Operating instructions

Oil-free

scroll compressors

Series

EO 6...EO 6 TR

EO 11...EO 16

EO 17...EO 22

EO 17 D...EO 22 D

Separate instructions:

Compressor control

Refrigerant compressed air dryer (DS)

Compressed air treatment

Operating instructions

for oil-free

scroll compressors

– EO 6 / EO 6 D / EO 6 R / EO 6 DR / EO 6 TR ( 5.5 kW)

– EO 11 / EO 11 D (11 kW)

– EO 16 / EO 17 / EO 17 D (16.5 kW)

– EO 22 / EO 22 D (22 kW)

IMPORTANT!

READ CAREFULLY BEFORE USE

RETAIN FOR FUTURE REFERENCE

BOGE KOMPRESSOREN

Otto Boge GmbH & Co. KG

Postfach 10 07 13

33507 Bielefeld, Germany

Otto-Boge-Straße 1-7

33739 Bielefeld, Germany

Phone: +49 5206 601-0

Fax: +49 5206 601-200

E-mail: info@boge.com

Net: www.boge.com

Translation of original operating instructions

Version: 02 / 2017

No. 596.1393.01

Nominal price: € 5.00

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page I

Table of contents

Table of contents

Part 1:

General

Part 2:

Safety

1.1 Who are these operating instructions aimed at? ........................ 1

1.2 Content of these instructions........................................................ 1

1.3 Other important documents .......................................................... 2

1.4 Guide for reading............................................................................ 2

Symbols and typographic aids.......................................................... 2

Structure of warning notices ............................................................. 3

1.5 Warranty and service ..................................................................... 4

Limitation of liability........................................................................... 4

Transport damage ............................................................................ 4

Service.............................................................................................. 4

Data on the rating plate .................................................................... 5

1.6 System subject to monitoring ....................................................... 5

2.1 General safety information ............................................................ 7

Intended use ..................................................................................... 7

Reasonably foreseeable misuse....................................................... 7

Responsibility of the operator ........................................................... 8

Personnel requirements.................................................................... 9

Special warning notices .................................................................. 10

2.2 Safety information for operating the compressor ..................... 11

Electrical equipment of the compressor.......................................... 12

Scroll compressor, drive, air system............................................... 13

Lubricant and refrigerant................................................................. 14

2.3 Servicing safety information ....................................................... 14

Safety information for maintenance and repair of the dryer

(EO...D)........................................................................................... 15

Part 3:

Product description

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page III

3.1 How the compressor works......................................................... 17

Compression process ..................................................................... 17

Cooling air requirement .................................................................. 18

Table of contents

3.2 Control of the compressor........................................................... 19

Net pressure ................................................................................... 19

Operating states ............................................................................. 19

Operating modes ............................................................................ 19

3.3 Safety and monitoring devices.................................................... 19

General ........................................................................................... 19

Emergency stop function / main switch (mains disconnecting

device) ............................................................................................ 20

Temperature monitoring ................................................................. 20

Decompression............................................................................... 20

3.4 Technical data............................................................................... 22

3.5 How the DS dryer works .............................................................. 26

DS refrigerant dryer ........................................................................ 26

3.6 How the DRL 6-2 dryer works ...................................................... 27

Device overview.............................................................................. 27

Functional principle of the DRL 6-2 ................................................ 28

Part 4:

Installation

3.7 Regulating the DRL 6-2 integrated dryer .................................... 28

Compressed air side....................................................................... 28

Refrigerant side .............................................................................. 28

Pressure dew point regulation ........................................................ 29

Condensate drainage ..................................................................... 29

4.1 Transporting the compressor...................................................... 31

General ........................................................................................... 31

Intermediate storage of the compressor before installation ............ 31

Transporting the compressor using a forklift truck .......................... 32

Transporting the compressor with a crane ..................................... 32

4.2 Installing the compressor ............................................................ 33

Specifications for the compressor room ......................................... 33

Checking the scope of the delivery ................................................. 36

Positioning the compressor ............................................................ 36

Removing the transport locks ......................................................... 36

Belt tension ..................................................................................... 36

Installation conditions for compressed air receivers ....................... 37

Installation conditions for DRL 6-2 and DS dryers.......................... 37

4.3 Assembly work ............................................................................. 38

General ........................................................................................... 38

4.4 Establishing the connections...................................................... 38

Connecting the compressor to the compressed air network........... 40

1Establishing the electrical connection ........................................... 40

Condensate outlet connection (EO...D, EO...DR)........................... 41

Page IV BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Table of contents

Part 5:

Commissioning

Part 6:

Servicing and

maintenance

5.1 Commissioning the compressor................................................. 43

Checking the installation conditions................................................ 43

Checking the pressure settings ...................................................... 44

Checking the rotation direction of the drive and fan motors ........... 44

Checking the leak tightness of the compressed air pipes............... 45

Opening the shut-off valves ............................................................ 45

Conducting a test run...................................................................... 45

5.2 Shutting down / recommissioning the compressor .................. 46

Shutting down the compressor for prolonged periods .................... 46

Recommissioning the compressor after a prolonged period of

inactivity .......................................................................................... 46

Refrigerant compressed air dryer ................................................... 46

5.3 Operating the DRL 6-2 DL dryer .................................................. 47

6.1 Basic information on servicing ................................................... 49

Servicing safety information............................................................ 49

Servicing by BOGE customer service recommended..................... 52

Servicing overviews ........................................................................ 52

Maintenance Intervals..................................................................... 56

Maintenance work between fixed servicing intervals...................... 56

Maintenance work at fixed servicing intervals ................................ 57

Maintenance work on the dryer (EO...D) ........................................ 58

General information on lubricants and refrigerants......................... 58

Disposing of used operating materials and condensates ............... 59

Pressure hoses............................................................................... 59

Spare and wearing parts................................................................. 59

6.2 Performing maintenance work between fixed servicing

intervals ......................................................................................... 60

Monthly: Check / replace supply air filter for switch cabinet

ventilation........................................................................................ 60

Monthly: checking / cleaning the suction filter ................................ 60

Every 1,500 operating hours: Cleaning the cooler.......................... 61

Every 5,000 or 10,000 operating hours: Cleaning the fan .............. 63

6.3 Having maintenance work performed at fixed servicing

intervals ......................................................................................... 65

Every 3,000 operating hours:

Changing the suction filter cartridge ............................................... 65

Every 3,000 operating hours / annually:

Function check of the safety valves................................................ 65

Every 3,000 operating hours / annually:

Checking the V-belts....................................................................... 66

Every 3,000 operating hours / annually:

Checking the non-return valves ...................................................... 66

Every 5,000 / 10,000 operating hours:

Scroll compressor servicing............................................................ 66

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page V

Table of contents

Every 10,000 operating hours: Replacing the V-belts .................... 66

Every 15,000 / 20,000 operating hours:

Replacing the scroll compressor..................................................... 68

6.4 Special maintenance work........................................................... 68

Drive motors with permanent lubrication ........................................ 68

6.5 Maintenance work on the DRL DL dryer 6-2 .............................. 68

Daily checks.................................................................................... 68

Weekly maintenance ...................................................................... 68

Annual maintenance ....................................................................... 68

6.6 Disposal after dismantling or replacement of parts.................. 69

6.7 Spare parts and additional equipment ....................................... 70

List of spare and wearing parts (for maintenance) ......................... 70

Spare parts for the DRL 6-2 DL dryer ............................................. 70

Spare parts for the DS dryer ........................................................... 70

List of available additional equipment............................................. 70

Part 7:

Remedying faults

Part 8:

Appendix

7.1 Basic information on remedying faults ...................................... 71

Compressor faults........................................................................... 72

Refrigerant dryer and treatment faults (EO...D) .............................. 73

