Bodine 22B2BEBL/SR, 22B4BEBL/SR, 22B4BEBL/SR-3N, 22B2BEBL/SR-D3, 22B2BEBL/SR-D4 Instructions for Installation

...

Instructions for Installation and Operation

M

TTM

N

T

E

G

R

A

IIN

T

E

G

R

moottoorr

A

m

BBrruusshhlleessss DDCC MMoottoorrss aanndd GGeeaarrmmoottoorrss wwiitthh

aaaa

aaaa

GGGG

GGGG

tttt

oooo

rrrr

ssss

tttt

oooo

rrrr

ssss

rrrr

mmmm

oooo

tttt

oooo

rrrr

oooo

rrrr

rrrr

mmmm

mmmm

ssss

tttt

oooo

rrrr

ssss

oooo

tttt

oooo

rrrr

oooo

tttt

oooo

rrrr

rrrr

eeee

eeee

mmmm

aaaa

aaaa

BBuuiilltt--IInn PPWWMM SSppeeeedd CCoonnttrrooll

DDDD

iiii

rrrr

eeee

cccc

tttt

DDDD

rrrr

iiii

vvvv

eeee

MMMM

DDDD

iiii

rrrr

eeee

cccc

tttt

DDDD

rrrr

iiii

vvvv

2222BB22BBEEBBLL//SSRR

2222BB44BBEEBBLL//SSRR

RRRR

iiii

gggg

hhhh

tttt

----

AAAA

nnnn

gggg

RRRR

iiii

gggg

hhhh

tttt

2222BB44BBEEBBLL//SSRR--33NN

PPPP

aaaa

rrrr

aaaa

PPPP

aaaa

rrrr

aaaa

2222BB22BBEEBBLL//SSRR--DD33

2222BB22BBEEBBLL//SSRR--DD44

2222BB33BBEEBBLL//SSRR--ZZ22

2222BB33BBEEBBLL//SSRR--ZZ33

2222BB22BBEEBBLL//SSRR--ZZ44

llll

----

AAAA

nnnn

gggg

llll

llll

eeee

llll

SSSS

llll

llll

eeee

llll

SSSS

oooo

eeee

MMMM

oooo

eeee

GGGG

eeee

llll

eeee

GGGG

eeee

hhhh

aaaa

ffff

tttt

hhhh

aaaa

ffff

tttt

ssss

ssss

www.bodine-electric.com Literature No. 074 01034.D (MW)

QUICK REFERENCE

IMPORTANT

Read this manual completely and carefully. Pay special attention to

all warnings, cautions, and safety rules. Failure to follow the

instructions could produce safety hazards which could injure

personnel or damage the control, motor, or other equipment. If you

have any doubts about how to connect the control or motor, refer to

the detailed sections of this manual.

