Bolens 19967-1 User Manual

NOTE*. Universal Drive Shaft 717-0135 is required to assemble snow thrower to tractor.

If 42" or'50" Deck Assembly is included with tractor. Universal Drive Shaft

717-0135 will not be required.

ASSEMBLY • OPERATION • MAINTENANCE • PARTS

40” SNOW THROWERS

ATTACHMENT

Important: Model Numbers

Read Safety Rules and

Instructions Carefully

Thank you for purchasing an

American built product.

PRINTED IN U.S.A.

191-967A

19967-1

FORM NO. 770-0312

LIMITED WARRANTY

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm,

any part or parts found to be defective in material or workmanship. Transportation charges

under this warranty must be paid by the purchaser unless return is requested by

MTD PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse,

excessive use, accident, neglect, improper maintenance, alterations, or unless the unit

has been operated and maintained in accordance with the instructions furnished. This

warranty does not apply to the engine, motor, battery, battery charger or component parts

thereof. Please refer to the applicable manufacturer’s warranty on these items.

This warranty will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distributor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit wilt not be accepted by the factory unless prior written

permission has been extended by MTD.

This warranty gives you specific legal rights. You may also have other rights which vary

from state to state.

SAFE OPERATION PRACTICES FOR SNOW

' TRAINING

1. Read the Owner’s guide instruction manuai

carefuily. Be throughiy familiar with the

controls and proper use of the equipment.

Know how to stop the unit and disengage the

controls quickly.

2. Never allow children to operate equipment.

Never allow adults to operate equipment

without proper instructions.

3. Keep the area of operation clear of all

persons, especially small children and pets.

4. Exercise caution to avoid slipping or falling,

especially when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the

equipment is to be used and remove all door

mats, sleds, boards, wires and other foreign

objects.

2. Disengage all clutches and shift into neutral

before starting engine.

3. Do not operate equipment without wearing

adequate winter outer garments. Wear foot

wear which will improve footing on slippery

surfaces.

4. Handle fuel with care. It is highly flammable.

(A) Use approved fuel container.

(B) Never add fuel to a running engine or hot

^;-*«**% ©nQin©.

(C) Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors.

(D) Replace gasoline cap securely and wipe

up spilled fuel.

5. Use a grounded three wire plug-in for all units

with electric drive motors or electric starting

motors.

6. Adjust collector housing height to clear gravel

or crushed rock surface.

7. Never attempt to make any adjustments while

engine is running (except where specifically

recommended by manufacturer).

8. Let engine and machine adjust to outdoor

temperature before starting to clear snow.

OPERATION

1. Do not put hands or feet near rotating parts.

Keep clear of discharge opening at all times.

2. Exercise extreme caution when operating on

or crossing a gravel drive, walks, or roads.

Stay alert for hidden hazards or traffic. Do not

carry passengers.

3. After striking a foreign object, stop the

engine, remove wire from spark plug,

thoroughly inspect the snow thrower for any

damage, and repair the damage before

restarting and operating the snow thrower.

4. If the snow thrower should start to vibrate

abnormally, stop the engine and check

immediately for the cause. Vibration is

generally a warning of trouble.

5. Stop engine whenever you leave the operating

position, before unclogging the collector/

THROWERS

impeller housing or discharge guide, and

making any repairs, adjustments, or inspec

tions.

6. Take all possible precautions when leaving

the vehicle unattended. Disengage the power

take-off, lower the attachment, shift into

neutral, set the parking brake, stop the

engine, and remove the key.

7. When cleaning, reparing, or inspecting make

certain collector/impeller, and all moving

parts have stopped. Disconnect spark plug

wire and keep away from plug to prevent

accidental starting.

8. Do not run engine indoors, except when

starting engine and for transporting snow

thrower in or out of building. Open doors.

Exhaust fumes are dangerous.

9. Do not clear snow across the face of slopes.

Exercise extreme caution when changing

direction on slopes. Do not attempt to clear

steep slopes.

