Page 1

CH-HADTB

March 2007

(Replaces CH-B-48D, 10/04)

Horizontal Air Discharge

Outdoor Discus®

Condensing Unit

Technical Guide

Model HDH, HDHS • 20-40 HP

Page 2

Standard & Optional Features

HDH Outdoor Discus® Condensing Units, Horizontal Air

Discharge

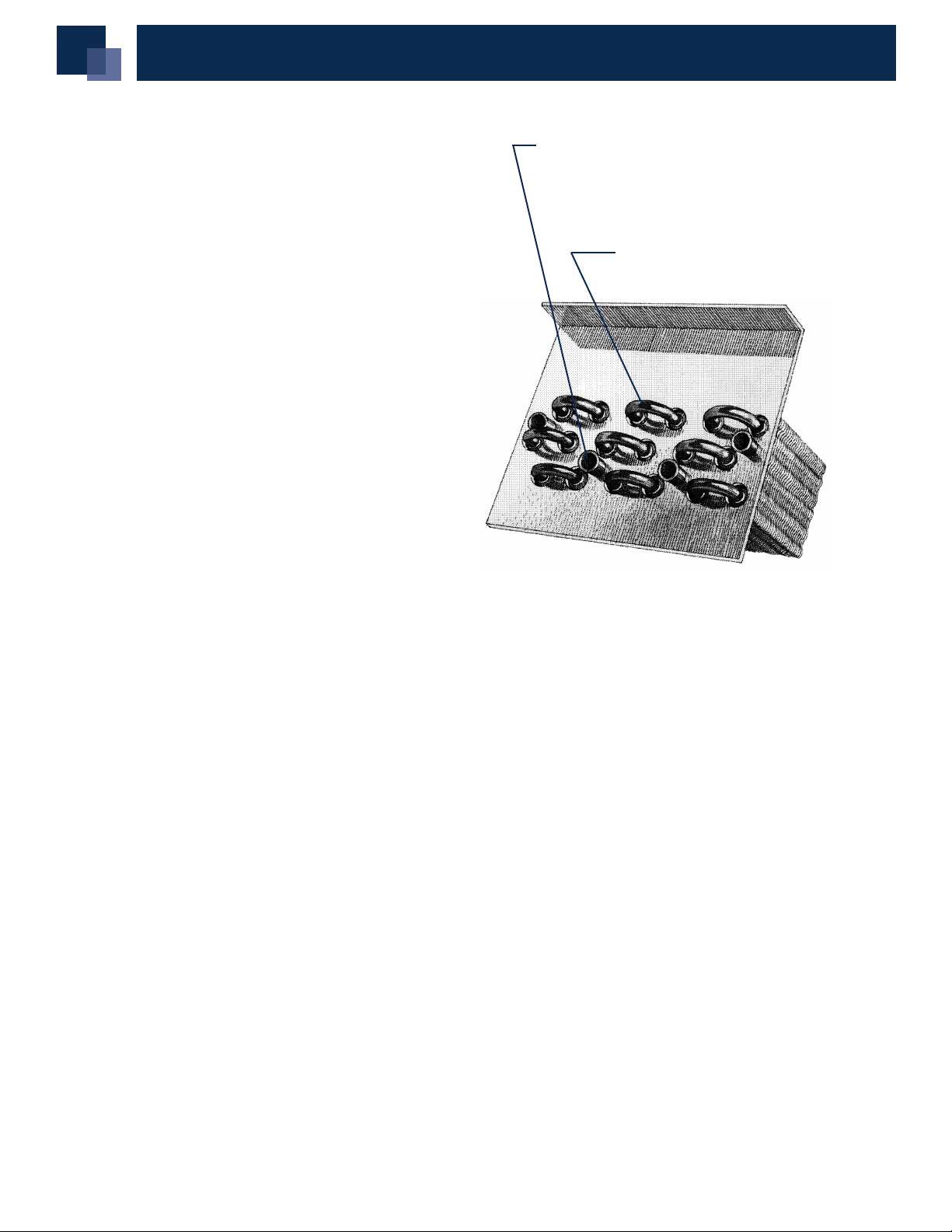

Leak Resistant Design

The HDH Outdoor Discus® Condensing Unit features a

new leak resistant design which includes:

• The Floating Tube

™

condenser coil design. Refrigerant

carrying copper tubes do not contact any metal

support tubes. Instead, the coil is constructed with

expanded anchor tubes which support the coil

construction and do not carry refrigerant. The coil

design eliminates one of the major causes of leaks in

refrigeration systems

• Limited five-year warranty against condenser tube

sheet and center support leaks

• Designed for use with R-404A or R-507

• R-22 models available for all temperature applications

• Polyol Ester Oil charge on all units

• Pre-bent copper tubes minimize braze joints on

internal piping

• All sweat type connections, no flare joints to leak

• Fixed high pressure switch eliminates capillary

tube. Adjustable low pressure control comed with

braided hose

• Sentronic

™

electronic oil safety control

• Service Mate™ module to assist troubleshooting

Standard Features

• High efficiency Copeland Discus

®

compressors with

POE oil

• Spring mounted compressor with suction and

discharge vibration eliminators

• Crankcase heater sleeve isolates the heater from

direct contact with the oil

• Thermally protected permanently lubricated PSC

condenser fan motors (all units have several motors)

• Two valve adjustable head pressure control

• Separate subcooling circuit in condenser for added

capacity and vapor free liquid

• Receivers are sized for sufficient pumpdown capacity

with inlet and outlet service valves

• Pressure relief valve on receiver

• Sealed liquid line filter drier and sight glass

Service Mate™ diagnostic module on Beacon II™ units

•

• Electrical controls including compressor contactor

and optional defrost control are located in easily

accessible control box with a hinged cover

• Pumpdown switch

• Cabinet is constructed from pre-painted G90 steel

• Convenient access panels for easy servicing to

internal components

Expanded (Locked) Auxiliary Tubes: These

tubes support the coil with ns and refrigerant

carrying tubes. They do not carry refrigerant

and are tightly tted on end supports and center

supports.

Free-Floating Circuited Coil Tubes:

These tubes carry refrigerant and never

touch any sheet metal (end supports and

center supports).

Factory-Installed Optional Features

• Replaceable core liquid filter/drier

• Liquid line solenoid valve

• Sealed suction filter

• Replaceable core suction filter

• Suction accumulator

• Oil separator with discharge line check valve

• Air defrost timer

• Electric defrost kits, including timer, evaporative fan

contractor with fusing, defrost heater contactor(s),

lockout relay and terminal strip

• Fusing for heater loads

• Heated and insulated receiver with time delay relay

• Fused disconnect switch

• Condenser fan cycling

• Compressor unloading

• Demand cooling on low temperature R-22 models

• Coated condenser coils for protection against

corrosion in harsh environments

• Beacon II™ Control System

• Alternative compressors (contact factory)

© 2007, Heatcraft Refrigeration Products LLC

2

Page 3

HD - Chandler Discus

Semi-Hermetic

Condensing Unit

H - Horizontal Air Discharge

Nominal Horsepower

2000 - 20 HP

2500 - 25 HP

2600 - 25 HP

2700 - 27 HP

3000 - 30 HP

3100 - 30 HP

3500 - 35 HP

4000 - 40 HP

®

Nomenclature/Beacon II

Nomenclature

H D H 0500 D 7 3

Electrical Characteristics

3 - 208-230/3/60 4 - 460/3/60

8 - 230/3/60

Refrigerant

6 - R-22, R-404A or R-507

Application Range

L - Low (0° F to -40° F Suction)

D - High - R-22 (10° F to 40° F suction) or

Medium R-404A or R-507 (-10° F to 30° F suction)

™

Now available with Beacon II

™

Beacon II™ is the next generation of Chandler’s patented, preassembled, factory installed refrigeration system

featuring an integrated microcomputer-based electronic control board. The Beacon II™ system comes completely

factory installed, wired and tested saving you time and money.

