Boekel

Orbitron V

Models 281111, 281111-2

Operating Instructions

N2400331 Rev. 2 01/2012

2

Table of Contents

Operating Instructions .................................................................... 1

1.0 Safety .................................................................................... 4

2.0 Product Information ............................................................. 5

3.0 Assembly .............................................................................. 5

3.1 Unpacking the Unit ......................................................................... 5

3.2 Installation ....................................................................................... 5

4.0 Operation ............................................................................. 5

4.1 Identification of Controls (See Figure 1) ....................................... 5

4.2 Timer Operation .............................................................................. 6

4.3 Tray Angle Adjustment (See Figure 2) .......................................... 6

5.0 Technical Specifications ..................................................... 7

6.0 Accessories .......................................................................... 7

7.0 Fault Diagnosis ..................................................................... 7

8.0 Maintenance and Service .................................................. 8

8.1 Cleaning .......................................................................................... 8

8.2 Replacement of Fuses .................................................................... 9

9.0 Warranty ............................................................................... 9

10.0 Service ................................................................................ 10

3

Figure 1

Rotator Front Panel

Power Switch Speed Control Timer Control

4

1.0 Safety

The following symbol marked on the equipment means:

Caution: Read these operating instructions fully before use and pay

particular attention to sections containing this symbol.

Attention: Suivre attentivement les instructions avant l’usage et

prêtez une attention particulière aux sections comportant ce

symbole.

Always observe the following safety precautions :

Use only as specified by the operating instructions or the intrinsic

protection may be impaired.

After transport or storage in humid conditions, dry out the unit

before connecting it to the supply voltage. During drying out

the intrinsic protection may be impaired.

Do not lift the Rotator by the Tray.

Risk of Binding: Assure that other equipment close to the Rotator

does not cause interference with the tray movement.

Connect only to a power supply that provides a safety ground

terminal.

Before moving, disconnect at the power supply socket. Do not

remove the plug from the rear of the unit.

Ensure that the power switch is easily accessible during use.

Do not block or restrict ventilation slots.

If liquid is spilled on top of the unit, disconnect it from the power

supply and have it checked by a competent person.

It is the user’s responsibility to carry out the appropriate

decontamination if hazardous material is spilled on or inside the

equipment.

This product must be used with an UL / CSA Certified power

supply cord set rated for a minimum temperature of 90˚C.

The Power Cord supplied with the unit is the disconnect means.

Do not position the unit so that it is difficult to operate the

disconnecting means.

Caution should be taken when operating the Orbitron V with

heavy loads at high speed. Always start the Orbitron V at low

speed and gradually increase the speed to the desired setting.

5

2.0 Product Information

The Boekel Orbitron V is a heavy duty 3-Dimensional gyratory mixer that

is designed for gentle as well as vigorous agitation, making it suitable

for a wide variety of applications. The Orbitron V is supplied with a 30

cm square platform and a non skid rubber mat.

3.0 Assembly

3.1 Unpacking the Unit

Remove the packing materials carefully, and retain for future

shipment or storage of the unit. Inspect for damage. Report all

shipping damage to the carrier immediately. Shipping damage is

covered by the carrier and repair/replacement for shipping

damages must be coordinated through the carrier. Complete and

return the Warranty Registration Card. Packages should contain:

Orbitron V

Power line cord

One 3/16” Hex key for tilt adjustment

Operating instructions

3.2 Installation

Place the Orbitron V on a clean, flat, and stable work surface to

ensure that the suction feet on the base of the unit will adhere to

the surface and adequately secure the system for use. Make sure

that the unit is placed a minimum of 8” from the edge of the

workbench and there is adequate clearance for the tray rotation to

ensure user safety.

4.0 Operation

4.1 Identification of Controls (See Figure 1)

The Power Switch controls power to the unit.

The Speed Adjustment Knob is used to increase or decrease the

rotational speed of the platform.

Note: The Orbitron V is equipped with a soft start motor control

feature. Upon activation of the speed control the motor will

have a three second delay and softly start the shaking

motion.

The Timer is used for timed operation. The maximum timer duration

is 12 hours.

