Bolens 190-746-000 User Manual

$1.00

28" TILLER

ATTACHMENT

IMPORTANT: Read Safety Rules and Instructions Carefully ^

Thank you for purchasing an American-built product.

Model Numbers

190-746-000

19746

TMO-33603B

FORM NO. 770-5307D

A

IMPORTANT

RULES FOR SAFE OPERATION

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD EN

DANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL

INSTRUCTIONS IN THIS MANUAL BEFORE ATTE ./IPTING TO OPERATE YOUR UNIT. FAILURE TO COMPLY WITH

THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL— A HEED ITS

WARNING.

t DANGER 1

Your unit was built to be operated according to the rules for safe operation in this manual.

As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. If you violate any of these rules, you may cause serious injury to yourself

or others.

A

READjTHE OWNER'S MANUAL carefully in its entirely

before attempting to assemble or operate this unit. I feep

this manual in a safe place for future and regular refer ince

and for ordering replacement parts.

This unit is a precision piece of power equipment not

2.

a plaything. Therefore exercise extreme caution at all

times.

Know the controls and how to stop the machine qui ckly.

3.

Do not allow children to operate vehicle. Do not i How

4.

adults to operate it without proper instruction. Only per

sons well acquainted with these rules of safe open ition

should be allowed to use your tiller attachment.

Wear sturdy, rough-soled work shoes and close-fitting

5.

slacks and shirts to avoid entanglement in the mc ving

parts. Never operate a unit in bare feet, sandal;, or

sneakers.

To prevent injury, do not carry passengers or give lides.

Keep children, pets and bystanders out of the area while

tilling. Only the operator should ride on the unit and on

ly ride in the seat.

Check overhead clearance carefully before driving i nder

7.

power lines, guy wires, bridges or low hanging tree

branches, before entering or leaving buildings, or in any

other situation where the operator may be struck oi pull

ed from the unit, which could result in serious injury

To maintain control of the unit and reduce the pos sibili-

8.

ty of upset or collision, operate the tractor smoothly

Avoid erratic operation and excessive speed.

Keep the area of operation clear of all persons, parti' ;ular-

ly small children and pets. Stop engine when the / are

in the vicinity of your unit. Although the are of opera

tion should be completely cleared of foreign objei ;ts, a

small object may have been overlooked and could be

accidently thrown by the tiller in any direction and i ;ause

injury to you or a bystander.

Stop the blade(s) when crossing gravel drives, wa ks or

10.

roads.

Disengage all attachment clutches and shift into n sutral

11.

before attempting to start engine

Disengage power to attachment(s) and stop engine

12.

before leaving operating position.

Do not put hands or feet near or under rotating narts.

13.

Keep clear of the tiller at all times as the rotating tines

can cause injury.

Disengage power to attachment(s) and stop engine

14.

before making any repairs or adjustments. Disconne it the

spark plug wire and keep the wire from the plug tn pre

vent accidental starting.

15. Before attempting to remove rocks, bricks and other

objects from tines, stop the engine and be sure the tines

have stopped completely. The tines may continue to

rotate for a few seconds after the engine is-shut off.

Therefore, be sure the tines have stopped completely.

Disconnect the spark plug wire and keep the wire away

from the plug to prevent accidental starting.

16. Disengage power to attachment(s) when transportating

or not in use.

17. Take all possible precautions when leaving vehicle un

attended such as disengaging power take-off, lowering

attachments, shifting into neutral, setting parking brake,

stopping engine and removing key.

18. Do not stop or start suddenly when going uphill or

downhill till up and down face of steep slopes; never

across the face. Use extreme caution if it is necessary

to drive the tractor up an incline or back the tractor down

an inclne because the front of the tractor could lift and

rapidly flip over backward which could cause serious

injury.

19. Reduce speed on slopes and in sharp turns to prevent

tipping or loss of control. Always keep the tractor in gear

when going down steep hills to take advantage of engine

braking action.

20. Stay alert for holes in terrain and other hidden hazards

which may cause the unit to tip over.

21. Use care when pulling loads or using heavy equipment.

A. Use only approved drawbar hitch points.

B. Limit loads to those you can safely control.

C. Do not turn' sharply. Use care when backing.

D. Use counterweight(s) or wheel weights when sug

gested in owner's manual.

Watch out for traffic when crossing or near roadways.

22.

