Bolens 247.29773 User Manual

owners

manual

lODEL NO

►47.297730

ZAUTION:

lead SAFETY

tULES and

NSTRUCTIONS

»refully

SEARS, ROEBUCK AND Oa, diloagoJlL 60684 USLA.

and SIMPSONS-SEARS UMITED. Toronto. Canada

RT NO. 770-6993

Sears

3 H.P. CHAIN DRIVE

TILLER

• Assembly

• Operating

• Maintenance

• Repair Parts

PRINTED IN U.S.A.

SrrrrrrrTrrrrTTTTTTTTTVTTTTTTTTTYTrrryWTTTTrgTTT^TrrrTTrrrT

rrrrrrrrrrrrins

FULL ONE YEAR WARRANTY

For one year from the date of purchase, Sears will repair any defect in material or

workmanship in this TILLER at no charge.

I If the TILLER is used for commercial or rental purposes, this warranty applies for only

* thirty days from the date of purchase,

Warranty service is available by contacting the nearest Sears store or Service Center

throughout the United States.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co.

Sears Tower

BSC 41 -3

Chicago, IL 60684

IMPORTANT

is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this

anuai in a safe place for future reference and for ordering replacement parts.

lis unit is shipped WITHOUT GASOLINE or OIL. After assembly, see operating section of this manual

r proper fuel and amount.

Dur tiller is a precision piece of power equipment, not a play thing. Therefore exercise extreme caution at

I times.

SAFE OPERATION PRACTICES FOR TILLERS

Read the Operating and Service Owner’s

Manual carefully. Be thoroughly familiar with

the controls and the proper use of the equip

ment.

Never allow children to operate a power tiller.

Only persons well acquainted with these rules

of safe operation should be allowed to use

your tiller.

Keep the area of operation clear of all

persons, particularly small children and pets.

Do not operate equipment when barefoot or

wearing open sandals. Always wear substan

tial footwear.

Do not wear loose fitting clothing that could

get caught on the tiller.

Do not start the engine unless the shift lever

is in the neutral (N) position.

11. Do not fill gasoline tank while engine is

running. Spilling gasoline on hot engine may

cause a fire or explosion.

12. Do not run the engine while indoors. Exhaust

gases are deadly poisonous.

13. Be careful not to touch the muffler after the

engine has been running, it is hot.

14. Before any maintenance work is performed or

adjustments are made, remove the spark plug

wire and ground it on the engine block for

added safety.

15. Use caution when tilling near buildings and

fences, rotating tines can cause damage or

injury.

16. Before attempting to remove rocks, bricks

and other objects from tines, stop the engine

and be sure the tines have stopped

completely. Disconnect the spark plug wire

and ground to prevent accidental starting.

Do not stand in front of the tiller while

starting the engine.

Do not place feet and hands on or near the

tines when starting the engine or while the

engine is running.

Do not leave the tiller unattended with the

engine running.

Do not walk in front of the tiller while the

engine is running.

park arrest muffler is available as an accessory part. The part number is listed in the parts section of this

nual. Check muffler legal requirements in your area.

17. Check the tine and engine mounting bolts at

frequent intervals for proper tightness.

18. Keep all nuts, bolts and screws tight to be

sure the equipment is in safe working

condition.

19. Never store the equipment with gasoline in

the tank inside of a building where fumes may

reach an open flame or spark. Allow the

engine to cool before storing in any

enclosure.

NOTE

INDEX

Warranty

Safe Operation Practices

Introduction............................................................. 4

Hardware Identification...........................................5

Tiiler Identification...................................................6

Assembly Instructions

Engine Preparation

...................................................................

........................................

............................................

.................................................

2

3

7

9

Operation................................................................10

Maintenance...........................................................12

Tiiier Repair Parts

Tiller Accessories

Engine Repair Parts..............................................21

How To Order Repair Parts

..................................................

..................................................

..................

Back Cover

16

19

INTRODUCTION

This Product has been designed, engineered and manufactured to give you the best possibie dependability

and performance.

Should you experience any problem you cannot easily remedy, please contact your nearest Sears, or

Simpson-Sears Service Department. They have well qualified, competent trained technicians and the proper

tools to service or repair this unit.