10. Never operate snow thrower without guards,

plates, or other safety protection devices in

place.

11. Never operate snow thrower near glass

enclosure, automobiles, window wells, drop

off, etc. without proper adjustments of snow

thrower discharge angle. Keep children and

pets away.

12. Do not overload machine capacity by

attempting to clear snow at too fast a rate.

13. Never operate machine at high transport

speeds on slippery surfaces. Use care when

backing.

14. Never direct discharge at bystanders or allow

anyone in front of unit.

15. Disengage power to collector/impeller when

transporting or not in use.

16. Use only attachments and accessories

approved by the manufacturer of snow

thrower (such as wheel weights, counter

weights, cabs, etc.).

17. Never operate the snow thrower without good

visibility or light. Always be sure of your

footing and keep a firm hold on the handles.

Walk, never run.

MAINTENANCE AND STORAGE

1. Check shear bolts, engine mounting bolts,

etc. at frequent intervals for proper tightness

to be sure equipment is in safe working

condition.

2. Never store machine with fuel in the fuel

tank inside a building where open flame or

spark are present. Allow engine to cool before

storing in any enclosure.

3. Always refer to owner’s guide instructions for

important details if snow thrower is to be

stored for an extended period.

4. Run machine a few minutes after throwing

snow to prevent freeze up of collector/

impeller.