When using any attachments, never direct discharge of

23.

material toward bystanders nor allow anyone near

vehicle while in operation.

Handle gasoline with care. It is highly flammable.

24.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a running or

hot engine or fill fuel tank indoors. Wipe up spilled

gasoline.

C. Open doors if engine is run in garage Exhause fumes

are dangerous. Do not run engine indoors.

Rules for Safe Operation (continued)

25. Keep the vehicle and attachments in good operating con

dition, and keep safety devices in place. Use guards as

instructed in operator's manual.

26. Keep all nuts, bolts, and screws tight to be sure the equip

ment is in safe working condition.

27. Never store the machine with fuel in the fuel tank inside

a building where ignition sources are present, such as

hot water and space heaters, clothes dryers, and the like.

Allow the engine to cool before storing in any enclosure.

28. To reduce fire hazard, keep engine free of grass, leaves

or excessive grease.

29. The vehicle and attachments should be stopped and in

spected for damage after striking a foreign object. The

damage should be repaired before restarting and

operating the equipment.

30. Do not change the engine governor settings or overspeed

the engine.

31. When using the vehicle with tiller, proceed as follows:

(1) Till only in daylight or in good artificial light.

(2) Never make any adjustments while engine is

running if operator must dismount to do so.

(3) Use caution when tilling near buildings and fences.

Rotating tines can cause damage or injury.

(4) Check the tine mounting bolts at frequent intervals

for proper tightness.

32. Look behind to make sure the area is clear before placing

the transmission in reverse and continue looking behind

while backing up. Disengage tiller before shifting into

reverse and backing up.

33. This unit should not be driven up a ramp onto a trailer

or truck under power, because the unit could tip over,

causing serious personal injury. The unit must be push

ed manually to load properly.

ASSEMBLY INSTRUCTIONS

NOTE

Right and left hand side of the unit is

determined from the driver's seat,

facing forward.

