Page 1

Owner’s Manual

CRAFTSMAN

6.5 Horse Power

Self-Propelled

CHIPPER-SHREDDER VACUUM

Model No.

247.77763

CAUTION: Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Printed in U.S.A.

770-10034

(8/98)

Page 2

TABLE OF CONTENTS

Content Page

Warranty Information 2 Service & Adjustment

Safe Operation Practices

Assembly 5

Operation 8 Parts List

Maintenance

3

13

Content

Off-Season Storage

Trouble-Shooting

WARRANTY INFORMATION

One-Year Warranty on Craftsman Chipper-Shredder Vacuum

For one year from the date of purchase, when this Craftsman chipper-shredder vacuum is maintained, lubricated,

and tuned up according to the operating and maintenance instructions in the owner’s manual, Sears will repair,

free of charge, any defect in material or workmanship.

This warranty excludes blades, chipper blades, flails, air cleaners, spark plugs, catcher bags and tires which are

expendable parts and become worn during normal use.

If this chipper-shredder vacuum is used for commercial or rental purposes, this warranty applies for only 30 days

from the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER IN THE

UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED

STATES.

Page

15

17

18

19

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., D/817WA, Hoffman Estates, II 60179

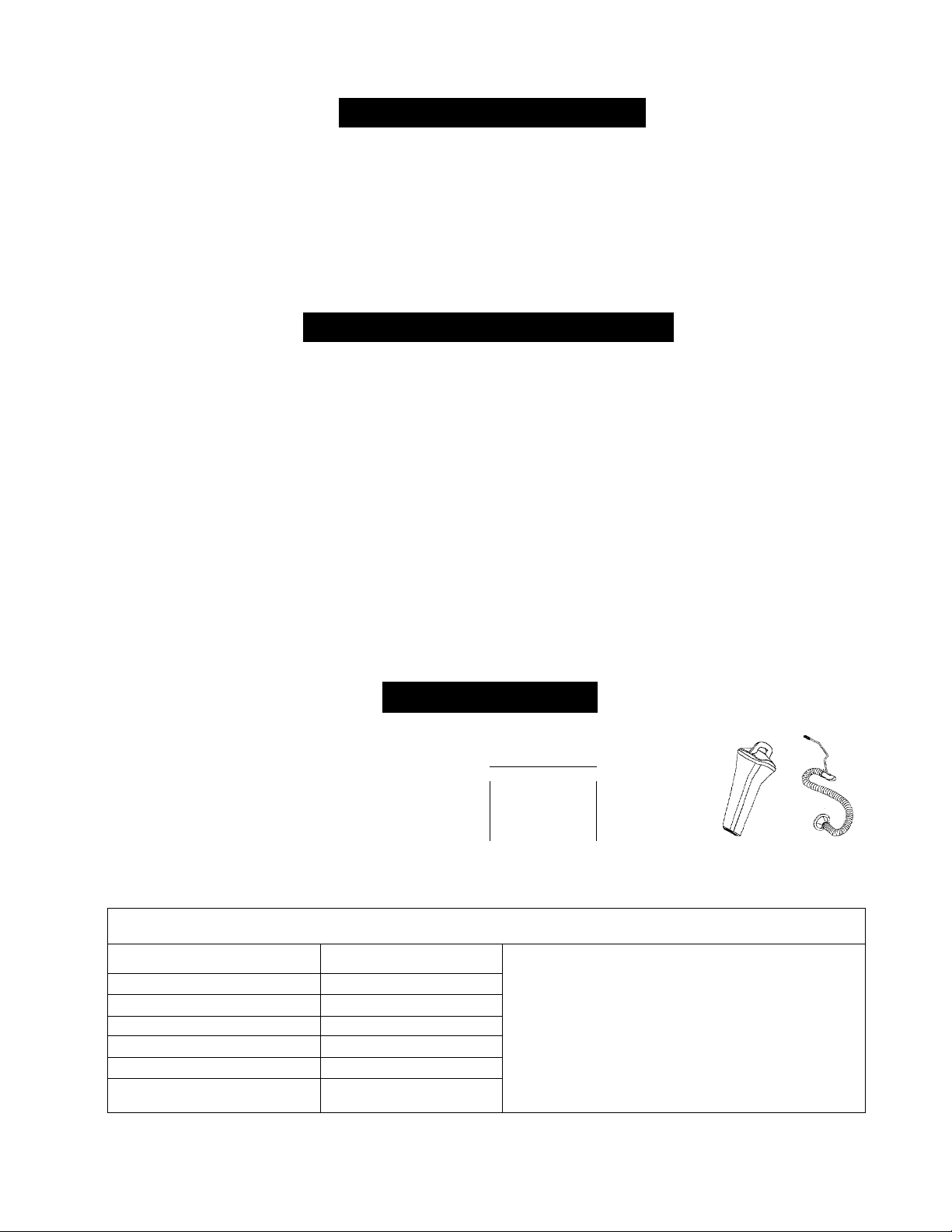

ACCESSORIES

These accessories are

available where the unit was

purchased. They are also

available at most Sears retail

outlets, and service centers.

Most Sears stores can order

repair parts for you when you

provide the model number of

your Craftsman chippershredder vacuum.

Horsepower:

Engine Oil Type

Engine Oil Capacity

Fuel Capacity:

Spark Plug

Spark Plug Gap

Tire Pressure

'Till

jy

Air

Filter

Plug

PRODUCT SPECIFICATION

6.5 Horse Power

SAE30

20 Ounces

Approx. 3 Quarts

Champion RN4C

.030"

24 P.S.I.

Engine Gas Fuel

Oil

HEEy

\ Gasoline

J

Can

Model Number

Serial Number.................................................................

Date of Purchase

Record both serial number and date of purchase and

keep in a safe place for future reference.

A

i

\r\

y

Stabilizer

.........

247;77763......................................

............................................................

10-foot

Hose Kit

Page 3

dk

A

SAFE OPERATION PRACTICES

This symbol points out important safety instructions which, if not followed, could endanger the per

sonal safety and/or property of yourself and others. Read and follow all instructions in this manual before

attempting to operate your chipper-shredder vacuum. Failure to comply with these instructions may result in

personal injury. When you see this symbol—heed its warning.

Your chipper-shredder vacuum was built to be operated according to the rules for safe opera-

DANGER" manual. As with any type of power equipment, carelessness or error on the part of

■ the operator can result in serious injury. If you violate any of these rules, you may cause seri

ous injury to yourself or others.

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved

forest-covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a

spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be

maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the

muffler is available through your nearest Sears Authorized Service Center (See the REPAIR PARTS section

of this manual.)

General Operation

• Read this owner’s guide carefully in its entirety before

attempting to assemble this machine. Read,

understand, and follow all instructions on the machine

and in the manual(s) before operation. Be completely

familiar with the controls and the proper use of the

machine before operating it. Keep this manual in a

safe place for future and regular reference and for

ordering replacement parts.

• Your chipper-shredder vacuum is a powerful tool, not a

plaything. Therefore, exercise extreme caution at all

times. Your unit has been designed to perform two

jobs; to chip and vacuum vegetation found in a normal

yard. Do not use it for any other purpose.

• Never allow children under 16 to operate the unit.

Children 16 years and older should only operate under

close parental supervision. Only responsible

individuals who are familiar with these rules of safe

operation should be allowed to use your unit.

• Keep the area of operation clear of all persons,

particularly small children and pets. Stop the engine

when they are in the vicinity of the unit.

• When feeding material into this equipment, be

extremely careful that pieces of metal, rocks, bottles,

cans or other foreign objects are not included.

Personal injury or damage to the machine could result.

• Always wear safety glasses or safety goggles, during

operation and while performing an adjustment or

repair, to protect eyes from foreign objects that may be

thrown from the machine.

• Wear sturdy, rough-soled work shoes and close fitting

slacks and shirt. Shirt and slacks that cover the arms

and legs and steel-toed shoes are recommended. Do

not wear loose fitting clothes or jewelry, and secure

hair above shoulder length. They can be caught in

moving parts. Never operate a unit in bare feet,

sandals or sneakers. Wear gloves when feeding

material in the chipper chute.

Do not operate the unit while under the influence of

alcohol or drugs.

Do not over-reach. Keep proper footing and balance at

all times.

Never place your hands or any part of your body or

clothing near or under rotating parts. Keep clear of the

discharge opening at all times Never insert your

hands or any part of your body or clothing into the

nozzle, chipper chute or discharge opening as the

rotating impeller can cause serious injury.

If it is necessary for any reason to unclog the feed

intake or discharge openings or to inspect or repair any

part of the machine where a moving part can come in

contact with your body or clothing, stop the machine,

allow it to cool, disconnect the spark plug wire from the

spark plug and move it away from the spark plug

before attempting to unclog, inspect or repair.

Never operate unit without vacuum bag and discharge

chute properly affixed to unit. Large zippered end of

bag must be closed to prevent objects from being

blown out.

Never operate unit without either the inlet nozzle or

optional hose attachment properly affixed to unit.

These devices shield the operator from accidental

contact with the rotating impeller. Never attempt to

convert the unit from nozzle to hose mode or vice versa

with the engine running.

Never attempt to remove or empty vacuum bag when

engine is running. Shut the engine off and wait for the

impeller to come to a complete stop before removing

the bag. The impeller continues to rotate for a few

Page 4

• seconds after the engine is shut off. Never place any

part of the body in the impeller area until you are sure

the impeller has stopped rotating.

• Keep all guards and safety devices in place and

operating properly.

• Do not allow an accumulation of processed material

to build up in the discharge area as this will prevent

proper discharge and can result in kick-back from the

chipper chute.

• Keep your face and body back from chipper chute to

avoid accidental bounce back of any material.

• If the cutting mechanism strikes a foreign object or if

your machine should start making an unusual noise

or vibration, immediately stop the engine, disconnect

the spark plug wire and move the wire away from the

spark plug. Allow the machine to stop and take the

following steps:

a. Inspect for damage

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to assure

continued safe operation.

• Muffler and engine become hot and can cause a burn.

Do not touch.

• Do not allow leaves or other debris to build up on

engine’s muffler. The debris could ignite and cause a

fire.

• Do not operate engine if air cleaner or cover over

carburetor air-intake is removed, except for

adjustment. Removal of such parts could create a fire

hazard.

Children

Tragic accidents can occur if the operator is not alert to the

presence of small children. Children are often attracted to

the chipping and vacuuming activity. Never assume that

children will remain where you iast saw them.

• Keep children out of the work area and under the

watchful eye of a responsible adult other than the

operator.

• Be alert and turn the unit off if a child enters the area.

• Never allow children under the age of 16 to operate

the chipper-shredder vacuum.

• Check and add fuel before starting the engine. Never

remove gas cap or add fuel while the engine is

running. Allow engine to cool at least two minutes

before refueling.

• Replace gasoline cap securely and wipe off any

spilled gasoline before starting the engine as it may

cause a fire or expiosion.

• Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

• Never refuel unit indoors because flammable vapors

will accumulate in the area.

• Never store the machine or fuel container inside

where there is an open flame or spark such as a gas

hot water heater, clothes dryer or furnace.

• Never run your machine in an enclosed area as the

exhaust from the engine contains carbon monoxide,

which is a odorless, tasteless and deadly poisonous

gas.

• To reduce fire hazard, keep engine and muffler free of

leaves, grass, and other debris build-up. Clean up

fuel and oil spillage. Allow unit to cool at least 5

minutes before storing.

• Before cleaning, repairing, or inspecting, make certain

the impeller and all moving parts have stopped.

Disconnect the spark plug wire and keep wire away

from spark plug to prevent accidental starting. Do not

use flammable solutions to clean air filter.

• Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

• Nevertamper with safety devices. Check their proper

operation regularly.

• After striking a foreign object, immediately stop the

engine, disconnect the spark plug wire from the spark

plug, and thoroughly inspect the unit for any damage.

Repair damage before starting and operating unit.

• Do not alter or tamper with the engine’s governor

setting. The governor controls the maximum safe

operating speed of the engine. Over-speeding the

engine is dangerous and will cause damage to the

engine and to other moving parts of the machine.

• Checkthe vacuum bag frequently for wear. Replace if

worn or damaged.

• Keep vacuum bag free of debris when not in use.

Service

• Use extreme care in handling gasoline and other

fuels. They are extremely flammable and the vapors

are explosive.

• Store fuel and oil in approved containers, away from

heat and open flame, and out of the reach of children.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

Your Responsibility

Restrict the use of this power machine to

persons who read, understand and follow the

A

warnings and instructions in this manual and on

the machine.

