Page 1

Owner's Operating

Service Instruction

10*

Manual

• ASSEMBLY

• OPERATION

• REPAIR PARTS

rrrrrirrryrryrmTrrrrnrmTrrrnrrrrnrryrrrry^^

Model No.

134-585A

For one year from date of purchase, MTD Products Inc will replace for the original purchaser, free

of charge, F.O.B. factory or authorized service firm, any part or parts found to Lie defective in material

or workmanship. All transportation charges on parts submitted for replacement under this warranty

must be paid by the purchaser. This warranty does not include replacement of parts which become

inoperative through misuse, excessive use, accident, neglect, iniproper maintenance or alterations by

unauthorized persons. This warranty does not inciude the engine, motor, battery, battery charger or any

component parts thereof. For service on these units, refer to the applicable manufiicturer's warranty.

The above warranty will apply only to the original owner and will be effecti^ra only if the warranty

card has been properly processed. It will not apply where the unit has been used a>mmerciaily.

Warranty service is available through your local authorized service dealer or distributor. UNDER

NO CiRCUMSTANCES WILL THE RETURN OF A COMPLETE UNIT BE ACCEPTED BY THE

FACTORY UNLESS PRIOR WRITTEN PERMISSION HAS BEEN EXTENDED.

JiXJULUJLUJLXJUUUUiJUl a » BXULRJULRJULRJLUJUIAJLRJULJLI.«.« « « »JLJ-8JUI.« »

MTD PRODUCTS INC

PRINTED IN U.S.A.

WARRANTY

5389 WEST 130th STREET

P. 0. BOX 2741 CLEVELAND OHIO 44111

FORM NO. 770-4904

Page 2

IMPORTANT

SAFE OPERATION PRACTICES FOR ELECTRIC RIDER

1 Know the controls and how to

stop quickly—READ THE

OWNER'S MANUAL.

2 Do not allow children to operate

vehicle. Do not allow adults to

operate it without proper in

structions.

3 Do not carry passengers. KEEP

CHILDREN AND PETS A SAFE

DISTANCE AWAY.

4 Clear work area of objects

which might be picked up and

thrown.

5 Place the clutch lockout in the

disengaged position and shift

into neutral before attempting

to start the drive motor.

6 Stop motors before leaving

operator position.

7 Stop motors before making

any repairs or adjustments.

8 Disengage power by turning off

switch when transporting or

not in use.

9 Take all possible precautions

when leaving vehicle unat

tended such as shifting into

neutral, setting parking brake,

stopping cutting deck blades,

drive motor and removing key.

10 Do not stop or start suddenly

when going uphill or downhill.

Mow up and down face of steep

slopes, at a slow forward speed,

never across the face.

11 Reduce speed on slopes and in

sharp turns to prevent tipping

or loss of control. Exercise

extreme caution when changing

direction on slopes.

12 Stay alert for holes in terrain

and other hidden hazards.

13 Use care when pulling loads.

safely control and to limit

current draw of drive motor.

a Use only approved drawbar

hitch points.

b Limit loads to those you can

safely control.

c Do not turn sharply. Use care

when backing.

14 Watch for traffic when crossing

or near roadways.

15 When mowing, be careful not

to direct discharge from mower

toward bystanders. Do not

allow anyone near vehicle while

in operation.

16 The gasses produced while the

batteries are being charged are

highly combustible. Never use

a match or any open flame to

check the water level in the

battery.

17 Keep the vehicle and attach

ment's) in good operating con

dition, and keep safety devices

in place. Use guards as in

structed in owner's manual.

18 Keep all nuts, bolts and screws

tight or in proper adjustment to

be sure the equipment is in safe

working condition.

19 To reduce fire hazard keep

drive motor free of grass and

leaves.

20 The drive motor and cutting

motors should be stopped and

the key removed before in

specting for damage after strik

ing a foreign object, and the

damage should be repaired be

fore restarting and operating

the equipment.

21 When using the vehicle proceed

as follows:

(1) Mow only in daylight or

in good artificial light.

(2) Never make a cutting height

adjustment while the

motor is running if opera

tor must dismount to do

so.

(3) Stop the drive and cutting

deck motors, remove key,

before removing grass

catcher and/or unclogging

chute.

(4) Check blade mounting nuts

for proper tightness at fre

quent intervals.

22 Check grass catcher bags fre

quently for wear or deteriora

tion. Replace with new bags for

safety protection.

Page 3

INDEX

Safe Operation Practices ........................................... 2

Lawn Mower Features

Hints for Best Performance ...................................... 4

Assembly .................................................................. 5

Operation .................................................................. 7

Maintenance

Troubleshooting

Transmission Parts Illustration and Parts List .... 17

............................................................

.............................................

.......................................................

3

10

16

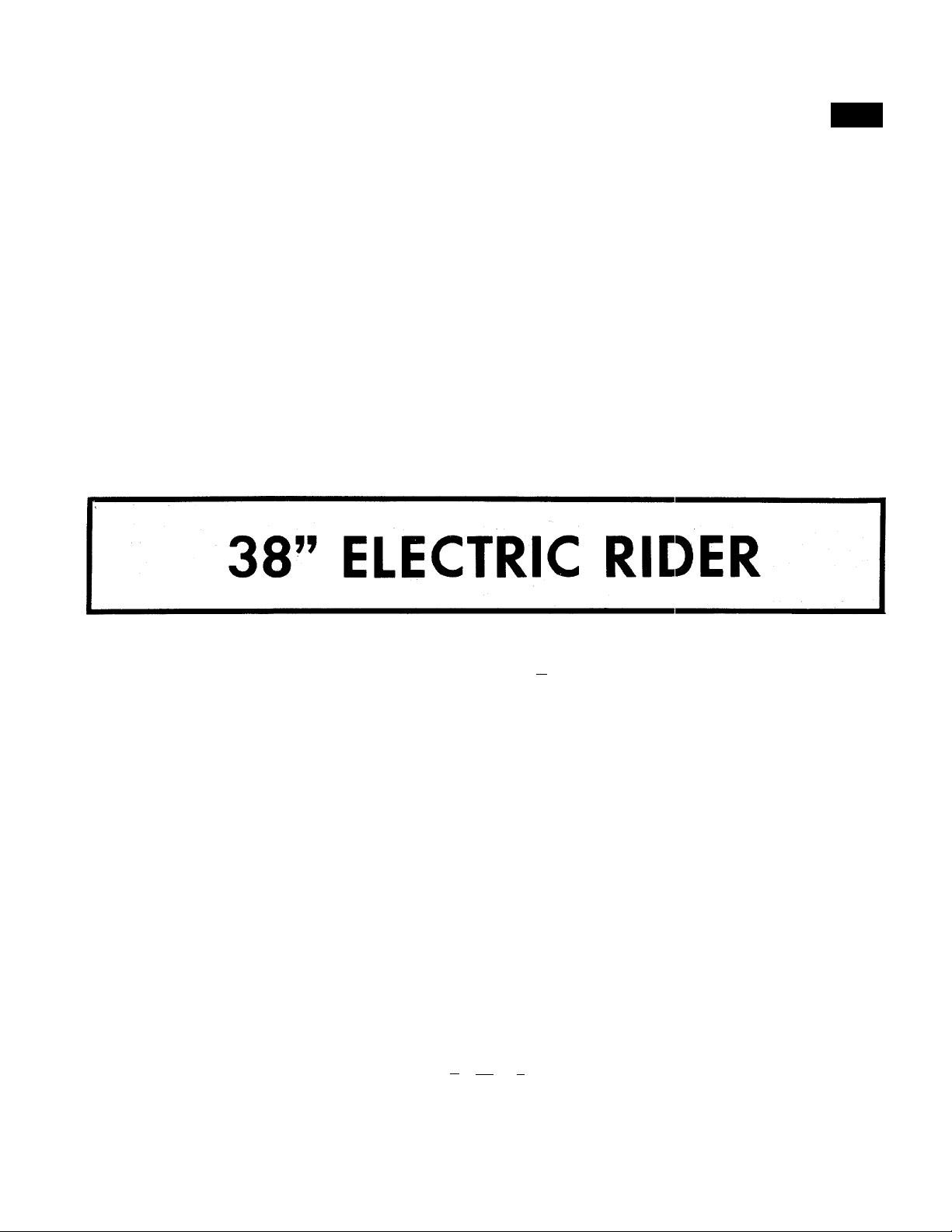

Lawn Mower Features

Blade Lift and Disengagement Lever

Lawn Mower Parts illustration................................. 18

Lawn Mower Parts List

Differential Parts Illustration and Parts List

Wiring Parts Illustration

Wiring Parts List

Traction Motor Parts Illustration and Parts List .. 28

Cutter Motor Parts Illustration and Parts List ... 29

Parts Information .................................................... 30

..........................................

............

..........................................

.....................................................

Clutch Lockout Lever

'.. 19

25

26

27

Adjustable Seat

18x6.50 Tires

Chute Deflector

Head Lamps

(36 Volt)

Three 12-Volt Batteries

Brake Peda

1 5x6.00 Tires

Page 4

Hints for Best Performance

This electric riding mower is the

ultimate in quietness and con

venience. It has its own character

istics that must be considered in

its operation. The "fuel" is in the

form of stored electricity in three

12-Volt batteries wired in series

to provide a 36-Volt system. The

gasoline engine and the electric

motor are similar in the way they

consume fuel (either gasoline or

electricity) by the fact that the

harder the unit is operated, the

faster the fuel is consumed. Cutting

at the maximum ground speed in

heavy grass will consume more

electrical energy than cutting at

an average speed in average or light

grass. The length of operating time

is in direct proportion to the way

the unit is driven and the cutting

conditions. As an example, the unit

will cut light grass for approxi

mately one hour at a modest

forward speed. That time may be

cut in half when cutting heavy grass

at high speed. The size of lawn to

be cut becomes the major influenc

ing factor in how the unit is used.

The built-in charging system takes

12 hours to 100% charge the

batteries.

Your riding mower is engineered

and designed to give you a mani

cured lawn with a minimum amount

of effort for the operator. The twin

blade cutting deck is designed to

effectively discharge the cut grass

from the deck onto the lawn or into

a grass catcher.

