Bolens 137-360-300 User Manual

MANUAL

TEN CENTS

ASSEMBLY

OPERATION

MAINTENANCE

137-360A

137-360-300

® PARTS LIST /-^P 4 C^cw4' STet/iT'

s

Usi+fcU.^

' ' ^ ^ ^ it 010

Tifi^ p io,гs’'^2As" M

R /a,s~o" x*/,aa

Important:

Read Safety Rules and

Instructions Carefully

Model Nos.

RIDING

MOWER

PRINTED IN U.S.A.

25”

FORM NO. 770-6678

I M PO RTANT

It is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this

manual in a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see operating section of this manual for

proper fuel and amount.

Your rotary mower is a precision piece of power equipment, not a plaything. Therefore exercise extreme

caution at all times.

SAFE OPERATION PRACTICES FOR RIDING VEHICLES

1. Know the controls and how to stop quickly—

READ THE OWNER’S MANUAL.

2. Do not allow children to operate vehicle. Do

not allow adults to operate it without proper

instruction. Only persons well acquainted

with these rules of safe operation should be

allowed to use your mower.

3. Do not carry passengers.

4. Keep the area of operation clear of all

persons, particularly small children and pets.

Stop engine when they are in the vicinity of

your mower. Although the area of operation

should be completely cleared of foreign

objects, a small object may have been over

looked and could be accidently thrown by the

mower in any direction.

5. Clear work area of objects which might be

picked up and thrown by the mower in any

direction.

6. Disengage all attachment clutches and shift

into neutral before attempting to start engine.

7. Disengage power to attachment(s) and stop

engine before leaving operator position.

8. Disengage power to attachment(s) and stop

engine before making any repairs or adjust

ments. Disconnect the spark plug wire and

keep the wire away from the plug to prevent

accidental starting.

9. Before attempting to unclog the mower or

discharge chute, stop the engine and be sure

the blade(s) have stopped completely. Dis

connect the spark plug wire and keep the wire

away from the plug to prevent accidental

starting.

10. Disengage power to attachment(s) when

transporting or not in use.

11. Take all possible precautions when leaving

vehicle unattended such as disengaging

power-take-off, lowering attachments, shift

ing into neutral, setting parking brake,

stopping engine and removing key.

12. Do not stop or start suddenly when going

uphill or downhill. Mow up and down face of

steep slopes; never across the face.

13. Reduce speed on slopes and in sharp turns to

prevent tipping or loss of control. Exercise

extreme caution when changing direction on

slopes.

14. Stay alert for holes in terrain and other hidden

hazards.

15. Use care when pulling loads or using heavy

equipment.

A. Use only approved drawbar hitch points.

B. Limit loads to those you can safely

control.

C. Do not turn sharply. Use care when

backing.

D. Use counterweight(s) or wheel weights

when suggested in owner’s manual.

16. Watch out for traffic when crossing or near

roadways.

17. When using any attachments never direct dis

charge of material toward bystanders nor

allow anyone near vehicle while in operation.

18. Handle gasoline with care—it is highly

flammable.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a

running or hot engine or fill fuel tank

indoors. Wipe up spilled gasoline.

C. Open doors if engine is run in garage-

exhaust fumes are dangerous. Do not run

engine indoors.

19. Keep the vehicle and attachments in good

operating condition, and keep safety devices

in place. Use guards as instructed in owner’s

manual.

20. Keep all nuts, bolts, and screws tight to be

sure the equipment is in safe working condi

tion.

21. Never store the equipment with gasoline in

the tank inside a building where fumes may

reach an open flame or spark. Allow engine to

cool before storing in any enclosure.

22. To reduce fire hazard keep engine free of

grass, leaves or excessive grease.

23. The vehicle and attachments should be

stopped and inspected for damage after

striking a foreign object, and the damage

should be repaired before restarting and

operating the equipment.

24. Do not change the engine governor settings or

overspeed the engine.

25. When using the vehicle with mower, proceed

as follows:

(1) Mow only in daylight or in good artificial

light.

(2) Never make a cutting height adjustment

while engine is running if operator must

dismount to do so.

