Page 1

BODY-SOLID,Inc.

1900 S. Des Plaines Ave.

Forest Park, IL 60130 USA

Phone:(708)427-3555

Fax:(708)427-3556

www.bodysolid.com

SCC-1200G

OWNER'S MANUAL

Page 2

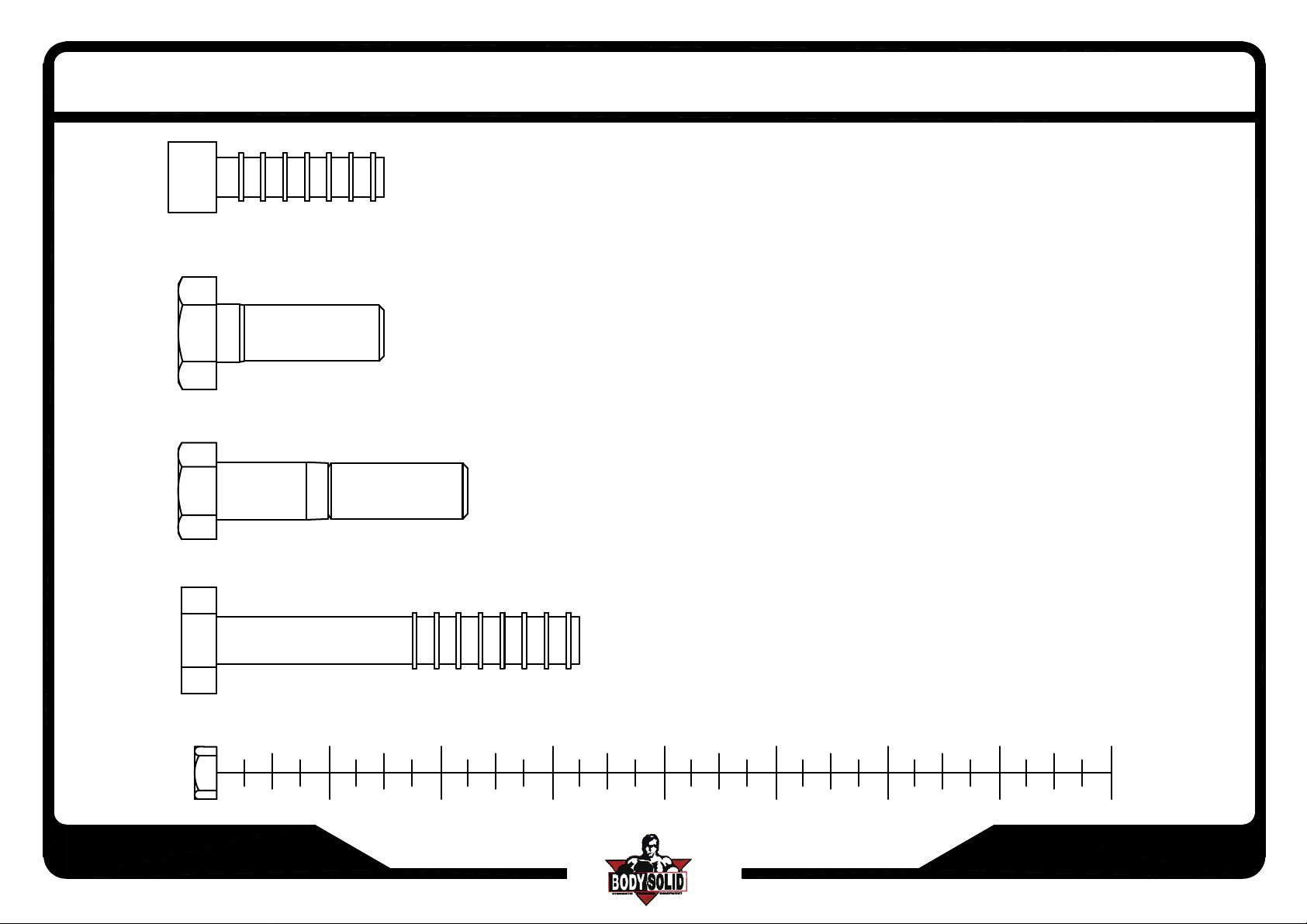

SCC-1200G

(A1)ROUND ALLEN HEAD 7/16"x1/2"L PARTIAL THREAD QTY.2

(A2)HEX BOLT 1/2"x1 1/2"L-13UNC PARTIAL THREAD QTY.2

ASSEMBLY INSTRUCTIONS