Page 5

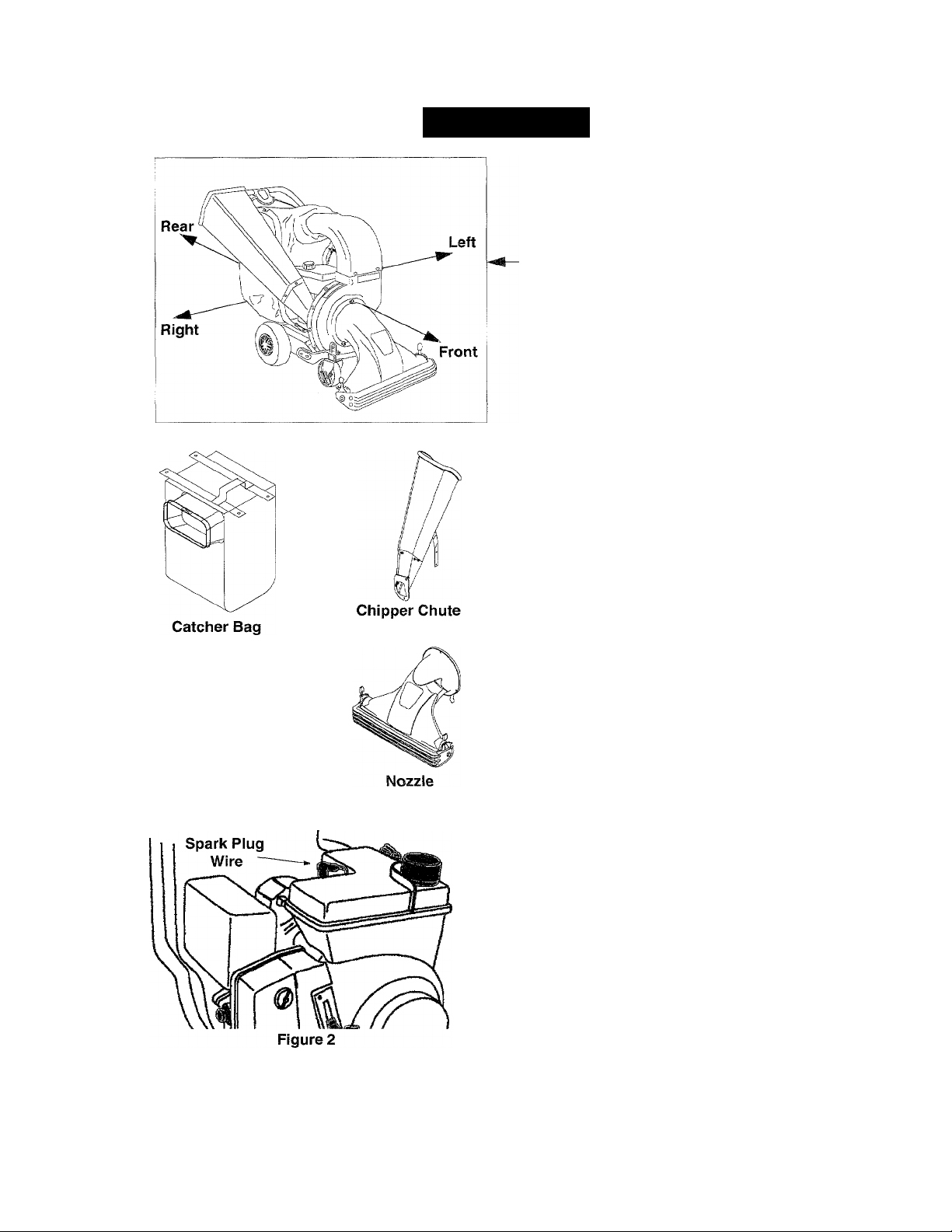

ASSEMBLY

IMPORTANT: This unit is shipped without gasoline

or oil in the engine. After assembly, see

OPERATION section of this manual for proper fuel

and engine oil fill-up.

NOTE: To determine right and left hand sides of your

chipper-shredder vacuum, stand behind the unit with

the engine farthest away from you.

Your chipper-shredder vacuum has been completely

assembled at the factory, except for the nozzle, the

chipper chute with support bracket and the catcher bag.

These parts are shipped loose in the carton. A pair of

safety glasses and a 20-oz. bottle of engine oil are also

included in the carton.

Removing From Carton

• Cut the corners of the carton.

• Remove all packing inserts.

• Remove ail loose parts. See Figure 1.

• Push down on handle to lift front of chippershredder vacuum and roll unit out of the carton.

• Make certain all parts and literature have been

removed before the carton is discarded.

r-j

20-oz. Bottle

of Engine Oil

Figure 1

with Support Bracket

Loose Parts

(See Figure 1.)

1. Nozzle

2. Chipper Chute with Support Bracket

3. Catcher Bag

4. Safety Glasses (Not Shown in Figure 1 )

5. A 20-oz. Bottle of Engine Oil

Tools Required

1. 1 /2" or adjustable wrenches

2. 7/16” or adjustable wrenches

3. Funnel (Recommended)

4. Pliers

Disconnecting Spark Plug

(See Figure 2.)

• Before proceeding with assembly of your new

chipper-shredder vacuum unit, disconnect the

spark plug wire from the spark plug on the

engine and move it away. This will prevent

accidental starting of the engine in any way.

Page 6

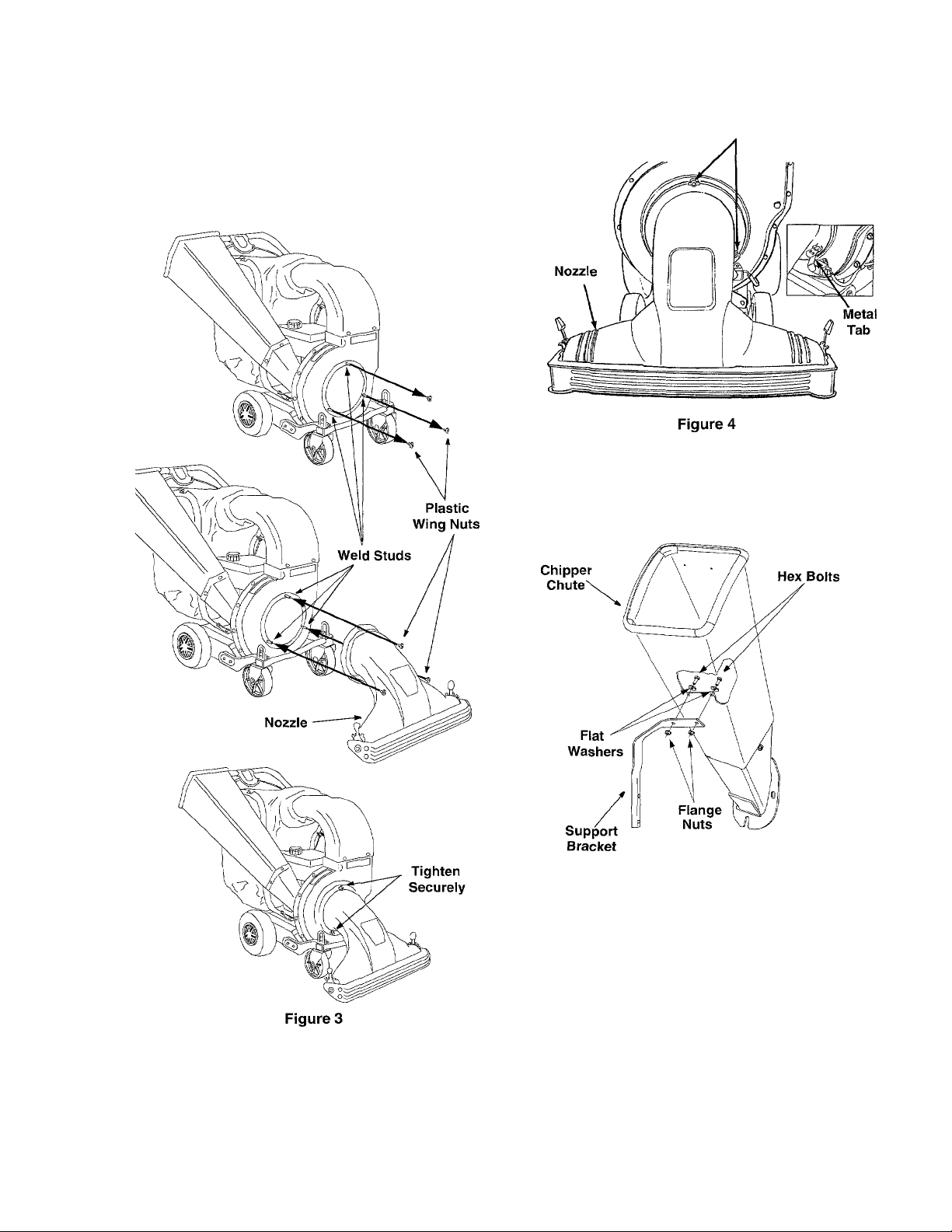

Attaching the Nozzle

(See Figure 3.)

• Remove the three plastic wing nuts from the

front of the chipper-shredder vacuum.

• Place the nozzle over the three weld studs.

• Secure with the plastic wing nuts just removed.

Plastic

Wing Nuts

Attaching the Chipper Chute

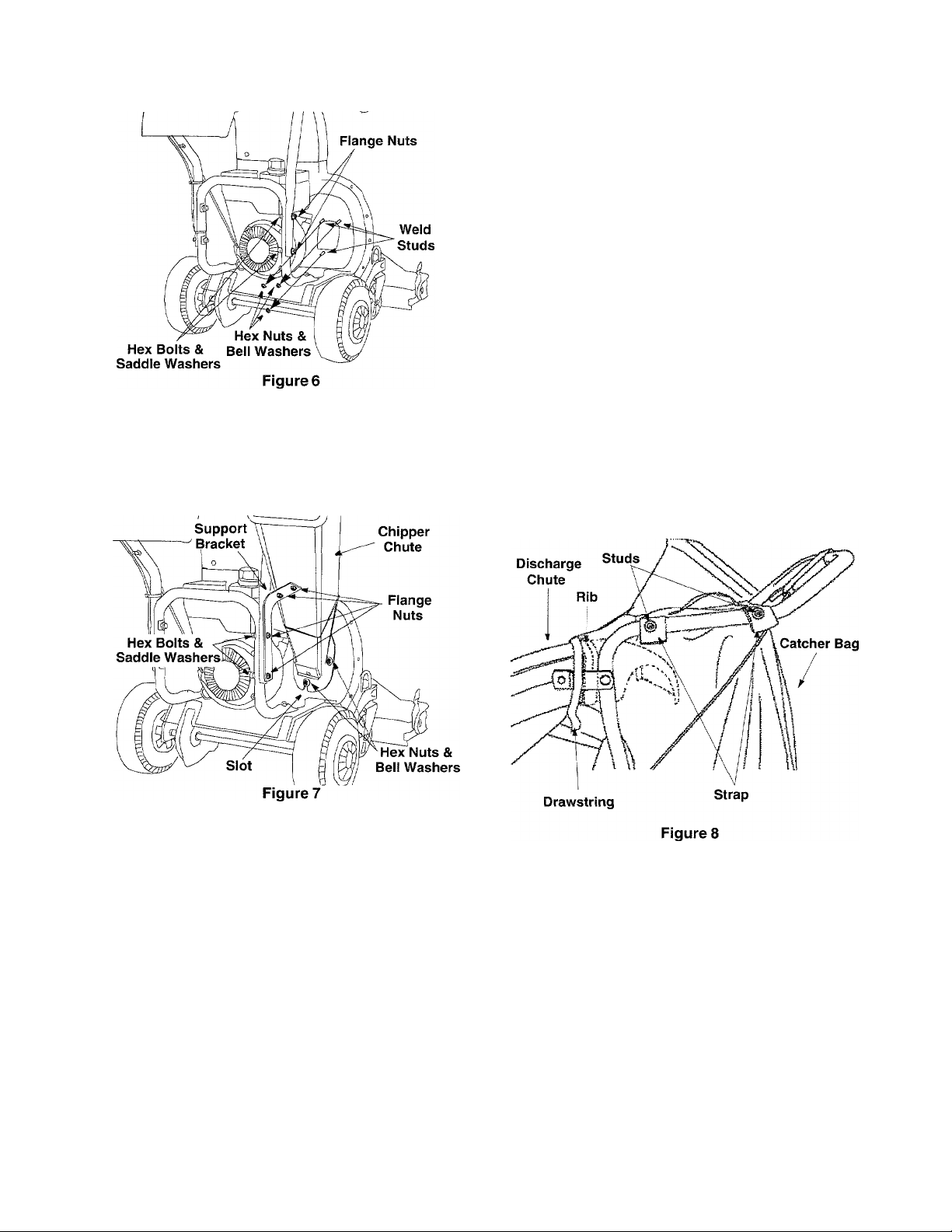

• Loosen, but do NOT remove, the two hex bolts,

flat washers, and flange nuts which are secured

to the support bracket. See Figure 5.

NOTE: The metal tab in the nozzle must depress the

safety switch on the front of the chipper-shredder

vacuum or the engine will not start. See Figure 4.

Figure 5

Remove the two flange nuts, hex bolts and

saddle washers which secure the right side of

the upper handle to the right side of the lower

handle. See Figure 6.

Next, remove the three hex nuts and bell

washers from the weld studs found beside the

opening on the right side of the chipper-shredder

vacuum. See Figure 6.

Page 7

Place the chipper chute over the weld studs

keeping the slotted side towards the bottom.

Loosely secure with the three hex nuts and bell

washers that were removed earlier. Do not fully

tighten the hex nuts at this point in the assembly.

See Figure 7.

• Align the support bracket with the holes in the

right side of the upper and lower handles where

the hex bolts were just removed. Push up

slightly on the chipper chute in order to better

align the holes in the support bracket with the

holes in the handles.

• Replace the hex bolts, saddle washers and

flange nuts to affix the support bracket to the

handle assemblies. See Figure 7.

• Follow by tightening all hardware securely first

on the chipper chute, then on the support

bracket, and finally on the handle.

Attaching the Catcher Bag

• Place the catcher bag inside of handle

assembly. Slip the opening on the bag over the

discharge chute, making certain it is over the rib

on the discharge chute.

• Place the four straps on the top of the bag over

the upper handle, hooking them on the studs.

• Squeeze the clamp on the drawstring and pull

the drawstring tight. Release the clamp. See

Figure 8.

