Page 1

LEAR

SIEGLER,

MODEL

100 WATT TRANSISTOR

PUBLIC

ADDRESS AMPLIFER

CHS100

.

IS1

INC.

INSTALLATION AND OPERATING MANUAL

READ THOROUGHLY BEFORE OPERATING EQUIPMENT

0

BOGEN

P.O.

PARAMUS, N. J. 07652

COMMUNICATIONS

BOX 500

DlVlSlON

Page 2

DESCRIPTION

The Bogen Model CHSlOO is a fully transistorized

public address amplifier rated at 100 watts. The unit

will accommodate two microphone inputs and two

auxiliary inputs for a tuner, tape recorder, or phono-

graph with a ceramic cartridge. The amplifier will

accommodate either high or low impedance microphones, and no transformer is required to change from

one microphone impedance to the other.

An optional accessory designed to mount on the

front panel of the CHSlOO provides two additional

high or low impedance microphone inputs. A BRIDGING

receptacle on the rear panel accepts additional

level, ‘high-impedance signals from a unit having its

own volume control. such as a

corder or tuner. The BRIDGING receptacle can also

be used as a high-impedance output to feed a tape

recorder or auxiliary amplifier. The master volume

control will not affect the bridging output level.

preamplifier, tape

high-

re-

TECHNICAL SPECIFICATIONS

1

POWER OUTPUT: 100 watts at less than 5%

distortion.

PEAK POWER: 200 watts.

FREQUENCY RESPONSE: 40 to 20,000 Hz

SENSITIVITY: Hi Z MIC, 4 mv; Lo Z MIC, 0.3 mv;

AUX, 0.3 volt; Bridging, 1 volt.

HUM AND NOISE

65 db; AUX input, 70 db.

INPUTS: 2 MIC, high (100 K ohms) or low (200

ohms) impedance; 2 AUX (300

ing (high impedance).

OUTPUTS: 2, 8, 16 ohm speakers; 25 volt CT

balanced

or BOOSTER,

pedance at 0.5V.

(below rated output): MIC input,

(m);

70 volt balanced

10K

at 5V; Bridging, high im-

Kfi);

(4%);

±2

db.

Bridg-

TAPE

Individual volume controls are provided for each

microphone input. A fader volume controls selects and

adjusts the level of the desired auxiliary input and

permits fading between the two inputs. A master volume control regulates the mixed output level.

arate

bass and treble controls permit adjustments for

tonal balance.

Outputs are provided for 2, 8 and

and for 25-volt and

systems. Two quick-disconnect plugs provide rapid

and convenient connections to speakers. The output

of the CHSlOO amplifier can also be fed to a tape re-

corder or booster amplifier.

The CHSlOO amplifier operates from a 105-125

volt AC source, and has a total power consumption

of 150 watts. A 1.75-ampere circuit breaker protects

the amplifier against overloads.

CONTROLS: 2 MIC volume; 1 AUX volume (fader

for two inputs);

TREBLE tone; POWER switch and indicator.

TONE CONTROL ACTION: Treble (at 10 K Hz),

t 11 db to -12 db, Bass(at 50 Hz), +10 db to

-10 db.

POWER REQUIREMENTS: 105 to 125 volts, 50 or

60 cycles AC, 150 watts.

SEMI-CONDUCTORS: 10 silicon transistors, 2

diodes.

DIMENSIONS:

SHIPPING WEIGHT: 24 pounds.

15¼”

70-volt

balanced speaker line

MASTER volume; BASS,

wide x

lO½”

16-ohm

deep x

5½”

Sep-

speakers

high.

ACCESSORIES

PMA-2 ADD-ON PREAMPLIFIER

The Bogen Model PMA-2 Preamplifier is designed

to provide two additional microphone channels for the

CHSlOO amplifier. Each preamp channel has its own

volume control and will accommodate either high-impedance or low impedance microphones. The unit is

connected to the Preamp Accessory socket on the top

chassis of the CHSlOO amplifier. When installed, the

PMA-2 control knobs protrude through the front panel

of the CHSlOO amplifier.

