Bolens 13875-8, 13885-8 User Manual

FIFTY CENTS

PRINTED IN U.S.A.

....

(MODEL 13885-8 SHOWN)

FORM NO. 770-7545

WARNING TO PURCHASERS

OF INTERNAL COMBUSTION ENGINE EQUIPPED

MACHINERY OR DEVICES IN THE STATE OF CALIFORNIA

The equipment which you have just purchased does not have a spark arrester. If this equipment is used on

any forest covered land, brush covered land, or grass covered unimproved land in the State of California,

before using on such land, the California law requires that a spark arrester be provided. In addition, spark

arrester is required by law to be in effective working order. The spark arrester must be attached to the

exhaust system and comply with Section 4442 of the California Public Resources Code.

2

It is sug~ested that this manual be read in its entirety before attempting to assemble or operate. Keep this

manual In a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see operating section of this manual for

proper fuel and amount.

Your rotary mower is a precision piece of. power equipment, not a plaything. Therefore exercise extreme

caution at all times.

SAFE OPERATION PRACTICES FOR RIDING VEHICLES

1. Know the controls and how to stop quicklyREAD THE OWNER'S MANUAL. D. Use counterweight(s) or wheel weights

2. Do not allow children to operate vehicle. Do when suggested.in own~r's ma~ual.

not allow adults to operate it without proper 16. Watch out for traffic when crossing or near

instruction. Only persons well acquainted roadways.

with these rules of safe operation should be 17. When using any attachments never direct disallowed to use your mower. charge of material toward bystanders nor

3. Do not carry passengers. allow anyone near vehicle while in operation.

4. Keep the area of operation clear of all 18. Handle gasoline with care-it is highly

persons, particular)y small children and pets. flammable. ..

Stop engine when they are in the vicinity of A. Use approved gasolln~ container.

your mower. Although the area of operation B. Neve! remove cap O! add g~soline to a

should be completely cleared of foreign ~unnlng or. hot enQlne or fll.1 fuel tank

objects, a small object may have been over- Indoors. WIP~ up s~llle? gasoll,ne.

looked and could be accidently thrown by the C. Open doors If engine IS run In garagemower in any direction. exh~us~ fumes are dangerous. Do not run

5. Clear work area of objects which might be engine Indoors.

picked up and thrown by the mower in any 19. Keep the vehicle and attachments in good

direction. operating condition, and keep safety devices

6. Disengage all attachment clutches and shift in place. Use guards as instructed in owner's

into neutral before attempting to start engine. manual.

7. Dis~ngage power to attachment(s) and stop 20. Keep all nut~, bolts~ a,nd screws ti,ght to b,e

engine before leaving operator position. s,ure the equipment IS In safe working condl-

8. Disengage power to attachment(s) and stop tlon.

engine before making any repairs or adjust- 21. Never st~re ,the equi,p~ent with gasoline in

ments. Disconnect the spark plug wire and the tank Inside a building where fumes may

keep the wire away from the plug to prevent reach an open flame or spark. Allow engine to

accidental starting. cool before storing in any enclosure.

9. Before attempting to unclog the mower or 22. To reduce fire hazard keep engine free of

discharge chute, stop the engine and be sure grass, leaves or excessive grease.

the blade(s) have stopped completely. Dis- 23. The vehicle and attachments should be

connect the spark plug wire and keep the wire stopped and inspected for damage after

away from the plug to prevent accidental striking a foreign object, and the damage

starting. should be repaired before restarting and

10. Disengage power to attachment(s) when operating the equipment.

transporting or not in use. 24. Do not change the engine governor settings or

11. Take all possible precautions when leaving overs peed the engine.

vehicle unattended such as disengaging 25. When using the vehicle with mower, proceed

power-take-off, lowering attachments, shift- as follows:

ing into neutral, setting parking brake, (1) Mow only in daylight or in good artificial

stopping engine and removing key. light.

12. Do !lot stop or start suddenly when going (2) Ne~er ma~e ~ cuttin,9 h~ight adjustment

uphill or downhill. Mow up and down face of while engine IS running If operator must

steep slopes; never across the face. dismount to do so.

13. Reduce speed on slopes and in sharp turns to (3) Shut the engine off and wait until the

prevent tipping or loss of control. Exercise blade .comes to a complete stop before

extreme caution when changing direction on removing the grass catcher.

slopes. (4) ~heck blade mounting bolts for proper

14. Stay alert for holes in terrain and other hidden tightness at frequent intervals.

hazards. 26. Check g,rass,catcher bags frequently for wear

15. Use care when pulling loads or .h or dete~loratlon. For safety prote.ct.i°n repla.ce

equipment. using eavy only with .n,ew ,bag meeting original equlp-

A. Use only approved drawbar hitch points. ment spe~lflcatlons. .

B. Limit loads to those you can safely 27. Look behln.d to make su!e ,the ,area IS clear

control. befo~e placing the transmission In reverse and

C. Do not turn sharply. Use care when backing up.

backing. 3

Limited Warranty. 2

Safe Operation Practices 3

Index. 4

Assembly. 5

Battery Information. 5

Before Starting Engine. 7

Controls. 8

Operation of Controls. 9

Cutting Tips. 11

Lubrication 12

GRASS CATCHER Model No. 19014-8 is

available as optional equipment Tor the mowers

shown in this manual.

+t

The mower should not be operated

without the entire grass catcher or

chute deflector in place.

12Adjustments.

13

Belt Removal. 15

Illustrated Parts for Rider. 20,22,24,26

Parts Lists for Rider. 21, 23, 25, 27

Illustrated Parts for Transaxle 28

PartsListforTransaxle 29

Electrical Diagram. 30Parts

Information. Back Cover

it CAUTION

Installation of tire to rim:

1. Lubricate tire beads and rim

flanges.

2. Do not exceed 30 P.S.I. when

seating beads.

3. Adjust to recommended pressure

after beads are sealed.

NOTE

Under normal usage bag material is

subject to wear, and should be

checked periodically. Be sure any

replacement bag complies with the

mower manufacturer's recommen-

dations.

For replacement bags, use only factory authorized replacement bag No.

