Instruction Manual

plus

TCU 40/80

W95900011

Revision F

June, 2004

Temperature Control Unit

Single Channel

301 Ballardvale Street Wilmington, MA 01887

Telephone: (978) 658-5410 Telex: 710-347-7672 Fax: (978) 658-7969

BOC EDWARDS

TABLE OF CONTENTS

SECTION TITLE PAGE

1 PREFACE ………………………………………………………………………………………….. 1

1.1 SAFETY CONSIDERATIONS …………………………………………………………………. 1

2 TCU 40/80

2.1 SCOPE OF THE MANUAL …………………………………………………………………….. 3

2.2 DESCRIPTION FOR THE TCU 40/80

2.3 LOCKOUT PROCEDURE ……………………………………………………………………… 3

2.4 SAFETY FEATURES ……………………………………………………………………………4

3 QUICK START PROCEDURE ……………………………………………………………………. 5

3.1 POWER UP ………………………………………………………………………………….….. 5

3.2 SETPOINT VERIFICATION …………………………………………………………………… 5

4 PRODUCT DESCRIPTION ……………………………………………………………….………. 6

4.1 REFRIGERATION AND COOLANT CIRCUITS …………………………………………….. 6

4.2 REFRIGERATION ……………………………………………………………………………… 9

4.2.1 IF COOLING IS REQUIRED ………………………………………………………………. 9

4.2.2 IF COOLING IS NOT REQUIRED ………………………………………………………….9

4.3 COOLANT CIRCUIT …………………………………………………………………………… 10

4.4 TEMPERATURE MONITORING ……………………………………………………………… 10

