PLA144X

LAT ROW STATION

Owner’s Manual

WWW.BODYSOLID.COM

WARNING

Safety and Maintenance

of Cables

IMPORTANT: Cables are

wear items. It is your

responsibility to prevent

unexpected breakage.

Cable inspection should

be performed daily.

Inspect all cables, the

nylon coating on all

cables, and the area

near the fitting at each

end of each cable.

Replace any damaged or

worn cable immediately.

Do not allow the machine

to be used until damaged

or worn cables are

replaced. Using or allowing

a machine to be used

with a suspect cable can

result in serious injury. See

Owner’s Manual for more

information.

Call 1-800-556-3113

THERE IS A RISK ASSUMED BY INDIVIDUALS WHO USE THIS TYPE OF EQUIPMENT.

TO MINIMIZE RISK, YOU MUST FOLLOW THESE RULES:

Inspect equipment before each workout. Check that all nuts, bolts, screws and pop pins

are in place and fully tightened. Also, before use, check cables for sign of wear. Replace all

worn parts immediately. Never use machine if any parts are damaged or missing.

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS INJURY.

Keep clear of the cables and all moving parts when machine is in use.

Always make sure all Snap Links are closed when doing cable/pulley/strap exercises.

Exercise with care. Perform your exercises at a smooth moderate pace; never perform jerky

or uncoordinated movements that may cause injury.

It is recommended that you workout with a training partner.

Do not allow children or minors to play on or around this equipment.

If unsure of proper use of equipment, call your local Body-Solid distributor or the

Body-Solid customer service center at 1-800-556-3113.

WARNING: Consult your physician before starting your exercise program. For your own

safety, do not begin any exercise program without proper instruction.

DO NOT REMOVE WARNING LABELS FROM

MANUAL OR MACHINE

2

PLA144X

TABLE OF CONTENTS

SAFETY INSTRUCTIONS.......................

•

PREPARATION.......................................

•

HARDWARE LIST...................................

•

HARDWARE ILLUSTRATION.................

•

PART LIST / ILLUSTRATION..................

•

PAGE 4

PAGE 5

PAGE 6

PAGE 7

PAGE 11

ASSEMBLY INSTRUCTIONS.................

•

EXPLODED VIEW...................................

•

CONTACT PAGE.....................................

•

PAGE 12

PAGE 20

PAGE 22

3

PLA144X

SAFETY INSTRUCTIONS

When using exercise equipment,

you should always take basic

precautions including the

following:

Read all instructions before using the .

•

These instructions are written to ensure your safety

and to protect the unit.

! " # ! $ % & $ ' ! % ( $ ) ! ( & ' " * !

.

" $ + * , ! -

Do not allow children on or near the equipment.

•

Use the equipment only for its intended purpose

•

as described in this guide. Do not use accessory

attachments that are not recommended by the

manufacturer. Such attachments might cause serious

injuries.

Wear proper excercise clothing and shoes for your

•

workout, no loose clothing.

Keep hands, limbs, loose clothing, and long hair well

•

out of the way of all moving parts

Use care when getting on or off the unit.

•

Do no overexert yourself or work to exhaustion.

•

If you feel any pain or abnormal symptoms, stop your

•

workout immediately and consult your physician.

Never operate unit when it has been dropped or

•

damaged. Return the equipment to a service center

for examination and repair.

Never drop or insert objects into any opening in the

•

equipment.

Always check the unit and its cables before each use.

•

Make sure that all fasteners and cables are secure

and in good working condition.

Do not use the equipment outdoors or near water.

•

Personal Safety During Assembly

PLA144X is designed for your enjoyment. By

The

following these precautions and using common sense,

you will have many safe and pleasurable hours of

healthful exercise with your Powerline .

After assembly, you should check all functions to

ensure correct operation. If you experience problems,

fi r st recheck the assembly instructions to locate any

possible errors made during assembly. If you are unable to correct the problem, call the dealer from whom

you purchased the machine or call 1-800-556-3113 for

the dealer nearest you.