764-0157

_IMPORTANT

After striking a foreign object, stop

the engine. Remove wire from spark

plug, thoroughly inspect the mower

for any damage, and repair the damage before restarting and operating

the mower.

The steering wheel and seat, witn the necessary

hardware, are easily assembled to the machine.

On the electric starter models, the battery must be

activated and installed as outlined in this section.

TIRE PRESSURE

FOR SHIPPING PURPOSES, THE TIRES ON

YOUR UNIT MAY BE OVER-INFLATED. TIRE

PRESSURE SHOULD BE REDUCED BEFORE

UNIT IS PUT INTO OPERATION. PRESSURE

SHOULD BE APPROXIMATEl Y.15 P.S.I. EQUAL

TIRE PRESSURE SHOULD BE MAINTAINED ON

All TIRES. MAXIMUM TIRE PRESSURE IS 30

P.S.I.

NOTE

Reference to right-hand or left-hand

side of machine is from the driver's

seat facing forward.

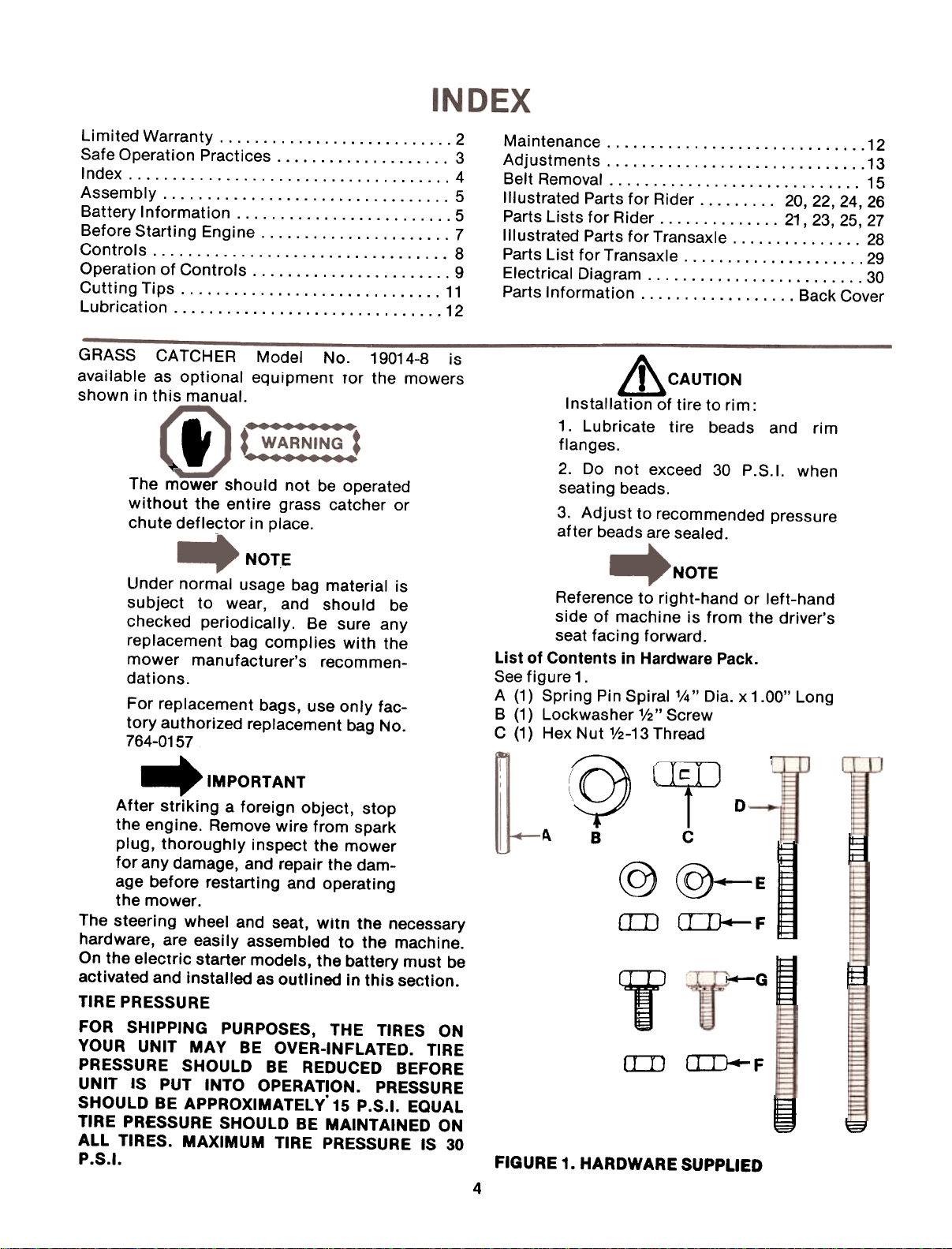

List of Contents in Hardware Pack.

See figure 1 .

A (1) Spring Pin Spiral 1/4" Dia. x 1.00" Long

B (1) Lockwasher V2" Screw

C (1) Hex Nut V2-13 Thread

~l ~

A.

B

@CI:I)

1

c

E B

a:::I)-4--F~

~GI

y

a=D

FIGURE 1. HARDWARE SUPPLIED

4

ra

/I

~

Ie

Maintenance.

I=I~DD.