8.1 Guidelines and standards ............................................................ 75

8.2 Application of the Pressure Equipment Directive ..................... 75

Scope.............................................................................................. 75

Classification and assessment of pressurised components ........... 76

Outcome of the assessment ........................................................... 76

Installation in compressed air systems ........................................... 76

8.3 Pneumatic circuit diagrams......................................................... 76

Pneumatic circuit diagram for EO 6, air-cooled .............................. 77

Pneumatic circuit diagram for EO 6 D, air-cooled........................... 78

Pneumatic circuit diagram for EO 6 R, air-cooled........................... 79

Pneumatic circuit diagram for EO 6 DR, air-cooled ........................ 80

Pneumatic circuit diagram for EO 6 TR, air-cooled ........................ 81

Pneumatic circuit diagram for EO 11 (D), air-cooled ...................... 82

Pneumatic circuit diagram for EO 16, air-cooled ............................ 83

Pneumatic circuit diagram for EO 17 (D), air-cooled ...................... 84

Pneumatic circuit diagram for EO 22 (D), air-cooled ...................... 85

8.4 List of maintenance work performed .......................................... 86

Page VI BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

General 1.1 Who are these operating instructions aimed at?

Part 1: General 1.1 Who are these operating instructions aimed at?

These instructions are aimed at end customers of BOGE who have purchased

a scroll compressor and wish to operate it.

In addition to reading these instructions, the user must meet the following prerequisites in order to ensure professional operation of the compressor. S / he

must:

– have an understanding of the control and of the accompanying operating

instructions.

– have an understanding of the accompanying operating instructions for the

additional components.

– be classified as skilled personnel or trained personnel with technical back-

ground knowledge in the field of compressed air technology.

1.2 Content of these instructions

These operating instructions deal exclusively with the functionality and operation of a BOGE type EO scroll compressor.

The prerequisite for safe operation of the scroll compressor is adherence to all

the stipulated safety information and directions for use. Personnel must therefore have carefully read and understood these operating instructions before

carrying out any work. In addition, the accident prevention regulations applicable in the location where the compressor is used as well as the general safety

regulations must be observed. The illustrations in these instructions are provided for basic understanding and may differ from the actual version of the

product. No claims can be made on this basis.

The following content and work descriptions do not (or only to a limited extent)

form part of these instructions:

– Work on the electrical installations, e.g. the electrical commissioning or

repairs to the control.

– Work on the DS refrigerant dryer, on the compressed air treatment com-

ponents or on accessories.

Work on the electrical installations may only be carried out by an authorised

and qualified electrician or BOGE Service personnel.

BOGE recommends having the control, compressor(s) and accessories set up

and commissioned by BOGE Service personnel. Repair and maintenance

work on the compressor should also be carried out by BOGE Service personnel.

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 1

General 1.3 Other important documents

1.3 Other important documents

– Lubricant and refrigerant safety data sheets (EO...D)

– Data sheets / documentation on the control and accessories

– Documentation for compressed air receiver (EO 6 R, EO 6 DR, EO 6 TR)

– Documentation for DS refrigerant dryer (EO 6 DR, EO 17 D, EO 22 D)

– Documentation for condensate drains and cyclone separator

1.4 Guide for reading

Symbols and typographic aids

Symbol

– Information 1

– Information 2

– Information 3

Action

or

● Action

1. Action 1

2. Action 2

3. Action 3

Æ Result of action Result

Meaning

Tips and additional information on

optimum operation

Tips and information that help you to

use the compressor in an optimum

manner are indicated by the symbol

shown.

List

Important information is listed clearly.

Directions for use I

Especially important directions for use

with one action are indicated by the

symbol shown.

Directions for use II

Directions for use with several actions

are numbered and must be carried out

in the specified sequence.

The outcome that will follow an action

is indicated by the arrow shown.

(1)

(2)

(3)

Page 2 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Figures

Figures may be divided into areas.

The individual areas are numbered.

General 1.4 Guide for reading

Structure of warning notices

Signal words

Signal word Meaning

DANGER Warns of a danger to persons that will imminently lead

to serious injury or death.

WARNING Warns of dangers to persons that could lead to serious

injury or death.

CAUTION Warns of dangers to persons that could lead to moderate

or minor injuries.

ATTENTION Warns of property damage.

Warning sign

The following general warning sign is used in this document:

Warning sign Meaning

Warns of a hazardous area.

Warning notice design

Warning notices are a combination of signal words, warning signs and information. They are structured as follows:

SIGNAL WORD

Type of danger

Source of the danger and consequences if the warning notice is not observed.

Î How to avoid the danger.

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 3

General 1.5 Warranty and service

1.5 Warranty and service

Limitation of liability

Transport damage

The manufacturer accepts no liability for direct or consequential damages due

to improper operation or servicing on the basis of the information contained

in these instructions. The product must only be operated by persons who are

familiar with the operating instructions, the product, and national laws, ordinances and regulations on work, safety and accident prevention.

We do not accept any liability for personal injury or property damage caused

by untrained persons, or by non-compliance with the regulations on work,

safety and accident prevention.

No claims for the modification of products that have already been supplied

may be made on the basis of the information, illustrations and descriptions in

this manual.

For your own safety, only use original spare parts and accessories. We do not

assume any liability for the use of other products and any consequential damage.

– Check the delivery for transport damage and completeness.

– Document defects and damage in writing immediately.

– Take photographs of damaged components.

Submit the written damage report.

BOGE accepts no liability for breakage or damage during transport. Please

check the item immediately after delivery and make a complaint to the last

carrier about any damage – even if the packaging is not damaged. In order to

secure your claim for damages against the shipping company, we would advise you to temporarily leave the delivery items and packaging materials in the

condition in which you found them when you identified the damage.

Please submit all other complaints to us within six days of receiving the delivery.

Service

To avoid delays, always provide the following

data for your compressor when submitting enquiries:

–Type

– Year of manufacture

–Number

Should you have any questions about this product, please contact

Technical Support on:

Telephone: +49 5206 601-140

If you require Service assistance, please contact BOGE Service on:

Telephone: +49 5206 601-100

Page 4 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

General 1.6 System subject to monitoring

m³/min

bar

kW

Type

Year of manufacture

Maschine number

Volume flow max.

Final compression pressure

Motor speed

rpm

Motor output

Data on the rating plate

Enter the technical data for your compressor from the rating plate or enclosed

data sheet into the figure below. If you have any queries this ensures that you

always have the most important information to hand.

Fig. 1.1: Data on the rating plate

1.6 System subject to monitoring

A compressor is often part of a pressure vessel system, which is subject to

monitoring according to § 14 of the BetrSichV (Ordinance on Industrial Safety

and Health). A system subject to monitoring shall only be put into service for

the first time or after significant modifications if an approved body or a competent person has inspected the system to ensure it is in proper working order

with regards to its assembly, installation, the conditions of erection and safety,

taking into consideration its intended mode of operation.

According to the BetrSichV, the compressed air system shall be subjected to

recurrent inspections by an approved body or competent person.

The operator must determine the inspection intervals within six months of

commissioning and come to an agreement with the approved inspection body.

The recurrent inspections must be arranged within the specified time frame

and documented by the operator.

Operators located outside the Federal Republic of Germany must observe the

national regulations for the country in which the device is used.

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 5

Safety 2.1 General safety information

Part 2: Safety 2.1 General safety information

Intended use

Reasonably foreseeable misuse

– BOGE compressors, including their additional equipment, are exclusively

intended for the compression and treatment of air for industrial purposes.

The air taken in must not contain any explosive or chemically unstable

gases or vapours.

– The specified operating limits of the compressor may not be exceeded.

– Only operate the compressor in line with the permissible ambient condi-

tions.

