Bolens 140-990A User Manual

.50

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

IMPORTANT:

Read Safety Rules

and Instructions

PRINTED IN U.S.A.

MODEL NUMBER

140-990A

16 H.P.

HYDROSTATIC

GARDEN

TRACTOR

NOTE

OPTIONAL 50" DECK

MODEL 190-992A

AVAILABLE

FORM N0.770-0253

INDEX

Safe Operation Practices......................................3

Know YourTractor.................................................4

Assembly Instructions...........................................5

Operating Instructions...........................................9

Maintenance

Trouble Shooting Chart.................................20 & 21

Hydrostatic Trouble Shooting Chart

Optional 12" Plow Instructions

......................................................

...................

............................

t

♦

♦

♦

♦

♦

♦

♦

♦

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm,

any part or parts found to be defective in material or workmanship. Transportation charges

for any parts submitted for replacement under this warranty must be paid by the purchaser

unless such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse,

excessive use, accident, neglect, improper maintenance, alterations, or unless the unit

has been operated and maintained in accordance with the instructions furnished. This

warranty does not apply to the engine, motor, battery, battery charger or component parts

thereof. Please refer to the applicable manufacturer’s warranty on these items.

LIMITED WARRANTY

♦

♦

This warranty will not apply where the unit has been used commercially.

13

22

23

Optional Tiller Attachment Instructions

Optional Cultivator Instructions

Optional Disc Instructions

Electrical System

Transaxle Parts

Hydrostatic Pump Parts

Tractor Repair Parts

Parts Information

..............................................

............................................

...............................

...............................

...................................

..........................

...................................

...............

29

30&31

32&33

34 thru 46

Back Cover

26

27

28

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

The equipment which you have just purchased does not have a spark arrester. If this equipment is used on

any forest covered land, brush covered land, or grass covered unimproved land in the State of California,

before using on such land, the California law requires that a spark arrester be provided. In addition, spark

arrester is required by law to be in effective working order. The spark arrester must be attached to the

exhaust system and comply with Section 4442 of the California Public Resources Code.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distributor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written

permission has been extended by MTD.

This warrany gives you specific legal rights. You may also have other rights which vary

from state to state.

TO PURCHASERS

OF INTERNAL COMBUSTION ENGINE EQUIPPED

MACHINERY OR DEVICES IN THE STATE OF CALIFORNIA

♦

♦

♦

♦

♦

♦

>

IMPORTANT

It is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this

manual in a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see operating section of this manual for

proper fuel and amount.

This unit is a precision piece of power equipment, not a plaything. Therefore exercise extreme caution at

all times.

SAFE OPERATION PRACTICES FOR RIDING VEHICLES

1. Know the controls and how to stop quickly—

READ THE OWNER’S MANUAL.

2. Do not allow children to operate vehicle. Do

not allow adults to operate it without proper

instruction. Only persons well acquainted

with these rules of safe operation should be

allowed to use your mower.

3. Do not carry passengers

4. Keep the area of operation clear of all per

sons, particularly small children and pets.

Stop engine when they are in the vicinity of

your mower. Although the area of operation

should be completely cleared of foreign ob

jects, a small object may have been over

looked and could be accidently thrown by the

mower in any direction.

5. Clear work area of objects which might be

picked up and thrown by the mower in any

direction.

6. Disengage all attachment clutches and shift

into neutral before attempting to start engine.

7. Disengage power to attachment(s) and stop

engine before leaving operating position.

8. Disengage power to attachment(s) and stop

engine before making any repairs or ad

justments. Disconnect the spark plug wire

and keep the wire away from the plug to pre

vent accidental starting.

9. Before attempting to unclog the mower or

discharge chute, stop the engine and be sure

the blade(s) have stopped completely. Discon

nect the spark plug wire and keep the wire

away from the plug to prevent accidental start

ing.

10. Disengage power to attachment(s) when

transporting or not in use.

11. Take all possible precautions when leaving

vehicle unattended such as disengaging

power-take-off, lowering attachments, shift

ing into neutral, setting parking brake, stop

ping engine and removing key.

12. Do not stop or start suddenly when going

uphill or downhill. Mow up and down face of

steep slopes; never across the face.

13. Reduce speed on slopes and in sharp turns to

prevent tipping or loss of control. Exercise ex

treme caution when changing direction on

slopes.

14. Stay alert for holes in terrain and other hidden

hazards.

15. Use care when pulling loads or using heavy

equipment.

A. Use only approved drawbar hitch points.

B. Limit loads to those you can safely control.

C. Do not turn sharply. Use care when back

ing.

D. Use counterweight(s) or wheel weights

when suggested in owner’s manual.

16. Watch out for traffic when crossing or near

roadways.

17. When using any attachments, never direct dis

charge of material toward bystanders nor

allow anyone near vehicle while in operation.

18. Handle gasoline with care. It is highly flam

mable.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a run

ning or hot engine or fill fuel tank indoors.

Wipe up spilled gasoline.

C. Open doors if engine is run in garage. Ex

haust fumes are dangerous. Do not run

engine indoors.

19. Keep the vehicle and attachments in good

operating condition, and keep safety devices

in place. Use guards as instructed in owner’s

manual.

20. Keep all nuts, bolts, and screws tight to be

sure the equipment is in safe working condi

tion.

21. Never store the equipment with gasoline in

the tank inside a building where fumes may

reach an open flame or spark. Allow engine to

cool before storing in any enclosure.

22. To reduce fire hazard, keep engine free of

grass, leaves or excessive grease.

23. The vehicle and attachments should be stop

ped and inspected for damage after striking a

foreign object. The damage should be

repaired before restarting and operating the

equipment.

24. Do not change the engine governor settings

or overspeed the engine.

25. When using the vehicle with mower, proceed

as follows:

(1) Mow only in daylight or in good artificial

light.

(2) Never make a cutting height adjustment

while engine is running if operator must

dismount to do so.

(3) Shut the engine off and wait until the

blade comes to a complete stop before

removing the grass catcher.

(4) Check blade mounting bolts for proper

tightness at frequent intervals.

26. Check grass catcher bags frequently for wear

or deterioration. For safety protection, replace

only with new bag meeting original equipment

specifications.

27. Look behind to make sure the area is clear

before placing the transmission in reverse

and backing up.

Rear Axle Range

Hydraulic

Lift Valve

KNOW YOUR TRACTOR

Power Take-Off Handle

Start/Park Lever

16 H.P. Cast Iron

Engine

27 X 9.50 Rear Wheels

Front Wheels

/■x

Cast Aluminum

' Grille

16 X 6.50

FIGURE 1.

ASSEMBLY

The Garden Tractor is packed and shipped in one

container and is fully assembled except for the

steering wheel, seat, battery and mounting the

three point hitch.

NOTE

Reference to left or right side

of machine is from the operator’s

position in the seat facing forward.