Page 8

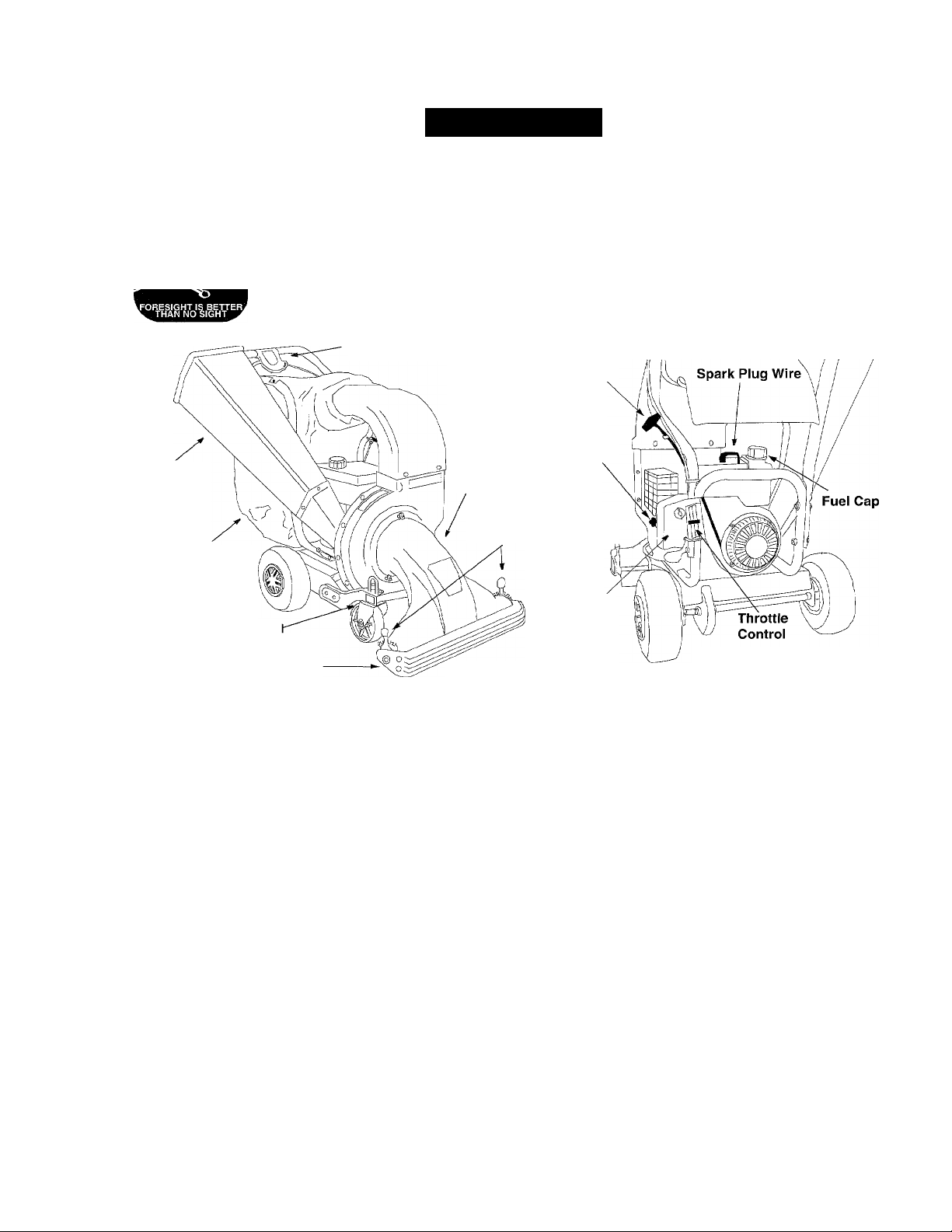

OPERATION

Know Your Chipper-Shredder Vacuum

Read this owner’s manual and safety rules before operating your chipper-shredder vacuum. Compare the

illustrations below with your equipment to familiarize yourself with the location of various controls and

adjustments. Save this manual for future reference.

11111 |ii| Wh The operation of any chipper-shredder vacuum can result in foreign objects being thrown into

^sAFET^AssEs'^ {|-|g eyes, which can result in severe eye damage. Always wear safety glasses, provided with

the Craftsman chipper-shredder vacuum, for operating this equipment or while performing any

adjustments or repairs on it.

Drive Clutch Control

Chipper

Chute

Catcher Bag

Front Caster Whee

Nozzle Door

Operating Controls

Chipper Chute

Allows twigs and small branches up to three inches in

diameter to be fed into the impeller for shredding.

Nozzle

Yard waste such as leaves and pine needles can be

vacuumed up through the nozzle.

Catcher Bag

Collects shredded material fed in through the chipper

chute or vacuumed in through the nozzle.

Drive Clutch Control

Squeezing the drive clutch control causes the

chipper-shredder vacuum to self-propel.

Nozzle Door

Nozzle ground clearance can be adjusted with the

nozzle door.

Starter

Handle

Primer

Nozzle

Nozzle Door Height

Adjustment Levers,

Air Filter

View from rear of

chipper-shredder vacuum

Figure 9

Front Caster Wheels

Allows for a choice in the manueverability of the

chipper-shredder vacuum.

Primer

The primer is used to assist in starting a cold engine

or restarting of a engine after a short shutdown.

Starter Handle

This is used to start the engine.

Throttle Control

Controls the engine speed and stops the engine.

Stopping the Engine

• Move throttle control lever to STOP position.

• Disconnect spark plug wire and move away from

the spark plug to prevent accidental starting while

the equipment is unattended.

Meets ANSi safety standards

Craftsman chipper-shredder vacuums conform to the safety standard of the American National Standards Institute (ANt

Page 9

Gas And Oil Fill-up

Oil (one 20-oz. bottle shipped with unit)

Only use high quality detergent oil rated with API

service classification SF, SG or SH. Select the oil’s

viscosity grade according to the expected operating

temperature. Follow the chart below.

NOTE: Although multi-viscosity oils (5W30, 10W30,

etc.) improve starting in cold weather, these

multiviscosity oils will result in increased oil

consumption when used above 32"F. Check engine

oil level more frequently to avoid possible engine

damage from running low on oil.

Colder

32°F

Warmer

A

A

A

WARNING: Never fill the fuel tank indoors.

Gasoline produces noxious fumes. Always

be certain to fill the fuel tank in a well

ventilated area to avoid inhalation of

gasoline fumes.

WARNING: Never smoke while fueling

your chipper-shredder vacuum. Gasoline

produces cumbustable fumes which can

ignite and cause personal injury.

WARNING: Do not fill closer than 1/2 inch

from the top of the fuel tank to prevent

spills and to allow for fuel expansion. If

gasoline is accidently spilled, move

chipper-shredder vacuum away from area

of spill. Avoid creating any source of

ignition until gasoline vapors have

disappeared.

5W30

Oil Viscosity Chart

• Remove oil fill dipstick.

• With the chipper-shredder vacuum on level

ground, use a funnel to fill engine with oil to

FULL mark on dipstick. Capacity is

approximately 20 oz. Be careful not to overfill.

Overfilling will cause the engine to smoke

profusely and will result in poor engine

performance. The oil bottle packaged with your

chipper-shredder vacuum contains 20 oz. of oil.

• Tilt chipper-shredder vacuum toward the left,

then re-level. Check the oil level making certain

not to rub the dipstick along the inside walls of

the oil fill tube. This would result in a false

dipstick reading. Refill to FULL mark on dipstick,

if necessary. Replace dipstick and tighten.

• Check oil level three times prior to starting

engine to be certain you’ve gotten an accurate

dipstick reading. Running the engine with too

little oil can result in permanent engine damage.

Gasoline

• Remove fuel cap from the fuel tank.

• Make sure the container from which you will

pour the gasoline is clean and free from rust or

foreign particles. Never use gasoline that may

be stale from long periods of storage in its

container. Gasoline that has been sitting for any

period longer than four weeks should be

considered stale.

• Fill fuel tank with approximately 3 quarts of

clean, fresh, lead-free grade automotive

gasoline. DO NOT use Ethyl or high octane

gasoline. Replace fuel cap.

SAE 30

• Check the fuel level periodically to avoid running

out of gasoline while operating the chippershredder vacuum. If the unit runs out of gas as it

is chipping, it may be necessary to unclog the

unit before it can be restarted. Refer to

Removing the Flail Screen

on page 15.

Starting The Engine

IMPORTANT: If your unit shows any sign of motion

with the drive clutch control in the disengaged

position, shut the engine off immediately. Readjust

following the instructions on page 16.

WARNING: Make sure that no one other

than the operator is standing near the

dk

A

chipper-shredder vacuum unit while starting

or operating.

Do not operate this unit unless the nozzle,

discharge chute, and the bag have been

properly installed.

Attach spark plug wire and rubber boot to spark

plug if not already attached.

Place the throttle control lever in FAST position.

Depress the primer three to four times slowly.

Wait about two seconds between each push.

When temperature is at or below 50°F/10°C, it

may be necessary to depress the primer five to

six times. You may have to use the primer to

restart a warm engine after a short shutdown.

Place one foot on the left rear wheel to prevent

the unit from skidding while starting.

Grasp starter handle and pull rope out slowly

until engine reaches start of compression cycle.

The rope will pull slightly harder at this point. Let

the rope rewind slowly.

Page 10

NOTE: While the engine is reaching the compression

cycle, you may hear a "clanking" noise. This noise is

caused by the impelier ftails pivoting and falling into

piace and iS normai. This noise wiii continue untili the

impeiier reaches full speed.

• Pull the rope with a rapid, continuous, full arm

stroke while keeping a firm grip on the starter

handle.

• Continuing to keep a firm grip on the starter

handle, let the rope rewind slowly. Do not let the

starter handle snap back against the eye bolt on

the handle. Repeat, if necessary, until engine

starts. Additional priming may be necessary.

• Move throttle control to IDLE position for a few

minutes to warm up the engine. Move it back to

fast when running.

• ALWAYS keep the throttle control in the Fast

postion when operating the chipper-shredder

vacuum.

NOTE: Engine may run very slowly for the first five to

ten seconds after it has been started untii the impeller

gains momentum and allows the engine to reach its

top RPM.

NOTE: To idie smoothly, a new engine may require 3

to 5 minutes of running at above the slow idle speed.

The idle speed has been adjusted for proper running

after this break-in period.

Stopping the Engine

• Move throttle control lever to STOP position.

• Disconnect spark plug wire and move away from

the spark plug to prevent accidental starting while

the equipment is unattended.

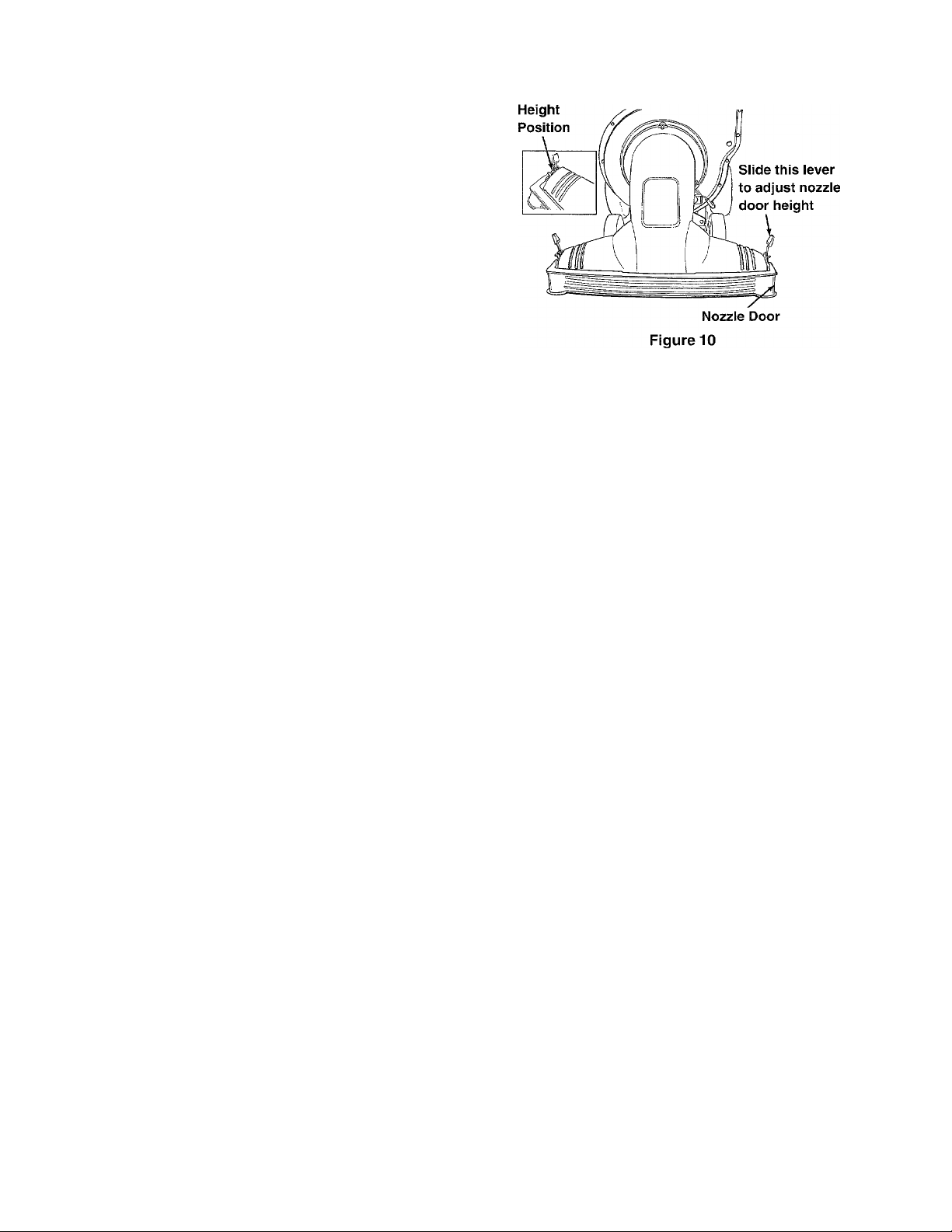

Adjusting Nozzle Height

• The nozzle door height adjustment levers have

five position settings and are found each side of

the nozzle door. See Figure 10. The nozzle door

height should be adjusted according to the

conditions.