– BOGE compressors are designed for stationary operation. Ensure that

they are only installed and operated in clean, dry rooms.

– Operating elements and the control are designed for operation by trained

or qualified personnel.

Type DRL and DS compressed air dryers

– These dryers are only suitable for dehumidifying compressed air.

The compressor must be operated within the technical limits of use. Observe

section “Technical data” on page 22. Non-observance of this data is deemed

improper and poses a risk for the operational safety of the compressor and a

danger to the operating personnel. Severe personal injury and / or property

damage may result.

– Never direct the compressed air produced towards persons. Danger of

death!

– Only use the compressed air produced as breathing air or allow it to come

into contact with food if it has been treated beforehand.

– This BOGE compressor is not explosion-proof. Do not operate in explosive

areas or potentially explosive atmospheres.

– Do not operate the compressor in rooms in which extreme dust, toxic or

flammable vapours and gases may be produced.

The following is not permitted:

– Compressing fluids other than those mentioned under intended use or

compressing fluids loaded with contaminants.

– Exceeding the final compression pressure indicated on the rating plate.

– Altering the safety devices and cladding or putting them out of operation.

– Removing or painting over signs and symbols on the compressor.

– Operation of the compressor by untrained or unauthorised persons.

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 7

Safety 2.1 General safety information

Responsibility of the operator

Obligations of the operator

The operator is obliged to

– operate the compressor only in a technically perfect, safe-to-operate condi-

tion

– provide a device that automatically switches off the power supply in the

event of a fault, to avoid injury from electric current

– check the completeness and function of the emergency stop device(s) at

regular intervals

– carry out a workplace risk assessment in his area of responsibility and

issue the ensuing operating instructions

– name a person responsible for the safe operation of the machine and the

coordination of all work performed on the machine

– avoid stressful situations when operating the compressor by means of

technological and organisational operations scheduling

– ensure proper workplace lighting is provided at the control section of the

compressor according to the local health and safety regulations

– observe the safety data sheets for the hazardous substances used and

make all information accessible to personnel in accordance with the safety

data sheet

– provide the compulsory personal protective equipment, instruct others on

its use and check that it is being worn at regular intervals

– determine the personnel responsible for various tasks on the machine

– instruct the personnel on a regular basis regarding all obligations concern-

ing the preservation of safety and order at the compressor site

– develop safe technology for the potential dismantling of the construction,

define responsibilities (work safety, supervision, workmanship), supervise

dismantling work and check compliance with the established protective

measures and instructions.

Operation regulations

The compressor unit operator is responsible for ensuring that it is installed,

operated and maintained properly. Operators of work equipment in the Federal Republic of Germany must adhere to the regulations and rules currently

valid for the Industrial Employers' Liability Insurance and Accident Insurance

associations and also the Ordinance on Industrial Safety and Health

(BetrSichV).

When operating the compressor unit outside the Federal Republic of Germany,

the accident prevention regulations of the country in which the compressor is

being operated must be observed in addition to the information contained in

these operating instructions. In the event that measures are required above

and beyond the legal regulations specified in the Federal Republic of Germany

or the information contained in these operating instructions, it is of utmost

importance that these be carried out prior to commissioning the compressor

unit.

Page 8 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Safety 2.1 General safety information

Personnel requirements

General

Only personnel authorised by the operator of the compressor may work with

or on the compressor. The personnel working on the compressor must observe all industrial safety regulations and operating instructions, successfully

carry out their responsibilities, and read and understand the operating instructions. Always wear compulsory personal protective equipment when working

on the compressor.

Only persons who are able to carry out work correctly and reliably and who

meet the following requirements may perform activities on the compressor:

– Only authorised specialists should be instructed to carry out assembly,

installation, service and maintenance work on the compressor.

– Work on the electrical installations may only be carried out by an author-

ised and qualified electrician. The electrical equipment must be disconnected from the mains and precautions taken to prevent it from being

switched back on again.

– The compressor must be operated by trained personnel.

Trained personnel

Trained personnel are persons whom the operator has given detailed information about the tasks assigned to them and the possible dangers.

Qualified personnel / specialist

Skilled personnel are persons who are able to successfully carry out work

assigned to them, recognise possible dangers independently and avoid injury

to persons or damage to property due to their professional training, knowledge

and experience as well as knowledge of the relevant regulations.

Qualified electrician

All work on the electrical system may only be carried out by a qualified electrician. Qualified electricians are persons who are able to successfully carry out

work assigned to them on electrical equipment, recognise possible dangers

independently and avoid injury to persons or damage to property as a result of

electrical current due to their specialist qualifications, knowledge and experience as well as knowledge of the relevant regulations.

Personal protective equipment (PPE)

In general for all work on the compressor

– protective clothing

– slip-resistant safety shoes and

– hearing protection, if applicable,

must be worn.

For special duties

– a protective helmet (for transportation with lifting gear)

– protective goggles (for work on pressurised parts / components)

– chemical-resistant protective gloves (when handling lubricants)

– cut and puncture-resistant protective gloves

must be worn.

Before starting work with operating materials (e.g. lubricating greases) without

wearing chemical-resistant protective gloves, a skin protection cream must be

applied. After finishing the work a skin care product must be applied.

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 9

Safety 2.1 General safety information

Special warning notices

To indicate particular dangers, the following warning symbols / pictograms are

used alongside warning notices.

Danger due to electric current

...warns of life-threatening dangers due to electric current.

Non-observance of the warning notice can cause serious or fatal injuries.

Activities that follow this warning notice may only be carried out by authorised and qualified electricians.

Danger from hot surfaces and operating materials

...warns of dangers from hot surfaces and operating materials.

Non-observance of the warning notice can result in serious burns.

Activities that follow this warning notice may only be carried out by authorised and qualified personnel.

Danger from automatic restart

...warns of dangers due to an automatic restart.

Non-observance of the warning notice can cause serious injuries due to

moving parts.

Activities that follow this warning notice may only be carried out by authorised and qualified personnel.

Danger from overpressure and sudden discharge of fluids

...warns of dangers from overpressure and sudden discharge of fluids.

Non-observance of the warning notice can cause serious injuries.

Activities that follow this warning notice may only be carried out by authorised and qualified personnel.

Dangers due to moving parts

...warns of dangers to body parts by being crushed, cut, sliced off or drawn in.

Non-observance of the warning notice can cause serious injuries due to

moving parts.

Activities that follow this warning notice may only be carried out by authorised and qualified personnel.

Danger due to hazardous or irritant substances

...warns of dangers from hazardous or irritant substances.

Non-observance of the warning notice can cause injuries to the skin, eyes

and respiratory tract.

Activities that follow this warning notice may only be carried out by authorised and qualified personnel.

Page 10 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Safety 2.2 Safety information for operating the compressor

2.2 Safety information for operating the compressor

WARNING

Danger of personal injury or property damage.

Non-observance of the following safety information may lead to injuries and

damage to the compressor.

Also observe the generally valid safety and accident prevention regulations

in addition to the information in these operating instructions.

1. Ensure that no commissioning and maintenance work is undertaken on the

compressor until these operating instructions are understood.

2. Only use the compressor for its intended purpose, as described in these

operating instructions.

3. The operator must ensure

– that only appropriately trained and authorised personnel work on this

compressor

– that no persons work on this compressor whose ability to react is im-

paired due to the use of drugs, alcohol, medication, etc.

– that the operating, maintenance and repair personnel are familiar with

all safety information and that it is being observed

– that the compressor is only operated in a safe operating condition.

4. Avoid any procedure which may compromise the safety of the compressor.

5. Always wear compulsory personal protective equipment for protection

against injuries from sharp corners or edges when working on the compressor.