2

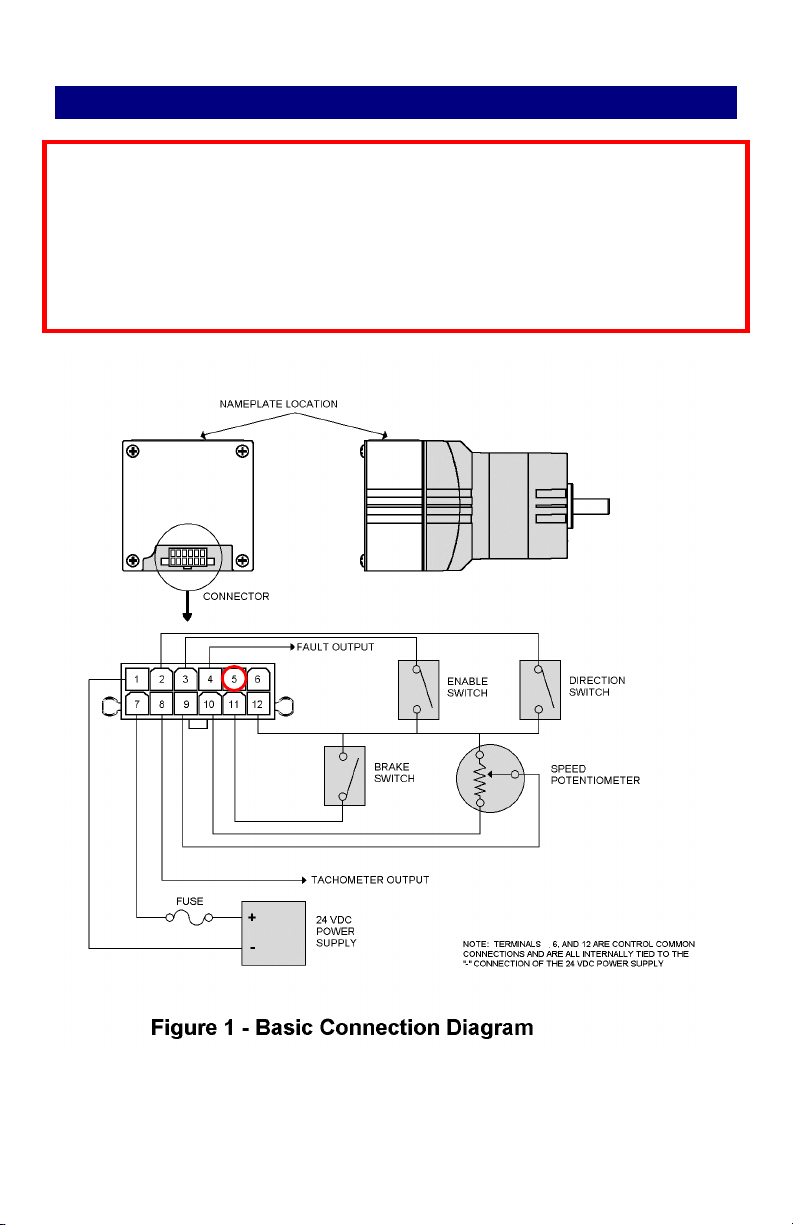

Pin No. 5 provides a Directi on Output Signal

CONTENTS

This manual contains the basic information needed to install and operate a Bodine

INTEGRAmotorTM brushless DC motor & control system. This manual does not

profess to cover all details or variations in equipment, nor to provide for every

possible contingency associated with installation, operation, or maintenance. No

warranty of fitness for purpose is expressed or implied. Should further information

be desired or should particular problems arise which are not covered sufficiently for

the user’s purpose, the matter should be referred to the Bodine Electric Company.

PAGE

QUICK REFERENCE 2

PRODUCT SPECIFICATIONS 4

IMPORTANT SAFETY PRECAUTIONS 5

INSTALLATION 6

Step 1 – Examine Before Installation 6

Step 2 – Mount the Control 6

Step 3 – Make Electrical Connections 10

Step 3a – Make Cable 10

Step 3b – Connect Remote Control Devices to Cable 10

Step 3c – Ground the INTEGRAmotorTM 14

Step 3d – Connect Fuse 14

Step 3e – Connect DC Power Supply to Cable 14

Step 3f – Plug Cable into INTEGRAmotorTM 14

OPERATION 15

Step 4 – Check System Before Starting 15

Step 5 – Operate the INTEGRAmotorTM 15

TROUBLESHOOTING 19

DECLARATION OF CONFORMITY 22

WARRANTY 23

Copyright 2010. Bodine Electric Company. All Rights Reserved. Printed in U.S.A.

