Page 1

MODELS MT60

&

MT125A

Solid-State

PA Components

INSTALLATION

UNPACKING

The amplifier was thoroughly checked before leaving the

factory. Inspect the amplifier and shipping container

carefully for evidence of improper handling during shipment. In case of damage, make an immediate claim to the

dealer or distributor from whom the unit was purchased. If

the amplifier was shipped to you, notify the carrier without

delay and file a claim.

INPUT CONNECTIONS

Keep the input lead away from the output lead and ac

power cables. Unless the driving source provides a

low-impedance output, keep the input lead under ten feet

MT60

POWER OUTPUT:

PEAK OUTPUT:

E:

:

PUT SENSITIVITY (FOR

RATED OUTPUT):

INPUT IMPEDANCE:

OUTPUT CONNECTIONS:

OUTPUT IMPEDANCE

(BALANCED OR UNBALANCED):

CONTROLS AND INDICATORS:

SEMICONDUCTORS:

POWER CONSUMPTION:

AUXPOWERRECEPTACLE:

OVERLOAD PROTECTION:

DIMENSIONS:

WEIGHT:

60 watts

120 watts

±2 dB,

30 Hz to 20k Hz

Less than 2% at rated output

-80

dB

below rated output

Less than 2

Hi Z

Hi Z 50k; Lo Z

25VCT, 25V,

25VCT;

AC power switch, ac power indicator lamp, volume control, music-speech selector

switch.

6 silicon transistors; 7 diodes 8 silicon transistors; 7 diodes

120VAC 60HZ. 168 watts @Rated

output

120VAC

(No Output) (No Output)

48-56 VDC, 1 Amp

output

48-56 VDC, 15 mA

Output)

550

AC circuit breaker. 1

circuit breaker. I

breaker, 95°

approximately 2 minutes.

8” W. x

18½

Ibs.

dB

variation from no load to full load.

0.2V;

Lo Z balanced with TL600 xfmr,

16fi, 70V terminals

(25V);

(70V)

60HZ, 22

watts

C.

with recovery in

13”

D. x 6¼” H.

TABLE I. COMPANION UNITS AND ACCESSORIES

Model

CAM

CM

CHS-M

CTM

MX6A-5

RPK-I 8

TL600 Low-impedance

TL10K

with TL600 xfmr; Bridging

8R;

@

watts

.65A

Quiescent

@

30 watts

@

Quiescent (No

.65A

Hold: DC

Hold; Thermal

60-Watt

and

125-Watt

Booster Amplifiers

Description

Five input solid-state preamplifier mixer.

Five input solid-state preamplifier mixer.

Seven input solid-state preamplifier mixer.

Seven input solid-state preamplifier mixer.

Six input solid-state preamplifier mixer.

Rack mounting kit 19” x 7” (mounts 2

units).

plug-in

transformer.

Bridging (1

125 watts

250 watts

±2 dB,

40 Hz to 20k Hz

Less than 2% at rated output

-80 dB

below rated output

.045V;

25VCT, 25V,

25VCT;

(7OV)

120VAC

120VAC 60HZ, 30 watts

48-56 VDC,

48-56 VDC, 15

390 watts

AC circuit breaker.

8” W. x

25

60HZ, 300 watts @ Rated

output

Output)

circuit breaker,

breaker, 104” C. with recovery in

approximately 2 minutes.

13”

Ibs.

plug-in transformer.

MT125A

Hi Z with TL

lOk

(25V); 8R, 16R; 40R

2.25

Amps @ 62.5

mA @

D. x 6¼” H.

10k

with TL

70V terminals

@

Quiescent

Quiescent (No

2.5A

Hold; DC

2.5A

Hold; Thermal

xfmr,

10k

watts

0.lV.

xfmr.

*Variations in performance

PRINTED IN U.S.A.

3-75

PMP #1390

characteristics normally

LEAR SIEGLER, INC.

will not

exceed I

dB.

54-5521-01

Page 2

in length. Refer to Table I for

Bogen

preamplifiers suitable

for use with the amplifier.

