Bolens 190756 User Manual

28" TILLER

Model Numbers

190-756-000

ATTACHMENT

N

IMPORTANT: Read Safety Rules and Instructions Carefully

Thank you for purchasing an American-built product.

190756

FORM NO. 770-7025H

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SA -ETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSON

AL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

A

BEFORE AHEMPTING TO OPERATE YOUR U JIT. WHEN YOU SEE THIS SYMBOL— A HEED ITS WARNING.

SAFE OPERATION PRACTICES

DANGER:

A

I. GENERAL OPERATION

1. Read, understand, and follow all instructions in 1he manual

before attempting to attach and operate your tiller Keep this

manual in a safe place for future reference and f< r ordering

repiacement parts.

2. Only allow responsible adults familiar with both tha tiller and

tractor instructions to operate the machine. Know c mtrols and

how to stop the machine quickly.

3. Do not put hands or feet under or near rotating ( arts. Keep

clear of tiller tines at all times.

4. Clear the area of objects such as rocks, toys, wire, etc. which

could become caught in the tiller tines. Always v»ear safety

glasses or eye shields during operation or while performing an

adjustment or repair, to protect eyes from foreign ot jects.

5. Be sure the area is clear of other people and pets before tilling.

Stop machine if anyone enters the area.

6. Never carry passengers. Only the operator should ide on the

unit and only ride in the seat.

7. Disengage tiller before shifting into reverse and tacking up.

Always look down and behind before and while back ng.

8. Slow down before turning. Operate the tractor smot thiy. Avoid

erratic operation and excessive speed.

9. Never leave a running machine unattended. Always disengage

attachment, place transmission in neutral, set park jrake, stop

engine and remove key before dismounting.

A. Raise and disengage tiller before making sharp turns.

Leaving tiller lowered and engage may adversely offset

steering/control of machine.

10. Disengage tiller when not tilling.

II. Stop engine and wait until tiller comes to a con píete stop

before making any repairs, adjusting or removing any rocks or

debris.

12. Till only in daylight or good artificial light.

13. Do not operate the machine while under the influer ce of alco

hol or drugs.

14. Watch for traffic when operating near or crossing ro sdways.

15. Use extra care when loading or unloading the machine into a

trailer or truck. This unit should not be driven up or down a

ramp onto a trailer or truck under power, becau ¡e the unit

could tip over, causing serious personal injury. Th( unit must

be pushed manually to load or unload properly.

16. Wear sturdy, rough-soled work shoes and close-fil ting slacks

and shirts. Do not wear loose fitting clothes or je\/elry. They

can be caught in moving parts. Never operate a mit in bare

feet, sandals, or sneakers.

17. Check overhead clearance carefully before driving u ider power

lines, wires, bridges or low hanging tree brand es, before

entering or leaving buildings, or in any other situé tion where

the operator may be struck or pulled from the i nit, which

could result in serious injury.

18. Disengage all attachment clutches, thoroughly dspress the

brake pedal, and shift into neutral before attempting to start

engine.

11. SLOPE OPERATION

Slopes are a major factor related to loss of control and tip-over

accidents which can result in severe injury or death. All slopes

require extra caution. If you cannot back up the slope o if you feel

uneasy on it, do not till on it.

This cutting machine is ;apahle of amputating hands and feet and throwing objects. Failure to observe

the following safety instructions could result in serious injury or death.

Till up and down slopes, not across.

Remove obstacles such as rocks, limbs, etc.

Watch for holes, ruts, bumps and objects hidden under the soil

(e.g. rocks). Uneven terrain could overturn the machine.

Use slow speed. Choose a low enough gear so that you will not

have to stop or shift while on the slope. Always keep tractor in gear

when going down slopes to take advantage of engine braking

action.

Keep all movement on the slopes slow and gradual. Do not make

sudden changes in speed or direction. Rapid engagement or brak

ing could cause the front of the machine to lift.