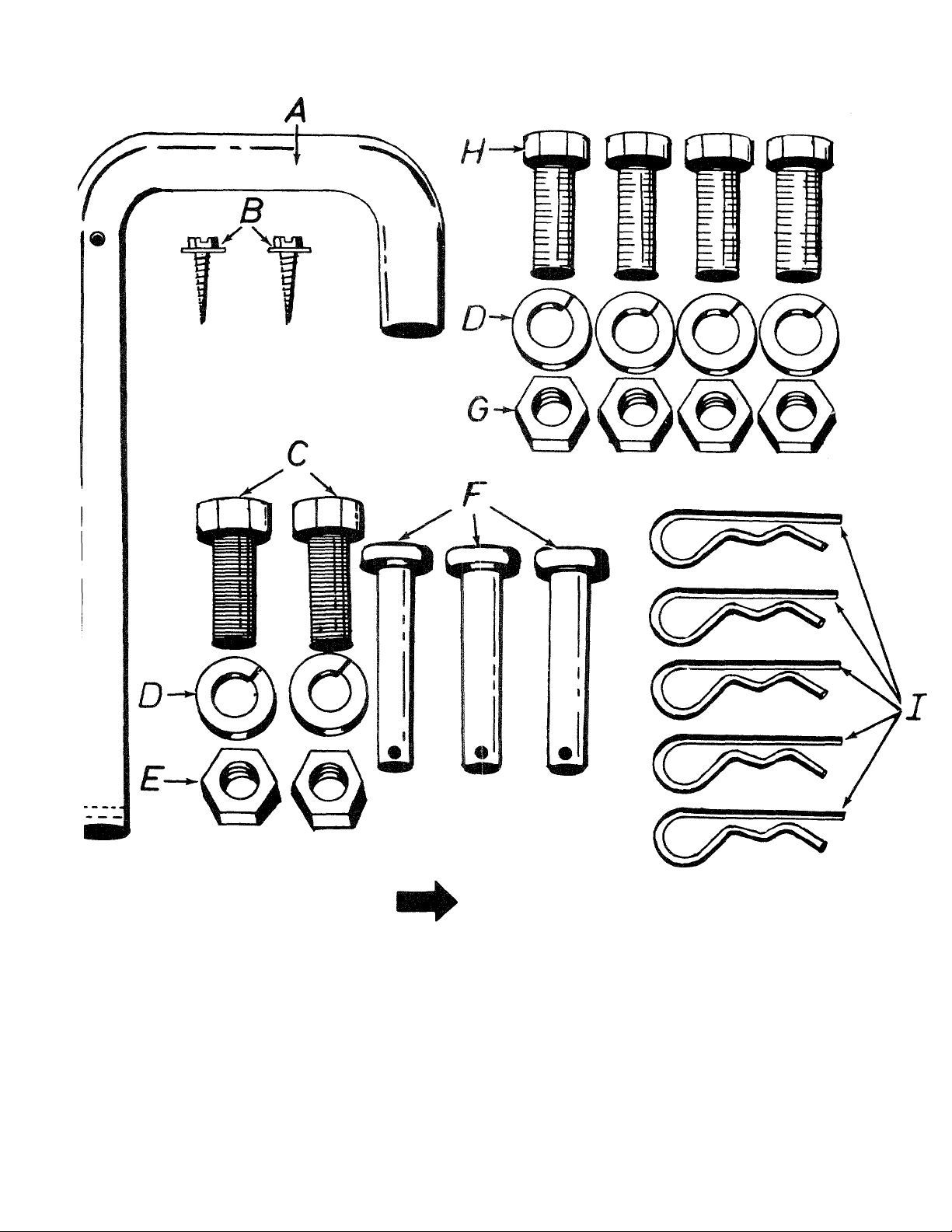

DDC AOOdUIDI\/ PARTS IN CARTON: See figures 2 and 3.

PRc-AooEivIdLY

NOTE

The right and left side of your tiiier

is determined from operator’s posi

tion.

Before any step is undertaken, the instructions for

that step should be read through.

TOOLS REQUIRED: See Figure 1

1. (1) V2” Socket, open or box wrench.

2. (2) 9/16” Socket, open or box wrench.

3. (1) Va” Flat Screwdriver.

'■:34 .jirHT

X

V

FIGURE 1.

