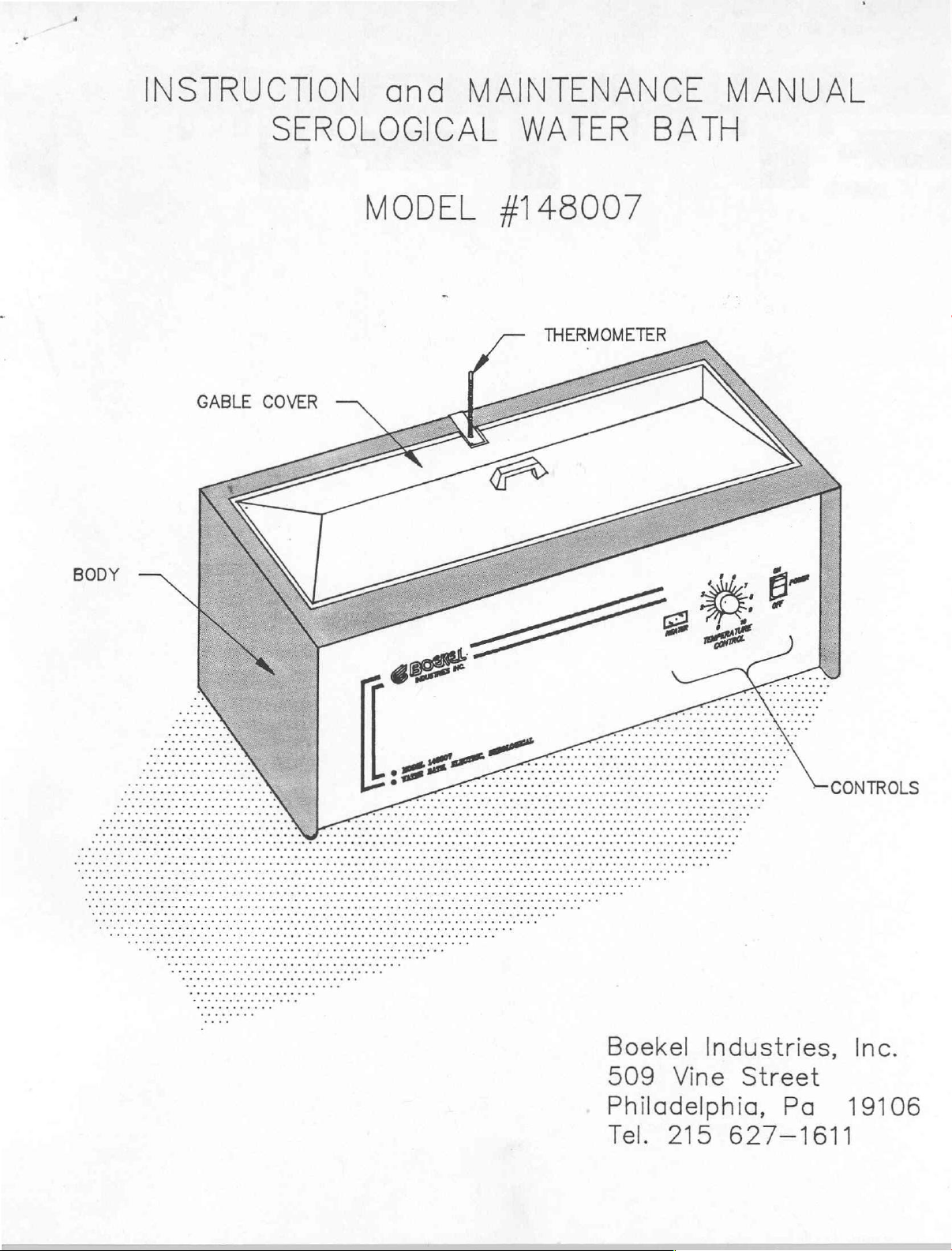

Boekel 148007 User manual

INSTRUCTION

and

MAINTENANCE

MANUAL

BODY

GABLE

SEROLOGICAL

MODEL

COVER

WATER

#148007

THERMOMETER

BATH

Boekel

509

Philadelphia,

Tel.