(3) Shut the engine off and wait until the

blade comes to a complete stop before

removing the grass catcher.

(4) Check blade mounting bolts for proper

tightness at frequent intervals.

26. Check grass catcher bags frequently for wear

or deterioration. For safety protection replace

only with new bag meeting original equip

ment specifications.

27. Look behind to make sure the area is clear

before placing the transmission in reverse and

backing up.

ASSEMBLY

GRASS CATCHER Model No. 197-015A is

available as optional equipment for the mowers

shown in this manual.

\ WARNING I

A CAUTION

Installation of tire to rim :

1. Lubricate tire beads and rim

flanges.

2. Do not exceed 30 P.S.I. when

seating beads.

3. Adjust to recommended pressure

after beads are sealed.

The mower should not be operated

without the entire grass catcher or

chute deflector in place.

NOTE

Under normal usage bag material is

subject to wear, and should be

checked periodically. Be sure any re

placement bag complies with the

mower manufacturer’s recommen

dations.

For replacement bags, use only fac

tory authorized replacement bag No.

764-0121.

The manufacturer DOES NOT recommend the use

of any accessory on these riding mowers other

than those manufactured by MTD Products Inc.

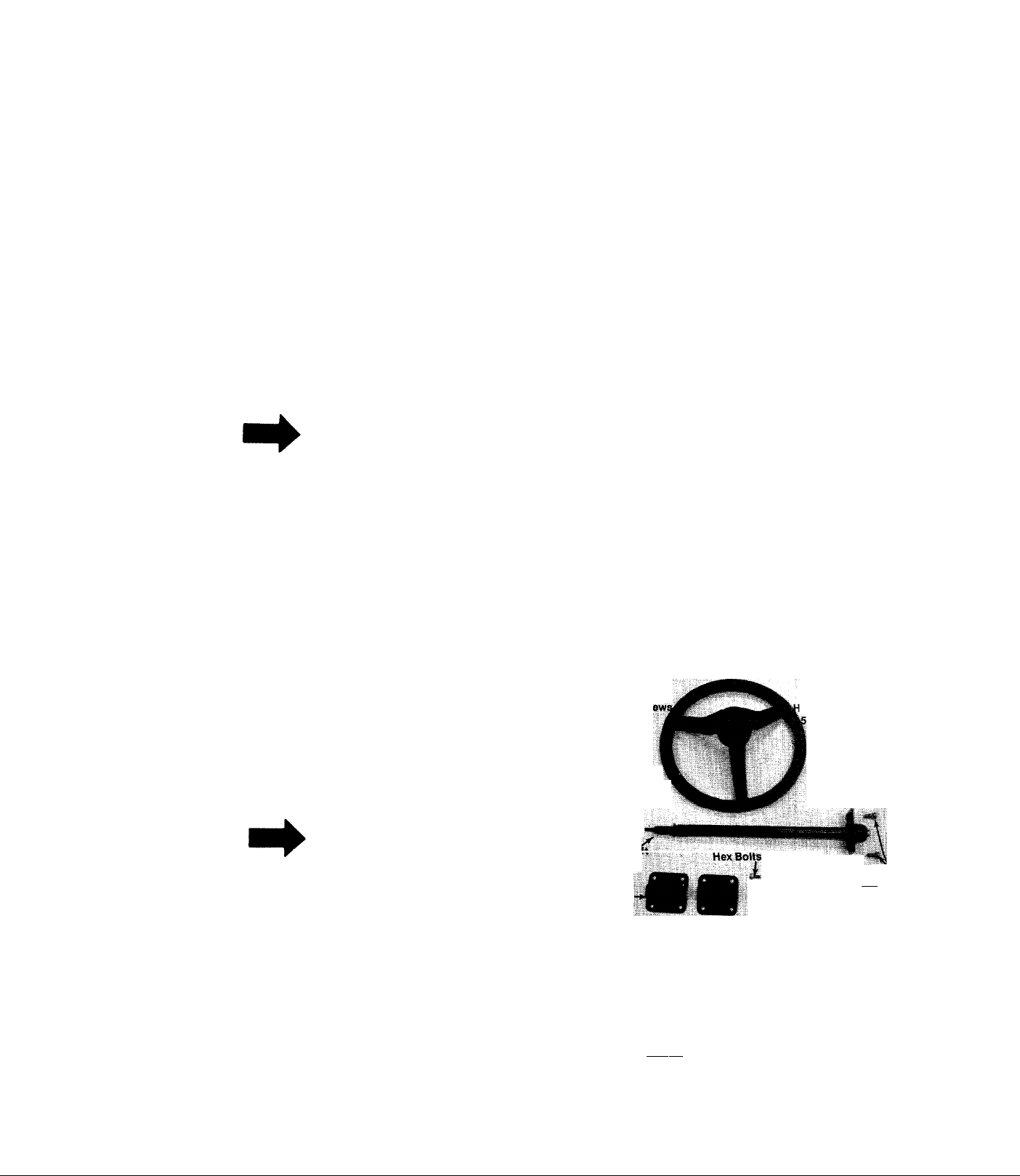

Your mower is shipped assembled except for the

steering wheel assembly and hood. These parts,

with the necessary hardware, are easily assem

bled to the machine, as outlined.

(1)1/4" Flat

I '■

Screwdriver

t '

V

•r-

\/

Wrench

FIGURE 1. TOOLS REQUIRED FOR ASSEMBLY

Long Truss Screws

P ^uts V4-20

Lockwashers

V4”Scr.

steering'^

Wheel

(2) 7/16" Wrenches

Steering Wheel

Cap

ex Nut

/16-18

Thd.".

Bell.-^-i

Washer ^

Wave Washer

NOTE

Reference to right-hand or left-hand

side of machine is from the driver’s

seat facing forward.

TIREPRESSURE

FOR SHIPPING PURPOSES, THE TIRES ON

YOUR UNIT MAY BE OVER-INFLATED. TIRE

PRESSURE SHOULD BE REDUCED BEFORE

UNIT IS PUT INTO OPERATION. PRESSURE

SHOULD BE APPROXIMATELY 15 P.S.I. EQUAL

TIRE PRESSURE SHOULD BE MAINTAINED.

MAXIMUM TIRE PRESSURE 30 P.S.I.

Steering Sha'

Tube Clamps

V4-20Thd.

i» .^»-'Cent. L-Nuts Bolts

*• : V4-20Thd.

Hex

Scms

FIGURE 2. PARTS IN CARTON AND HARDWARE

PACK

, ■ V. CAUTION

Do not use rear plastic cover to lift

unit.

FIGURES.

FIGURES.