6. To avoid dangers from debris or parts lying around, the work area of the

compressor must be kept clean and tidy at all times.

7. Always squat when working on components mounted at a low height, never

stoop. When working on components mounted higher up, always stand up

straight.

8. It is imperative that the limit values for the final compression pressure specified on the rating plate are not exceeded.

9. Do not operate the compressor without the required protective and safety

devices. The built-in safety devices must not be removed or shut down.

10.Ensure that all safety cladding and doors are closed before commissioning

the compressor and that they are not opened during operation.

11.When dismantling the safety cladding or safety devices for repair or maintenance work, the compressor must be shut down as described in these

operating instructions. All cladding and safety devices must be reattached

and closed immediately upon completion of the repair or maintenance

work.

12.Only operate the compressor using the additional equipment (options) recommended or authorised by the manufacturer.

13.Only undertake modifications or conversions of the compressor in agreement with BOGE, taking all relevant safety regulations into consideration.

The manufacturer accepts no liability for damages resulting from unauthorised modifications to the compressor.

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 11

Safety 2.2 Safety information for operating the compressor

14.Never operate the compressor when one or more parts (e.g cable, plug)

are damaged, it is not in perfect working order, or damage is detected or

suspected.

15.Observe all safety and danger signs on the compressor.

Integrated DRL 6-2 compressed air dryer (EO 6 D, EO 11 D) and attached

DS compressed air dryer (EO 6 DR, EO 17 D, EO 22 D)

The integrated Type DRL refrigerant compressed air dryer is also referred to

below as a DL dryer.

16.For all information and tips on the attached DS dryer, please read the separate operating instructions for the dryer.

17.BOGE accepts no liability for non-observance of the safety regulations during handling, operation, maintenance or repair work.

18.The operational capability and service life of the refrigerant compressed air

dryer as well as the avoidance of premature repairs are dependent on the

correct operation, maintenance and professional repair of the device according to the instructions given in these operating instructions.

Electrical equipment of the compressor

DANGER

Risk of electric shock!

Coming into contact with live parts inside the switch cabinet or where the

electrical equipment is housed can be fatal.

Î Never open the electrical equipment and switch cabinet during operation.

Î Work on the electrical equipment may only be carried out by an author-

ised and qualified electrician.

Î Prior to all work:

1. Disconnect all power infeeds using a mains disconnecting device.

2. Take precautions to prevent them being switched back on again.

3. Check that all system components are de-energised.

4. Earth and short circuit.

5. Cover or enclose adjoining live parts.

Î Check the electrical equipment of the compressor at regular intervals for

defects such as loose connections or scorched cables. Have any defects

rectified immediately.

Î Make sure to have all electrical systems and fixed electrical installations

checked by a qualified electrician at least every four years. Any modifications carried out after inspection must conform to EN 60204-1.

Î Check that all safety devices on the machine are functioning properly at

regular intervals.

Î Only use original fuses.

Î Never touch the relay outputs and the I/O terminals. Dangerous voltage

may still be present even when the machine is disconnected from the

mains.

Page 12 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Safety 2.2 Safety information for operating the compressor

Scroll compressor, drive, air system

WARNING

Danger from overpressure, e.g. due to sudden discharge of fluids or

bursting of components!

In the event of damage, malfunctioning or incorrect use, fluids under high

pressure can escape from pipes or individual components and cause severe

injuries.

Î Work on the system and components may only be carried out by skilled

personnel.

Î Wear PPE.

Î Depressurise pressurised system components before working on them.

Î It is forbidden to operate the compressor unit without suitable safety

devices.

Î Safety devices must not be removed or shut down.

Î The maximum permitted operating limits must not be exceeded.

WARNING

Risk of burns from hot surfaces and fluids!

High temperatures are produced during the compression process. There is

a risk of injury from touching hot surfaces or from hot fluids escaping.

Î The compressor unit must not be operated without suitable safety devic-

es, e.g. isolating protective equipment.

Î The work may only be carried out by skilled personnel.

Î Wear PPE.

Î Before carrying out any work ensure that all hot components have cooled

down to 50°C.

WARNING

Moving parts or sharp edges!

Risk of injury due to moving parts or sharp edges that can cause body parts

to become caught, jammed, cut off or crushed. Non-observance of the safety

information can result in serious injuries.

Î The compressor unit must not be operated without suitable safety devic-

es, e.g. isolating protective equipment.

Î The work may only be carried out by skilled personnel.

Î Wear PPE.

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 13

Safety 2.3 Servicing safety information

Lubricant and refrigerant

CAUTION

Risk of injury due to contact with hazardous substances, e.g. from

inhalation!

Lubricants pose a potential danger to health and the environment as a result

of their content.

Î Avoid contact with skin and eyes.

Î Wear PPE.

Î Do not inhale vapours or mists.

Î Fire, naked flames and smoking are strictly prohibited when handling

hazardous substances.

Î Observe the information on the relevant safety data sheets.

2.3 Servicing safety information

CAUTION

Risk of injury when using unsuitable materials and components, e.g.

as a result of mechanical failure!

Î Only use original spare parts, lubricants and operating materials ap-

proved by BOGE during repair or maintenance.

DANGER

Risk of electric shock!

Coming into contact with live parts inside the switch cabinet or where the

electrical equipment is housed can be fatal.

Î To avoid such dangers, the power supply of the compressor must be

equipped with a mains disconnecting device. The mains disconnecting

device must conform to EN 60204-1. The main switch installed as standard complies with this requirement.

– Maintenance work may only be carried out by appropriately trained per-

sons.

– Ensure that adjustments, fault rectification and repairs are only carried out

by specialists or appropriately trained persons.

Page 14 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Safety 2.3 Servicing safety information

Prior to maintenance or repair work:

– Ensure that work on the electrical equipment of the compressor is only

carried out by qualified electricians.

– Work on live parts or devices is prohibited. Exceptions are governed by the

appropriate regulations, e.g. DIN VDE 0105.

– Prior to starting work on the electrical system the power supply must be

switched off and precautions taken to prevent it from being switched back

on again. All dismantled covers and safety devices must be refitted immediately after work is finished.

1. Switch off the compressor using the OFF button.

2. Disconnect all power infeeds using a mains disconnecting device.

3. Take precautions to prevent them being switched back on again.

4. Check that all system components are de-energised.

5. Earth and short circuit.

6. Cover or enclose adjoining live parts.

7. Fix a warning sign to the control and fill in the name of the person who

is authorised to switch the machine back on.

8. Disconnect the compressor from the compressed air network (depressurise or block pressurised pipes).

– Exercise extreme caution during repair or maintenance work that requires

the compressor to be operational. Ensure that persons stay away from the

danger area.

– The operator must check the compressor daily for externally visible dam-

age and defects and report any changes (including operational behaviour)

immediately.

– When the automatic restart (Auto-Restart) is activated, the compressor will

start automatically following a power failure. Prerequisite: the net pressure

is lower than the set switch-on pressure.

Safety information for maintenance and repair of the dryer (EO...D)

The refrigerant dryer is integrated in the compressor housing (EO 6 D,

EO 11 D, 17 D, EO 22 D) or attached (EO 6 DR).

CAUTION

Risk of injury due to moving parts, hot surfaces or sudden discharge

of pressurised fluids!

Î The operator must observe current EU Regulation Nos. 517/2014 and

303/2008. Existing internal plant regulations must also be adhered to.

Î Repair and maintenance work on the refrigerant compressed air dryer

may only be carried out by trained BOGE Service personnel. Non-observance can lead to injuries and damage to the compressor unit.

– Never temporarily or permanently remove, modify or adjust protective or

safety devices on the dryer.

– Only use original spare parts.

– All maintenance and repair work should only be carried out when the sys-

tem is stationary and disconnected from the mains power supply. Ensure

that the dryer cannot be accidentally switched on.