4.5 FRONT PANEL …………………………………………………………………………………. 10

4.6 REAR PANEL ……………………………………………………………………………………12

4.7 SPECIFICATIONS ……………………………………………………………………………… 13

4.8 DIMENSIONS …………………………………………………………………………………... 14

5 INSTALLATION ……………………………………………………………………………………15

5.1 RECEIVING AND UNPACKING ……………………………………………………………… 15

5.2 LOCATION ………………………………………………………………………………………15

5.2.1 SECURING THE UNIT ……………………………………………………………………….15

5.2.2 INSTALLING THE SECONDARY CONTAINMENT RECEPTACLE ……………………. 15

5.2.3 FLOOR LEVELERS …………………………………………………………………………. 15

5.3 STACKING ……………………………………………………………………………………… 16

5.3.1 TIE-BOLTS …………………………………………………………………………………...16

5.4 FACILITIES ……………………………………………………………………………………...16

5.4.1 50 Hz Installations………………………………………………………………………………16

5.4.2 WATER AND COOLANT CONNECTIONS ………………………………………………...16

5.4.3 WATER ………………………………………………………………………………………..18

5.4.4 COOLANT …………………………………………………………………………………….18

5.4.5 REMOTE CONNECTIONS ………………………………………………………………….. 18

6 OPERATION ……………………………………………………………………………………….. 19

6.1 PREPARATION ………………………………………………………………………..………...19

6.2 POWERING UP THE TCU 40/80 plus …………………………………………………………. 19

6.3 CHANGING THE SETPOINT VALUE (SV1) ………………………………………………….20

