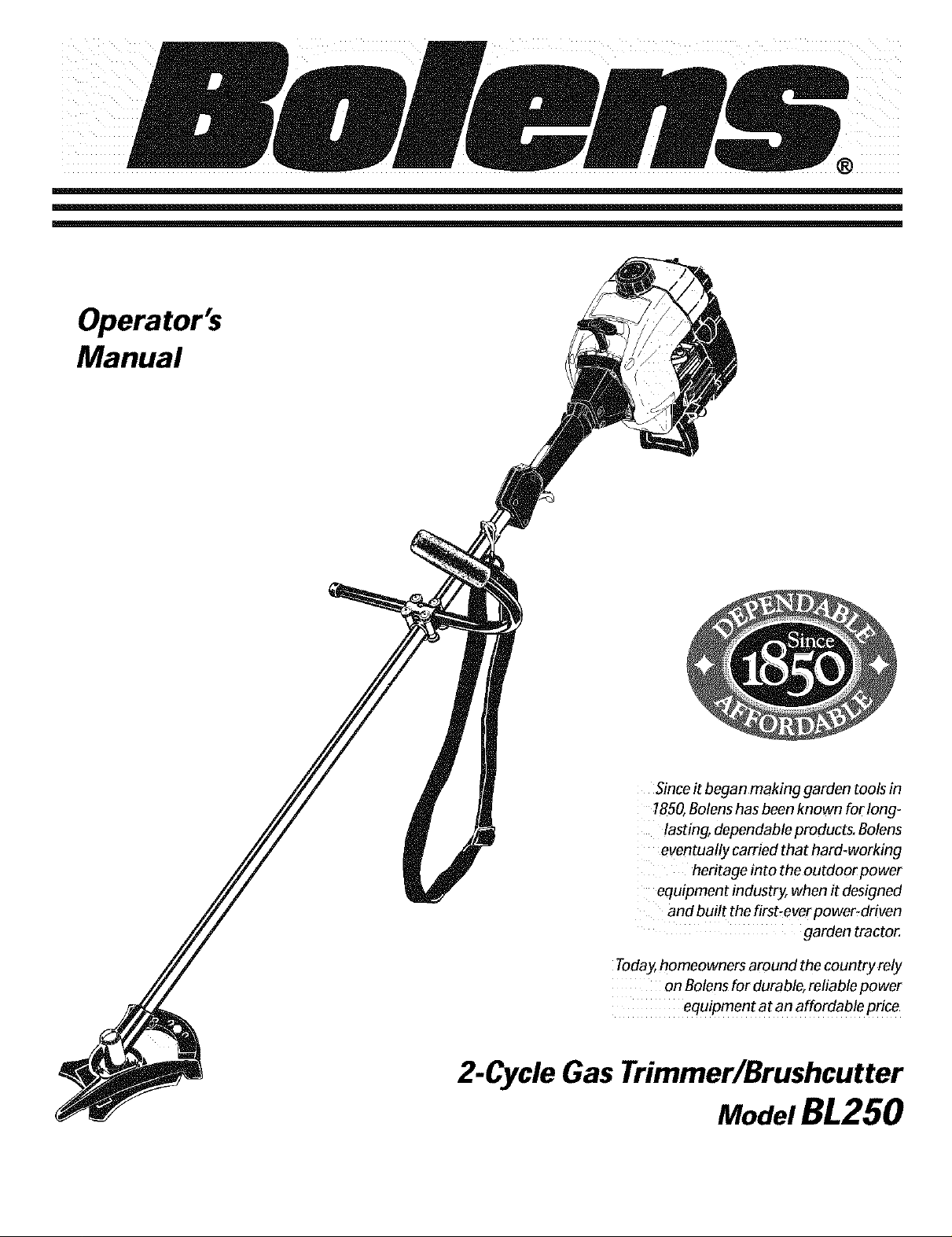

Operator's

Manual

®

Since it began making garden tools in

1850,Bolens has beenknown for long-

lasting, dependable products. Bolens

eventually carried that hard.working

hedtage into the outdoor power

equipment industry, when it designed

and built the first-ever power-driven

garden tractor.

Today,homeowners around the country rely

on Bolens for durable, reliable power

equipment at an affordable price.

2-Cycle Gas Trimmer/Brushcutter

ModelBL250

INTRODUCTION

THANKYOU

Thank you for buying this quality product. This modern

outdoor power tool will provide many hours of useful service.

You will find it to be a great labor-saving device. This

operator's manual provides you with easy-to-understand

operating instructions. Read the whole manual and follow all

the instructions to keep your new outdoor power tool in top

operating condition.

PRODUCT REFERENCES, ILLUSTRATIONS AND

SPECIFICATIONS

All information, illustrations, and specifications in this manual

are based on the latest product information available at the

time of printing. We reserve the right to make changes at any

time without notice.

Bump HeadT_isa trademark of MTD SOUTHWESTINC.

SplitLineTMisa trademark of MTD SOUTHWESTINC.

