Page 1

© Copyright 2012 Bogen Communications, Inc.

Specifications subject to change

54-2207-01A 1206

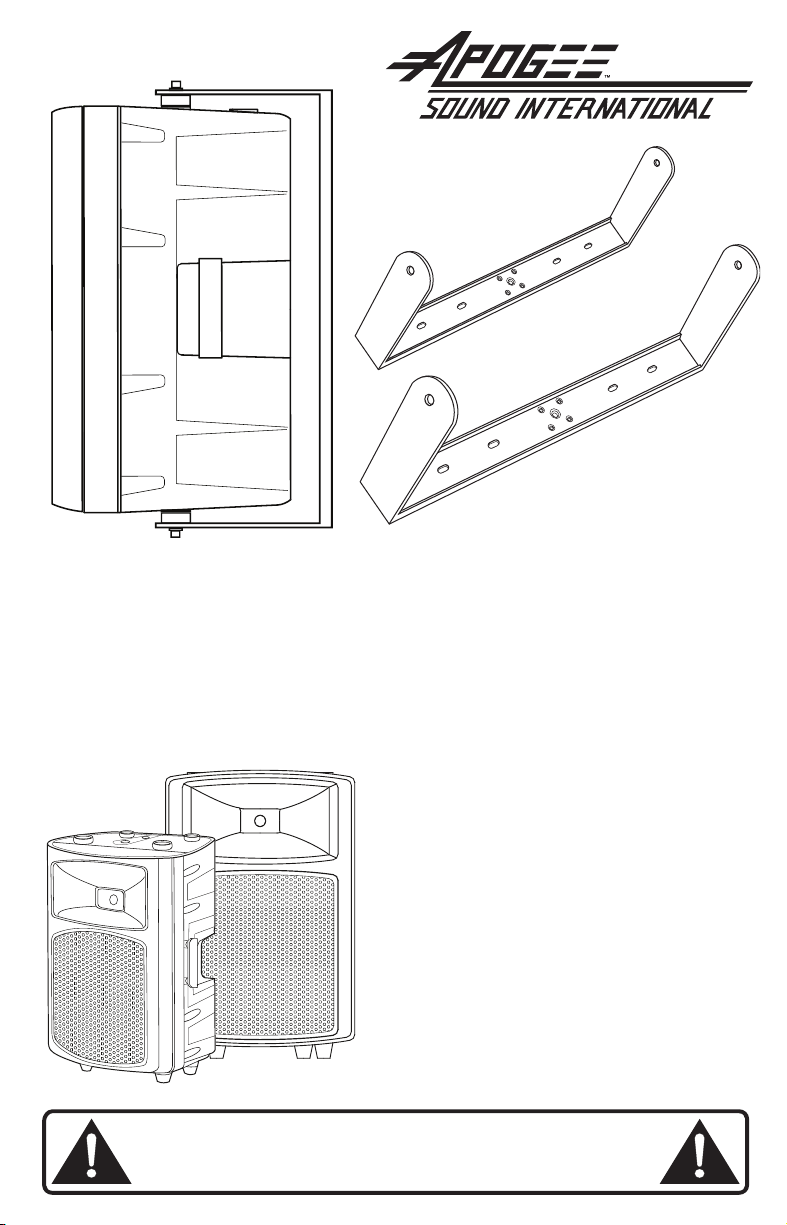

Installation Instruction Manual

108-2120, 108-2150

AMT-Series Yoke Rigging Kits

For Apogee

AMT-12 and AMT-15

Loudspeakers

108-2150

YOKE

108-2120

YOKE

AMT-12

YOU MUST ACCURATELY FOLLOW THE INSTRUCTIONS FOR ALL THE

PARTS INVOLVED IN THIS INSTALLATION. FAILURE TO DO SO CAN

CAUSE SERIOUS INJURY OR DEATH TO OTHERS AND MAY EXPOSE

YOU AND/OR YOUR COMPANY TO POSSIBLE LEGAL ACTION.