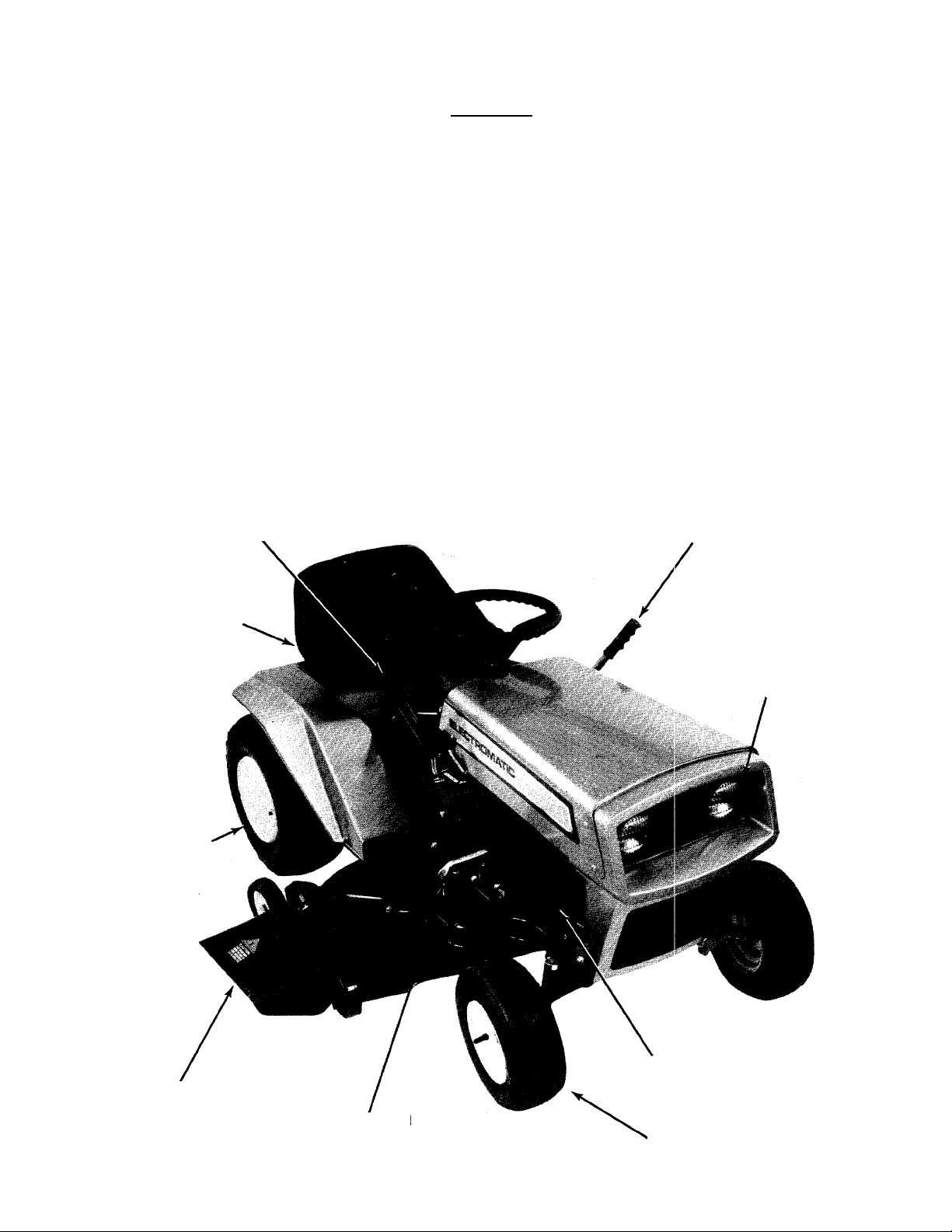

If you are cutting without a grass

catcher and the grass is wet, thick

or lush you should cut in a counter

clockwise direction to discharge

the grass towards the cut section of

your lawn. Recutting large amounts

of clippings will cause windrows

of grass.

When cutting with a grass catcher

kit, you can cut either clockwise or

counter clockwise. Plan your cutting

so you always trim with the left

side of the deck and have clearance

for the grass catcher.

Grasses such as Merion or Kentucky

Blue should not be cut less than 2

inches high. Infrequent cutting re

moves too much of the leaf surface.

Never cut off more than '/3 of the

grass blade.

It is important to have the blade

of your mower sharp when cutting.

Details on blade sharpening are ex

plained in the Maintenance Section

of this handbook. Cutting with a

dull blade generally results in a

white cast over a recent cut lawn

and later the tips of the blades turn

brown.

Avoid cutting wet grass because it

will clog up under the deck and will

not discharge properly. The general

appearance will be much better

when the grass is dry when you cut

it. A new lawn has much softer

blades of grass and has a higher

moisture content. It is extremely

important for this type of lawn to be

cut with a sharp blade.

Following the same pattern every

time when you mow your lawn can

develop ridges at right angles to the

direction of mowing. By changing

your direction of mowing (diagonal

or right angle) you can prevent

this.

Grass Catcher Model No. 194-01 5A

is available as optional equipment

for the mower shown in this manual.

Warning: The mower shall not be

operated wihout the entire grass

catcher or chute deflector in place.

Note: Under normal usage bag

material is subject to wear, and

should be checked periodically. Be

sure any replacement bag complies

with the mower manufacturer's

recommendations. Use factory

replacement bag No. 764-122.

Page 5

Assembly

NOTE: Reference to Left or Right

side of machine is from the oper

ator's position in the seat facing

forward.

The Riding Mower is packed and

shipped in one container and is

fully assembled except for the

steering wheel, seat and activating

the batteries.

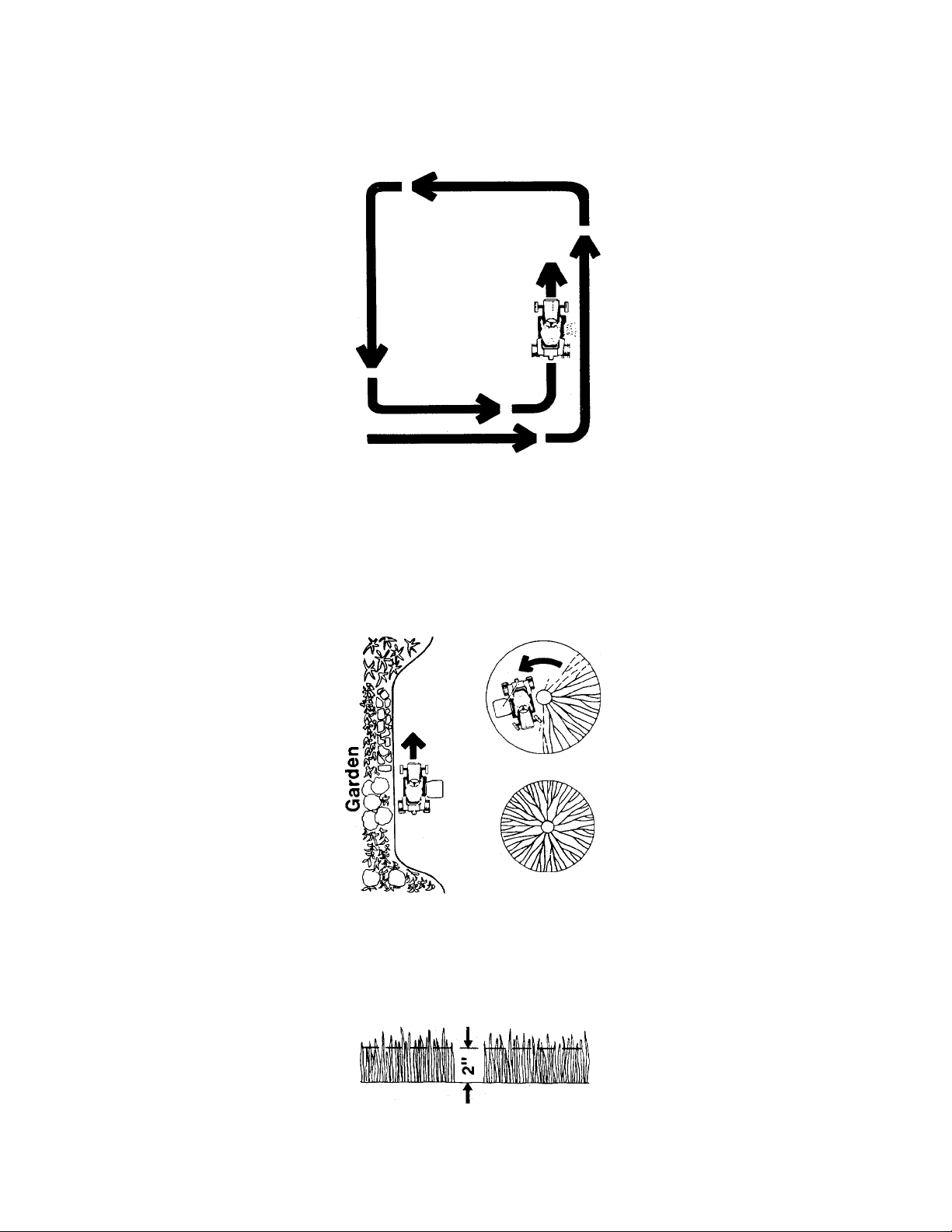

Attaching Steering Wheel

1 Place the steering wheel over

the steering column extending

through the dash. Line up the

flats on the steering column with

the flats in the steering wheel.

(See figure 1.)

2 Place the washer with the

cupped side down over the

steering column anu secure.

3 Place the cap over the center

of the steering wheel and seat

it with your hand.

Nut

Seat Assembly

1 Hook the carriage bolt into the

slot in the bottom of the seat

See Figure 1.

Carriage Bolt

nf-

Figure 2

2 Place the seat on the spring in

one of the four adjustment

holes. (See figure 3.)

3 Secure the seat with the large

lockwasher and nut.

i^ctivating the Batteries

^ Warning: ^

Electrolyte contains sul

phuric acid which is harmful to skin,

eyes and clothing. Avoid direct

contact with the electrolyte at all

times.

Fill batteries in an area where clean

water is available for flushing the

skin and eyes at all times.

Wear glasses (preferably safety

glasses) to protect the eyes while

handling electrolyte.

Electrolyte Antidotes

External: Flood with water, then

cover with moistened sodium bicar

bonate (baking soda). If eyes are

involved, wash first with water then

with 1 per cent solution of freshly

prepared sodium bicarbonate (bak-

ng soda). Call pyhsician immedi

ately.

Internal: Do not use emetics, stom

ach pumps, carbonates or bicar

bonates. Give at least 2 to 3 oz. of

milk of magnesia, or preferably

aluminum hydroxide gel diluted

with water. If these alkalies are not

available, the whites of eggs (2 to

3) well beaten may be used. Give

large quantities of water. Prevent

collapse. Call physician immedi

ately.