Copyright o2002 MTD SOUTHWESTINC,All Rights Reserved.

SERVICE INFORMATION

Service on this unit both within and after the warranty period

should be performed only by an authorized and approved

service dealer.

For service call 1-330-558-7220 or 1-866-840-6483 to

obtain a list of authorized service dealers near you.

DO NOT RETURN THE UNIT TO THE RETAILER. PROOF OF

PURCHASE WILL BE REQUIRED FORWARRANTY SERVICE.

Before beginning, locate the unit's model plate. It lists the

model and serial numbers of your unit. Referto the sample plate

below and copy the information for future reference.

so,,.,.,,o.,,..,o,x..,o.,....,,o,o.

MDUPPN:

Set.No:

i llHlililHllllilHllillllHll

TABLE OF CONTENTS

Service Information ................................... 2

Rulesfor Safe Operation ............................... 3

Know Your Unit ....................................... 6

Assembly Instructions ................................. 7

Oil and Fuel Information ............................. 10

Starting/Stopping Instructions ....................... 11

Operating Instructions ............................... 12

Maintenance and Repair Instructions ................. 14

Cleaning and Storage ................................ 19

Accessoriesand Replacement Parts ................... 19

Troubleshooting Chart ............................... 20

Specifications ........................................ 21

Warranty Information ................................ 24

Parts List .............................. Inside Back Cover

CONTENTS OF CARTON

• Model BL250Trimmer/Brushcutter

A Large Bump HeadCutting Attachment

A 4-Tooth Brush Blade

A J-Handle and Hardware

• Cutting Attachment Shield with Hardware

• Shoulder Harness

• Locking RodTool

• Operator's Manual

• Product Registration Card

• Bottle of 2-Cycle Oil

A This item will either be installed on the unit or in the

hardware pack

Copy the model / parent part

number here:

Cop]/the serial number here:

Makesureyou carefully read and understand this manual before

starting or operating this equipment.

THISPRODUCTISCOVEREDBYONEORMOREU.S.PATENTS.

OTHERPATENTSPENDING.

Examine all parts to make certain that nothing is missing and

no breakage has occurred during shipping. Any damaged or

missing part must be replaced before using this product.

CALIFORNIA PROPOSITION 65 WARNING

THE ENGINE EXHAUSTFROM THIS PRODUCT

CONTAINS CHEMICALS KNOWN TO THESTATE

OF CALIFORNIA TO CAUSE CANCER,BIRTH

DEFECTS,OR OTHER REPRODUCTIVE HARM.

2

RULES FOR SAFEOPERATION

NOTE: For users on U.S. Forest Land and in the states of California, Maine, Oregon, and Washington. All U.S. Forest Land and

the state of California (Public Resources Codes 4442 and 4443), Oregon, and Washington require by law that certain internal com-

bustion engines operated on forest brush and/or grass-covered areas be equipped with a spark arrestor, maintained in effective

working order, or the engine be constructed, equipped, and maintained for the prevention of fire. Check with your state or local

authorities for regulations pertaining to these requirements. Failure to follow these requirements could subject you to liability or a

fine. This unit is factory equipped with a spark arrestor. If it requires replacement, ask your LOCAL SERVICE DEALER to install

the Accessory Part #182747 Spark Arrestor.

Read the Operator's Manual(s) and follow all warnings and safety instructions.

Failure to do so can result in serious injury to the operator and/or bystanders.

FOR QUESTIONS, CALL 1-330-558-7720 or 1-866-840-6483

• SAFETY SYMBOLS •

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and their explanations, deserve

your careful attention and understanding. The safety warnings do not by themselves eliminate any danger. The instructions or

warnings they give are not substitutes for proper accident prevention measures.

SYMBOL MEANING

SAFETYALERT SYMBOL: Indicates danger, warn- 1

ing or caution. Attention is required in order to l

avoid serious personal injury. May be used in I

conjunction with other symbols or pictographs. I

DANGER: Failure to obey a safety warning will 1

result in serious injury to yourself or to others, l

Always follow the safety precautions to reduce I

the risk of fire, electric shock and personal injury. I

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.

SYMBOL MEANING

WARNING: Failureto obey a safety warning can

result in injury to yourself and others. Always fol-

low the safety precautions to reduce the risk of

f re,e ectr c shock, and persona njury.

CAUTION: Failure to obey a safety warning may

result in property damage or personal injury to

yourself or to Others. Always follow the safety

precautions to reduce the risk of fire, electric

shock, and persona njury.

• IMPORTANT SAFETY INFORMATION •

READALL INSTRUCTIONS

WARNING: When using the unit, you must follow

the safety rules. Please read these instructions

before operating the unit in order to ensure the

safety of the operator and any bystanders. Please

keep these instructions for later use.

BEFORE OPERATING

• Read the instructions carefully. Be familiar with the controls

and proper use of the unit.

• Do not operate this unit when tired, ill or under the influ-

ence of alcohol, drugs or medication.

• Children under the age of 15 must not use the unit; teens

may operate the unit with adult guidance.

