Bock Water heaters Electric Water Heaters User Manual

Commercial Electric

Energy Saver

Water Heaters

Meet or exceed ASHRAE 90.1b (current edition) performance standards

50, 80 & 119 gallon capacities with inputs

from 6 to 54 kW

3” Non-CFC foam insulation

Surface Mounted Thermostat (SF Model): offers

sequenced element operation through variable

thermostat settings for each element.

Immersion Thermostats with Contactors (CF Model):

offer accurate temperature control to 180° F.

Elements: screw in style

Surface Mounted Thermostat models have nickel

chromium wire embedded in magnesium oxide sheathed

in copper and electroplated to minimize degradation of

the anode. Incoloy sheathed elements are optional.

Immersion Thermostat models have low watt density

incoloy sheathed elements standard, which resists

burnout caused by dry re or lime buildup.

Porcelain glass lined with dual magnesium anode

rods: to prohibit corrosion for longer life.

ASME and NSF Construction avaliable

3-Year Limited Warranty

Energy Saver

120

80

50

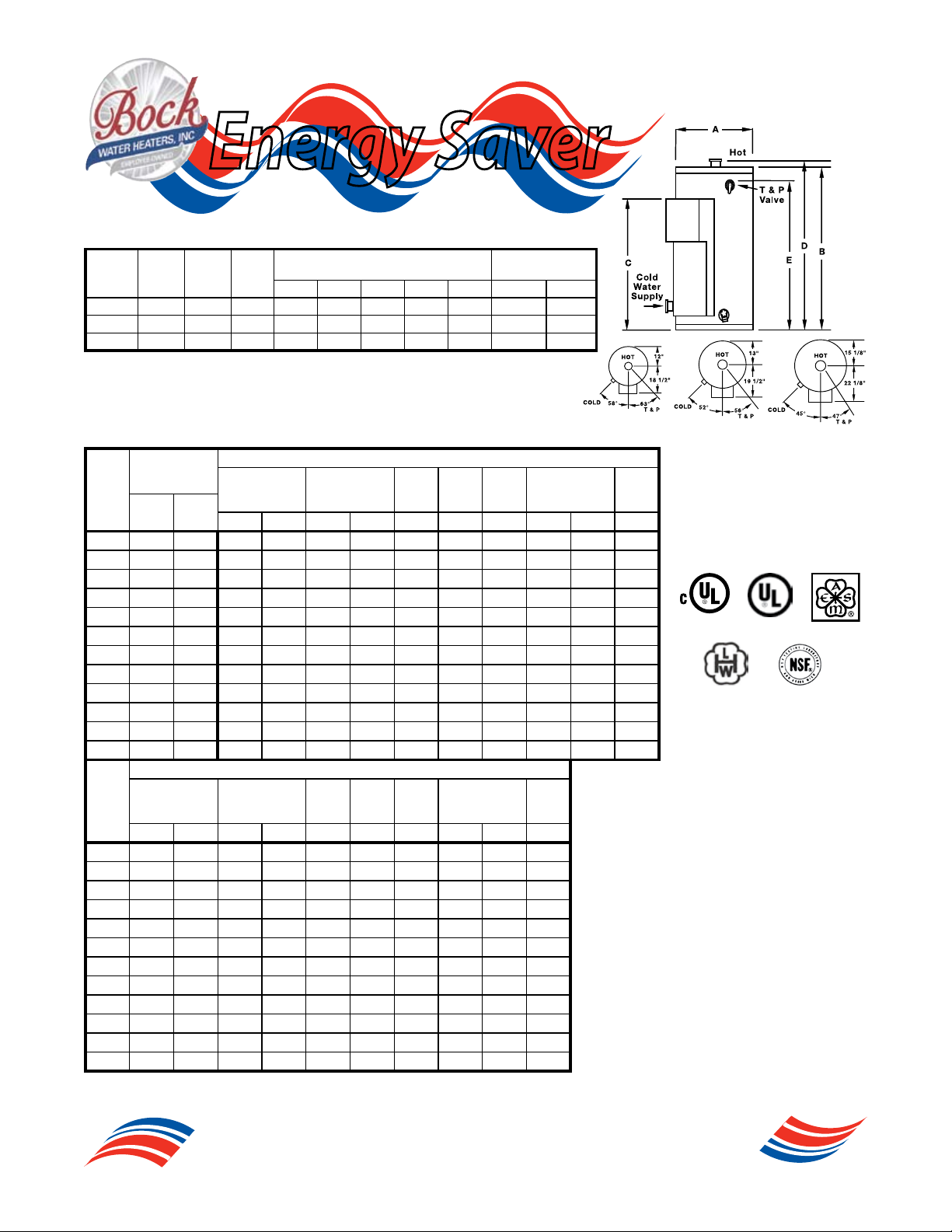

Dimensions and Capacities

Storage

Model

50F-* 50 ** 1-1/2 24 47-3/4 46-1/2 49-1/4 41 270 302

80F-* 80 ** 1-1/2 26 60-1/4 46-1/2 61-3/4 52-1/2 335 378

120F-* 119 ** 1-1/2 30-1/4 64-1/2 50-1/4 66 55 430 485

*When order surface mounted thermostat, add the letter “S” before the “F”. Example 50SF