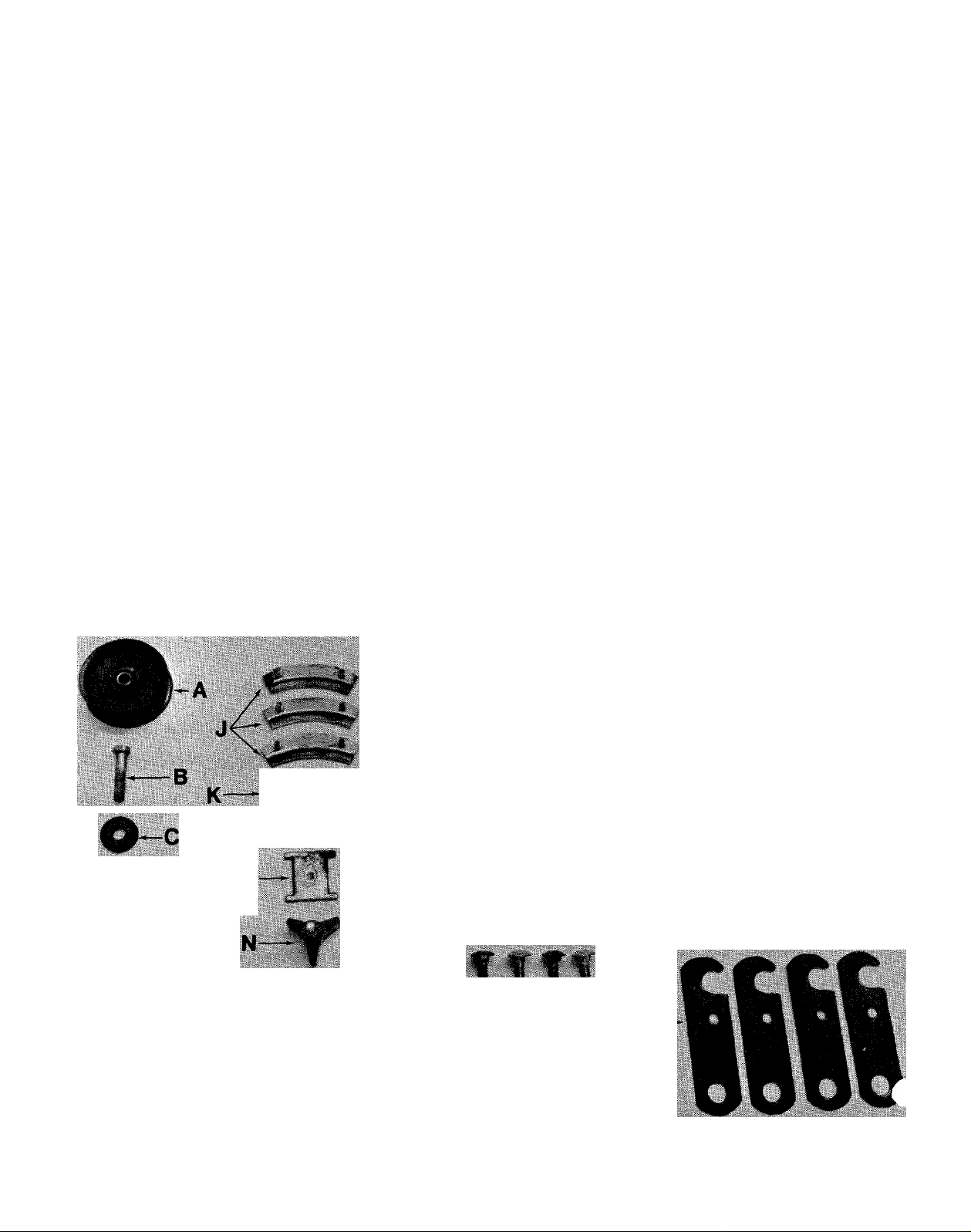

CONTENTS OF HARDWARE PACK: (See figure 1)

A

B

C

D

E (2)

F (2) Hair Pin Cotters Y

G (10) Hex bolts 3/8-16 x 3/4 long

H (10) Flat washers 3/8" I.D.

1 (10) Hex lock nuts 3/8-16 thread

J

K (6)

L

M

N

0

P

Q

R (4)

S

Idler pulley

(1)

Hex bolt 3/8-24 x 1-3/4" long U (4)

(1)

Belleville washer

(1)

Hex lock nut 3/8-24 thread W

(1)

Clevis pin

(3) Flange keepers

Hex lock nuts 1/4-20 thread

Cotter pin

(1)

Chute crank bracket

(1)

Hand knob

(1)

(2) Hex bolts 5/16-18 x 1" long

Lock washers 5/16" I.D.

(2)

(2) Hex nuts 5/16-18 thread

Hex bolts 1/2-13 x 1-1/4" long

(4) Spacers

o-Iinililll

O O O

P—C o

T (4)

V (4)

X (4)

Z

AA (4)

AB

AC

AD

AE

AF

AG (4)

AH

Al

AJ

AK

o-n

Lock washers 1/2" I.D.

Hex lock nuts 1/2-13 thread

Carriage bolts 5/16-18 x 5/8" long

(4)

Lock washers 5/16" I.D.

Hex nuts 5/16-18 thread

(4)

Carriage bolts 3/8-16 x 3/4" long

(4)

Belleville washers 3/8" I.D..

Hex nuts 3/8-16 thread

(2) Shoulder bolts 7/16-14 thread

(2)

Lock washers 7/16" I.D.

(2) Hex nuts 7/16-14 thread

(4)

Hex bolts 5/16-18 x 3/4" long

(4)

Lock washers 5/16" I.D.

Hex nuts 5/16-18 thread

(4)

Hex bolts 7/16-20 X 1" long

(4)

Lock washers 7/16" I.D.