Avoid starting or stopping on a slope. If tires lose traction, disen

gage tiller and proceed slowly straight down the slope.

For your safety, use the slope gauge included as part of this manual

to measure slopes before operating this unit on a sloped or hilly

area. If the slope is greater than 15° as shown on the slope gauge,

do not operate this unit on that area or serious injury could result.

Do not turn on slopes unless necessary; then, turn slowly and

gradually downhill, if possible.

Do not operate unit near drop-offs, ditches or embankments. A

wheel over the edge or an edge caving in could cause sudden over

turn.

Do not operate tractor on wet grass. Reduced traction could cause

sliding.

Do not try to stabilize the machine by putting your foot on the

ground.

III. CHILDREN

Tragic accidents can occur if the operator is not alert to the pres

ence of children. Children are often attracted to the machine and

the tilling activity. Never assume that children will remain where

you last saw them.

IV. SERVICE

DO:

DO NOT:

1. Keep children out of the tilling area and in watchful care of an

adult other than the operator.

2. Be alert and turn machine off if children enter the area.

3. Before and when backing, look behind and down for small chil

dren.

4. Never carry children. They may fall off and be seriously injured

or interfere with the safe machine operation.

5. Never allow children to operate the machine.

6. Use extra care when approaching blind corners, shrubs, trees

or other objects that may obscure vision.

1. Use extra care in handling gasoline and other fuels. They are

flammable and vapors are explosive.

a. Use only an approved container.

b. Never remove gas cap or add fuel with the engine running.

Allow engine to cool at least two minutes before refueling.

Do not smoke.

c. Never refuel the machine indoors.

d. Never store the machine or fuel container inside where

there is an open flame, or spark, such as a water heater,

space heater, clothes dryer and the like.

2. Never run a machine inside a closed area.

3. Check frequently and keep nuts and bolts tight and keep equip

ment in safe working condition.

4. Never tamper with safety devices. Check their proper operation

regularly. Use all guards as instructed in this manual.

5. To reduce fire hazard, keep machine free of grass, leaves or

N

other debris build-up. Clean up oil or fuel spillage. Allow

machine to cool before storing.

6. Stop and inspect the equipment for damage if you strike an

object (e.g. rock). Repair, if necessary, before re-starting and

operating the machine.

7. Never make adjustments or repairs with the engine running.

8. Check brake operation frequently. Adjust and service as

required.

9. Muffler, engine, and belt guards become hot during operation

and can cause a burn. Allow to cool down before touching.

10. Do not change the engine governor settings or overspeed the

engine.

DANGER: of power equipment, carelessness or error on the part of the operator can result in serious injury. If you vio

Your unit was built to be operated according to the rules for safe operation in this manual. As with any type

A

late any of these rules, you may cause serious injury to yourself or others.