• Inspect the unit before use. Replace damaged parts. Check

for fuel leaks. Make sure all fasteners are in place and

secure. Replace cutting attachment parts that are cracked,

chipped or damaged in any way. Make sure the cutting

attachment is properly installed and securely fastened. Be

sure that the cutting attachment shield is properly

attached, and positioned as recommended. Failure to do so

can result in personal injury to the operator and

bystanders, as well as damage to the unit.

• Use only a O.O95-inch (2.41 ram) diameter genuine factory

replacement line. Never use metal-reinforced line, wire,

chain or rope. These can break off and become dangerous

projectiles.

• Be aware of risk of injury to the head, hands and feet.

• Squeeze the throttle control and check that it returns auto-

matically to the idle position. Make all adjustments or

repairs before using the unit.

• Clear the area to be cut before each use. Remove rocks,

broken glass, nails, wire, string and other objects which

may be thrown or become entangled in the cutting attach-

ment. Clear the area of children, bystanders and pets; keep

them outside a 50-foot (15 m.) radius, at a minimum. Even

then, they are still at risk from thrown objects. Encourage

bystanders to wear eye protection. If you are approached,

stop the unit immediately.

SAFETY WARNINGS FOR GAS TRIMMERS

WARNING: Gasoline is highly flammable and its

vapors Can explode if ignited. Follow the ensu-

ing precautions.

• Store fuel only in containers specifically designed and

approved for the storage of such materials.

• Always stop the engine and allow it to cool before filling

the fuel tank. Never remove the fuel tank cap or add fuel

when the engine is hot. Never operate the unit without the

fuel cap securely in place. Loosen the fuel tank cap slowly

to relieve any pressure in the tank.

• Add fuel in a clean, well-ventilated outdoor area where

there are no sparks or flames. Remove the fuel cap slowly,

and only after the engine stops. Do not smoke while fuel-

ing or mixing fuel. Wipe up any spilled fuel from the unit

immediately.

• Avoid creating a source of ignition for spilled fuel. Do not

start the engine until fuel vapors dissipate.

3

RULES FOR SAFEOPERATION

• IMPORTANT SAFETY INFORMATION •

• Move the unit at least 30 feet (9.1 m) from the fueling

source and site before starting the engine. Do not smoke.

Keep sparks and open flames away from the area while

adding fuel or operating the unit.

WHILE OPERATING

• Neverstartorruntheunitinsideaclosedroomorbuildin 9.

Breathing exhaust fumes can be fatal. Operate this umt

only in awell-ventilated outdoor area.

• Wear safety glasses or goggles that meet ANSI Z87.1 stan-

dards and are marked as such. Wear ear/hearing protection

when operating this unit. Wear a face or dust mask if the

operation is dusty.

• Wear heavy long pants, boots, gloves and a long sleeve

shirt. Do not wear loose clothing,jewelry, short pants, san-

dals or go barefoot. Secure hair above shoulder level.

• The cutting attachment shield must always be in place while

operating the unit. Do not operate unit without both trim-

ming lines extended, and the proper line installed. Do not

extend the trimming line beyond the length of the shield.

• This unit has a clutch. The cutting attachment remains sta-

tionary when the engine is idling. If it does not, have the

unit adjusted by an authorized service technician.

• Adjust the J-handle to your size in order to provide the best

grip.

• Be sure the cutting attachment is not in contact with any-

thing before starting the unit.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Be in the starting position when-

ever pulling the starter rope. Both the operator and unit

must be in a stable position while starting. Refer to the

Starting/Stopping Instructions.

• Usethe right tool. Only use this tool for its intended purpose.

• Do not overreach. Always keep proper footing and balance.

• Always hold the unit with both hands when operating.

Keep a firm grip on both handles or grips.

• Keep hands, face, and feet at a distance from all moving

parts. Do not touch or try to stop the cutting attachment

when it rotates.

• Do not touch the engine, gear housing or muffler. These

parts get extremely hot from operation, even after the unit

is turned off.

• Do not operate the engine faster than the speed needed to

cut, trim or edge. Do not run the engine at high speed

when not cutting.

• Always stop the engine when cutting is delayed or when

walking from one cutting location to another.

• If you strike or become entangled with a foreign object,

stop the engine immediately and check for damage. Do

not operate before repairing damage. Do not operate the

unit with loose or damaged parts.

• Stop the unit, switch the engine to off, and disconnect the

spark plug for maintenance or repair.

• Use only genuine factory replacement parts and acces-

sories for this unit. These are available from your autho-

rized service dealer. Use of any non-original factory parts or

accessories could lead to serious injury to the user, or dam-

age to the unit, and void your warranty.

• Keep unit clean of vegetation and other materials. They may

become lodged between the cutting attachment and shield.

• To reduce fire hazard, replace a faulty muffler and spark

arrestor. Keep the engine and muffler free from grass,

leaves, excessive grease or carbon build up.

WHILE OPERATING WITH CUTTING BLADE

• Read and understand all safety warnings before operating

this unit.