AMT-15

Page 2

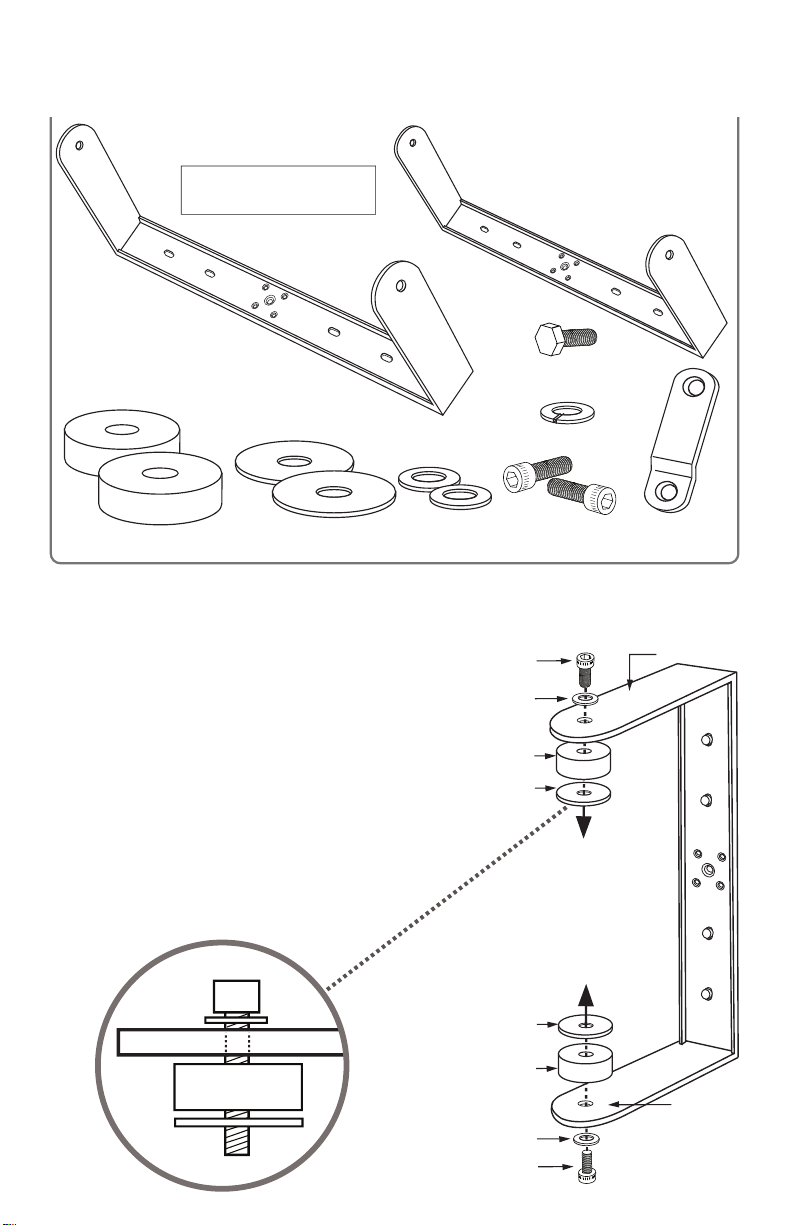

108-2120 & 108-2150

AMT-Series Yoke Rigging Kit Components

(2) STEEL

WASHERS

1. Assembling the AMT-Series Yoke Kit

(2) M8 SOCKET

HEAD BOLTS

(2) NEOPRENE

RUBBER WASHERS

(2) STEEL SPACERS

AMT-15 YOKE KIT CONTAINS

BOLTS, WASHERS & SPACERS

SHOWN BELOW

108-2150

AMT-12 YOKE KIT CONTAINS

BOLTS, WASHERS & SPACERS

SHOWN BELOW

108-2120

EACH YOKE KIT IS

SOLD SEPARATELY

INTO RIGGING

POINT ON AMT

SPEAKER TOP

M8 SOCKET

HEAD BOLT

STEEL

WASHER

STEEL

SPACER

NEOPRENE

RUBBER

WASHER

NEOPRENE

RUBBER WASHER

M8 SOCKET

HEAD BOLT

STEEL WASHER

STEEL SPACER

YOKE

ARM

YOKE ARM

INTO RIGGING

POINT ON AMT

SPEAKER BOTTOM

DETAIL

SIDE VIEW

BOLT

WASHER

YOKE ARM

SPACER

RUBBER

WASHER

(1) TIE POINT

BRACKET

Preparing the AMT-Series Yoke Kit for

Assembly with the AMT Loudspeaker

AFTER FIRST SECURELY ATTACHING THE

YOKE to a mounting surface (see section 3),

the loudspeaker can be attached to the yoke.