Figure 1

Figure 3

Page 6

Assembly

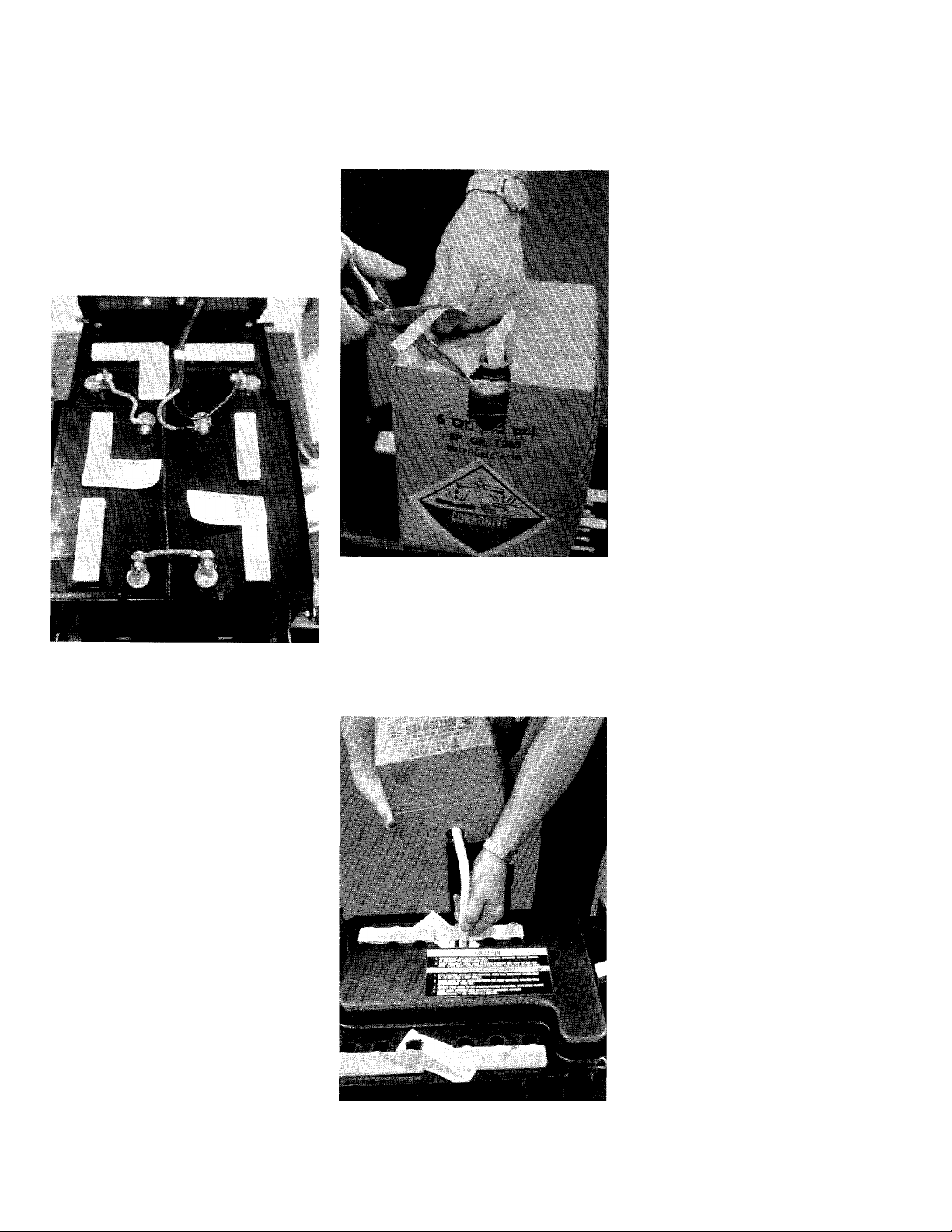

Compare the wiring of the bat

teries against figure 4 to be sur«

the batteries are wired as they

should be. Batteries that are

wired wrong could cause a

dead short when they are

activated.

Figure 4

2 It will be necessary to purchase

locally 18 quarts of Sulphuric

Acid Electrolyte (Sp. Gr, 1.265)

to activate the battery.

6 Charge the batteries as outlined

in the Maintenance Section of

this handbook.

7 Add the remaining acid to fill

the batteries to the split ring.

Tire Pressure

For shipping purposes, the tires on

your unit may be over-inflated. Tire

pressure should be reduced before

unit is put into operation. Pres

sure should not exceed 15 P.S.I.

Equal tire pressure should be

maintained.

Figure 5

Fill the batteries with the acid.

Only fill them until the acid

level is 14” above the plates.

Do not fill to the split ring at

this time.

3 Cut the sealed end from the fill

tube on the acid pack. (See

figure 5.)

4 Pinch the tube to keep the acid

from flowing from the tube

until you have the acid pack in

position as shown in figure 6.

Figure 6

Page 7

Operation

CAUTION

1 Keep al

place.

2 Before leaving operators posi

tion;

Shift transmission into neutral

Set the parking brake

Disengage the blade engage

ment lever

Shut off all motors

Remove ignition key

3 Wait for all movement to stop,

remove the ground v\/ire to the

battery before servicing the

machine.

4 Keep people and pets a safe

distance away from the ma

chine.

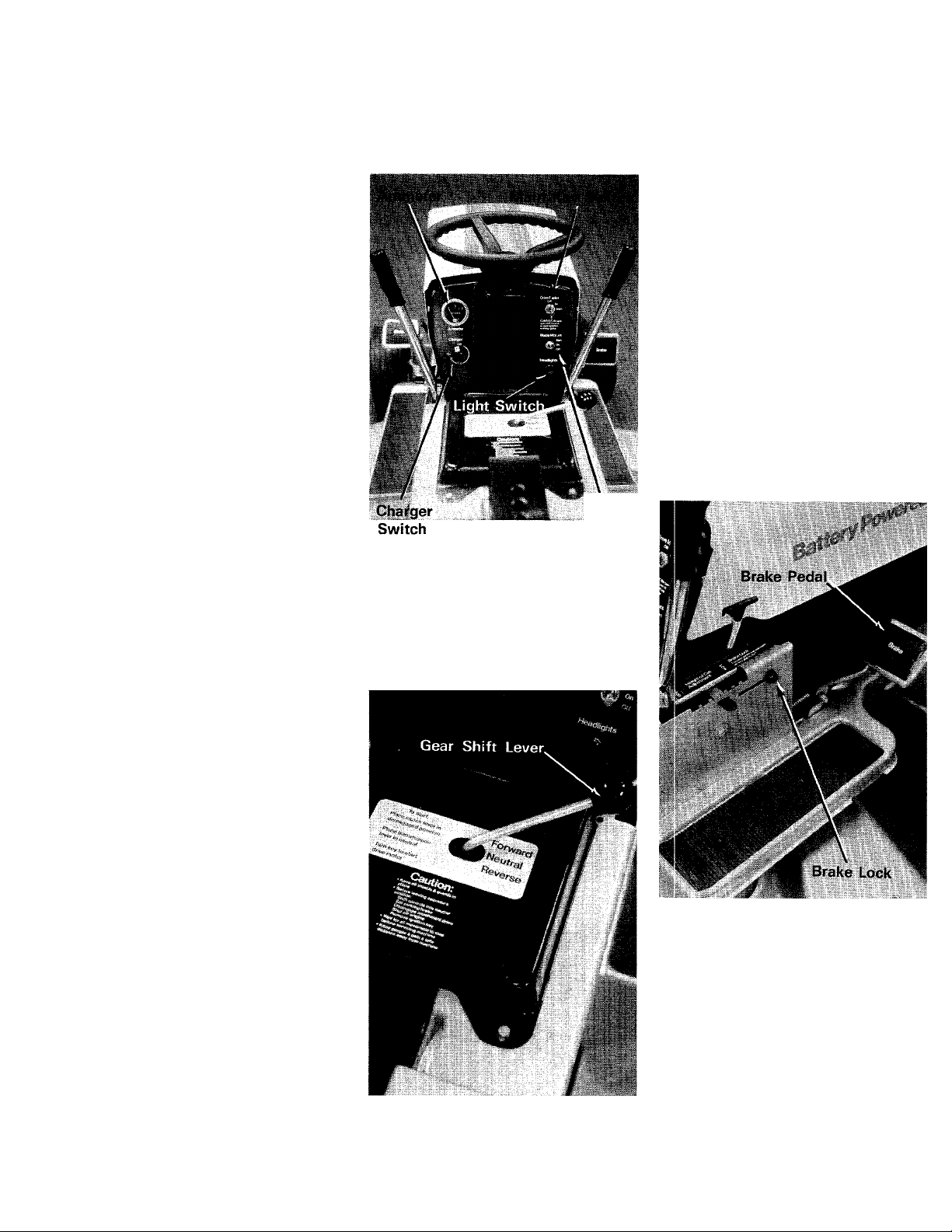

Main Key Switch

Turn the key to the START position

to start the traction motor. The

taction motor operates the drive to

the rear wheels. Once the motor

is running, release the key. The

switch will return to.the ON posi

tion. To stop the motor, turn the

key to the OFF position. This switch

must be in the ON position before

the blades can be operated. (See

figure 7.)

Caution; Remove the key from the

riding mower when the mower is

not in use to prevent accidental

starting.

shields and guards in

EJrake Pedal

The brake pedal is located on the

right side of the mower and is

operated by depressing it with your

right foot. When coming to a com

plete stop it is necessary to depress

both the clutch and the brake.(See

figure 9.)

Etrake Lock

The brake lock is located on the

right side of the mower. To lock

the brake, depress the brake pedal

and lift up the lock button. The

pedal will stay depressed. To re

lease, depress the pedal. (See fig

ure 9.)

Mother

Blade

Switch

Figure 7

Gear Shift Lever

The gear shift lever is used to shift

into FORWARD, NEUTRAL or RE

VERSE. (See figure 8.)

Mower Blade Switch

Raise the switch to the START

position. After the motors are

running, release the switch and it

will return to the ON position. Move

the switch to the OFF position to

stop the blades. The traction motor

fnust be running before the mower

blades can operate. Turning off the

main key switch will shut off both

the traction motor and the blade

motors. (See figure 7.)

Figure 9

Clutch Pedal

The clutch pedal is used to dis

engage the drive mechanism.

Depressing the clutch pedal at any

time will slow you down or, if

depressed all the way, will stop the

mower. (See figure 10.)

Figure 8

Page 8

Operation

Clutch Lockout

When the clutch pedal is depressed

all the way it can be locked by

placing the clutch lockout in the

START position as shown in figure

10.

Stop Lever

The stop lever allows you to regu

late the nnaximunn ground speed

of the riding mower by setting the

stop lever in any one of the five

settings. The farther forward the

stop lever is set, the faster your

ground speed. (See figure 10.)

Charger Switch

This switch turns on the charger

to recharge the batteries. The cord

for the charger is located under

the hood. Details for charging the

batteries is in the Maintenance

Section of this handbook.. (See

figure 7.)

Lift Lever

The lift lever is used to raise the

cutting deck. (See figure 11.)

Cutting Controis

The cutting controls consist of the

height of cut stop and the wheel

height adjusters.