• Always use the shoulder harness when using the brush

blade accessory.

• Keep the J-handle between the operator and cutting

attachment or blade at all times.

• NEVER cut when the cutting blade is 30 inches (76 cm) or

more above the ground level.

• Blade thrust may occur when the spinning blade contacts

an object that it does not immediately cut. Blade thrust can

be violent enough to propel the unit and/or operator in

any direction, possibly causing a loss of control. Blade

thrust can occur without warning if the blade snags, stalls

or binds. This is more likely to occur in areas where it is dif-

ficult to see the material being cut.

• For operation with the brush blade, do not cut anything

thicker than 1/2 inch or a violent kickback could occur.

• Do not attempt to touch or stop the blade when it isrotating.

• A coasting blade can cause injury while it continues to spin

after the engine is stopped or the throttle trigger is

released. Maintain proper control until the blade has com-

pletely stopped rotating.

• Do not run the unit at high speed when not cutting.

• If you strike or become entangled with a foreign object, stop

the engine immediately and check for damage. Have any

damage repaired before attempting further operations. Do

not operate unit with a bent, cracked or dull blade. Discard

blades that are bent, warped, cracked or broken.

• Do not sharpen the cutting blade. Sharpening the blade

can cause the blade tip to break off while in use. This can

result in severe personal injury. Replace the blade.

• Do not use the cutting blade for edging or as an edger; severe

personal injury to yourself or others may incur. Usethe cutting

blade only for the purpose asdescribed in this manual.

• Stop the engine IMMEDIATELY if you feel excessive vibra-

tion. Vibration is a sign of trouble. Inspect thoroughly for

loose nuts, bolts or damage before continuing. Repair or

replace affected parts as necessary.

After Use

• Clean cutting blades with a household cleaner to remove any

gum buildup. Oil the blade with machine oil to prevent rust.

• Lock up and store the cutting blade in an appropriate area

to protect the blade from unauthorized use or damage.

OTHER SAFETY WARNINGS

• Never store a fueled unit inside a building where fumes

may reach an open flame or spark.

• AIIowthe engine to cool before storing or transporting. Be

sure to secure the unit while transporting.

• Store the unit in a dry area, locked up or up high to prevent

unauthorized use or damage, out of the reach of children.

• Never douse or squirt the unit with water or any other liq-

uid. Keep handles dry, clean and free from debris. Clean

after each use, see Cleaning and Storage instructions.

• Keep these instructions. Refer to them often and use them

to instruct other users. If you loan someone this unit, also

loan them these instructions.