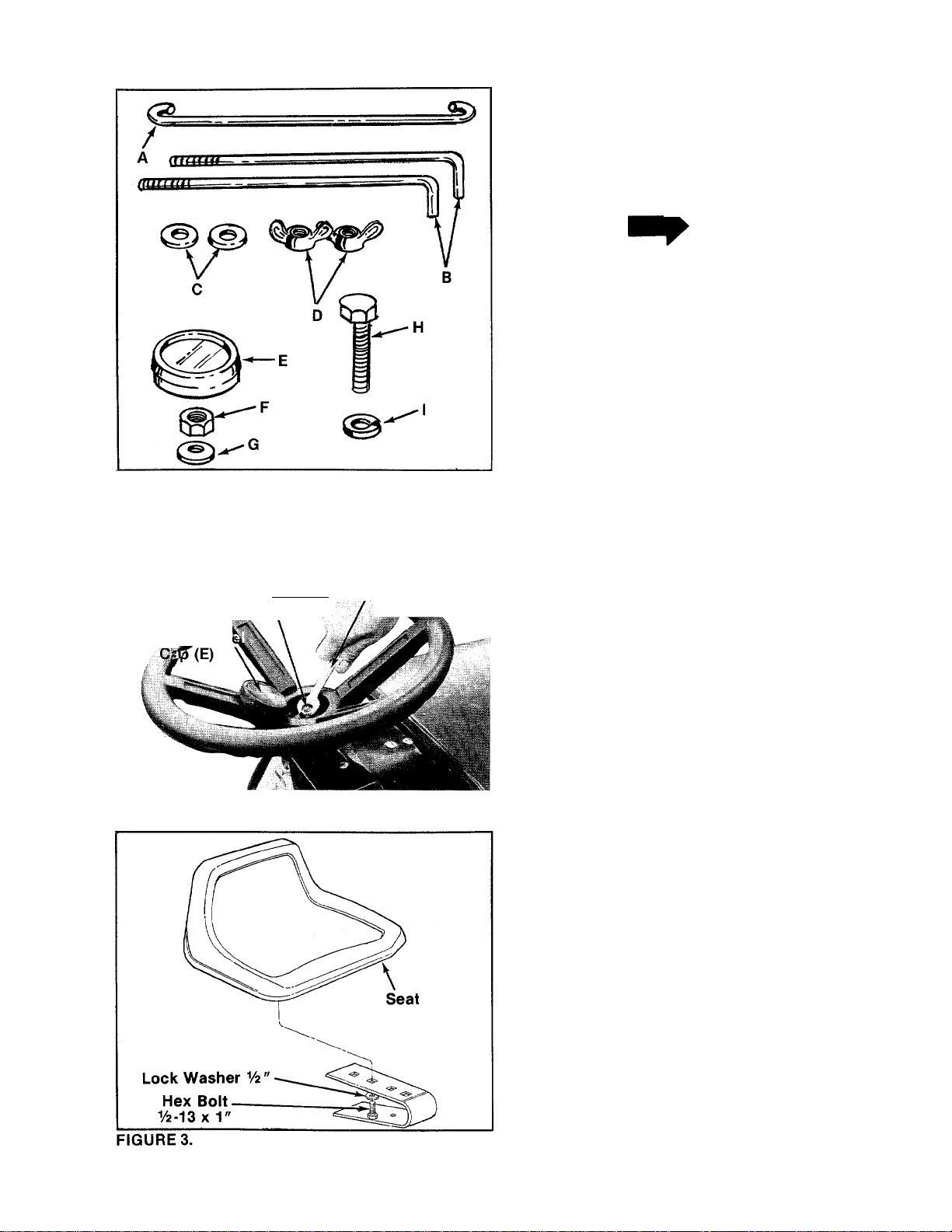

-Contents of Hardware Pack

(See figure 1.)

A (1) Battery Hold Down

B (2) Battery Hold Down Rods

C (2) Fiat Washers

D (2) Wing Nuts

E (1) Steering Wheel Cap

F (1) Hex Lock Nut 5/16-18Thread

G (1) Belleville (Curved) Washer

H (1) Hex Bolt 1/2-13x1.00" Long

I (1) Lock Washer 1/2" I.D.

Hex Lock-Htrt (F)__V2" W jiich

Belleville

Steerlnr/mie

FIGURE 2.

ATTACHING STEERING WHEEL

1. Place the steering wheel over the steerng

column extending through the dash. Line up

the flats on the steering column with the flats

------

in the steering wheel. (See figure 2.)

2. Place the belleville (curved) washer (G) with

the cupped side down over the steering col

umn and secure with hex lock nut (F).

3. Place the steering wheel cap (E) over the

center of the steering wheel and seat it with

your hand.

ATTACHING THE SEAT

Select one of four seat positions on the tractor

-seat spring. Secure seat to seat spring with hex

bolt (H) and lock washer (I). (See figure 3.)

BATTERY INFORMATION

^ WARNIN^

A. Battery acid must be handled with great care

as it will blister the skin and damage clothing.

It is advisabie to wear goggies, rubber gloves,

and a protective apron when working with it.

B. Neutraiize acid spiiled on clothing with dilute

ammonia water or a water soiution of baking

soda. If acid gets on clothes, dilute it with

clean water first, then neutralize.

C. If for any reason acid should be spattered in

the eyes, wash it out immediately with clean

cold water. Seek medical aid if discomfort con

tinues.

D. Since battery acid is corrosive to metals, do

not pour into any sink or drain. Rinse empty

electroiyte containers and mutilate before

discarding.

^ DANGER \

BATTERIES CONTAIN SULFURIC

ACID AND MAY CONTAIN EXPLO

SIVE GASES (when electrolyte has

been added)

A. Keep sparks, flame, cigarettes away.

B. Hydrogen gas is generated during charging

and discharging.

C. Ventilate when charging or using in enclosed

space.

D. When using a charger—to avoid sparks,

NEVER connect or disconnect charger clips to

battery while charger is turned on.

E. Always shield eyes, protect skin and clothing

when working near batteries.

3. Fill each cell carefully using 1.265 specific

gravity electrolyte. Fill each cell to the top of

the separators. Do not overfill.

4. Let the battery sit for 20 minutes for the

chemical reaction to take place.

5. Charge the battery at a MAXIMUM RATE OF 5

AMPS until the specific gravity reads 1.265.

Use a hydrometer to check the specific gravi

ty.

A

An excessive rate of charge will

damage the battery.

6. Check the level of electrolyte. Adjust level to

bottom of split ring if necessary with elec

trolyte.

7. Replace fill caps.

8. Once the battery has been activated never add

anything except distilled water or a good

grade of drinking water.

9. If your battery has been installed in your unit

at the factory:

A. Use a hydrometer to check the specific

gravity. The specific gravity should be

1.265 at 80° F.

If it is less, remove the fill caps and use a

B.

battery charger to bring the specific gravi

ty up to 1.265. NEVER CHARGE AT MORE

THAN 5 AMPS.

Replace the fill caps.

C.

The positive cable has been attached to

D.

the positive terminal of the battery at the

factory. You only have to attach the

negative cable (grounded) to the negative

(Neg, N or -) terminal of the battery with a

hex head bolt, lock washer and nut.