Industries,

Vine

215

Street

627-1611

Pa

CONTROLS

Inc.

19106

1.

Introduction

It

and

all

tempting

with

operation.

THIS

May

equipment

maintenance

EQUIPMENT.

create

is

important

operators

to

use

DO

a

failure.

SEROLOGICAL

CATALOG

that

acquainted

it.

NOT

Such

hazardous condition

Specific

requirements

-

UNDER

action

these

with

ANY

will

WATER

NO.

148001

instructions

the

precautions

to

insure

CIRCUMSTANCES

not

leading

BATH

units'

only

operation

will

safe

void

to

be

completely

be

noted

and

-

ALTER

the

operator

before

together

trouble-free

OR

MODIFY

warranty

injury

read

at-

but

or

This

serological

tions

It is

over

(with

55°C

2.

has

added

constructed

table

front

desired

is

terior

including

designed

an

gable

above

Equipment

The

been

measure

Temperature

hydraulic

panel

thermally

point.

type

bracket.

thermometer

indicate

water

bath.

water

procedures

operating

cover)

ambient

Description

water

painted,

of

of

is

temperature

insulated

cool

All

even

units

This

all

temperatures

bath

pharmaceutical,

to

maintain

bath

surface

stainless

control

thermostat.

the

range

or

with

body

both

only

within

is

an

to

when

are

provided

together

thermometer

intended

together

bath

from

upper

the

bath

is

constructed

to

enhance

protection.

steel.

is

achieved

A

adjustment

the

minimize

chamber

with

is

throughout

to

with

clinical

temperature

slightly

temperature

uncovered.

appearance

through

single

operating

control

required

heat

temperature

with

a

stainless

of

suitable

the

be

other

above

of

The

range.

loss

a

mercury

operating

used

laboratory

and

environmental

within

limit

stainless

water

the

knob

and

is

temperature

for

+0.5°C

ambient

of

and

chamber

use

mounted

for

The

to

at

filled

steel

a

variety

applica-

or

to

approximately

steel.

to

provide

is

of

an

adjus-

on

achieving

entire

keep

the

the

boiling

immersion

mounting

range

limits

of

of

work.

less

100°C

ТЕ

ап

also

the

any

unit

ex-

to

the

It

The use

minimizing

stainless

peratures.

to

provide

bracket.

is

recommended

of

this

power

steel

It

clearance

cover

consumption.

and has

also

has

for

that

will

a

a

cut-out

the

the

optimize

This

handle

thermometer

optional

temperature

gable

for

safe

at

the

gable

cover

handling

center

and

cover

control

is

constructed

of

the

thermometer

at

be

high

back

mounting

used.