6.4 TEMPERATURE CONTROLLER PID SETTINGS …………………………………..……….. 20

6.5 REMOTE SET POINT ………………………………………………………………………….. 20

6.6 FLOW RATE ADJUSTMENT ………………………………………………………………….. 21

plus

…………………………………………………………………………………….. 3

plus

…………………………………………….………. 3

TCU 40/80 plus Temperature Control Unit i

7 MAINTENANCE ……………………………………………………………………………………22

7.1 HAZARD WARNINGS ………………………………………………………………………….22

7.2 HAZARDS ………………………………………………………………………………………. 24

7.3 FILLING THE RESERVOIR …………………………………………………………..……….. 24

7.4 DRAINING/BLEEDING THE COOLANT RESERVOIR ……………………………………... 25

7.5 TEMPERATURE PROBE CALIBRATION ……………………………………………………. 25

7.6 PREVENTIVE MAINTENANCE SCHEDULE ……………………………………………….. 25

7.7 SEMI-ANNUAL PREVENTATIVE MAINTENANCE ………………………………………... 26

7.7.1 REQUIRED EQUIPMENT …………………………………………………………………... 26

7.7.2 PREPARATION ……………………………………………………………………………... 26

7.7.3 VERIFY SYSTEM STATUS ………………………………………………………………… 26

7.7.4 REFRIGERATION LEAK CHECK …………………………………………………………. 26

7.7.5 FLUORINATE LEAK CHECK ……………………………………………………………… 26

7.7.6 WATER LEAK CHECK …………………………………………………………………….. 26

7.7.7 INSULATION REPAIR ……………………………………………………………………... 27