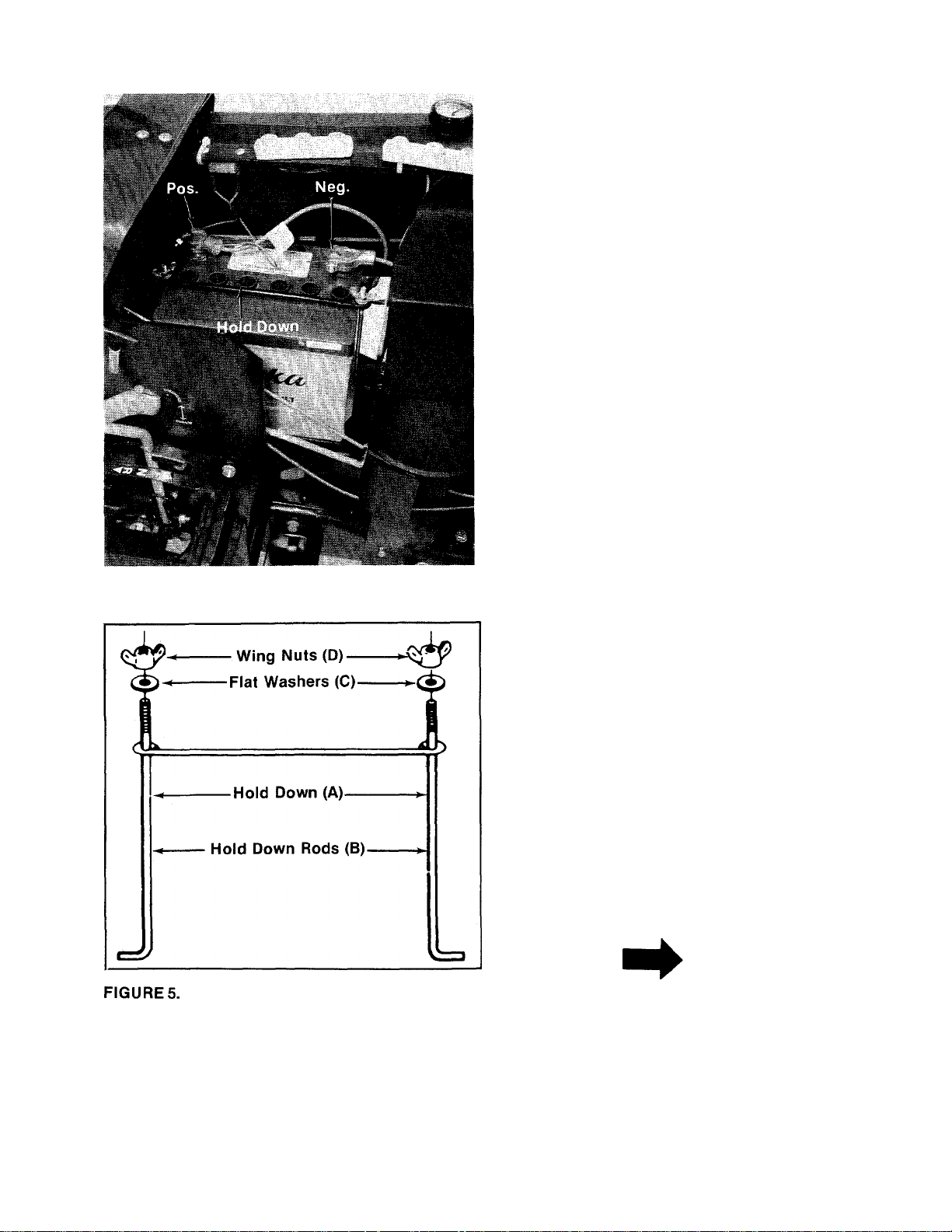

INSTALLING THE BATTERY

CAUTION

ACTIVATING THE BATTERY

NOTE

If your battery is activated (elec

trolyte in the battery) and installed

in the tractor, go directly to step 9.

1. Place the battery to be filled on a workbench.

Never activate a battery in the unit.

2. Remove the fill caps from all cells.

NOTE

The positive battery terminal is

marked Pos. (-t-). The negative bat

tery terminal is marked Neg. (-).

1. Place the battery in the battery case with the

Negative (-) terminal to the front.

^I^NOTE

Do not push the battery back all the

way.

2. Attach the positive battery cable (which has

two wires) to the positive battery terminai.

— (See figure 4.)

3. Attach the negative battery cable (grounded,

single wire) to the negative battery terminal.

FIGURE 4.

■321/2

FIGURES.

Pull Rod

11

Clevis End

Assemble the hold down rods (B) and hold

4.

down (A) before you place It over the battery

(see figure 5) using wing nuts (D) and flat

washers (C).

Place the battery hold down assembly over

5.

the battery and slide the battery into place.

(See figure 4.)

\ WARNING {

Place the hold down on the side op

posite the terminals.

6. Hook the hold down rods into the battery case

and tighten fingertight. (Do not overtighten.)