WMT-I LINE MATCHING TRANSFORMER

The Bogen WMT-1 line input/line output matching

transformer is an accessory which has been designed

-2-

especially for matching

500/600

to a

former it may be used

distributing background music which has been transmitted over leased telephone lines. The, accessory

also functions as an output matching transformer in

feeding special program material over a 500/600 ohm

telephone line for transmission to a local broadcast

studio.

LVP-I ACCESSORY

The Bogen Model LVP-1 is a plug-in accessory

which permits the user to provide microphone precedence when used with a customer supplied switch

ohm line.

either inputs from or outputs

As an input matching

with the Bogen amplifier for

trans-

Page 3

and the Bogen amplifier. The LVP-1 may also be used

as

a remote volume control in conjunction with the

Model RVC-1 remote volume control.

RVC-I REMOTE VOLUME CONTROL

The Bogen Model RVC-1 accessory permits the

amplifier to provide remote volume control when used

in conjunction with LVP-1 accessory.

MODEL LPC-4 PHONO PLAYER TOP

Model LPC-4 is a complete four-speed phono-

player designed to be mounted directly on top of the

amplifier. The unit comes complete with all necessary

hardware, and can be easily installed and connected

to amplifier with only a screwdriver. A tone arm

hous-

ing a dual-stylus turnover cartridge is included with

record player.

LK-IO CONTROL GUARD LOCKING PLATE

The Bogen Model LK-10 control guard locking

plate is designed to prevent unauthorized tampering

with the controls of amplifier. It comes complete with

two sets of keys. The key cannot be removed when

the lock is in open position.

RPK-27 RACK PANEL

The Bogen Model RPK-27 rack panel kit is designed to mount the

out the PMA-2 preamplifier) in a standard 19”

rack. The rack panel is finished in gray enamel.

INSTALLATION

UNPACKING power cables.

Inspect the shipping container and amplifier for

indications of improper handling. The amplifier was

carefully checked before leaving factory. If the unit

has been damaged, make an immediate claim to the

dealer

or distributor from whom it was purchased. If

the amplifier was shipped to you, notify the trans-

portation company without delay and place your claim.

CONNECTIONS BETWEEN COMPONENTS

For high-impedance inputs, use single-conductor,

low-capacity shielded wire for connecting the record

player, tape recorder, and other components to the

amplifier. Keep leads under ten feet in length.

For low-impedance microphone inputs, use

singleconductor shielded wire, in lengths from 50 to 500

feet depending on the characteristics of the microphone.

Speakers may be connected with standard flexible line cord (zip-cord), and up to 100 feet of cable

may be used without appreciable loss.

Make certain that all input cables are kept away

from speakers cables, power cables, and power trans-

formers, and that speaker cables are kept away from

POWER AND

The amplifier is furnished with an AC line cord

terminated in a three-prong plug. Plug the line cord

into a three-wire grounded outlet providing a nominal

120-volt, 50-60 cycle power source. This

the amplifier as well as supply power to it.