Height of Cut Stop

Lift the stop and set it at the de

sired cuting height. (See figure 11

To set the cutting deck in the sus

pended position, set the height of

cut stop in the desired cutting

height and then set the deck wheels

so they just clear the ground. (See

figure 12.)

Lift Lever

High Position/ Low Position

Figure 10.

Light Switch

The headlamps are operated by

pulling out the light switch located

on the dash board. The headlamps

will only operate when the traction

motor is running. (See figure 7.)

Ammeter

The ammeter registers the rate of

battery charge. It only registers

when the charger is plugged in and

the switch is in the ON position.

(See figure 7.)

Wheei Height Adjusters

Move the lever towards the wheel

and set it in the desired cutting

height. (See figure 12.)

There are six different cutting

heights. The cutting height can be

set in two different ways; FULL

FLOAT position where the deck

follows the contour of the ground,

and the SUSPENDED position

where the deck hangs from the

frame of the rider. The suspended

position is normally used for cutting

rough uneven ground.

To set the cutting deck in the full

float position, set the wheel height

adjusters in the desired cutting

height. Set the height of cut stop

in the low position. (See figure 11.)

Height of Cut Stop

Figure 11

Figure 12

Page 9

Operation

Starting the Traction Motor

1 Place the Clutch Lockout Lever

in the START position.

2 Turn the Main Key Switch to the

START position. As soon as

the motor is running, release the

key and the switch will return

to the ON position.

3 Turn the key to the OFF position

to stop the traction motor.

Note: The blade motors also shut

off if the Main Key Switch is turned

to the OFF position.

Starting the Biade Motors

1 Start the traction motor as

outlined in the paragraph above.

2 Raise'the Mower Blade Switch

to the START position. As soon

as the motors are running, re

lease the switch and it will re

turn to the ON position.

3 To stop the blades from ro

tating, depress the mower blade

switch to the OFF position.

Note: The blades will also shut off

when the Main Key Switch is turned

off.

WARNING

i

Do not attempt to clear the chute

or perform any cleaning or repairs

of the riding mower without

turning off the main key switch and

removing the key from the switch.

Operating the Mower

1 Set the desired cutting height.

2 Start the traction motor.

3 Set the clutch stop lever in the

slow or medium speed range.

Note: As you become familiar with

the operation of the mower you may

wish to move the stop lever to a

faster position.

t

4 While holding down the clutch

pedal, move the clutch lockout

lever forward.

5 Put the gear shift lever into

either FORWARD or REVERSE.

Note: Do not force the gear shift

lever. If the lever cannot be moved

from NEUTRAL to one of the

drive positions, release the clutch

pedal slowly, depress it again, and

then move the gear shift lever as

required.

6 Once the machine is in motion,

remove your foot from the

pedal. The mower will now move

ahead or to the rear, and the

use of the steering wheel will

provide directional control.

7 The mower is brought to a stop

by pressing your right foot

against the brake pedal and your

left foot against the clutch

pedal. The drive belt will be

disengaged and the brake will

be applied.

Note: The rider should be operated

in the slow speeds when climbing

a hill or descending. This reduces

the current draw going uphill and

retards the forward speed going

downhill.

Operating the Cutter Blades

The blades can be started either

while the mower is moving or

standing still.

Move the Mower Blade Switch to

the START position, as soon as the

motors are running, release the

switch and it will return to the ON

position.

To stop the blades from rotating,

depress the Mower Blade Switch

to the OFF position or.turn off the

Main Key Switch.

Note: When the riding mower is

being used for other than mowing

operations the blades should be

shut off.

Maintenance and adjustments for

the engine are covered in the Engine

Operating and Maintenance Instruc

tions section of this handbook.

I

Figure 13

Figure 14

Page 10

Maintenance

-1 ul ■* JK" Í/T.JSS-.i*

.....

Figure 15

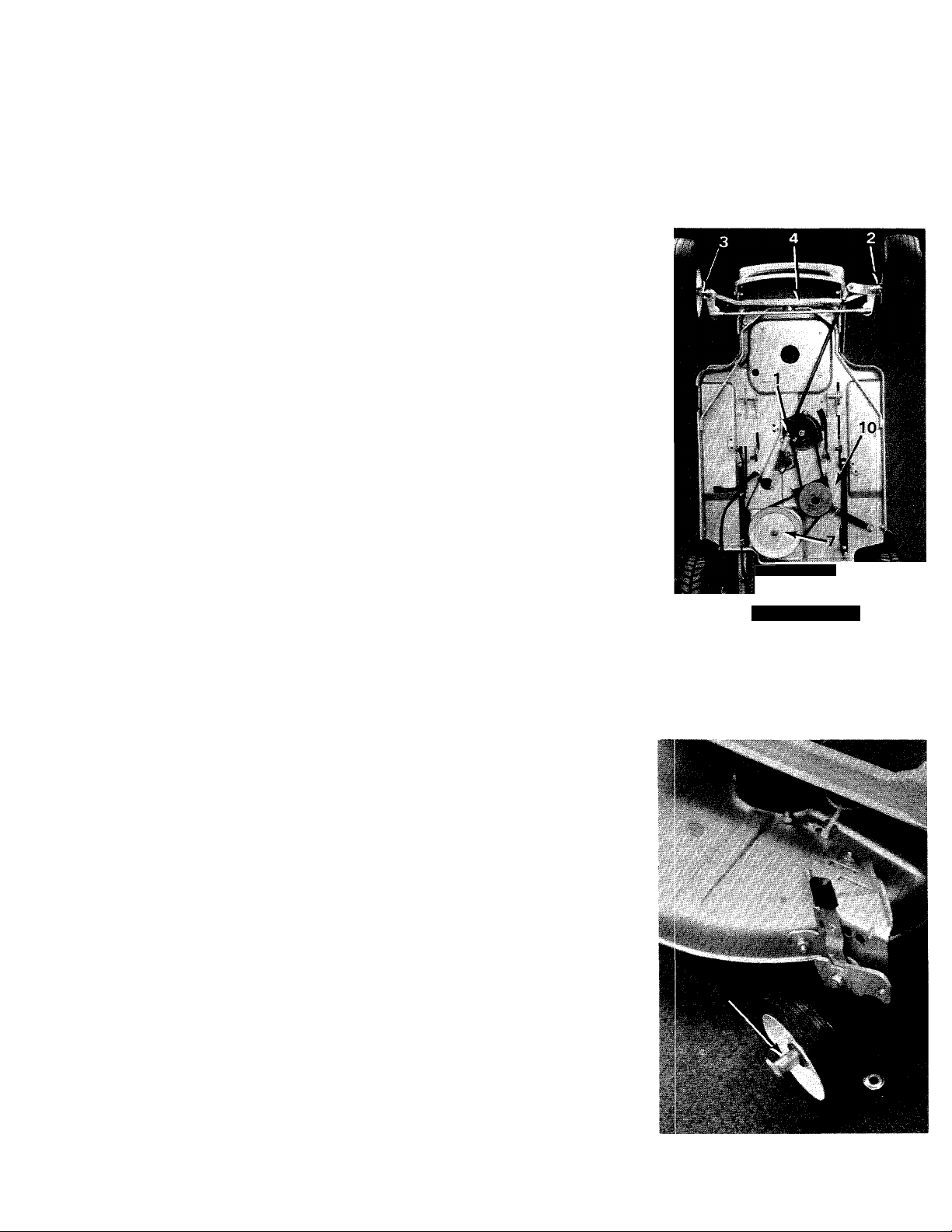

Lubrication

Steering 1—Rack and pinion, lubri

cate with multi-purpose automotive

grease once a year. (See figure

13.)

King Pin 2—Oil with SAE 30 oil

once a year. (See figure 13.)

Wheel Bearings 3—Oil with SAE

30 oil four times a year. (See figure

13.)

Front Pivot Bolt 4—Oil with SAE

30 oil once a year. (See figure 13.)

Deck Wheels 5—Remove the axle

bolts and lubricate with multi-pur

pose automotive grease once a year.

(See figure 14.)

Rear Axle Bearings 6—Oil with

SAE 30 oil once a year. Four bear

ings. (See figure 13.)

Transmission 7—The transmission

is pre-lubricated and does not have

to be checked. If disassembled,

lubricate with 5 ounces of 450°F.

grease. (See figure 13.)

Differential 8—The differential is

pre-lubricated and does not have to

be checked. If disassembled lubri

cate with 2 ounces of 450°F.

grease. (See figure 13.)

Variable Speed Pivot 9—Lubricate

with SAE 30 oil or very light grease

I

every 25 hours or anytime the

clutch pedal operates stiff. Remove

the gear shift knob and transmis

sion cover to lubricate. (See figure

15.)

Variable Speed Pulley 10—Lightly

oil with SAE 10 oil so the center

section of the pulley slides up

and down freely. The two end

bearings are sealed and require no

lubrication.

General—The following parts

should be oiled once a year with

SAE 30 oil:

All deck links

Clutch and brake pivot points

and linkage

Fleight Adjustment Levers

Steering Column bearings

The following items have sealed

bearings and require no further

lubrication.

Idler Bearings

Tie Rod Ends

Battery Charger

WARNING

THE GASES PRODUCED WHILE

THE BATTERIES ARE BEING

CHARGED ARE HIGHLY COMBUS

TIBLE. THE HOOD SHOULD BE

RAISED UNTIL THE CHARGER

SWITCH RETURNS TO THE OFF

POSITION. KEEP OPEN FLAMES

AWAY FROM THE UNIT AND DO

NOT SMOKE IN THE AREA.

The batteries in your riding mower

are specially built to withstand re

peated charging without damage.

Whenever the mower is not being

used, the charger cord should be

plugged into a 110-1 25 volt AC

grounded outlet. The charger will

draw 7.5 amps, until the battery is

charged to 80% of its capacity,

and then it will taper off.

After the cord is plugged into the

outlet, turn the charger switch

clockwise until it stops. The timer

behind the switch will rotate it to the

OFF position at which time the

batteries will be charged to their

fullest capacity. The switch will

not begin to rotate until the batteries

have reached 80% of their capacity.

This will take approximately 5 hours

maximum.

Caution; Always turn the charger

switch to the OFF position before

removing the cord from the outlet.

The charger cord should be left

plugged into a live outlet at all times

when the mower is not in use. A

timer built into the charger will

automatically turn on the charger

once a day for a few minutes and

charge the batteries. This will keep

the batteries at full capacity. This

is very important during winter

storage. A battery will lose

50% of its capacity if it is

not used for a 90 day period.

This can cause a battery to freeze

and crack during extreme cold

weather. Some heat is generated

from the charger while it is oper

ating. This is normal. (See figure

16.)

10

Page 11

Maintenance

The ammeter shows you the rate

at which your batteries are charg

ing. Maximum charging rate

is approximately 7 to 8 amps. The

charging rate will drop to 3 amps

during the latter part of charging.