• Slide the height adjustment lever forward or

backward for adjusting the nozzle door upwards

or downwards. See Figure 10.

WARNING: Keep your hands, feet and

any loose clothing clear of the nozzle any

A

time the engine is running. When the

engine is running, a vacuum is being

created in the nozzle which can draw in

loose clothing.

WARNING: Never make any adjustments

on the nozzle while the engine is running.

A

NOTE: Raise the nozzle height to vacuum a thick

layer of lea ves; lower the nozzle height for smoother

lawns.

Operation of your

Chipper-Shredder Vacuum

Your chipper-shredder vacuum is designed to chip

small tree branches and twigs, shred leaves and

vacuum foliage and other lawn debris. For

convenience in operation, your Craftsman chippershredder vacuum is equipped with a drive clutch

control allowing it to "self-propel."

WARNING: The impeller (chipping/

shredding mechanism) is rotating at all

A

A

IMPORTANT: Your chipper-shredder vacuum is

equipped with a safety switch at the front left portion

of the impeller housing. The metal tab on the nozzle

must depress this switch for the engine to start. Be

certain the nozzle is properly in place before

attempting to start the unit. See Figure 4 on page 6.

A

times when the engine is running.

WARNING: Keep your hands away from

the nozzle opening and NEVER place your

hands or arms inside of the chipper chute

when the engine is running. Doing so could

result in serious personal injury.

WARNING: Always survey the area to be

vacuumed thoroughly before operating the

chipper-shredder vacuum. Clear the area

of any obstructions such as toys, dog

chains, etc. Running over such an

obstruction can result in personal injury as

well as damage to the chipper-shredder

vacuum.

Do not vacuum up anything other than normal

yard waste such as leaves or pine needles.

10

Page 11

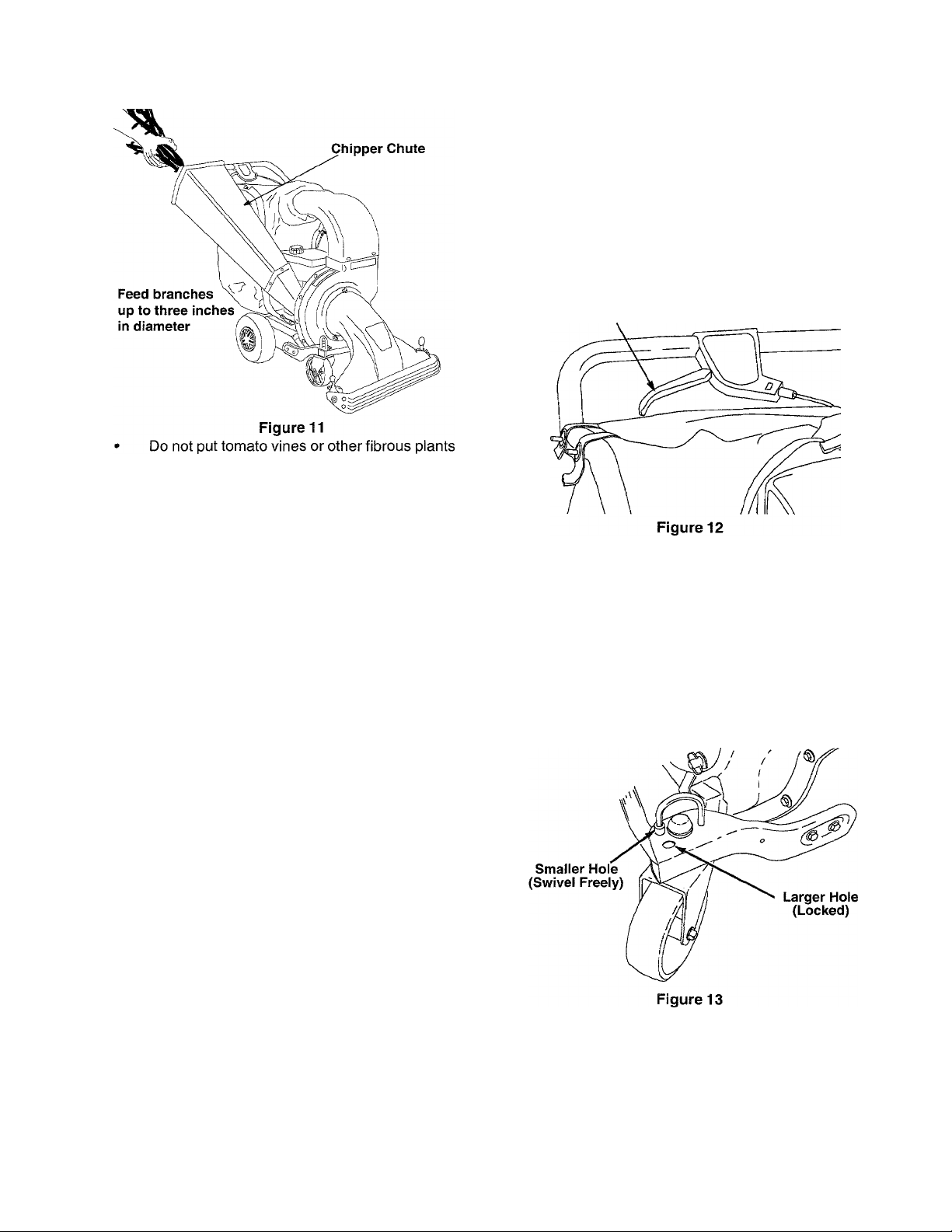

into the chipper chute unless it is thoroughly

dried out. Do not place any material other than

normal yard waste such as leaves, twigs or

branches up to three inches in diameter into the

chipper chute. See Figure 11.

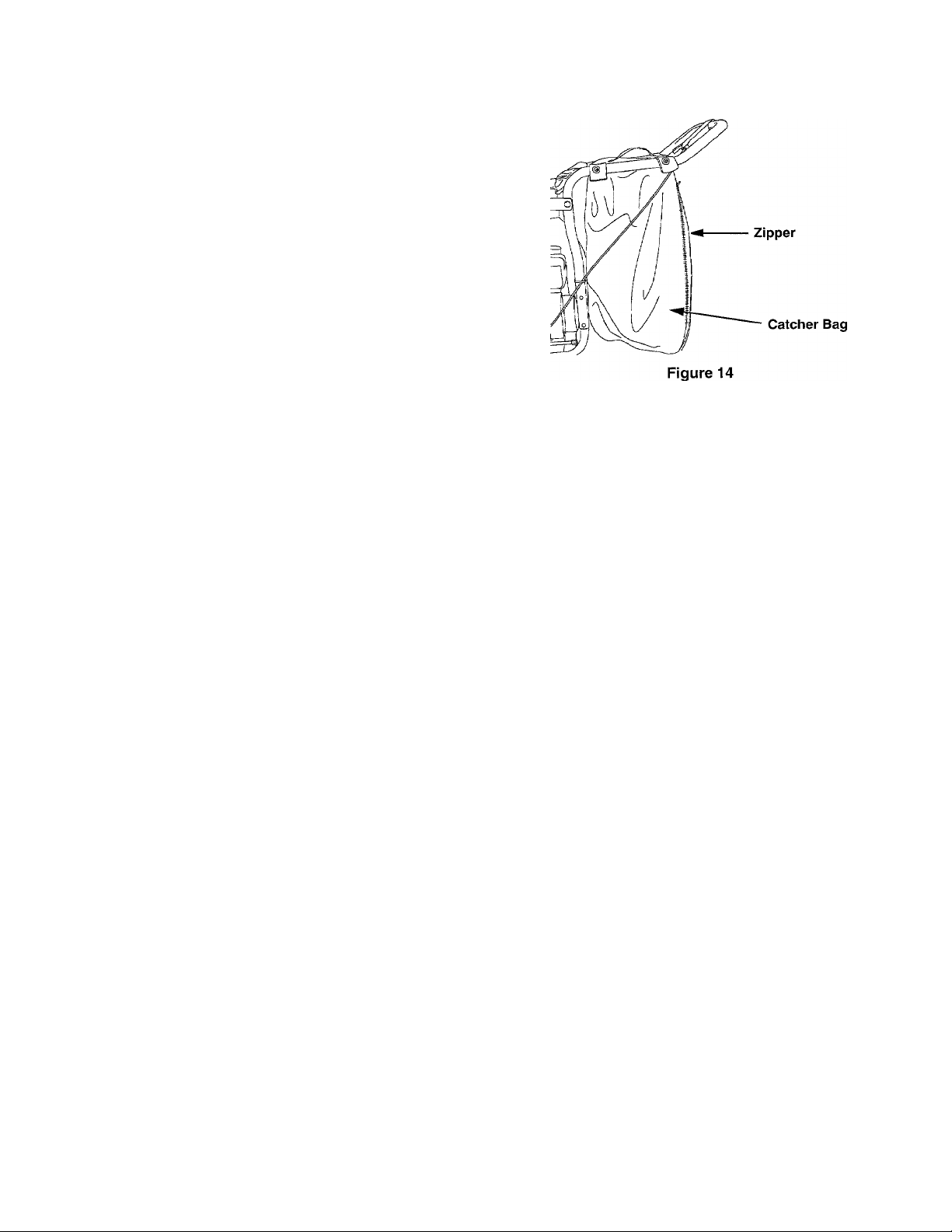

Drive Clutch Control

Squeezing the drive clutch control engages the drive

mechanism to the rear wheels and causes the

chipper-shredder vacuum to self-propel. Release the

drive clutch control slightly to slow down the chippershredder vacuum’s ground speed when negotiating

an obstacle or making a turn. Release the drive clutch

control completely to stop the rear wheels from

driving. See Figure 12.

Drive Clutch

Control

WARNING: Personal injury and/or

dk

• For best performance, keep the chipper blades

• If the discharged material starts to become

• If the flail screen, located inside the housing in

NOTE: Care should be taken not to shut off the

damage to the unit could result if you try to

feed any material other than specified.

sharp.

stringy, or if the rate of discharge slows down

considerably, the chipper blades may have

become dull. To sharpen or replace the blade,

refer to Service and Adjustment section on

page 15.

the discharge area, becomes clogged, remove

the screen and clean. For instructions on

cleaning the screen, refer to the Service and

Adjustment section on page 15.

engine or to run out of gasoline while operating the

chipper-shredder.

• Check the fuel level periodically to avoid running

out of gasoline.

• To eliminate the possibility of jamming, never

turn engine off until all chipping is completed.

If the unit runs out of gas or is turned off as it is

shredding or chipping, it may be necessary to unciog

the unit before it can be restarted. Refer to “Removing

the Flail Screen” in Service and Adjustment section

on page 15.

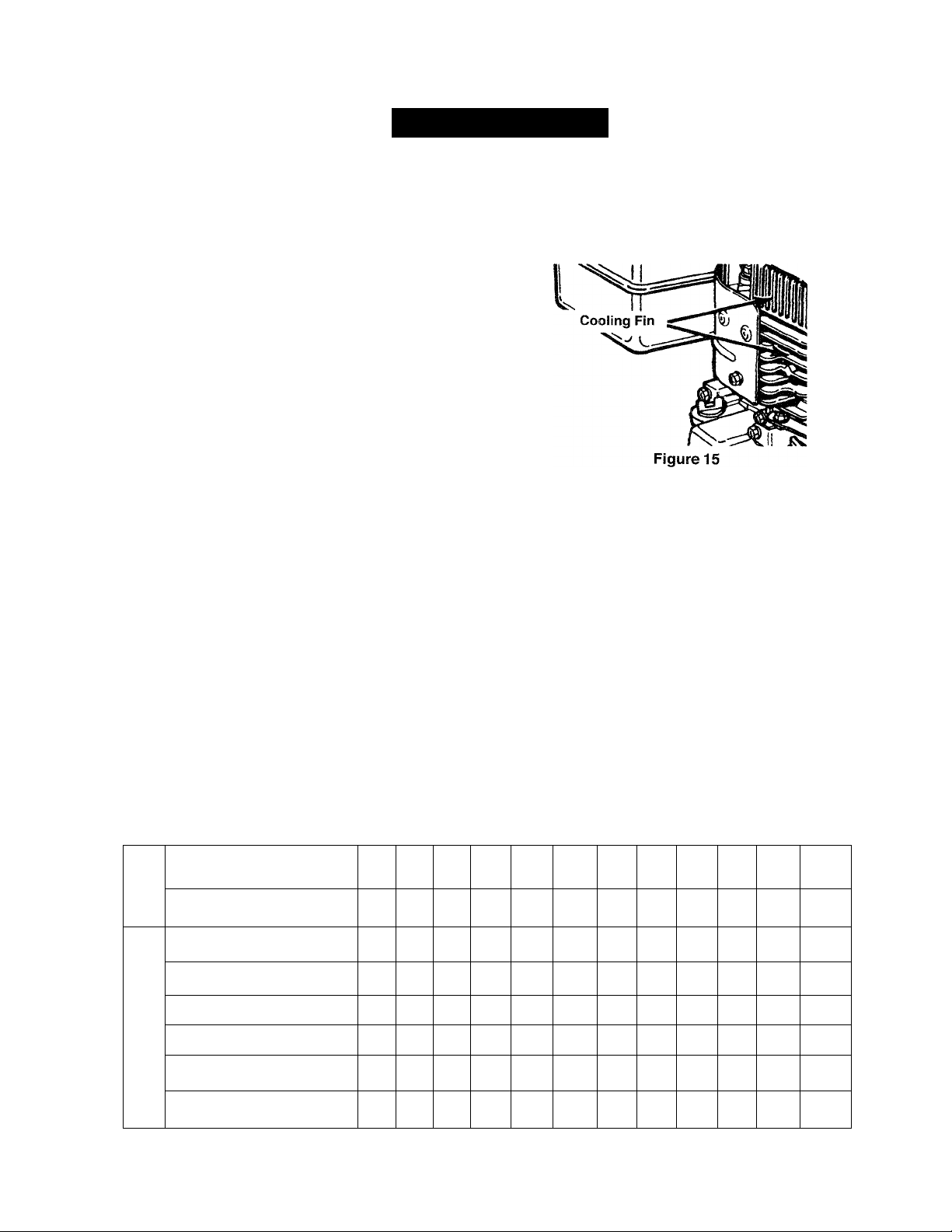

Front Caster Wheels

Your chipper-shredder vacuum is equipped with

caster front wheels. The casters can be locked in a

straight ahead position or can be left to swivel freely.

