Bock Water heaters 66W-370, 66W-399, 80W-180, 80W-199, 80W-250 Service Manual

...

Energy Saver

COMMERCIAL 24 VOLT FLUE DAMPER

SERIES WATER HEATER

ATMOSPHERIC GAS WATER HEATERS

SERVICE

MANUAL

Troubleshooting Guide and

Instructions for Service

(To be performed ONLY by

qualied service providers)

Models Covered

by This Manual:

Manual 47324A Save this manual for future reference.

For the Bock Water Heaters

“W” Series Models:

38W-155

75W-(125, 160, 300)

66W-(370, 399)

80W-(180, 199, 250)

80W-(425, 450, 505)

100W-(199, 250, 270, 300)

W-Series

Atmospheric Gas

Table of Contents

Service

Page Procedure

Introduction 3 - - Tools Required for Service 3 - - Sequence of Operation 4 - - Troubleshooting 5 - - Thermostat Circuit Testing 6 24-I

Pilot Operation Testing 8 24-II

Main Burner Operation Testing 10 24-III

Main Burner and Pilot Removal and Inspection 12 24-IV

Flue Baffle Removal and Inspection 14 24-V

Anode Removal and Inspection 15 24-VI

Generic Parts List 16 - - Glossary of Terms/Notes 19 - - -

2

W-Series

It is intended for this manual to be used by qualied service personal for the primary purpose of

troubleshooting, analysis, and repair of the Bock 24 Volt Flue Damper W-Series Water Heater.

Understanding the “Sequence of Operation” section of this manual will contribute greatly to

troubleshooting this product.

Troubleshooting begins simply by resetting the water heater and observing the lighting sequence

to determine failure mode. This step-by-step procedure beginning on Page 5 will direct the service

provider to a series of test procedures to determine the root cause of failure.

Contact Technical Support immediately if diagnosis is not determined using the methods described

in this service manual.

Tools Required for Service

Manometer: Two types available, a liquid “U” tube type or a digital (magna-helic) type.

This device is used to measure gas and/or air pressures and vacuum.

Multi-Meter: A digital type is strongly recommended. This device is used to measure

electrical values. The meter you select must have the capability to

measure volts AC, volts DC, amps, micro amps and ohms.

Introduction

Thermometer: Used to measure water temperature. An accurate thermometer is

recommended.

Water Pressure Gauge: Used to measure water supply pressure. Also used to determine tank

pressure by adapting to the drain valve of the heater.

Jumper Leads: A length of wire (12” min.) with alligator clip at both ends.

Various Hand Tools: Pipe wrench, channel locks, open-end wrench set, 12” crescent wrench,

allen wrench set, torx bit set, screw drivers (common and phillips), long

reach (12”) magnetic tip phillips head screw driver #2 tip, ¼” nut driver,

pliers (common and needle nose), socket set including a 1 - 1/16” deep

well socket, wire cutters, wire strippers, wire crimpers, torpedo level, small

shop vac, step ladder, and ashlight.