6

4.2 Timer Operation

For continuous operation turn the Timer to the Hold position. The

unit will continue to operate until either the timer is turned off, or

until the power switch is turned off. For timed operation turn the

Timer until the pointer is aligned with the desired time. The timer

markings are in hour units. The unit will shut off when the time

expires.

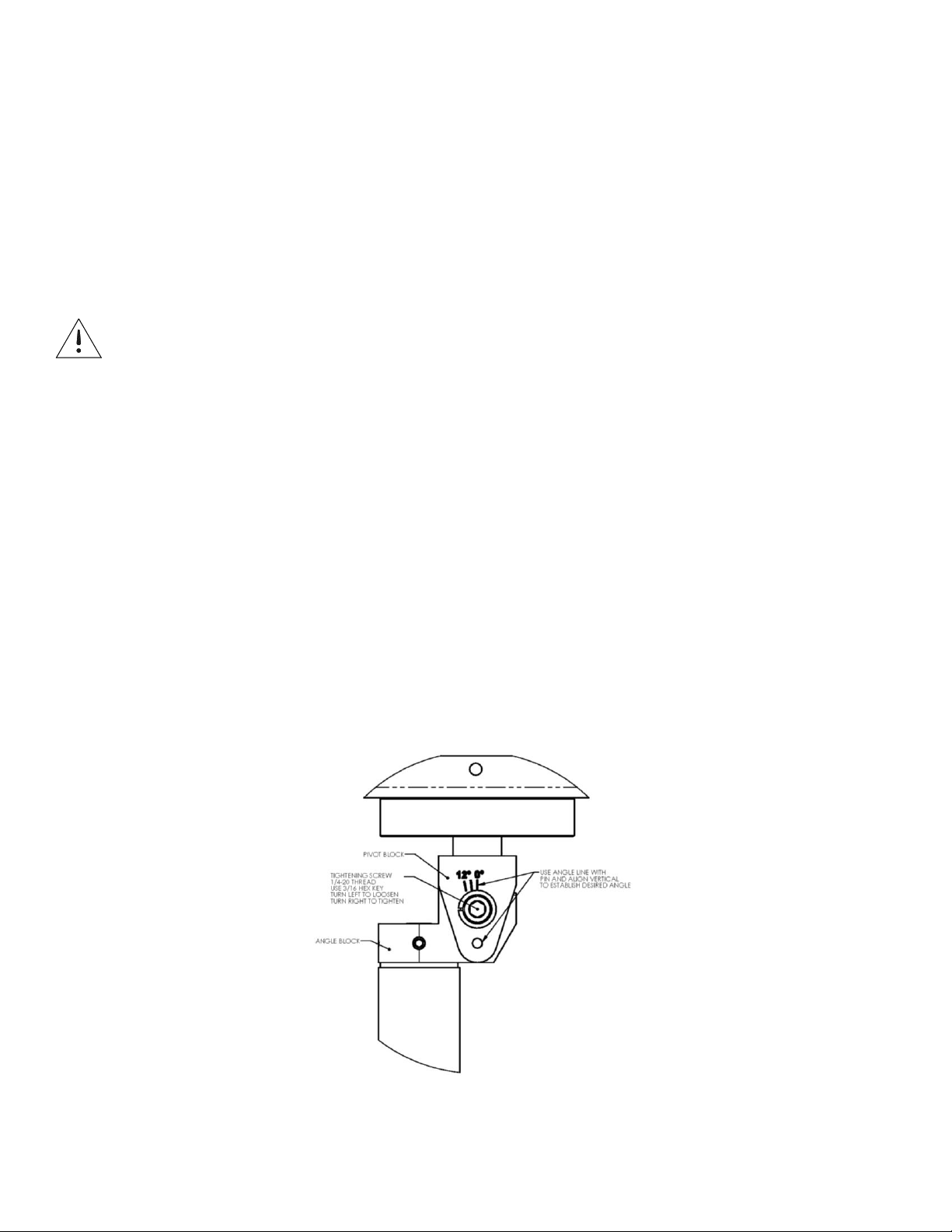

4.3 Tray Angle Adjustment (See Figure 2)

Warning! Remove power from the equipment before adjusting Tray

angle.

Remove load from Tray.