*When ordering the Immersion thermostat add the letter “C” before the “F”. Exampe 50CF

*For ASME construction add an “A” to the model number. Example 50CF-A

**Add a “6”, “9”, “12”, “13.5”, “15”, “18”, “24”, “27”, “30”, “36”, “45”, or “54” to the model number to indicate kW

input desired. Example 50S(C)F-6

(gal)

kW

Input

Inlet

Pipe

Dia.

A B C D E Standard ASME

Dimensions

Shipping Weight

(lbs)

Operating Characteristics

Recovery

kW

Input

6 28 25 28.8 16.6 25 14.4 21.6 10 9 12.5 7.2 5.8

9 42 37 43.2 25 37.2 21.6 32.4 14 13 18.7 10.8 8.7

12 55 50 57.6 33.3 50 28.9 43.3 19 17 25 14.4 11.5

13.5 62 56 64.9 37.5 56.2 32.5 48.7 21 19 28.1 16.2 13

15 69 62 72.1 41.6 62.5 36.1 54.1 23 21 31.2 18 14.4

18 83 74 86.5 50 75 43.4 64 28 25 37.5 21.6 17.3

24 110 99 115.4 66.7 100 57.8 86.6 37 34 50 28.9 23.1

27 124 112 129.8 75 112.5 65 97.4 41 38 56.2 32.5 26

30 138 124 144.2 83.3 125 72.2 108.3 46 42 62.5 36.1 28.9

36 165 149 173 100 150 86.7 129.9 55 50 75 43.3 34.6

45 207 186 216.3 125 187.5 108.3 162.4 69 63 93.7 54.1 43.3

54 248 223 259.6 150 225 130 194.9 83 75 112.5 65 52

kW

Input

6 3(2) 3 3(2) 3 3 3 3 3(2) 3 3

9 3 3 3 3 3 3 3 3 3 3

12 3 3 3(2) 3 3 3 3 3(2) 3 3

13.5 3 3 3 3 3 3 3 3 3 3

15 3 3 3 3 3 3 3 3 3 3

18 3 3 3 3 3 3 3 3 3 3

24 4 6 4 6 4 6 6 4 6 6

27 6 6 6 6 6 6 6 6 6 6

30 6 6 6 6 6 6 6 6 6 6

36 6 6 6 6 6 6 6 6 6 6

45 9 9 9 9 9 9 9 9 9 9

54 9 9 9 9 9 9 9 9 9 9

Units with amperage draw of 48 amps or more require factory installed internal fusing.

***If the number of elements on non-fused models is different, it is indicated in parentheses (), following the AMP draw.

@

90°F

100°F

Rise

Rise

208 Volts

Phase

1 3 1 3 1 3 3 1 3 3

208 Volts

Phase

1 3 1 3 1 3 3 1 3 3

Number of Elements (Fused Models)***

240 Volts

Phase

Full Load Current Amperes (Fused Models)***

277

380

240 Volts

Phase

277

Volts

Phase

380

Volts

Phase

Volts

Phase

415

Volts

Phase

Volts

Phase

415

Volts

Phase

480 Volts

Phase

480 Volts

600

Volts

Phase

600

Phase

Volts

Phase

Dielectric Fittings: Factory Installed

T&P Valve: Factory Installed

Brass Drain Valve: Factory Installed

Relief Valve Opening: 3/4”

Hand-hole Cleanout Opening: Standard

Pressures (all): Working Pressure, 150 psi;

Testing Pressure, 300 psi

Warning: Do not install on combustible ooring.

Installation should be in accordance with all

national and/or local codes. In the absence of

local codes, refer to NFPA 31, NFPA 54 or ANSI

Z.21.10.1.

Caution: The recommended maximum hot water

termperature setting for normal residential use is

120°F. Bock recommends a tempering valve or

anti-scald valve be installed and used according to

the manufacturer’s directions to prevent scalding.

www.bockwaterheaters.com

110 South Dickinson Street , Madison, Wisconsin 53703

Toll Free 800.794.2491•Phone 608.257.2225●Fax 608.257.5304

Where Applicable

80031 Rev 3/08

Loading...

Loading...