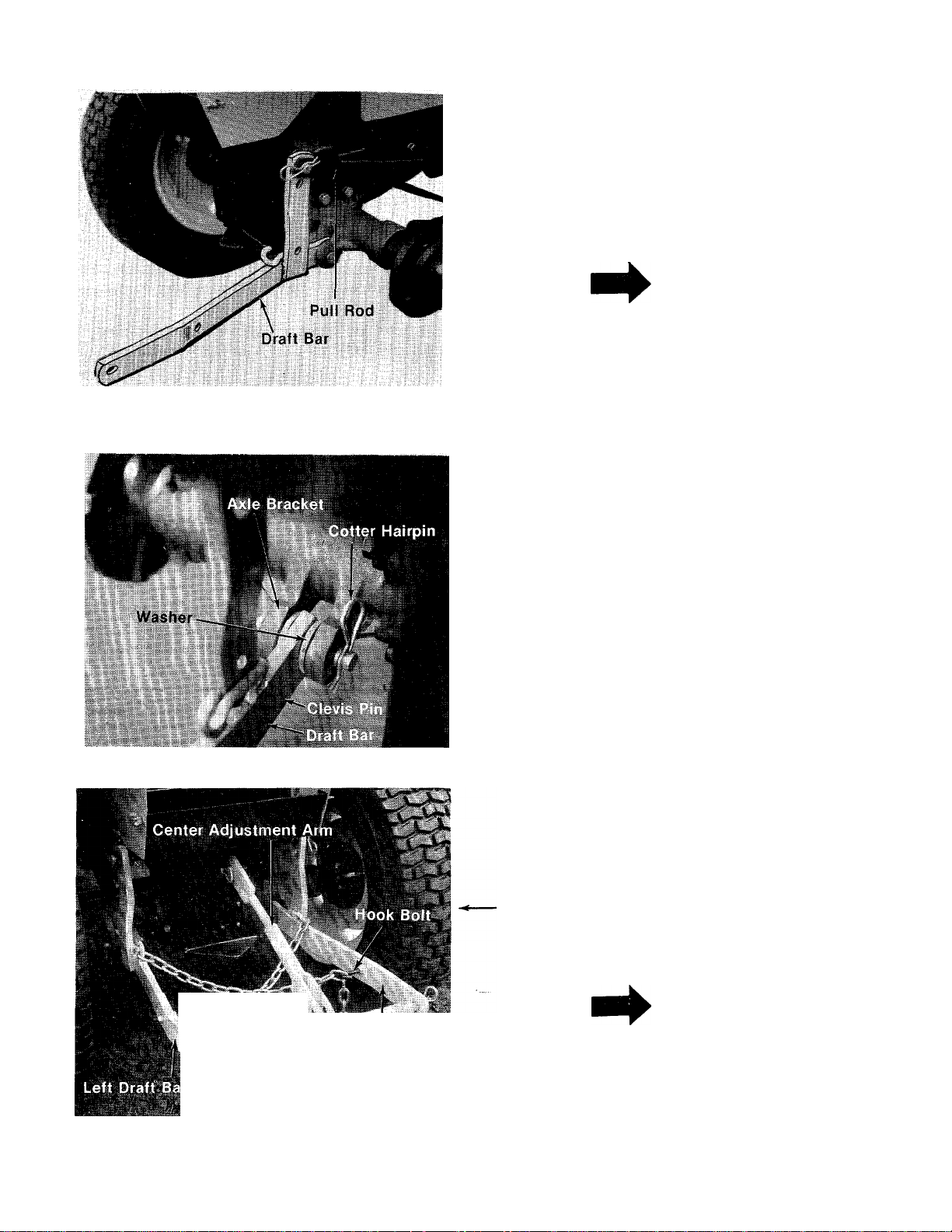

ASSEMBLING THE THREE POINT HITCH

NOTE

Use the three point hitch only for

the rear attachments such as the

moldboard plow, disc and cultivator.

If you are using the mowing deck,

snow blade or snow thrower it is not

necessary to attach the three point

hitch.

1. Adjust the clevis ends on both pull rods so

that they measure 32Va inches. (See figures.)

FIGURE?.

2. Assemble each draft bar to the axle brackets

using the longest clevis pins, two large

washers, and secure with a cotter hairpin.

—(See figures 7 and 8.)

NOTE

Refer to figure 9 to determine which

is the right and left draft bars.

3. Attach the flat end of the pull rod to the top

hole in the draft bar with the shorter clevis

pin, flat washer cotter hairpin. (See figure 7.)

4. Assemble the draw bar to the draft bars and

secure each end with a cotter hairpin. (See

figure 9.)

5. Screw one hex nut all the way on to each of

hook bolts.

FIGURES.

FIGURES.

h -

......

..........

■■■*:•> 7:-^: VN

- d

6. Place a lock washer next to the hex nut and in

sert the hook bolt through the inside of the

draft bar. Secure using a second nut. Do not

tighten. (See figure 9.)

7. Fasten the chains to the hooks welded on the

draft bars. Cross the chains over and attach to

the opposite hook bolts.

NOTE

Pull the chains to make them as

tight as possible.

8. Tighten the outside nuts on the hook bolts un

til there is approximately one inch of play in

the center of the chains.

9. Tighten the inside nuts on the hook bolts.

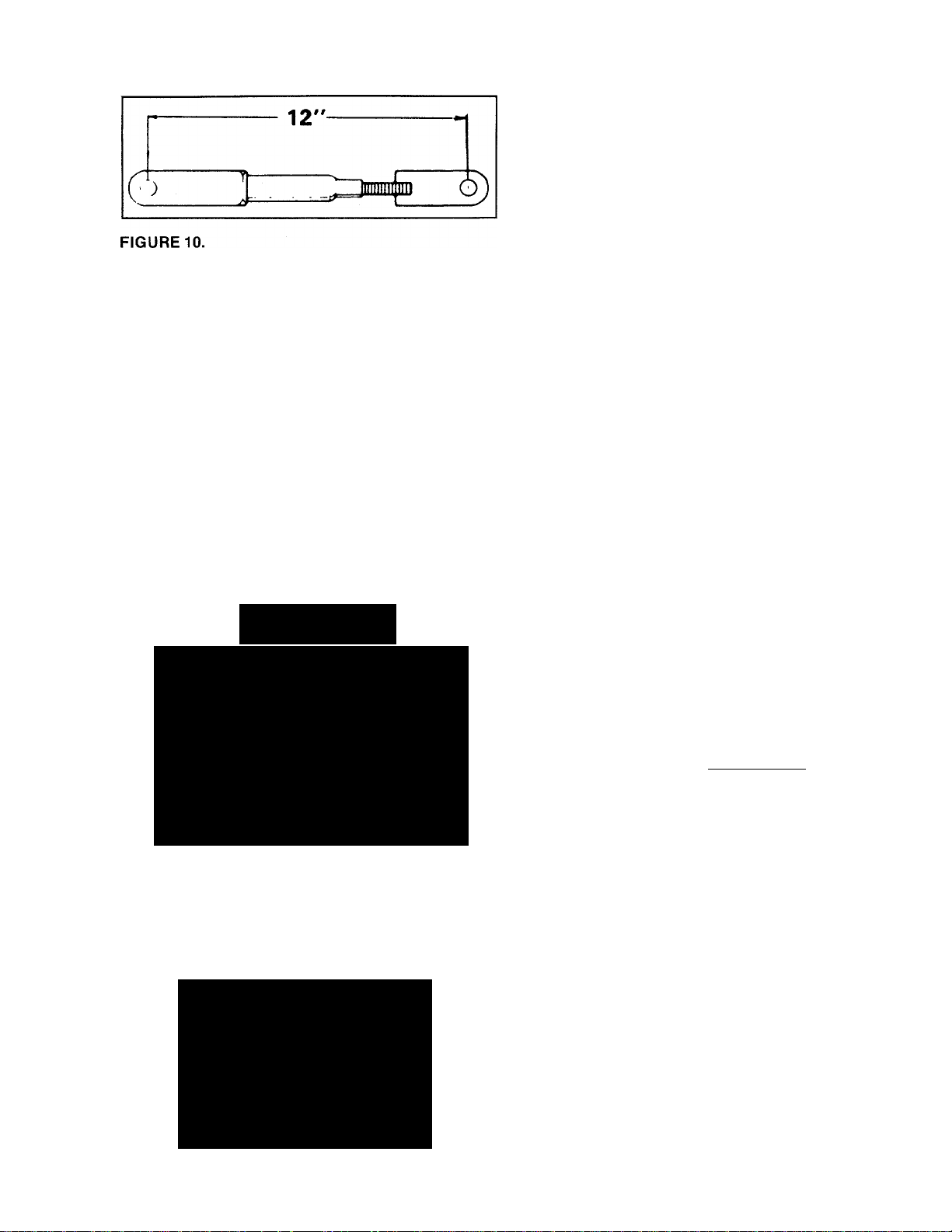

10. Assemble and adjust the two halves of the

center adjustment arm until it is 12 inches

long. (See figure 10.)

11. Assemble the flat end of the center adjust

ment arm to the upper hole in the center hitch

bracket with a clevis pin, two flat washers and

a cotter hairpin. (See figure 9.)

TIRE PRESSURE

Reduce the rear wheel tire pressure to 15 p.s.i. for

operation. The tires have been over-inflated for

shipping. Equal tire pressure should be main

tained on all tires. Maximum tire pressure is 30

p.s.i.

HYDROSTATIC TRANSMISSION

See the maintenance section of this manual for

correct lubrication and level for the oil in the

hydrostatic transmission.