7.7.8 LAMP CHECK/REPLACEMENT …………………………………………………………... 27

7.8 ANNUAL PREVENTATIVE MAINTENANCE ………………………………………………..28

7.8.1 REQUIRED EQUIPMENT …………………………………………………………………... 28

7.8.2 REQUIRED SUPPLIES ……………………………………………………………………… 28

7.8.3 SOLENOID VALVE COIL REPLACEMENT ……………………………………………… 28

7.8.4 SYSTEM CHECK ……………………………………………………………………………. 30

7.9 PREVENTATIVE MAINTENANCE CHECKLIST …………………………………………….39

8 TROUBLESHOOTING …………………………………………………………………………….. 40

9 ACCESSORIES AND SPARE PARTS ……………………………………………………………..54

10 OPTIONS …………………………………………………………………………………………… 55

10.1 LON WORKS …………………………………………………………………………………… 55

10.1.1 REFERENCE ………………………………………………………………………………… 55

10.1.2 OVERALL DESCRIPTION …………………………………………………………………. 55

10.1.3 REQUIREMENTS …………………………………………………………………………… 56

10.1.4 INTERFACES ………………………………………………………………………………... 59

10.2 RS232 TEL ………………………………………………………………………………………. 71

10.2.1 BLOCK DIAGRAM …………………………………………………………………………. 71

10.2.2 OPERATION MODE AND CONTENTS OF FUNCTION …………………………………. 71

10.2.3 DESCRIPTION OF EXTERNAL CONTROL AND MONITORING SIGNALS …………... 73

10.3 RS485 SERIAL COMMUNICATION ………………………………………………………….. 92