Battery Maintenance

Follow the instructions in the above

paragraph covering the charging

of the batteries. To charge a set

of batteries to 100% of capacity

will take a maximum of 12 hours.

Reading your ammeter during the

charging will give you an indication

of the state of charge of your bat

teries. If the ammeter reading is

over 6 Amps, you have less than

80% of capacity.

A hydrometer can be used to

check the state of charge of the

batteries. Always read a hydrometer

at eye level to obtain a true reading.

Keep the float vertical. A hy

drometer is designed to give the

correct reading at 80°F. This is

the electrolyte temperatuer, not the

air temperature. Draw enough elec

trolyte into the hydrometer so the

float does not touch the bottom of

the tube. A correction chart is

necessary to obtain a true reading.

(See figure 17.)

Temperature

°F.

120 -F.016

115

110

105

100

95

90 +.004

85

80

75

70

65 -.006

60

55 -.010

50 -.012

45 -.014

40

35 . -.018

30 -.020

25 -.022

20 ■ -.024

15 -.026

10

Figure 18

Correction Chart

Correction

+ .014

+ .012

+ .010

+ .008

+ .006

1 +.002

0

-.002

-.004

-.008

-.016

-.028

Figure 16

Charging Hints

1 Be sure the outlet used to

charge the battery is live and

does not shut off when you turn

off the lights.

2 Only use the charger built into

the mower to charge the bat

teries. Do not use any other

charger.

3 Do not use the battery in the

mower to “jump" any other

vehicle.

Figure 17

1.260 SpGr 1.280 SpGr 100% Chg

1.230 SpGr 1.250 SpGr 75% Chg

1.200 SpGr 1.220 SpGr 50% Chg

1.170 SpGr 1.190 SpGr 25% Chg

1.140 SpGr 1.160 SpGr Very little

1.110 SpGr 1.130 SpGr Discharged

Figure 19

Examples of Reading

Specific Gravity

Hydro. Read. (fig. 17) 1.230 SpGr

Electrolyte Temp. 30° F.

Temp, Correction (fig. 18) -.020

Corrected SpGr* 1.210 SpGr

Hydro. Read, (fig

Electrolye Temp.

Temp. Correction (fig

Corrected SpGr*

*Compare to figure 19.

useful capacity

1.230 SpGr

17)

100° F.

18) -F.008

1.238 SpGr

11

Page 12

Maintenance

Water

Drinking water, except mineral

water, may be used in the batteries.

If your local water has a high min

eral content (hard water) use

distilled water in your batteries.

Do not add electrolyte if the liquid

level is down, only water.

If you add water to the battery

it will lower the specific gravity of

the electrolyte but the battery has

not lost any of its charge. If water

is added during freezing weather be

sure you charge the battery as

outlined in Battery Charger para

graph. Failure to do this can freeze

and crack a battery.

Batteries that use excessive

amounts of water indicate that they

are being over-charged and the

riding mower should be examined

by a serviceman.

Battery Removal

If the batteries are removed from

the riding mower for any reason,

remove the plastic cover by pulling

the pins and unsnapping it. Remove

the cables in the order shown in

figure 20.

This will help prevent your wrench

from arcing if it slips.

Note: Refer to figure 20 when you

reconnect the battery to make sure

it is connected properly.

Headlamps

The headlamps are 36-Volt.

Use only authorized replacements.

(GE 4350 or order from the mower

manufacturer by part number

725-377)

Automatic Reset Breakers

For your protection, both the

traction motor and the mower blade

motors have automatic reset break

ers that will shut off the motors

if they overheat as a result of over

loading. Cutting high grass at an

excessive speed is a common cause

for overheating.

Caution: If one blade motor cuts

out from overheating, both motors

will stop.

If the automatic reset breaker on

the traction motor opens, it will take

about 30 minutes before it will

reset itself.

If the automatic reset breaker on

one of the blade motors opens, it

will take about five minutes before

they will reset themselves.

Fuse (Buss WDA 100)

The 100 Amp. fuse is located

inside the charger box in back of

the dashboard. Unsnap the plastic

cover to check the fuse. There are

three extra fuses in your assembly

pack. DO NOT SUBSTITUTE any

other fuse or any other material in

place of the correct fuse.

The fuse has two purposes. One is

to protect the wiring against a

direct short and the other is to pro

tect the electrical circuit against

overloads.

If either the traction motor or blade

motors are overworked for a long

period of time the automatic reset

breakers will open and the over

heated motor will shut off as ex

plained in the above paragraphs.

If a heavy surge of current is drawn

through either the traction motor

or blade motors the 100 Amp. fuse

can melt. An example of this would

be cutting heavy grass while climb

ing a hill at a fast ground speed.

Figure 20

In the event of a melted fuse, review

how the machine was operated

prior to fuse melting. If the machine

was not heavily loaded, a failure

within the circuitry may have

occurred and the reason

for it melting should be corrected

before a new fuse is installed.

To remove the fuse, remove the

plastic cover, loosen the two nuts

on each end of the fuse and take

the free ends off the two terminals.

Replace it with a Buss WDA 100

fuse. (Manufacturers number

725-376)

12

Page 13

Maintenance

Tighten the adjusting nuts equally

on both sides. Tighten until the

chain has V4 inch slack between

the sprockets.

Figure 21

Blade Replacement

Remove the retainer nut and lockwasher. Pull the blade from the

motor shaft. (See figure 22.)

Figure 23

Brake Adjustment

To adjust the brake on your rider,

follow these steps:

1 Depress the brake pedal and lift

the brake lock so the pedal

stays in the depressed position.

2 Place the clutch loc <out in the

START position.

3 Try to push the rider. If the rider

can be moved, tighten the

brake adjustment nut as shown

in figure 23.

Note: It is not necessary to tip the

rider up on end as shown in the

photograph. The adjusting nut can

be reached with the rider in the

normal operating position.

4 Tighten the adjustment nut one

turn and test the rider. Repeat

if necessary.

Figure 24

The adjusting nuts can be tightened

individually to align the rear axle

if necessary.

Tighten the four locknuts after the

adjustment is made.

Wheel Alignment

The caster (forward slant of the

king pin) and the camber (tilt of the

wheels out at the top) requires

no adjustment. Automotive steering

principles have been used to de

termine the caster and camber on

the rider. The front wheels should

toe-in Ys inch. See figure 25.)

To adjust follow these steps;

Figure 22

When grinding or filing the blade,

remove equal amounts of metal

from both edges to keep the blade

in balance.

Chain Adjustment

To tighten the chain, loosen the

two locknuts on each side of the

rear axle. (See figure 24.)

13

II Remove the elastic locknut and

drop the tie rod end from the

steering arm. (See figure 25.)

Page 14

Maintenance

2 Loosen the hex jam nut on the tie

rod.

3 Adjust the tie rod assembly for

correct wheel alignment.

Note: Dimension B should be ap

proximately Vs inch less than

dimension A.

4 To increase dimension B screw

the rod into the tie rod end.

5 To decrease dimension B un

screw the tire rod from the tie

rod end.

6 Reassemble the rod. Check

dimensions.

Removing the Variable Speed Belts

The variable speed belts can be

removed from the rider without

removing the cutting deck and

batteries, however, they can be

removed as the photographs show

to give you more working room.

To Remove the Batteries and

Cutting Deck

1 Before lifting up one end of the

mower, remove the batteries

as outlined in the Battery Re

moval Section of this manual.

2 Lift up the front of the rider and

tip it back so it rests on the

rear wheels and the seat back.

3 Remove the cutting deck by

unplugging the two leads to

the mower blade motors, and

removing the six cotter pins

on the lower deck links.

4 Place the lift lever in the locked

out position.

Motor Puiley

Upper Bolt*.

5 Remove the nut and lockwasher

on the transmission pulley and

pull the pulley off the spindle.

(See figure 27.)

6 Remove the lower belt from the

variable speed pulley. (See

figure 28.)

7 Slide the center section of the

variable speed pulley towards

you and unhook the upper belt.

8 Reassemble in reverse order

with the new belts

Figure 28

14

Page 15

Maintenance

Troubleshooting

If a problem is encountered which

cannot be solved, refer to the chart

on page 16 for a possible remedy.

Off-season Storage

If the machine is to be inoperative

for a period longer than 30 days,

the following procedures are

recommended:

1 Clean the entire mower and

motors thoroughly.

2 Lubricate all lubrication points

indicated in figures 13 to 15,

then wipe the entire machine

with an oiled rag in order to

protect the surfaces.

3 Check the water level in the

batteries and add water if

necessary.

4 Plug the charger into an outlet

that has power all the time. Set

the charger switch to the ON

position. When the batteries are

completely charged, the timer

will turn on the charger once a

day for a few minutes to keep

the batteries at full charge.

15

Page 16

Trouble Shooting Chart

Problem

Traction Motor will not run.

Blade motors will not run. A Traction motor not running.

Mower will not move (Traction Motor running)

A Clutch lockout is not in the START position.

B Defective key switch.

C Motor overheated from excessive current draw

Allow the automatic reset breaker to reset itself

This takes about 30 minutes.

D Main fuse blown.

E Defective solenoid.

F Wire loose or disconnected.

G Defective motor.

B Defective mower blade switch.

C Motor overheated from cutting heavy grass at

excessive speed. Allow the automatic reset

breaker to reset itself. This takes about five

minutes.

D Defective solenoid.

E Wire loose or disconnected.

F Defective motor.

A Transmission in neutral.

B Clutch lockout is in the START position.

C Broken or thrown V-belt.

D Broken chain on rear axle.

E Broken or missing key in transmission (input

pulley, output sprocket, clutch collar or pinion

gear on input shaft).

F Gears in differential stripped.

Ammeter registers zero when

charger is turned on.

Batteries will not hold a charge.

Uneven mowing. A Wheel adjusters are not set the same.

Uncut strips of grass.

A The charger is not plugged into a live outlet.

B Loose cables between the batteries.

C Loose wire in the charging system.

D Charger is not working.

E Fuse blown in the charger.

A Very low water level in batteries.

B Battery (or batteries) defective.

B Bent deck.

C Ground speed is too fast for full float cutting.

Adjust deck so it is suspended and reduce

speed.

D Low battery voltage.

A Ground speed too fast.

B Dull blades.

C Short blade(s).

D Bent deck.

E Low battery voltage.

16

Page 17

REF.

PART

NO.

COLOR

NO.

1

716-104

2

748-204 #41 Sprocket Center 8 Tooth

3

714-129

4

711-854

5

714-126

6

717-123

7

748-855

8 712-117

9

748-856 Bevel Gear

10

748-857 Clutch Collar

11

12

717-124 Transmission Case—R.H.—

'3

710-195

1

___

8583

CODE

E-Ring for .500" Dia. Shaft

#4 Hi-Pro Key 3/32 x %" Dia.