MATERIALS REQUIRED:

1. Funnel (for gas and oil - NOTE: DO NOT MIX)

2. SAE 30 heavy duty detergent oil. 1 Va pints.

3. Gas (regular)

4. Cleaning rag

FIGURE 2.

m

FIQtJRES.

\

/

CURE 4. (SHOWN IN FULL SCALE)

THE LETTERS LISTED BELOW WILL BE

REFERRED TO THROUGHOUT THE FOLLOWING

TEXT FOR EASIER HARDWARE IDENTIFICA

TION.

NOTE

LIST OF CONTENTS IN HARDWARE PACK:

A (1) “U”-Clevis Pin V2” Dia.

B (2) Self Tapping Screws #8 x .62”

C (2) Hex Screws 3/8-24x1.00”

D (6) Lockwasher 3/8” Screw

E (2) Hex Nut 3/8-24 Thread

F (3) Clevis Pins

G (4) Hex Nuts 3/8-16 Thread

H (4) Hex Screws 3/8-16 x 1.00”

I (5) Hair Pin Cotter

TILLER

IDENTIFICATION

Recoil Rope

Starter

Handle Bar

/

Shift

Lever •

Throttle

Ccnîroî

-Control Rod

Fuel Tank

■Drag Stake

4

/

Tine

Assemblies

-Stake Support

Beit Cover

'Wheel Yoke

FIGURES.