10.3.1 MODIFIED ELECTRICAL CONTROLS DRAWER …………………………………………...92

10.3.2 RS485 MODICON MODBUS PROTOCOL ………………………………………………… 92

10.3.3 INSTALLATION AND SE-UP OF RS485 INTERFACE BOX ASSEMBLY ……………... 93

10.3.4 RS485 MODICON MODBUS PROTOCOL SPECIFICATION FOR TCU 40/80 ………….. 102

10.3.5 RS485 4X MEMORY MAP FOR TCU 40/80 HEAT EXCHANGER ………………………. 103

10.3.6 RS485 TCU 40/80 MESSAGE EXAMPLE ………………………………………………….. 104

APPENDIX ……………………………………………………………………………………………………105

RETURN OF BOC EDWARDS EQUIPMENT – PROCEDURE (FORM HS1) ………….…………….. 106

RETURN OF BOC EDWARDS EQUIPMENT – DECLARATION (FORM HS2) ……………………...107

LEGAL NOTICES, LIMITATIONS AND DISCLAIMERS …………………………………………….. 108

MSDS (MATERIAL SAFETY DATA SHEET) – “SUVA” HP62 ……………………………………….109

ii TCU 40/80 plus Temperature Control Unit

ILLUSTRATIONS

FIGURE TITLE PAGE

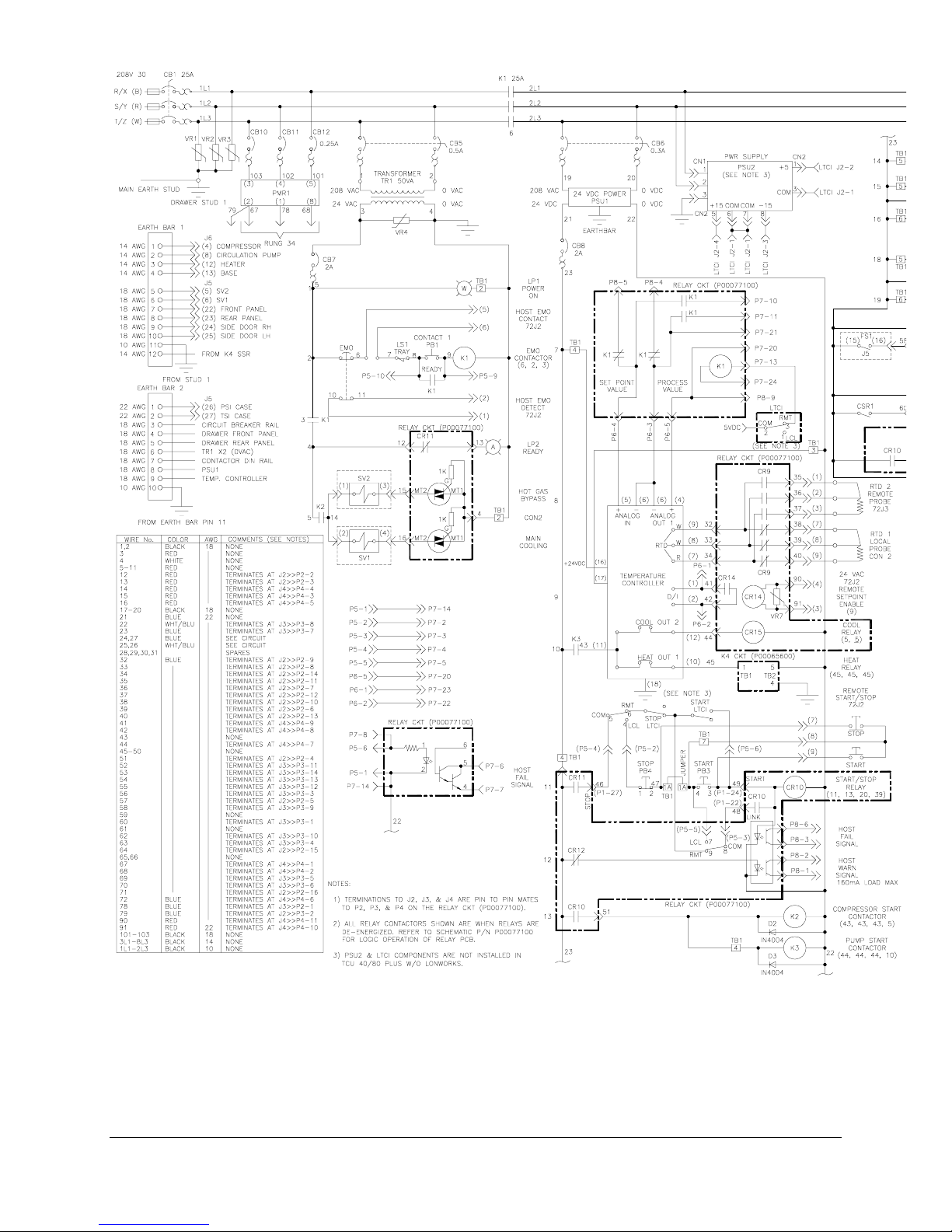

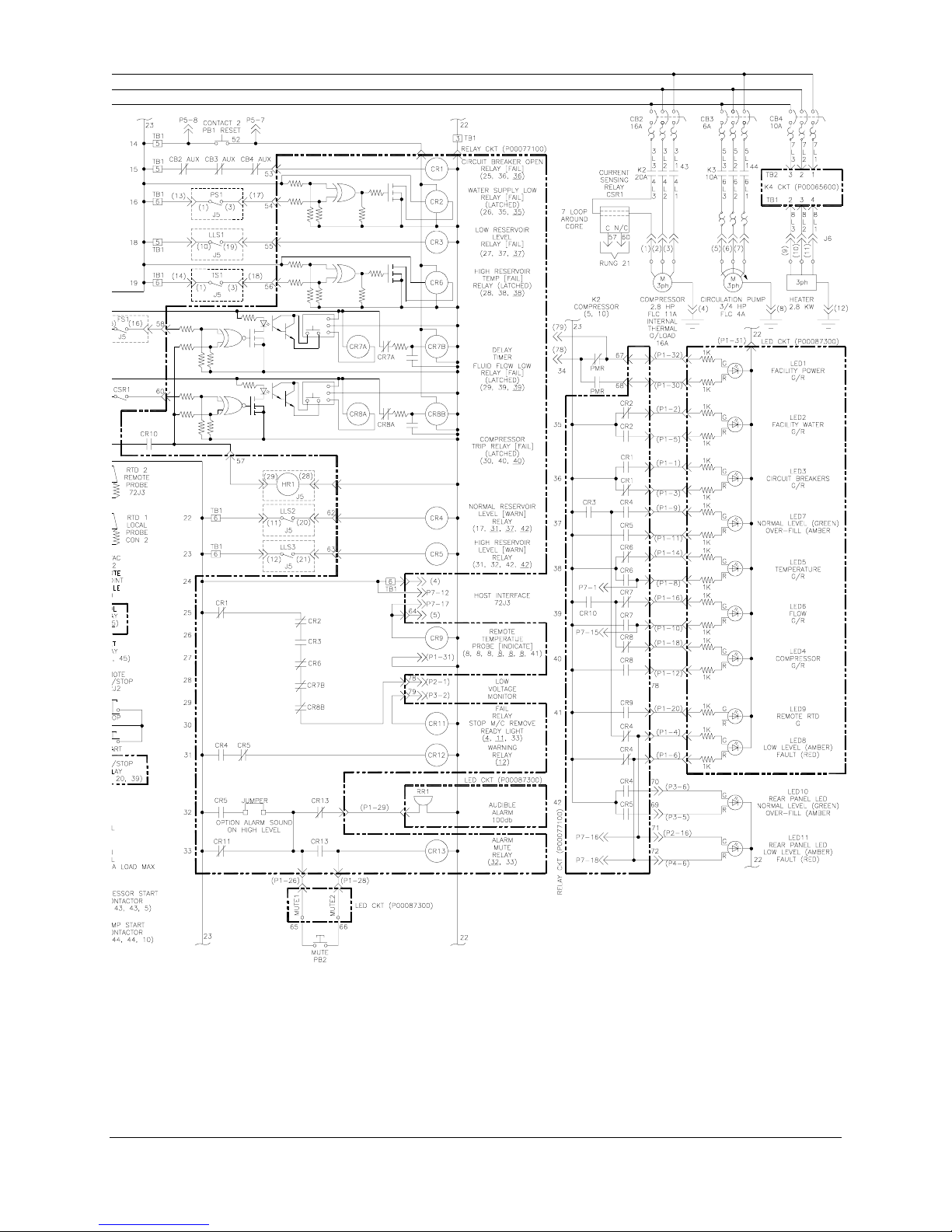

FIGURE 1 – REFRIGERATION AND COOLANT COMPONENTS …………………………………… 6

FIGURE 2 – REFRIGERATION AND COOLANT COMPONENTS …………………………………… 7

FIGURE 3 – REFRIGERATION AND COOLANT CIRCUITS …………………………………………. 9

FIGURE 4 – FRONT PANEL ……………………………………………………………………………… 10

