Page 1

OWNER’S GUIDE

MODEL A12

A-SERIES ENVIRONMENT-PROOF

HIGH-OUTPUT/LONG-THROW LOUDSPEAKER

Specifications subject to change without notice.

© 2014 Bogen Communications, Inc.

54-2172-01F 1503

Page 2

A12 Loudspeaker (1)

Mounting Knobs (2)

Yoke (1)

Rubber Friction Disk (2)

Safety Attachment Bolt (1)

Ownerʼs Guide (1)

PACKAGE CONTENTS

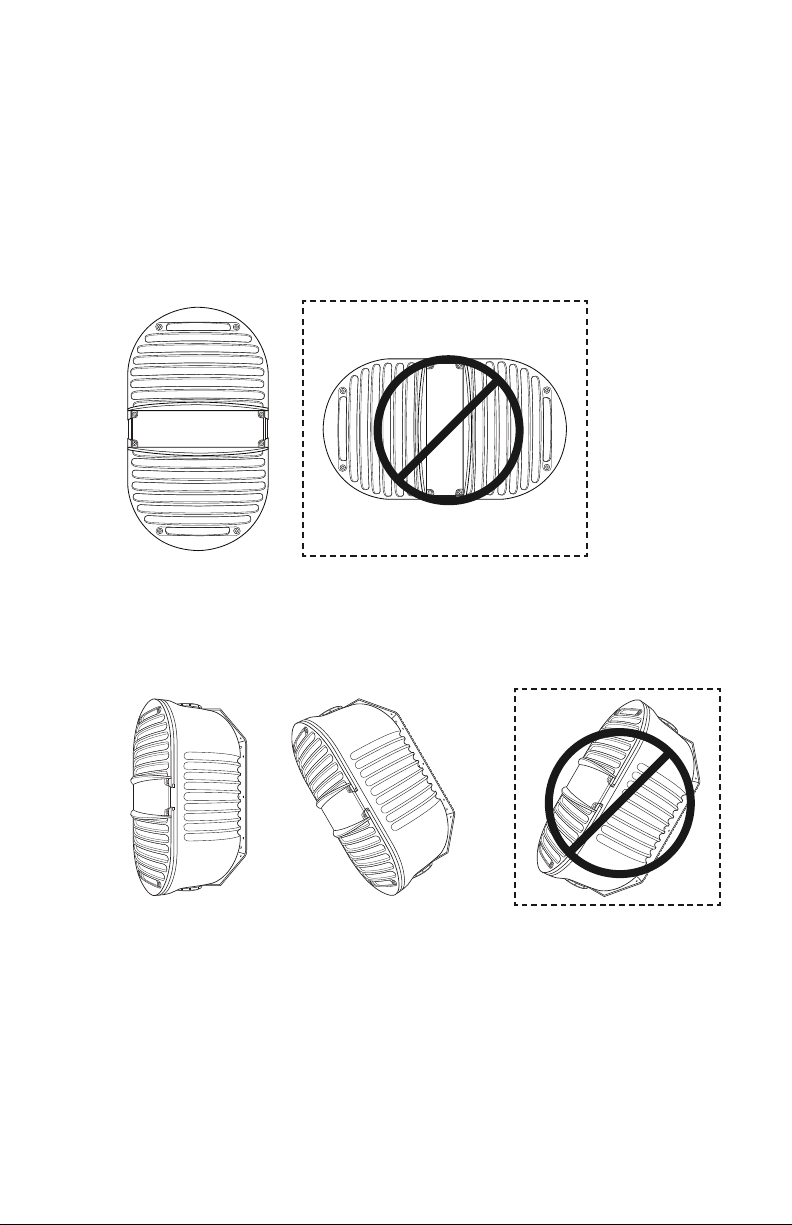

SPEAKER ORIENTATION

CORRECT

The A12 Armadillo Loudspeaker is acoustically designed to operate in a vertical

orientation. This orientation will provide 90 degrees of horizontal coverage and

45 degrees of vertical coverage.