Obtaining Service

Please use this Owner’s Manual to make sure that

all parts have been included in your shipment. When

ordering parts, you must use the part number and

description from this Owner’s Manual. Use only

Powerline by Body Solid replacement parts when

servicing this machine. Failure to do so will void your

warranty and could result in personal injury.

For information about product operation or

service, check out the offi cial Powerline website

at www.bodysolid.com or contact an authorized

Powerline dealer or a Powerline factory-authorized

service company or contact Body-Solid customer

service at one of the following:

To ll Free: 1-800-556-3113

Phone: 1-708-427-3555

Fax: 1-708-427-3556

Email: service@bodysolid.com

Before beginning assembly, please take the time to

•

read the instructions thoroughly.

Read each step in the assembly instructions and

•

follow the steps in sequence. Do not skip ahead. If

you skip ahead, you may learn later that you have

to disassemble components and that you may have

damaged the equipment

Assemble and operate the

•

surface. Locate the unit a few feet from the walls or

furniture to provide easy access.

on a solid, level

Or write to: Body-Solid, Inc.

Service Department

1900 S. Des Plaines Ave.

Forest Park, IL 60130 USA

Retain this Owner’s Manual for

furture reference. Part numbers

are required when ordering parts.

4

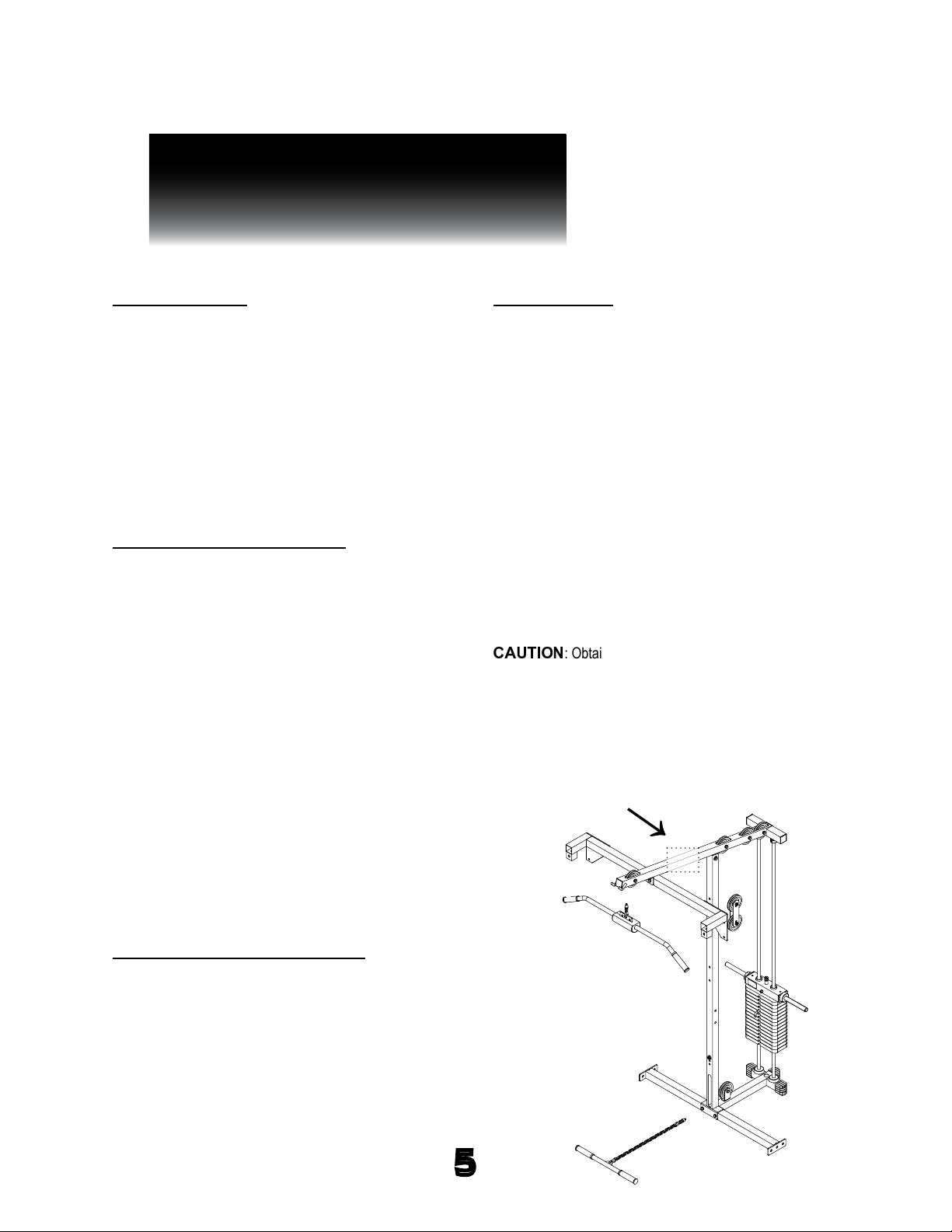

PLA144X

PREPARATION

Required tools

The basic tools that you must obtain before assembling

the PLA144X include but are not limit to:

• Standard Wrench Set

• Metric Wrench Set

• Adjustable Wrench

• Standard / Metric Allen Key Set

Installation Requirements