FIGURE 5 – ELECTRICAL REAR PANEL ……………………………………………………………… 12

FIGURE 6 – TCU DIMENSIONS …………………………………………………………………………. 14

FIGURE 7 – TCU DIMENSIONS …………………………………………………………………………. 14

FIGURE 8 – STACKED TCU 40/80

FIGURE 9 – SYSTEM REAR VIEW ……………………………………………………………………… 17

FIGURE 10 – WATER CONNECTIONS …………………………………………………………………. 18

FIGURE 11 – TEMPERATURE CONTROLLER ………………………………………………………… 20

FIGURE 12 – LAMP REPLACEMENT …………………………………………………………………… 27

FIGURE 13 – SOLENOID COIL REPLACEMENT ……………………………………………………… 29

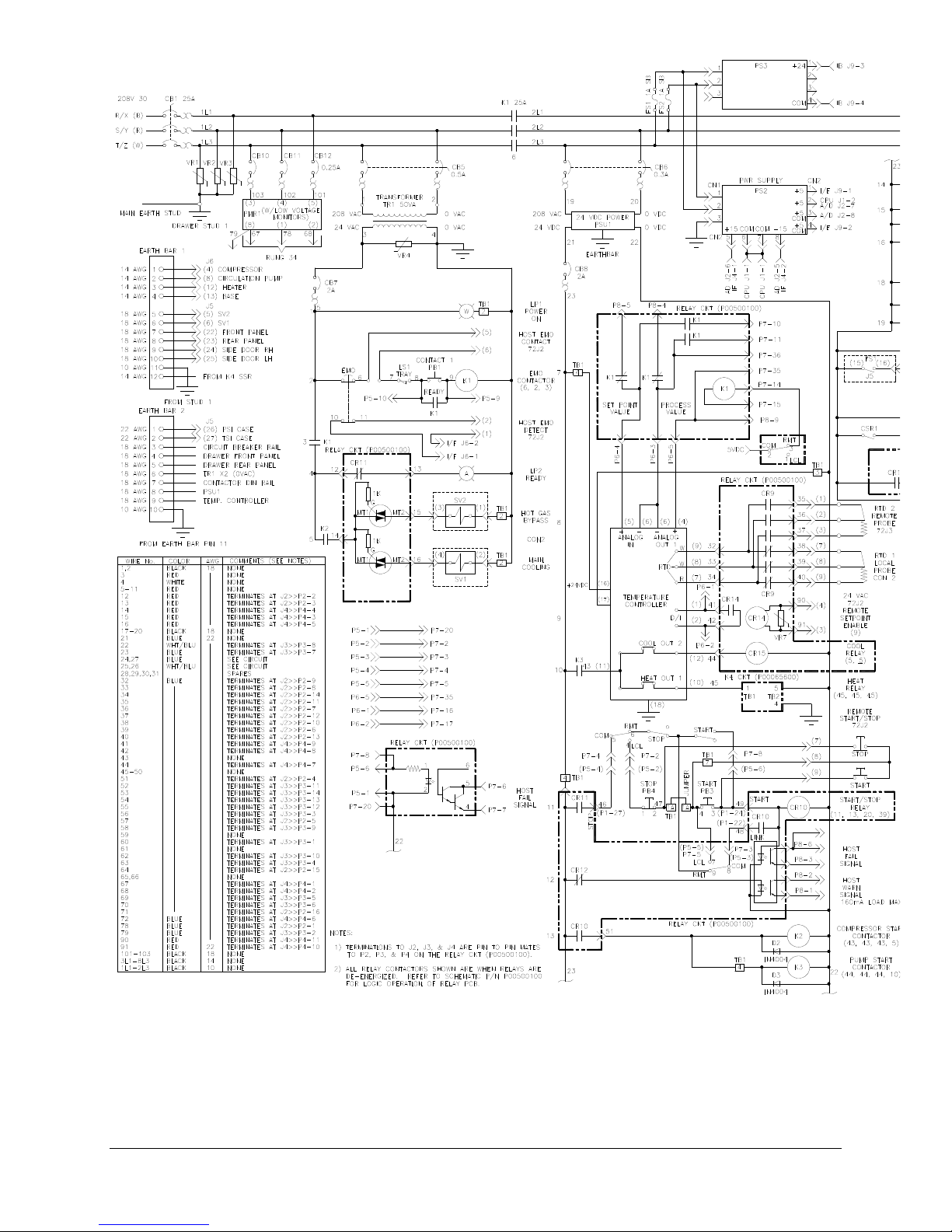

FIGURE 14 – ELECTRICAL DRAWER ANALOG………………………………………………………. 49

FIGURE 15 – ELECTRICAL DRAWER SCHEMATIC …………………………………………………. 51

FIGURE 16 – REMOTE INTERFACE ……………………………………………………………………. 53

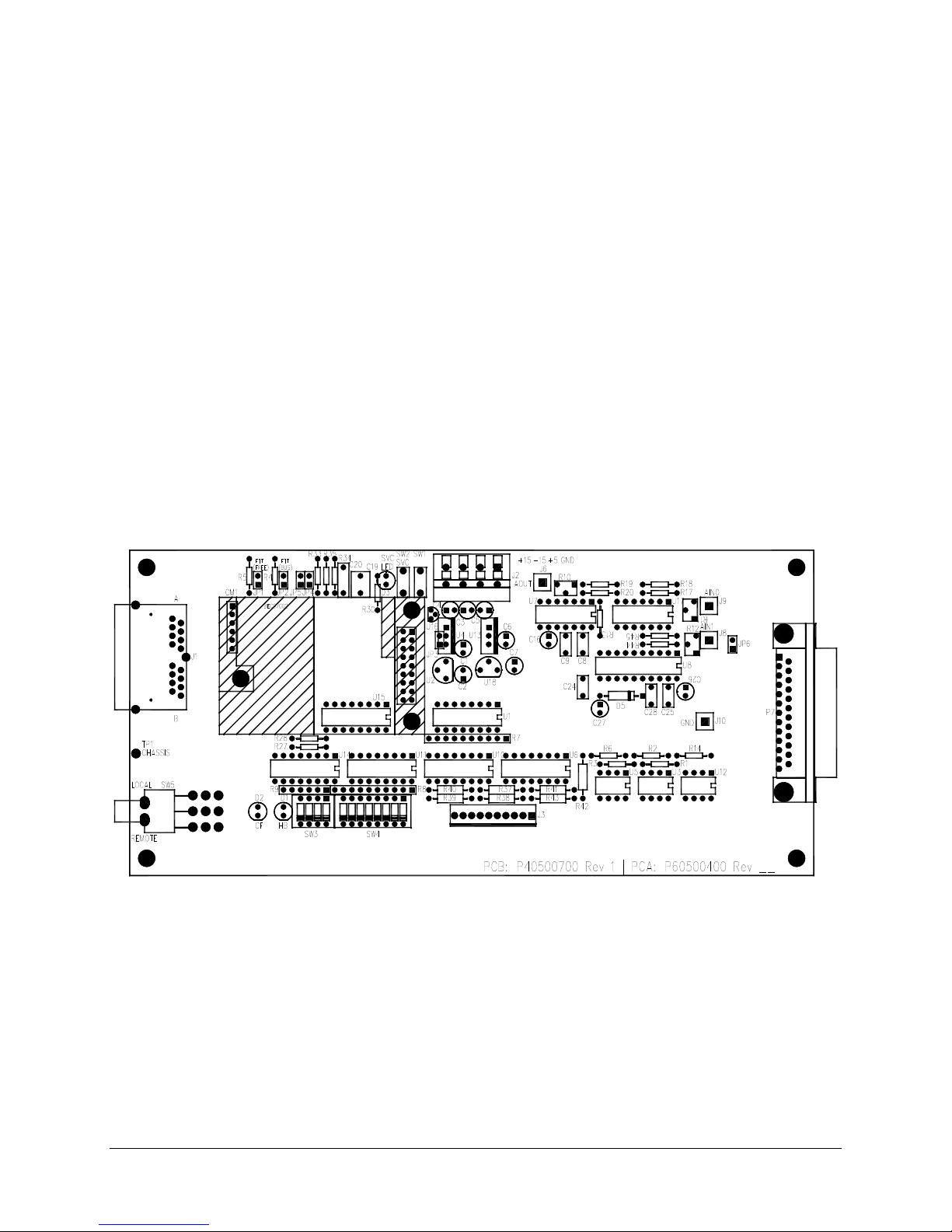

FIGURE 17 – OVERALL LTCI ARCHITECTURE ……………………………………………………… 55

FIGURE 18 – LTCI PHYSICAL LAYOUT ………………………………………………………………. 56

FIGURE 19 – ELECTRICAL REAR PANEL …………………………………………………………….. 65

FIGURE 20 – ELECTRICAL DRAWER LONWORKS……………………………………………………. 66

FIGURE 21 – ELECTRICAL DRAWER SCHEMATIC …………………………………………………….68

FIGURE 22 – REMOTE INTERFACE ……………………………………………………………………… 70

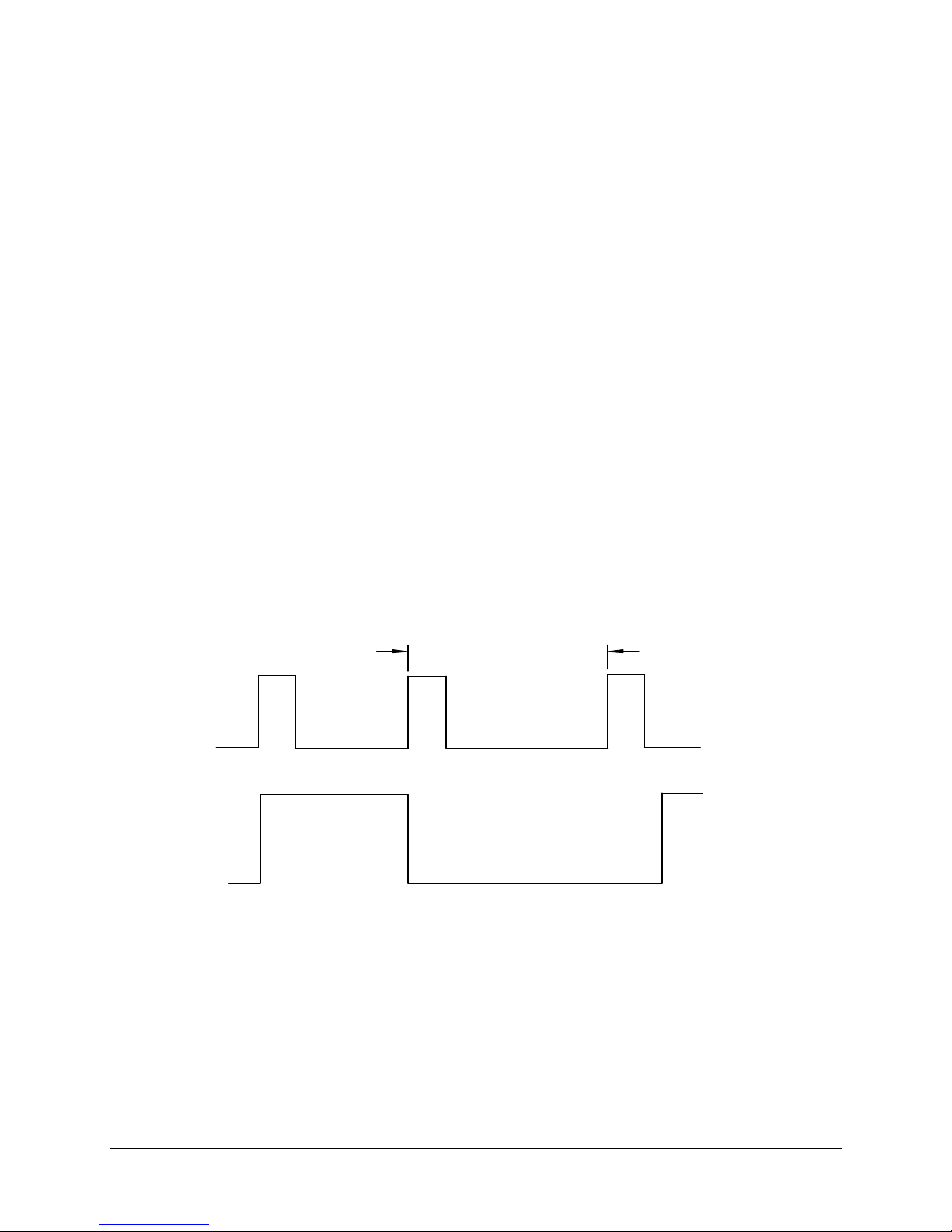