HIGH IMPEDANCE INPUT: The amplifier can be driven to

mV

full output from any source developing 200

across one

of the Hi-Z inputs. Wire a single-conductor, low-capacity

shielded input cable to a standard phono plug (Cinch

18A,

or equivalent) and connect to one of the Hi-Z jacks on the

rear of the chassis.

LOW IMPEDANCE INPUT: The amplifier may be driven

Bogen

from a low-impedance

TL-600 transformer is installed in socket

chassis. Connect a twisted, shielded pair

X1

(Bogen

Model

on top of the

BB-8450,

or equiv.) input cable to the BAL. INPUT LOW Z terminal

strip on the rear of the unit. Use the two terminals on the

right of the strip and connect the cable shield to the GND

terminal on the left. If an unbalanced input is required,

connect a jumper from the GND terminal to the adjacent

input terminal.

CAUTION

Remove all power from unit before installing

transformers.

BRIDGING INPUT: The inputs for two or more amplifiers

may be paralleled without loss of gain. To do this, install a

Bogen

Model

TL-IOK

transformer in socket X1 on top of

the chassis. Connect the bridged inputs to BAL LOW Z

terminal strip on the rear of the unit. Use the two terminals

on the right of the strip and connect the cable shields to the

GND terminal on the left. If an unbalanced input is

required, connect a jumper from the GND terminal to the

adjacent input terminal.