SAVE THESE INSTRUCTIONS

4

RULES FOR SAFEOPERATION

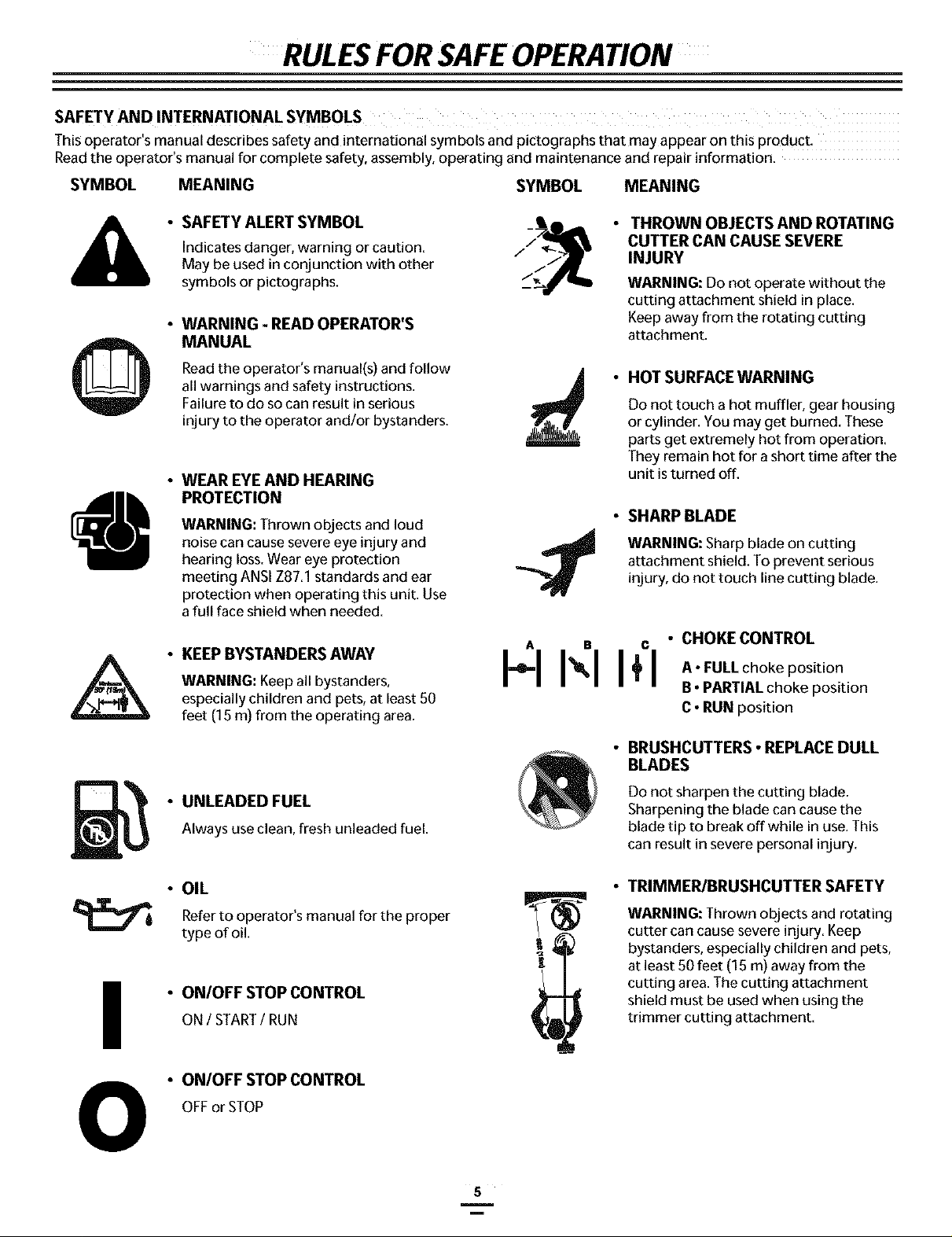

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and piCtographs that may appear on this product.

Readthe operator's manual for complete safety,assembly, operating and maintenance and repair information.

SYMBOL MEANING SYMBOL MEANING

THROWN OBJECTS AND ROTATING

Indicates danger, warning or caution. / _-

May be used in conjunction with other / //_

• SAFETY ALERT SYMBOL __

symbols or pictographs. _/

WARNING - READ OPERATOR'S

MANUAL

CUTTER CAN CAUSE SEVERE

INJURY

WARNING: Do not operate without the

cutting attachment shield in place.

Keep away from the rotating cutting

attachment.

@

Read the operator's manual(s) and follow

all warnings and safety instructions.

Failure to do so can result in serious

injury to the operator and/or bystanders.

• WEAR EYE AND HEARING

PROTECTION

WARNING: Thrown objects and loud

noise cancause severe eye injury and

hearing loss.Wear eye protection

meeting ANSIZ87.1 standards and ear

protection when operating this unit. Use

a full face shield when needed.

KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders,

especially children and pets, at least 50

feet (15 m) from the operating area.

• UNLEADED FUEL

Always useclean, fresh unleaded fuel.

HOT SURFACE WARNING

Do not touch a hot muffler, gear housing

or cylinder. You may get burned. These

parts get extremely hot from operation.

They remain hot for a short time after the

unit isturned off.

SHARP BLADE

WARNING: Sharp blade on cutting

attachment shield. To prevent serious

injury, do not touch line cutting blade.

• CHOKE CONTROL

I<1I Cl

BRUSHCUTTERS • REPLACE DULL

BLADES

Do not sharpen the cutting blade.

Sharpening the blade can cause the

blade tip to break off while in use. This

can result in severe personal injury.

A • FULLchoke position

B• PARTIALchoke position

C• RUN position

• OIL

Referto operator's manual for the proper

type of oil.

• ON/OFF STOP CONTROL

I

O OFFor STOP

ON / START/ RUN

• ON/OFF STOP CONTROL

TRIMMER/BRUSHCUTTER SAFETY

WARNING: Thrown objects and rotating

cutter can cause severe injury. Keep

bystanders, especially children and pets,

at least 50 feet (15 m) away from the

cutting area. The cutting attachment

shield must be used when using the

trimmer cutting attachment.