Follow these installation requirements when assembling

the PLA144X:

Set up the PLA144X on a solid, fl at surface. A smooth,

fl a t surface under the machine helps keep it level.

Provide ample space around the machine. Open space

around the machine allows for easier access.

For aesthetic purposes, insert all bolts in the same

direction unless specifi ed (in text or illustrations) to do

otherwise.

Leave room for adjustments. Tighten fasteners such as

bolts, nuts, and screws so the unit is stable, but leave

room for adjustments. Do not fully tighten fasteners until

instructed in the assembly steps to do so.

Assembly Tips

Read all “Notes” on each page before beginning each step.

While you may be able to assemble the

illustrations only, important safety notes and other tips may be

included in the text.

Some pieces may have extra holes that you will not use. Use

only those holes indicated in the instructions and illustrations.

NOTE: With so many assembled parts, proper

alignment and adjustment is critical. While

tightening the nuts and bolts, be sure to leave

room for adjustments.

NOTE: The bottles that are marked “Poison” is your

touch up paint. Keep away from children.

/ 0 1 2 3 4 5

assemble the PLA144X by yourself then do

not attempt to do so as this could result in

injury. Review the Installation Requirements

before proceeding with the following steps.

: Obtain assistance! If you feel like you can’t

YOUR S/N # CAN

BE FOUND HERE

PLA144X using the

Fill out and mail the warranty card.

Ordering Replacement Parts

If you need to order replacement parts please be

prepared to provide the following information

when contacting us so that we can assist you better.