Rotate Speed Adjustment Knob counterclockwise until the

Tray is rotating slowly.

When the pivot block is easily accessible for adjustment turn

the Power Switch off.

Insert the supplied 3/16” hex key into the Tightening Screw

and turn it counterclockwise to loosen the screw.

To Increase the Tray angle, pivot the tray clockwise to a

maximum set angle of 12°.

To decrease the Tray angle, pivot the platform

counterclockwise to a minimum set angle of 0°.

After adjusting the angle, tighten the Tightening Screw turning

it clockwise until it is tight.

Remove hex key and ensure that there are no obstructions

before starting the operation the Orbitron V.

Figure 2

7

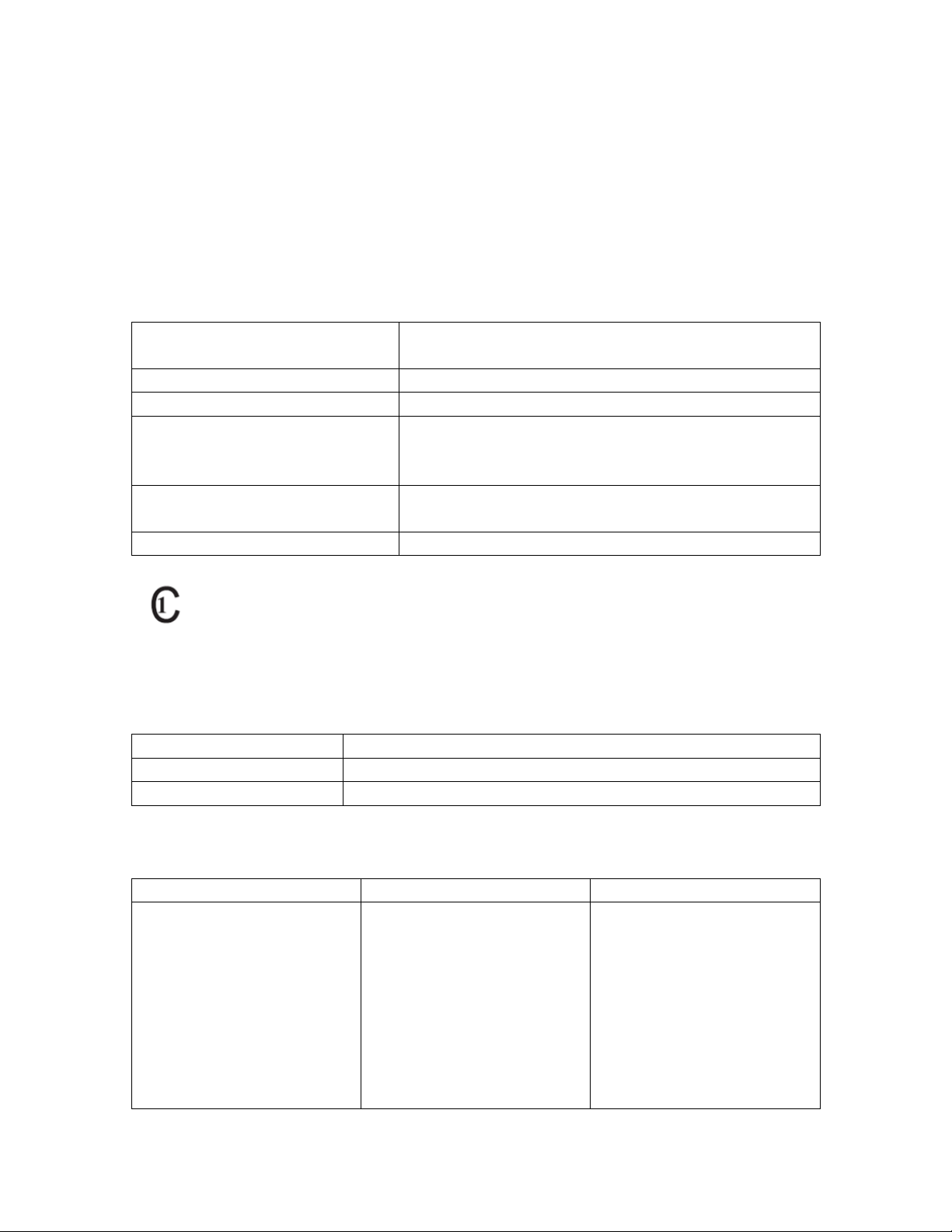

5.0 Technical Specifications

Ambient Operating

Temperature

0°C to 40°C

Tilt Range

0° to 12°

Load Capacity

9 Kg (20 lb)

Supply Ratings

Model 281111: 115 VAC ± 10%, 0.73 A, 60 Hz

Model 281111-2: 230 VAC ± 10%,, 0.7 A,

50/60 Hz

Power Rating

Model 281111: 50 W

Model 281111-2: 60 W

Rotational Speed

Variable from 5 to 120 rpm

Model Number

Description

260312

Double Stacking Tray

C2202208

Dimpled Rubber Mat

Symptom

Possible Cause

Action Required

Unit does not operate

a. Unit not switched on

b. Unit not plugged

into power supply

c. Fuses blown

d. Power supply failure

a. Switch on

b. Plug in, switch on

c. Replace fuses (see

section 8.2)

d. Check that other

electrical

appliances on the

same circuit are

This equipment is for indoor use only and will meet its performance

figures within the ambient temperature range of 0°C to 40°C, with

maximum relative humidity of 80% non-condensing. Installation

category II (transient voltages). Pollution degree 2 in accordance

with IEC 664. For operation at altitudes of up to 2000 meters (6500

feet).

This product has been tested to the requirements of CAN/CSA later version of the same standard incorporating the same

level of testing requirements.

6.0 Accessories

7.0 Fault Diagnosis

8

working

No rotation

a. Speed Adjustment

Knob is positioned

to off position.

b. An obstruction

prevents tray

rotation

c. Motor failure

a. Turn Speed

Adjustment Knob

clockwise until

desired rotation

speed is reached

b. Remove obstruction

c. Have unit checked

by a competent

service person

8.0 Maintenance and Service