This is best accomplished with two people,

one to hold the loudspeaker in place, the

other to insert the hardware (bolts, washers,

spacers). The bolt, flat steel washer, steel

spacer, and rubber washer need to be used

on each end of the cabinet (top & bottom) to

securely hold the loudspeaker in place.

Diagram A

(1) M8 LOW-HEAD

SOCKET CAP SCREW

(1) LOCK WASHER

2. Safety Cable

Anchor Tie Point

NOTE: Be sure that all the hardware

has been tightened securely. However,

DO NOT over-tighten.

TOP VIEW

YOKE

ARM

SOCKET

HEAD

BOLT

DO NOT

USE THIS

RIGGING

POINT

USE THIS

RIGGING

POINT

ROTATE

BOTTOM VIEW

YOKE

ARM

REMOVE

ALL 4 FEET

FROM THE

BOTTOM OF

SPEAKER

Remove Feet from AMT Speaker

If the enclosure will be pivoted more than

a few inches to the left or right / up or down,

remove the 4 feet from the bottom of the

enclosure. This will allow the speaker to

rotate fully. When the desired angle has

been set, fully tighten both the top and

bottom socket head screws.

Holding the loudspeaker in place, line up the holes in the yoke with the holes in

the top and bottom of the enclosure closest to the front of the cabinet. The first

bolt/washer/spacer/rubber washer combination needs to be installed in the correct

order (see Diagram A) on one end of the bracket and speaker, then can be partially

tightened. The second bolt/washer/spacer/rubber washer combination can then

be installed at the other end of the bracket and speaker and partially tightened.

Once the desired orientation of the speaker is selected, the bolts can be fully

tightened to prevent the enclosure from pivoting.

USE THIS

RIGGING

POINT

DO NOT

USE THIS

RIGGING

POINT

NOTE: Be sure to use the Rigging Point which is toward the front of the speaker on

both the top and bottom of the speaker enclosure to attach the Yoke socket head bolt.

SOCKET

HEAD

BOLT

A convenient Safety Cable Anchor Tie

Point Bracket is provided with the yoke.

This attaches to the rear thread/rigging

point in the top of the speaker using

the supplied low profile socket head

bolt with the lock washer. The attached

bracket can now be rotated to the most

convenient angle for attaching a safety

cable (cable to be user supplied).

YOKE ARM

SAFETY CABLE

ANCHOR TIE

POINT BRACKET

SPEAKER

(TOP VIEW)

SOCKET

CAP SCREW

LOCK

WASHER

Page 3

2. Safety Cable

Anchor Tie Point

NOTE: Be sure that all the hardware

has been tightened securely. However,

DO NOT over-tighten.

TOP VIEW

YOKE

ARM

SOCKET

HEAD

BOLT

DO NOT

USE THIS

RIGGING

POINT

USE THIS

RIGGING

POINT

ROTATE

BOTTOM VIEW

YOKE

ARM

REMOVE

ALL 4 FEET

FROM THE

BOTTOM OF

SPEAKER

Remove Feet from AMT Speaker

If the enclosure will be pivoted more than

a few inches to the left or right / up or down,

remove the 4 feet from the bottom of the

enclosure. This will allow the speaker to

rotate fully. When the desired angle has

been set, fully tighten both the top and

bottom socket head screws.

Holding the loudspeaker in place, line up the holes in the yoke with the holes in

the top and bottom of the enclosure closest to the front of the cabinet. The first

bolt/washer/spacer/rubber washer combination needs to be installed in the correct

order (see Diagram A) on one end of the bracket and speaker, then can be partially

tightened. The second bolt/washer/spacer/rubber washer combination can then

be installed at the other end of the bracket and speaker and partially tightened.

Once the desired orientation of the speaker is selected, the bolts can be fully

tightened to prevent the enclosure from pivoting.

USE THIS

RIGGING

POINT

DO NOT

USE THIS

RIGGING

POINT

NOTE: Be sure to use the Rigging Point which is toward the front of the speaker on

both the top and bottom of the speaker enclosure to attach the Yoke socket head bolt.

SOCKET

HEAD

BOLT

A convenient Safety Cable Anchor Tie

Point Bracket is provided with the yoke.