1. Model Number

2. Place of Purchase

3. Serial Number (S/N)

4. Part # and Description

5

PLA144X

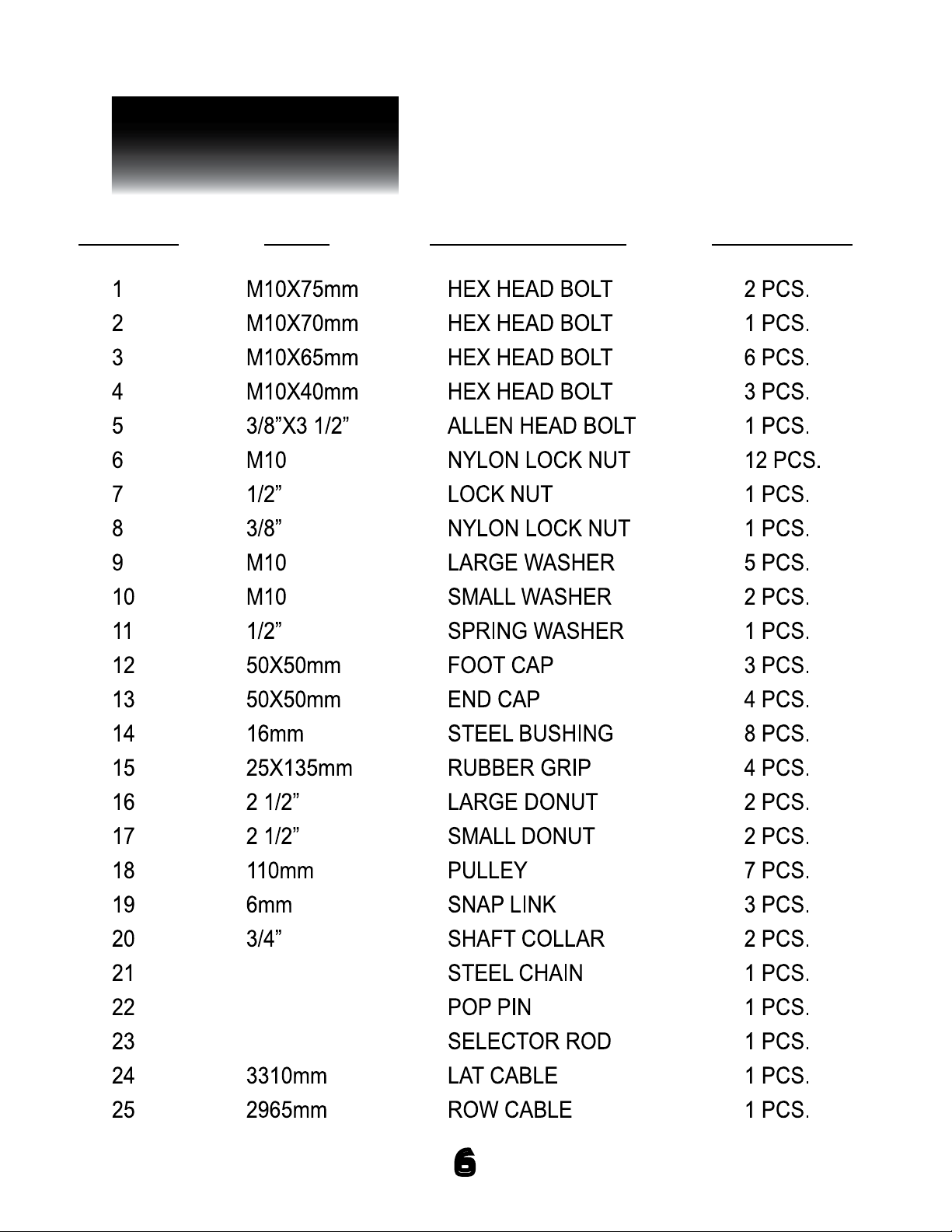

HARDWARE LIST

QUANTITYDESCRIPTIONSIZEPART #

6

PLA144X

,7,

¨w¿®z®>P°¸>®¨zÅ^

V

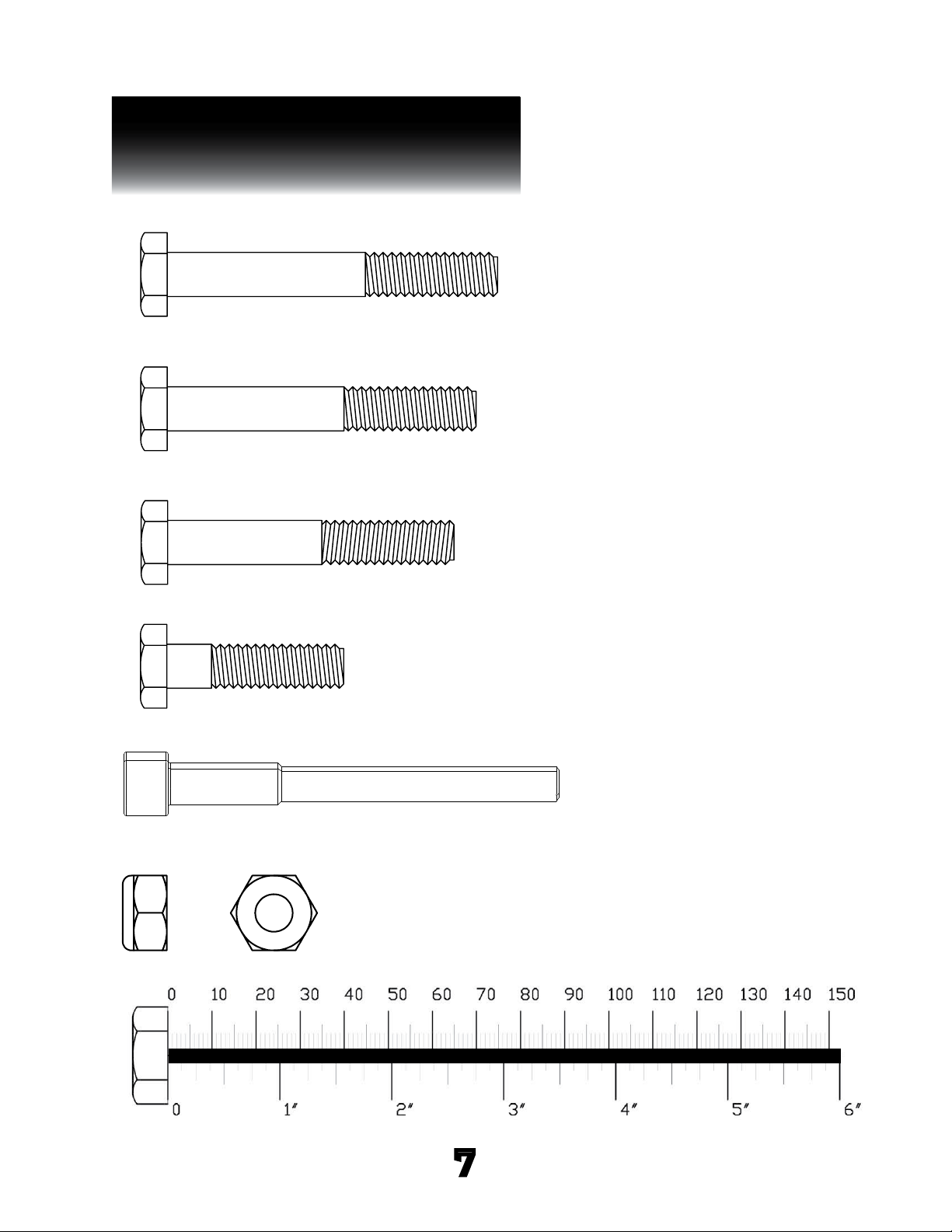

HARDWARE ILLUSTRATION

Part #1 M10X75mm hex head bolt QTY. 2

Part #2 M10X70mm hex head bolt QTY. 1

Part #3 M10X65mm hex head bolt QTY. 6

Part #4 M10X40mm hex head bolt QTY. 3

Part #5 3/8”X3 1/2” allen head bolt QTY. 1

Part #6 M10 nylon lock nut QTY. 12

7

PLA144X

,7,

¨w¿®z®>P°¸>®¨zÅ^

V

HARDWARE ILLUSTRATION CONT.

Part #7 1/2” nylon lock nut QTY. 1

Part #8 3/8” nylon lock nut QTY. 1

Part #9 M10 large washer QTY. 5

Part #10 M10 small washer QTY. 2

Part #11 1/2” spring washer QTY. 1

8

PLA144X

,7,

¨w¿®z®>P°¸>®¨zÅ^

V

HARDWARE ILLUSTRATION

Part #12 50x50mm foot cap QTY. 3

Part #13 50X50mm end cap QTY. 4

Part #14 16mm steel bushing QTY. 8

Part #15 25X135mm rubber grip QTY. 4

Part #16 2 1/2” large donut QTY. 2

9

PLA144X

,7,

¨w¿®z®>P°¸>®¨zÅ^

V

HARDWARE ILLUSTRATION CONT.