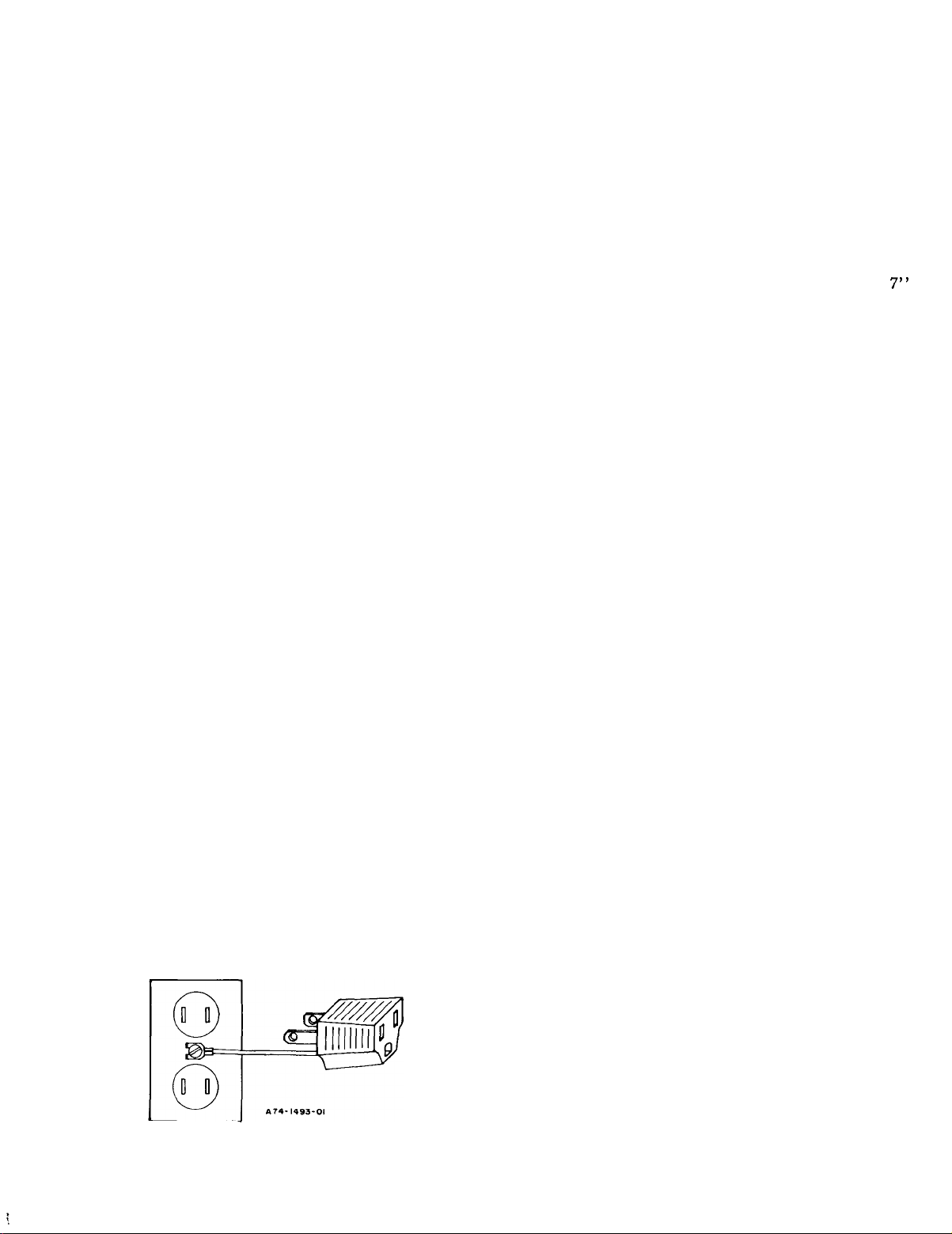

It is advisable to ground the amplifier. Therefore,

if a three-wire outlet is not available, an adapter such

Leviton

as

ard two-wire outlet for use with three-wire plugs. The

adapter is provided with a grounding pigtail which

should be connected to the screw holding the wall plate

to the receptacle, as shown in figure 1.

In some areas, the

grounded. In this case it will be necessary to

connect a grounding wire between the GND ter

minal

water or steam pipe.

No. 5017 should be used to convert a stand-

on the rear chassis of the amplifier and a

CHSlOO

GROUNDlNG

NOTE

amplifier (with or with-

will

ground

wall plate

screw is not

x

7”

INPUT CONNECTIONS

MICROPHONES

Two microphones may be connected to the amplifier, and either or both may be used simultaneously.

Either high or low-impedance microphones may be

used. The amplifier is shipped with an adaptor in the

microphone receptacles, which permits high-impedance

microphone inputseither from a phone plug or from

a standard

MClF

Figure 1

microphone connector.

-

Grounding Line Cord Adapter

Z:

Connect a high-impedance microphone (10,000

HI

ohms or more) to the MIC 1 HI

Z

receptacle on the

rear panel of the amplifiet (see figure 2). Connect a

second high-impedance microphone to the receptacle

marked MIC 2 HI

Z.

Use a single-conductor shielded

cable, terminating either in a phone plug or a standard

microphone connector (Amphenol 75-MClF or equiv-

alent). Remove the adaptor from the microphone receptacle when the phone plug is used. The cable

length from the microphone to the amplifier should be

kept under 10 feet.