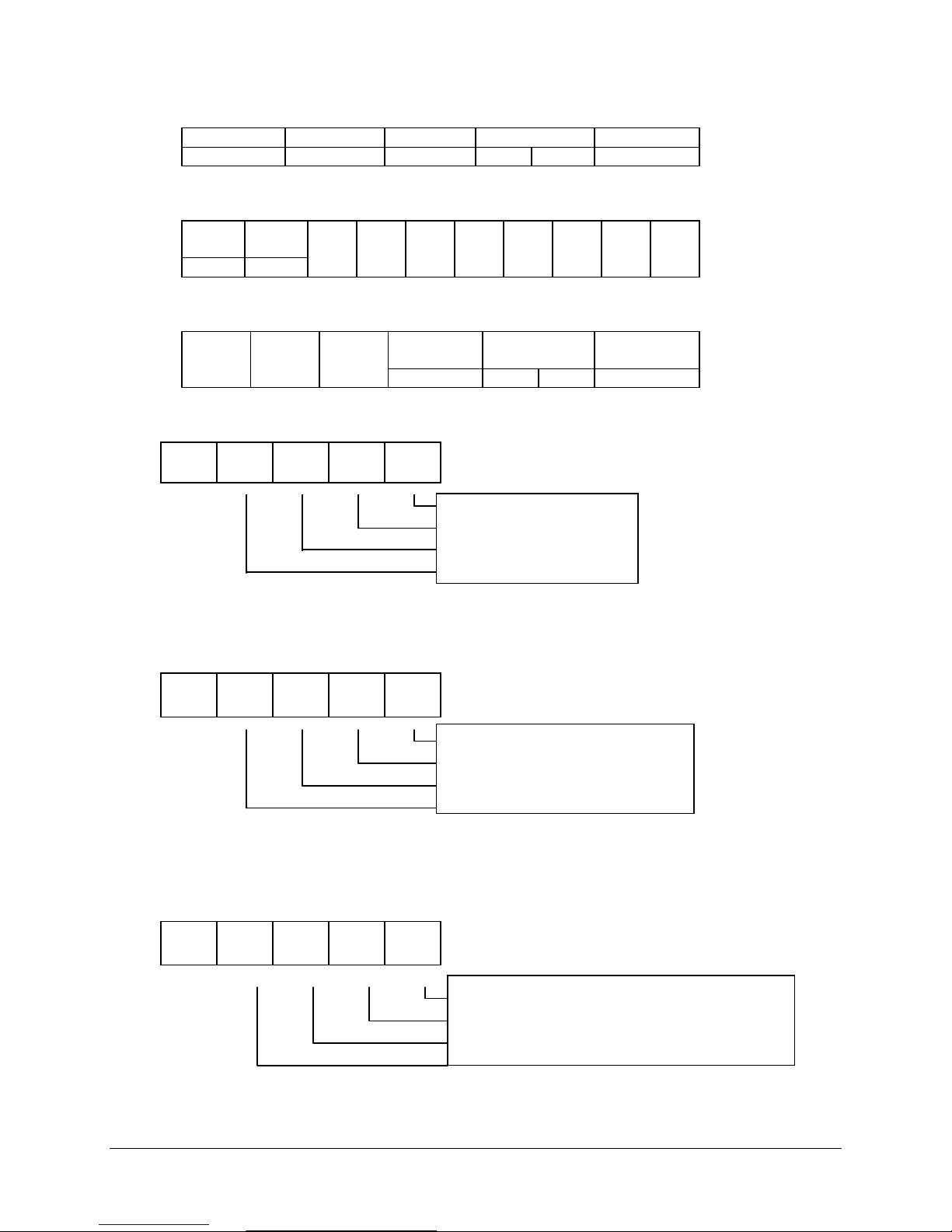

FIGURE 23 – BLOCK DIAGRAM ………………………………………………………………………….. 71

FIGURE 24 – “RUN”/”STOP” SIGNAL ……………………………………………………………………..73

FIGURE 25 – CONTROL SIGNAL STATE …………………………………………………………………74

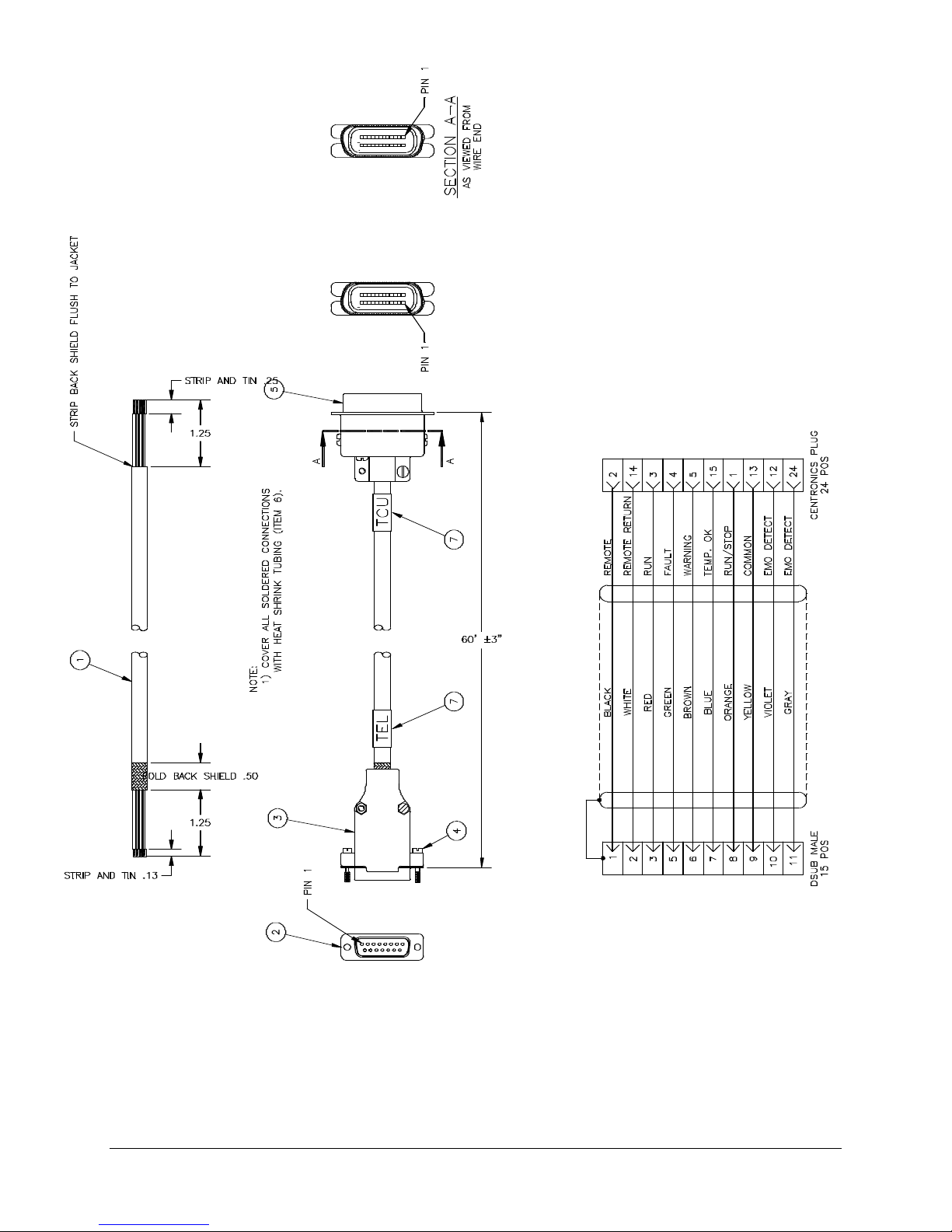

FIGURE 26 – PIN ASSIGNMENT FOR TCU-TEL CABLE ……………………………………………….. 75

FIGURE 27 – ELECTRICAL REAR PANEL ………………………………………………………………..84

FIGURE 28 – RS232 ELECTRICAL DRAWER ……………………………………………………………. 86

FIGURE 29 – RS232 POWER DISTRIBUTION SCHEMATIC …………………………………………….88

FIGURE 30 – ASSEMBLY CABLE TCU HOST COMMUNICATION …………………………………… 90

FIGURE 31 – ASSEMBLY CABLE TCU RS232 COMMUNICATION ……………………………………91

FIGURE 32 – RS485 ELECTRICAL DRAWER COMPONENT LAYOUT ………………………………..94

FIGURE 33 – RS485 ELECTRICAL DRAWER SCHEMATIC ……………………………………………. 96

FIGURE 34 – RS485 INTERFACE BOX – PHYSICAL DIMENSIONS …………………………………... 98

FIGURE 35 – RS485 INTERFACE BOX WITH TOP COVER REMOVED ………………………………. 99

FIGURE 36 – MICROPROCESSOR PCA – JP7 PIN DESCRIPTION AND FUNCTION …………………99

plus

SYSTEMS ……………………………………………………… 16

TCU 40/80 plus Temperature Control Unit iii

ILLUSTRATIONS (continued) ….