3

W-Series

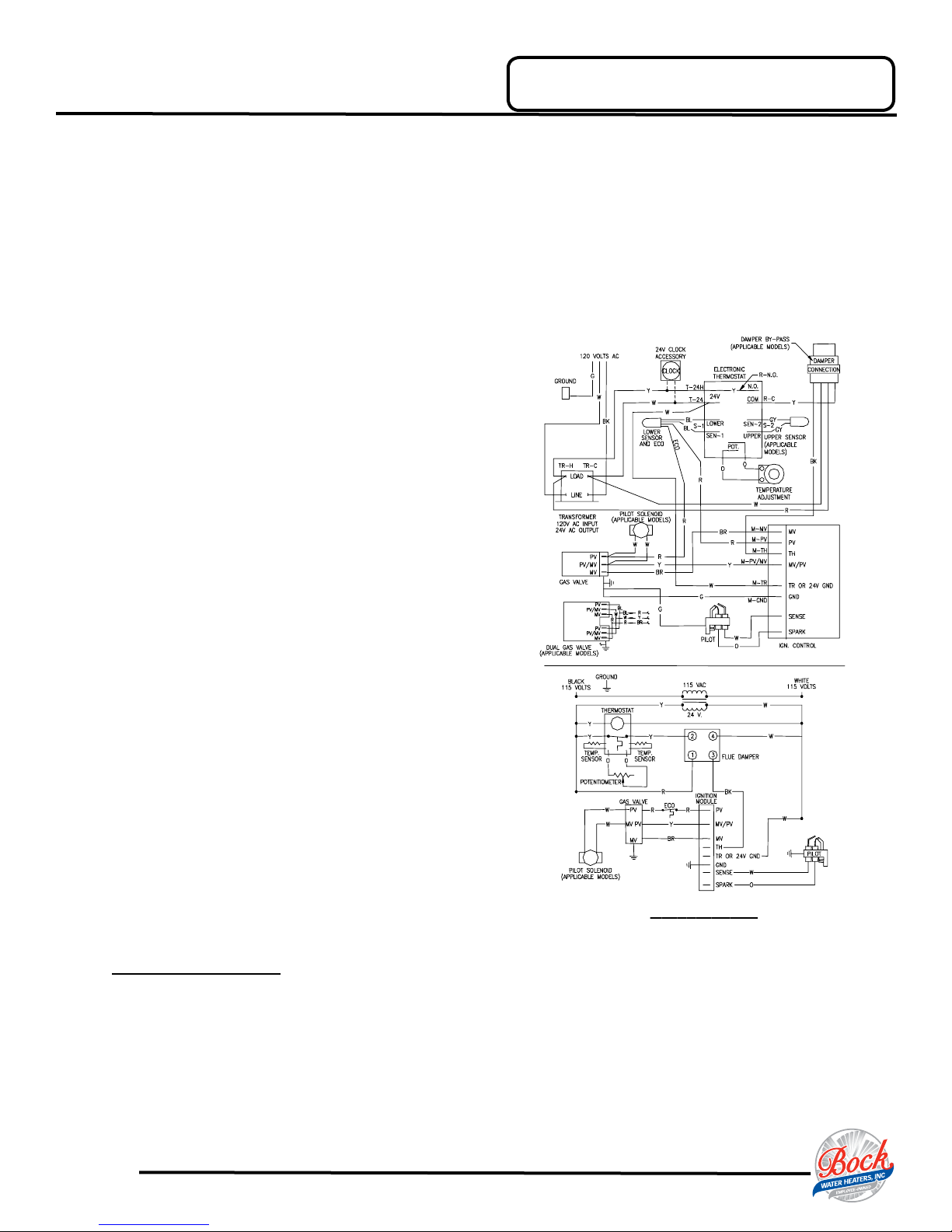

WIRING DIAGRAM

1. Thermostat calls for heat. The relay closes on the thermostat board, sending 24 volts from the

“COM” terminal of the thermostat board to the ue damper.

2. Flue damper begins to rotate open. Once damper is full open, 24 volts is allowed to continue through

damper to the “TH” terminal of ignition module.

3. LED on ignition module illuminates.

4. Trial for ignition (90 second trials, 3 trials with 30 second pause between trials)

Ignition module simultaneously sends:

1. 24 volts from “MV/PV” terminal, to “MV/PV”

terminal of gas valve (common terminal).

2. 24 volts from “PV” terminal, through the ECO

located in the lower thermister, to “PV” terminal of

gas valve to establish gas ow at pilot.

3. Low current high voltage from “spark” terminal,

to generate spark at the pilot and ignite pilot gas

ow.

Sequence of Operation

4. Pilot ame proving signal (measured in micro

amps) from the “sense” terminal, to prove pilot

ame.

5. Once pilot ame is proven, spark will stop.

6. Once spark stops, 24 volts is sent from “MV” terminal on

module, to “MV” terminal on gas valve to establish main

burner gas ow. Main burners ignite from the pilot ame.