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 15

Safety 2.3 Servicing safety information

– Prior to the removal of a pressurised component, disconnect the dryer

from all pressure sources and relieve the pressure load on the dryer.

– Do not use flammable solvents to clean the dryer.

– Ensure exceptional cleanliness during all maintenance and repair work.

Keep parts and exposed openings clear of dirt by covering them with a

clean cloth, paper or adhesive strips.

– Never weld on pressurised components or modify them in any way.

– Ensure that no tools, loose parts, etc. are left behind in the system.

Handling refrigerant

CAUTION

Contact with refrigerant can cause poisoning and irritation of the respiratory tract.

Refrigerant contains harmful substances that can lead to poisoning and irritation of the respiratory tract.

Î Repair and maintenance work on the refrigerant compressed air dryer

(EO...D, EO...DR) may only be carried out by trained BOGE Service personnel.

Î Wear personal protective equipment.

Î Observe the refrigerant safety data sheet.

– Wear protective goggles and protective gloves.

– Do not allow liquid refrigerant to come into contact with the skin (causes

frostbite).

– Do not inhale refrigerant vapour.

– To avoid higher concentrations, ventilate the workrooms well. Opening

windows and doors is insufficient – a ventilation system is required, preferably on the connection point or near the ground.

– Do not smoke – burning cigarettes can cause the refrigerant to decom-

pose. The substances produced as a result are toxic and must not be

inhaled.

– Do not allow refrigerant to escape when it is topped up or during repair

work.

– If the concentration of refrigerant suddenly increases (e.g. due to burst

pipelines), leave the room immediately and enter only when there is sufficient ventilation.

– Welding and soldering work should only be carried out on refrigerating

systems in well-ventilated rooms. Refrigerant will decompose when exposed to flames and electric arcs. The resulting decomposition products

are toxic.

– Before commencing welding or soldering work on refrigeration systems,

the refrigerant must be removed.

– A strong odour indicates decomposition of the refrigerant:

– Leave the room immediately. Ventilate the room well.

Page 16 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Product description 3.1 How the compressor works

Part 3: Product description

Compression process

3.1 How the compressor works

BOGE scroll compressors are oil-free, stationary, electrically powered air compressors. A scroll compressor functions according to the positive displacement

principle. It consists of two spirals; the moving spiral continuously compresses

the drawn-in air against the fixed spiral using an eccentric motion. The spirals

thereby form several increasingly narrower chambers within the coils. The gas

being pumped is sucked in from outside, compressed within the pump and

emitted via a connection in the centre of the spiral. This provides a constant,

oil-free flow of compressed air of up to 10 bar overpressure.

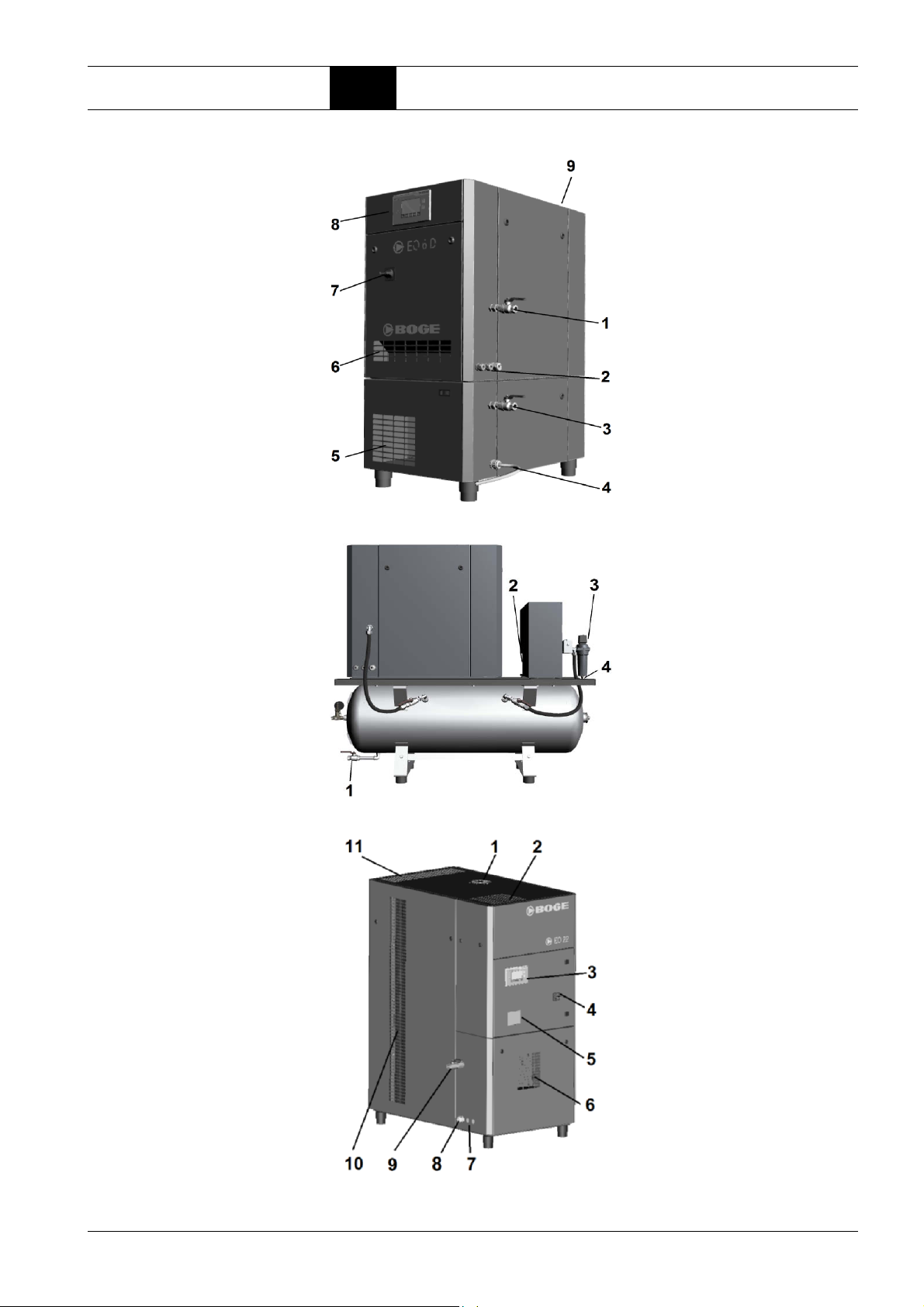

Fig. 3.1: Scroll unit EO 6

Fig. 3.2: Scroll unit EO 11...EO 22

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 17

Product description 3.1 How the compressor works

1Drive pulley

Power transmission from the electric motor to the compressor in the corresponding design using V-belt.

2 Drive motor

The electric motor drives the compressor with the corresponding transmission ratios and V-belt.

3 Suction filter

The suction filter cleans the air drawn in from the compressor stage.

4 Safety valve

The safety valve limits the maximum pressure in the system to a defined

limit value. It blows off if the final pressure is exceeded due to a fault.

5 Temperature sensor

This sensor monitors the temperature of the compressed air.

6 Non-return valve

The non-return valve is located before the primary cooler and prevents

compressed air from flowing back into the compressor from the compressed air network.

7 Airend / scroll compressor

Cooling air requirement

Please refer to the following table for the cooling air requirement and the size

of the supply air inlets for your compressor. Ensure that flaps and weather protection grids have the necessary free cross section. We generally recommend

that you contact a specialist company to carry out the duct design and construction work.