• Lift and place pins in the larger holes for locked,

straight ahead operation. Place pins in smaller

holes to allow casters to rotate freely for more

manueverability. See Figure 13. Lock wheels in

straight position when operating on slopes.

11

Page 12

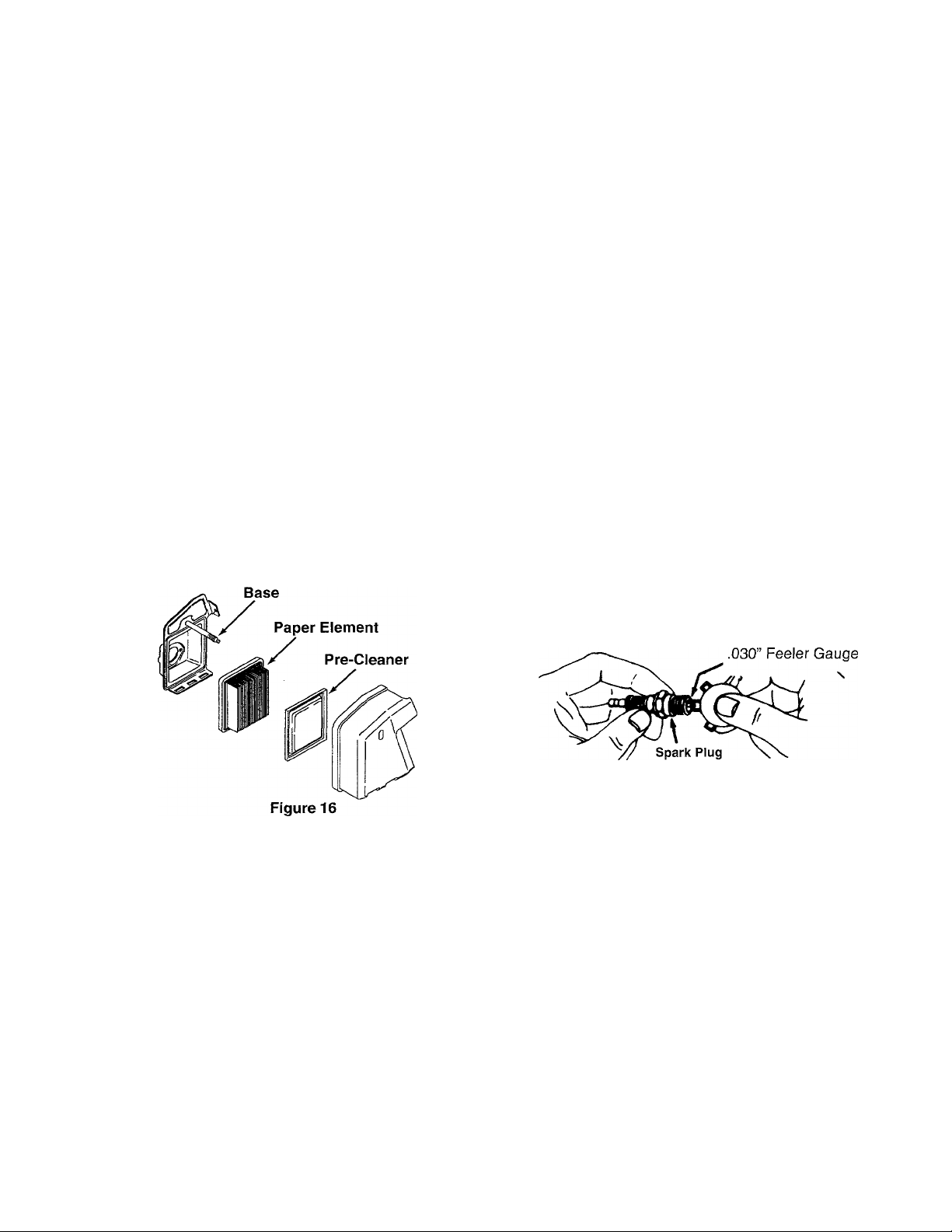

Catcher Bag

• To empty the catcher bag, open the large zipper

on the left side of the catcher bag and remove

the shredded debris from it. See Figure 14.

WARNING: Never operate your chippershredder vacuum without the catcher bag

A

A

properly in place. Doing so can result in

personal injury.

WARNING: Always make certain the

catcher bag is zipped closed before

operating the chipper-shredder vacuum.

Not doing so can result in personal injury.

12

Page 13

MAINTENANCE

General Recommendations

• Always observe safety rules when performing

any maintenance.

« The warranty on this chipper-shredder vacuum

does not cover items that have been subjected to

operator abuse or negligence. To receive full

value from the warranty, operator must maintain

the equipment as instructed in this manual.

• Some adjustments will need to be made

periodically to maintain your equipment properly.

• All adjustments in the Service and Adjustments

section on page 15 of this manual should be

checked at least once each season.

• Follow the maintenance schedule given below.

• Periodically check all fasteners and make sure

these are tight.

WARNING: Always stop the engine and

dk

disconnect the spark plug wire before

performing any maintenance or adjustments.

Lubrication

• Lubricate pivot points on the nozzle door height

adjustment levers according to chart below using

a light oil.

• Apply grease gun to the lube fittings found on the

front caster wheels according to chart below.

Cleaning

• Clean the chipper-shredder vacuum thoroughly

after each use.

• Wash the bag periodically with water. Allow to dry

thoroughly in the shade. Do not use heat.

Customer Responsibilities

Clean engine periodically. Remove dirt and

debris with a cloth or brush.

Frequently remove grass clippings, dirt and

debris from cooling fins (see Figure 15), air intake

screen and levers and linkage. This will help

ensure adequate cooling and engine speed.

• Yearly or every 25 hours, whichever occurs first,

remove the blower housing and clean it to avoid

overspeeding, overheating and engine damage.

Clean more often if necessary.

NOTE: Cleaning with a forceful spray of water is not

recommended as it could contaminate the fuel system.

Change Engine Oil

• Only use high quality detergent oil rated with API

service classification SF, SG or SFI. Select the

oil’s viscosity grade according to your expected

operating temperature. Refer to page 9 of this

manual for viscosity chart.

Maintenance Schedule

t-

o

Lube pivot points & casters

Z3

a

o

cc

Clean equipment

a.

Check engine oil </

Change engine oil

lU

z

Service air cleaner

o

z

UJ

Service spark plug

Service muffler

Clean engine

/

/

❖

/

13

Record service dates here

Page 14

• Stop engine and wait several minutes before

checking oil level. With engine on level ground,

the oil must be to FULL mark on dipstick,

• Change engine oil after the first five hours of

operation, and every twenty-five hours

thereafter.

To Drain Oil

Drain oil while engine is warm. Follow the instructions

given below.

• Remove oil drain plug from the left side of the

engine and allow oil to run out into a suitable

container.

• When engine is drained of all oil, replace drain

plug securely.

• Refill with approximnately 20 oz. of fresh oil.

Refer to GAS AND OIL FILL-UP section.

• Replace dipstick.

c. Wrap in a clean cloth and squeeze (do not

twist) until completely dry, or allow to air dry.

d. Saturate with engine oil and squeeze (don’t

twist) to distribute oil. Remove excess oil.

e. Replace pre-cleaner making sure that the

screen side is towards the paper element.

NOTE; If the pre-cleaner is torn or damaged in any

way, replace it.

• If necessary, replace paper filter (do not attempt

to clean). Install new filter on base.

• Slide pre-cleaner over filter.

• Install cover and wing nut.

• Tighten wing nut securely.

WARNING: Temperature of muffler and

A

nearby areas may exceed 150° F(65°C).

Avoid these areas.

Air Cleaner

The air cleaner prevents damaging dirt, dust, etc.,

from entering the carburetor and being forced into the

engine and is important to engine life and

performance. The air cleaner consists of a pre

cleaner or foam filter, and a paper filter. See Figure

16. Never run the engine without air cleaner

completely assembled.

Wing

Nut

To Service Air Cleaner:

1. Service pre-cleaner after every 25 hours of use,

or at least once a season.

2. Service filter every 100 hours of use, or at least

once a season.

3. Service pre-cleaner and filter more often under

dusty conditions.

• Remove wing nut and cover. See Figure 16.

• Slide pre-cleaner off filter. Clean the inside of

base and cover thoroughly.

• Clean pre-cleaner as follows;

a. Wash in water and detergent solution, and

squeeze (do nottwist) until all dirt is removed.

b. Rinse thoroughly in clear water.

Spark Plug

• Clean the spark plug and reset the gap to .030"

at least once a season or every 50 hours of

operation. See Figure 17. Spark plug

replacement is recommended at the start of

each season. Refer to engine parts list for

correct spark plug type.

NOTE: Do not sandblast spark plug. Sparkplug

should be cleaned by scraping or wire brushing and

washing with a commercial solvent.

Figure 17

Servicing Muffler

• Inspect muffler periodically, and replace if

necessary.

• If your engine is equipped with a spark arrester

screen assembly, remove after every 50 hours

of use for cleaning and inspection. Replace if

damaged.

WARNING: Do not operate the chippershredder vacuum without a muffler or

dk

tamper with the exhaust system. Damaged

mufflers or spark arresters could create a fire

hazard.

14

Page 15

SERVICE & ADJUSTMENTS

Removing Flail Screen

If the discharge area becomes clogged, remove the

flail screen and clean area as follows.

• Stop the engine. Make certain the chippershredder vacuum has come to a complete stop.

Disconnect the spark plug wire before

unclogging the discharge chute.

• Remove the catcher bag from the unit.

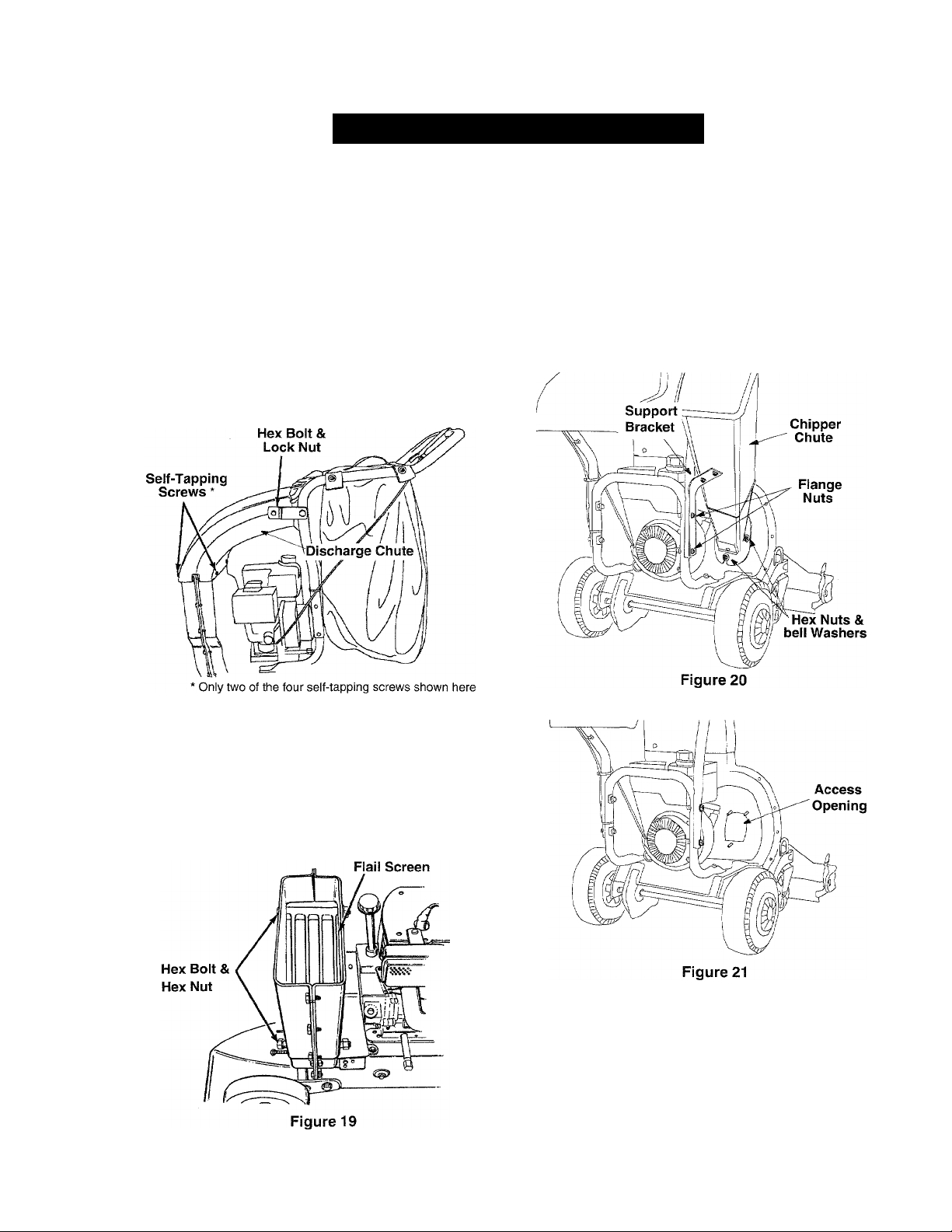

• Remove hex bolt and lock nut from the top side

section of the discharge chute. See Figure 18.