3

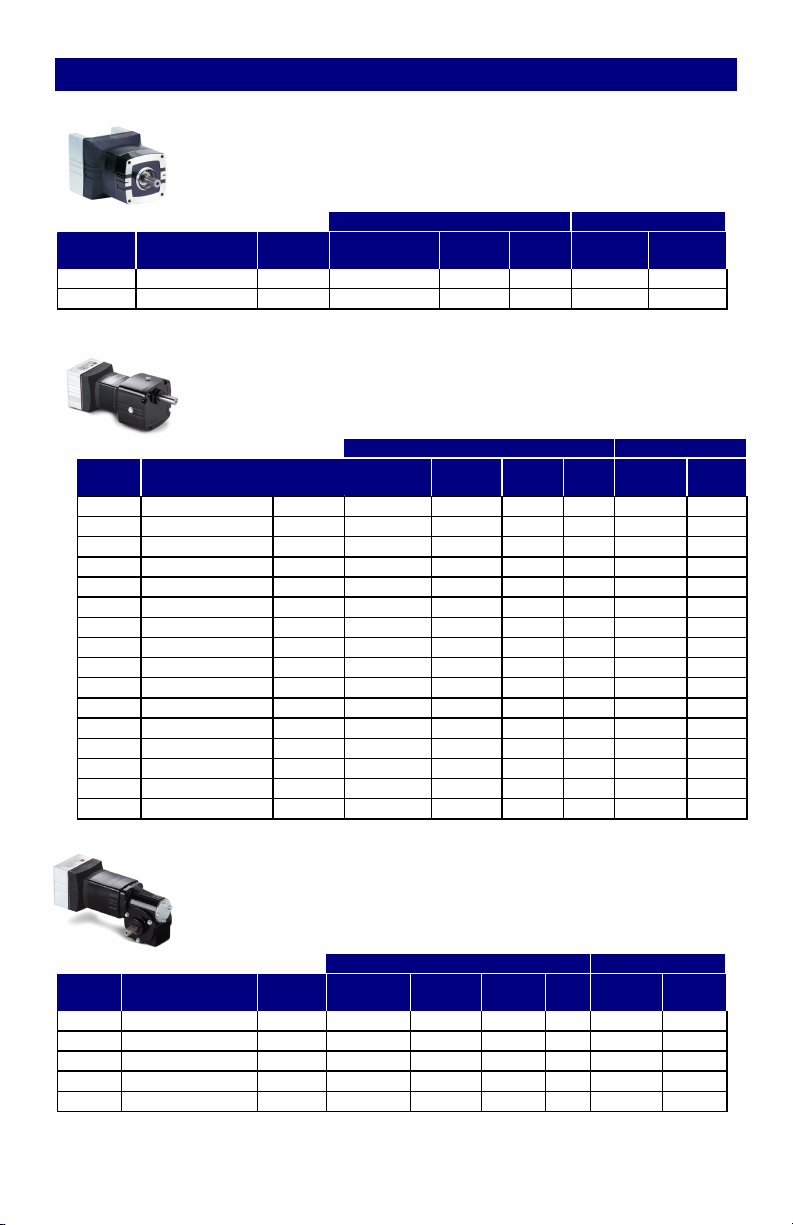

PRODUCT SPECIFICATIONS

-

MOTOR OUTPUT CONTROL INPUT

Model

Number

3802

3804

GEARMOTOR OUTPUT CONTROL INPUT

Model

No.

N3826

3827

N3828

3829

N3834

N3835

3836

N3837

3857

N3858

N3859

3860

N3861

N3862

3863

N3864

GEARMOTOR OUTPUT CONTROL INPUT

Model

No.

N3865

3866

N3867

3868

N3869

4

Ambient Rating: +25°C (+77°F)