Required cooling air quantity (see also Technical data)

inlet

1

)

Cooling air

requirement

Compressor

Type Drive

rating

Required fan

output for room

ventilation

Air cooling

Required

supply air

[kW] [m³/h] [m²] [m³/h]

EO 6 / EO 6 R 5.5 1500 0.25

EO 6 D 5.5 1705 0,25

EO 6 DR 5.5 1705 0,25

EO 6 TR 2x 5.5 3000 0.50

780 (8 bar)

660 (10 bar)

780 (8 bar)

660 (10 bar)

780 (8 bar)

660 (10 bar)

780 (8 bar)

660 (10 bar)

EO 11 / EO 11 D 11 4900 0.65 2840

EO 16 16.5 6000 0.75 3500

EO 17 / EO 17 D 16.5 6000 0.75 3500

EO 22 / EO 22 D 22 7000 0.90 4300

1)

For the cooling air requirement a temperature difference of + 4°C between the room and ambient temperature has

been taken as a basis.

Table 3.1: Cooling air requirement, required supply air inlet and duct cross

sections.

Page 18 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Product description 3.2 Control of the compressor

3.2 Control of the compressor

Net pressure

Operating states

Operating modes

In the compressor, the pressure behind the secondary cooler is referred to

as the net pressure. The control switches the compressor on and off during

operation depending on the net pressure.

All control systems for compressors are based on two principal operating

states:

1. Load-run

– The compressor supplies the maximum amount of compressed air.

– To do so it consumes maximum power.

2. Standstill – ready for operation

– The compressor is stopped, but is ready for operation.

– If compressed air is required, it switches automatically to load-run.

By combining the two operating states intermittent mode is achieved:

In intermittent mode the energy balance is optimal.

– The compressor is operated in load-run.

– The compressor comes to a standstill once the switch-off pressure p

has been reached. It does not consume any power.

– Once the pressure has fallen to the switch-on pressure p

back to load-run.

, it switches

min

max

General

3.3 Safety and monitoring devices

The safety devices and BOGE monitoring system ensure a high level of operating safety.

The control reacts as follows in response to a safety device:

– The compressor is switched off immediately.

– The fault is shown via a visual display.

CAUTION

Risk of injury due to moving parts, overpressure or thermal hazards!

Î It is forbidden to operate the compressor without the installed safety

devices.

Î The safety devices must not be removed or shut down.

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 19

Product description 3.3 Safety and monitoring devices

The following safety and monitoring devices are installed as standard:

Emergency stop function / main switch (mains

disconnecting device)

Temperature monitoring

The emergency stop function serves to avert or prevent a prevailing emergency situation, where such a situation is the result of conduct by individuals or an

event posing an unexpected danger. The emergency stop function is provided

by the main switch control element (mains disconnecting device). When the

main switch is pressed, compressor operation is stopped immediately and the

switch cabinet and control are no longer live. Dangerous voltage may still be

present in the relay outputs and the I/O terminals even when the machine is

disconnected from the mains.

The main switch is located in a prominent position on the front of the compressor housing.

NOTE

Only the off button of the control must be used to switch the compressor off

during normal operation.

The following temperatures are monitored:

– Final compression temperature per unit

– Intake air temperature

– Compressed air outlet temperature

A compressor switches off when the maximum permitted compressed air

outlet temperature is reached. A scroll unit switches off when the maximum

permitted final compression temperature of the unit is reached.

Decompression

If the compressor needs to be switched off due to a fault:

1. Switch off the compressor (OFF button).

2. Acknowledge the fault.

3. Remedy the fault.

4. Switch on the compressor (ON button).

A mechanical safety valve on each unit (see fig. 3.1 and 3.2) and on the compressed air receiver (see fig. 3.3) prevents the maximum permitted pressure

from being exceeded.

WARNING

Risk of injury from flying parts caused by overpressure, e.g. pressurised components bursting or detonating!

Î It is forbidden to operate the compressor without the installed safety

devices.

Î The safety devices must not be removed or shut down.

Î The specified final compression pressure must not be exceeded.

Page 20 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Product description 3.3 Safety and monitoring devices

CAUTION

Risk of injury due to thermal danger caused by sudden discharge of

extremely hot fluids at high flow velocity!

Danger caused by noise due to the sudden escape of large quantities

of gas!

If the maximum permitted pressure is exceeded (e.g. in the event of a fault

or an incorrect setting), the entire air delivery of an airend is blown off.

Î The compressor should only be operated with the housing closed.

Fig. 3.3: Safety valve (1) on receiver EO 6 R

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 21

Product description 3.4 Technical data

3.4 Technical data

Technical data EO 6...EO 6 TR, part 1

Type EO 6 EO 6 D EO 6 R EO 6 DR EO 6 TR

Dimensions

– Width [mm] 670 670 1785 1760 1825

– Depth [mm] 1000 1000 745 745 1000

– Height [mm] 972 1385 1670 1670 1725

Standard receiver capacity [l] – – 270 270 350

Weight [kg] 250 336 368 405 647

Maximum emitted sound pressure level [±3 dB(A)]

as per EN ISO 2151

Super silenced 8 bar / 10 bar [dB(A)] 62 / 59 62 / 59 62 / 59 62 / 59 62 / 59

Measuring surface [dB(A)] 15 15 15 15 15

Sound power level 8 bar / 10 bar [dB(A)] 77 / 74 77 / 74 77 / 74 77 / 74 77 / 74

Compressor

Max. final compression temperature [°C] 250 250 250 250 250

Compressed air outlet temperature over intake air

temperature, approx. [K]

Volume flow in accordance with ISO 1217 Annex C at:

= 8 bar [m3/min] 0.62 0.62 0.62 0.62 1.24

– p

max

– p

= 10 bar [m3/min] 0.49 0.49 0.49 0.49 0.98

max

Drive motor

Rated power [kW] 5.5 5.5 5.5 5.5 2x 5.5

Nominal speed

– with motors for 50 Hz [rpm] 1465 1465 1465 1465 2x 1465

– with motors for 60 Hz [rpm] 1765 1765 1765 1765 2x 1765

Protection class IP 55 55 55 55 55

Design IMB33333

ISO class FFFFF

Electrical Connection

Supply voltage / frequency

Recommended fuse protection at 400 V

Supply voltage / frequency of dryer

1)

2) 3)

1)

[V/Hz]

[A]

[V/Hz] – 230 / 50 – 230 / 50 –

Deviating voltage / frequency

Supply voltage / frequency [V/Hz]

2) 3)

Recommended fuse protection at 220 V / 230 V

Recommended fuse protection at 380 V / 440 V

1)

Standard equipment. Supply voltages and frequencies are detailed on a sign in the switch cabinet.

2)

Different supply voltages alter the values for the fuses.

3)

Use fuse cut-outs gG or miniature circuit-breakers with C characteristic.

* per compressor.