(~~

~

(I]J""-F

0 (2) Hex Screws 1/4-20 x 5.50" Long

E (2) Lockwashers 1/4" Screw

F (4) Hex Nuts 1/4-20 Thread

G (2) Hex Sems Screws 1/4-20 x .62" Long

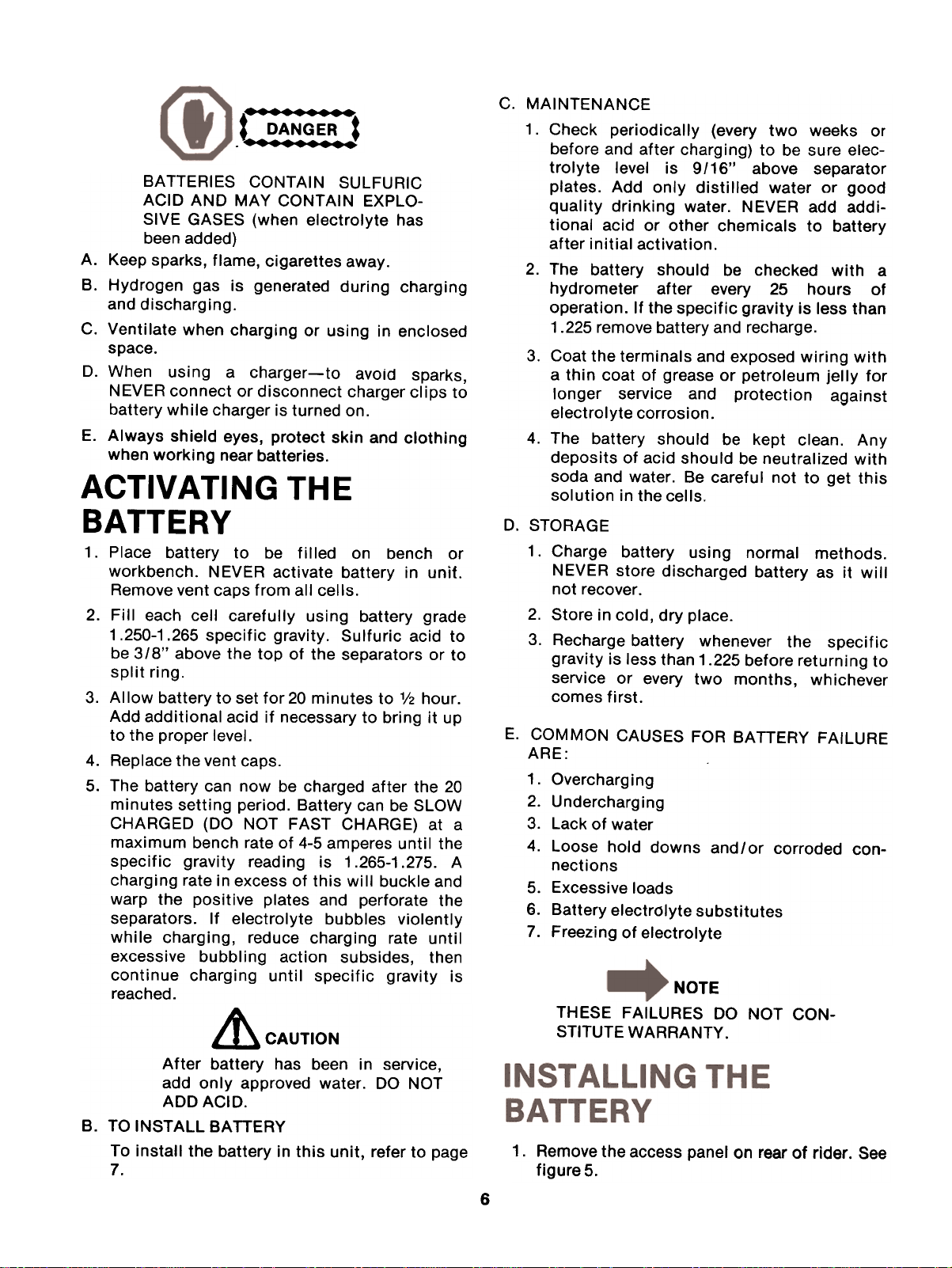

The seat spring has three holes to provide a

forward or backward adjustment of the seat. To

check for the best seat position, sit in the seat and

work the foot pedal. If adjustment is needed,

unfasten the seat and replace it in a forward or

backward hole. See figure 3.