Environmental Protection: IP-00

Frame Type Weight

22B2BEBL/SR 2.5 200 to 2500 25 1/16 24 4.0

22B4BEBL/SR 3.5 200 to 2500 50 1/8 24 6.0

Frame Type Weight

22B2BEBL/SR-D3 3.8 33 to 417 5.8 6:1 1/16 24 4.0

22B2BEBL/SR-D3 3.8 17 to 208 12 12:1 1/16 24 4.0

22B2BEBL/SR-D3 3.8 11 to 139 17 18:1 1/16 24 4.0

22B2BEBL/SR-D3 3.8 7 to 83 29 30:1 1/16 24 4.0

22B2BEBL/SR-D3 3.8 3 to 42 40 60:1 1/16 24 4.0

22B2BEBL/SR-D4 3.8 2 to 28 40 90:1 1/16 24 4.0

22B2BEBL/SR-D4 3.8 1 to 14 40 180:1 1/16 24 4.0

22B2BEBL/SR-D5 3.8 0.7 to 8 40 300:1 1/16 24 4.0

22B3BEBL/SR-Z2 5.3 33 to 417 10 6:1 1/11 24 5.0

22B3BEBL/SR-Z2 5.3 17 to 208 20 12:1 1/11 24 5.0

22B3BEBL/SR-Z2 5.3 11 to 139 31 18:1 1/11 24 5.0

22B3BEBL/SR-Z3 5.3 7 to 83 52 30:1 1/11 24 5.0

22B3BEBL/SR-Z3 5.3 3 to 42 95 60:1 1/11 24 5.0

22B2BEBL/SR-Z4 4.8 2 to 28 97 90:1 1/16 24 4.0

22B2BEBL/SR-Z4 4.8 1 to 14 100 180:1 1/16 24 4.0

22B2BEBL/SR-Z4 4.8 0.7 to 8 120 300:1 1/16 24 4.0

Frame Type Weight

22B4BEBL/SR-3N 5.4 3 to 42 37 60:1 1/8 24 6.0

22B4BEBL/SR-3N 5.4 5 to 62 37 40:1 1/8 24 6.0

22B4BEBL/SR-3N 5.4 10 to 125 35 20:1 1/8 24 6.0

22B4BEBL/SR-3N 5.4 20 to 250 22 10:1 1/8 24 6.0

22B4BEBL/SR-3N 5.4 40 to 500 11 5:1 1/8 24 6.0

(lbs)

(lbs)

(lbs)

SPECIFICATIONS OF DIRECT DRIVE MODELS

Speed

(rpm)

Torque

(oz-in)

HP Volts

(VDC)

SPECIFICATIONS OF PARALLEL SHAFT MODELS

Speed

(rpm)

Torque (lb

in)

Gear

Ratio

HP Volts

(VDC)

SPECIFICATIONS OF RIGHT ANGLE MODELS

Speed

(rpm)

Torque

(lb-in)

Gear

Ratio

HP Volts

(VDC)

Cont.

Amps

Cont.

Amps

Cont.

Amps

IMPORTANT SAFETY PRECAUTIONS

“The use of electric motors and generators, like that of all other utilization of

concentrated power, is potentially hazardous. The degree of hazard can be

greatly reduced by proper design, selection, installation, and use, but

hazards cannot be completely eliminated. The reduction of hazard is the

joint responsibility of the user, the manufacturer of the driven or driving

equipment, and the manufacturer of the motor or generator.”*

Please read through this operations manual in detail and observe those

paragraphs with the safety alert symbol.

WARNING

CAUTION

CAUTION

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

CAUTION used without the safety alert

symbol indicates a potentially hazardous

situation which, if not avoided, may result in

property damage.

WARNING

Do not touch printed circuit board (PCB) right after

turning off power.

Do not attempt to wire circuitry while power is on.

Do not attempt to examine components and signals on

the PCB while the INTEGRAMOTORTM is operating.

Do not attempt to disassemble or modify internal

components or wiring of the INTEGRAMOTORTM.

* Standards Publication No. ANSI/NEMA MG-2, “Safety Standard for Construction and Guide for

Selection, Installation and Use of Electric Motors and Generators.” (Ref.: www.nema.org).

5

INSTALLATION

This product should only be installed by a qualified person familiar

with its operation and associated hazards. The National Electrical

Code (NEC), local electrical and safety codes, and when

applicable, the Occupational Safety and Health Act (OSHA) should

be observed to reduce hazards to personnel and property.

Step 1. Examine before installation

CAUTION

The PCB of the INTEGRAmotor

TM

is vulnerable to static

electrical charges. For this reason, the

INTEGRAMOTORTM is packaged in an anti-static bag.