ASSEMBLY

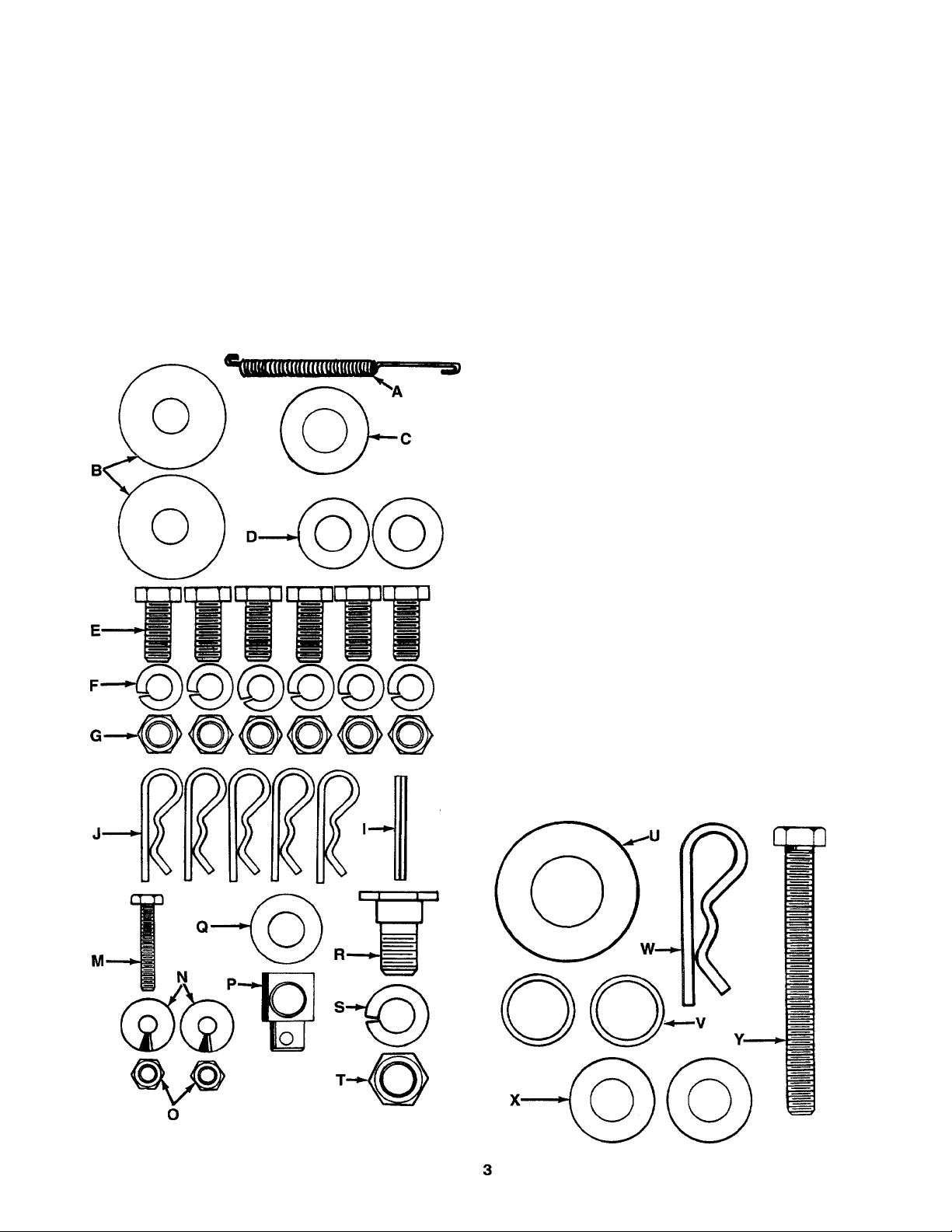

Contents of Hardware Pack (See figure 1):

A

B

C

D

E

F

G

I

J

K

M

N

N

0

P

Q

R

S

T

u

V

w

X

Y

*Not used on all models

Extension Spring

(1)

Flat Washers 1/2“ I.D. x 1-1/2" O.D.

(2)

Flat Washer 5/8" I.D. x 1-1/4" O.D.

(1)

Flat Washers 1/2" I.D. x 1" O.D.

(2)

Hex Bolts 3/8-24 x 7/8" Long

(6)

Lock Washers 3/8" I.D.

(6)

Hex Nuts 3/8-24 Thread

(6)

Spiral Pin

(1)

Hairpin Clips 1/2" Diameter

(5)

Extension Springs (Not Shown)

(4)

Hex Bolt 1/4-20 x 1.25“ Long*

(1)

Cupped Washers 1/4" I.D.*

(2)

Hex Nuts 1/4-20 Thread*

(2)

Ferrule

(1)

Spacer 1/2" I.D. x 1" O.D. x 1/2" Long

(1)

Shoulder Bolt

(1)

Lock Washer 1/2" I.D.

(1)

Hex Jam Nut 1/2-20 Thd.

(1)

Flat Washer 1/2" I.D. x 1-1/4" O.D.