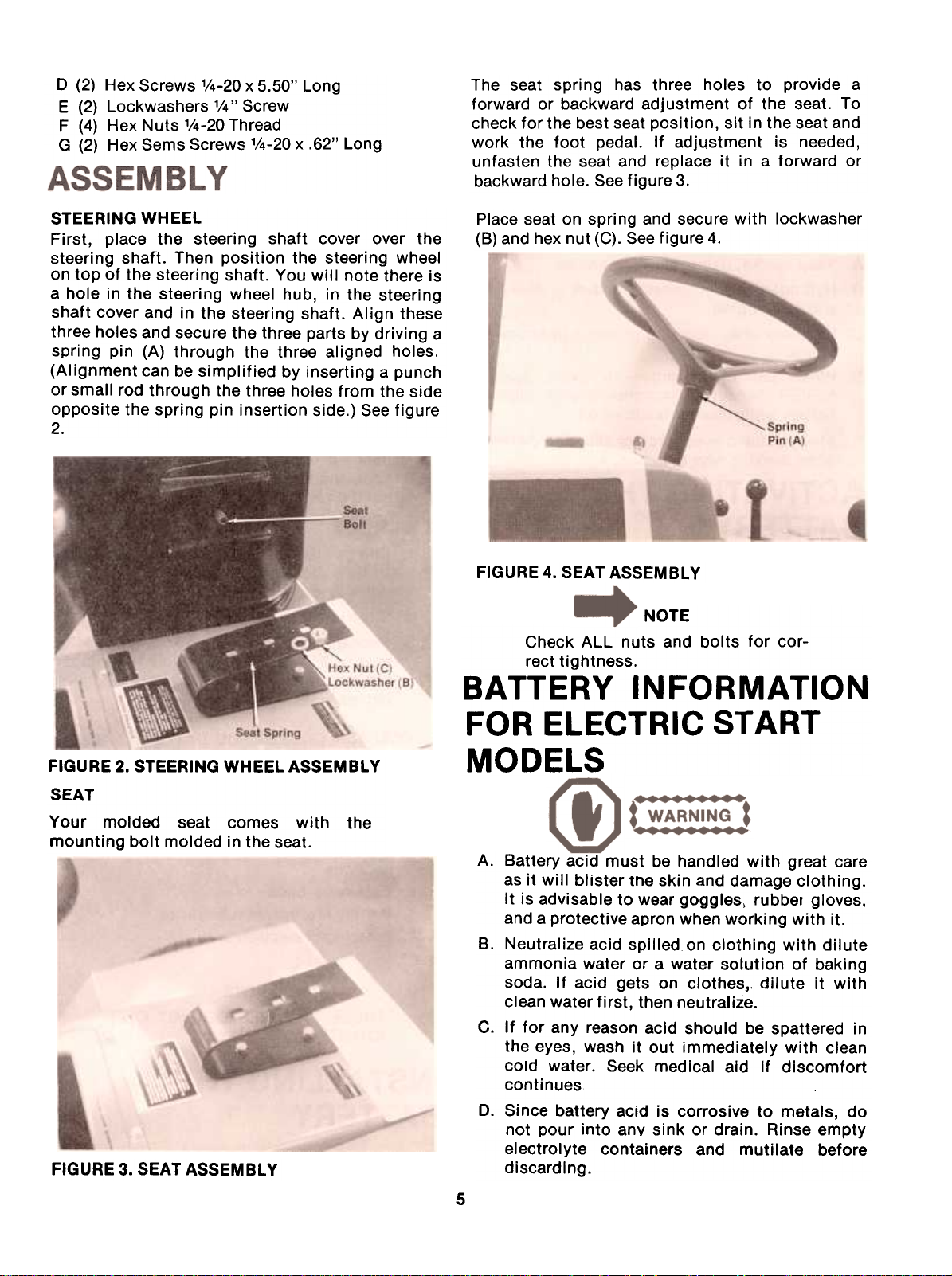

STEERING WHEEL

First, place the steering shaft cover over the

steering shaft. Then position the steering wheel

on top of the steering shaft. You will note there is

a hole in the steering wheel hub, in the steering

shaft cover and in the steering shaft. Align these

three holes and secure the three parts by driving a

spring pin (A) through the three aligned holes.

(Alignment can be simplified by inserting a punch

or small rod through the three holes from the side

opposite the spring pin insertion side.) See figure

2.

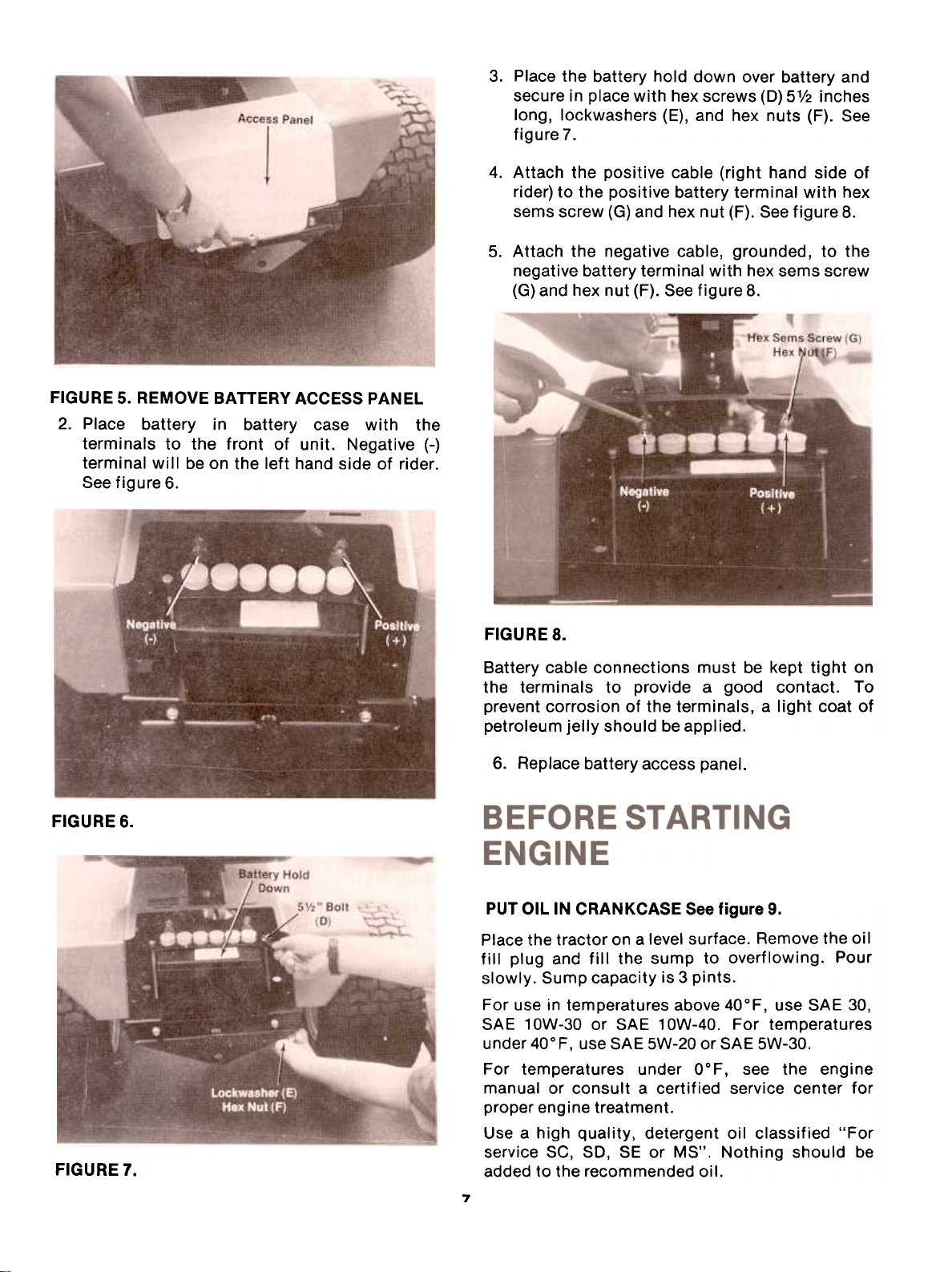

Place seat on spring and secure with lockwasher

(8) and hex nut (C). See figure 4.

FIGURE 4. SEAT ASSEMBLY

NOTE

Check ALL nuts and bolts for cor-

rect tightness.

FIGURE 2. STEERING WHEEL ASSEMBLY

SEAT

Your molded seat comes with the

mounting bolt molded in the seat.

FIGURE 3. SEAT ASSEMBLY

BATTERY INFORMATION

FOR ELECTRIC START

MODELS

Battery acid must be handled with great care

as it will blister tne skin and damage clothing.

It is advisable to wear goggles, rubber gloves.

and a protective apron when working with it.