(4)

Hex nuts 7/16-20 thread

(4) Front hanger links

AB—Y f

I—r * - ? ; : ; i 0 « Q—« *

i-D

a i-E

AC —O O

AD—'S C

"-i AElln

s—e 0 0 c ®'

T—o COO

V-

W-

X-

rtf

C-- c c

c c

Y

AH’

Al —O O O O

Aj__« « i >?

lit*

z

AK

AA—v*

FIGURE 1

BOLT lYi

ELLEVILLE

ASHER (Z)

ASSEMBLY INSTRUCTIONS

TOOLS REQUIRED

(1) Adjustable wrench

(1) 9/16" Open end or box wrench

(1) 1/2" Open end or box wrench

(1) 7/16" Open end or box wrench

(1) 3/4" Open or box wrench

(1) 11/16" Open end or box wrench

(1) Drift or punch

(1) Pairofpliars

FIGURE 2

HOUSING

SKID SHOE HEX NUT (AA)

\

DRIFT CUTTER

CARRIAGE BOLT IV)

HEX NUT IX)

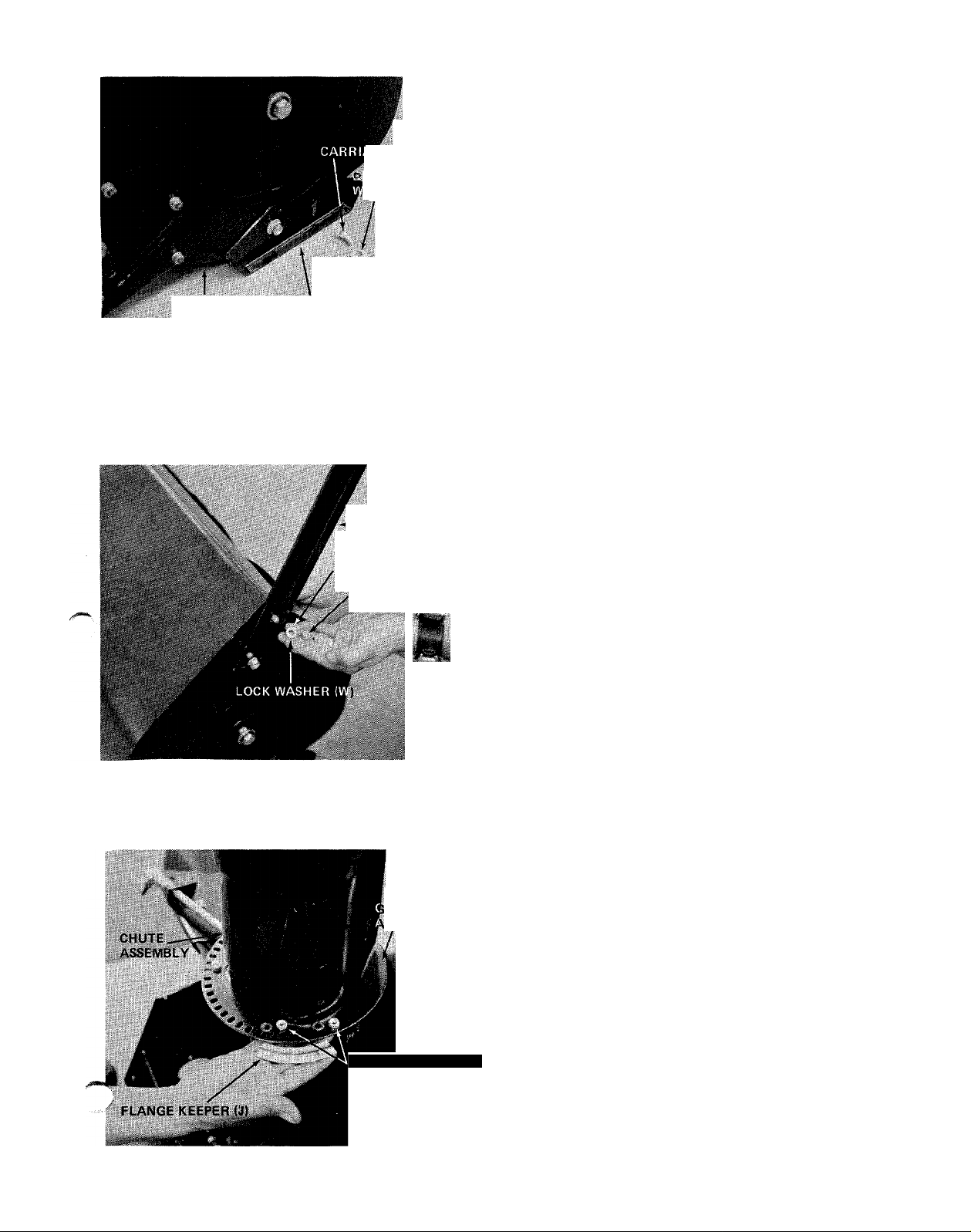

1. Assemble the skid shoes to each side of snow

_ thrower housing. Place head of carriage bolt (Y)

to the inside of housing and fasten with be)leville

washer (Z) and hex nut (AA). Only make finger

tight at this time. See figure 2.

2.

Assemble the drift cutters to each side of snow

thrower housing. Place head of carriage bolt (V)

to the inside of housing and fasten with lock

washer (W) and hex nut (X). A 1/2" wrench is

required. See figure 3.

FIGURES

FIGURE 4

REASE THIS

REA

HEX LOCK NUTS (K)

Apply a little grease to the lip of the chute

opening before assembly of chute. See figure 4.

4.

Set the chute assembly in place on the chute

opening of snow thrower housing. Secure in place

with three flange keepers (J) and six hex lock

nuts (K). A 7/16" wrench is required. See figure 4.

IDLl ri PULLEY 'A, HUH Sll

FIGURE 5

IDLER PULLEY (A)