LO Z: Connect low-impedance microphones (600 ohms

or less) to the LO Z terminal strip on the rear panel

(see figure 2). Use a single-conductor shielded cable.

The conductor is connected to the MIC 1 terminal and

the shield to GND. Connect a second low-impedance

microphone to the terminal strip in the same manner,

with the high side of the cable to the MIC 2 terminal

-3-

Page 4

and the shield to GND. Low-impedance microphones

may be used with cable lengths from 50 to 500 feet,

depending on the characteristics of the microphone.

Remove the adapter plug from the microphone

receptacle when thelow-impedance input is used.

CAUTION

Figure 2

Rear View CHS100 Amplifier

-

PHONOGRAPH

Phonographs employing a ceramic or crystal type

cartridge may be connected to either the AUX 1 or

AUX 2 receptacle. Use single-conductor shielded

cable terminated in a standard single-prong phono

plug. It is recommended that a separate ground wire

be connected between the phono player base and the

GND terminal on the Output Terminal Strip on the rear

panel of the amplifier (see figure 2). This is not re-

quired when using the Bogen Model LPC-4 phono

player accessories.

AUXILIARY

A radio tuner, tape recorder or any other high-

level, high-impedance signal source may also be connected to the AUX inputs. An input level of at least

0.3 volts is required to obtain full output from the

amplifier.

The input from a 500/600-ohm line is also connected to the AUX receptacle through a WMT-1 line

matching transformer. For detailed connections, see

the instruction sheet furnished with the Bogen Model

WMT-1 accessory.

REMOTE VOLUMECONTROL

Each of the three input channels may have its

volume controlled remotely by utilizing Bogen LVP-1

and RVC-1 accessories. Remote control permits ad-

justment of volume from distances up to 2,000 feet.

The LVP-1 unit is plugged into the appropriate

REMOTE ACCESSORY SOCKET, located on the top

chassis (see figure 3). It is necessary to remove the

top section of the amplifier

cage to reach the accessory

sockets. This is done by loosening the two sheet

metal screws at the rear of the amplifier and lifting

the top section off.

The leads from the RVC-1 accessory are con-

nected to the MIC 1, MIC 2 or AUX terminal and

GND

on the REMOTE CONTROL PRECEDANCE strip on

the rear panel (see figure 2). Complete installation

information is contained in the instruction sheet furnished with the LVP-1 and RVP-1 accessories.

MIC

2

(LVP-I)

MIC I

(LVP-I)

Figure 3 - Location of Accessory Sockets

-4-

Page 5

MICROPHONE PRECEDENCE

Each of the microphone channels can be connected to provide precedence over the AUX channel

by means of the

ordinary single-pole, single-throw switch. The LVP-1

accessory

CESSORY socket on the top of the chassis (see figure

3). Connect the switch to the MIC 1 or MIC 2 terminal

on the REMOTE CONTROL PRECEDENCE strip on

the rear panel (see figure 2). For complete installation

information, see the instruction sheet furnished with

the LVP-1 and RVP-1 accessories.

Bogen

LVP-1 accessory unit and an

is plugged into the AUX REMOTE AC-

WMT-I ACCESSORY INPUT

To connect the input from a 500/600-ohm line,

mount the WMT-1 transformer on the WMT-1 mounting

holes on the rear chassis (see figure 2). Connect the

500/600-ohm

on the accessory. Connect the phono plug on the

1 to the AUX 1 or AUX 2 input of the amplifier.

input to the three-screw terminal board

WMT-

OUTPUT CONNECTIONS

NOTE

If

another sound source has been plugged into

the AUX input, the

the

MIC

input of the amplifier. However, the

WMT-1 wiring must first be modified, as described in the instruction sheet furnished with

the accessory.

WMT-1

may be connected to

AUXILIARY POWER

The auxiliary power receptacle is a three-wire

grounded outlet. Hence, any associated equipment connected to it with a three-prong line cord will be grounded, providing the amplifier line cord has been properly

grounded. Both the amplifier power switch and the

phono on-off switch must be used in turning off a

cordplayer connected to the auxiliary receptacle. Flats

may develop on the idler wheel of the phonograph if

only the amplifier power switch is used to stop the

record player.

re-

SPEAKERS

The amplifier may be used with speaker systems

rated at 2, 8 and 16 ohms and with

constant-voltage speaker systems. For detailed information on the installation of multiple speaker systems, refer to the Speaker Installation Instructions

(No. 54-5001-02) included with this unit.