• Remove the four self-tapping screws from the

bottom of the discharge chute. (Be careful not to

drop the hardware into the chute.) Remove the

discharge chute. See Figure 18.

Servicing Chipper Blades

• Disconnect the spark plug wire and move it

away from the spark plug. Remove the flail

screen as instructed in the previous section.

• Remove the two flange nuts which secure the

support bracket to the handle assembly. Follow

by removing the three hex nuts and bell washers

which secure the chipper chute to the impeller

housing. See Figure 20

• Remove the chipper chute to allow access to the

impeller assembly. See Figure 21.

Figure 18

• Remove the two hex bolts and hex nuts which

extend through the housing. Lift the flail screen

from inside the housing. See Figure 19.

• Clean the screen by scraping or washing with

water. Reinstall the screen.

NOTE: Be certain to reassemble the flail screen with

the curved side DOWN.

15

A

WARNING: Make sure to wear heavy duty

gloves for this job. While accessing the

chipper blade, you may have to clean the

screw head of dust and shredded particles to

enable the alien wrench to operate.

the wrench carefully so that you do not

cut your hand on the chipper blade.

Handle

Page 16

• Locate one of the chipper blades in the access

opening by rotating the impeller by hand.

• Remove the blade using a 3/16" alien wrench on

the outside of the blade and 1/2" wrench on the

impeller assembly, inside the housing. Torque

hardware to 250/300 inch pounds.

• Remove the other blade in the same manner.

Replace or sharpen blades.

• If sharpening, make certain to remove an equal

amount from each blade.

• Reassemble following above instructions in

reverse order.

NOTE: Make sure that the blades are reassembled

with the sharp edge facing upward, as viewed from

the access plate opening.

Adjusting Carburetor

WARNING: If any adjustments are made to

A

The carburetor has been pre-set at the factory and

should not require adjustment. If your engine does

not operate properly due to suspected carburetor

problems, take your chipper-shredder vacuum to your

nearest SEARS service center.

the engine while the engine is running (e.g.

carburetor), keep clear of all moving parts.

Be careful of heated surfaces and muffler.

Drive Clutch Cable Adjustment

Adjust the drive clutch control if you notice the

following:

a. The chipper-shredder-vacuum moves

forward with the drive clutch control

disengaged.

b. The chipper-shredder-vacuum does not

self-propel with the drive clutch control

engaged.

c. The drive belt is slipping (unit hesitates

while engine maintains the same speed).

• Use the adjustment wheel located in the clutch

control housing to tighten or loosen (slack) in the

drive cable. See Figure 22 .

• In addition, the adjustment wheel may also be

used to determine the position in which the drive

clutch control is engaged. If it is more

comfortable to have the drive engaged with the

lever further away from the handle, tighten (take

up slack) in the drive cable.

Engine Speed

The engine speed on your chipper-shredder vacuum

has been set at the factory. Do not attempt to

increase the engine RPM. If you think that the engine

is running too fast or too slow, take your chippershredder vacuum to the nearest SEARS service

center for repair and adjustment.

WARNING: Do NOT attempt to alter the

A

engine speed by tampering with the engine’s

governor linkage. Doing so could result in

serious personal injury and damage to the

engine. The engine RPM has been set at the

factory.

Figure 22

Replacing Transmission Drive Belt

Do not attempt to replace the transmission drive belt

on your chipper-shredder vacuum. Special tools are

required. In the event you need to have the belt

replaced, take the unit to the nearest SEARS service

center.

16

Page 17

OFF-SEASON STORAGE

Prepare your Craftsman chipper-shredder vacuum

for storage at the end of the season or if the unit wiii

not be used for 30 days or longer. A yeariy check-up

by your iocai Sears service center is a good way to

ensure that the unit runs properly next season.

Chipper-Shredder Vacuum

• Clean the equipment thoroughiy.

• Wipe equipment with an oiled rag to prevent

rust. Use a light oil or silicone to wipe.

• Service the engine following instructions below.

• Store unit in a clean, dry area. Do not store next

to corrosive materials such as fertilizer.

Engine

IMPORTANT: It is important to prevent gum deposits

from forming in essential fuel system parts such as

the carburetor, fuel filter, fuel line, or gas tank during

storage. Also, experience indicates that alcohol

blended fuels (called gasohol or using ethanol or

methanol) can attract moisture which leads to

separation and formation of acids during storage.

Acidic gas can damage the fuel system of an engine

while in storage.

• Drain the fuel tank.

• Start the engine and let it run until the fuel lines

and carburetor are empty.

• Drain carburetor.

• Never use engine or carburetor cleaner

products in the fuel tank or permanent damage

may occur.

NOTE: Fuel stabilizer is an acceptable alternative in

minimizing the formation of fuel gum deposits during

storage.

• Add stabilizer to gasoline in fuel tank or storage

container.

• Always follow the mix ratio found on stabilizer

container.

• Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the

carburetor.

• Do not drain the gas tank and carburetor if using

fuel stabilizer. Drain all the oil from the

crankcase (this should be done after the engine

has been operated and is still warm) and refill

the crankcase with fresh oil.

• If you have drained the fuel tank, protect the

inside of the engine as follows.

• Remove spark plug, pour approximately 1/2

ounce (approximately one tablespoon) of engine

oil into cylinder and crank slowly to distribute oil.

• Replace spark plug.

Other

• Do not store gasoline from one season to

another.

• Replace the gasoline can if it starts to rust. Rust

and/or dirt in the gasoline will cause problems.

• Store unit in a clean, dry area. Do not store next

to corrosive materials, such as fertilizer.

NOTE: If storing in an unventilated or metal storage

shed, be certain to rustproof the equipment by coating

with a light oil or silicone.

17

Page 18

TROUBLE-SHOOTING

Problem Possible Causes

Engine fails to start

Loss of power, erratic operation

Engine overheats

Too much vibration

Fuel tank empty, or stale fuel.

Spark plug wire disconnected.

Faulty sparkplug.

Nozzle safety switch not depressed.

Spark plug wire loose.

Blocked fuel line or stale fuel.

Water or dirt in fuel system.

Carburetor out of adjustment.

Dirty air cleaner.

Carburetor not adjusted

Engine oil level low.

Loose parts or damaged impeller

Corrective Action

Fill tank with clean, fresh fuel.

Connect wire to spark plug.

Clean, adjust gap or replace.

Adjust metal tab so it depresses the

safety switch.

Connect and tighten spark plug wire.

Clean fuel line; fill tank with clean, fresh

gasoline.

Disconnect fuel line at carburetor to

drain fuel tank. Refill with fresh fuel.

Contact your local Sears service

center.

Service air cleaner following

instructions on page 14.

Contact your local Sears service

center.

Fill crankcase with proper selection of

oil.

Stop engine immediately, disconnect

spark plug wire, tighten all bolts and

nuts and make necessary repairs. If

vibration continues, consult with your

local Sears service center.

Unit does not discharge

Rate of discharge slows considerably

or composition of discharged material

changes

For repairs beyond the minor adjustments listed above, please contact your local Sears service center.

Discharge chute clogged

Foreign object lodged in impeller.

Vacuum bag is full.

Dull chipper blades

Clean flail screen and blower housing

following instructions on page 15.

Stop engine immediately, disconnect

spark plug wire, and remove lodged

object.

Empty the bag.

Sharpen or replace blades following

instructions on page 15.

18

Page 19

PARTS LIST

Sears Craftsman 6.5 H.P. Chipper-Shredder Vacuum Model 247.77763

KEY

NO.

1 631 -0086

2

3 710-0969 Screw, Truss Hd Tapp

4 720-0190 Knob, Height Adj. 2

5 731-1831 Flap, Nozzle Rear 1

6

7 732-0754 Spring Lever

8

9 738-0913

10 781-0702 Bracket, Door Index RH

11

12 764-0522 Bag, 3 Bushel 1

13 731-1838A

PART

NUMBER

Nozzle Assembly Complete

(Includes Keys 2-11)

631-0049 Door Assembly, Black 1

631-0085

736-3084

781-0703

Nozzle, Black, w/ Switch Bracket 1

Washer, Flat, .510 x 1.20 x .060 2

Screw, Shoulder, .50 x 5/8-16

Bracket, Door Index LH

Discharge Chute

DESCRIPTION QTY.

19

1

2

2

2

1

1

1

Page 20

Sears Craftsman 6.5 H.P. Chipper-Shredder Vacuum Model 247.77763

Page 21

Sears Craftsman 6.5 H.P. Chipper-Shredder Vacuum Model 247.77763

KEY

NO.

1

2 681-0097A

3

4

5 710-0805 Screw, Hex Cap, 5/16-18 x 1.5 1

6

7 710-0604

8

9 710-0896

10 710-1331 Screw, Phil Cntrsnk, #10-16 x 1.25

11

12 711-0737

13 712-0138 Nut, Hex, 1/4-28 1

14 712-3004A Nut, Hex Flange Lock, 5/16-18 GR5

15 719-0359 Adapter, Engine Mtg 1

16

17 731-0620

18 731-1059

19 731-1646 Belt Cover 1

20 731-1735 Upper Clutch Cover 1

21 731-1736 Lower Clutch Cover

22 736-0329 Washer, Lock, 1/4

23 736-0451 Saddle Washer, .320 x .93 7

24 736-3008 Washer, Flat, .344 x .75 x .12

25 741-0413 Bearing, Flange, .631 ID x .72 OD 2

26 746-0714 Cable, Clutch, 56.0

27 747-0815 Eye Bolt

28

29 749-0980

30 749-0996 Handle, Upper

31

32

33 781-0700 Bracket, Axle 2

34 681-0087

35

36

37 732-0306 Spring, Compression

38

39 736-0366 Washer, Flat, .64 x 1.12 x .12

40

41 737-3000 Fitting, Lube, 3/16

42 741-0487A

43

44 734-1804

45 750-1042

46

47

48 712-0431

PART

NUMBER DESCRIPTION QTY

1539-019 Nut, Push, .25

Frame Assembly

710-0157

710-3180 Screw, Hex Cap, 5/16-18 x 1.75 6

710-0502A

710-0841

710-3008 Screw, Hex Cap, 5/15-18 x .75 GR5 3

725-0157 Cable Tie

747-0929A

781-0647

781-0697

714-0104

726-0214

736-0264

736-0931

747-0924

710-0521

681-0088

Screw, Hex Cap, 5/16-24 x .75 1

Screw, Hex Wash Hd Tapp,

3/8-16 X 1.25

Screw, Hex Wash Hd Tapp, 5/16-18 x .62 4

Screw, Phil Cntrsnk, #10-12 x .75

Screw, Hex Wash Hd, 1/4-14 x .62

Pin, Stud, .250 X 1.75 4

Lever, Drive Control 1

Cap, Cable Mtg 1

Belt Keeper 1

Handle, Lower

Bracket, Chute Stabilizing 1

Transmission Cover 1

Bracket Assembly, Front Wheel 1

Pin, Internal Cotter

Cap, Push, 5/8

Washer, Flat, .330 x .630 x .06 2

Washer, Flat, .203 IDx.403 OD .040 2

Bearing, Flange, .632 ID

Pin, Front Wheel Lock 2

Wheel, 6.00 x 2.00 2

Spacer, .384 ID x .5 OD x 2.3 Lg 2

Screw, Hex Cap, 3/8-16 x 3.0 2

Bracket Assembly, Pivot Wheel 2

Nut, Hex Flange Lock, 3/8-16

4

1

4

3

3

2

10

2

1

1

1

1

1

1

1

2

2

2

4

2

4

2|

21

Page 22

Sears Craftsman 6.5 H.P. Chipper-Shredder Vacuum Model 247.77763

KEY

NO.

2 710-1273

3 736-0217

4 736-0247

5

10

11 736-0119

PART

NUMBER

1 681-0108

681-0107

711-0833B Pin, Clevis

6

7 710-1054

712-0411

8

9 715-0166

719-0329

DESCRIPTION QTY.

Impeller Ass’y (Includes Keys 5-13)

Screw, Hex Cap, 3/8-24 x 2.75 GR5 1

Washer, Lock, 3/8 Heavy Duty

Washer, Flat, .406 x 1-1/4 HD 1

Impeller 1

Screw, Flat Hd. Cap, 5/16-24 x 1.0 4

Nut, Hex Insert Lock, 5/16-24

Pin, Spirol,.156x1.000 Std.