[A]3232323232*

)

2) 3

[A]2525252525*

15 15 15 15 15

400 / 50 400 / 50 400 / 50 400 / 50 400 / 50

25 25 25 25 25*

230 / 50

220/440 / 60

220 / 60

380 / 60

440 / 60

230 / 50

220/440 / 60

220 / 60

380 / 60

440 / 60

230 / 50

220/440 / 60

220 / 60

380 / 60

440 / 60

230 / 50

220/440 / 60

220 / 60

380 / 60

440 / 60

230 / 50

220/440 / 60

220 / 60

380 / 60

440 / 60

Page 22 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Product description 3.4 Technical data

Technical data EO 11...EO 22 D, part 1

Type EO 11 / EO 11 D EO 16 EO 17 / EO 17 D EO 22 / EO 22 D

Dimensions

– Width [mm] 915 915 915 915

– Depth [mm] 1520 1520 1520 1520

– Height [mm] 1460 1460 1880 1880

Weight [kg] 585 / 620 710 774 / 808 896 / 934

Maximum emitted sound pressure level [±3 dB(A)]

as per EN ISO 2151

Super silenced 8 bar / 10 bar [dB(A)] 62 / 59 66 / 63 62 / 59 64 / 61

Measuring surface [dB(A)] 20 20 20 20

Sound power level 8 bar / 10 bar [dB(A)] 82 / 79 86 / 83 82 / 79 86 / 81

Compressor

Max. final compression temperature [°C] 250 250 250 250

Compressed air outlet temperature over intake air

temperature, approx. [K]

Volume flow in accordance with ISO 1217 Annex C at:

= 8 bar [m3/min] 1.24 1,86 1.86 2.48

– p

max

– p

= 10 bar [m3/min] 0.98 1.47 1.47 1.96

max

Drive motor

Rated power [kW] 2 x 5.5 3x 5.5 3x 5.5 4x 5.5

Nominal speed

– with motors for 50 Hz [rpm] 1465 1465 1465 1465

– with motors for 60 Hz [rpm] 1765 1765 1765 1765

Protection class IP 55 55 55 55

Design IMB 3 3 3 3

ISO class FFFF

Electrical Connection

Supply voltage / frequency

Recommended fuse protection at 400 V

Supply voltage / frequency of dryer

1)

2) 3)

1)

[V/Hz]

[A]

[V/Hz] 230 / 50 – 230 / 50 230 / 50

Deviating voltage / frequency

Supply voltage / frequency [V/Hz]

)

2) 3

Recommended fuse protection at 220 V / 230 V

Recommended fuse protection at 380 V / 440 V

1)

Standard equipment. Supply voltages and frequencies are detailed on a sign in the switch cabinet.

2)

Different supply voltages alter the values for the fuses.

3)

Use fuse cut-outs gG or miniature circuit-breakers with C characteristic.

[A] 8080

)

2) 3

[A]

10 10 8 8

400 / 50 400 / 50 400 / 50 400 / 50

50 50 63 63

230 / 50

220/440 / 60

220 / 60

380 / 60

440 / 60

230 / 50

220/440 / 60

220 / 60

380 / 60

440 / 60

230 / 50

220/440 / 60

220 / 60

380 / 60

440 / 60

230 / 50

220/440 / 60

220 / 60

380 / 60

440 / 60

6363

50 50

6363

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 23

Product description 3.4 Technical data

Technical data EO 6...EO 6 TR, part 2

Type EO 6 EO 6 D EO 6 R EO 6 DR EO 6 TR

Intake air temperature

– min. [°C] +5 +5 +5 +5 +5

– max. [°C] +40 +40 +40 +40 +40

Cooling air requirement

– Required ventilator output for compressor room

ventilation [m

– Cooling air requirement 8 bar / 10 bar [m

Operating pressure values

1)

(factory settings)

– p

= 8 bar: Switch-off pressure p

max

Switch-on pressure p

– p

= 10 bar: Switch-off pressure p

max

Switch-on pressure p

max

min

max

min

Safety valve on scroll unit

Response pressure at:

– p

= 8 bar [bar] 12 12 12 12 12

max

– p

= 10 bar [bar] 12 12 12 12 12

max

Dimensions / weights for optional compressed

air receivers

– Receiver capacity [l] – – 350 350 –

– Dimensions (width x depth x height) [mm] – –

– Weight [kg] – – 390 427 –

– Receiver capacity [l] – – 500 500 500

– Dimensions (width x depth x height) [mm] – –

– Weight [kg] – – 420 457 677

1)

For compressors for other operating pressures p

= p

min

3

/h]

3

/h] 780 / 660 1100 / 980 780 / 660 780 / 660 780 / 660

1500 2000 1500 1705 3000

[bar]88888

[bar]77777

[bar]1010101010

[bar]99999

– 1 bar.

max

1825 x 770

x 1725

1975 x 795

x 1785

1770 x 770

x 1725

1920 x 795

x 1785

–

1975 x 1000

x 1785

Page 24 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Product description 3.4 Technical data

Technical data EO 11...EO 22 D, part 2

Type EO 11 / EO 11 D EO 16 EO 17 / EO 17 D EO 22 / EO 22 D

Intake air temperature

– min. [°C] +5 +5 +5 +5

– max. [°C] +40 +40 +40 +40

Cooling air requirement

– Required ventilator output for compressor room

ventilation [m

– Cooling air requirement [m

– Free fan compression [Pa] 20 20 20 20

– Free fan compression [mm WS] 2 2 2 2

Operating pressure values

1)

(factory settings)

– p

= 8 bar: Switch-off pressure p

max

Switch-on pressure p

– p

= 10 bar: Switch-off pressure p

max

Switch-on pressure p

max

min

max

min

Safety valve on scroll unit

Response pressure at:

– p

= 8 bar [bar] 12 12 12 12

max

– p

= 10 bar [bar] 12 12 12 12

max

1)

For compressors for other operating pressures p

= p

min

3

/h]

3

/h] 2840 3500 3500 4300

4900 6000 6000 7000

[bar] 8 8 8 8

[bar] 7 7 7 7

[bar]10101010

[bar] 9 9 9 9

– 1 bar.

max

Technical data for DS dryer

Model

of dryer

Compressor

type

Weight

approx.

[kg] [kg / t] [bar] [°C] [m3/h] [kW] [V]

DS 4-2

DS 7-2

DS 30

EO 6 DR 10 bar

EO 6 DR 8 bar

EO 17 D

EO 22 D

24 0,16 / 0,23 16 65 90 0,15 230

24 0,16 / 0,23 16 65 90 0,14 230

35 0,36 / 0,51 16 65 550 0,78 230

Technical data for dryer DRL 6-2

Model

of dryer

Compressor

type

Weight

approx.

[kg] [kg / t] [bar] [°C] [m3/h] [kW] [V]

DRL 6-2

EO 6 D

EO 11 D

35 0,34 / 0,49 16 60 550 0,22 230

Refrigerant

volume R134a /

equivalent

CO

2

approx.

Refrigerant

volume R134a /

equivalent

CO

2

approx.

Max.

operat-

ing

pressure

Max.

operat-

ing

pressure

Max.

compressed air

inlet tempera-

ture

Max.

compressed air

inlet tempera-

ture

Cooling

air

require-

ment

Cooling

air

require-

ment

Power

con-

sumption

Power

con-

sumption

Supply

voltage

Supply

voltage

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 25

Product description 3.5 How the DS dryer works

3.5 How the DS dryer works

The Type DS dryer is only used with Type EO 6 DR, EO 17 D and EO 22 D

compressors.

DS refrigerant dryer

Read the user documentation supplied with the integrated or attached Type

DS dryer as well as the information provided here.

The dryer contains a refrigerating system that cools the compressed air. The

steam saturation limit is reduced in the process causing condensate to form,

which is discharged by an automatic condensate drain. The greater the cooling temperature difference of the compressed air, the larger the quantity of

condensed water. The lower the cooling temperature of the compressed air,

the lower the moisture content. The lower limit of compressed air cooling is

deduced from the dryer's operating principle, i.e. that moisture separation in

liquid form can only take place above the freezing point of water.

Automatic condensate drain on the dryer

When the capacitive level sensor signals that the condensate container is full,

the internal solenoid valve is opened and the condensate is forced through

the drain pipe by the operating pressure. The condensate drain electronics

ensure that the outlet opening is closed before the compressed air can escape.

If the condensate outlet is faulty, the valve opens in cycles (approx. every

2 seconds) to remedy the fault automatically. For more information, please

refer to the separate operating instructions for the condensate drain.

Page 26 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Product description 3.6 How the DRL 6-2 dryer works

3.6 How the DRL 6-2 dryer works

The DRL 6-2 dryer is only installed in Type E 6 D and EO 11 D compressors.