(A3)HEX BOLT 1/2"x2 1/4"L PARTIAL THREAD QTY.8

(A4)HEX BOLT 1/2"x3 1/4"L PARTIAL THREAD QTY.14

SCC1200G-082005

1

2

3

45

6

7

8

Page 1.1

Page 3

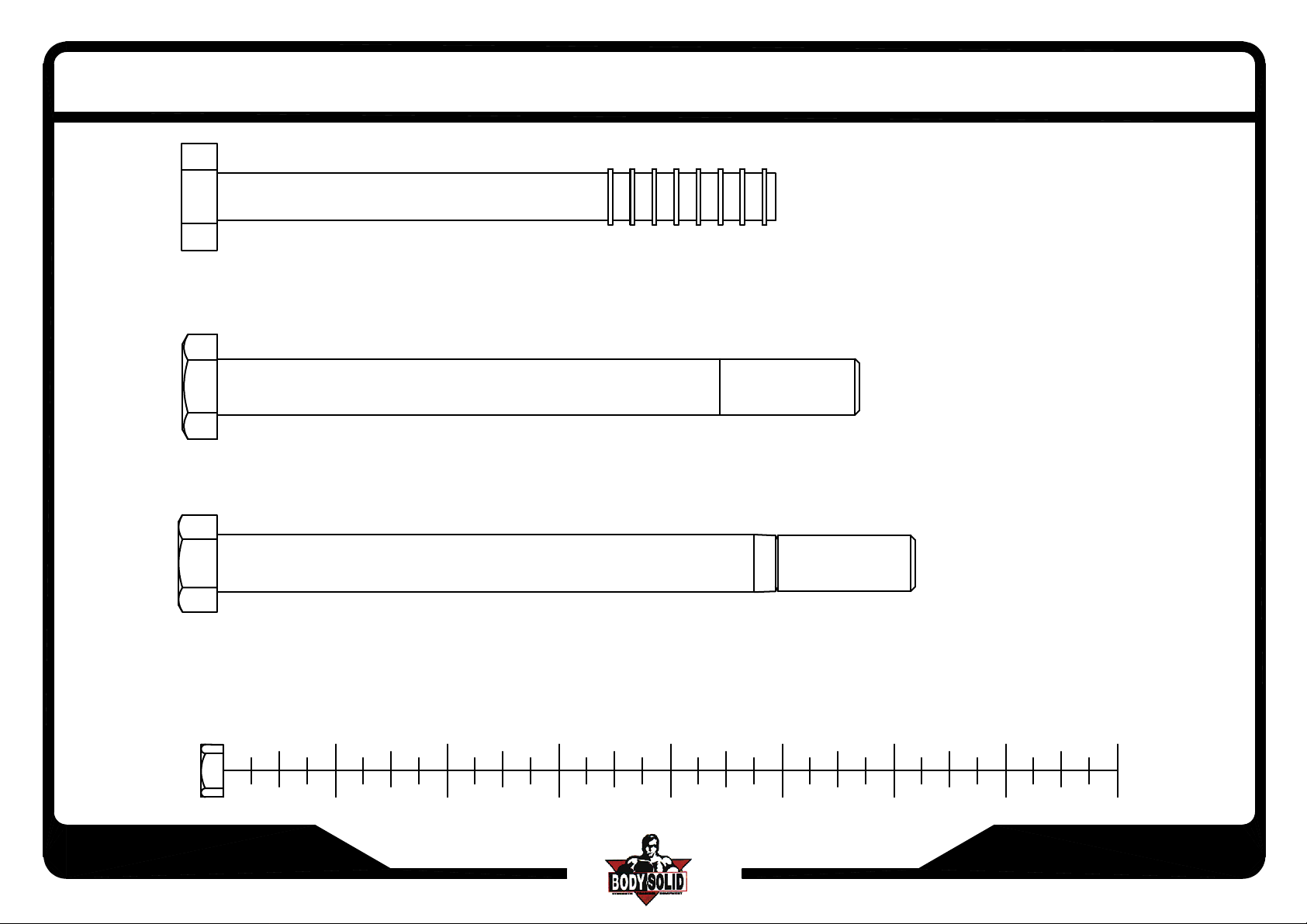

SCC-1200G

(A5)HEX BOLT 1/2"x5"L PARTIAL THREAD QTY.4

(A6)HEX BOLT 1/2"x5 3/4"L PARTIAL THREAD QTY.4

ASSEMBLY INSTRUCTIONS

(A7)HEX BOLT 1/2"x6 1/4"L PARTIAL THREAD QTY.2