Beacon II™ offers:

• Complete factory installation, wiring and testing which saves time and money

• Simple field electrical connections and 24 volt wiring between condensing and evaporator units

• Preset factory superheat allowing the system to run more efficiently and reducing future adjustments

• Monitors and controls box temperature, evaporator superheat, condenser fan cycling, system status and defrost

from outside the box

• Monitor and make system changes remotely via modem and exclusive Beacon II™ Smart II software

• Data logging capabilities with Smart Controller

Beacon II™ Smart Controller

The Beacon II™ Smart Controller is an optional system monitoring and programming control device. It allows

for adjustments to be made at the push of a button from a conveniently mounted location. The Beacon

II™ Smart Controller also allows you to monitor and make changes to the refrigeration system via modem

connection from anywhere in the world. The Beacon II™ has been updated to allow the user to make even more

precise adjustments than the first phase of the Beacon II™ Smart Controller. One Smart Controller can program

and control up to four separate condensing units with up to four evaporators on each system. That’s more

control in your hands!

™

Beacon II

Smart II Software

Beacon II™ Smart II Software makes it easy to adjust and monitor one or more refrigeration systems as well

as capture minute by minute system conditions. This Windows-based software allows you to connect to the

Beacon II™ Smart Controller from anywhere in the world to monitor the systems, make adjustments and log

minute by minute system conditions. This data logging capability is critical in the food service industry.

™

Beacon II

Smart Defrost

Beacon II™ Smart Defrost, available only on the Beacon II™ Smart Controller, enables the Beacon II™ system to

sense frost accumulation and initiate defrost only when it is necessary. Using the Beacon II™ Smart Controller,

you preset defrost times. At each scheduled defrost time, Smart Defrost checks system performance to see if a

defrost is necessary. If not, it simply does not defrost, waiting until the next scheduled defrost time.

3

Page 4

Features & Options

Two Valve Adjustable

Head Pressure Control

Receiver Service

Valves

Oversized Receiver

(Standard)

Features & Options

Front View (20 to 40 HP)

(shown with front grill removed)

Sealed Liquid Filter

(Replaceable Core Available)

Two Valve

Adjustable Head

Pressure Control

Liquid Subcooling

Circuit

Liquid Line

Shutoff Valve

Sealed Suction Filter

(Replaceable Core Available)

(Optional)

Side View (20 to 40 HP)

Oil Separator

(Optional)

Easy Access to Compressor

for Service and Maintenance

Suction Accumulator

(Optional)

Oil Separator (Optional)

Receiver Service

Valves

Sealed Liquid Line Filter

(Replaceable Core Available)

Oversized Receiver

(Standard)

4

Page 5

Performance

Performance

Model

Number

HDH2000D6 4DA3R18ME 192,250 48,447 175,180 44,145 159,520 40,199 143,470 36,154 128,950 32,495 115,490 29,103 103,320 26,037

HDH2500D6 4DH3R22ME 247,640 62,405 228,520 57,587 209,570 52,812 190,910 48,109 172,660 43,510 115,350 39,148 138,240 34,836

HDH2600D6 4DH3R22ME 257,980 65,011 237,390 59,822 217,110 54,712 197,260 49,710 177,940 44,841 159,590 40,217 141,670 35,701

HDH3000D6 4DJ3R28ME 292,440 73,695 269,910 68,017 247,540 62,380 225,520 56,831 204,020 51,413 183,670 46,285 163,760 41,268

HDH3500D6 6DH3R35ME 362,560 91,365 334,660 84,334 307,260 77,430 280,600 70,711 255,060 64,275 230,670 58,129 207,850 52,378

HDH4000D6 6DJ3R40ME 409,570 103,212 381,640 96,173 351,010 88,455 322,590 81,293 295,020 74,345 268,640 67,697 243,400 61,337