Device overview

Fig. 3.4: DRL 6-2 dryer overview with pressure dew point display

The following components are accessible on the integrated dryer after removing the housing walls:

1 Compressed air inlet

2 Compressed air outlet

3 Condensate drain

4 Pressure dew point display

– Blue field: pressure dew point too low

– Green field: pressure dew point OK

– Red field: pressure dew point too high

5 Condenser

6 Compressor

7 Electrical connection

8 Air / air or air / refrigerant heat exchanger incl. insulation

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 27

Product description 3.7 Regulating the DRL 6-2 integrated dryer

Functional principle of the DRL 6-2

Compressed air side

The dryer contains a refrigerating system that cools the compressed air. The

steam saturation limit is reduced in the process causing condensate to form,

which is discharged by a condensate drain.

The greater the cooling temperature difference of the compressed air, the

larger the quantity of condensed water.

The lower the cooling temperature of the compressed air, the lower the moisture content. The lower limit of compressed air cooling is deduced from the

dryer's operating principle, i.e. that moisture separation in liquid form can only

take place above the freezing point of water.

3.7 Regulating the DRL 6-2 integrated dryer

The DRL 6-2 dryer is installed in Type EO 6 D and EO 11 D compressors.

The compressed air that is pre-cooled and moisture-saturated in the aftercooler enters the refrigerant dryer and is precooled in the first cooling stage in

the air / air heat exchanger ((8), see fig. 3.4), without any additional external

energy. This is performed against the flow of the already cooled compressed

air, which heats up as a result. In the second cooling stage in the refrigerant /

air heat exchanger that is cooled by the built-in refrigeration system, cooling to

the desired pressure dew point takes place. The cooled compressed air is then

heated again in the air / air heat exchanger as already described. The pressure dew point is shown on the pressure dew point display.

Refrigerant side

CAUTION

Risk of injury due to contact with hazardous substances, e.g. from

inhalation!

Î Wear PPE.

Î Avoid contact with skin and eyes.

Î Do not inhale vapours or mists.

Î Observe the information on the relevant safety data sheets.

The refrigerant is injected into the refrigerant / air heat exchanger and vaporised. This removes heat from the compressed air flow.

An output control system on the refrigerant side controls the required compressed air output, in order to ensure that the pressure dew point remains

constant in all output ranges.

The refrigerant compressed in the refrigerant compressor is condensed in

the condenser and becomes available again for vaporisation.

Page 28 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Product description 3.7 Regulating the DRL 6-2 integrated dryer

Pressure dew point regulation

Condensate drainage

The DL dryer can be operated permanently under partial load, caused by reduced compressed air flow or a lower compressed air inlet temperature, with

an output in the range 0 – 100%.

The level-controlled condensate

drain automatically drains condensate from the DL dryer.

Fig. 3.5: Condensate drain

When the level sensor signals that the condensate container is full, a valve is

opened and the condensate is forced through the drain pipe by the operating

pressure.

The condensate drain electronics ensure that the outlet opening is closed

before the compressed air can escape.

If the condensate outlet is faulty, the condensate drain switches to Timer mode

and the valve opens in cycles (approx. every five seconds per minute) to remedy the fault automatically. For more information, please refer to the separate

operating instructions for the condensate drain.

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 29

Installation 4.1 Transporting the compressor

Part 4: Installation

General

Intermediate storage of the compressor before installation

4.1 Transporting the compressor

Please observe the generally accepted safety and accident prevention regulations when transporting the compressor. BOGE accepts no liability for damage caused by incorrect transportation

ATTENTION

Danger of property damage!

Î The transport of the compressor should only be carried out by properly

instructed and authorised personnel.

Î The capacity of the lifting gear (lift truck or stacker) must correspond at

least to the weight of the compressor / system.

Î Note the location of the compressor's centre of gravity before lifting it. The

location of the centre of gravity is specified both in the supplied dimensioned drawing and on the compressor packaging.

Î All loose and rotatable parts must be removed before lifting the system.

Î Lifting lugs on certain component parts (e.g. electric motor) are exclu-

sively intended for lifting the individual part, not for lifting the entire compressor.

If the compressor is not being installed immediately after delivery, it must be

stored in a sheltered location. During intermediate storage, ensure that the

compressor is protected from dust and humidity.

.

NOTE

Observe the specifications and notes regarding the admissible environmental influences for intermediate storage (see chapter „Specifications for the

compressor room“).

BOGE will not assume any liability for consequential damage as the result

of improper storage.

Contact BOGE Service after an extended period of intermediate storage.

In the case of intermediate storage for more than two months also ensure

to observe the information on commissioning after a prolonged period of

inactivity (see chapter "5.1 Commissioning the compressor").

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 31

Installation 4.1 Transporting the compressor

Transporting the compressor using a forklift truck

Transporting the compressor with a crane

Move the compressor to the installation site as described in the following

sections.

ATTENTION

Danger of property damage!

Inappropriate transportation may damage the compressor.

Î Do not subject the safety cladding to force during transportation.

Ensure that the forks are underneath the

base frame or transport pallet of the compressor (see figure).

Fig. 4.1: Transport using a forklift truck

ATTENTION

Danger of property damage!

Inappropriate transportation may damage the compressor.

Î Do not subject the safety cladding to force during transportation.

Î Only lift the compressor using the supplied transport pallet.

Î Protect the compressor using wooden shoring (see arrows in the next

figure).

Î Remove transport bracing.

Î Only use suitable slings of a sufficient minimum length.

Attach the lifting tackle slings under the

ends of the compressor base frame or

supplied transport pallet.

See the supplied dimensioned drawing

for details regarding the centre of gravity.

Fig. 4.2: Transport with crane

Page 32 BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D

Installation 4.2 Installing the compressor

4.2 Installing the compressor

Specifications for the compressor room

Installation surface

The compressor can be installed on a level industrial floor with no foundations.

No special fastening elements are required.

ATTENTION

Danger of property damage!

Î There should be no external vibrations affecting the compressor site.

Sound protection

Only install compressors in workrooms if the sound pressure level of their

measuring surfaces does not exceed 85 dB (A).

CAUTION

Danger due to noise!

A sound pressure level exceeding 80 dB (A) can cause permanent hearing

defects in persons who always work in the vicinity of the compressor.

Î These persons must wear hearing protection while working near the com-

pressor.

Admissible ambient conditions

– Installation altitude 0 to 1000 MSL

– Closed room, frost-free, dry

– Ambient condition +5°C to +40°C

– Relative humidity 0% to 60%

ATTENTION

Danger of property damage!

Non-observance of the admissible ambient temperatures may lead to the

following problems:

– The compressor switches off when the maximum permitted compressed

air outlet temperature is exceeded.

– Pipes and valves may freeze up at lower temperatures.

Measures to be taken to ensure that admissible ambient temperatures

are maintained:

Î Avoid having any heat-radiating pipelines or units in the vicinity of the

compressor or insulate them well.

Î Never install the compressor in the cooling air flow of other machinery.

Î Provide the supply air inlets with adjustable louvres to ensure that the

temperature does not fall below the minimum temperature in winter.

BOGE Operating instructions for scroll compressors, series EO 6...EO 22 D Page 33

Installation 4.2 Installing the compressor

Ventilation of the compressor room

Non-observance of the following instructions can cause the maximum permitted final compression temperature to be exceeded. The compressor will

switch itself off if this happens.

CAUTION

Hazardous materials and substances!

Risk of poisoning or fire when compressing hazardous fluids.

Î Arrange the compressor intake openings or ducts in such a way that dan-

gerous admixtures cannot be drawn in. Dangerous admixtures include

solvent vapours, dusts and other harmful substances. Avoid creating flying sparks in the vicinity of the compressor.