(1)

Split Spacers .505" I.D. x .57" O.D.

(2)

Hairpin Clip 3/8" Dia.

(1)

Flat Washers 3/8" I.D. x 5/8" O.D.

(2)

Hex Bolts 5/16-18 x 3-1/4" Long

(2)

■N,

FIGURE 1.

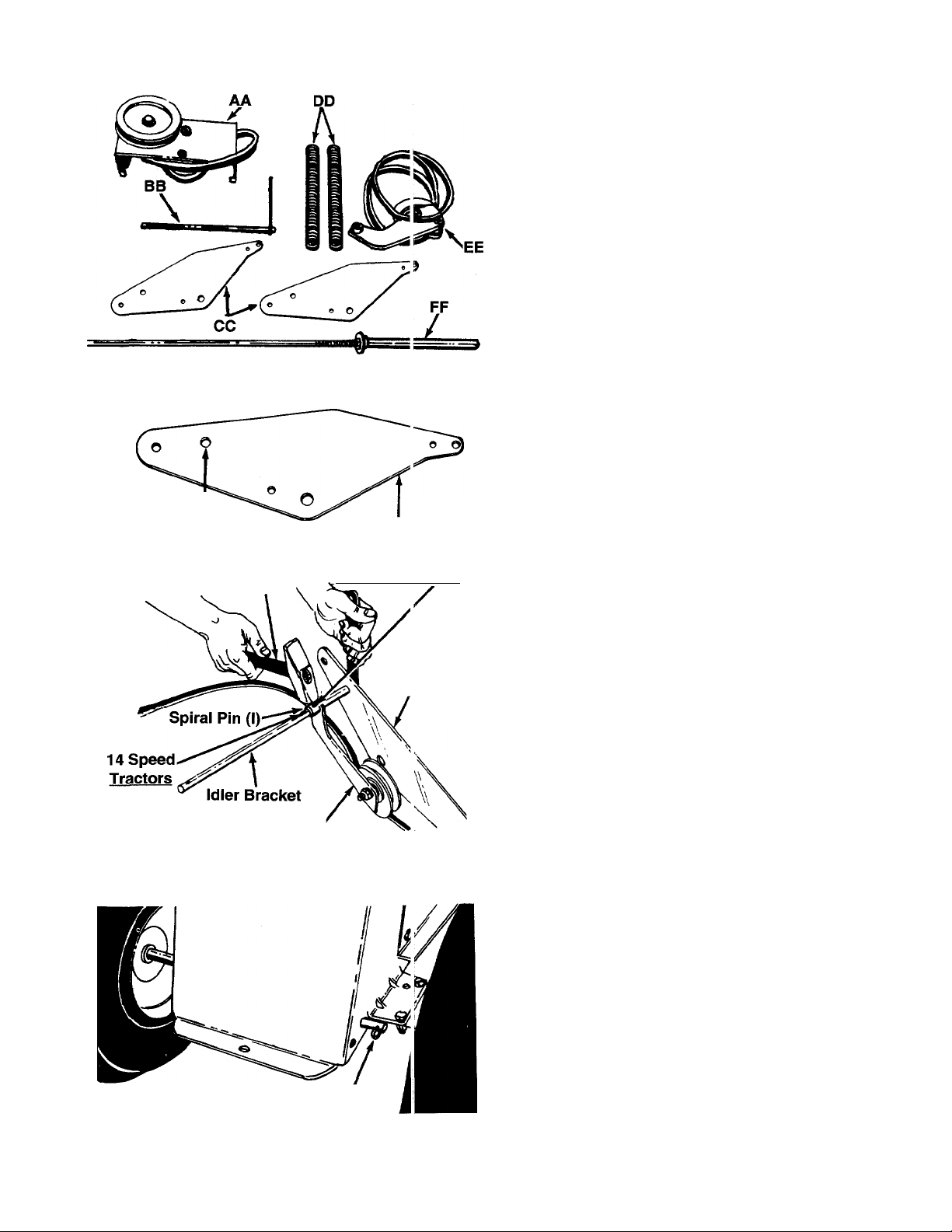

FIGURE 2.