Model

Number

HDH2000D6 4DA3R18ME 161,760 40,764 148,750 37,485 137,170 34,567 124,400 31,349 112,590 28,373 90,350 22,769 71,130 17,925

HDH2500D6 4DH3R22ME 207,520 52,295 191,910 48,361 175,830 44,309 159,720 40,249 144,820 36,495 118,170 29,779 96,910 24,421

HDH2600D6 4DH3R22ME 218,290 55,009 200,370 50,493 182,980 46,111 166,100 41,857 150,190 37,848 121,950 30,731 99,290 25,021

HDH3000D6 4DJ3R28ME 249,490 62,871 231,280 58,283 213,640 53,837 194,710 49,067 176,740 44,538 142,560 35,925 112,080 28,244

HDH3500D6 6DH3R35ME N/A N/A 281,570 70,956 260,600 65,671 239,390 60,326 217,310 54,762 176,610 44,506 139,540 35,164

HDH4000D6 6DJ3R40ME N/A N/A 325,470 82,018 301,520 75,983 276,060 69,567 252,510 63,633 207,470 52,282 166,890 42,056

Model

Number

HDH2700L6 6DL3F93KE 162,540 40,960 134,870 33,987 120,360 30,331 107,210 27,017 94,180 23,733 81,930 20,646 60,570 15,264

HDH3000L6 6DT3F11KE 176,540 44,488 146,440 36,903 132,070 33,282 117,350 29,572 103,290 26,029 90,150 22,718 67,600 17,035

HDH3100L6 6DT3F11KE 185,920 46,852 153,480 38,677 136,800 34,474 121,600 30,643 106,770 26,906 93,020 23,441 69,570 17,532

Model

Number

HDH2700L6 6DL3F93KE 148,740 37,480 118,280 29,810 104,150 26,250 90,920 22,910 78,450 19,770 66,490 16,750 N/A N/A

HDH3000L6 6DT3F11KE 172,070 43,360 137,350 34,610 121,000 30,490 105,680 26,630 91,430 23,040 78,870 19,880 56,530 14,240

HDH3100L6 6DT3F11KE 178,630 45,010 141,520 35,660 124,500 31,370 108,630 27,380 93,820 23,640 79,860 20,130 57,640 14,530

Compressor

Model

Compressor

Model

Compressor

Model

Compressor

Model

Capacity BTUH @ 95ºF Ambient KCAL/H @ 35ºC Ambient Evaporator Temperature ºF / ºC

40°F/4.4°C

BTUH KCAL/H

35°F/-1.7°C

BTUH KCAL/H

30°F/-1.1°C

BTUH KCAL/H

Medium Temperature R-22

25°F/-3.9°C

BTUH KCAL/H

20°F/-6.7°C

BTUH KCAL/H

15°F/-9.4°C

BTUH KCAL/H

10°F/-12.2°C

BTUH KCAL/H

Capacity BTUH @ 95ºF Ambient KCAL/H @ 35ºC Ambient Evaporator Temperature ºF / ºC

30°F/-1.1°C

BTUH KCAL/H

0°F/-17.8°C

BTUH KCAL/H

0°F/-17.8°C

BTUH KCAL/H

25°F/-3.9°C

BTUH KCAL/H

Medium Temperature R-404A or R-507

-10°F/-23.3°C

BTUH KCAL/H

Low Temperature R-404A or R-507

-10°F/-23.3°C

BTUH KCAL/H

20°F/-6.7°C

BTUH KCAL/H

-15°F/-26.1°C

BTUH KCAL/H

-15°F/-26.1°C

BTUH KCAL/H

Low Temperature R-22

15°F/-9.4°C

BTUH KCAL/H

-20°F/-28.9°C

BTUH KCAL/H

-20°F/-28.9°C

BTUH KCAL/H

10°F/-12.2°C

BTUH KCAL/H

-25°F/-31.7°C

BTUH KCAL/H

-25°F/-31.7°C

BTUH KCAL/H

0°F/-17.8°C

BTUH KCAL/H

-30°F/-34.4°C

BTUH KCAL/H

-30°F/-34.4°C

BTUH KCAL/H

-10°F/-23.3°C

BTUH KCAL/H

BTUH KCAL/H

BTUH KCAL/H

-40°F/-40°C

-40°F/-40°C

5

Page 6

Specifications

Specications/Electrical Data

Model

Numbers

Compressor Connections

Model HP

Liquid

in / cm

Suction

in / cm

(90% Full)