Remove the INTEGRAmotorTM from the bag only in an

area protected from electrostatic discharges (ESD).

Check the items you received against the model numbers specified on your

purchase order. The serial number is printed on an adhesive label on the top side

of the control housing. The first four digits in the serial number correspond to the

model number. Carefully examine the product for shipping damage. Parts errors

should be reported to Bodine. Shipping damage claims should be made to the

freight carrier.

CAUTION

Do not connect the INTEGRAmotorTM to the power supply if

there is any sign of shipping damage.

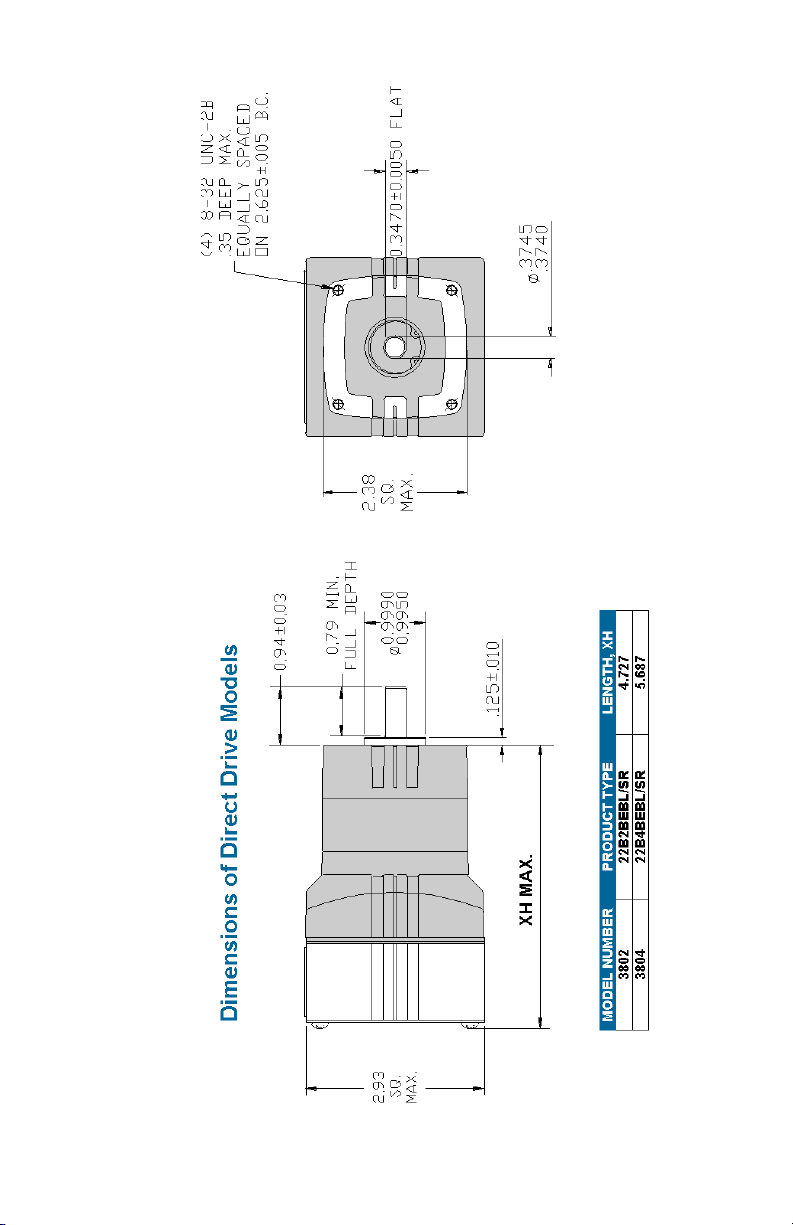

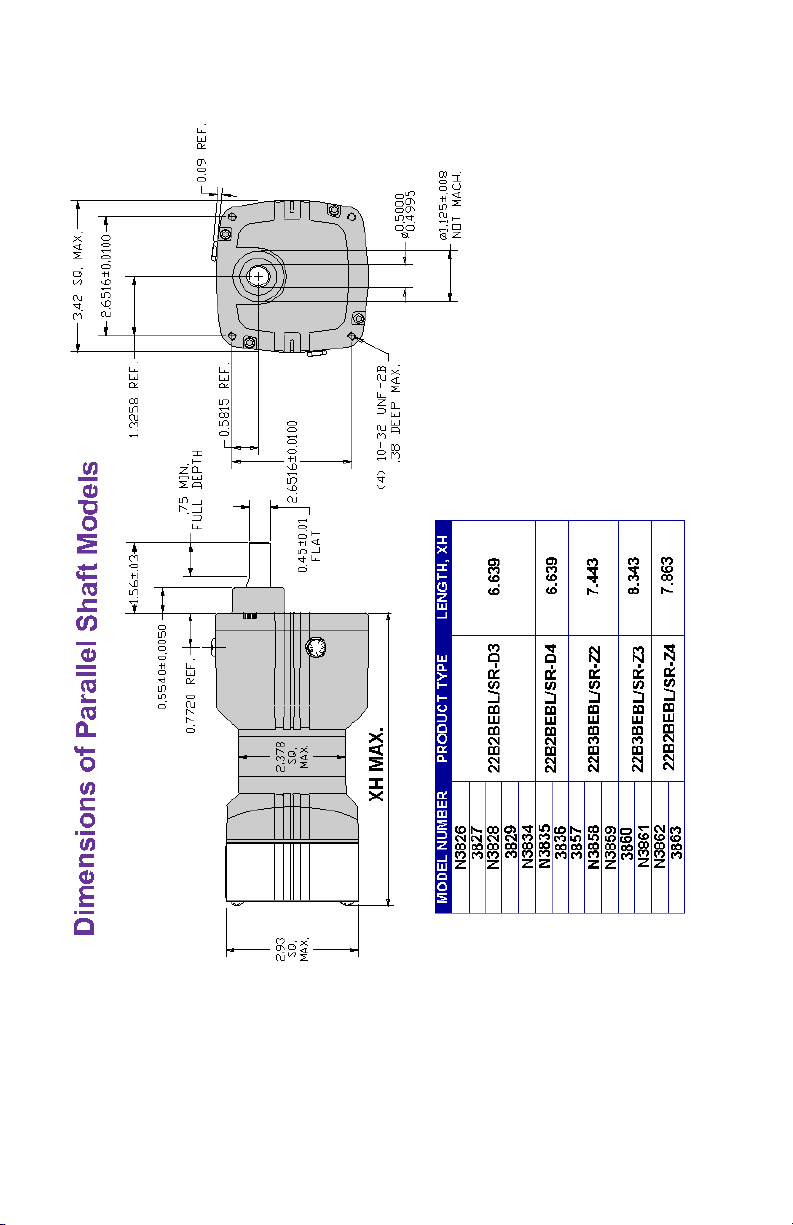

Step 2. Mount the INTEGRAMOTORTM

Install the INTEGRAMOTORTM onto a firm base by inserting screws into the four

threaded holes in the mounting surface. See the following dimension drawings

for location of mounting holes.

INTEGRAmotorsTM without gearing can be mounted in any position. Our

standard gearmotors are designed for universal horizontal mounting orientation.

Consult the factory for suggestions if the gearmotors are mounted vertically.

Surrounding air temperature can be from 0O C to +25O C (rated ambient temp.).

Prevent liquid from dripping onto the INTEGRAmotorTM.

Avoid environments that are humid or that have corrosive gas.

Avoid locations near radioactive matter, flammable material, or by equipment

that emits electromagnetic interference (EMI).

Avoid mounting the INTEGRAmotorTM to a surface that experiences excessive

vibration.

6

7

8

Loading...

Loading...