B. Neutralize acid spilled on clothing with dilute

ammonia water or a water solution of baking

soda. If acid gets on clothes,. dilute it with

clean water first, then neutralize.

C. If for any reason acid should be spattered in

the eyes, wash it out immediately with clean

cold water. Seek medical aid if discomfort

continues

D. Since battery acid is corrosive to metals, do

not pour into any sink or drain. Rinse empty

electrolyte containers and mutilate before

discarding.

A.

5

,' t DANGER *-.~.

BATTERIES CONTAIN SULFURIC

ACID AND MAY CONTAIN EXPLO-

SIVE GASES (when electrolyte has

been added)A.

Keep sparks, flame, cigarettes away.

B. Hydrogen gas is generated during charging

and discharging.C.

Ventilate when charging or using in enclosed

space.

D. When using a charger-to avoid sparks,

NEVER connect or disconnect charger clips to

battery while charger is turned on.

E. Always shield eyes, protect skin and clothing

when working near batteries.

ACTIVATING THE

MAINTENANCE

1. Check periodically (every two weeks or

before and after charging) to be sure elec-

trolyte level is 9/16" above separator

plates. Add only distilled water or good

quality drinking water. NEVER add addi-

tional acid or other chemicals to battery

after initial activation.

2. The battery should be checked with a

hydrometer after every 25 hours of

operation. If the specific gravity is less than

1.225 remove battery and recharge.

3. Coat the terminals and exposed wiring with

a thin coat of grease or petroleum jelly for

longer service and protection against

electrolyte corrosion.

4. The battery should be kept clean. Any

deposits of acid should be neutralized with

soda and water. Be careful not to get this

solution in the cells.

BATTERY

1. Place battery to be filled on bench or

workbench. NEVER activate battery in unit.

Remove vent caps from all cells.

2. Fill each cell carefully using battery grade

1.250-1.265 specific gravity. Sulfuric acid to

be 3/8" above the top of the separators or to

split ring.

3. Allow battery to set for 20 minutes to V2 hour.

Add additional acid if necessary to bring it up

to the proper level.

4. Replace the vent caps.

5. The battery can now be charged after the 20

minutes setting period. Battery can be SLOW

CHARGED (DO NOT FAST CHARGE) at a

maximum bench rate of 4-5 amperes until the

specific gravity reading is 1.265-1.275. A

charging rate in excess of this will buckle and

warp the positive plates and perforate the

separators. If electrolyte bubbles violently

while charging, reduce charging rate until

excessive bubbling action subsides, then

continue charging until specific gravity is

reached.

~ CAUTION

After battery has been in service,

add only approved water. DO NOT

ADD ACID.

B. TO INSTALL BATTERY

To install the battery in this unit, refer to page

7.

D. STORAGE

1. Charge battery using normal methods.

NEVER store discharged battery as it will

not recover.

2. Store in cold, dry place.

3. Recharge battery whenever the specific

gravity is less than 1.225 before returning to

service or every two months, whichever

comes first.

COMMON CAUSES FOR BATTERY FAILURE

ARE:

1. Overcharging

2. Undercharging

3. Lack of water

4. Loose hold downs and I or corroded connections

5. Excessive loads

6. Battery electrolyte substitutes

7. Freezing of electrolyte

NOTE

THESE FAILURES DO NOT CONSTITUTE WARRANTY.