5

RULES FOR SAFEOPERATION

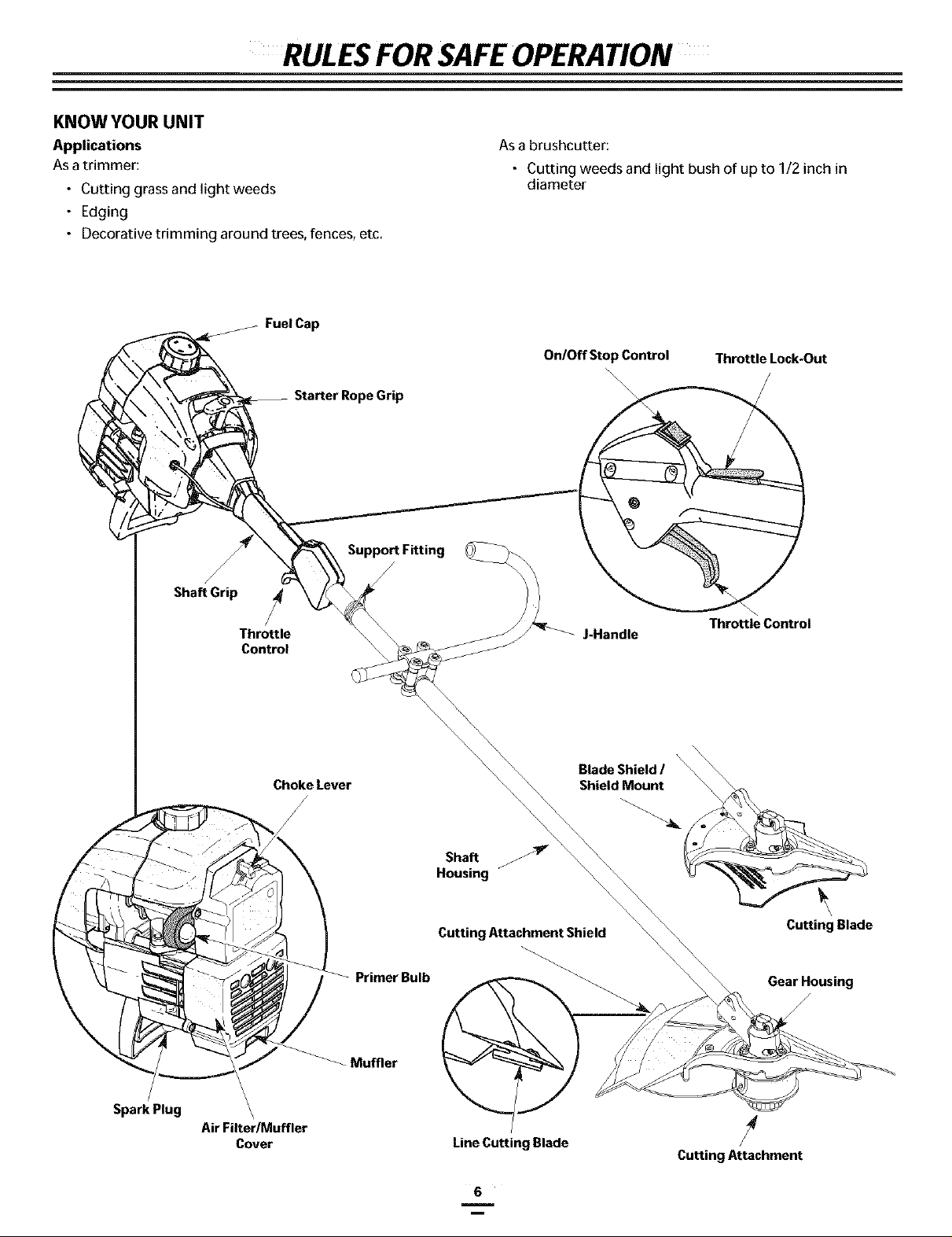

KNOW YOUR UNIT

Applications

As a trimmer:

• Cutting grass and light weeds

• Edging

• Decorative trimming around trees, fences, etc.

FuelCap

As a brushcutter:

• Cutting weeds and light bush of up to 1/2 inch in

diameter

j/

Shaft Grip

Throttle

Control

Starter Rope Grip

Choke Lever

SupportFitting

/

On/Off Stop Control

J-Handle

Blade Shield / _

Throttle Lock-Out

Throttle Control

Spark Plug

_ Muffler

\

\

\

\

Air Filter/Muffler

Cover

Primer Bulb

Shaft

Housing

Cutting Attachment Shield

/

Line Cutting Blade

6

Shield _1_ _

Cutting Blade

Gear Housing

/

Cutting Attachment

ASSEMBLY INSTRUCTIONS

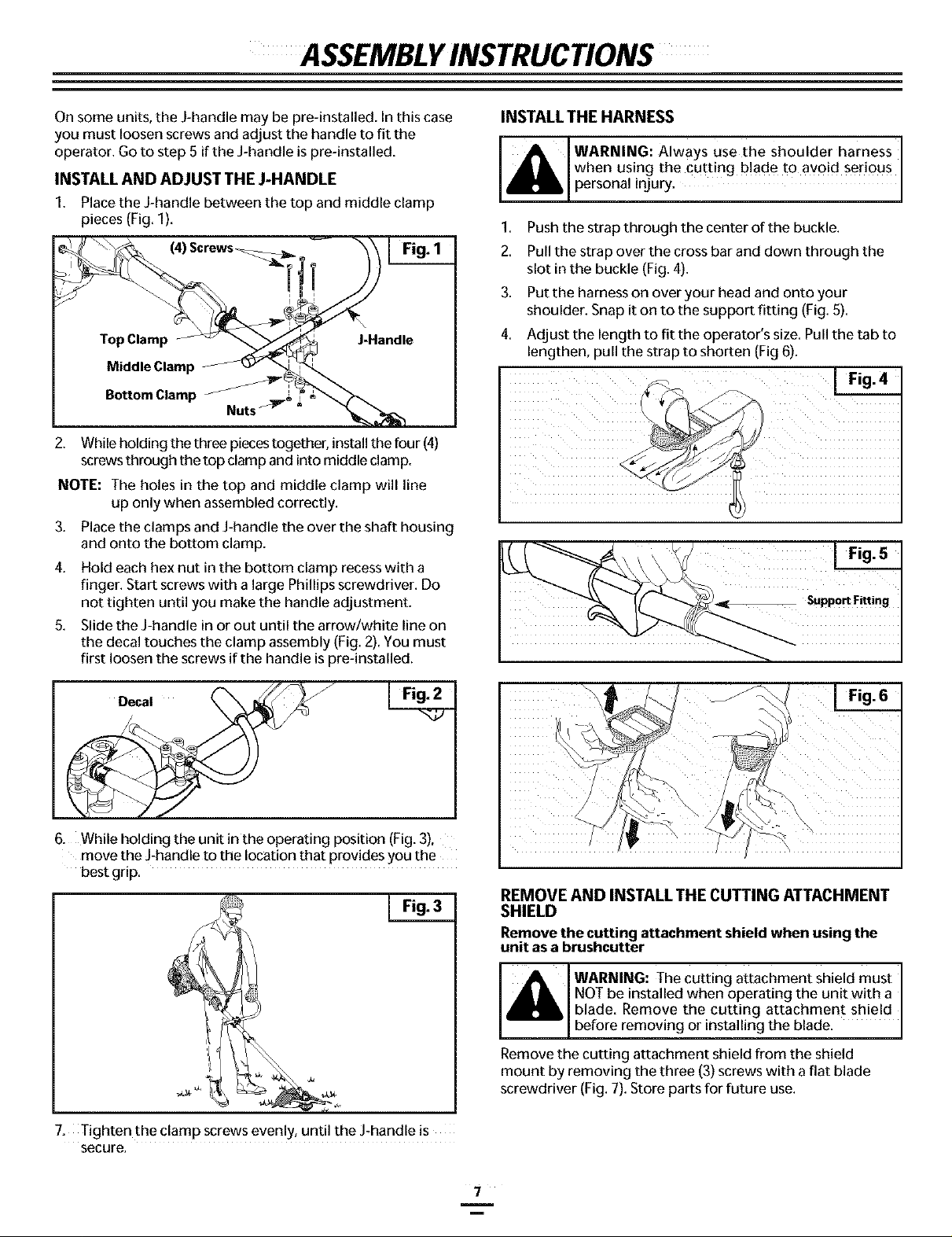

On some units, the J-handle may be pre-installed. In this case

you must loosen screws and adjust the handle to fit the

operator. Go to step 5 if the J-handle is pre-installed.

INSTALL AND ADJUST THE J-HANDLE

1. Placethe J-handle between the top and middle clamp

pieces (Fig. 1).

Fig. 1

Top Clamp J-Handle

Middle Clamp

Bottom Clamp

Nuts _- '

2. While holding the three pieces together, install the four (4)

screws through the top clamp and into middle clamp.

NOTE: The holes in the top and middle clamp will line

up only when assembled correctly.

3. Place the clamps and J-handle the over the shaft housing

and onto the bottom clamp.

4. Hold each hex nut in the bottom clamp recess with a

finger. Start screws with a large Phillips screwdriver. Do

not tighten until you make the handle adjustment.

5. Slide the J-handle in or out until the arrow/white line on

the decal touches the clamp assembly (Fig. 2). You must

first loosen the screws if the handle is pre-installed.

INSTALL THE HARNESS

WARNING: Always use the Shoulder harness I

when using the Cutting blade to avoid serious

persona njury. I

1. Push the strap through the center of the buckle.

2. Pull the strap over the cross bar and down through the

slot in the buckle (Fig. 4).

3. Put the harness on over your head and onto your

shoulder. Snap it on to the support fitting (Fig. 5).

4. AdJust the length to fit the operator's size. Pull the tab to

lengthen, pull the strap to shorten (Fig 6).

J

Decal Fig. 2

6. While holding the unit in the operating position (Fig. 3),

move the J-handle to the location that provides you the

best grip.

Fig. 3

7. Tighten the clamp screws evenly, until the J-handle is

secure.

REMOVE AND INSTALL THE CUTTING ATTACHMENT

SHIELD

Remove the cutting attachment shield when using the

unit as a brushcutter

NOT be installed when operating the unit with a /

_I WARNING: The cutting attachment shield must /

Remove the cutting attachment shield from the shield

mount by removing the three (3) screws with a flat blade

screwdriver (Fig. 7). Store parts for future use.

blade, Remove the Cutting attachment shield /

before removing or installing the blade. ]