SCC1200G-082005

1

2

3

45

6

7

8

Page 1.2

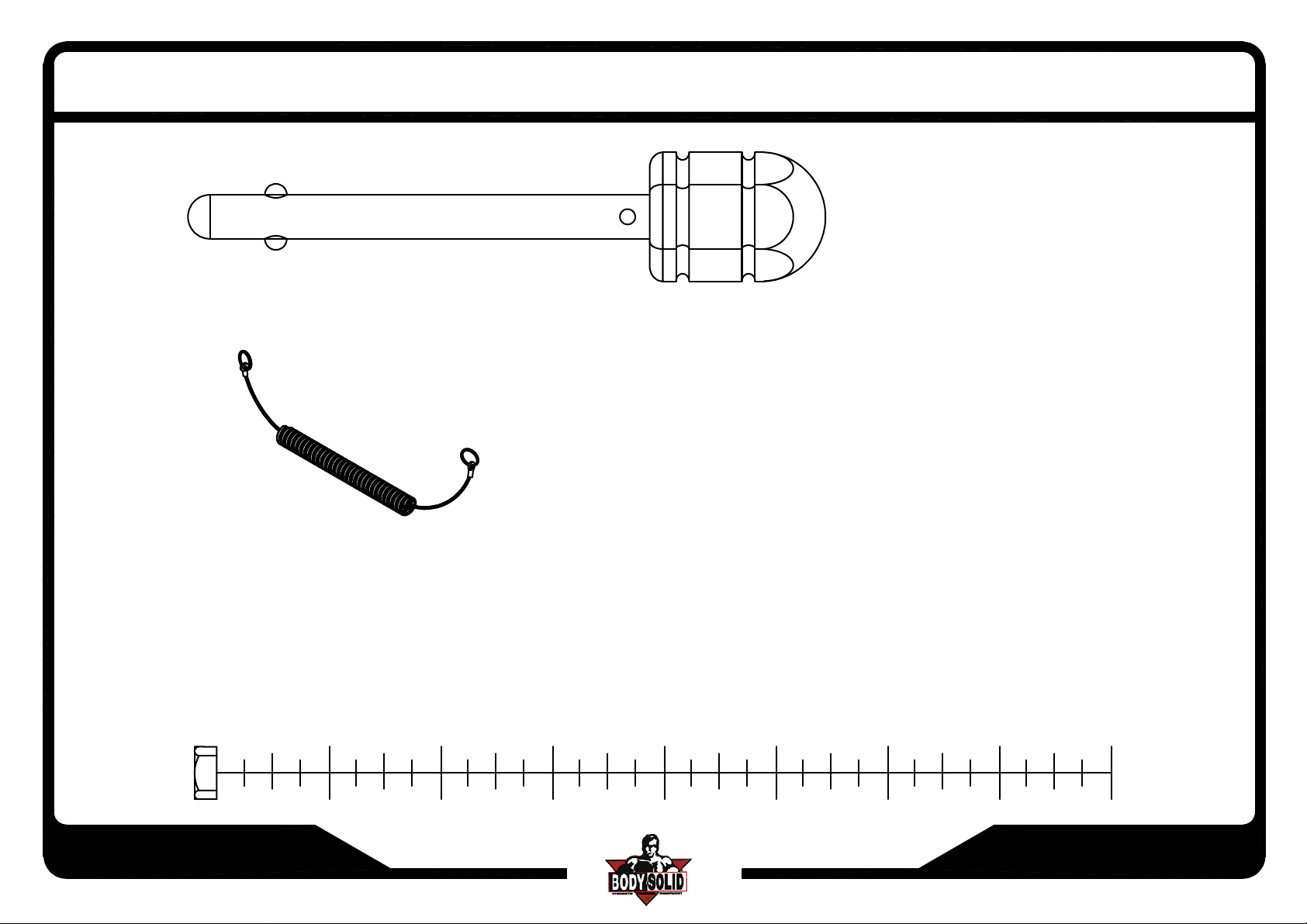

Page 4

SCC-1200G

(A8)10LB PIN(8250-021) QTY.2

ASSEMBLY INSTRUCTIONS

(A9)ELASTIC BOLT QTY.2

SCC1200G-082005

1

2

3

45

6

7

8

Page 1.3

Page 5

SCC-1200G

ASSEMBLY INSTRUCTIONS

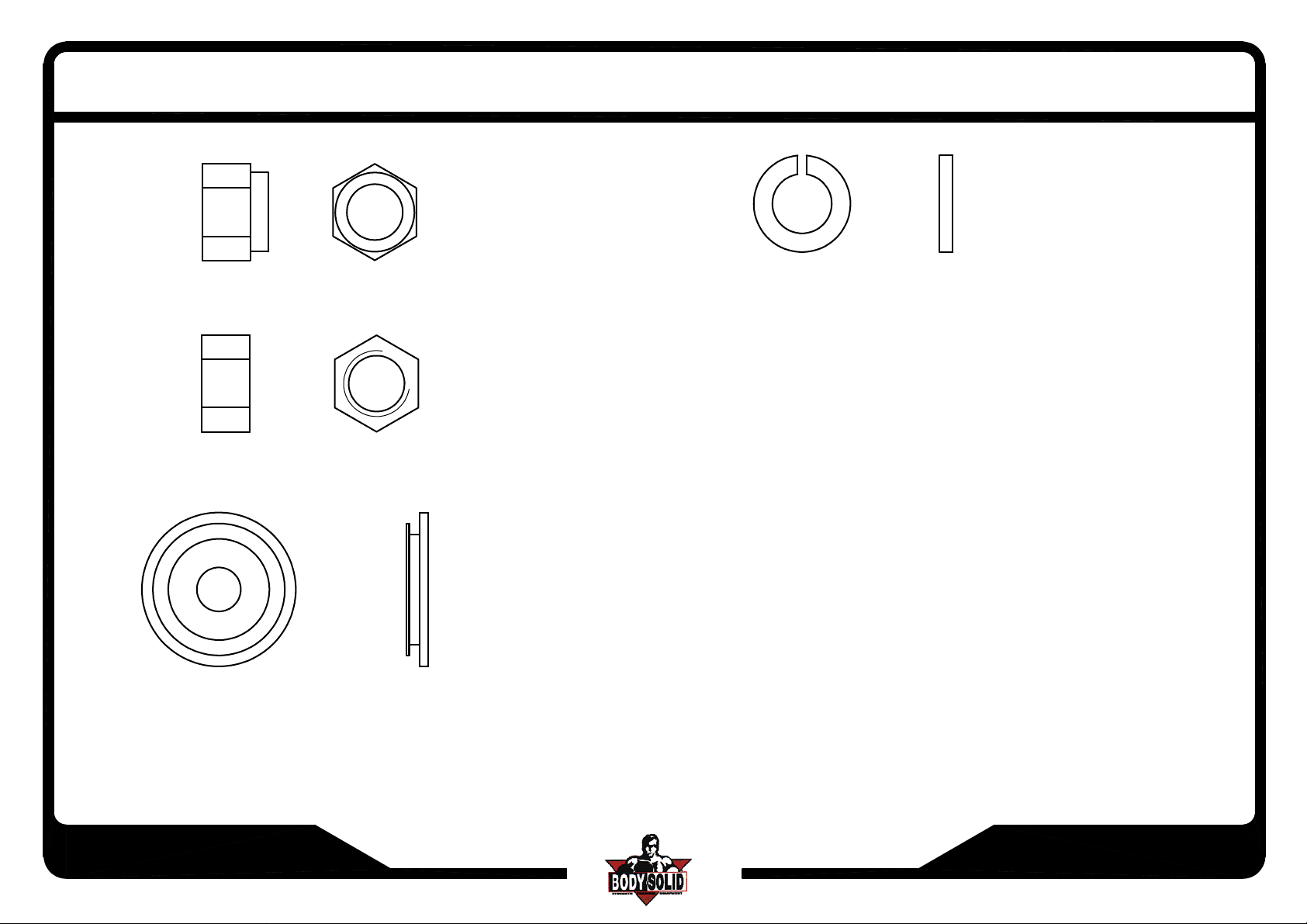

(B1)NYLON LOCK NUT 1/2" QTY.32

(B2)LOCK NUT 1/2"-13UNC QTY.2

(C1)1/2"(I.D.)ROUND END CAP WASHER QTY.60

(C2)1/2"(I.D.)SPRING WASHER QTY.2

SCC1200G-082005

Page 1.4

Page 6

SCC-1200G

ASSEMBLY INSTRUCTIONS

HARDWARE ILLUSTRATION

D1.1/2" BOLT CAP(9212-024)------------------------[60PCS]

D2.

n4 1/2" PULLEY(9213-010A)-----------------------[6PCS]

n4 1/2" PULLEY(9213-010B)-----------------------[8PCS]

D3.