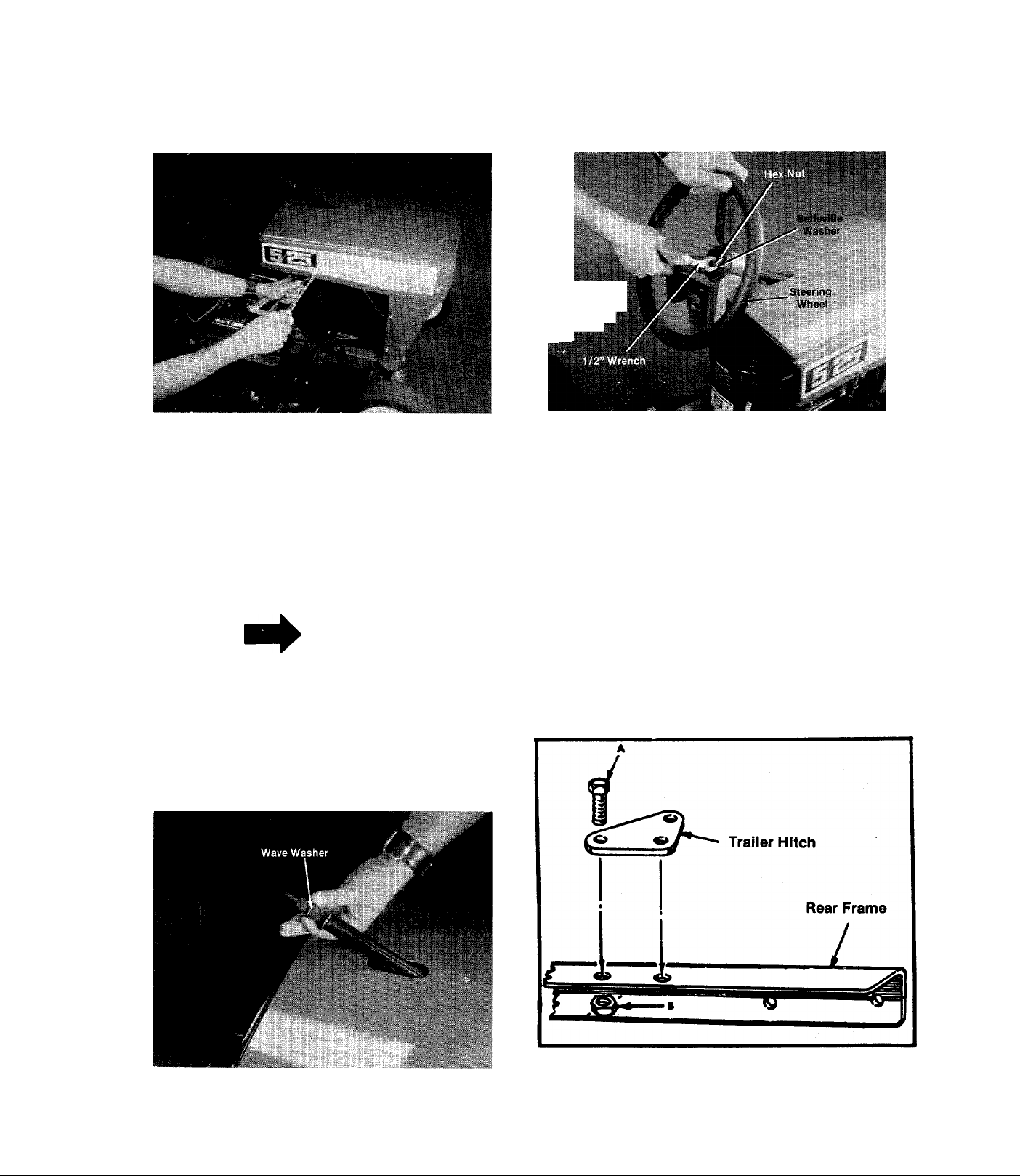

1- Place steering shaft pinion in steering gear

and fasten with two hex sems bolts. A Vz”

wrench is required. See figure 4.

3. Place the other tube clamp on top of steering

shaft and secure with four hex screws and hex

iocknuts. Two 7/16” wrenches are required.

See figure 6.

FIGURES.

2. Place one tube clamp under steering frame.

See figures.

4. Assemble the hood with long truss screws to

the rear of hood, and the short truss screws to

the front of hood. Fasten with lockwashers

and hex nuts to the tnside. See f igure 7.

. -.v'4

vSPiP

FIGURE?.

5. Place wave washer, steering wheel, belleville

washer over end of steering shaft and secure

with hex nut, using a I/2” wrench. See figures

8 and 9.

NOTE

It may be necessary to reach inside

the hood and push up on steering

shaft to get the steering wheel on.

FIGURES.

6- Place steering wheel cap in position and

press by hand.

7. Position the trailer hitch on the center of the

rear frame section and fasten with bolts A and

nuts B. See figure 10.

8. Check ALL nuts and bolts for correct

tightness.

FIGURE 8.