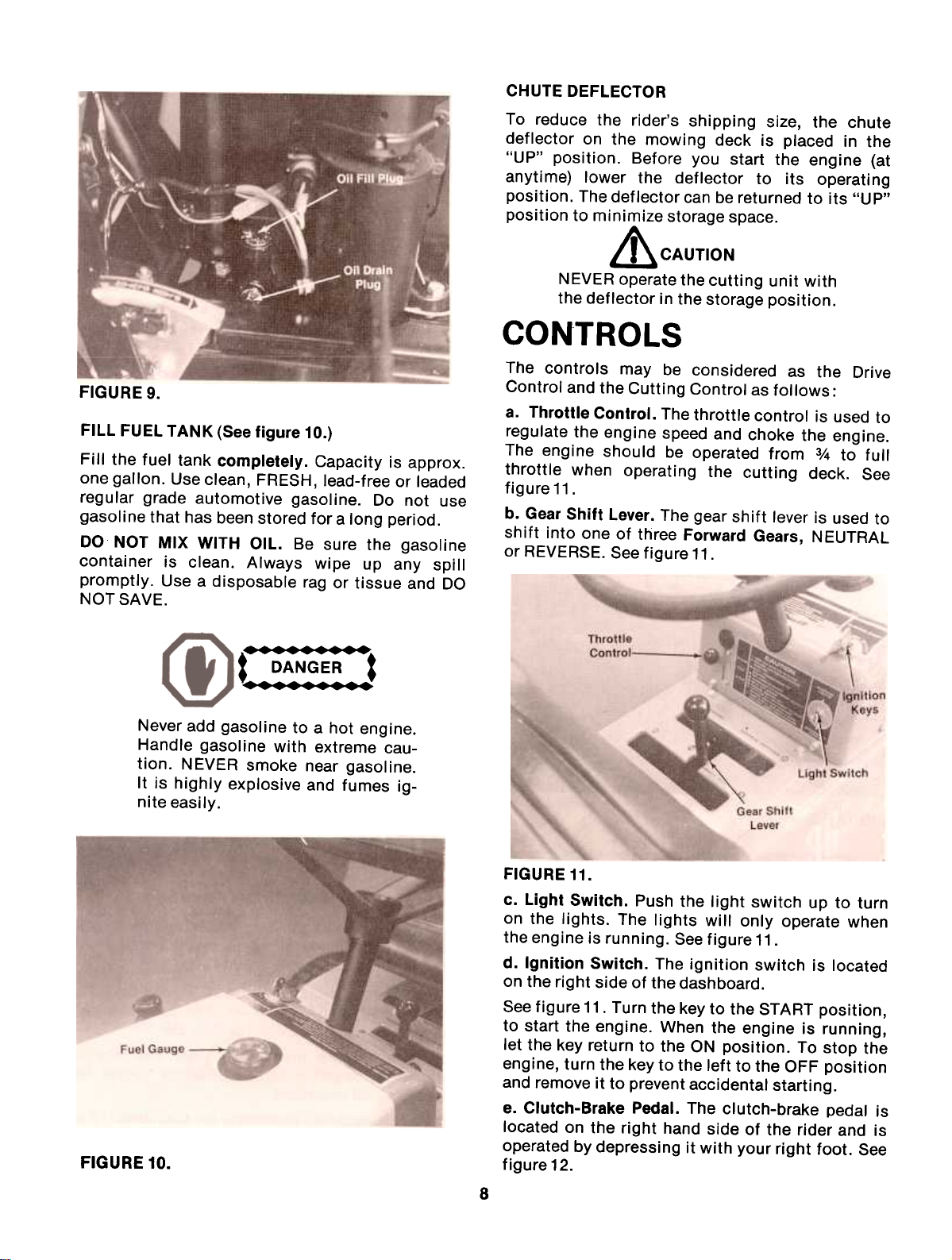

Remove the access panel on rear of rider. See

figure 5.

C.

E.

1.

6

FIGURE 5. REMOVE BATTERY ACCESS PANEL

2. Place battery in battery case with the

terminals to the front of unit. Negative (-)

terminal will be on the left hand side of rider.

See figure 6.

3. Place the battery hold down over battery and

secure in place with hex screws (0) 5V2 inches

long, lockwashers (E), and hex nuts (F). See

figure 7.

Attach the positive cable (right hand side of

rider) to the positive battery terminal with hex

sems screw (G) and hex nut (F). See figure 8.

Attach the negative cable, grounded, to the

negative battery terminal with hex sems screw

(G) and hex nut (F). See figure 8.

FIGURE 6.

FIGURE 7.

FIGURE 8.

Battery cable connections must be kept tight on

the terminals to provide a good contact. To

prevent corrosion of the terminals, a light coat of

petroleum jelly should be applied.

Replace battery access panel.

PUT OIL IN CRANKCASE See figure 9.

Place the tractor on a level surface. Remove the oil

fill plug and fill the sump to overflowing. Pourslowly.

Sump capacity is 3 pints.

For use in temperatures above 40°F, use SAE 30,

SAE 10W-30 or SAE 10W-40. For temperatures

under 40°F, use SAE 5W-20 or SAE 5W-30.

For temperatures under OaF, see the engine

manual or consult a certified service center for

proper engine treatment.

Use a high quality, detergent oil classified "For

service SC, SO, SE or MS". Nothing should be

added to the recommended oil.

7

4.

5.

6.

CHUTE DEFLECTOR

To reduce the rider's shipping size, the chute

deflector on the mowing deck is placed in the

"UP" position. Before you start the engine (at

anytime) lower the deflector to its operating

position. The deflector can be returned to its "UP"

position to minimize storage space.

CONTROLS

The controls may be considered as the Drive

FIGURE 9.

FILL FUEL TANK (See figure 10.)

Fill the fuel tank completely. Capacity is approx.

one gallon. Use clean, FRESH, lead-free or leaded

regular grade automotive gasoline. Do not use

gasoline that has been stored for a long period.

DO NOT MIX WITH OIL. Be sure the gasoline

container is clean. Always wipe up any spillpromptly.

Use a disposable rag or tissue and DO

NOT SAVE.

Control and the Cutting Control as follows:

a. Throttle Control. The throttle control is used to

regulate the engine speed and choke the engine.

The engine should be operated from 3/4 to full

throttle when operating the cutting deck. See

figure11.

b. Gear Shift Lever. The gear shift lever is used to

shift into one of three Forward Gears, NEUTRAL

or REVERSE. See figure 11 .

~CAUTION

NEVER operate the cutting unit with

the deflector in the storage position.

Never add gasoline to a hot engine.

Handle gasoline with extreme cau-tion.

It is highly explosive and fumes ignite easily.

FIGURE 10.

DANGER ~

'

NEVER smoke near gasoline.

FIGURE 11.

c. Light Switch. Push the light switch up to turn

on the lights. The lights will only operate when

the engine is running. See figure 11.

d. Ignition Switch. The ignition switch is located

on the right side of the dashboard.

See figure 11. Turn the key to the START position,

to start the engine. When the engine is running,

let the key return to the ON position. To stop the

engine, turn the key to the left to the OFF position

and remove it to prevent accidental starting.