Use This Hole

For Mounting

Idler Bracket

Support Arm

FIGURE 3.

Hammer

Support Arm (BB)

Idler Bracket

Assembly (EE)

Support Pivot

Bracket (CC)

Ail Other Tractors

Supp< >rt Pivot

Bracl:et (CC)

'Loose Parts in Carton (See figure 2):

AA (1) Carriage Bracket Assembly

BB (1) Idler Bracket Support Arm Assembly

CC (2) Support Pivot Brackets

DD (2) Compression Springs

EE (1) Idler Bracket Assembly

FF (1) Lift Rod Assembly

NOTE: Right and ieft hand side of the unit is deter

mined from the driver’s seat, facing forward.

1. Remove the cutting deck from your tractor if one

is attached.

2. Preassemble the idler bracket support arm (BB)

to one support pivot bracket (CC) and idler brack

et assembly (EE) as follows.

A. Place the idler bracket support arm down

through the hole in support pivot bracket

----------

shown in figure 3. Then slide the idler bracket

assembly over the idler bracket support arm.

B. Secure the idler bracket assembly to the idler

bracket support arm using spiral pin (I), using

the hole in the idler bracket support arm as

follows. See figure 3.

14 Speed Tractors: Secure by placing spiral pin in

the hole further away from the support pivot bracket.

All Other Tractors: Secure by placing spiral pin in

the hole nearest the support pivot bracket.

FIGURE 4.