Output Shaft

#9 Hi-Pro Key 3/16 X %" Dia.

Transmission Case—L.H.

Flange Bearing

Hex Centerlock V4-28*

Shift Yoke Assembly

Hex Hd. Cap Scr. %-28 x .62"

DESCRIPTION

Complete

Comp. (Witb Detent Hole)

Lg.*

NEW

PART

REF.

PART

NO.

NO.

14

741-862

15 732-863

16 736-116

17 716-106

18 716-865

19

748-866

20 748-867

21 738-159

736-192

22

736-921

23

24 712-922

25 737-120 Greose—High Temp. 450° F.

717-222

26

COLOR

CODE

DESCRIPTION

Detent Ball

Detent Spring

Flat Washer .635 I.D. x .93

O.D.

E-Ring for .625" Dia. Shaft

Snap Ring for .500" Dia. Shaft

Pinion Gear

Bearing .627 I.D.

Pinion Shaft

Flat Washer .531 I.D. x .93

O.D.

Spring Lockwasher ’/2" Scr.*

Hex Jam Not ’/?-20 Thd.*

{5 oz.)

Transmission Complete

NEW

PART

*For faster service obtain standard nuts, bolts, and washers locally,

cally, order by part number and size as shown on parts list.

If these items cannot be obtained lo-

17

Page 18

134-585A

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

RIGHT HAND VIEW

18

Page 19

PARTS LIST FOR RIGHT HAND VIEW MODEL 134-585A

REF.

NO.

n

12

PART

NO.

723-296

712-287

13 710-289

14

736-119

COLOR

CODE DESCRIPTION

Hood Lock Ass'y.

Hex Nut'/4-20 Thd.*

Hex Scr. '/4-20 X .50" Lg.*

Spring Lockwasher 5/16"

Scr.*

15

16

712-267

—

Hex Nut 5/16-18 Thd.*

Lift Handle Ass'y. See

Breakdown

17

736-192 Flat Washer .531 I.D. x .93

O.D.

18 11869 Lockout Link Ass'y.

19

20

21

11494

11493

712-923

734-497

Lift Bracket—R.H.

Lift Bracket—L.H. (Not Shown)

Hex Center Locknut %-18 Thd.

Front Wheel Ass'y.—Comp.

15 X 6.00

734-498

Front Wheel Tire Only

22 734-499 Front Wheel Rim Ass'y. Only

23 710-312

Hex Scr. %-18 X 1.31" Lg.

24 711-169 Collar %" I.D.

25 750-207 Front Wheel Bearing

28 712-342 Hex Jam Nut %-16 Thd.*

29

30 10495

31

32

33

34

35

36

37

38

39

40

10555 Front Pivot Bar Ass'y.

Front Pivot Brkt.

710-195 Hex Scr. '/4-28 x .62" Lg.*

726-106

11399

Push On Flange Palnut

Adapter Plate Ass'y.

732-261 Torsion Spring

11633 Chute Cover Ass'y. Comp.

11574

712-193

11840

736-169

Chute Cover Ass'y.

Cone Nut %-24 Thd.

Upper Frame Cover

Spring Lockwasher %" Scr.*

736-232 Wave Washer .530" I.D. x

.78 O.D. X .013

NEW

PART

REF.

NO.

41

PART

NO.

738-234

COLOR

CODE

DESCRIPTION

Snoulder Scr. .500" Dia. x

.295

42

43

712-267

736-119

Hex Nut 5/16-18 Thd.*

Spring Lockwasher 5/1 6-1 6

Thd.*

44 710-198

Hex Hd. Sems Scr. 5/16-18

X 1.36"

45 732-255

714-107

46

47 11023

48 11056

Seat Spring

Internal Cotter Pin '/2" Dia.*

Deck Link Ass'y.

Parking Brake—Lever Ass'y.—

R.H.

726-121

49

50 8118

51 11030

52 710-201

Push Cap ’A" Dia.—Black

G'rip

L ft Handle R.H.

Hex Hd. Cap Scr. %-l 6 x

.62" Lg.*

53

736-219

Belleville Washer .400 I.D.

'x 1.13 O.D.

54 748-201

Spacer .635 I.D. x .88 O.D. x

.57

55

736-233

Wave Washer .660 I.D. x .82

O.D. X .029

56

57

58 731-208

11029 Handle Pivot Bracket

11032 Lift Handle Brkt. Ass'y.

Grille Insert

59 11031 Lift Handle L.H.

60 11034 Clutch Handle Brkt. Ass'y.

61

62

63

712-267

735-126

11027

Hex Nut 5/16-18 Thd.

Washer-Rubber

Handle Brkt. Assy.

64 Rubber Grip

NEW

PART

*For faster service obtain standard nuts and bolts locally. If these items

cannot be obtained locally, order by part number and size as shown

on the parts list.

(459-Mag. Flake)

When ordering parts, if color or finish is important use the appropriate

color code shown above (e.g. Mag Flake finish—11839 (459).)

19

Page 20

134-585A

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

LEFT HAND VIEW

20

Page 21

PARTS LIST FOR LEFT HAND VIEW MODEL 134-585A

REF.

NO.

1

2

PART

NO.

731-220

712-158

COLOR

CODE

DESCRIPTION

Steering Wheel Cap

Hex Center Locknut 5/16-18

Thd.

4

3

5

6

736-219

731-219

712-222

736-174

Belleville Washer .400" I.D. 30

X 1.13 O.D.

Steering Wheel 12.0 Dia.

Push Nut%" Dia.

Wave Washer .660" I.D. x

.88 O.D. X .50" Lg.*

7

738-200

8

757-241 Seat Ass'y. Comp.—10.0"

9

736-921 Spring Lockwasher ’/2" Scr.*

10

712-206

11

12

11839-

734-528

—459

Steering Shaft

Hex Nut V2-I 3 Thd.

Rear Fender

Rear Wheel Ass'y.—Comp,

18 X 6.50

734-294

Rear Wheel Tire Only 18 x

6.50

13

14

15

9262

10473

710-258 Hex Hd. Cap Scr. L4-20 x

Rear Wheel Rim Ass'y.

Rear Wheel Hub Ass'y.

.62" Lg.*

16

710-198 Hex Sems Scr. 5/16-18 x

.75" Lg.*

17

725-358

18

712-267 Hex Nut 5/16-18 Thd.*

19

736-119 Spring Lockwasher 5/16"

Cutter Motor 36 Volts

Scr.*

723-241

20

Foot Pad 15.75" Lg. x 4.0"

Wide

21

710-259 Hex Sems Scr. 5/16-18 x

.62" Lg.*

22

23

24

25

9098 Front Axle Ass'y. L.H.

723-156 Ball Joint Ass'y. (Tie Rod End)

711-169

710-494

Collar %" I.D.

Sq. Hd. Set Scr. 5/16-18 x

.38 Cup Pt.

^6

711-256

Tie Rod %-24 (Threaded Both

Ends)

NEW

PART

REF.

NO.

27

PART

NO.

748-184 Flange Bearing .630 I.D,

28 723-156

29

719-197

31 11836—459

32 712-287

33 736-329

34 710-286

35 712-375

COLOR

CODE

DESCRIPTION

Ball Joint Ass'y. (Tie Rod End)

9095 Front Axle Ass'y. R.H.

Front Grille Comp.

Front Hood

Hex Nut ’/4-20 Thd.*

Spring Lockwasher Vi" Scr.*

Truss Hd. Mach. Scr. Vi-20

Hex Center Locknut %-16 Thd.

36 11488 Dash Panel

37

38

736-105

710-253

Belleville Washer

Hex Hd. Cap Scr. %-l 6 x

1.00" Lg.*

39 747-138

40

41

42

43

—

735-156

12381

748-228 Hex Flange Bearing ,505 I.D.

Steering Rod

Steering Ass'y. See Breakdown

Headlight Door Mounting

Dash Panel—Box Ass'y.

Bronze

44 12372 Steering Rod Bracket

710-412 Hex Hd. Cap Scr. Vi-28 x .75"

45

Lg.*

46

47

11048 Steering Segment

1 1074

Steering Housing Ass'y.

48 715-120 Spring Pin Spirol %" Dia. x

1.00" Lg.

736-329

49

Spring Lockwasher Vi" Scr.*

50 712-138 Hex Nut ’/4-28 Thd.*

710-412 Hex Scr. ’/4-28 x .75" Lg.*

51

731-232 Dash Panel Cover

52

712-267

53

725-377 36 Volt Headlight

54

Hex Nut 5/16-18 Thd.*

57 1 1487 Upper Frame

58 710-473

59 736-147

60 712-425

61 731-310

Tuss Mach. Scr. #10-24 x.50" Lg.

Ext. L-Wash. #10 Scr.*

Sq. Nut #10-24 Thd.*

Shield

NEW

PART

N

N

N

*For fatter service obtain standard nuts and bolts locally. If these items

cannot be obtained locally, order by part number and size as shown

on the parts list.

21

(459—Mag. Flake)

When ordering parts, if color or finish is important use the appropriate

color code shown above (e.g. Mag Flake finish—11839 (459).)

Page 22

134-585A

-U9

no \ ns

KJ

74?

^ I ^ ■''

/

4

''

DECK AND FRAME VIEW

22

Page 23

PARTS LIST FOR DECK AND FRAME VIEW MODEL 134-585A

PART

REF.

NO.

1 7 25 -3 74

2 7 31 -2 33

3 7 36 -1 75

4 71 2-2 8 7

5 114 92

6 1149 1

7

736 -1 75

8 7 10 -2 89 He x S c r. ' /4- 20 X .50" Lg .*

710 -2 59 H ex S em s S cr. 5/ 1 6-1 8 x

9

10 71 2- 28 7 Hex N ut /4- 20 T hd .*

1 1

736 -1 75

12

13

710 -2 86

14 7 10 -2 86

15

16 1061 4 Peda l P a d V in yl

17

712 -7 98 Hex N ut % -1 6 T h d.*

18 7 36 -1 69 Sprin g Lo ck wa sh er % " Sc r'. *

19

738 -1 40 S h ou lde r Sc r. .43 7 " D ia . x

20 1109 4 Clu tc h C o nn ec tin g Br kt.

21 ‘

‘71 0-3 2 2 Hex S em s Sc r. 5/ 16 -1 8 x

22 714 -1 29

23

726 -1 00

24

732 -2 45

25

710 -1 98 He x S e ms S cr . 5 /1 6- 18 x

26

738 -2 13 S ho uld e r S cr . .4 98 " Dia . x

27

28 7 12 -2 67

29

736 -1 19

COLOR

CODE DESCRIPTION

NO.