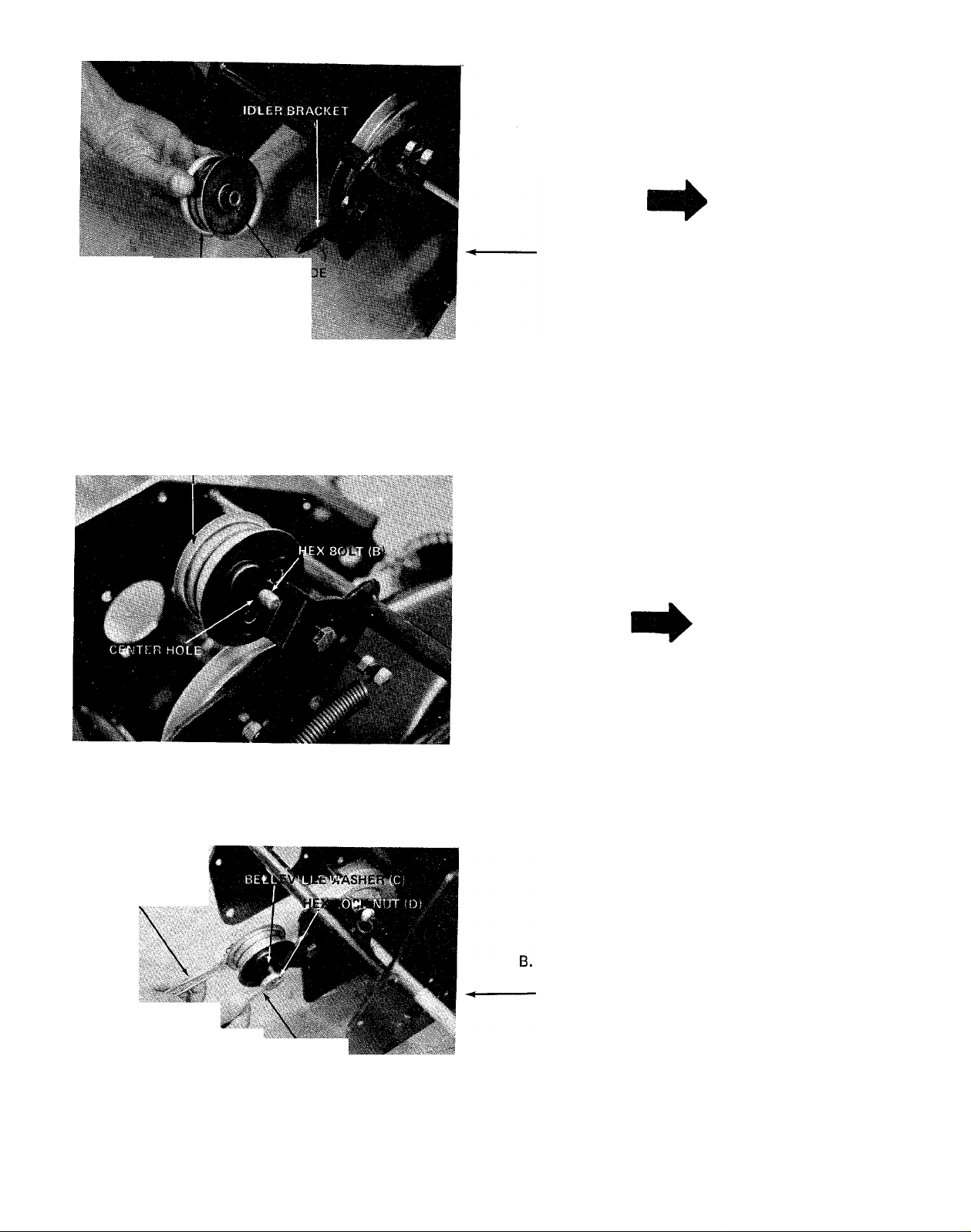

5. Assemble the idler pulley (A) to the idler bracket

on snow thrower housing.

NOTE

Hub side of idler pulley must be

assembled towards the idler bracket.

See figure 5.

A.

Place hex bolt (B) through idler pulley (A)

and through center hole on idler bracket. See

figure 6.

FIGURE 6

ADJUSTABLE

WRENCH

■

NOTE

The idler bracket has three holes for

belt tension adjustment. Normally, the

center hole on the idler bracket is used

when assembling the idler pulley. When

the belt is assembled to the snow

thrower (Step numbers 11, 12 and

13), the idler pulley may be moved to

the top hole if the belt is too tight.

Secure idler pulley (A) and hex bolt (B) to

idler bracket with belleville washer (C) and hex

lock nut (D). An adjustable wrench and a 9/16"

wrench is required. See figure 7. Tighten securely.