while

of

tem-

edge

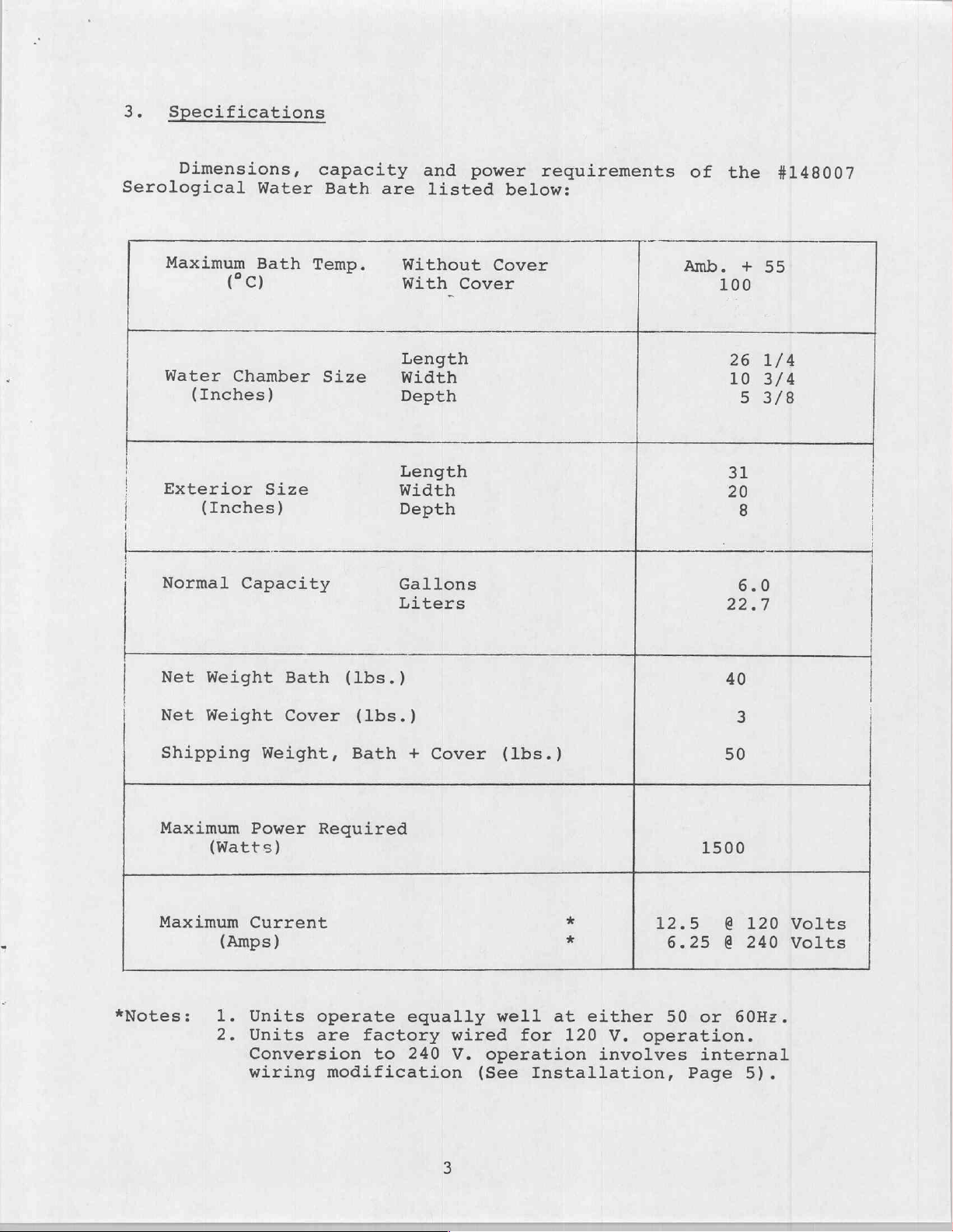

3.

Specifications

Dimensions,

Serological

Maximum

Water

(Inches)

|

Exterior

|

|

|

|

(Inches)

Normal

Water

Bath

(če)

Chamber

Size

Capacity

capacity

Bath

Temp.

Size

are

Without

With

Length

Width

Depth

Length

Width

Depth

Gallons

Liters

and

listed

Cover

power

below:

Cover

requirements

of

Amb.

the

+

100

26

10

513/8

31

20

8

6.0

22.7

#148007

55

1/4

3/4

|

|

i

Net

|

Net

Shipping

Maximum

Maximum

*Notes:

Weight

Weight

Power

(Watts)

Current

(Amps)

+

Units

Nr

eo

Units

Conversion

wiring

Bath

Cover

Weight,

(lbs.)

(lbs.)

Bath

Reguired

operate

are

factory

to

modification

Cover

+

equally

wired

240

V.

(lbs.)

well

for

operation

(See

Installation,

at

120

1500

12.5

6.25

either

V.

involves

50

or

operation.

internal

Page

40

8

50

@

120

@

240

60Hz.

5).