OPERATION

CAUTION

1. KEEP ALL SHIELDS & GUARDS IN PLACE

2. BEFORE LEAVING OPERATOR’S POSITION:

SHIFT CONTROLS INTO NEUTRAL

SET PARKING BRAKE

DISENGAGE ATTACHMENT DRIVE

SHUT ENGINE OFF

REMOVE IGNITION KEY

3. WAIT FOR ALL MOVEMENT TO STOP BEFORE SERVICING MACHINE

4. KEEP PEOPLE & PETS A SAFE DISTANCE AWAY FROM MACHINE

Before starting the engine fill the crankcase with

oil. Refer to the Engine Operation and

Maintenance manual.

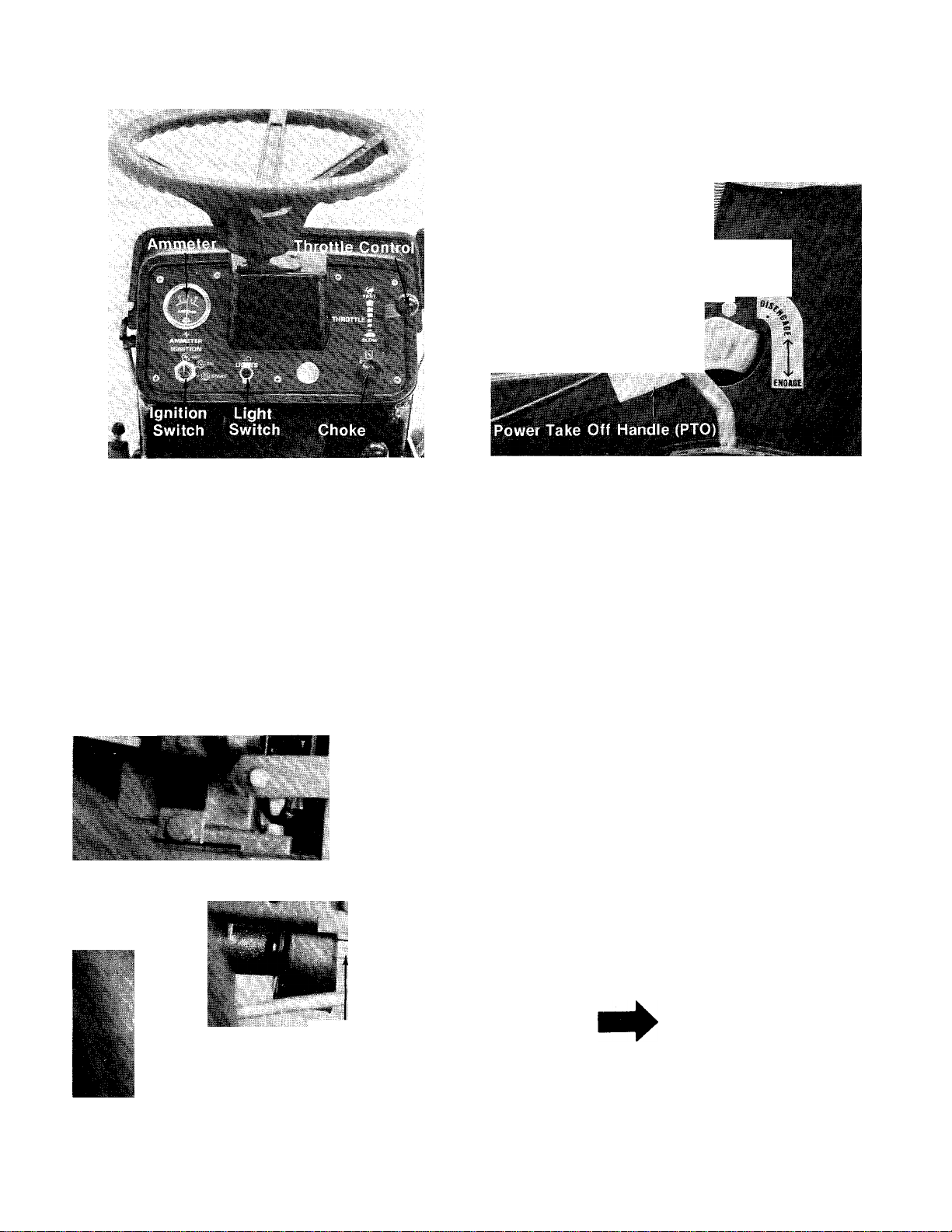

Throttle Control

The throttle control is located on the right side of

the dashboard and is used to regulate the engine

speed. (See figure 11.) The engine should be

operated from 3/4 to full throttle “FAST” when

operating any equipment that uses the tractor

engine as a source of power such as the cutting

deck, snow thrower or rotary tiller.

Choke Control (See figure 11.)

Pull the choke knob all the way out. Set throttle in

the “FAST” position. A warm engine requires less

choking.

Ignition Switch (See figure 11.)

The ignition switch is located on the left side of

the dashboard. Turn the key to the “START” posi

tion to start the engine. When the engine is run

ning leave the key in the “ON” position. To stop

the engine turn the key to the “OFF” position.

I WARNING I

Remove the key from the tractor

when the tractor is not in use to pre

vent accidental starting.

Your garden tractor is equipped with a chute

deflector and internal baffle on the (optional) cut

ting deck. The tractor must not be operated

without these pieces in their proper place.

CAUTION

DO NOT OPERATE

MOWER UNLESS

GUARD IS IN ITS

PROPER PLACE.

Light Switch (See figure 11.)

The head lamps are operated by a toggle light

switch located on the dashboard. The head lamps

will only operate when the engine is running. Flip

the toggle switch up to turn on lights and down for

off.

Ammeter (See figure 11.)

The ammeter registers the rate of battery charge

or discharge. The ammeter should register on the

plus ( + ) side when the engine is running in the

“FAST” position until the battery is completely

charged.

With a fully charged battery or with the engine id

ling, the ammeter may not show a charge.

FIGURE 11. FIGUREIS.

-f-

\t ■'

f :-

”i< ■ .‘•^-'■V'-íí“'-'!

‘4

' i

Power Take Off Operation (PTO)

There are two PTO’s on your tractor. The front PTO

is a pulley located behind the grille and is used to

operate the snow thrower. This PTO is directly

connected to the engine and operates whenever

the engine is running.

The rear PTO is located under the tractor and is

used to operate the grass cutting deck and rotary

tiller. (See figure 12.)

H-:;- '

The rear PTO is operated by the PTO lever. (See

figure 13.)

■^NOTE

The PTO lever must be in the

DISENGAGED position to start the

engine.

High/Low Axle Range

Your tractor is equipped with a two speed rear ax

le for greater versatility. (See figure 14.) The LOW

range is used when operating the rotary tiller,

moldboard plow and should also be used when ex

tra power is required.

HIGH range operation is for normal loads, grass

cutting and normal use.

LOW Range (0-4 mph)

HIGH Range (0-8 mph)

The Axle Range Lever must be in either the HIGH

or LOW range position. The tractor will not move if

it is in the center position.

FIGURE 12.

■t.

Power Take Off

(PTO)

NOTE

When pushing the tractor by hand

with the engine shut off, place the

Axle Range Lever between the

HIGH and LOW position. The hydro

static pump will not rotate and the

tractor will be easier to push.