This attaches to the rear thread/rigging

point in the top of the speaker using

the supplied low profile socket head

bolt with the lock washer. The attached

bracket can now be rotated to the most

convenient angle for attaching a safety

cable (cable to be user supplied).

YOKE ARM

SAFETY CABLE

ANCHOR TIE

POINT BRACKET

SPEAKER

(TOP VIEW)

SOCKET

CAP SCREW

LOCK

WASHER

Page 4

50 Spring Street, Ramsey, NJ 07446 USA • Tel. 201-995-2001 • www.apogee-sound.com

Apogee Sound 108-2120 & 108-2150 AMT Yoke Rigging Kits are warranted to be free from defects in material or workmanship for three (3) years from the date of sale to the original

purchaser. Any part of the product covered by this warranty that, with normal installation and use, becomes defective will be repaired or replaced by Apogee, at our option, provided

the product is shipped insured and prepaid to: Apogee Sound Factory Service Department, 50 Spring Street, Ramsey, NJ 07446, USA. The product will be returned to you freight prepaid.

This warranty does not extend to any of our products that have been subjected to abuse, misuse, improper storage, neglect, accident, improper installation or have been modified or

repaired or altered in any manner whatsoever, or where the serial number or date code has been removed or defaced.

THE FOREGOING LIMITED WARRANTY IS APOGEE’S SOLE AND EXCLUSIVE WARRANTY AND THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY. APOGEE SOUND

MAKES NO OTHER WARRANTIES OF ANY KIND, EITHER EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE ARE HEREBY DISCLAIMED AND EXCLUDED TO THE MAXIMUM EXTENT ALLOWABLE BY LAW. Apogee's liability arising out of the manufacture,

sale or supplying of products or their use or disposition, whether based upon warranty, contract, tort or otherwise, shall be limited to the price of the product. In no event shall Apogee

be liable for special, incidental or consequential damages (including, but not limited to, loss of profits, loss of data or loss of use damages) arising out of the manufacture, sale or

supplying of products, even if Apogee has been advised of the possibility of such damages or losses. Some States do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from State to State.

Products that are out of warranty will also be repaired by the Apogee Sound Factory Service Department – same address as above or call 201-934-8500. The parts and labor involved

in these repairs are warranted for 90 days when repaired by the Apogee Sound Factory Service Department. All shipping charges in addition to parts and labor charges will be at the

owner's expense. All returns require a Return Authorization number.

7/22/2008

Limited Warranty; Exclusion of Certain Damages

YOKE

ARM

3. Mounting Yoke Assembly & AMT Speaker

4 PROPERLY

SELECTED

FASTENERS,

DEPENDING ON

THE BUILDING

STRUCTURE.

(4 REQUIRED,

USER SUPPLIED)

Surface

Mount

YOKE

ARM

4 FLAT HEAD

SOCKET

SCREWS

(SUPPLIED)

MACHINED ALUMINUM STAND

FITTING KIT FOR YOKE

(SOLD SEPARATELY)

140-05

HORIZONTAL

TRIPOD MOUNT

WARNING: Customer is to be responsible for the mounting

hardware and selection of mounting surface. Both the

mounting hardware and surface into which the unit is

to be attached must be specified to withstand 10X the

weight of the suspended assembly. Also, a safety cable

should be attached to the unit so as to prevent from fall

should the mounting hardware/surface attachment fail.

AMT-12/15

SPEAKER

AND YOKE

ASSEMBLY

ALUMINUM

STAND

FITTING

TRIPOD

Horizontal Stand

Mount

CEILING MOUNT

HORIZONTAL & VERTICAL WALL MOUNT

© Copyright 2012 Bogen Communications, Inc.

Specifications subject to change

54-2207-01A 1206

Installation Instruction Manual

108-2120, 108-2150

AMT-Series Yoke Rigging Kits

For Apogee

AMT-12 and AMT-15

Loudspeakers

108-2150

YOKE

108-2120

YOKE

AMT-12

YOU MUST ACCURATELY FOLLOW THE INSTRUCTIONS FOR ALL THE

PARTS INVOLVED IN THIS INSTALLATION. FAILURE TO DO SO CAN

CAUSE SERIOUS INJURY OR DEATH TO OTHERS AND MAY EXPOSE

YOU AND/OR YOUR COMPANY TO POSSIBLE LEGAL ACTION.

AMT-15

Loading...

Loading...