D4.2"x4" FOOT CAP(9211-028)-------------------------[8PCS]

n4" RUBBER DOUNT(9310-017)-----------------[4PCS]

D5.

D6.STIRRUP HANDLE(8290-002)---------------------[2PCS]

D7.SPRING SNAP LINK(8810-001)--------------------[2PCS]

n3/4" SHAFT COLLAR(9211-050)----------------[4PCS]

D8.

D9.WEIGHT SELECTOR BAR(8220-061)-----------[2PCS]

D10.CHROME TOP PLATE(8400-002)---------------[2PCS]

D11.8300mm STEEL CABLE----------------------------[2PCS]

D12.60X50 NYLON BUSHING(9211-033)-----------[4PCS]

D13.

n5/8" ROUND END CAP(9211-015)-----------[4PCS]

D14.2"x4" RUBBER DOUNT(9212-009)-------------[4PCS]

D1 D2 D3

D4

D7

D10 D11

D5

D8

D6

D9

SCC1200G-082005

D12

D13

D14

Page 2

Page 7

SCC-1200G

ASSEMBLY INSTRUCTIONS

PARTS ILLUSTRATION SHEET

A[2PCS] WEIGHT STACK FRAME

B[2PCS]UPRIGHT PILLAR

C[1PCS] TOP CROSS SUPPORT

E[2PCS] BOTTOM PILLAR FRAME

F[2PCS] BOTTOM PULLEY FRAME

D[2PCS] TOP PULLEY FRAME

G[2PCS]

MIDDLE PULLEY HOLDER

SCC1200G-122010

Page 3

Page 8

SCC-1200G

ASSEMBLY INSTRUCTIONS

HARDWARE ILLUSTRATION

H[1PCS]

ADJUSTABLE CROSSOVER FRAME

I[4PCS]8280-004

CHROME GUIDE ROD

K[1PCS]

ADJUSTABLE CROSSOVER FRAME

J[2PCS]8323-014

TOP PLATE PULLEY FRAME

L[2PCS]9220-009

PROTECT PLABK

SCC1200G-122010

Page 4

Page 9

SCC-1200G

ASSEMBLY INSTRUCTIONS

Ax2

Above shows STEP 1

assembled and completed

SCC1200G-082005

D4x2

D4x2

Ex2

D1x4

D13x2

B1x4

D14x2

C1x4

Fx2

D14x2

D13x2

D4x2

D1x4

A6x4

C1x4

D4x2

Page 5

Page 10

SCC-1200G

Above shows STEP 2

assembled and completed

ASSEMBLY INSTRUCTIONS

D1x4

B1x4

C1x4

C1x4

A5x4

D1x4

Dx2

D8x2

Ix2

D8x2

*:Before the assembling of the weight stacks:

Finish (step 1) and adjust the distance between

the two bases to 3307mm(130in)

SCC1200G-082005

D10x2

D5x2

Ix2

D5x2

PAGE 1

)