10

FIGURE 14.

FIGURE 15.

Hydraulic Lift Lever

The hydraulic lift lever is used to raise or lower all

of the tractor attachments. Move the lever forward

to raise the attachment and move the lever

backwards to lower the attachment. (See figure

14.)

Brake Pedal

The brake pedal is located on the right side of the

tractor. Depressing the brake pedal operates the

brake. It is used for emergency stopping only.

When you depress the brake pedal the control

lever will return close to the neutral position. The

control lever is used for normal stopping. (See

figure 15.)

Parking Brake

To set the parking brake, depress the brake pedal,

pull up the parking brake knob and release the

brake pedal. It will stay in the raised position. To

release the parking brake, depress and release the

brake pedal. (See figures 14 and 15.)

Control Lever (Hydrostatic)

The control lever is used to regulate the ground

speed of the tractor. Moving the control lever to

its extreme position makes the tractor travel

faster. Moving the control lever forward (F) moves

the tractor forward, moving the control lever

backwards (R) reverses the tractor. The control

lever is used to regulate the ground speed of the

tractor. (See figure 15.)

To increase rear wheel torque (pulling power)

move the control lever towards the neutral posi

tion. The tractor responds similar to shifting to a

lower gear with a gear type transmission.

The control lever is used for normal slowing down

and stopping by moving the control lever towards

neutral (N). It is especially useful when rotary till

ing hard or rough ground. Additional braking may

be obtained by moving the control lever gradually

in the opposite direction of your travel.

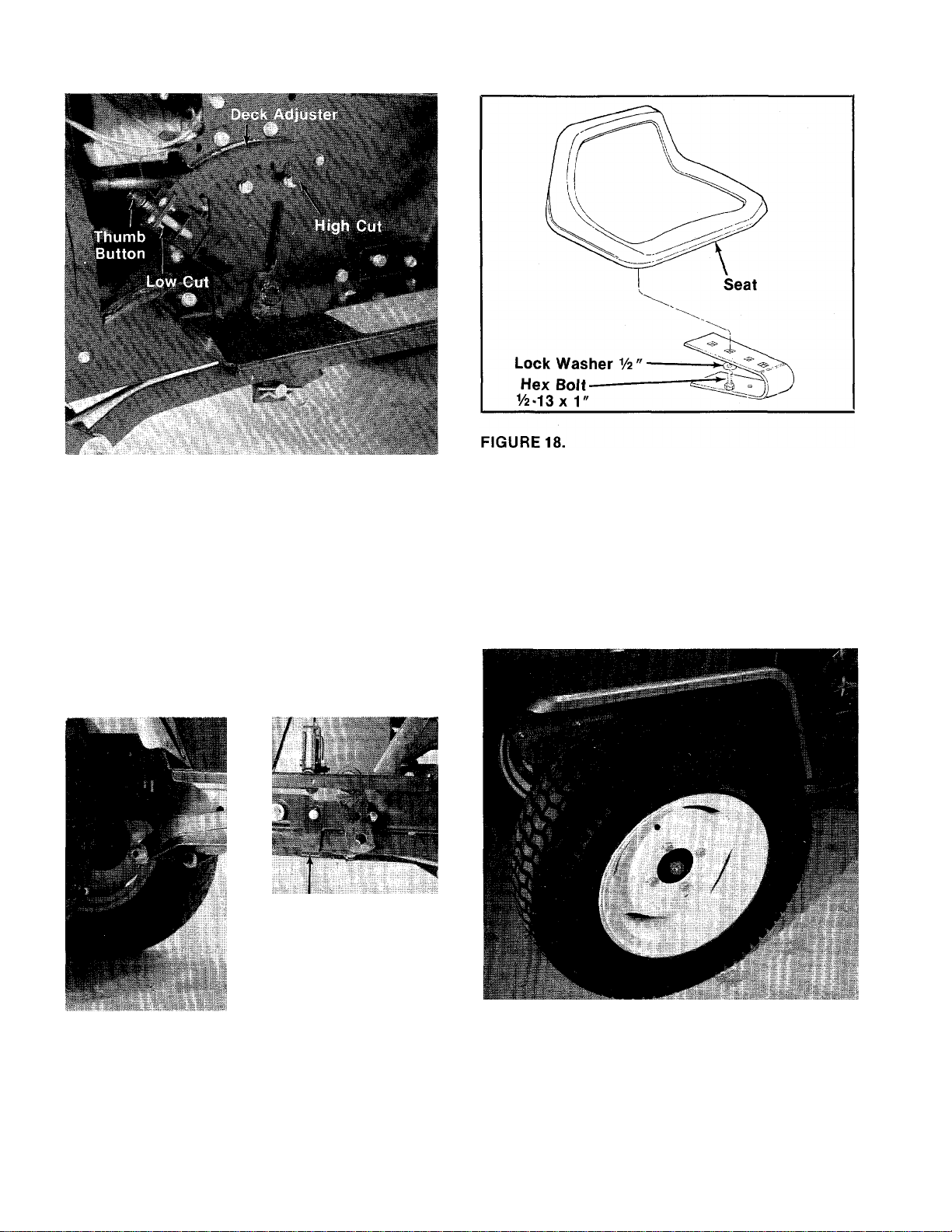

Deck Adjuster

The deck adjuster is located on the left side of the

tractor and is used in conjunction with the mow

ing deck wheels to set the cutting height of the

mowing deck. To operate the deck adjuster,

depress the thumb button and move the deck ad

juster forward to lower the cutting height and

move it towards the rear to raise the cutting

height.

The deck adjuster and the wheels on the mowing

deck must be adjusted so the deck is parallel to

the ground. (See figure 16.)

The deck is designed to raise and float over

ground irregularities to prevent scaiping.

11

FIGURE 16.

Carriage Locks

The carriage locks hold the quick disconnect

frame in the raised position when the rear at

tachments are used.

Remove the carriage locks, raise the quick discon

nect frame by hand and reassemble the carriage

locks to the inside so they hold the quick disonnect frame up. (See figure 17.)

Carriage

Lock

Rear Wheel Width

The rear wheels can be reversed to increase or

decrease the width. To reverse the wheels, raise

the back of the tractor and block it well. Remove

the four lug bolts holding the rim to the rear axle

hub. Reverse the wheel and reassemble. (See

figure 19.)

FIGURE 17. FIGURE 19.

Seat Adjustment

The seat is adjustable to four positions. Remove

the bolt holding the seat to the spring to change

positions. (See figure 18.)

Operating the Tractor

1. Start the engine as outlined in the Engine

Operating and Maintenance manual.

12

2. The engine should be run with the throttle

control in the “FAST” position to obtain the

maximum efficiency. The sound you may hear

when you accelerate is the normal operating

sound of the hydrostatic transmission. The

faster you push the control lever forward or

backward, the louder the sound.

3. Release the brake and move the control lever

into either the forward (F) or reverse (R) posi

tion.

4. The brake pedal is used for emergency stop

ping only. Normal stopping is done by using

the control lever. When the brake pedal is

depressed the control lever will return close

to the neutral position so the tractor brake will

stop the tractor, however, the tractor may

creep either forward or backward when the

brake pedal is released.