Blade, Flail 3

Washer, Lock, 5/16

12 781-0490 Blade, Chipper

—

781-0735

Clip, Retainer (Not Shown) 3

1

1

3

4

3

4

2

KEY

NO.

10

11 781-0780

PART

NUMBER

681-0068

1

710-0751 Hex Cap Screw

2

712-3010

3

712-3027 Hex Flange Nut, 1/4-20

4

728-0175

5

731-1574A Chipper Chute, Black

6

735-0249

7

736-0173 Flat Washer, .28 x .74 x .063

8

736-0242 Bell Washer, .34 x .872

9

Chipper Chute Assembly

Hex Nut, 5/16-18

Pop Rivet

Chute Flap

DESCRIPTION QTY.

781-0633 Chute Flap Strip

Chute Bracket

1

5

3

5

3

1

1

5

3

1

1

22

Page 23

Sears Craftsman 6.5 H.P. Chipper-Shredder Vacuum Model 247.77763

KEY

NO.

PART

NUMBER

1 781-0653

2 781-0627

3 781-0599

4 736-0119

5 731-1613

726-0272

6

7

725-3166

8 725-1700

9 723-0438

10 719-0326

712-3004A

11

DESCRIPTION

QTY.

Blade, Flail Housing

Cover, Chipper Blade

Blade, Upper Shredder 1

KEY

NO.

1

12

1 13

14 710-3008 Screw, Hex Cap, 5/16-18 x .75 2

PART

NUMBER

712-0421

Knob, 5/16-18 3

DESCRIPTION

712-0384 Nut, Hex Center Lock, 1/2-13 2

Washer, Lock, 5/16 3 15 710-1268 Screw, Wash Hd Tapp #10-16

Cover, Safety Switch Mtg.

Clamp

Switch, Snap Mount

Cover, Switch

Rubber Seal

Screen, Discharge

Nut, Hex Flange Lock, 5/16-18

1 16

1

1 18

1

2

1 21

4

710-0896 Screw, Wash Hd Tapp 1/4-14 1

710-0772 Screw, Hex Cap, 5/16-18x2

17

710-0604 Screw, Wash Hd Tapp 5/16-18

710-0382 Screw, Hex Cap, 1/2-13 x 5.0 2

19

20

681-0098

Housing Ass’y, Inner Flail

681-0060 Housing Ass’y, Outer Flail 1

629-0241A

22

Harness, Wire

23

QTY.

2

3

18

1

1

Page 24

Sears Craftsman 6.5 H.P. Chipper-Shredder Vacuum Model 247.77763

KEY

NO.

1

2

3 754-0457

4

5

6

PART

NUMBER

DESCRIPTION

781-0677 Chain Case LH

781-0676

Chain Case RH

V-Belt, 3/8 X 24.68

748-0313

741-0413

736-0336

Spacer, .630 x 1.25 x .29

Bearing, Hex Flange, .631 ID

Washer, Flat, 5/8 x 1.0

7 713-0422 Chain, Endless, #41 x 50 Inks

8 710-0896

9 710-0603

Screw, Hex Wash Hd,

Screw, Hex Wash Hd Tapp

5/16-18 x .5

10 618-0256

Trans. Assembly Complete

11 611-0063 Shaft Assembly, Axle

12 10662B Spring, Plastic Ratchet

QTY.

1

1

1

KEY

NO.

13

PART

NUMBER

DESCRIPTION QTY.

634-0136 Wheel Assembly, Complete

634-0129

Ratchet Rim Ass’y, Complete 2

734-0210 Tire, Pneumatic, 10x4

2 734-0255 Valve, Tubeless Air

2

2

14

1

15

7 16

2 17

18

1

1

19

4

20

741-0487A

712-0456

712-3027 Nut, Hex Flange Lock, 1/4-20

714-0104 Pin, Internal Cotter

736-0366

748-0188B

748-0381

748-0405

734-1984

Bearing, Flange, .632 ID

Nut, Special Hex 1/4-20 4

Washer, Flat, .64 x 1.12 x .12

Pawl, LH .345 ID

Pawl, RH .345 ID (Not Shown) 2

Ratchet, Wheel, .5 Serr ID x 1.62

Hubcap, 4.0

24

2

2

2

4

4

2

4

2

2

2

Page 25

Sears Craftsman 6.5 H.P. Chipper-Shredder Vacuum Model 247.77763

24

KEY

NO.

1

PART

NUMBER

DESCRIPTION QTY.

618-0255 Transmission Assembly, Complete

Includes Ref. Nos. 2 thru 20

2 16500A

3 711-1118

Hex Bearing Cup 1

Shaft, Output w/ 6T Sprocket 1

4 717-1432 Gear, Helical 34T

5 721-0213 Seal, Oil, .625 X.812

736-0187 Washer, Flat, .64 x 1.24 x .06 HD

6

7 736-0336

8 741-0413

Washer, Flat, 5/8 x 1.0 2 25 712-0138

Bearing, Hex Flange, .631 ID

9 741-0414 Bearing, Flange, .629 ID

10 741-0415 Bearing, Flange, .566 ID

11

719-0325

12

748-0373

13 719-0324A

Housing, Lower 1

Bearing, Flange, .503 ID

Housing, Upper 1 31 738-0440 Shoulder Spacer, .375 x .165 1

14 748-0208A Bearing, Flange, .378 ID

15 710-0589

16 717-1433

17

721-0329

18 736-0314

Screw, Hex Tapp, #10-16 x .75 3 33

Shaft, Pinion 10T 1

Seal, Oil, .50 X .687 1 35

Washer, Thrust, .382 x .684 2

KEY

NO.

1

19 736-0520

20

21

PART

NUMBER DESCRIPTION QTY.

Washer, Flat, .504 x .70 x .030

741-0479

Bearing, Thrust, .375 x .812 1

656-0008 Pulley Ass’y, Idler w/ Bearing, 1

Includes Ref. No. 22

1 22

1

1

741-0556 Bearing, Needle, .375 x .375

23 710-0589 Screw, Hex Tapp, #10-16 x .75 1

24 710-1062

Screw, Hex w/ Patch, 1/4-20 x 1.25 1

Nut, Hex. 1/4-28

1

26

712-3045 Nut, Hex Jam, 5/16-24 L.H. Thd 1

1

27 732-0357A Spring, Extension, 1.12 Lg 1

1 28 736-0270 Washer, Bell, .265 x .75 x .06 1

29

1

30

1 32

736-0329

736-0425 Washer, Bell, .325 x .930 x .045

738-0826

Washer, Lock, 1/4

Shoulder Bolt, 1/4-28 x .375 1

756-0618 Pulley, Flat, 5.06 Dia 1

34

782-7569 Belt Keeper

782-7570

Bracket, Idler

25

1

1

1

1

2

1

1

Page 26

Sears Craftsman 6.5 H.P. Engine Model No. 143.986501

for Chipper-Shredder Vacuum Model 247.77763

279 161

V" 161A /

26

Page 27

Sears Craftsman 6.5 H.P. Engine Model No. 143.986501

for Chipper-Shredder Vacuum Model 247.77763

KEY

NO.

1

PART

NUMBER

37120A

Cylinder (Incl. 2)

2 26727 Dowel Pin

4 31857

5 30969

14 651052

15 37108

16 37110

30 36831

35 651053

37 29216

38 37109

40 40004

40005

41 36070

36071

42 40006

Oil Drain Extension

Extension Cap 154 650913 Rocker Arm Stud

Washer

Governor Rod

Governor Lever

Crankshaft 159 35626 Rocker Arm Cover Gasket

Screw, TorxT-15, 10-32 x 63/64"

Lock Nut, 10-32 161

Retaining Ring

Piston, Pin & Ring Set (Std.) 173

Piston, Pin & Ring Set (.010" OS)

Piston & Pin Ass'y (Std.) (Incl. 43) 182

Piston & Pin Ass'y (.010" OS) (Incl. 43) 184 26756 Carburetor To Intake Pipe Gasket

Ring Set (Std.)

DESCRIPTION

KEY

NO.

150

151 31673 Valve Spring Cap

153

155

157 650914 Nut, 1/4-28

158

160

161A

178

185

40007 Ring Set (.010" OS) 207

43 20381

45

46

32875A Connecting Rod Ass'y (Incl. 46 & 49) 224 36581 Intake Pipe Gasket

3261OA

48 35616

49 36611

50

37040

64 651015 Screw, 1/4-20 X 1-1/8"

69 36624

70 36625

75

80

27897 Oil Seal

30574A

81 30590A

82 30591

83

36057

86 650488

89 610961

119 36719

120

36721 Cylinder Head

Piston Pin Retaining Ring 223

Connecting Rod Bolt

Valve Lifter

Oil Dipper

Camshaft

238

239

240

245 36046

245A

Cylinder Cover Gasket

250

Cylinder Cover (Incl. 75 thru 83) 250A

251

Governor Shaft 252

Washer

Governor Gear Ass'y (incl. 81)

Governor Spool

275

277 650988 Screw, 1/4-20 x 2-9/32"

278

Screw, 1/4-20 X 1-1/4" 279

Flywheel Key

280 36893

Cylinder Head Gasket 305

307

125 36471 Exhaust Valve (Std.) (Incl. 151) 308

36472 Exhaust Valve (1/32" OS) (Incl. 151)

310

126 29314C Intake Valve (Std.) (incl. 151) 380

29315C

130

130A

650912 Screw, 5/16-18 x 1-1/2"

650999

135 34645

Intake Valve (1/32" OS) (incl. 151)

Screw, 5/16-18x2-41/64"

Resistor Spark Plug (RN4C)

390

400 36720 Gasket Set

PART

NUMBER

DESCRIPTION

37039 Valve Spring

36649 Push Rod Guide

35624A

Rocker Arm

36629 Push Rod

36630A Rocker Arm Cover

651008 Screw, 1/4-20 X 31/64"

651012

Stud

36675A Breather Tube

650852

Nut, 1/4-20

650451 Screw, 1/4-20 x 1"

36631 Intake Pipe

36632

Throttle Link

650451 Screw, 1/4-20 X 1"

28820 Screw, 10-32 X 1/2"

27272A Air Cleaner Gasket

36633A Air Cleaner Body (Incl. 239)

Air Cleaner Filter

36634 Air Cleaner Filter (Poly)

37073

Air Cleaner Cover

37074 Air Cleaner Baffle

650886 Wing Nut

650821

36722

36674

650852

Screw, 10-32 X 1/2"

Muffler

Spacer

Nut & Lock Washer

Heat Shield

35554 Oil Fill Tube

35499

"0" Ring

37079 Fill Tube Clip

36902 Dipstick

640025B

590736

— 754299A Replacement Short Block (Not Shown)

Carburetor (Incl. 184)

Rewind Starter

27

Page 28

Sears Craftsman 6.5 H.P. Engine Model No. 143.986501

for Chipper-Shredder Vacuum Model 247.77763

KEY

NO.

1 37111

PART

NUMBER

DESCRIPTION

Extension Spring

2 32600 Oil Seal

3

4 36622

5

6

11

12 650815

36621 Air Baffle (Left) 30

Air Baffle (Right) 32

30200 Screw, 10-24x9/16" Thd. 33

36623A Blower Housing Extension

611205

Flywheel 35

Bell Washer 36 36863

13 650816 Flywheel Nut

14 34443B Solid State Ignition

15 610118

16 651007

Spark Plug Cover 40 29443

Torx Screw T-15,10-24 x 15/16" 41

17 36711 Governor Link

18

36054

Ground Wire

20 36736 Control Bracket

21

22

24

610973

650821

651008

Terminal 46

Screw, 10-32X 1/2"

Screw, 1/4-20x31/64"

KEY

NO.

26

28

PART

NUMBER

DESCRIPTION

36638 Control Knob

36864 Blower Housing

650821 Screw, 10-32 X 1/2"

35985B Starter Cup

— Rivet (Purchase Locally)

34 30705 Fuel Line

26460 Fuel Line Clamp

Fuel Tank

37 36246

38 34080

Fuel Cap

Spacer

Wire Clip

36644 Fuel Tank Bracket

42 651010 Screw, 1/4-20x7/8" Thd.

43 36261

Lubrication Decal

44 35703 Speed Control Decal

590736 Rewind Starter

—

36720 Gasket Set (Not Shown)

28

Page 29

Sears Craftsman 6.5 H.P. Engine Model No. 143.986501

for Chipper-Shredder Vacuum Model 247.77763

carburetor

KEY

NO.

—

1

2 631767

4 631184

5

6 631036

7

16

PART

NUMBER

640025B

631615

631183

650506

632164

DESCRIPTION

Carburetor

Throttle Shaft & Lever Assembly

Throttle Return Spring

Dust Seal Washer

Dust Seal (Throttle)

Throttle Shutter

Shutter Screw

Fuel Fitting

17 650417 Throttle Crack Screw/ldle Speed

18 630766

20 640018

631867

25

27 631024

28 632019

29 631028

631021 Inlet Needle, Seat, & Clip Inci. 31)

30

631022 Spring Clip

31

35 36045

Tension Spring

Restrictor Screw

Float Bowl

Float Shaft

Float

Float Bowl "0"-Ring

Primer Bulb/Retainer Ring

36 640019 Main Nozzle Tube

37 632547 ”0''-Ring, Main Nozzle Tube

40 640015

44

27110

47

630748

631027 Welch Plug, Atmospheric Vent

48

High Speed Bowl Nut

Bowl Nut Washer

Welch Plug, Idle Mixture Well

KEY

NO.