In installations where speakers will remain connected to the amplifier permanently, connect the speaker directly to the output terminals on the rear panel

(see figure 2). Connect one lead to the terminal cor-

responding to the speaker system’s impedance and

the other lead to COM 1.

For 25-volt operation, connect leads between 25

V (6-8

operation, remove the shorting link between COM 1

and GND. Connect the high sides of the balanced

line between the 25 V (6-8

The balanced line ground is connected to the 25 VCT

(1.5-2

leads to the 70 V (4912) and COM 2 terminals. Connect a jumper between the COM 2 and GND terminals,

if grounding is desired. For balanced line operation,

disconnect the jumper between COM 2 and GND.

Q) terminal and COM 1. For balanced 25-volt

Q) and the COM terminals.

a)

terminals.

For

70-volt

operation,

connect the speaker line

25-volt

and

70-volt

For standard impedance loudspeakers and 25-volt

systems, connect the speaker line leads to pins 1 and

2 of the plug. Connect the wired plug to either speak-

er socket, then attach the impedance selector to the

appropriate output terminal which corresponds to the

impedance of the loudspeaker. For 25-volt systems,

the impedance selector is attached to the 25 V (6-812)

terminal.

For 70-volt operation,

are connected to pins 2 and 3 of the speaker plug.

Connect the impedance selector to the COM 2 terminal.

the speaker line leads

BRIDGING OUTPUT

The BRIDGING receptacle on the rear panel pro-

vides a high-impedance output to feed a tape recorder

or auxiliary amplifier. The MASTER Volume Control

will not affect the bridging output level.

WMT-I ACCESSORY OUTPUT

By utilizing a

a zero-level output at

for feeding a telephone line. The WMT-1 accessory is

connected to the WMT-1 HI

panel. See the instruction sheet furnished with the

WMT-1 transformer for complete installation directions.

Bogen

WMT-1 bridging transformer,

500/600

ohms may be obtained

Z

output jack on the rear

For installations that are moved constantly, connect the speaker to the speaker socket on the rear

panel. Two speaker plugs

are furnished with the amplifier for use in

connections to the speaker sockets.

(Bogen

Part No. 85-0147-01)

making

TAPE OR BOOSTER AMPLIFIER

To drive a booster amplifier or tape recorder, connect a patch cord (with a standard phono plug) from

the TAPE/BOOSTER output jack to the input of the

booster amplifier or tape recorder.

-5-

Page 6

CONTROL FUNCTIONS

POWER SWITCH

The POWER switch on the front panel turns the

amplifier ON and OFF.

MICROPHONE I

The MIC 1 control on the front panel is used to

adjust the volume of the Microphone 1 input. It is

turned clockwise (to the higher numbers) to increase

the volume and counterclockwise to reduce it. Set the

control to the zero position (indicated by a triangle)

when the Microphone 1 input is not used.

MICROPHONE 2

The MIC 2 control on the front panel is used to

adjust the volume of the Microphone 2 input. It is

turned clockwise (to the higher numbers) to increase

the volume and counterclockwise to reduce it. Set the

control to the zero position (indicated by a triangle)

when the Microphone 2 input is not used.

AUXILIARY

The AUX

pose. It selects either of the two auxiliary inputs and

it controls the volume of the selected auxiliary input. To select the AUX 1 input, rotate the control

counterclockwise past the center position (indicated

by a triangle between the two l’s). Turning this control more counterclockwise increases the AUX 1

volume.

To select the AUX 2 input, rotate the control

clockwise past the center position. Turn the control

more clockwise to increase the AUX 2 volume. If the

auxiliary input is not to be used, set the control to

the center position.