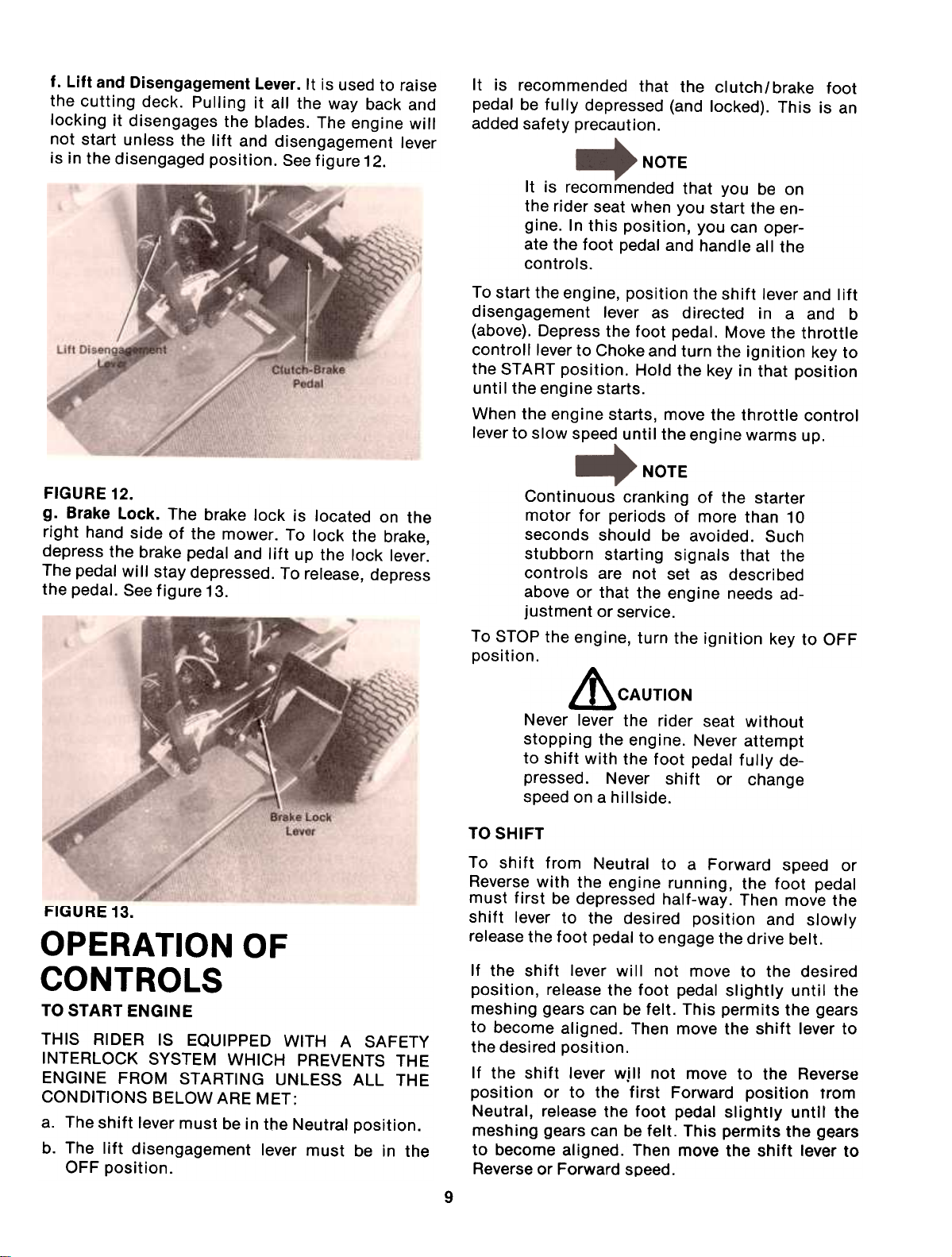

e. Clutch-Brake Pedal. The clutch-brake pedal is

located on the right hand side of the rider and is

operated by depressing it with your right foot. See

figure 12.

*

8

f. Lift and Disengagement Lever. It is used to raise

the cutting deck. Pulling it all the way back and

locking it disengages the blades. The engine will

not start unless the lift and disengagement lever

is in the disengaged position. See figure 12.

FIGURE 12.

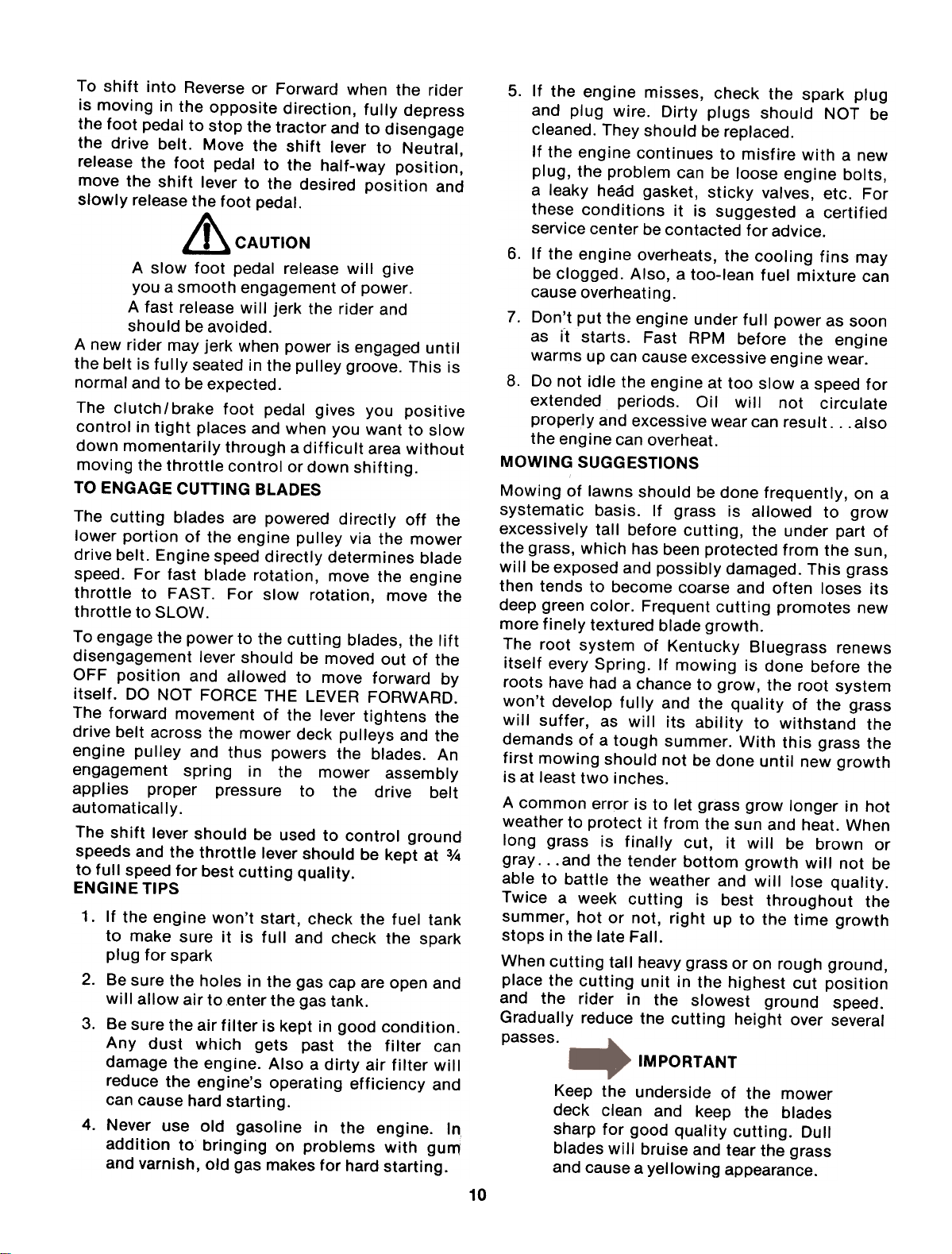

g. Brake Lock. The brake lock is located on the

right hand side of the mower. To lock the brake,

depress the brake pedal and lift up the lock lever.