8.1 Cleaning

All Boekel laboratory products are designed to comply with

IEC1010-1. No routine maintenance is required.

Disengage power cord prior to cleaning. If a spill occurs, use

appropriate clean-up procedures as required for radiation or

biohazard control. The outer casing can be cleaned with a cloth

dampened with water. Periodic inspection of the work surface

should be performed to ensure that the surface is clean and the

suction feet on the base of the unit adhere to the work surface to

stabilize the system for use. Do not immerse the Orbitron V in water.

9

Fuse

Drawer

Figure 3

8.2 Replacement of Fuses

There are two supply fuses located in the fuse drawer. To change

the fuses:

Turn power switch to the off position

Disconnect the unit from the power supply

Remove the line cord from the power entry module on the

back of the unit

Pull back on the fuse drawer catch

Pull out the fuse drawer (See Figure 3)

Check and replace with the correct fuses if necessary. The

fuses should be 5mm x 20mm quick acting, rated 250V for

230V units, 5mm x 20mm time delay, rated 250V for 115V units.

Model 281111 (115 V AC): 1.25AT

Model 281111-2 (230 V AC): 1.00AF

Push the fuse drawer back in. Reconnect unit to power

supply.

9.0 Warranty

When used in laboratory conditions and according to these

operating instructions, Boekel warrants this product to be free of

defective material and workmanship for a period of two years from

the date of manufacture. The liability of Boekel for any defective

equipment during the warranty period shall be limited to the repair

of such equipment or replacement thereof without charge for parts

or labor.

10

10.0 Service

Should service be required, contact Boekel Scientific Customer

Service. A Returned Material Authorization (RMA) number is

required before this Boekel product can be returned for any reason.

A Decontamination Certificate must be completed, signed by the

user, and returned to Boekel Scientific prior to receiving the RMA

number. Please be sure to mark the outside of the returned goods

package with this RMA number to ensure prompt handling.

Boekel Scientific

855 Pennsylvania Boulevard

Feasterville, PA 19053

Phone: (215) 396-8200 or (800) 336-6929

Fax: (215) 396-8264

e-mail: boekel-info@boekelsci.com

Loading...

Loading...