Part #17 2 1/2” small donut QTY. 2

Part #18 110mm pulley QTY. 7

Part #19 6mm snap link QTY. 3

Part #20 3/4” shaft collar QTY. 2

Part #23 selector rod QTY. 1

10

PLA144X

PART LIST

PartA

top frame

[1pcs]

PartD

top plate

[1pcs]

PartB

vertical frame

[1pcs]

PartE

lat bar

[1pcs]

PartC

base frame

[1pcs]

PartF

row bar

[1pcs]

PartG

pulley plate

[2pcs]

PartH

guide rod

[1pcs]

11

PartI

lat bar pad

[1pcs]

PLA144X

STEP 1

BE CAREFUL TO ASSEMBLE ALL COMPONENTS

IN THE SEQUENCE THAT THEY ARE PRESENTED.

NOTE:

finger tighten all hardware in this step. DO NOT wrench tighten

until the last step. some components may be pre-assembled.

nylon lock nuts will not fully screw onto bolts, must wrench tighten.

1A. attach vertical frame (B) and base frame (C) to the

back frame of your PSM144X using:

2 - (#1) M10X75mm hex head bolt

2 - (#6) M10 nylon lock nut

1B. insert a foot cap onto each end opening of base

frame (C) using:

3 - (#12) 50X50mm foot cap

1C. insert each chrome guide rod (H) thru a large

rubber donut and into base frame (C) using:

2 - (#16) 2 1/2” large rubber donut

1D. slide all weight plates onto chrome guide rods (H).

1E. attach selector rod (#23) to top plate (D) using:

1 - (#5) 3/8”X3 1/2” allen head bolt

2 - (#10) M10 small washer

1 - (#8) 3/8” nylon lock nut

1F. slide a small rubber donut (#17) onto each post

end of top plate (D).

1G. insert top plate (D) onto chrome guide rods (H) and

secure selector rod (#23) to weight plates using

pop pin (#22).

12

PLA144X

STEP 1

Above shows STEP 1

assembled and completed

BACK FRAME OF YOUR

PSM144X

13

PLA144X

STEP 2

BE CAREFUL TO ASSEMBLE ALL COMPONENTS

IN THE SEQUENCE THAT THEY ARE PRESENTED.

NOTE:

finger tighten all hardware in this step. DO NOT wrench tighten

until the last step. some components may be pre-assembled.

nylon lock nuts will not fully screw onto bolts, must wrench tighten.

2A. slide a 3/4” shaft collar (#20) onto each chrome

guide rod (H). secure the guide rods by inserting the

shaft collar / guide rod into the rear bottom openings

of top frame (A) and tighten allen bolts.

2B. attach top frame (A) to vertical frame (B) using:

1 - (#3) M10X65mm hex head bolt

2 - (#9) M10 large washer

1 - (#6) M10 nylon lock nut

2C. attach top frame (A) to the top frame of your

PSM144X using:

1 - (#2) M10X70mm hex head bolt

1 - (#9) M10 large washer

1 - (#6) M10 nylon lock nut

2D. attach a 110mm pulley (#18) to the pulley holder on

base frame (C) using:

1 - (#4) M10X40mm hex head bolt

1 - (#6) M10 nylon lock nut

2E. insert a 50X50mm end cap (#13) into each opening of

top frame (A). 4 total to be used.

2F. assemble row bar (F) by inserting a 25X135mm rubber

grip (#15) on each side. attach a snap link (#19) to

the eye hole of row bar (F) followed by the steel chain

and another snap link.

14

PLA144X

STEP 2

Above shows STEP 2

assembled and completed

TOP FRAME OF YOUR

PSM144X

15

PLA144X

STEP 3

BE CAREFUL TO ASSEMBLE ALL COMPONENTS

IN THE SEQUENCE THAT THEY ARE PRESENTED.

NOTE:

THIS STEP IS TO SHOW YOU WHERE THE PULLEYS NEED TO BE

INSTALLED AND WHAT HARDWARE YOU WILL NEED IN ORDER TO

INSTALL THEM. YOU MUST INSTALL THE PULLEYS WHILE YOU ROUTE

THE CABLES. CABLE ROUTING IS FOUND ON THE NEXT STEP.