FIGURE 1

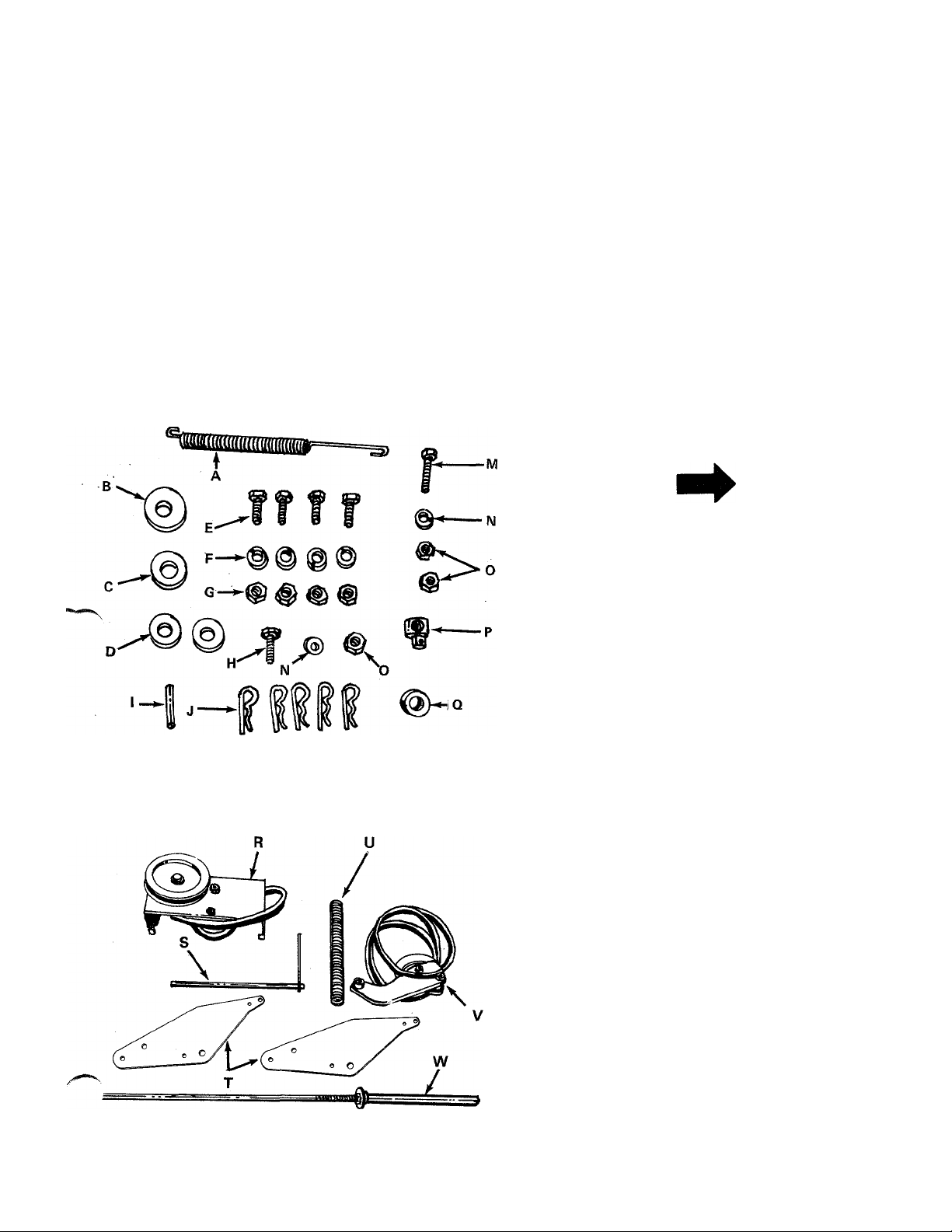

-Contents of Hardware Pack {See figure 1):

A (1)

B (1)

C (1)

D (2)

E

F

G

H

I

J

K

M^(l)

N (2)

O (3)

P (1)

Q (1)

Extension Spring

Flat Washer 1/2" I.D. x 1-1/2" O.D.

Flat Washer 5/8" I.D. x 1-1/4" O.D.

Flat Washers 1/2" I.D. x 1" O.D.

Hex Bolts 3/8-24 x 7/8" Long

(4)

Lock Washers 3/8" I.D.

(4)

Hex Nuts 3/8-24 Thread

(4)

Hex Bolt 5/16-24 x 1" Long

(1)

Spiral Pin

(1)

Hairpin Cotters

(5)

Extension Springs (Not Shown)

(4)

Hex Bolt 5/16-24 x 1-1/2" Long

Lock Washers 5/16" I.D.

Hex Nuts 5/16-24 Thread

Ferrule

Spacer 1/2" I.D. x 1" O.D. x 1/2" Long

• Loose Parts in Carton (See figure 2):

R (1) Carriage,Bracket Assembly

S (1) Idler Bracket Support Arm Assembly

T (2) Support Pivot Brackets

U (1) Compression Spring

V (1) Idler Bracket Assembly

W (1) Lift Rod Assembly

FIGURE 2

FIGURE 3

IDLER BRACKET

ASSEMBLY (V)