FIGURE 10. TRAILER HITCH

CONTROLS

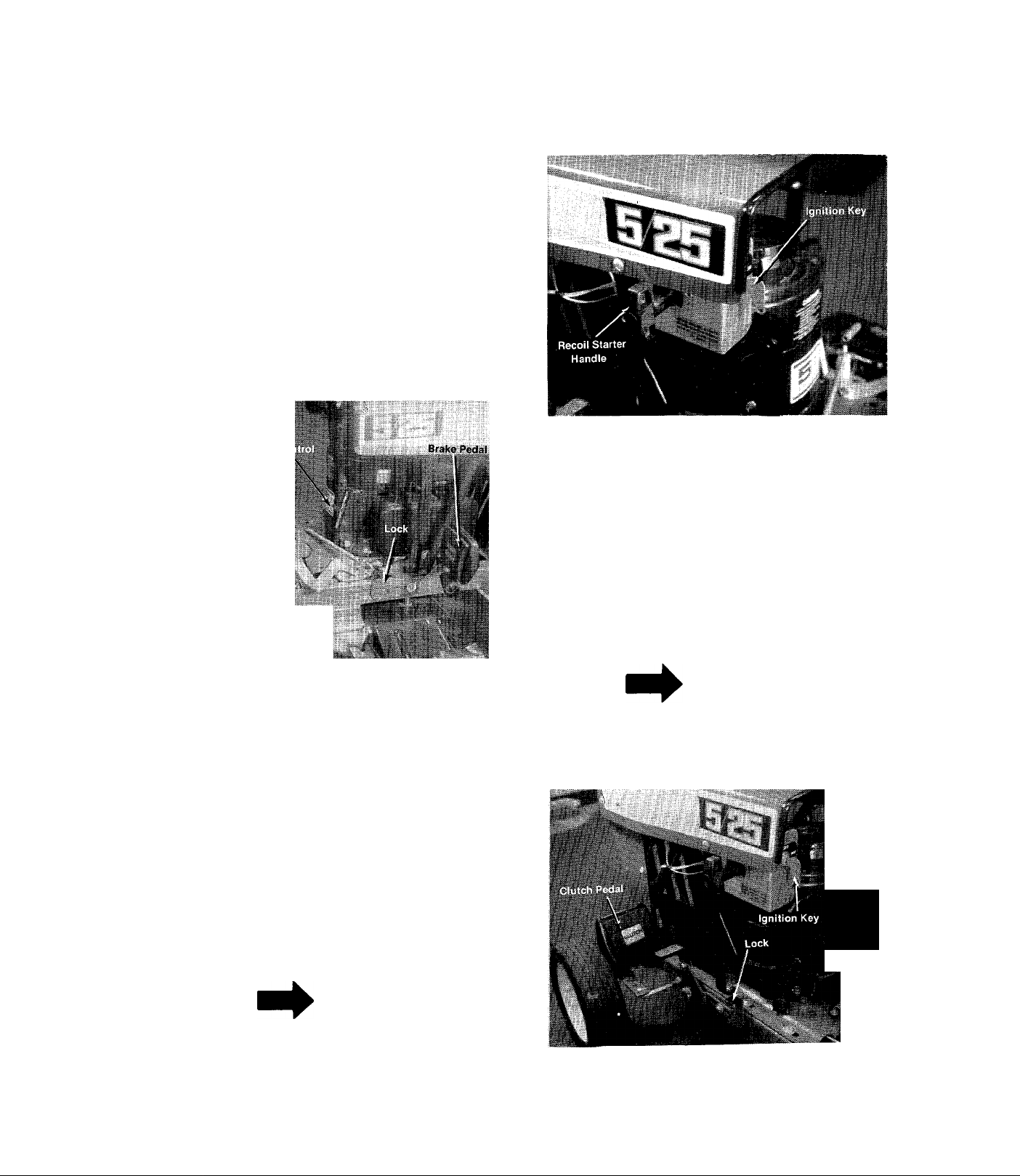

The controls on your mower may be considered as

the Throttle Control, Recoil Starter Handle,

Ignition Key, Blade Engagement Lever, Brake

Pedal, Clutch Pedal and the Gear Shift Lever.

A. Throttle Control actuates the butterfly in the

carburetor and may be set at CHOKE, FAST or

SLOW. See figure 11.

/

f

. Ik..:

Bl.icl«’ bnq.iqomi'nt

Lever

FIGURE 12

C. The Ignition Key must be turned to the right to

the ON position before the Recoil Starter Han

dle is pulled to start the engine. Turn the Igni

tion Key to the left to the OFF position to stop

the engine. See figures 12 and 13.