n

i

30

1

(

m

m

7

30

3

t

u

bo

A

Page 6

Page 11

SCC-1200G

ASSEMBLY INSTRUCTIONS

D1x4

B1x4

D12

K

Above shows STEP 3

assembled and completed

D3

D1

B1

G

D1x2

B1x2

C1x2

C1x2

A4x2

D1

B1

D1x2

C1

C

D3

G

C1

A7

D12

H

A3

Bx2

D1

D12

B1

C1x4

C1x4

A4x4

D1x4

D1x2

B1x2

C1x2

C1x2

A4x2

D1x2

D12

D1

B1

SCC1200G-122010

C1

C1

A3

Page 7

Page 12

SCC-1200G

ASSEMBLY INSTRUCTIONS

D3

A2x2

Above shows STEP 4

assembled and completed

D1x2

B1x2

C1x2

A1x2

D1x2

B1x2

C1x2

D1x2

B1x2

C1x2

C1x2

A3x2

B2x2

C2x2

A

D1x2

Jx2

C1x2

A3x2

D1x2

D3x2

SCC1200G-082005

D3x2

C1x2

A3x2

D1x2

A8x2

DETIAL A

D9x2

Page 8

Page 13

SCC-1200G

ASSEMBLY INSTRUCTIONS

D2x6

C1x6

B1x6

D1x6

Above shows STEP 5

assembled and completed

C1x6

A4x6

D1x6

D7x2

D6x2

SCC1200G-082005

Page 9

Page 14

SCC-1200

ASSEMBLY INSTRUCTIONS

D11

Cable to constitute illustration

D11

*

D11

*

SCC1200G-122010

*:NEED TO LOOSEH BOTH ALLEN HEAD BOLT

IN ORDER TO REMOVE SHAFT

Page 9.1

Page 15

SCC-1200G

Step-1 is spelled as SETP-1

The Steps should read as fo l lows

NOTE: DO NOT TIGHTEN NUTS

AND BOLTS SECURELY UNTIL YOU HAVE COMPLETED ALL ASSEMBLY STEP

Step - 1

*Attach D14 Rubber Dount's to Bottom of A Weight Stack Frame.

*Insert D4 Foot Cap's into ends of E Bottom Pillar Frame,

F Bottom Pulley Frame and A Weight Stack Frame.

*Attach E Bottom Pillar Frame and F Bottom Pulley Frame to A Weight Stack Frame.

Step - 2

*Attach I Chrome Guide Rod's and D5 Rubber Donut's to A Weight Stack Frame.

*In this order slide Weight Stack, D10 Chrome Top Plate,

and D8 Shaft Collar's onto I Chr ome Guide Rod's.

*Insert D Top Pulley Frame onto I Chrome Guide Rod's and then attach to A Weight Stack Frame.

*Insert D8 Shaft Collar's into D Top Pulley Frame.

*Repeat all the steps above in order to assemble opposite side.

Step - 3 - Use this step on both sides

*Attach D3 Pulley to G Middle Pulley Holder.

*Attach G Middle Pulley Holder to K or H Adjustable Crossover Frame.

*Insert D12 Nylon Bushing's to both sides of K or H Adjustable Crossover Frame.

*Slide K or H Adjustable Crossover Frame onto B

Upright Pillar - Pull red mushroom cap adjuster to slide on.

*Attach B Upright Pillar to E Bottom Pillar Frame and D Top Pulley Frame

*Attach C Top Cross Support to D Top Pulley Frame

Step - 4 - Use this step on both sides

*Attach J Top Plate Pulley Frame and small ring of A9 Elastic Bolt to D9 Weight Selector Bar.

*Attach D3 Pulley to J Top Plate Pulley Frame.

*Attach D9 Weight Selector Bar to D10 Chrome Top Plate.

*Attach large ring of A9 Elastic Bolt to A8 10Lb. Pin.

*Attach D3 Pulley to E Bottom Pillar Frame.

*Attach D3 Pulley to F Bottom Pulley Frame.

ASSEMBLY INSTRUCTIONS

CABLE CROSSOVER

SAFETY RULES

1. Periodically check that all nuts, bolts and screws are fully tightene d on

your CABLE CROSSOVER MACHINE.

2. Exercise with care.Perform your exercises at a smooth moderate pace;

never perform jerky or uncoordinated movements that may cause injury.

3. It is recommended that you should workout with a training parther.

4. Warning:

EXERCISE PROGRAM.IT IS ADVISABLE TO HAVE A PHYSICAL

EXAMINATION BEFORE YOU ENTER ANY EXERCISE PROGRAM.

FOR YOUR OWN SAFETY,DO NOT BEGIN ANY EXERCISE

WITHOUT PROPER INSTRUCTION.

Step - 5 - Use this step on both si des.

*Attach D2 Pulley to insid e of D Top Pulley Frame.

*Attach D3 Pulley to ou tside of D Top Pulley Fram e.

*Attach D6 Stirrup Handle to H and K Adjustable Crossover Frame.

Step - 6

*Attach Cables as shown in cable routing instructions.

*Tighten all Bolts

*Attach all Bolt Caps and L Protect Plate.

CONSULT YOUR PHYSICIAN BEFORE STARTING YOUR

SCC1200G-122010

Page 10

Page 16

SCC-1200G

Above shows STEP 6

assembled and completed

ASSEMBLY INSTRUCTIONS

L

SCC1200G-082005

L

Page 11

Loading...

Loading...