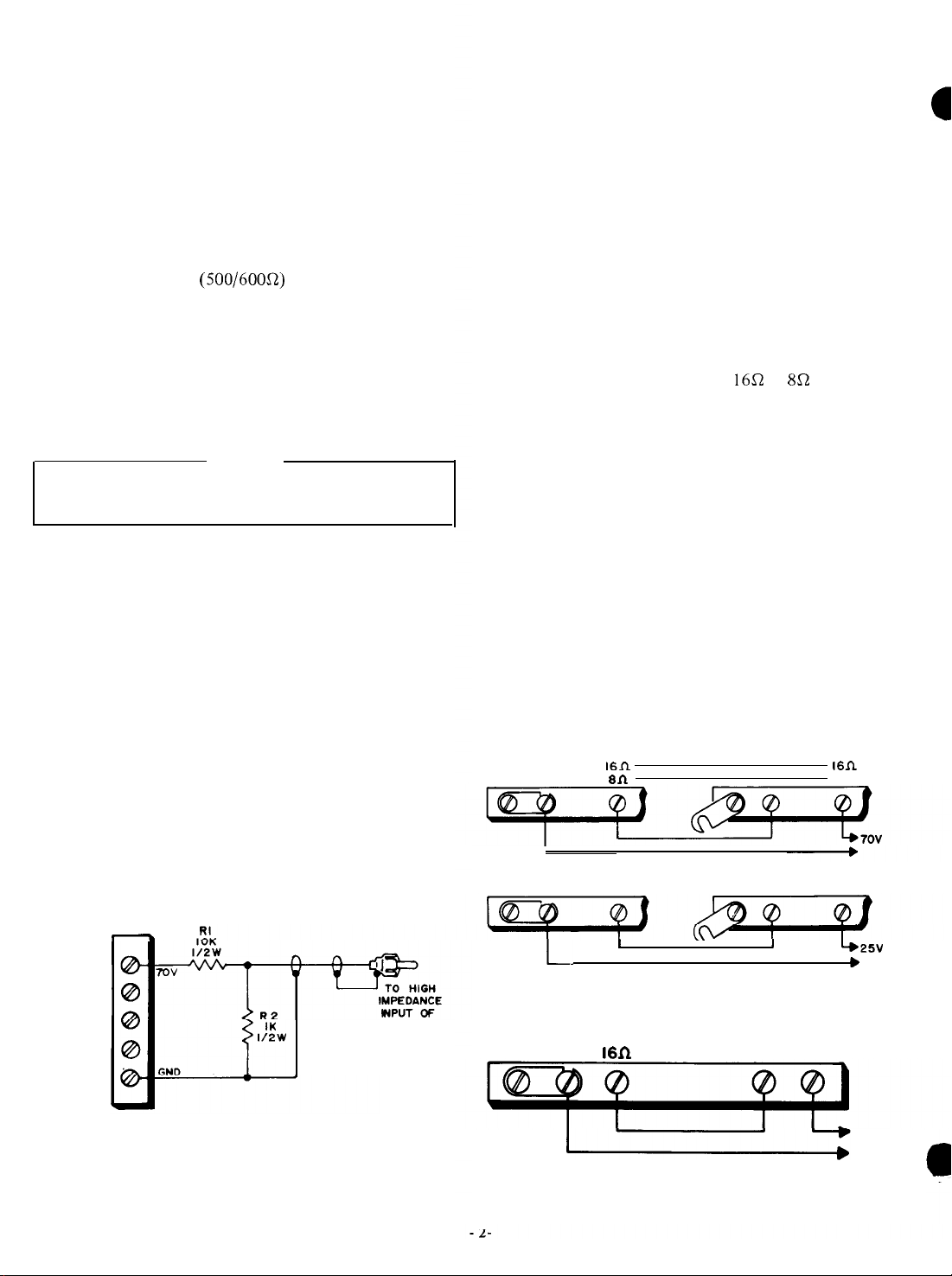

CONSTANT-VOLTAGE INPUT: The amplifier can be

driven from a standard public address amplifier that

provides a

25volt

or

70-volt

constant voltage output. To do

this, connect the output of the amplifier to one of the Hi-Z

INPUT

resistors shown in

jacks

via a resistor network (see figure 1). The

figure 1

are in addition to the normal

loudspeaker load on the output of the public address

amplifier.

OUTPUT CONNECTIONS

Speakers may be connected with standard flexible line

cord (zip-cord) and up to 100 feet of cable may be used

without appreciable loss. Class II wiring is acceptable unless

prohibited by local codes.

70V

CONSTANT-VOLTAGE

OUTPUT. For 70V constant-

voltage operation, connect the speaker leads to the 70V

and COM 2 terminals on the rear of unit. If ground-

ing is required, connect a jumper from the COM 2 to GND.

25V

CONSTANT-VOLTAGE OUTPUT. For

25V

constantvoltage unbalanced operation, connect the speaker leads to

25V

and COM 1, leaving the link connected between

COM

1

and GND. For balanced operation, open the link

COM 1

between

and GND. If the output transformer center

tap must be grounded, connect a jumper between 25VCT

and GND.

16 OHM

&

8 OHM OUTPUT.

For 16fi or 8R operation,

connect the speaker leads between the desired output

1.

terminal and COM

If ungrounded operation is desired,

open the link between COM 1 and GND.

CONNECTING AMPLIFIERS IN SERIES

Pairs of

Bogen MT1 25A

amplifiers or MT60 amplifiers

can be connected in series to effectively double the power

output into the same loadline. See Figure 2 for connection

diagrams. Be certain to remove the link between COM 1 and

GND of amplifier No. 2.

Depending on the impedance of the signal source, apply

the input signal to the HI Z or LO Z input of amplifier No.

1. Use jumpers to connect the appropriate input of

amplifier No. 2 in parallel with that of amplifier No. 1.

It is necessary that both amplifier volume controls be at

the same setting to assure that each amplifier will share the

load equally.

AMPLIFIER I

COM1

GND

AMPLIFIER I

GND

COM1

25VCT

AMPLIFIER 2

COM1

GND

AMPLIFIER 2

GND

COM1

FOR MT60

8R FOR MT125

874-1017-01

25VCT

_

a

OUTPUT

TERMINAL

STRIP OF

DRIVER

AMPLIFIER

AT 70V RI . 10K,

AT

25V

RI -

3.3K, ½W

Figure 1 - Connection to Constant -

P.A. Amplifier Driver.