D. The Blade Engagement Lever engages and

disengages the blade. Pull the Blade Engage

ment Lever back to stop the blade. Move the

Blade Engagement Lever forward to’engage

the blade. See figure 11.

FIGURE 11.

B. The Recoil Starter Handle is located on the left

hand side of the hood. To operate the recoil

starter handle, twist it until it is in the horizon

tal position and pull to start the engine. After

the engine starts, return the Recoil Starter

Handle to the mounting bracket and turn it to

the vertical position as shown in figure 12.

NOTE

The clutch must be disengaged, the

blade must be disengaged and the

ignition key must be on before the

engine will start.

NOTE

Engage the Blade Engagement Lever

slowly.

i '' ,

FIGUREIS.

The Gear Shift Lever is used to select either

E.

forward or reverse. See figure 11.

NOTE

Do not shift gears while in motion.

F.

The Clutch Pedal is operated with your left

foot. The Clutch Pedal, when depressed, dis

engages the engine from the transmission so

you can stop the movement of the rider mower

to shift gears. The Clutch Pedal can be locked

in the DISENGAGED position by depressing

the Clutch Pedal and lifting the clutch lock

with your left hand. To release the Clutch

Pedal, depress it with your foot. See figure 13.

G. The Brake Pedal is operated with your right

foot and is used to stop the forward or reverse

motion of the rider. To engage the brake,

depress the Brade Pedal with your right foot.

To set the parking iDrake, depress the brake

and lift the lock. To release, depress the brake

pedal. See figure 11.

A

Parking brake must be disengaged

before unit is put into motion.

Unit is equipped with separate brake

and clutch pedals. To efficiently

stop, it is necessary to disengage

clutch when applying brakes.