Volts

Volts

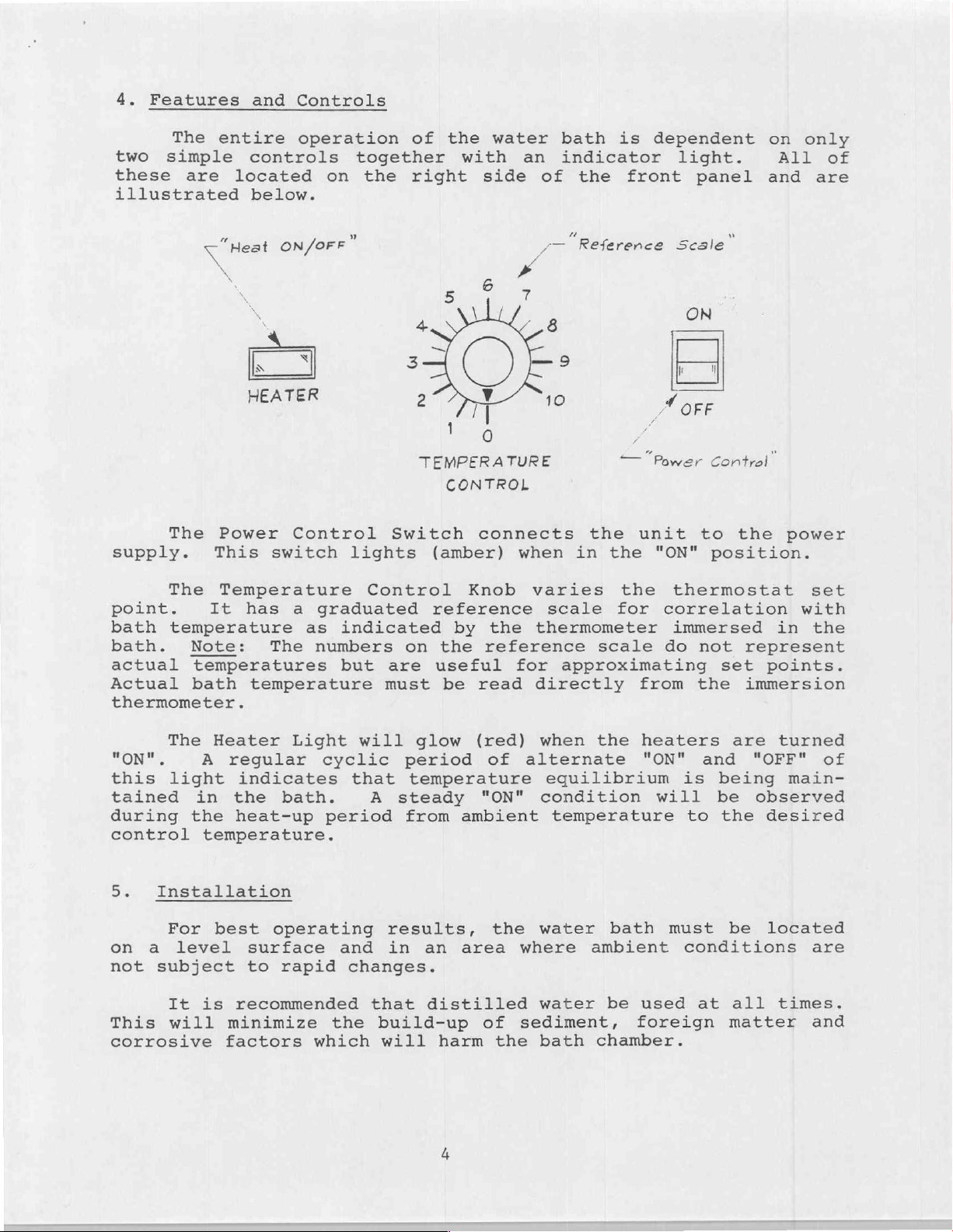

4.

Features

The

two

these

illustrated

simple

are

and

entire

controls

located

below.