9 1G" WRENCH ^

FIGURE 7

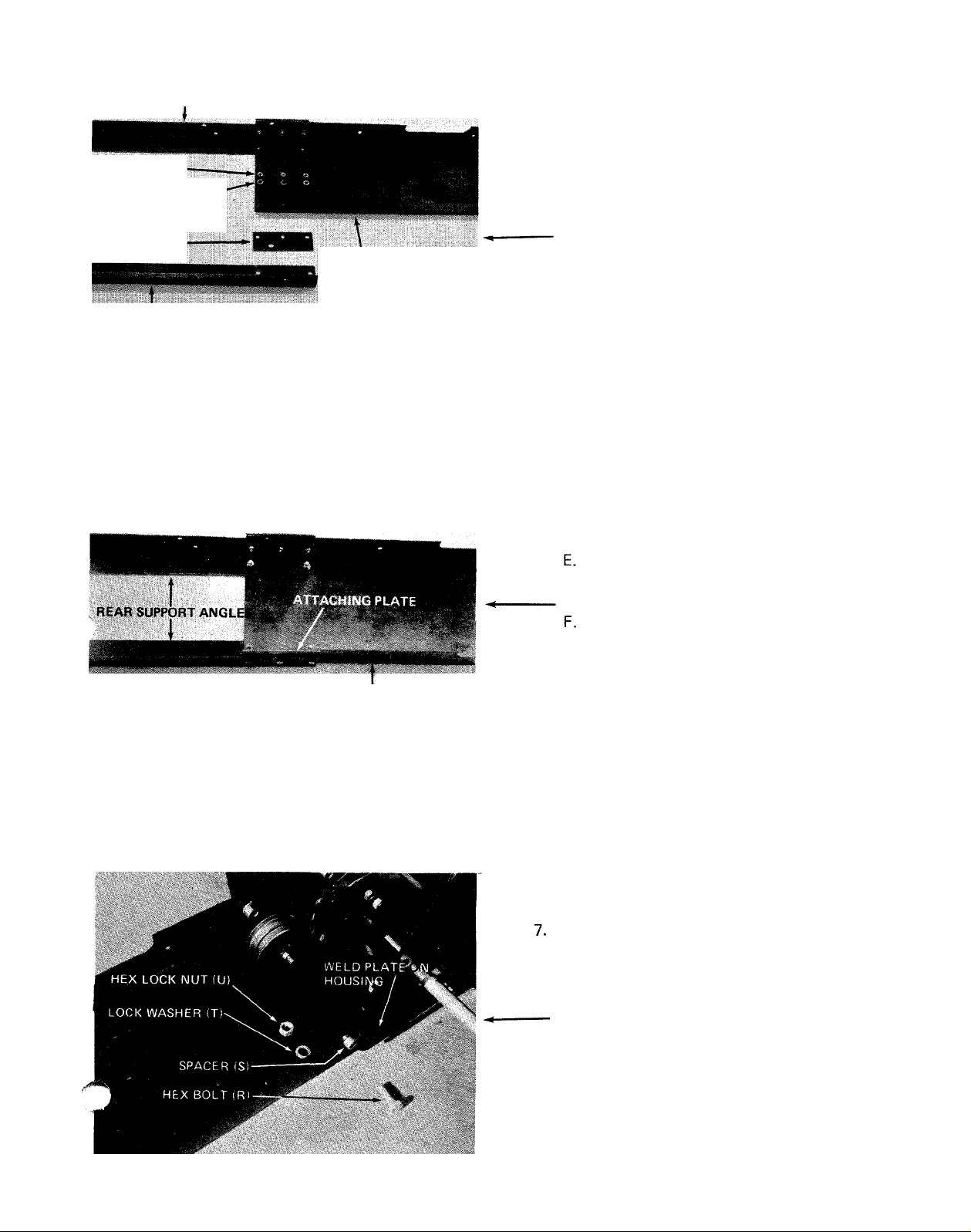

REAR SUPPORT ANGLE L.H.

HEX NUT (I)

LOCK WASHER (H)

ATTACHING

PLATE

REAR SUPPORT

ANGLE R.H.

FIGURE 8

FRONT SUPPORT

CHANNEL

■HEX BOLT (G)

6. Preassemble the front support channel and the

rear support angles as follows;

A. Place the front support channel on a work

bench or the floor. Place the rear support

angles in position as shown in figure 8.

B. Place the attaching plates between front

support channel and rear support angles. See

figure 8.

C. Place hex bolts (G) through holes in side of

rear support angles, attaching plates and front

support channel. See figure 8.

D. Secure hex bolts (G) with lock washers (H)

hex nuts (I). Make only finger tight. See

figure 8.

FIGURE 9

Raise front support channel up and secure

the bottom four holes with hex bolts (G),

lock washer (H) and hex nuts (I). See figure 9.

Tighten all ten bolts and nuts with 9/16"

wrench and adjustable wrench.

FRONT SUPPORT CHANNEL

Assemble the front support channel to the snow

thrower housing. Place the front support channel

between weld plates on housing. On one side,

place spacers (S) between channel and housing

and secure with hex bolts (R), lock washers (T)

and hex lock nuts (W). See figure 10. Just start

nuts on by hand. Using a drift pin or punch on

by hand. Using a drift pin or punch on the other

side, line up spacers (S) between channel and

housing and secure in same manner. An adjustable

wrench and a 3/4" wrench is required.Tighten

securely.

FIGURE 10

Loading...

Loading...