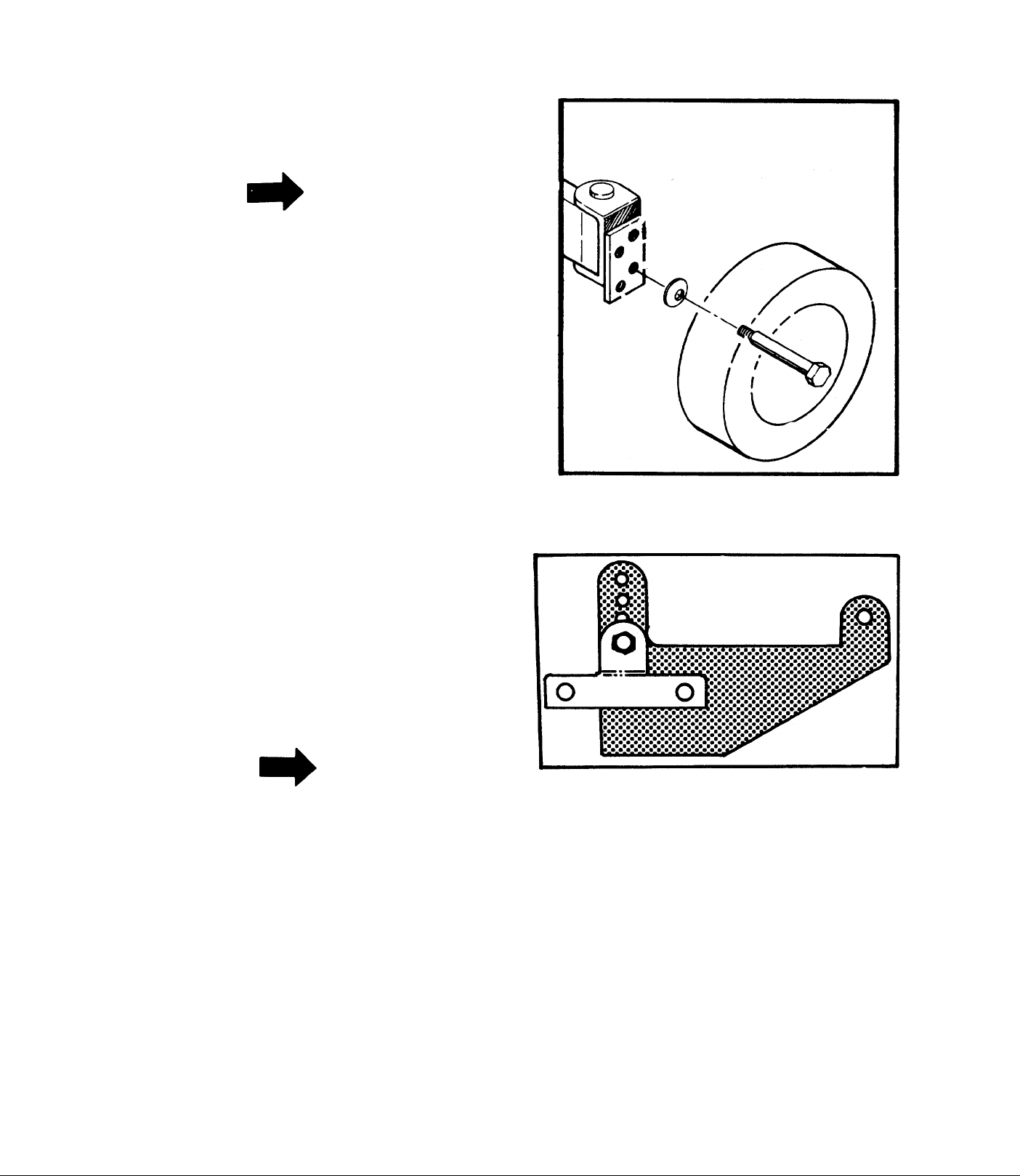

H. The height adjustment for the cutting blade is

made by removing the front axle bolts and

moving the front wheels to one of the four

cutting positions. See figure 14.

The height adjustment on the rear wheels is made

by removing the bolt on the height adjustment on

each side of the rear axle and selecting one of the

four positions. See figure 15.

CAUTION

NOTE

FIGURE 14. FRONT WHEEL ADJUSTMENT

FIGURE 15. REAR WHEEL ADJUSTMENT

CAUTION

Keep all shields and guards in place.

Before leaving operator’s position:

Shift transmission to neutral

Set the parking brake

Disengage the blade engagement lever

Shutoff the engine

Remove the ignition key

Wait for all movement to stop before servicinj

k3.

machine.

|4.

Keep people and pets a safe distance away

from rnachine.

MAINTENANCE

CRANKCASE OIL

I WARNING \

Remove the spark plug lead before

performing any maintenance on the

machine.