3

7

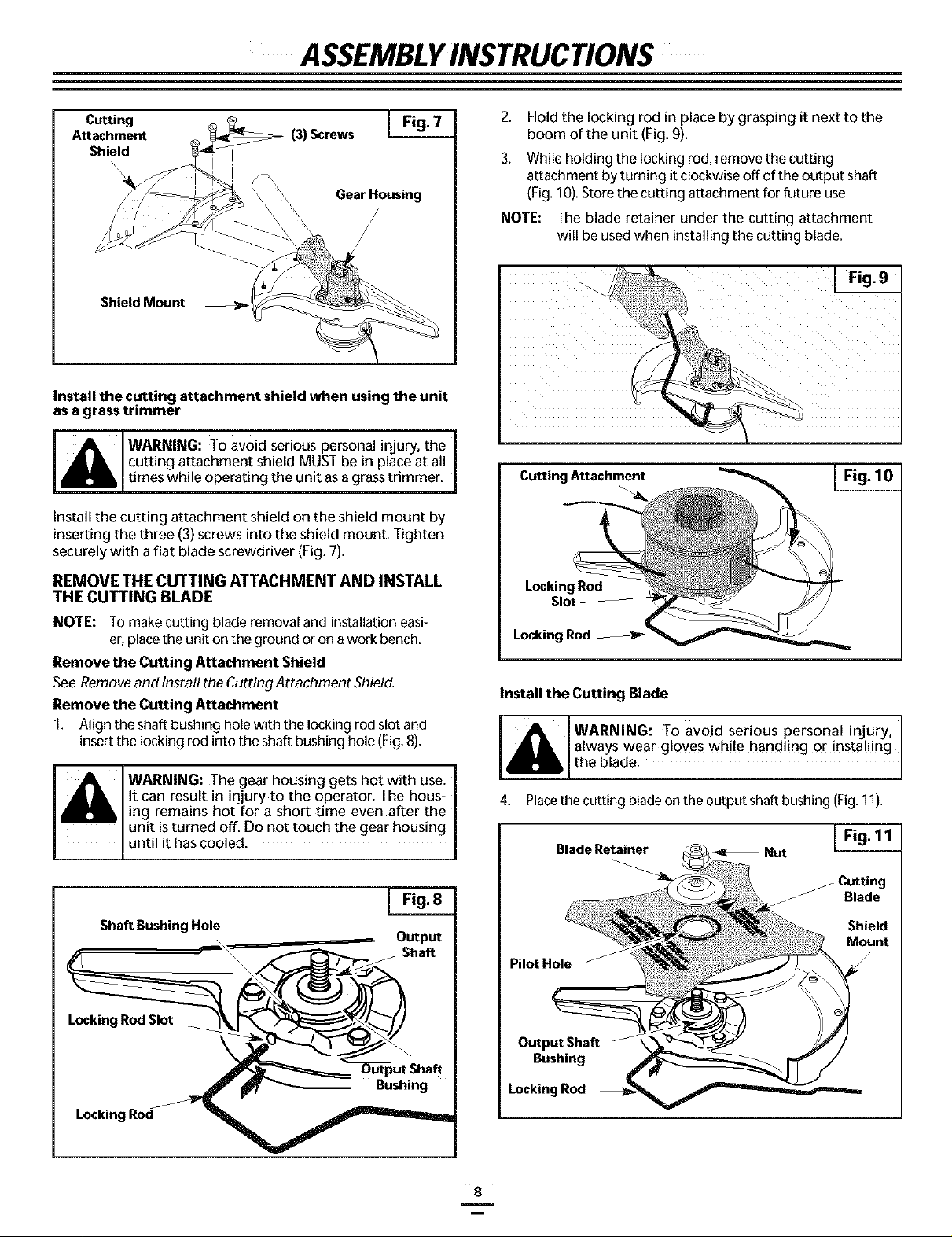

ASSEMBLYINSTRUCTIONS

AttachmentCutting (3) Screws i Fig. 7

Shield

\

Gear Housing

Shield Mount ___

Install the cutting attachment shield when using the unit

as a grass trimmer

WARNING: To avoid serious personal injury, the

cutting attachment shield MUST be in place at all

times while operating the unit as agrass trimmer.

Install the cutting attachment shield on the shield mount by

inserting the three (3) screws into the shield mount. Tighten

securely with a flat blade screwdriver (Fig. 7).

2. Hold the locking rod in place by grasping it next to the

boom of the unit (Fig. 9).

& While holding the locking rod,remove the cutting

attachment by turning it clockwiseoff of the output shaft

(Fig.10).Storethe cutting attachment for future use.

NOTE: The blade retainer under the cutting attachment

will be used when installing the cutting blade.

Cutting Attachment

REMOVE THE CUTTING ATTACHMENT AND INSTALL

THE CUTTING BLADE

NOTE: To make cutting blade removal and installation easi-

er, place the unit on the ground or on a work bench.

Remove the Cutting Attachment Shield

See Remove and Install the Cutting Attachment.Shield.

Remove the Cutting Attachment

1. Align the shaft bushing hole with the locking rod slot and

insert the locking rod into the shaft bushing hole (Fig. 8).

Shaft Bushing Hole J Fig.___88

Output

___ Shaft

Locking Rod

Slot

Locking Rod

Install the Cutting Blade

4, Place the cutting blade on the output shaft bushing (Fig. 11).

Locking Rod_

_===_==_Ut Shaft

___ Bushing

8

Loading...

Loading...