Hairpin

Clip

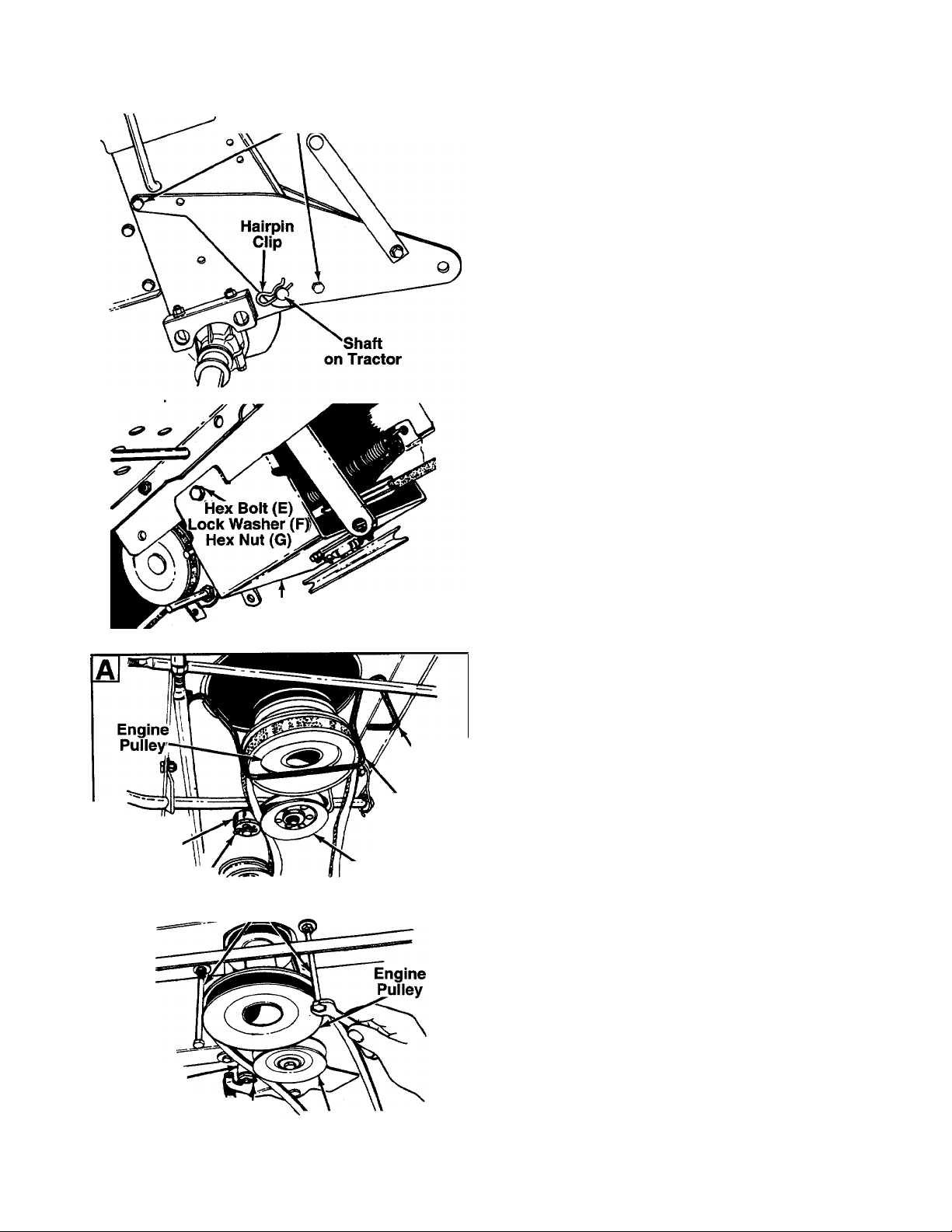

3. Remove the two hairpin clips from the shaft on

■ the rear of your tractor. See figure 4. These will

be reassembled in steps 4 and 7.

4. Place the support pivot bracket (with idler bracket

and support arm attached) in position on the rear

left hand side of tractor. See figure 5. Place large

hole in pivot bracket over shaft on tractor. Secure

with one hairpin clip removed in step 3.

5. Remove the transmission cover for easier access

when installing the support pivot brackets to the

tractor frame.

Hex Bolts (E)

Lock Washers (F)

s

Hex Nuts (G)

6. Align the holes in the support pivot bracket with

the holes in the tractor frame. Secure the support

pivot bracket to the tractor frame with hex bolts

(E), lock washers (F) and hex nuts (G) as shown

— in figure 5.

7. Assemble the other support pivot bracket to the

right hand side of tractor in the same manner,

securing shaft on tractor with hairpin clip removed

in step 3.

8. Tighten securely all four nuts and bolts which

were used in assembly of pivot support brackets.

N

FIGURE 5

FIGURE 6.

Round

Hairpin Clip

B

Belt

Guard

i;

(Belt Keepers)

Hex Bolts

Carriage Bracket

Assembly (AA)

fdler Pulley

Belt

Guard

Release

Wire

Beit

Guard

9. Secure end of idler bracket support arm assembly

on the right side of tractor with one flat washer

(D) and hairpin clip (J).

10. Place carriage bracket assembly (AA) in position

beneath the running board support rod on the

tractor so belt will attach to engine pulley. Secure

each side of carriage bracket to frame with hex

bolts (E), lock washers (F) and hex nuts (G).

------

Tighten securely. See figure 6.

11. If so equipped, remove the round belt guard from

the idler on tractor by removing the hairpin clip.

------

See figure 7A or 7B.

12. Remove the engine pulley belt guard by either

unscrewing the belt guard release and swinging

the engine pulley belt guard out of the way (see

figure 7A), or removing the two long hex bolts

which act as belt keepers (see figure 7B).

13. Place the belt which is preassembled to the car

riage bracket assembly around the idler pulley

and engine pulley on the tractor.

14. Reassemble the round belt guard and hairpin clip.

Reassemble the engine pulley belt guard(s).

Round

Belt

Guard Hairpin

FIGURE 7.

Clip

Idler Pulley

Loading...

Loading...