Maintenance and adjustments for the engine are

covered in the Engine Operating and Maintenance

Instructions manual.

MAINTENANCE

Lubrication

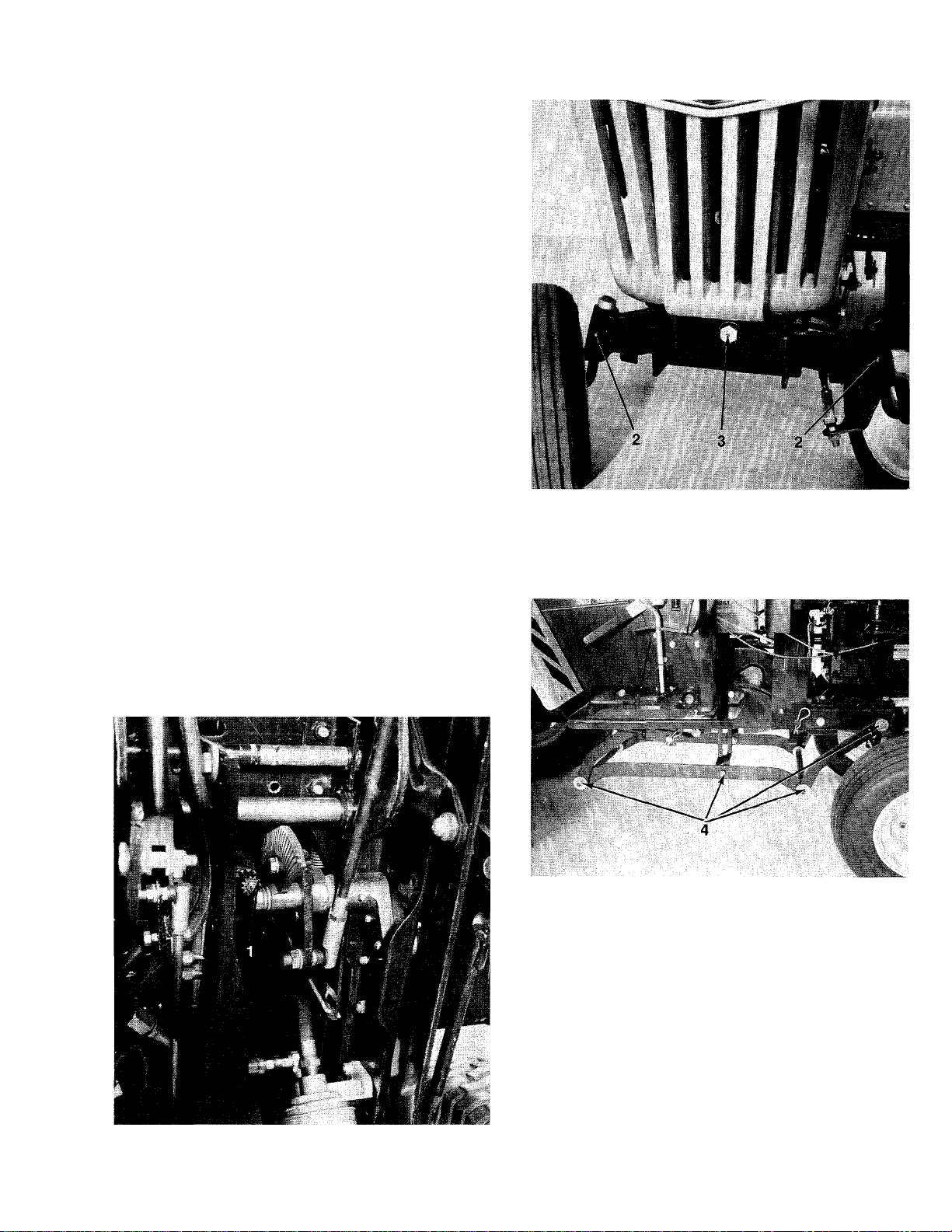

Item numbers 1 through 4 must be lubricated once

a year with multi-purpose automotive grease.

1. Steering Gear—(See figure 20.)

2. King Pin—(See figure 21.)

3. Pivot Bolt—(See figure 21.)

4. Deck Linkage—Oil with SAE 30 oil on all pivot

points once a season. (See figure 22.)

FIGURE 20.

FIGURE 21.

FIGURE 22.