½W

74-0730-A

POWER

AMPLIFIER

Voltage

Figure 2 - Connecting Amplifiers in Series

GND COM I

A74-2018-01

Figure 3 - MT1

MT60 AND

25A

Connections for

MT125A

COM2 7ov

120-Volt

Operation

120V

125W

Page 3

CONNECTIONS FOR

(MT125A

Figure 3 shows connections for

selected frequencies for laboratory or industrial

applications.

POWER CONNECTIONS.

The booster amplifier may be operated from 120 vac or

48V

to

120 VAC SOURCE. Connect the ac power cord to a 120

vac. source. Use a 3-wire receptacle with the center pin

connected to earth ground.

If desired, auxiliary equipment may be connected to the

AUX POWER receptacle on top of the unit. Do not exceed

power ratings on the schematic diagram.

48V

source capable of delivering power indicated in the Technical Specifications table. A two-prong polarized plug

Part No.

supplied with the amplifier for making dc connections.

Connect dc cable to source making certain to observe

proper polarity.

VOLUME CONTROL

A volume control located on the rear of the unit is used

primarily to compensate for variations in preamplifier

output levels. The VOLUME control permits the gain of the

amplifier to be preset so that the preamplifier volume

control may be operated near the center of its range, rather

than at an extreme maximum or minimum. The VOLUME

control is a screwdriver adjustment which needs to be set

only once for any given preamplifier input.

DC POWER OPERATION

When the amplifier is operated from a dc power source,

the ac power switch and ac power indicator lamp will be

inoperative and there will be no power at the AUX POWER

receptacle on top of the chassis. Turn the amplifier on and

off from the power switch on the dc power supply or by

inserting and removing the dc power leads on the rear of

the unit.

ONLY)

56V

dc.

-

56V DC SOURCE. Connect the amplifier to a dc

85-0109-01;

120-VOLT

Cinch Jones No. P-302-CCT) is

OUTPUT

120-volt

output at

(Bogen

MAINTENANCE

AC OPERATION

There are two overload protective devices used with ac

operation, the circuit breaker and the temperature overload

thermal breaker.

AC CIRCUIT BREAKER. If the circuit breaker opens, the

ac power lamp will go out and the amplifier will have no

output, but there will be power at the AUX POWER

receptacle on top of the unit. Set the ac power switch to

off and momentarily depress the red button on the circuit

breaker to reset it. Return the ac power switch to on. If the

breaker trips again, do not attempt to reset it but have the

trouble investigated by a qualified technician.

THERMAL BREAKER. If the temperature thermal breaker

opens,

power lamp will remain on. Wait approximately two

minutes for the breaker to reset. If the breaker resets and

then opens again, investigate the cause of the temperature

overload. This may be due to improper connections at the

output terminals or to excessive environmental heat with

inadequate ventillation. The thermal breaker will open

when the temperature at any one of the output transistors

is excessive.

DC OPERATION

operation, the circuit breaker and the temperature overload

thermal breaker. If either device opens, there will be no

audio output. The ac power lamp does not light during dc

operation.

THERMAL BREAKER, See the applicable paragraph under

“AC OPERATION”.

REPLACING TRANSISTORS

are considerably more reliable than the best vacuum tubes.

This is why some transistors are soldered into equipment

like resistors or capacitors. If the unit is inoperative, it

generally is safe to assume that the transistors have not

failed and that the trouble is elsewhere in the equipment.

replacement, be certain to remove all power from the unit

to prevent possible voltage transients in the circuit which

might damage the transistor. To prevent overheating the

transistor when soldering or unsoldering a lead, grip the

lead between the point of heat and the case with pliers or

tweezers. These will act as a heat sink to conduct heat away

from the transistor. Do not bend a transistor lead closer

than

good heat dissipation. Make certain there is no foreign

matter on the contact surfaces between the transistor and

the heat sink and brush a thin coating of heat transfer

compound (such as Dow Corning No. 340 Compound

silicon grease or equivalent) on both surfaces. Similarly coat

any insulators used between the transistor and the heat sink

and secure the transistor firmly to the heat sink.