The ignition module constantly monitors pilot ame. If the

pilot ame is lost, pilot and main burner are shut down.

After a 30 second purge period, module will attempt to

re-light pilot beginning at sequence 4 above.

7. Main burner res until the thermostat is satised. The

relay on the thermostat board opens, interrupting 24 volts

through the damper and ignition module. Pilot and main

burner are turned off.

8. Flue damper rotates to the closed position.

LOCKOUT CONDITION

Ignition module will “lockout” if the pilot cannot be lit after 3 ignition trials. The ignition module indicates a

lockout condition by the continuing ash of the LED located on the module.

Lockout reset is accomplished by interrupting 120 VAC to the unit for at least 5 seconds.

4

W-Series

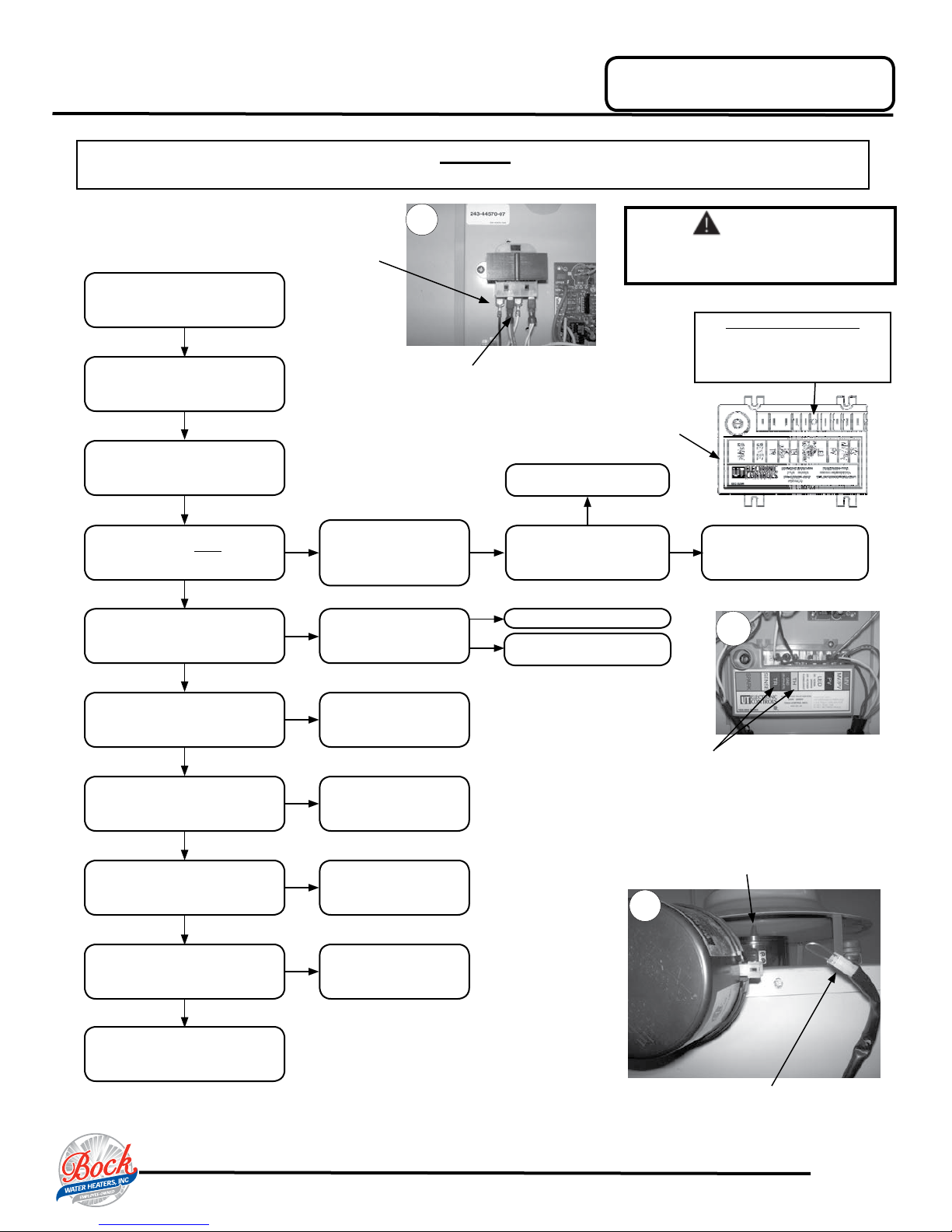

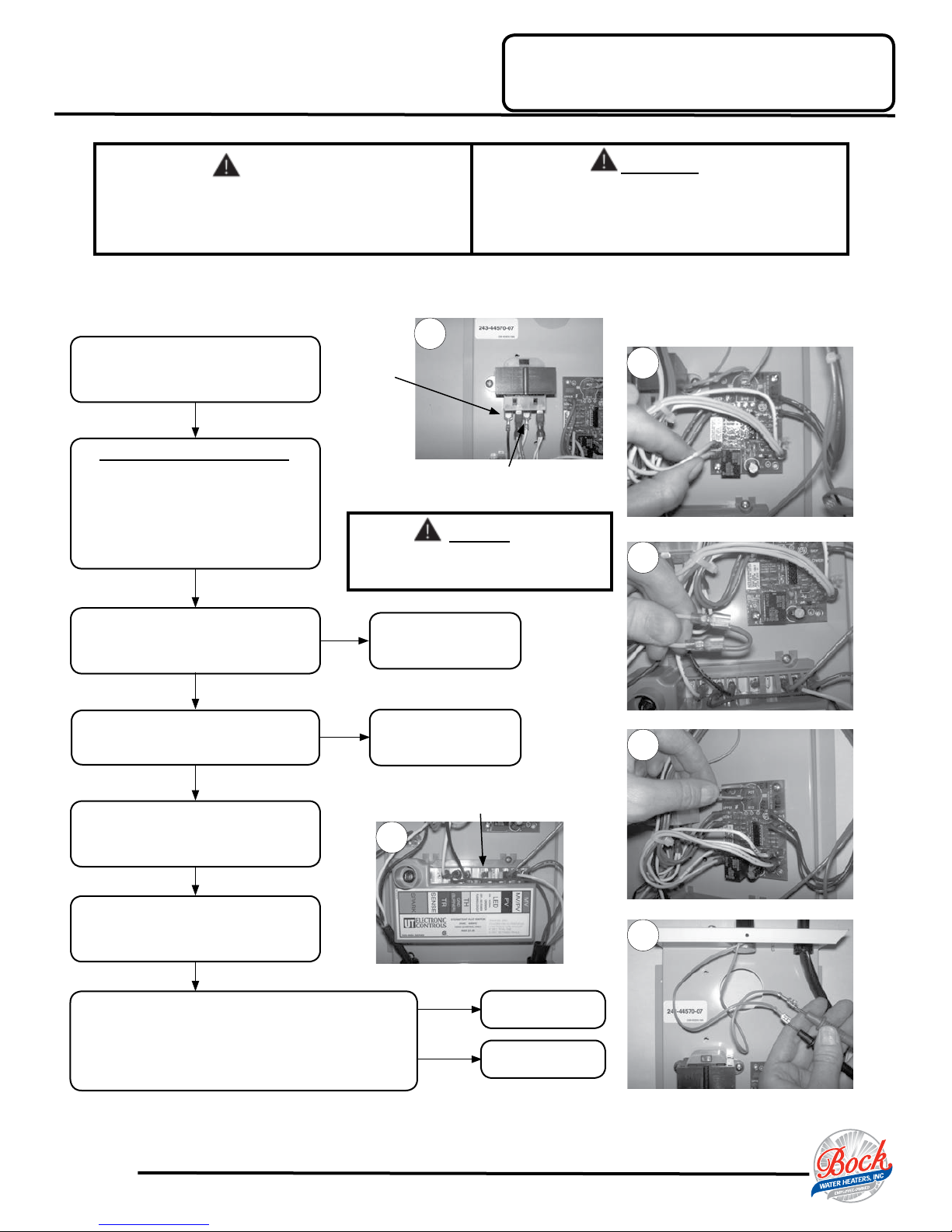

1

1A

2

Use Caution Not to Damage Connectors When Making Voltage Measurements or Jumping Terminals.