The pedal will stay depressed. To release, depress

the pedal. See fig ure 13.

It is recommended that the clutch/brake foot

pedal be fully depressed (and locked). This is an

added safety precaution.

NOTE

It is recommended that you be on

the rider seat when you start the engine. In this position, you can operate the foot pedal and handle all the

controls.

To start the engine, position the shift lever and lift

disengagement lever as directed in a and b

(above). Depress the foot pedal. Move the throttle

controillever to Choke and turn the ignition key to

the START position. Hold the key in that position

until the engine starts.

When the engine starts, move the throttle control

lever to slow speed until the engine warms up.

NOTE

Continuous cranking of the starter

motor for periods of more than 10

seconds should be avoided. Such

stubborn starting signals that the

controls are not set as described

above or that the engine needs ad-

justment or service.

To STOP the engine, turn the ignition key to OFF

position.

FIGURE 13.

OPERATION OF

CONTROLS

TO START ENGINE

THIS RIDER IS EQUIPPED WITH A SAFETY

INTERLOCK SYSTEM WHICH PREVENTS THE

ENGINE FROM STARTING UNLESS ALL THE

CONDITIONS BELOW ARE MET:

a. The shift lever must be in the Neutral position.

b. The lift disengagement lever must be in the

OFF position.

~ CAUTION

Never lever the rider seat without

stopping the engine. Never attempt

to shift with the foot pedal fully depressed. Never shift or change

speed on a hillside.

TO SHIFT

To shift from Neutral to a Forward speed or

Reverse with the engine running, the foot pedal

must first be depressed half-way. Then move the

shift lever to the desired position and slowly

release the foot pedal to engage the drive belt.

If the shift lever will not move to the desired

position, release the foot pedal slightly until the

meshing gears can be felt. This permits the gears

to become aligned. Then move the shift lever to

the desired position.

If the shift lever wjll not move to the Reverse

position or to the first Forward position Trom

Neutral, release the foot pedal slightly until the

meshing gears can be felt. This permits the gears

to become aligned. Then move the shift lever to

Reverse or Forward speed.

9

To shift into Reverse or Forward when the rider

is moving in the opposite direction, fully depress

the foot pedal to stop the tractor and to disengage

the drive belt. Move the shift lever to Neutral,

release the foot pedal to the half-way position,

move the shift lever to the desired position and

slowly release the foot pedal.

~ CAUTION

A slow foot pedal release will give

you a smooth engagement of power.

A fast release will jerk the rider and

should be avoided.

A new rider may jerk when power is engaged until

the belt is fully seated in the pulley groove. This is

normal and to be expected.

The cl utch I brake foot pedal gives you positive

control in tight places and when you want to slow

down momentarily through a difficult area without

moving the throttle control or down shifting.

TO ENGAGE CUTTING BLADES

The cutting blades are powered directly off the

lower portion of the engine pulley via the mower

drive belt. Engine speed directly determines blade

speed. For fast blade rotation, move the engine

throttle to FAST. For slow rotation, move the

throttle to SLOW.

To engage the power to the cutting blades, the lift

disengagement lever should be moved out of the

OFF position and allowed to move forward by

itself. DO NOT FORCE THE LEVER FORWARD.

The forward movement of the lever tightens the

drive belt across the mower deck pulleys and the

engine pulley and thus powers the blades. An

engagement spring in the mower assembly

applies proper pressure to the drive beltautomatically.

The shift lever should be used to control ground

speeds and the throttle lever should be kept at 3/4

to full speed for best cutting quality.

ENGINE TIPS

1. If the engine won't start, check the fuel tank

to make sure it is full and check the spark

plug for spark

2. Be sure the holes in the gas cap are open and

will allow air to enter the gas tank.

3. Be sure the air filter is kept in good condition.

Any dust which gets past the filter can

damage the engine. Also a dirty air filter will

reduce the engine's operating efficiency and

can cause hard starting.

4. Never use old gasoline in the engine. In

addition to bringing on problems with gum:

and varnish, old gas makes for hard starting.

5. If the engine misses, check the spark plug

6. If the engine overheats, the cooling fins may

7. Don't put the engine under full power as soon

8. Do not idle the engine at too slow a speed for

MOWING SUGGESTIONS

Mowing of lawns should be done frequently, on a

systematic basis. If grass is allowed to grow

excessively tall before cutting, the under part of

the grass, which has been protected from the sun,

will be exposed and possibly damaged. This grass

then tends to become coarse and often loses its

deep green color. Frequent cutting promotes new

more finely textured blade growth.

The root system of Kentucky Bluegrass renews

itself every Spring. If mowing is done before the

roots have had a chance to grow, the root system

won't develop fully and the quality of the glass

will suffer, as will its ability to withstand the

demands of a tough summer. With this grass the

first mowing should not be done until new growth

is at least two inches.

A common error is to let grass grow longer in hot

weather to protect it from the sun and heat. When

long grass is finally cut, it will be brown or

gray. ..and the tender bottom growth wi II not be

able to battle the weather and will lose quality.

Twice a week cutting is best throughout the

summer, hot or not, right up to the time growth

stops in the late Fall.

When cutting tall heavy grass or on rough ground,

place the cutting unit in the highest cut position

and the rider in the slowest ground speed.

Gradually reduce tne cutting height over several

passes.

and plug wire. Dirty plugs should NOT be

cleaned. They should be replaced.

If the engine continues to misfire with a new

plug, the problem can be loose engine bolts,

a leaky head gasket, sticky valves, etc. For

these conditions it is suggested a certified

service center be contacted for advice.

be clogged. Also, a too-lean fuel mixture can

cause overheating.

as It starts. Fast APM before the engine

warms up can cause excessive engine wear.

extended periods. Oil will not circulate

properJy and excessive wear can result. ..also

the engine can overheat.

IMPORTANT

Keep the underside of the mower

deck clean and keep the blades

sharp for good quality cutting. Dull

blades will bruise and tear the grass

and cause a yellowing appearance.

10

Loading...

Loading...