BOGEN SERVICE

you have it. If trouble ever develops, do not hesitate to ask

our advice or assistance. Information can be obtained by

writing to Service Department,

500, Paramus, N.J. 07652.

designation of your unit. Describe the difficulty and

include details on the electrical connections to and the

types of associated equipment, such as preamplifier,

speakers, etc. We will send you service information if the

trouble appears simple. If the trouble requires servicing, we

-3-

there will be no audio output but the ac

There are two overload protective devices used with dc

Transistors show little, if any, deterioration with age and

If a transistor must be unsoldered for testing or

1/

16” from the transistor case.

Power transistors must be properly mounted to insure

We are interested in your

When communicating with us, give the model and series

Bogen

equipment for as long as

Bogen

Division, P.O. BOX

Page 4

will send you the name and address of the nearest

authorized

Do not return the unit to

Bogen

service agency.

Bogen

without prior clearance

from our Service Department. If you do ship the unit, pack

it carefully to avoid damage in transit. Send the unit, fully

insured and prepaid, via United Parcel or Railway Express.

Do not ship via parcel post unless so instructed.

service agencies or directly from the factory. When ordering

a part, specify a part number and description of the part as

listed. Specify the model of the unit and give the series

designation,

which is a letter followed by numbers,

screened on the chassis. For parts on circuit boards, also

give the component board assembly number, which begins

with “45”.

REPLACEMENT PARTS

Most components used in the amplifier are standard

parts available through reputable parts jobbers. The parts

listed here may be obtained from

Ref. No.

Al

Part No.

45-9933-01

45-9938-01

94-5067-01

Printed Circuit Board

c2

C5

C9,ll

Cl0

CR1,3,4,5

CR2

Ql

79-008-063

79-008-062

79-112-002

79-l 12-007 (MT60)

96-5333-01

96-5202-01

96-5321-01

MPS-6767 (Motorola)

Q2

96-5342-01

MJE 172 (Motorola)

45-9866-01

45-9865-01

R17,19

R18,20

76-107-105

76-l 16-003

Bogen

distributors,

(MT60)

(MT1 25A)

(MT1

25A)

When replacing transistors, use those made by the

specified manufacturers. Transistors from other suppliers

may not be satisfactory. Certain resistors must be

AllenBradley. These are designated by “AB” on the schematic

diagram.

Ref. No.

CHASSIS ELECTRICAL PARTS

Cl04

Part No.

79-509-054

(MT60)

79-509-075 (MT1 25A)

Cl05

CBlOl, 102

CB103 94-00

79-009-07 1

94-0017-15 (MT125A)

14-03

CR 101,102,

103

96-5241-01 (MT60)

96-5355-01 (MT125A)

1101 94-0302-04

QlOl,

103

96-5351-01

2N6254

(RCA) (MT60)

(MT60)

QlOl-104

RlOl

SW1

SW102

TlOl

96-5315-01 (MT125A)

77-001-372

81-003-059

8 l-002-098

83-776-000 (MT60)

83-766-000 (MT1 25A)

T102

83-427-O 10 (MT60)

83-425-000 (MT1 25A)

OWNER’S WARRANTY

Bogen solid

workmanship for one year from the date of sale to the original purchaser, provided that the

equipment has not been subjected to abuse or accident or altered in any way. Any part of the

equipment covered by this warranty which, with normal installation and use, becomes defective

will be

insured to our authorized service station or to the

Forest Avenue,

or will be returned to you freight prepaid.

Models containing vacuum tubes carry the same warranty as above, except that

apply to the vacuum tubes, which are guaranteed for 90 days.

The registration card enclosed with the equipment must be completed and mailed within five

days of purchase

state sound and intercom equipment is guaranteed against defects in material and

repaired

or replaced by

Paramus,

to place

Bogen,

provided the equipment IS delivered or

New Jersey 07652. The equipment may be picked up by you personally

the warranty in effect.

-4-

Bogen

Factory

Service

shipped

Department, Route 4 and

prepaid and

it

does not

Page 5

Loading...

Loading...