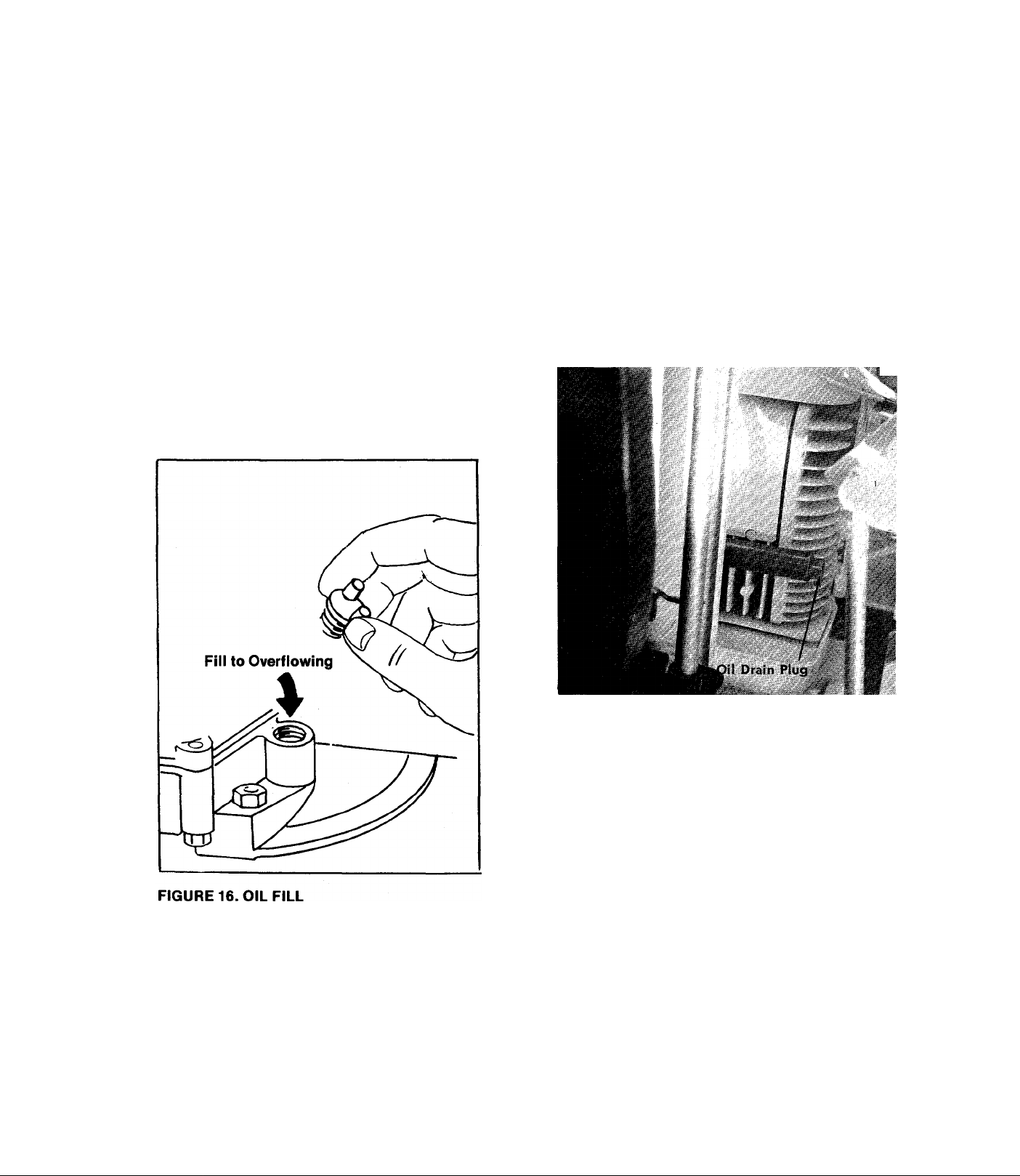

a. Oil Check

Check the oil level in the crankcase before each

use of the machine and after every two hours of

operation. Keep the oil level to the overflovving

point. See figure 16.

Step 1. With the machine on level ground, place a

suitable metal container under the oil

drain plug located on the front of the

engine. See figure 17.

Step 2. After the oil has been drained completely

from the crankcase, replace the drain plug

and tighten.

Step 3. With the machine on level ground, remove

the oil filler plug. See figure 16. Fill the

crankcase until the oil overflows from the

oil fill hole. Fill slowly to avoid air locks.

The crankcase holds approximately 1 %

pints of good quality SAE 30 type MS

engine oil. Replace the oil filler plug.

b. Oil Change

After the first two hours of operating a new

engine, drain the oil from the crankcase while the

engine is stili hot and refiil the crankcase with

new oil; thereafter, change the oil after every 25

hours of operation. This procedure ensures for

minimum wear of engine parts and provides for

virtually trouble-free operation. To change the oil,

proceed as follows:

FIGURE 17. OIL DRAIN

a. Steering Gears. Lubricate with multi-purpose

automotive type grease once a season.

b. Front Wheel Bearings. Remove the front axle

bolts and coat the axle with a multi-purpose

automotive type grease and reassemble once a

season. See figure 18.

c. King Pins. Lubricate the king pins after every

25 hours of operation with SAE 30 oil. Wipe up

excessive oil with a rag. See figure 18.

d. Rear Axle Bearings. Lubricate the rear axle

bearings after every 25 hours of operation with

SAE 30 oil. Wipe up excessive oil with a rag.

See figure 19.

e. Chain. Remove thé chain once each season,

clean in kerosene, dry and lubricate with a rag

saturated in SAE 30 ojl. See figure 19.

f. Transmission. The transmission has been lu

bricated at the factory and does not need to be

checked.

Loading...

Loading...