3A. attach a 110mm pulley (#18) to the front of

top frame (A) using:

1 - (#3) M10X65mm hex head bolt

2 - (#14) 16mm steel bushing

1 - (#6) M10 nylon lock nut

3B. attach a 110mm pulley (#18) to the middle of

top frame (A) using:

1 - (#3) M10X65mm hex head bolt

2 - (#14) 16mm steel bushing

1 - (#6) M10 nylon lock nut

3C. attach two 110mm pulleys (#18) to the rear of

top frame (A) using:

2 - (#3) M10X65mm hex head bolt

4 - (#14) 16mm steel bushing

2 - (#6) M10 nylon lock nut

3D. attach two 110mm pulleys (#18) in between both pulley

plates (G) using:

2 - (#4) M10X40mm hex head bolt

2 - (#6) M10 nylon lock nut

16

Above shows STEP 3

assembled and completed

PLA144X

STEP 3

17

PLA144X

STEP 4

BE CAREFUL TO ASSEMBLE ALL COMPONENTS

IN THE SEQUENCE THAT THEY ARE PRESENTED.

NOTE:

THIS STEP IS TO SHOW YOU HOW TO ROUTE YOUR ROW BAR AND LAT

BAR CABLE. YOU WILL HAVE TO INSTALL THE PULLEYS AS SEEN IN STEP

3 AND THE CABLES AT THE SAME TIME. BE SURE TO ONLY HAND

TIGHTEN THE BOLTS/NUTS FOR PULLEYS AT FIRST, DON’T FULLY

TIGHTEN UNTIL ALL CABLES AND PULLEYS ARE FULLY INSTALLED.

4A. insert a 25X135mm rubber grip (#15) onto each end of

lat bar (E). attach a 6mm snap link (#19) to the center

hole located in the middle of lat bar (E). lastly, atta c h

lat bar pad (I) to the center of lat bar (E).

4B. LAT CABLE (#24, 3310mm), (L1) - attach the ball end of

the lat cable to the snap link that is hooked onto lat bar

(E). (L2) - install the pulley and route the cable over the

pulley. (L3) - install the pulley and route the cable over the

pulley and then down to (L4). (L4) - install the pulley and

route the cable around the pulley and then up to (L5).

(L5) - install the pulley and route the cable over the pulley

and then over to (L6). (L6) - install the pulley and route the

cable over the pulley and then down to (L7). (L7) - attach

the bolt end of the cable to the selector rod along with

the 1/2” lock nut (#7) and the 1/2” spring washer (#11).

4C. ROW CABLE (#25, 2965mm), (R1) - attach the ball end of

the row cable to the snap link that is attached to the end of

the row bar chain. (R2) route the other end of the cable

around the already installed pulley and up to (R3).

(R3) install the pulley and route the cable over the pulley

and then down to (R4). (R4) attach the cable to vertical

frame (B) using:

1 - (#3) M10X65mm hex head bolt

2 - (#9) M10 large washer

1 - (#6) M10 nylon lock nut

18

Above shows STEP 4

assembled and completed

PLA144X

STEP 4

19

PLA144X

EXPLODED VIEW

20

PLA144X

NOTES

21

PLA144X

c

Copyright 2011. Body-Solid. All rights reserved. Body-Solid reserves the right to change design and specications when we feel it will improve the product.

Body-Solid machines maintain several patented and patent pending features and designs. All rights reserved on all design patents and utility patents.

Body-Solid

Built for Life

®

www.bodysolid.com

please write your serial number in the boxes below

S/N # - - - -

1900 S. Des Plaines Ave.

1900 S. Des Plaines Ave.

Forest Park, IL 60130

Forest Park, IL 60130

Phone:(708)427-3555

Phone:(708)427-3555

Fax:(708)427-3556

Fax:(708)427-3556

Hours: M-F 8:30 - 5:00 CST

Hours: M-F 8:30 - 5:00 CST

22

Loading...

Loading...