R-22

lbs / kg

Receiver

R-404A

lbs / kg

HDH2000D6 4DA3R18ME 20 7/8 2.22 1-5/8 4.13 144 65.5 125 56.8 1,475 669.0

HDH2500M6 4DH3R22ME 25 1-1/8 2.86 2-1/8 5.40 144 65.5 125 56.8 1,550 703.1

HDH2600D6 4DH3R22ME 25 1-1/8 2.86 2-1/8 5.40 219 99.6 190 86.4 1,800 816.5

HDH3000D6 4DJ3R28ME 30 1-1/8 2.86 2-1/8 5.40 219 99.6 190 86.4 1,810 820.9

HDH3500D6 6DH3R35ME 35 1-1/8 2.86 2-1/8 5.40 219 99.6 190 86.4 1,930 875.4

HDH4000D6 6DJ3R40ME 40 1-1/8 2.86 2-1/8 5.40 219 99.6 190 86.4 1,980 898.1

HDH2700L6 6DL3F93KE 27 1-1/8 2.86 2-1/8 5.40 144 65.5 125 56.8 1,550 703.0

HDH3000L6 6DT3F11ME 30 1-1/8 2.86 2-1/8 5.40 144 65.5 125 56.8 1,550 703.0

HDH3100L6 6DT3F11ME 30 1-1/8 2.86 2-1/8 5.40 219 99.6 190 86.4 1,890 857.3

Electrical Data

Approx.