12 Vo lt B a tte ry — De ep

Cyc le (3 )

Bat te ry Co ve r

Spr in g W a sh er .2 70 " I .D . x

.51 O. D. X .030

Hex N u t ’/4 -2 0 Th d .*

Bat te ry Ho ld B rac ke t

Bat te ry Pl ate

Spr in g W a sh er .2 70 " I .D . x

.51 O. D. X .030

,62 " L g.*

Spr in g W a sh er .2 70 " I .D . x

.51 O. D X .030

1 1 49 0

110 37 Clu tch P e da l A ss 'y.

1 1 03 9 Ped a l "U " -B rkt . A ss 'y.

Bat te ry Si de P an el— R .H .

Truss Mach. Scr. Vi-2 0 x . 50 " Lg.*

Truss Mach. Scr. 14-20 x .50"

.18 0

1.0 0" Lq

#4 Hi- Pr o- Ke y 3/3 2 x / s" D ia.

Pus h Nu t % " R od

Bra ke S pr ing

.75 " L g.*

1.4 50 " L g.

Hex N u t 5 /16 -1 8 Th d. *

Spr in g L oc kw a sh er 5/ 16 "

Scr.*

30 712 -26 7

31

1 1 48 9

32

118 71

33

736 -1 19

Hex N u t 5 /16 -1 8 Th d. *

Bat te ry Si de P an el— L .H .

Frame Ass 'y. —Lower

Spring Lockwasher 5/16"

Scr.*

34

35

36

712 -2 67

114 95

736 -1 19

Hex N u t5/ 16 -1 8 T h d.*

Motor Belt Guard

Spring Lockwasher 5/16"

Scr.*

37

38

39

40

41

712 -2 67

756 -2 07

712 -9 22

736-921

712 -2 67

Hex Nut 5/16-18" Thd.*

Motor Pulley 3.00" O.D. Split

Hex Jam Nut %-20 Thd.

Spring Lockwasher V2“ Scr.*

Hex Nut 5/16-18" Thd.*

NEW

PART

Lg.*

REF.

NO.

PART

NO.

42

736 -1 1 9 Spri ng Lo ck w as he r 5 /1 6"

43

754 -1 57 " V" -3 elt 2 1/3 2- 28 " L g .

44

710 -5 1 5

45 10438

46

47 74 8- 17 7

48 71 5- 12 4

49

748 -1 8

50

750 -1 44

51

750 -1 46

52

741 -1 39

53

725 -3 58

54

55

742 -1 36

56

736 -1 58 S p rin g Lo ck wa sh er %" Sc r.*

57

712 -2 42

58

710 -1 98

59

710 -2 89

60

71 1-5 7 1

61

62

710 -1 95

63

732 -2 61

64

65

726 -1 06

66

738 -1 1 9

67

734 -2 95

68 712 -1 1

69

736 -1 05

70

71

736 -1 05

72

73

74

736 -3 29

75

712 -2 87

76 7 36 -1 1

77

712 -2 67

78

712 -9 22

79

736-921

80

754 -1 36

81

756 -1 74

82

714 -1 29

COLOR

CODE

123 90

1

114 97 — 4 52

113 99

115 74 — 4 59

6

109 49

109 37

112 36

112 37

9

DESCRIPTION

Scr .*

Hex H d . C ap S cr . /2 -2 0 x

3,5 0" Lg .*

Var ia ble S pe ed P ul ley A ss 'y .

38. 0" Ele c . R id er D ec k A s s'y .

She a ve H alf

Spr in g P in — Sp ir ol 5/3 2" D ia .

x .6 2" Lg .*

Mo va ble S he a ve P art A ss 'y.

Ste el Tu bin g

Spa ce r .52 0" I. D. x .69 2 O. D,

Ball B ea rin g .5 0" I.D . x 1 .3 8"

C.D ,

Cut ter M ot or 36 V olt s

Dec k As s'y . Co m p.

19. 0 i nc h B la de

Hex J am N u t % -l 1" T hd .*

Hex S em s S cr, 5 /16 -1 8 x

.75 " L g.*

Hex S cr . ’/ 4-20 X .50" Lg .*

Piv ot Pin

Ada p ter P lat e A s s'y .

Hex S cr . ’A -2 8 x . 62 " L g .*

Tor s o n S prin g

Chu te C ov er A ss 'y.

Pus h Nu t ’ A" R od

Sho u lde r S c r. . 62 5" D ia. x

1.7 5" Lg .

Wh ee l A ss 'y . 5 .0" D ia .

Hex In se rt ed L oc kn ut % -2 4

Thd .

Bell ev ille W a sh e r

Spr in g L ev er A ss 'y. w ith K no b

Bell ev ille W a sh e r

Wh ee l P iv ot Ba r

Wh ee l B ra ck et A ss 'y.— R .H .

Wh ee l B ra ck et A ss 'y.— L .H .

Not C al led O ut

Spring Lockwasher ’A" Scr.*

Hex N u t /4-20 Thd.*

Spring Lockwasher 5/Id"

Scr .*

Hex N u t 5/16-18" Thd.*

Hex Jam Nut /2-20 Thd.

Spring Lockwasher /2" Scr.*

"V"-Belt 21/32 X 31." Lg.

Transmission Pulley .50" I.D.

#4 Hi-Pro-Key 3/32 x %" Dia.

NEW

PART

N

*For faster service obtain standard nuts and bolts locally. If these items

cannot be obtained locally, order by part number and size as shown

on the parts- list.

(459—Mag. Flake)

When ordering parts, if color or finish Is important use the appropriate

color code shown above (e.g. Mag Flake finish—11839 (459).)

23

Page 24

PARTS LIST (CONTINUED) FOR DECK AND FRAME VIEW MODEL 134-585A

REF.

NO.

PART

NO.

711-494 Spacer .510" I.D. x .760 O.D.

83

DESCRIPTION

X .390

711-242 Spacer .380" I.D. x 1.010 x

84

.320

736-119

85

712-429

86

87 712-798

736-169

88

11069 Variable Speed Plate Ass'y.

89

90

91

92 710-376

93

94

95

96

97 712-429 Hex Inserted Locknut 5/16-

98

99

100

101

102

103

104 11067

105 736-114

106 11056

107

108 736-119

109 11024

110 761-137

1 11 HH-02-03631

112

113'

116

11036 Brake Pedal Brkt. Ass'y.

11065

732-208 Variable Drive Spring

725-357 Traction Motor 36 Volts

714-507

11064 Clutch Rod—Vari. Spd.

11072

711-404

736-244

712-429

736-264

719-922

712-267

HH-06-03031

HH-05-03034

710-316

Spring ockwasher 5/1 6"

Scr.*

Hex Inserted Locknut 5/16-

18 Thd.

Hex Nut %-16 Thd.*

Spring Lockwasher %" Scr.*

Vari. Spd.—Beit Guard Ass'y.

Hex Scr. 5/16-18 x 1.00" Lg.*

Cotter Pin 3/32" Dia. x .75"

Lg.*

18 Thd.

Variable Speed—Link

Shoulder Nut

Flat Washer .141 I.D. x .28

O.D.

Hex Inserted Locknut 5/16-

18 Thd.

Flat Washer .344" I.D. x .62"

O.D.

Hex Jam Nut 1/2-20 Thd.

Vari. Speed—Eccenter Ass'y.

Internal Lockwasher I/2" Scr.*

Parking Brake—Lever Ass'y.—

R.H.

Hex Nut 5/16-18 Thd.*

Spring Lockwasher 5/16"

Scr.*

Deck Link

Disc Brake Ass'y.—Comp.

Locknut

Compression Spring

Push Pin

Hex Scr. %-16 X 3.50" Lg.

NEW

PART

REF.

NO.

114 HH-03-03097

115

1 17 761-138

118

119 HH-12-03045

120

121 HH-18-02770

122

123 712-429 Hex Inserted Locknut 5/16-

124 10364 Rear Axle Plate

125

126

128

129 10360

130

131 710-198

132

133

134

135 747-106

136 712-267

137

138

139 710-412

140 722-115

141

142 736-329

143

144 714-115

145 10396

146 710-289

147

148 731-309

149

PART

NO.

HH-15-02533

HH-12-03041

712-375 Hex Center Locknut %-16 Thd.

HH-03-03032

710-437

748-151

712-429

10362

732-157

736-119

10398

713-160

713-154

Friction Pad 1.600 Dia. x .370 T

# 420 Chain Vz" Pitch x 87

717-222

11853

712-138

746-133

714-101

DESCRIPTION

Backup-Wash.

Spacer for Disc Brake

Casting, Cam Side

Casting, Carrier Side

Cam Lever

Thrust Washer 5/16" I.D.

18 Thd.

Chain Adjusting Link 5/16-

18 X 4.38" Lg.

Flange Bearing with Flats

.753 I.D.

Hex Inserted Locknut 5/16-

18 Thd.

Axle Bolt Plate Ass'y.

Rear Axle Brkt. Ass'y.

Hex Sems Scr. 5/ 16-1 8 x

.75" Lg.*

Spring .38 O.D. x 3.25

Spring Lockwasher 5/16"

Scr.*

Disc Brake Brkt. Ass'y.'

Brake Rod .25" Dia. x 23.50".,

Lg-

Hex Nut5/16-18 Thd.*

Links

#420 Master Link Vz" Pitch

Type II

Single Speed Transmission Ass'y.

Hex Scr. ’/4-28 x .75" Lg.*

Ball Knob—Black

Transmission Shift Lever Ass'y.

Spring Lockwasher Scr.*

Hex Nut ’/4-28 Thd.*

Cotter Pin ’/a" Dia. x 1.00" Lg.*

Transmission Support Brkt. Ass'y.

Hex Scr. ’/4-20 X .50" Lg.*

Wire Clip—Open Type

Bushing

Intern. Cot. Pin Vz Dia.

NEV

PA

ik.

-

N

*For faster service obtain standard nuts and bolts locally. If these items

cannot be obtained locally, order by part number and size as shown

on the parts list.

(459—Mag. Flake)

When ordering parts, if color or finish is important use the appropriate

color code shown above (e.g. Mag Flake finish—11839 (459).)

24

Page 25

DIFFERENTIAL 10483

12 15

PARTS LIST FOR DIFFERENTIAL 10483

REF.

NO.

PART

NO.

719-150

1

2 738-130

738-13

3

748-185

4

748-158

5

711-276

6

736-187

7

736-188

8

9 9133

715-247

10

11 710-526

712-237

12

719-150

13

14 715-123

15 736-119

16 748-169

17

737-120

COLOR

CODE

DESCRIPTION

Housing Half (1)

Shaft-—Short (1)

Shaft—Long (1)

Gear—-Double "D" Hole (2)

Gear—Round Hole (2)

Drive Pin (1)

Flat Washer (2)

Washer (2)

Sprocket (1)

Spirol Pin 3/16" Dia. X 1.00"

Lg.* (2)

Hex Hd. Cap Scr. 5/16-24 x

4.00" Lg.* (4)

Hex Locknut 5/16-24 Thd. (4)

Housing Half (1)

Dowel Pin 3/16" Dia. x .62"

Lg. (2)

Spring Lockwasher 5/16"

Scr.* (8)

Flange Bearing (2)

Grease—High Temp. 450°F.