The control can be

trol when both auxiliary inputs are connected. This

makes it possible to gradually and smoothly reduce

the level of one input and then increase the other

when changing inputs. The effect is one of fading from

one auxiliary input to the other.

l/AUX

2 control serves a two-fold pur-

also

used as a “fader” con-

RESET MARKER

Each volume control has a red reset marker on the

skirt of the knob. This marker is used to log a par

ticular setting. This is done as follows. Adjust the

volume controls to the desired levels. Slide the reset

markers to coincide with the midpoint mark on the

front panel. The individual knob can now be returned

to zero or any other point, allowing instant resetting

to the predetermined level.

MASTER

Rotate MASTER control to maximum clockwise.

Set the MIC and AUX input volume controls to the

highest level likely to be used, and then mix inputs

as desired. Use the MASTER control to regulate the

overall volume of the output signal.

BASS

The BASS control is used to adjust the tonal

balance of the amplifier output. The center position of

the control (indicated by a triangle between the two

l’s) provides flat frequency response. Rotation of

this control in the counterclockwise direction reduces

(cuts) bass response of the amplifier. Clockwise rotation of the control increases bass response.

The BASS control may also be used to remove

low-frequency noise such as phono rumble or hum. In

situations where acoustic feedback (howling) is likely,

rotate this control counterclockwise. This reduces the

feedback effect and permits higher volume levels than

would other wise be possible.

TREBLE

The TREBLE control adjusts the tonal balance of

the amplifier output. The center position (indicated

by a triangle between the two l’s) provides flat fre-

quency response and is generally used when program

sources and speaker systems are of the highest qual-

ity. Rotation of the control in a counterclockwise

direction reduces the high frequency response of the

amplifier; clockwise rotation increases it. This con-

trol can also be used to remove high-frequency noise,

such as record scratch.

INSTALLATION AND

FEEDBACK

If speakers are located too close to the micro-

phone, acoustic feedback (squealing or howling) may

result. In this case, adjust the volume, and the BASS

and TREBLE controls if necessary, to the point

where feedback is eliminated. In addition, move the

speakers to increase the distance between the speakers and microphone.

HUM

A low-frequency hum may be heard if the con-

nections between the signal sources and the ampli-

fier are incorrect or defective. Recheck all connections for continuity if hum occurs. Try reversing the

amplifier power plug and the plugs of other units such

as the phono player connected in the system. Check

OPERATING

for broken wires, shields and poor connector contacts.

Keep input cables away from the speaker cables. Keep

speaker cables away from transformers and AC power

lines. In the case of a phono player, it may be

cessary to connect a separate ground wire from the

chassis of the phono player to the GND on the rear

of the amplifier.

HINTS

MICROPHONE TECHNIQUE

Speak directly into the microphone in a normal

voice, at a distance of approximately 6 inches to one

foot from the microphone.

Speak deliberately with even speed and loudness.

Don’t shout. Pause frequently between words-and pro-

nounce each word carefully. Sound final consonants.

Do not sing-song or drop words here and there.

-6-

ne-

Page 7

BOGEN

long as you have it. If trouble ever develops with

your unit, please do not hesitate to ask our advice or

assistance. Information can be obtained by writing to

Service Department, Bogen Communications, P.O.

Box 500, Paramus, New Jersey 07652.

ber and serial number of your unit. Completely des-

cribe the difficulty encountered and the effects each

operating control has upon the symptoms of trouble.

Include details on electrical connections to associated

equipment, and list such equipment. When we receive

this information, we will send you service information

if the trouble appears to be simple. If the trouble requires servicing, we shall send you the name and address of the nearest Bogen authorized service agency

to which you can send your unit for repairs.

using the original shipping carton, or a similar container and filler material, to prevent damage in tran-

CIRCUIT BREAKER

ectrical overload by a

reset the breaker, press the red reset button, located

on the top chassis left side, as shown in figure 2.

SERVICE

We are interested in your Bogen amplifier for as

When communicating with us, give the model num-

When shipping your unit, pack the amplifier well,

sit. Send the unit, fully insured and prepaid, via railway express. Do not ship via parcel post unless so

instructed. The unit will be promptly repaired and returned to you via express collect.