WRONG

The A12 is a ported speaker, designed to shed water, and includes a unique waterrepellent scrim. This scrim covers the ports and horn throat to slow the ingress of

water, but a small amount of water may still enter the cabinet. Weep holes are provided at the bottom of the speaker baffle to drain any water that enters the cabinet.

NOTE: It is very important that the speaker be mounted with its face either vertical

or facing down. Never install the speaker with the face tilted up, as this will undermine the water-shedding aspects of the design and allow excessive water to enter

the cabinet.

WRONG

2

CORRECT

Page 3

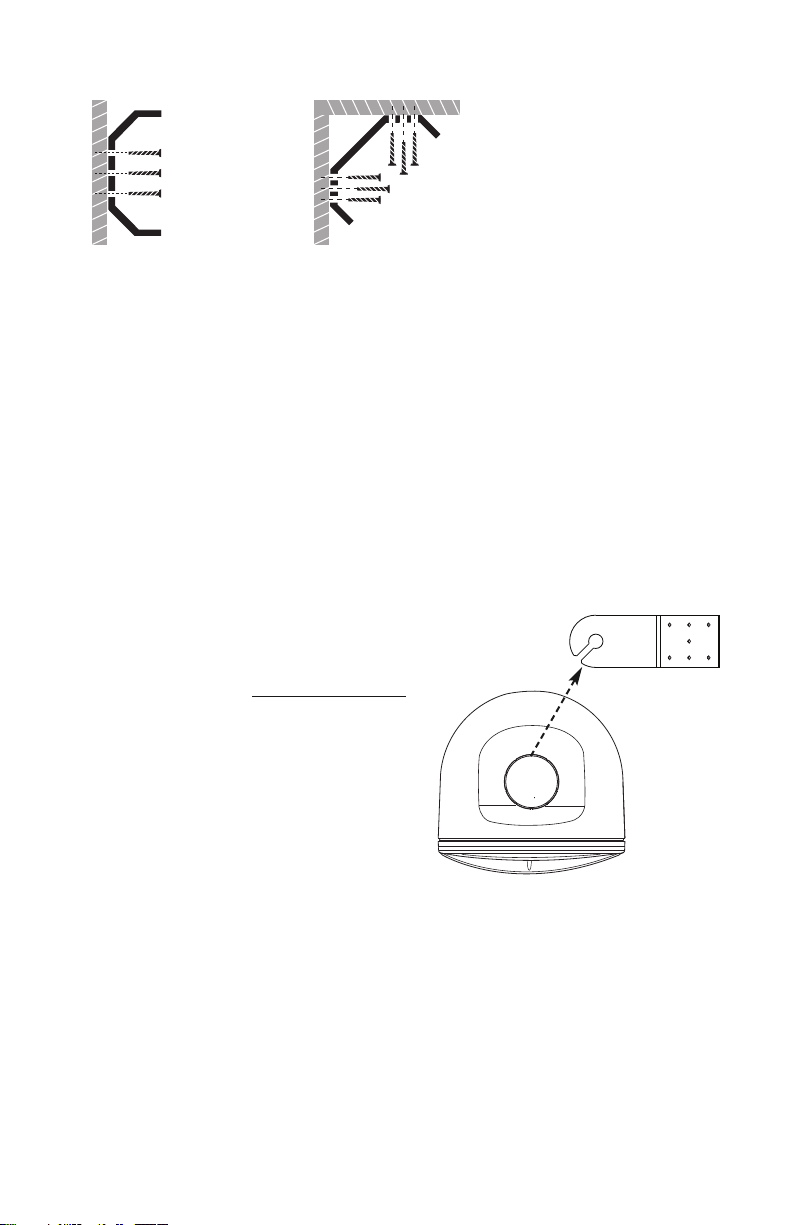

YOKE INSTALLATION

After selecting the speaker location, securely attach the yoke to the surface. An

Adjustable Tilt-Mount Adapter (TMA812) is available to provide various tilt angles.

The TMA812 allows attachment to walls and posts.

WARNING: Mounting brackets must be secured in accordance with local codes.

If in doubt, consult a professional contractor to determine the integrity of the structure to which the bracket will be attached. When required, a safety cable can be

secured to the back of the speaker using the threaded brass insert on the back of

the speaker housing and the forged steel safety bolt (included).