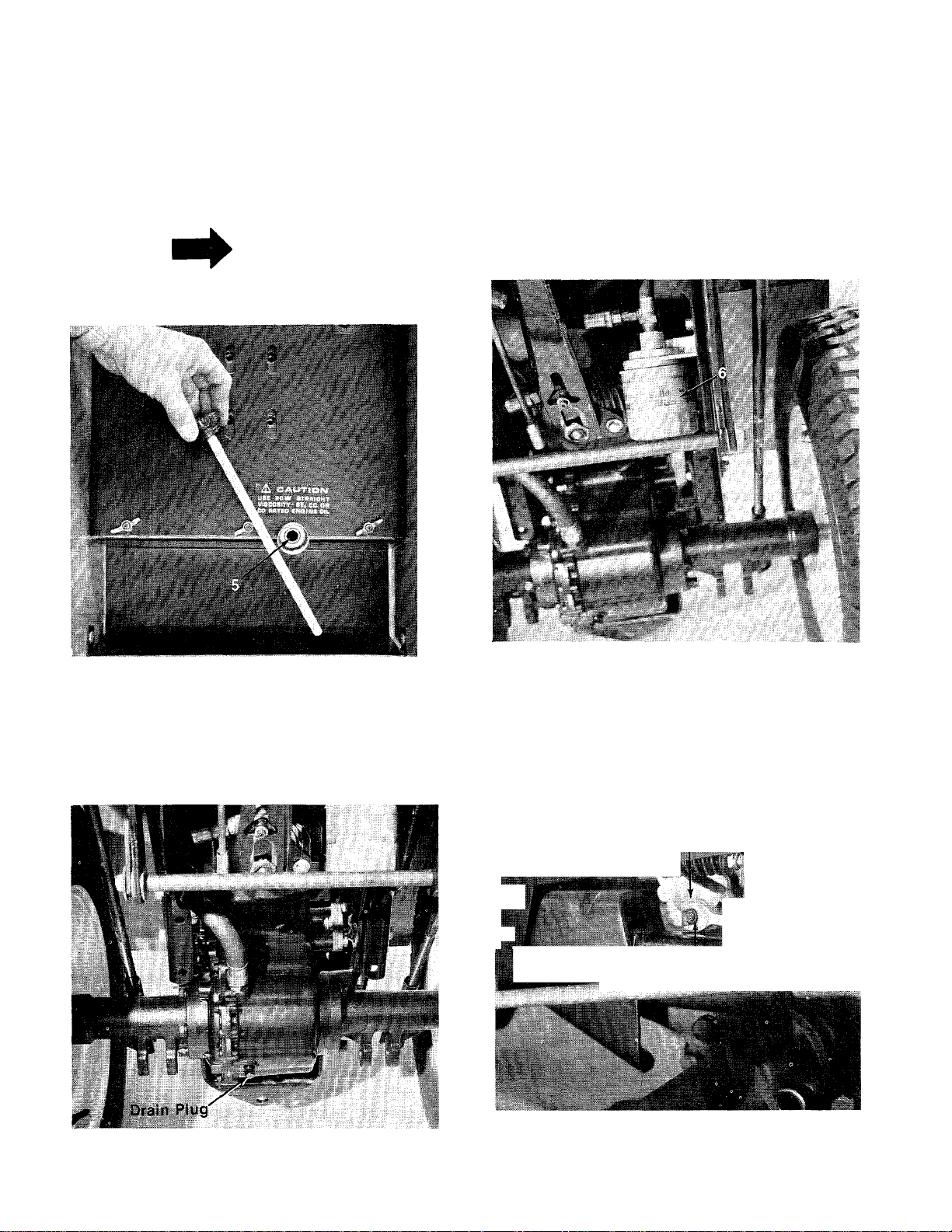

5. Hydrostatic Transmission

(See figure 23.) The dipstick for the

hydrostatic transmission is located behind

the seat. This dipstick checks the oil level in

the hydrostatic transmission, transaxle and

hydraulic lift system.

The oil level should be maintained to the

FULL mark on the dipstick. Check the oil level

every 8 hours of operation.

Use 20 weight oil with a zinc additive package

of .07% minimum. The following list of oils

meet these specifications:

13

Rykon Industrial Oil #31

Amoco 300, 20 wt.

Rotella, 20 wt.

Rimula Series 3, 20 wt.

X100 Motor Oil, 20 wt.

Havoline Motor Oil, 20 wt.

Ursa, Extra Heavy, 20 wt.

NOTE

If the above oils cannot be obtained,

SAE 20 motor oil with a SE rating

may be substituted.

6. Oil Filter

(See figure 25.) A full flow replaceable oil

filter, located under the left side of the frame,

should be replaced initially after twenty hours

of operation and thereafter every 100 hours for

commercial or industrial applications and

yearly for normal usage. It can be removed by

turning it counterclockwise by hand. Use

Fram filter PH-16 or equivalent.

FIGURE 23.

The capacity of the unit is 5 quarts. However,

because the oil will not completely drain from the

lift system and hydrostatic transmission, you will

only drain approximately 3 quarts. To drain,

remove the plug from the bottom of the transaxle.

(See figure 24.)

FIGURE 25.

7. Hydrostatic Control—Lubricate between the

control slide and the control adjustment plate.

(See figure 35.)

Disc Brake Adjustment

Disc Brake

k'-

■A

Disc

FIGURE 24.

FIGURE 26.

14

The disc brake is iocated on the ieft side of the

transaxle. To adjust, tighten the lock nut. (See

figure 26.) (Wheel is removed for clarity.) The lock

nut should be tightened just enough to stop the

tractor when the brake pedal is depressed, allow

ing the disc to turn freely between the brake pads

when the pedal is relased.

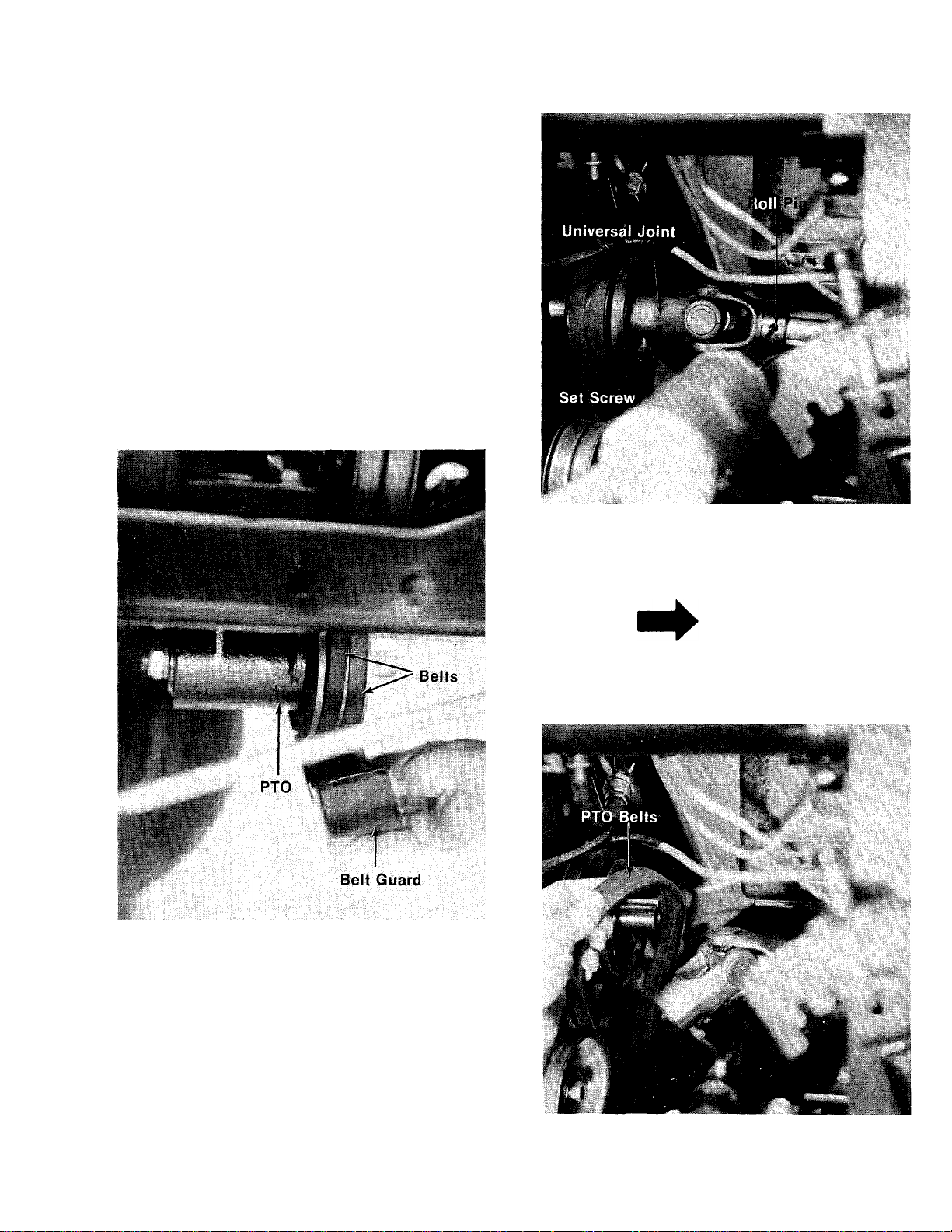

PTO Belt Removal

1. Place the PTO Lever in the disengaged posi

tion.

2. Remove the lower belt guard. (See figure 27.)

FIGURE 28.

6. Remove the PTO belts. (See figure 29.)

7. Reassemble in reverse order using matched

belts.

FIGURE 27.

3. Loosen the set screw in the universal joint.

(See figure 28.)

4. Drive out the roll pin in the universal joint.

(See figure 28.)

NOTE

PTO belts must be replaced using

matched sets.

5. Slide the universal joint towards the rear of

the tractor.

FIGURE 29.

15

Loading...

Loading...