The amplifier circuitry is protected against el-

1¾

ampere circuit breaker. To

If the circuit breaker trips again, do not attempt

REPLACEMENT PARTS

The components used in Bogen equipment, with

exception of items listed below, are standard parts

through all reputable parts jobbers. However, several

parts are custom-made to strict Bogen specifications

and should be replaced only with genuine Bogen

parts. These custom-made parts are listed here and

available through Bogen distributors, service

are

agencies or direct from the factory.

Ref. No.

c2, c3

Cl2

Cl8

Cl9

Cl04

106

C105,

CBlOl

CRl,

CR2

Q3, Q4

Q7

QlOl,

Q102, Q103

Part No.

79-008-034

79-008-048

79-005-039

79-008-036

79-009-065

79-009-053

94-0008-02

96-5184-01

96-5213-01

96-5228-01

96-5

187-01

96-5213-01

96-5131-01

96-5162-04

Description

Capacitor, Electrolytic,

25 mfd,

Capacitor, Electrolytic,

50 mfd, 25V

Capacitor, Electrolytic,

1000 mfd,

Capacitor, Electrolytic,

50 mf d,

Capacitor, Electrolytic,

4000 mfd,

Capacitor, Electrolytic,

2000 mfd; 40V

Circuit Breaker, 2 Amp

Diode, 200 PIV, 3 Amp

Transistor

Transistor BC239C

Transistor S2285

Transistor

Transistor 40234

Transistor

15V

15V

15V

5OV

2N5089

2N5089

2N3055

(95V)

to operate the unit. Check the amplifier to determine

the cause of the overload, or consult a Bogen representative or competent serviceman.

TRANSISTOR REPLACEMENT

Transistors and semiconductor diodes do not ordinarily require routine testing.

does not perform properly and it is suspected that a

transistor or diode is at

nician should test them.

However,

dicate that a transistor might be faulty, it must be

removed from the circuit for checking. The plug-in

transistors, of course, can easily be replaced. When

replacing plug-in transistors, use Dow Corning N

340 Compound Silicon Grease (or equivalent). Brush

compound on heat sink, insulator, and transistor. Be

certain that no foreign matter is on heat sink, insulator, or transistor. To insure proper thermal contact, screw down plug-in transistors securely.

PRINTED CIRCUIT REPAIR

When testing or replacing components on the

printed circuit, take care not to damage the board by

application of excessive heat or pressure. A 40-watt

pencil iron normally is sufficient to unsolder com-

ponent parts. If component leads are cut, always pull

them through from the top of the board

from the printed side. Do not insert the leads of re-

placement components into the board without first

clearing the holes. This may be done by heating the

solder and inserting a pick from the underside of the

board.

When ordering a part, specify part number and

description of the part as listed below. Specify the

model and give the series designation, which is a run

letter followed by numbers, stamped or screened on the

rear of the chassis. Also, give the component board

assembly number

boards.

Ref. No.

R5

R17

R18

R28

R34

R35

R43

R44

R45

R46, R47

R48, R49

SW101

TlOl

T102

T103

7

if previous tests by a technician in-

(45-)

Part No. Description

77-00 l-646

77-001-649

77-00 l-649

77-00 l-647

77-001-648

77-00 l-648

76-

113-098

75-412-56 1

75-842-221

75-743-511

75-742-100

81-003-025

83-726-000

83-396-000

83-

397-000

94-0197-O 1

85-0147-O 1

03-0594-01

03-0595-01

02-9029-01

fault, only

for all parts mounted on PC

Control, AUX Volume (CT fader)

Control, MIC 1 Volume

Control, MIC 2 Volume

Control, Bass (BD taper)

Control, Treble (Audio taper)

Control, Master Volume

(Audio taper)

Resistor,

Resistor,

Resistor,

Resistor,

Resistor,

Switch, Power

Transformer,

Transformer, Driver

Transformer, Output

Bulb, No. 19

Plug, Speaker,

Knob & Skirt (O-10)

Knob

Reset Marker

When

the receiver

a qualified tech-

-

0.2m,

5 watt

56Oa,

2 watt

220Q,

3 watt

51012,

7 watt

l(M1,

7 watt

Power

3-pin

&

Skirt (5-O-5)

never pull

O.

Page 8

Loading...

Loading...