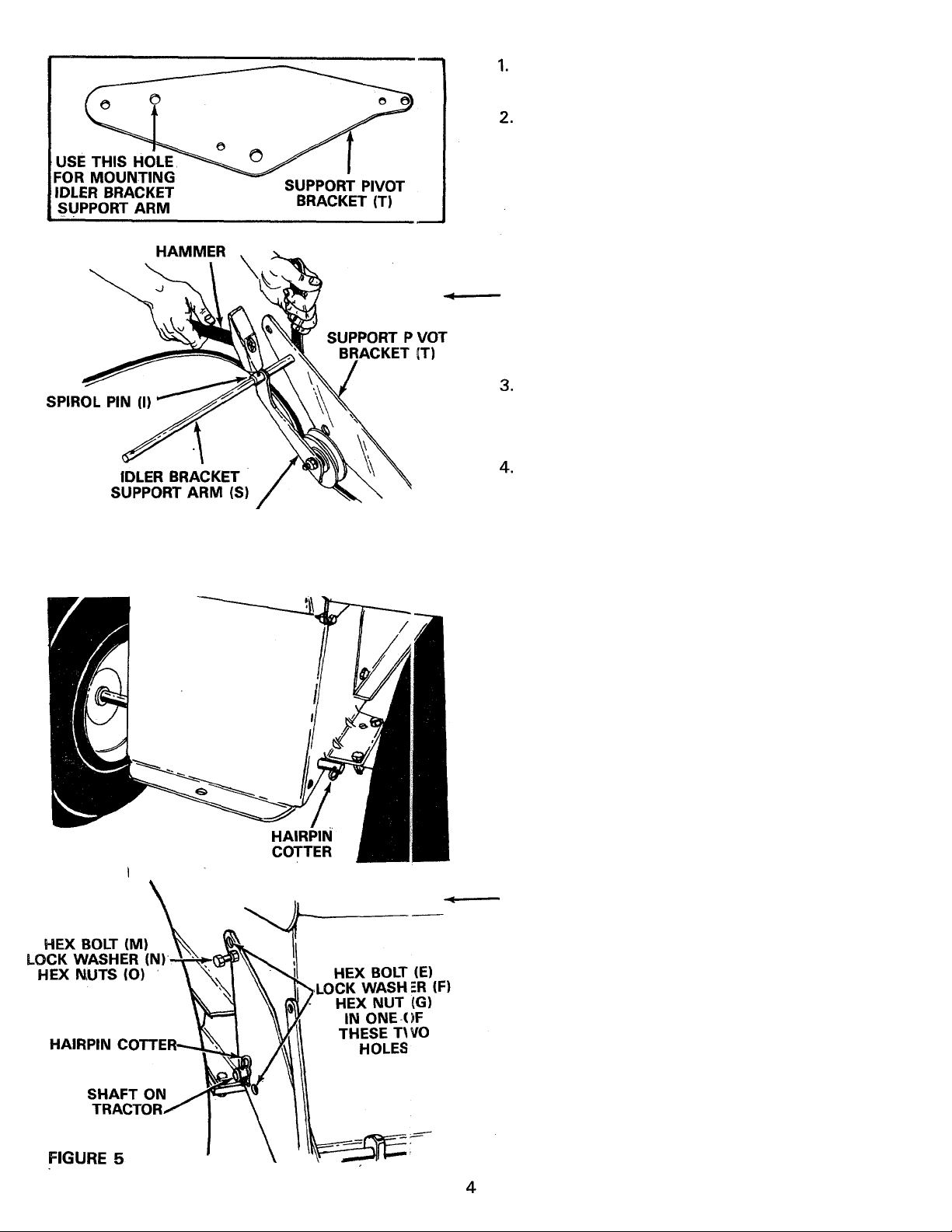

Remove the cutting deck from your tractor if one

is attached.

Preassemble the idler bracket support arm (S)

to one support pivot bracket (T) and idler bracket

assembly as follows.

A. Place the idler bracket support arm down

through the hole in support pivot bracket

shown in figure 3.

B. Next, slide the idler bracket assembly (V)

over the idler bracket support arm. Secure

with spiral pin (I). See figure 3. Be certain

pivot support bracket is assembled as

shown before securing with spiral pin.

Remove the two hairpin cotters from the shaft

on the rear of your tractor. See figure 4. These

will be reassembled in steps 4 and 8.

Place the support pivot bracket (with idler

bracket and support arm attached) in position

on the rear left hand side of tractor. See figure

5. Place large hole in pivot bracket over shaft

on tractor. Secure with one hairpin cotter

removed in step 3.

FIGURE 4

5. Thread one hex nut (0) all the way onto hex bolt

(M) (1 1/2" long).

6. Align the holes in the support pivot bracket with

the holes in the tractor frame. Secure the

support pivot bracket to the tractor frame by

placing hex bolt (M) (with hex nut attached)

through support pivot bracket and hole in frame

as shown in figure 5. Secure with lock washer

(N) and hex nut (O), finger tight only.

If there is a 3/8" hole in the tractor frame down

by the shaft on the tractor, insert hex bolt (E)

through the hole in support pivot bracket and

tractor frame. If no hole is there, insert the bolt

through the hole in the top forward part of

bracket and frame. Secure with lock washer (F)

and hex nut (G).

8. Assemble the other support pivot bracket to the

right hand side of tractor in the same manner,

except use hex bolt (H) (1" long) instead of the

longer hex bolt and the extra hex nut.

9. Tighten securely all four nuts and bolts which

were used in assembly of pivot support

brackets.

10.

Secure end of idler bracket support arm

assembly on the right side of tractor with one

flat washer (D) and hairpin cotter (J).