(2 oz.)

NEW

_PAfiI

*For faster service obtain standard nuts, bolts, and washers locally. If these items cannot be obtained lo

cally, order by part number and size as shown on parts list.

25

Page 26

Page 27

REF.

NO.

1

10

11

12

2

3

4

5

6

7

8

9

PART

NO.

725-377

725-388

725-358

725-358

725-376

725-373

725-268

725-150

725-389

725-370

725-374

725-369

PARTS LIST FOR SCHEMATIC

COLOR

CODE

36 Volt DC Headlight 13

Electric Wire

Cutter Motor R.

Cutter Motor L.

Fuse too

Diode

Safety Switch (Normally Open) 18

Electric Wire 8 Ga.-Red

Electric Wire

Solenoid—36 Volt

12 Volt Battery 21

Solenoid—36 Volt

DESCRIPTION

NEW

PART

REF.

NO.

PART

725-378

725-371

14

725-201

725-372

15

725-357 Drive Motor

16

725-202

17

725-386

725-368

19

725-440

710-198

20

736-119

712-267

22

NO.

COLOR

CODE

DESCRIPTION

Metal Strip

Ignition Switch

Ignition Key (Not Shown)

Cutter Switch

Light Switch

Ammeter

Motor Harness

Wire Harness N

Hex Sems Scr. 5/16-18 x .75" Lg.*

L-Wash. 5/16" Scr.*

Hex Nut 5/16-18 Thd.*

’7ó?S‘-37S' 36~i/.

NEW

PART

Black and

Stripped Green

Red

Harness Connector Looking into

Plug Motor Marked IL

Red

Yellow

Green

czif—Green

Drive Motor Connector Looking into Plug

Black Bridge Wire

Black

710-117 Hex Scr. (5/16-24x1.00)

736-242 Bell Wash (5/16)

736-249 Fib. Wash (.34 I.D. x 1.00 O.D. x .063)

736-248 Fib. Wash (.34 I.D. x .62 O.D. x .063)

3 Fib. Wash (.34 I.D. x 1.00 O.D. x .063)

Red Bridge Wire

Reid

Harness Connector Looking into

Plug Motor Marked IR

Red and Orange

Black

-242 Bell Wash (5/16)

Terminal

712-256 Hex

736-159 FI.

27

Jam Nut (5/16-24)

Vl/asher (5/16)

-376 Fuse (100 Amp.)

725-

,736-159

,712-256

Page 28

Traction Motor

2

3 4

20 21 22

Q ;■«

5

Model 725-357 C BOSH 06277-21-M048HM

REF.

NO.

1 01 137-21-SC48HM

2 06330-25-CP48HM

3

4 01225-25-BB48HM

5 01144-26-PL48HAA Plate, Bearing Retainer

6

7

8 06331-23-HC48HM

9

10 EC 3164

11

PART

NO.

Scr., Bearing Retainer Plate

Cap, Drive End-Vent

Not required

01 141-23-SC48HM Thru Bolts

06327-21-AT48HM

01 11 3-25-SC48HM

01219-24-BR48HM

Bearing, Drive End

Armature Assembly

Hsg., Assy., Motor-Vent

Scrs., Brush Holder Retain.

Retainer, Brush Shunt

Brush & Bolt Assy.

DESCRIPTION

PARTS LIST

REF.

NO.

12 SP 551013 Brush Spring

13 01112-27-BH48HM

14 SC 3080-1

15 EC 3046-4 Holder, Motor Protector

01238-20-SW48HM

16

17 01111-29-BG48HM Bearing, Commutator Cap

01216-22-WA48HM Washer, Insulating

18

19 06328-23-CP48HM

20 WA 3074-1 Washer, Insulating

21

WA 1 -9 CA or ZN

22 NT 7-8 CA or ZN Nut

PART

NO.

Brush Holder

Scr., Motor Protector Holder

Cap, Commutator End

Washer

DESCRIPTION

Motor Protector & Bracket

28

Page 29

Cutter Motor

2

3 4

Il 18

Vli

r’/ Il

5

14

—^ 16-

REF.

NO.

01137-21-SC48HM

1

PART

NO.

2 01149-24-CP48HM

01138-23-RG48HM

3

01127-22-BB48HM

4

01144-26-PL48HM

5

01140-25-SC48HM

6

01 173-22-AT48HM

7

01162-23-HG48HM

8

01 113-25-SC48HM

9

EC 3164

10

Model 725-358 (01119-27-M048HM)

DESCRIPTION

Screw, Bearing Retainer

Cap, Drive End

Ring, Retaining

Bearing, Drive End

Plate, Bearing Retaining

Thru Bolts

Armature Assembly

Housing Assembly, Motor

Screw, Brush Holder

Retainer, Brush Shunt

PARTS LIST

REF.

NO.

1 lA 01107-24-CB48HM Brush & Cable Assembly

12

SP 551013

13

01112-27-BH48HM Brush Holder

14

SC 3080-1

16A

01217-20-SW48HM

17

01111-29-BG48HM

18 Not required

01148-22-CP48HM

19A

PART

NO.

Brush Spring

Screw, Thermal Overload

Retainer

Thermal Overload Switch &

Cable Assy.

Bearing, Commutator Cap

Cap, Commutator End

DESCRIPTION

29

Page 30

PARTS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

Parts and service for all MTD manufactured power

equipment are available through the authorized serv

ice firms listed below. All orders should specify the

model number of your unit, parts numbers, descrip

tion of parts and the quantity of each part required.

A 1 Engine & Mower Co.

327 East 9th Street

Salt Lake City, Utah 84102

American Eieetric Ignition Co.

124 N. W. 8th Street

Oklahoma City, Oklahoma 73102

Auto Eieetric & Carburetor Co.

2S25 4th Avenue, S.

P. O. Box 1948

Birmingham, Alabama 35233

Automotive Equipment Service Co.

3117 Holmes Street

Kansas City, Missouri 64109

Bailey's Rebuild inc.

1325 E. Madison Street

Seattle Washington 98102

Bleckrie, Inc.

7900 Lorain Avenue

Cleveland, Ohio 44102

Brown Equipment Distributor Inc.

110 Beech Street

Corydon, Indiana 47112

Bullard Supply

2409 Commerce Street

Houston, Texas 77003

Carl A. Anderson Co.

623 S. 16th Street

Omaha, Nebraska 68102

Catto A Putty, Inc.

P. O. Box 2408

510 Soledad Street

San Antonio, Texas 78205

Center Supply Company

6867 New Hampshire Avenue

Takoma Park, Maryland 20012

Dixie Sales Company

P. O. Box 1408

327 Battleground Avenue

Greensboro, North Carolina 27402

East Point Cycle & Key Shop

1617 Whiteway

East Point, Georgia 30044

Gamble Distributors

West End Avenue

Carthage, New York 13619

Garden Equipment Co., Inc.

6600 Cherry Avenue

Long Beach, California 90805

Gardenville Supply, Inc.

Pipersville, Pennsylvania 18947

Henry W. O'Neil & Assoc., Inc.

410 North Goodman Street

Rochester, New York 14609

Henzier, Inc.

2015 Lemay Ferry Road

St. Louis, Missouri 63125

Kenton Supply

8216 North Denver Avenue

Portland, Oregon 97217

Kimber't Inc.

115 W. Geddes St.

Syracuse, New York 13204

The Lawnmower Shop

1340 El Camino Real

San Carlos, California 94070

Marr Brothers

423 E. Jefferson

Dallas, Texas 75203

Mathews Auto Electric Co.

420 East 2nd Street

Tulsa Oklahoma 74120

McClure Lawn & Garden Supply

1114 Lexington Avenue

Mansfield, Ohio 44907

Memphis Cycle & Supply Co.

421 Monroe Avenue

Memphis Tennessee 38103

Morton B. Collins Co.

300 Birnie Avenue

Springfield, Massachusetts 01107

Moz-AII of Florida, Inc.

365 Greco Avenue

Coral Gables, Florida 33146

DEFECTIVE OR MISSING PARTS must be reported

to the factory immediately. Such claims must include

your model number and date of purchase.

National Central, Div. of

Joe Sterling, Inc.

Drawer "D" 687 Seville Rd.

Wadsworth, Ohio 44281

Parts & Sales Inc.

2101 Industrial Pkwy.

Elkhart, Indiana 46514

Power Equipment Distributor

36463 So. Gratiot Avenue

Mt. Clemens, Michigan 48043

Power Lawn & Garden Equip. Co.

2551-2571 J. F. Kennedy Road

Dubuque, Iowa 52001

Radco Distributors

2403 Market Street

P. O. Box 3216

Jacksonville, Florida 32206

Raub Supply Company

James & Mulberry Sts.

Lancaster, Pennsylvania 17604

Richmond Battery A Ignition

P. O. Box 25369 - 957 Myers St.

Richmond, Virginia 23260

Smith Hardware Company

515 N. George Street

Goldsboro, North Carolina 27530

South Denver Lawn Equip. Co.

527 West Evans

Denver, Colorado 80223

Suhren Engine

8330 Earhart Blvd.

New Orleans, Louisiana 70118

Sutton's Lawn Mower Shop

Route 4, Box 343

North Little Rock, Arkansas 72117

Warner Equipment

7520 Lyndale Avenue, So.

Minneapolis, Minnesota 55423

Woodson Salas A Service

1702 North Sylvania

Ft. Worth, Texas 76111

♦

♦

♦

♦

t

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

FORM NO. 770-4904

The purpose of warranty is to protect the customer from defects in workmanship and materials,

defects which are NOT detected at the time of manufacture. It does not provide for the unlimited

and unrestricted replacement of parts. Use and maintenance are the responsibility of the cus

tomer. The manufacturer cannot assume responsibility for conditions over which it has no

control. Simply put, if it's the manufacturer's fault, it's the manufacturer's responsibility; if

it's the customer's fault, it's the customer's responsibility.

CLAIMS AGAINST THE MANUFACTURER'S WARRANTY INCLUDES

1. Replacement of Missing Parts on new equip- 1. Model Number of unit involved,

ment.

2. Replacement of Defective Parts within the

warranty period.

3. Repair of Defects within the warranty

period.

WARRANTY PARTS AND SERVICE POLICY

All claims MUST be substantiated with the

following information:

2. Date unit was purchased or first put into

service.

3. Date of failure.

4. Nature of failure.

30

▼

t

♦

♦

♦

♦

♦

♦

t

t

♦

♦

♦

♦

PRINTED IN U.S.A.

Loading...

Loading...