Shipping

Weight

lbs / kg

Medium/High Temperature Units

Model

Number

HDH2000D63 4DA3R18ME 208-230/3/60 66.0 308 3 3/4 13.2 87.9 125 117.9 175 30.0 90.0 107.9 150 20 70

HDH2000D64 4DA3R18ME 460/3/60 33.0 154 3 3/4 6.6 43.9 70 58.9 80 15.0 50.0 58.9 80 15 40

HDH2500D63 4DH3R22ME 208-230/3/60 82.2 428 3 3/4 13.2 105.3 175 135.3 200 30.0 90.0 125.3 175 20 70

HDH2500D64 4DH3R22ME 460/3/60 41.1 214 3 3/4 6.6 52.7 90 67.7 100 15.0 50.0 67.7 100 15 40

HDH2600D63 4DH3R22ME 208-230/3/60 82.2 428 4 3/4 17.6 109.7 175 139.7 200 30.0 90.0 129.7 200 20 70

HDH2600D64 4DH3R22ME 460/3/60 41.1 214 4 3/4 8.8 54.9 90 69.9 100 15.0 50.0 69.9 100 15 40

HDH3000D63 4DJ3R28ME 208-230/3/60 94.0 470 4 3/4 17.6 123.0 200 163.0 225 40.0 120.0 153.0 225 30 90

HDH3000D64 4DJ3R28ME 460/3/60 47.0 235 4 3/4 8.8 61.5 100 76.5 110 15.0 70.0 76.5 110 15 50

HDH3500D63 6DH3R35ME 208-230/3/60 107.0 565 4 3/4 17.6 137.8 225 177.8 250 40.0 120.0 167.8 250 30 90

HDH3500D64 6DH3R35ME 460/3/60 53.5 283 4 3/4 8.8 68.9 110 83.9 125 15.0 80.0 83.9 125 15 50

HDH4000D68 6DJ3R40ME 230/3/60 142.0 594 4 3/4 17.6 176.3 300 216.3 300 40.0 150.0 216.3 300 40 120

HDH4000D64 6DJ3R40ME 460/3/60 71.0 297 4 3/4 8.8 88.1 150 103.1 150 15.0 80.0 103.1 150 15 50

MCA = Minimum Circuit Ampacity

MOP = Maximum Overcurrent Protection

†

Reduced nameplate amperage must be requested at time of order

Compressor

Voltage

Supply

Compressor

RLA LRA Qty. HP FLA MCA MOP MCA MOP

Condenser

Fan Motor

Beacon II

or Air Defrost

™

Electric Defrost Units Reduced Amp Elec. Def. Units

Unit Cooler Amps Unit Cooler Amps

Fan

Motors

Defrost

Heaters

MCA MOP

Fan

Motors

Defrost

Heaters

†

6

Page 7

Electrical Data

Electrical Data (cont.)