Controls

operation

together

on

the

of

right

the

with

water

side

an

of

bath

indicator

is

the

dependent

front

light.

panel

on

All

and

only

of

are

s.

The

supply.

The

point.

bath

bath. Note:

actual

temperature

Actual

thermometer.

Power

This

Temperature

It

temperatures

bath

ON/oFF"

N

へ

>

N

HEATER

Control

switch

has

a

graduated

as

The

numbers

temperature

Switch

lights

Control

indicated

on

but

are

must

TEMPERATURE

CONTROL

connects

(amber)

Knob

reference

by

the

the

reference

useful

be

for

read

ノー

Reference

when

in

varies

scale

thermometer

approximating

directly

the

the

scale

—

the

for

Power

unit

from

Scale

ON

Il

|

A

OFF

Control”

to

"ON"

position.

thermostat

correlation

immersed

do

not

set

the

w

the

in

represent

points.

immersion

power

set

with

the

The

"ON".

this

tained

during

control

5.

on

not

light

in

the

Installation

For

a

level

subject

It is

This will

corrosive

Heater

A

regular

indicates

the

temperature.

best

bath.

heat-up

operating

surface

to

rapid

recommended

minimize

factors

Light

cyclic

period

which

will

that

A

and

changes.

that

the

glow

period

temperature

steady

from

results,

in

an

distilled

build-up

will

harm

(red)

of

"ON"

ambient

the

area

of

the

when

alternate

equilibrium

condition

temperature

water

where

water

ambient

sediment,

bath

the

heaters

"ON"

bath

be

used

foreign

chamber.

is

will

to

must

conditions

at

and

being

be

the

are

"OFF"

observed

desired

be

located

all

matter

turned

of

main-

are

times.

and

V.

power

supply,

be

performed

mance

The

with

A.

CAUTION:

SUPPLY

THE

water

supply.

a

wiring

the

Being

power

resting

protect

PROPER

bath

by

qualified

following

certain

source,

NEVER

UNLESS

has

If

change

on

a

its

YOU

VOLTAGE

been

it

is

is

detailed

that

turn

soft

finish.

CONNECT

ARE

AND

factory

desired

required.

service

the

it

surface

THE

CERTAIN

SUITABLY

to

personnel

instructions:

unit

upside

such

BATH

THAT

wired

operate

This

is

disconnected

down

as

TO

A

IT

GROUNDED.

for

operation

with

wiring

and

with

cardboard

POWER

IS

OF

change

in

strict

its

240

from

top

or

with

V.

power

should

confor-

any

surface

cloth

120

to

Remove

screw

Locate

at

the

the

fasteners

the

edge

in-line

Wiring

for

#1 - "А".

Wiring

#1

To

(1)

(2)

(3)

(4)

Replace

"B"

for

В".

change

Loosen

Remove

#1

and

Move wire

Re-tighten

wire

above.

bottom

terminal

with

120

240

from

screws

the

#3.

ends

bottom

of

the

V.

V.

short

from

all

are

plate

for

the

Heater

120

plate

later

block

internal

operation

operation

V.

to

on

terminals

jumper

terminal

terminal

fully

using

-

being

replacement.

which

partition

Light

is

is

240

V.

wire

#5

screws,

inserted.

same

sure

is

mounted

(See

Illustration

as

shown

as

shown

operation:

#1,

#3

between

to

terminal

screws

to

and

and

being

removed

retain

on

a

approximately

on

Illustration

on

Illustration

#5.

terminals

#3.

certain

the

bracket

#1).

that

in

step

Turn

from

unit

240

Volt

CAUTION:

CUT

THE

ADAPTER

right

OR

REMOVE

POWER

side

power

DO

CORD

PLUG.

up

source.

NOT,

THE

PLUG.

-

it

UNDER

THIRD

DO

is

now

ANY

(GROUND)

NOT USE

ready

CIRCUMSTANCES,

PRONG

A

TWO-PRONG

for

operation

FROM

Loading...

Loading...