—

1

PART

NUMBER

590736

590599A

2 590600

3 590696

4

590601

5 590697

590698

6

7 590699

8 590700

11

590705

12 590535

590701

13

DESCRIPTION

Rewind Starter

Spring Pin (Inci. 4)

Washer

Retainer

Washer

Brake Spring

Starter Dog

Dog Spring

Pulley & Rewind Spring Assembly

Starter Housing Assembly

Starter Rope (98" x 9/64" diameter)

Starter Handie

rewind

starter

29

Page 30

For the repair or replacement parts you need

delivered directly to your home

Call 7 am - 7 pm, 7 days a week

1 -800-366-PART

(1-800-366-7278)

For in-home major brand repair service

Call 24 hours a day, 7 days a week

1-800-4-REPAIR

(1-800-473-7247)

For the location of a

Sears Parts and Repair Center in your area

Call 24 hours a day, 7 days a week

1-800-488-1222

For information on purchasing a Sears

Maintenance Agreement or to inquire

about an existing Agreement

call 9 am - 5 pm, Monday-Saturday

1 -800-827-6655

REPAIR SERVICES

America's Repair Specialists

Page 31

Manual del propietario

6.5 caballos de fuerza

Autopropulsada

Astiiladora-Desmenuzadora-Aspiradora

Modelos No.

247.777763

Precaución:

Antes de operar este

equipo lea y observe todas

las reglas e instrucciones

de seguridad

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Printed in U.S.A.

770-10034

(7/98)

Page 32

TABLA DE MATERIAS

Contenido

Garantía

Reglas de seguridad 3 Servicio y ajustes

Armado 5 Almacenamiento

Operación

Página

2 Mantenimiento

8 Tabla de localización de fallas

Contenido

Página

13

15

17

18

INFORMACION DE GARANTIA

GARANTIA COMPLETA DE UN ANO PARA LA ASTILLADORA-ASPIRADORA A GASOLINA CRAFTSMAN

Por un año desde la fecha de compra cuando esta astilladora-aspiradora a gasolina Craftsman sea mantenida, lubricada y

puesta a punto de acuerdo con las instrucciones de operación y mantenimiento en el manual del operario, Sears reparará

libre de costo cualquier defecto de material o de mano de obra.

Esta garantía excluye las cuchillas, desgranadoras, filtros, bujías, bolsas del retén y neumáticos, las cuales son partes

desechadles que se desgastan durante el uso normal.

Esta garantía se aplica por 30 días solamente a partir de la fecha de compra, si la astilladora-desmenuzadora se usa para

fines comerciales o de alquiler.

EL SERVICIO DE GARANTIA ESTA DISPONIBLE EN EL CENTRO DE SERVICIO DE SEARS MAS CERCANO EN LOS

ESTADOS UNIDOS.

Esta garantía le otorga derechos legales específicos y usted puede también tener otros derechos que varían de estado a

estado.

SEARS, ROEBUCK AND CO. DEPT. D817WA, HOFFMAN ESTATES, IL 60179

ACCESSORIOS

Estos accesorios y aditamentos

estaban disponibles cuando la

astilladora-aspiradora se

compró originalmente. Están

también disponibles en la

mayoría de las tiendas

minoristas y centros de

catálogo y servicio de Sears. La

mayoría de las tiendas de

Sears pueden ordenar esos

artículos para usted con el

número de modelo de su

astil ladora-aspi radora.

Caballos de fuerza

Capacidad de aceite de motor

Capacidad de combustible 3 cuartos (sin plomo)

Bujía Champion RN4C

Presión del neumático

Filtro

de aire

Bujía Aceite Recipiente Estabilizador Tapón del manauera^de

de motor de gasolina apisonador Jp¡radora

ESPECIFICACIONES DEL PRODUCTO

6.5 H P

SAE 30 (20 onzas)

24 P.S.I.

Número de modelo

Número de serie.

Los números de modelo y de serie se encuentran en el

rotulo.pegado al producto.

Usted debería registrar el número de serie y la fecha de

compra y guardarlos en un lugar seguro para referencia

futura.

247.77763

Page 33

PRACTICAS SEGURAS DE OPERACION

Este símbolo señala instrucciones importantes de seguridad las cuales, si no se observan, podrían poner en

peligro la seguridad personal y/o la propiedad suya y de otras personas. Lea y observe todas las instrucciones de

A

A

A

Operación general

• Lea cuidadosamente esta guía del propietario en su

totalidad antes de intentar armar esta máquina. Lea,

comprenda y observe todas las instrucciones en la

máquina y en el manual(es) antes de la operación.

Guarde este manual en un lugar seguro para referencia

futura y regular y para ordenar piezas de repuesto.

• Su astilladora-aspiradora es una herramienta poderosa y

no un juguete. Por consiguiente ejerza una precaución

extrema en todo momento. Su unidad ha sido diseñada

para desempeñar dos tareas; astillar y aspirar vegetación

hallada en un patio normal. No la use para ningún otro fin.

• Nunca permita que niños menores de 16 años operen la

unidad. Los niños de 16 años de edad y mayores deben

operar solamente bajo una supervisión paterna estrecha.

Debe permitirse operar la unidad a individuos

responsables que estén familiarizados con estas reglas

de operación segura solamente.

• Mantenga el área de operación despejada de todas las

personas, particularmente niños pequeños y animales

domésticos. Apague el motor cuando están cerca de la

unidad.

• Al alimentar material al equipo, sea extremadamente

cuidadoso que no se incluyan piezas de metal, rocas,

botellas, latas u otros objetos extraños. Podrían resultar

lesiones personales o daños a la máquina.

• Use siempre lentes de seguridad o anteojos de

seguridad, durante la operación y al efectuar ajustes o

reparaciones, para proteger los ojos contra objetos

extraños que pueden ser despedidos por la máquina.

• Use zapatos de trabajo resistentes, de suela áspera y

pantalones y camisa ajustadas. Se recomiendan camisas

y pantalones que cubran los brazos y las piernas y

zapatos de puntera de acero. No use ropas holgadas ni

este manual antes de intentar operar su astilladora-aspiradora motorizada. No cumplir con estas instrucciones

puede resultar en lesiones personales. Cuando vea este símbolo obedezca su advertencia.

Su astilladora-aspiradora fue fabricada para operarse de acuerdo con las reglas para una opera

ción segura en este manual. Al igual que con cualquier tipo de equipo motorizado, la falta de

PELIGRO ^cuidado o error de parte del operador puede resultar en lesiones graves. No observar las

instrucciones siguientes de seguridad podría resultar en lesiones graves o en la muerte.

El escape del motor de este producto contiene substancias químicas conocidas por el Estado de California como

causantes de cáncer, defectos de nacimiento u otras lesiones reproductivas.

Esta unidad está equipada con un motor de combustión interna y no debe usarse en o cerca de tierras no

mejoradas cubiertas de bosques, matorrales, y/o hierbas, a menos que el sistema de escape esté equipado con

un supresor de chispas que cumpla con las leyes del estado o federales aplicables (de existir). Si se usa un

supresor de chispas debe ser mantenido en buenas condiciones de trabajo por el operador.

En el Estado de California lo indicado arriba es requerido por ley (Sección 4442 del Código de Recursos Públicos

de California). Otros Estados pueden tener leyes similares. Las leyes federales se aplican en las tierras federales.

Está disponible un supresor de chispas para el silenciador en su Centro de Servicio Autorizado Sears más

cercano (Vea la sección de PIEZAS DE REPUESTO de este manual).

joyas y sujete el cabello para que esté por encima de los

hombros. Pueden quedar atrapadas en las piezas

móviles. Nunca opere una unidad con los pies descalzos,

sandalias o zapatillas. Al alimentar material en la canaleta

de la astilladora, use guantes.

• No opere la unidad mientras está bajo los efectos del

alcohol o las drogas.

• No se incline demasiado. Manténgase firmemente

parado y en equilibrio en todo momento.

• Nunca coloque sus manos o ninguna parte de su cuerpo

o ropas cerca de o debajo de piezas giratorias.

Manténgase alejado en todo momento de la abertura de

descarga. Nunca inserte sus manos ni ninguna parte de

su cuerpo ni ropa dentro de la boquilla, canaleta de la

astilladora o la abertura de descarga ya que la hélice

giratoria puede causar lesiones graves.

• Si por alguna razón es necesario destapar la toma de

alimentación o de la abertura de descarga o inspeccionar

o reparar cualquier parte de la máquina donde una pieza

móvil puede entrar en contacto con su cuerpo o ropa,

apague la máquina, permita que se enfríe, desconecte el

conductor de la bujía de la bujía y aléjela de la bujía antes

de Intentar destapar, inspeccionar o reparar.

• Nunca opere la unidad sin que la bolsa de la aspiradora y

la canaleta de descarga estén bien fijadas a la unidad.

Para evitar que los objetos grandes sean impulsados, el

extremo grande de cierre a cremallera de la bolsa debe

estar cerrado.

• Nunca opere la unidad sin que la boquilla de entrada o el

aditamento opcional de la manguera estén

apropiadamente fijados a la unidad. Esos mecanismos

protegen al operador contra el contacto accidental con la

hélice giratoria. Nunca trate de convertir la unidad del

modo de boquilla al de manguera o viceversa con el

motor funcionando.

Page 34

• Nunca trate de retirar ni vaciar ia bolsa de la aspiradora

cuando el motor está funcionando. Apague el motor y

espere hasta que la hélice se detenga completamente

antes de retirar la bolsa. La hélice continúa girando

durante unos segundos después de apagar el motor.

Nunca coloque ninguna parte del cuerpo en el área de la

hélice hasta que esté seguro que la hélice ha detenido

su giro.

• Mantenga todas las guardas y mecanismos de

seguridad en su lugar y operando apropiadamente.

• No permita una acumulación de material procesado en

el área de descarga ya que esto impedirá la descarga

apropiada y puede resultar en contragolpe de la

canaleta de la astilladora.

• Mantenga su rostro y cuerpo detrás de la canaleta de la

astilladora para evitar un rebote accidental del material.

• Si el mecanismo de corte golpea un objeto extraño o si

su máquina comienza a emitir un ruido o vibración no

común, apague inmediatamente el motor, desconecte el

conductor de la bujía y mueva el conductor alejado de la

bujía. Permita que la máquina se detenga y tome los

pasos siguientes.

• Inspeccione por daños.

• Repare o reemplace las piezas dañadas.

• Inspeccione por piezas flojas y ajuste para asegurar una

operación segura continuada.

• El silenciador y el motor se calientan y pueden causar

quemaduras. No los toque.

• No permita que hojas u otros desechos se acumulen

sobre el silenciador del motor. Los desechos podrían

encenderse y causar un incendio.

® No opere el motor si se retira el filtro de aire o la cubierta

sobre la toma del carburador, excepto para ajustar. El

retiro de tales piezas podría crear un riesgo de incendio.

Niños

Pueden ocurrir accidentes trágicos si el operador no está

alerta a la presencia de niños pequeños. Los niños se

sienten atraídos a menudo a la actividad de astillado y

aspiración. Nunca suponga que los niños permanecerán

donde usted los vio por última vez.

• Mantenga a los niños fuera del área de trabajo y bajo los

ojos vigilantes de un adulto responsable que no sea el

operador.

• Esté alerta y apague la unidad si un niño entra al área.

• Nunca permita que niños menores de 16 años de edad

operen la astilladora-aspiradora.

Permita que ei motor se enfríe por dos minutos por lo

menos antes de cargar combustible.

• Vuelva a colocar la tapa de gasolina y limpie la gasolina

derramada antes de arrancar ei motor, ya que puede

causar un incendio o explosión.

• Apague todos los cigarrillos, cigarros, pipas y otras

fuentes de encendido.

• Nunca cargue combustible a la unidad bajo techo ya que

los vapores inflamables se acumularán en el área.

• Nunca almacene la máquina ni el recipiente de

combustible bajo techo donde haya llamas abiertas o

chispas, tales como calentadores de agua caliente a

gas, secadora de ropas u hornos.

• Nunca haga funcionar su máquina en un área cerrada ya

que el escape del motor contiene monóxido de carbono,

que es un gas inodoro, insípido y envenenador mortal.

• Para reducir el riesgo, mantenga el motor y el silenciador

libre de hojas, césped, y otras acumulaciones de

desechos. Limpie los derrames de combustible y aceite.

Permita que la unidad se enfríe por 5 minutos por lo

menos antes de arrancar.

• Asegúrese que la hélice y todas las piezas móviles estén

detenidas antes de limpiar, reparar o inspeccionar.

Desconecte el conductor de la bujía y mantenga el

conductor alejado de la bujía para prevenir el arranque

accidental. No use soluciones inflamables para limpiar el

filtro de aire.

• Mantenga todas las tuercas, pernos y tornillos bien

ajustados para asegurarse que el equipo esté en buenas

condiciones de trabajo.

• Nunca manipule los mecanismos de seguridad.

Inspeccione regularmente su operación apropiada.

• Después de golpear un objeto extraño, apague

inmediatamente el motor, desconecte el conductor de la

bujía de la bujía, e inspeccione completamente la unidad

por daños. Repare el daño antes de arrancar y operar la

unidad.

• No altere ni manipule la graduación del regulador del

motor. El regulador controla la velocidad operativa

máxima del motor. Es peligroso hacer funcionar el motor

a una velocidad excesiva y causará daños al motor y a

otras piezas móviies de las máquinas.

• inspeccione frecuentemente la bolsa de la aspiradora

por desgaste. Reemplace si está gastada o dañada.

• Cuando no está en uso, mantenga la bolsa de la

aspiradora libre de desechos.

Servicio