MOUNTING THE SPEAKER ON THE YOKE

The A12 yoke allows the speaker to be

slipped onto it with the locking knobs

attached. First, both knobs need to be

removed and the supplied rubber friction

disks applied to the speaker enclosure

where the knobs clamp. Do not apply the

friction disks directly to the mounting

knobs. Next, screw the knobs back onto

the enclosure about two turns and simply

slide the knob shafts down the slots in the

yoke. Now tighten the knobs making sure

that the shoulder of the knob seats

properly through the large hole at the end

of the yoke.

SOME FACTORS TO CONSIDER

Distance is not the only factor affecting sound intensity. Also consider what adjacent

surfaces may affect the sound (including but not limited to buildings, walls, and

overhangs). These structures may provide positive effects (low frequency

reinforcement) or negative effects (high-frequency reflections that will degrade

intelligibility).

TOP-DOWN VIEW

WALL MOUNT

90° WALL/CEILING MOUNT

(Secure both ends)

3

Page 4

Low-impedance:

Remove jumper, use

COM (–) and

16Ω terminals.

Jumper can be installed on

any two unused terminals

for safekeeping.

REAR-PANEL CONNECTIONS

70V:

With jumper in place, use

COM (–) and one tap

selection (choose 8, 16,

32, 64, or 128 watts).

Shown without jumper

UNDERPOWERING VS. OVERPOWERING

Surprisingly, speaker damage can be caused by amplifiers with too little power.

An underpowered, overdriven amp sends heavily distorted, clipped audio to the

speakers. This can damage the high-frequency drivers. Clipping is usually audible;

it may vary from a harsh sound to a fuzzy or blurry sound. If you hear clipping at

loud volume levels, turn down the volume until the distortion is no longer present.

On the other hand, overpowering a speaker can cause mechanical damage or electrical failure by overstressing the speakerʼs components. The speaker must be

powered appropriately to ensure its longevity and performance.

PAINTING

The speaker enclosure and grille can be painted with automotive paints or spray

paints specially designed to adhere to plastics. Perforated grilles require special

care when painting so that the holes do not become plugged with paint. Applying

several very light coats works best. Be sure to mask the port and horn throat scrim

so that no paint will get on those items.

4

Page 5

70V SYSTEM CONFIGURATION

Note: Jumper in place

To next speaker

This example uses the 16W tap.

In a real installation, any of the

five 70V taps (8W, 16W, 32W,

64W, or 128W) may be used.

From amp

When designing a 70V system, the total of all the power tap settings of all the

connected speakers cannot exceed the output power of the 70V amplifier. The

example below shows five speakers connected in parallel. Using the 16W terminals,

an amplifier is needed with a power rating of at least (5) ×(16) = 80W. A good rule

of thumb is to select an amplifier with 20% more power; in this case, an amplifier

that delivers about 100W.

When using multiple low-impedance speakers wired in parallel, it is important to

know the total load that these speakers present to the amplifier and to

select an amplifier that is stable into that load. The A12 has a 16-ohm input

impedance which allows for easy paralleling of multiple speakers. In the example

on the next page, four speakers are paralleled on each amplifier output, so that

each run has a total impedance of 4 ohms. The amplifier is selected to be stable

into this load impedance.

LOW-IMPEDANCE SYSTEM CONFIGURATION

5

+

+

Page 6

Example of Low-Impedance System Configuration

+

_

+

_

To next speaker

From amp

Jumper has been removed

Note: Jumper stored for safekeeping

Total load impedance can be calculated this way:

Rs is the impedance of the speaker, for the A12 it is equal to 16 ohms.

Note: If all speakers are the same Rs , it is simply:

Low-impedance amplifiers have power ratings based on driving a particular load

impedance, typically a 4-ohm load. Some rate power into an 8-ohm load. If the

speaker loadʼs impedance is greater than the amplifierʼs rated impedance, the

speaker will not consume the amplifierʼs total rated power. Since the A12 is a

16-ohm speaker, operating a single A12 with an amplifier rated for 4 ohms will

result in the A12 speaker consuming only 1/4 of the amplifierʼs maximum capacity.