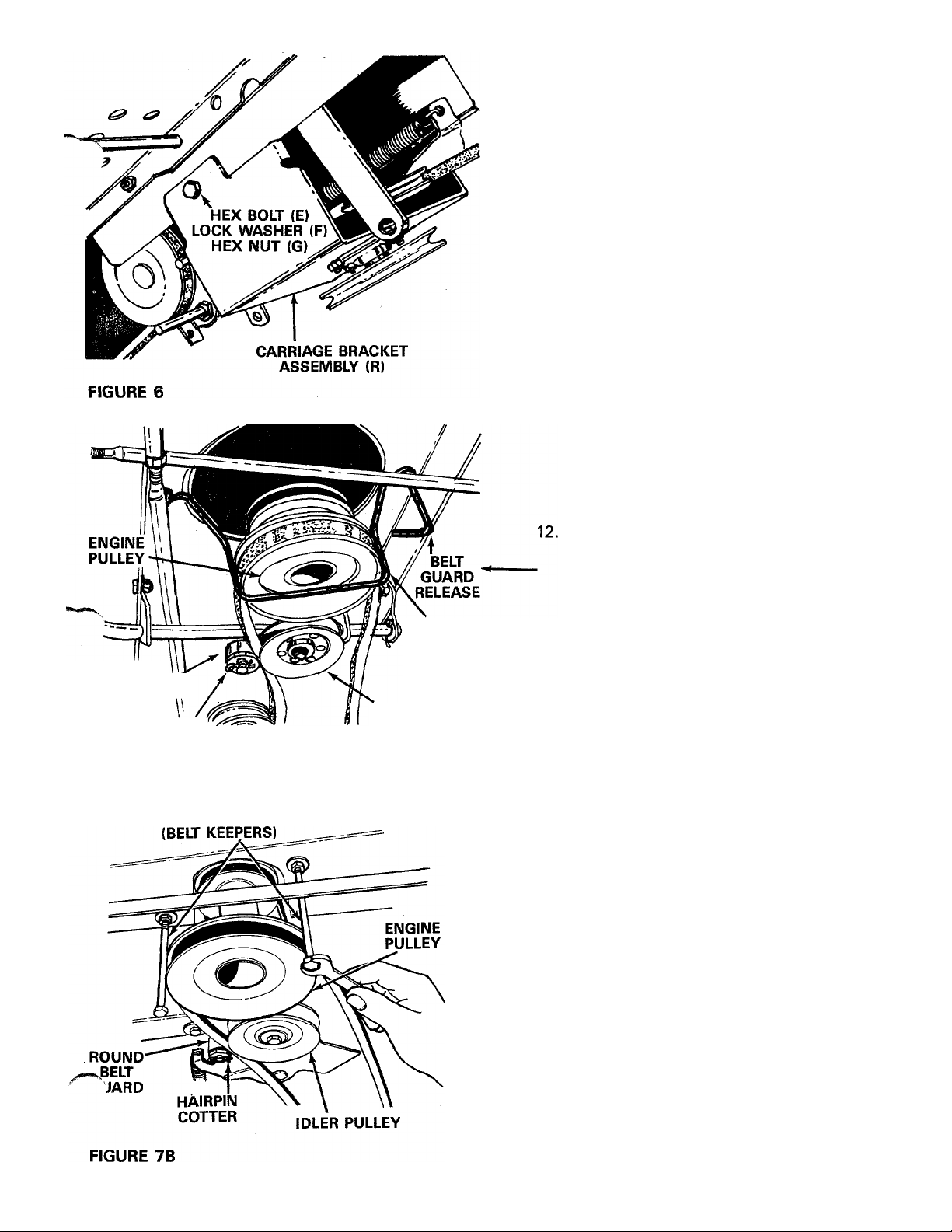

11.

Place carriage bracket assembly (R) in position

beneath the running board support rod on the

tractor. Secure each side of carriage bracket to

frame with hex bolts (E), lock washers (F) and

hex nuts (G). Tighten securely. See figure 6.

Remove the round belt guard from the idler on

tractor by removing the hairpin cotter. See figure

7A or 7B.

ROUND

BELT Til

GUARD

HAIRPIN COTTER'

II

FIGURE 7A

HEX BOLTS

WIRE

BELT

GUARD

IDLER PULLEY

13. Remove the engine pulley belt guard by either

unscrewing the belt guard release and

swinging the engine pulley belt guard out of the

way (see figure 7A), or removing the two long

hex bolts which act as belt keepers (see figure

7B).

14. Place the belt which is preassembled to the

carriage bracket assembly around the idlen

pulley and engine pulley on the tractor.

15. Reassemble the round belt guard and hairpin

cotter. Reassemble the engine pulley belt

guard(s).

Loading...

Loading...