Low Temperature Units

™

Model

Number

Compressor

Voltage

Supply

Compressor

Condenser

Fan Motor

Beacon II

or Air Defrost

RLA LRA Qty. HP FLA MCA MOP MCA MOP

HDH2700L63 6DL3F93KE 208-230/3/60 80.0 450 3 3/4 13.2 103.7 175 133.7 200 30.0 90.0 123.7 175 20 70

HDH2700L64 6DL3F93KE 460/3/60 40.4 225 3 3/4 6.6 51.9 80 66.9 100 15.0 50.0 66.9 100 15 40

HDH3000L63 6DT3F11ME 208-230/3/60 95.6 470 3 3/4 13.2 120.4 200 150.4 225 30.0 90.0 123.7 175 20 70

HDH3000L64 6DT3F11ME 460/3/60 47.8 235 3 3/4 6.6 60.2 100 75.2 110 15.0 50.0 75.2 110 15 40

HDH3100L63 6DT3F11ME 208-230/3/60 95.6 470 4 3/4 17.6 124.8 200 154.8 225 30.0 90.0 144.8 225 20 70

HDH3100L64 6DT3F11ME 460/3/60 47.8 235 4 3/4 8.8 62.4 100 77.4 110 15.0 50.0 77.4 110 15 40

MCA = Minimum Circuit Ampacity

MOP = Maximum Overcurrent Protection

†

Reduced nameplate amperage must be requested at time of order

Electric Defrost Units Reduced Amp Elec. Def. Units

Unit Cooler Amps Unit Cooler Amps

Fan

Motors

Defrost

Heaters

MCA MOP

Fan

Motors

Defrost

Heaters

†

Condensing Units with Remote Loads Using Two Defrost Heater Contractors

™

Model

Number

Compressor

Voltage

Supply

Compressor

Condenser

Fan Motor

Beacon II

or Air Defrost

RLA LRA Qty. HP FLA MCA MOP MCA MOP

HDH2000D63 4DA3R18ME 208-230/3/60 66.0 308 3 3/4 13.2 87.9 125 117.9 175 30.0 90.0 107.9 150 20 70

HDH2000D64 4DA3R18ME 460/3/60 33.0 154 3 3/4 6.6 43.9 70 58.9 80 15.0 50.0 58.9 80 15 40

HDH2500D63 4DH3R22ME 208-230/3/60 82.2 428 3 3/4 13.2 105.3 175 135.3 200 30.0 90.0 125.3 175 20 70

HDH2500D64 4DH3R22ME 460/3/60 41.1 214 3 3/4 6.6 52.7 90 67.7 100 15.0 50.0 67.7 100 15 40

HDH2600D63 4DH3R22ME 208-230/3/60 82.2 428 4 3/4 17.6 109.7 175 139.7 200 30.0 90.0 129.7 200 20 70

HDH2600D64 4DH3R22ME 460/3/60 41.1 214 4 3/4 8.8 54.9 90 69.9 100 15.0 50.0 69.9 100 15 40

HDH3000D63 4DJ3R28ME 208-230/3/60 94.0 470 4 3/4 17.6 123.0 200 163.0 225 40.0 120.0 153.0 225 30 90

HDH3000D64 4DJ3R28ME 460/3/60 47.0 235 4 3/4 8.8 61.5 100 76.5 110 15.0 70.0 76.5 110 15 50

HDH3500D63 6DH3R35ME 208-230/3/60 107.0 565 4 3/4 17.6 137.8 225 177.8 250 40.0 120.0 167.8 250 30 90

HDH3500D64 6DH3R35ME 460/3/60 53.5 283 4 3/4 8.8 68.9 110 83.9 125 15.0 80.0 83.9 125 15 50

HDH4000D68 6DJ3R40ME 230/3/60 142.0 594 4 3/4 17.6 176.3 300 216.3 300 40.0 150.0 216.3 300 40 120

HDH4000D64 6DJ3R40ME 460/3/60 71.0 297 4 3/4 8.8 88.1 150 103.1 150 15.0 80.0 103.1 150 15 50

HDH2700L63 6DL3F93KE 208-230/3/60 80.8 450 3 3/4 13.2 103.7 175 133.7 200 30.0 90.0 123.7 175 20 70

HDH2700L64 6DL3F93KE 460/3/60 40.4 225 3 3/4 6.6 51.9 80 66.9 100 15.0 50.0 66.9 100 15 40

HDH3000L63 6DT3F11ME 208-230/3/60 95.6 470 3 3/4 13.2 120.4 200 150.4 225 30.0 90.0 140.4 225 20 70

HDH3000L64 6DT3F11ME 460/3/60 47.8 235 3 3/4 6.6 60.2 100 75.2 110 15.0 50.0 75.2 110 15 40

HDH3100L63 6DT3F11ME 208-230/3/60 95.6 470 4 3/4 17.6 124.8 200 154.8 225 30.0 90.0 144.8 225 20 70

HDH3100L64 6DT3F11ME 460/3/60 47.8 235 4 3/4 8.8 62.4 100 77.4 110 15.0 50.0 77.4 110 15 40

MCA = Minimum Circuit Ampacity

MOP = Maximum Overcurrent Protection

†

Reduced nameplate amperage must be requested at time of order

Electric Defrost Units Reduced Amp Elec. Def. Units

Unit Cooler Amps Unit Cooler Amps

Fan

Motors

Defrost

Heaters

MCA MOP

Fan

Motors

Defrost

Heaters

†

7

Page 8

Dimensional Diagrams

20 TO 40 HP

Model

Number

HDH2000D6 42-1/4 107.00 102-1/2 260.00 48-3/4 124.00 104-3/16 265.00 3

HDH2500D6 42-1/4 107.00 102-1/2 260.00 48-3/4 124.00 104-3/16 265.00 3

HDH2600D6 42-1/4 107.00 132-1/2 337.00 48-3/4 124.00 134-3/16 341.00 4

HDH3000D6 42-1/4 107.00 132-1/2 337.00 48-3/4 124.00 134-3/16 341.00 4

HDH3500D6 42-1/4 107.00 132-1/2 337.00 48-3/4 124.00 134-3/16 341.00 4

HDH4000D6 42-1/4 107.00 132-1/2 337.00 48-3/4 124.00 134-3/16 341.00 4

HDH2700L6 42-1/4 107.00 102-1/2 260.00 48-3/4 124.00 104-3/16 265.00 3

HDH3000L6 42-1/4 107.00 102-1/2 260.00 48-3/4 124.00 104-3/16 265.00 3

HDH3100L6 42-1/4 107.00 132-1/2 337.00 48-3/4 124.00 134-3/16 341.00 4

A

In/Cm

B

In/Cm

Dimensions

In/Cm

C

D

In/Cm

No.

Fans

Visit our website at www.chandlerref.com for technical literature online.

Since product improvement is a continuing effort,

we reserve the right to make changes in specifications without notice.

A Brand of Heatcraft Refrigeration Products LLC

2175 West Park Place Blvd. • Stone Mountain, GA • 30087

800-321-1881 • FAX 770-465-5990

www.chandlerref.com

CH-HADTB-0307 | Version 001

Loading...

Loading...