Likewise a single A12 will consume only 1/2 of the power capacity of an amplifierʼs

8-ohm power rating. Most real world applications will require more than a single

A12, and paralleling the speakers will decrease the total impedance of the load as

mentioned above.

6

AMPLIFIER WITH DUAL 4 OUTPUTS

16 16 16

16 16 16

4 SPEAKERS PER CHANNEL CONNECTED IN PARALLEL

16

1

(1/Rs + 1/Rs ... 1/Rs)

= Total Load Impedance

Rs

# of Speakers

= Total Load Impedance

16

Page 7

LIMITED WARRANTY; EXCLUSION OF CERTAIN DAMAGES

The Bogen Model A12 is warranted to be free from defects in material and workmanship for five (5) years from

the date of sale to the original purchaser. Any part of the product covered by this warranty that, with normal

installation and use, becomes defective (as confirmed by Bogen upon inspection) during the applicable warranty

period, will be repaired or replaced by

Bogen, at Bogen’s option, provided the product is shipped insured and prepaid to: Bogen Factory Service

Department, 4570 Shelby Air Drive, Suite 11, Memphis TN 38118, USA. Repaired or replacement product will

be returned to you freight prepaid. This warranty does not extend to any of our products that have been

subjected to abuse, misuse, improper storage, neglect, accident, improper installation or have been modified

or repaired or altered in any manner whatsoever, or where the serial number or date code has been removed

or defaced.

THE FOREGOING LIMITED WARRANTY IS BOGEN’S SOLE AND EXCLUSIVE WARRANTY AND THE

PURCHASER’S SOLE AND EXCLUSIVE REMEDY. BOGEN MAKES NO OTHER WARRANTIES OF ANY

KIND, EITHER EXPRESS OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED AND EXCLUDED TO THE MAXIMUM EXTENT ALLOWABLE BY LAW. Bogen's liability arising out of the manufacture, sale or supplying of

products or their use or disposition, whether based upon warranty, contract, tort or otherwise, shall be limited

to the price of the product. IN NO EVENT SHALL BOGEN BE LIABLE FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, LOSS OF PROFITS, LOSS OF DATA

OR LOSS OF USE DAMAGES) ARISING OUT OF THE MANUFACTURE, SALE OR SUPPLYING OF PRODUCTS, EVEN IF BOGEN HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES OR LOSSES.

Some States do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have

other rights which vary from State to State.

Products that are out of warranty will also be repaired by the Bogen Factory Service Department – same

address as above or call 201-934-8500. The parts and labor involved in these repairs are warranted for 90

days when repaired by the Bogen Factory Service Department. All shipping charges in addition to parts and

labor charges will be at the owner's expense. All returns require a Return Authorization number. For most

efficient warranty or repair service, please include a description of the failure.

11/2014

SPECIFICATIONS

A12

Frequency Response (-10 dB)

*

55 Hz to 17.5 kHz

LF Driver

Dual Metal-Composite 6-1/2" Cone Woofers,

MLS Voice Coil Guidance System

HF Driver

Weatherproof 1.9"Mylar Diaphragm

Constant Directivity Horn, 1" Exit

Sensitivity (1W/1 m)

94.5 dBspl

Dispersion 90° Horizontal, 45° Vertical

Impedance Ratings

Low (16 ohms) / High (70V)

Power Input (Max.)

225W @ 16 ohms; 128W @ 70V

Power Settings (in watts)

70V: 128, 64, 32, 16, 8

Grille Material Perforated Polypropylene

Enclosure Material Mineral-filled Polypropylene, with UV Inhibitor

Terminations

Dual 4-Terminal Barrier Strips with Gold-plated,

Rust-proof Screws

Product Weight 22 lb.

Speaker Dimensions

10-1/4"W x17-7/8" H x 11-3/4" D

Included Accessories Color-matched, Stainless Steel Mounting Bracket

Optional Accessories

Adjustable Tilt-Mount Adapter

(Model TMA812, sold separately)

Environmental

Designed to meet or exceed Mil-Std-810E

* Half-space response

7

Page 8

www.bogen.com

Loading...

Loading...