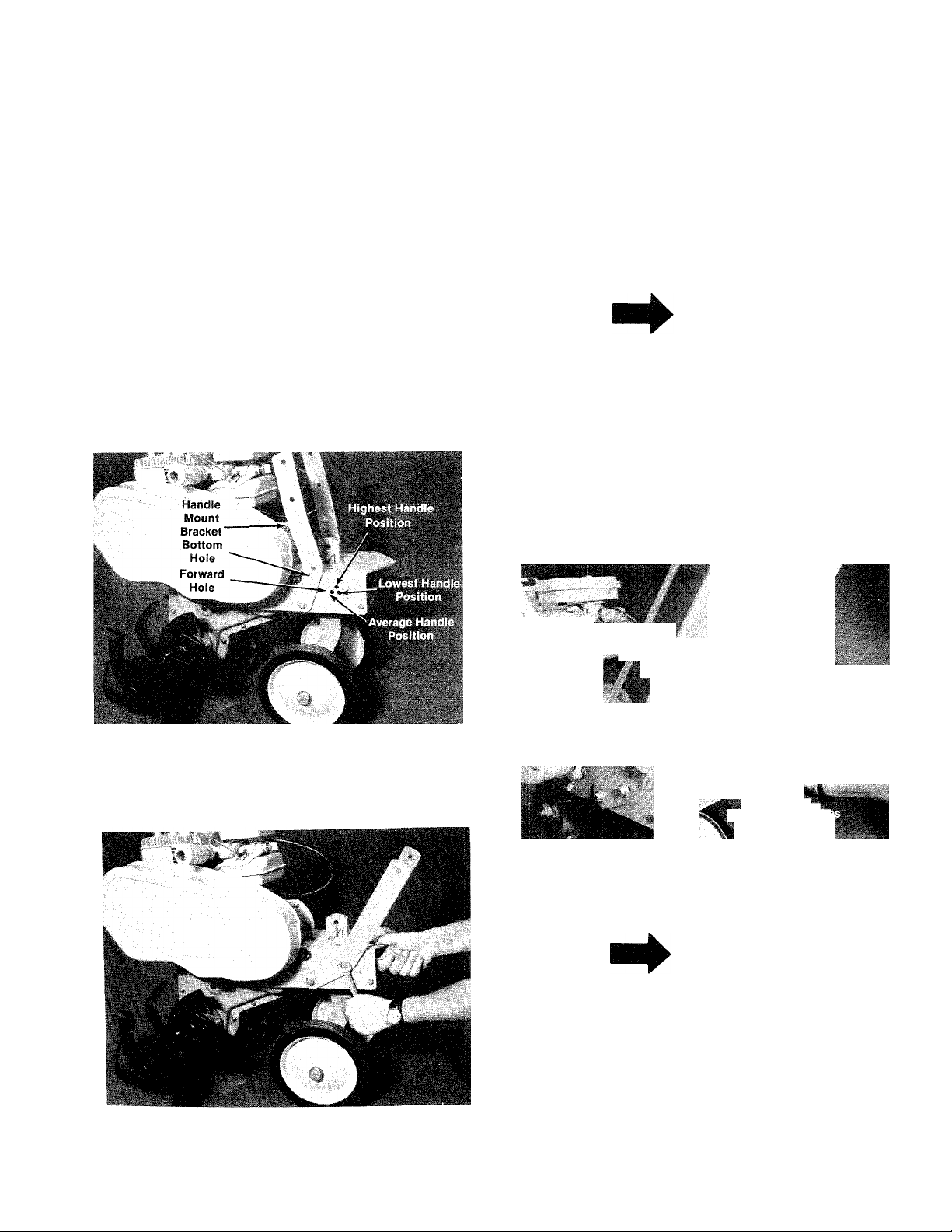

ASSEMBLY

INSTRUCTIONS

Secure handle mount brackets with hex bolt (C),

lockwasher (D) and hex nut (E). See hardware,

page 4.

1. Handle Panel Attachment.

For shipping purposes, the handle mounting

brackets are pivoted forward. With a 9/16” wrench

loosen the hex bolt holding the handle mount

brackets. See figure 6.

Pull handle mount brackets back so that the

bottom hole in bracket lines up with forward hole

in chassis. See figure 5, 6 and 7.

The handle panel is attached by sliding it down

over the handle brackets on the chassis and

installing four hex bolts in the lower holes of the

handle panel. Place bolts through the handle

panel; head to the outside. See figure 6.

NOTE

Do not tighten until all four bolts are

in place.

Four hex bolts (H), lockwashers (D) and hex nuts

(G) will be found in the hardware pack. See figure

8.

Handle Bracket

FIGURE 6.

Handle Pans!

■

' i

iV <

FIGURES.

2. Throttle Control Lever.

NOTE

The throttle control has four holes in the

lever bracket. The holes on the outside

edge are to be used for mounting on this

unit. See figure 9.

FIGURE 7.

Place throttle control lever up through the handle

panel and secure with two self tapping screws (B),

using a V4” flat screwdriver. See figure 10.

-v!2;" . ■

^e these'

Do not use

these holes

•■ '-'M

Place the shift lever (located on handle panel) in

neutral (N) position. Place other end of control

rod in shift lever and secure with hair pin cotter.

Idler Bracket.

' ■* ’*■':’'»'J

FIGURE 9.

^1

?■

Self Tapping

Screw

Throttle

Control V

J

%

Fnrrula and

■it'irpi.n C:;ri2r

..'■h'i

FIGURE 11.

4. Tine Attachment.

a. The outer tines have been reversed on the

tine shaft for shipping purposes. See

figure 12.

Remove outer tines from the tine shaft and

reinstall with the tine hub facing inward as

illustrated in figure 13. Secure tines with

clevis pins (F) and hair pin cotters (I).

b. The inner tine assemblies have been

installed at the factory and in their correct

operating position and do not require

changing.

c. See tine adjustment for information on

changing width of tilling path, page 11.

Screwdriver

FIGURE 10.

3. Clutch Control Rod.

The control rod comes from the factory with the

ferrule preadjusted. (See figure 11.) Place ferrule

in idler bracket. Secure with hair pin cotter.

NOTE

Figure 11 has the belt guard re

moved for clarity, it is not necessary

to remove for control rod assembly.

FIGURE 12.

Clevis Pin

FIGURE 13.

5. Drag Stake Support Attachment.

Slide the drag stake support into the chassis and

secure with “U” clevis (A) and hair pin cotter (!).

See figure 14.

FIGURE 15.

ENGINE

PREPARATION

in fresh

ddc of gasoline

FIGURE 14.

6. Drag Stake Attachment.

Slide the drag stake into the drag stake support

depth and secure with clevis pin (F) and hair pin

cotter (I). See figure 15.

FIGURE 16.

1. Before starting, fill crankcase with 1 V4 pints

of SAE 30 heavy duty detergent oil or to top of

filler neck. Be sure that the engine is level.

See figure 16.

2. Change oil after first 2 hours of operation and

every 25 hours thereafter. Check oil every 8

operating hours.

3. Fill fuel tank with clean fresh regular grade of

gasoline.

Loading...

Loading...