Rear Terminals

Verify primary and secondary

voltage at the transformer.

(see photo 1)

If LED on ignition module is

ashing, reset water heater by turning

“OFF” power. Wait 5 seconds and turn

power back “on”.

Rotate thermostat dial to the

highest setting.

(120 VAC)

primary

CAUTION

Forward Terminals

primary

(24 VAC)

Troubleshooting

120 Volt Exposure. Use Caution

Ignition Module

See “thermostat testing.”

(page 6)

DANGER

to Avoid Personal Injury

Ignition Module LED Status

OFF = No power to module

ON = Module has power

Flashing = Module is in lock-out

Does damper vane move to the full

Does LED light on ignition module

open position?

Y

illuminate?

Y

Is there pilot ame?

Y

Does main burner operate?

Y

Does burner continue until

thermostat set point is reached?

Y

Does ue damper rotate to the

closed position?

Y

Remove damper from

N

N

N

N

N

N

heater and jump black

& yellow wires of heater

harness.

(see photo 2)

Is there 24 VAC between

terminals “TR” & “TH” of the

ignition module?

(see photo 1A)

See “pilot will not light.”

(page 8)

See “pilot lights,

no ame signal.”

(page 9)

See “main burner

short cycle.”

(page 11)

Check for debris limiting

damper rotation. If no

debris, replace damper.

N

Does LED light on

ignition module

illuminate?

Y

N

Replace ignition module

Check damper

harness connection

Check for 24 VAC

Y

across terminals

“TR” & “TH”

Damper vane shown in open position. If damper

is closed, disconnect from harness and

REMOVE damper from water heater.

Check for debris limiting

damper rotation. If no

debris, replace damper.

System okay.

Harness shown disconnected from damper

with BLACK and YELLOW wires jumped.

5

W-Series

3

4

5

7

6

8

Service Procedure 24-I

Thermostat Circuit Testing

DANGER

120 Volt Exposure. To avoid personal injury,

use caution while performing this procedure.

Be careful when making voltage

measurements or jumping terminals

not to damage or deform connectors or

CAUTION

connector pins.

This procedure assumes the ue damper is in working order. Be sure damper opens under its own power when the

thermostat circuit is bypassed. Damper must be open or removed during this test. Do not force damper open using your

hands or tools.

With power on to water heater, verify

primary and secondary voltage at

the transformer.

(see photo 3)

THERMOSTAT CIRCUIT BYPASS

Turn power “OFF” to water heater and

locate thermostat board inside control box

of water heater. Disconnect YELLOW wires

from the thermostat board at location

“N.O.” & “COM.” Use a jumper to connect

these two wires together.

(see photos 4 & 5)

Rear

Terminals

Primary

(120 VAC)

Forward Terminals

Secondary

(24 VAC)

DANGER

Do not leave thermostat jumper in

place for normal operations.

Turn power on to water heater.

Does LED on ignition module illuminate?

Does pilot and main burner operate?

Remove jumper and reconnect wires to

thermostat board. Wires are identied for

Disconnect ORANGE potentiometer (temp

adjustment dial) wires from thermostat

Check potentiometer for proper resistance values of:

Greater than 4800 Ohms with dial at minimum setting.

Less than 50 Ohms with dial at maximum setting.

(see photo 6)

Y

Y

Turn power “OFF.”

proper connection to board.

board. (see photo 7)

(see photo 8)

Are readings correct?

N

N

Verify transformer voltage.

(see photo 3)

See pilot operation testing.

(page 8)

LED Location

N

Y

Replace potentiometer.

Check thermisters.

(see page 7)

6

Loading...

Loading...