FIGURE TITLE PAGE

TABLE 1 – SAFETY FEATURES ………………………………………………………………………….. 4

TABLE 2 – FRONT PANEL INDICATORS ……………………………………………………………… 5

TABLE 3 – REFRIGERATION AND COOLANT COMPONENTS ………………………………………..8

TABLE 4 – FRONT PANEL CONTROLS ………………………………………………………………….. 11

TABLE 5 – FRONT PANEL LED INDICATORS ………………………………………………………….. 11

TABLE 6 – TEMPERATURE CONTROLLER …………………………………………………………… 11

TABLE 7 – DESCRIPTION OF REAR PANEL COMPONENTS AND INDICATORS ………………… 12

TABLE 8 – FRONT PANEL POWER UP INDICATOR CONDITIONS ………………………………… 19

TABLE 9 – ELECTRICAL HAZARDS CLASSIFICATIONS …………………………………………… 24

TABLE 10 – PREVENTIVE MAINTENANCE SCHEDULE ……………………………………………….25

TABLE 11 – FAULTS IDENTIFIED BY FRONT PANEL LAMPS ……………………………………….. 40

TABLE 12 – FAULTS INDICATED BY THE FRONT PANEL LED INDICATORS …………………….. 42

TABLE 13 – FAULTS IDENTIFIED BY REAR PANEL INDICATORS …………………………………..46

TABLE 14 – MISCELLANEOUS FAULT CONDITIONS ………………………………………………….47

TABLE 15 – ACCESSORIES ………………………………………………………………………………...54

TABLE 16 – ANALOG TEMPERTURE SIGNAL CHARACTERISTICS ………………………………... 58

TABLE 17 – LTCI NETWORK VARIABLES ……………………………………………………………… 61

TABLE 18 – DEFINITIONS OF NVOSTATUS NETWORK VARIABLE ……………………….……….. 62

TABLE 19 – DESCRIPTION OF REAR PANEL COMPONENTS AND INDICATORS ………………….65

TABLE 20 – AVAILABLE FUNCTIONS …………………………………………………………………... 72

TABLE 21 – PIN ASSIGNMENTS AT THE TCU HOST CONNECTION ……………………….……….. 75

TABLE 22 – CONTROL CODE ……………………………………………………………………………...76

TABLE 23 – HEADER CODE ………………………………………………………………………………. 76

TABLE 24 – DESCRIPTION OF REAR PANEL COMPONENTS AND INDICATORS ………………….85

TABLE 25 – TCU 40/80 “J72J1” CONNECTOR MODIFIED FOR RS485 ……………………….………..100

TABLE 26 – HOST RS485 COMMUNICATION CONNECTOR …………………………………………..101

iv TCU 40/80 plus Temperature Control Unit

1. Preface

1.1 Safety Considerations

Many safety features have been designed into the TCU 40/80 plus to protect the operator and the

equipment. The following symbols are used in this manual to indicate the various safety

conditions.

General Alert

Electric Shock

General Alert symbol denotes the potential of

personal hazards or equipment failure.

Warnings are given when failure to observe the

instruction could result in injury or death to

persons.

Cautions are given where failure to observe the

instruction could result in damage to the

equipment, associated equipment and process.

Statement on avoiding the hazard.

Electric Shock symbol denotes the presence of

high voltage or current. It calls attention to the

procedure, practice, or the like, which if not done

correctly or adhered to could result in injury or

death.

Statement on avoiding the hazard.

Eye Protection

Toxic Gases

Eye Protection symbol denotes a hazard which

could cause injury or irritation to the eyes.

Statement on avoiding the hazard.

Toxic Gases symbol denotes a personal hazard.

It calls attention to the procedure, practice, or the

like, which if not done correctly or adhered to

could result in injury or death.

Statement on avoiding the hazard.

TCU 40/80 Temperature Control Unit 1

Hot Surfaces

Hot Surfaces symbol denotes a hazard which

could cause injury or burns.

Statement on avoiding the hazard.

Hand

Hand Protection symbol denotes a hazard which

could cause injury or burns

Protection

Statement on avoiding the hazard.

High Pressure

High Pressure symbol denotes a personal hazard

or equipment failure. It calls attention to the

procedure, practice, or the like, which if not done

correctly or adhered to could result in equipment

damage, injury or death.

Statement on avoiding the hazard.

Extreme

Extreme Temperature symbol denotes a hazard

which could cause injury or burns.

Temperatur

e

Statement on avoiding the hazard.

2 TCU 40/80 plus Temperature Control Unit

2. TCU 40/80 plus

2.1 Scope of the Manual

This manual provides information on the installation, start-up and operation of Edwards High Vacuum

Model 40/80 Temperature Control Unit (TCU 40/80

The Quick Start Procedure on page 5 is a step by step guide for the start up and use of an installed,

working system.

Installation, starting on page 17, provides instructions and information for installing the system. The

installer must have sufficient technical understanding of electrical and mechanical systems to properly use

this information.

Operation, starting on page 21, provides more complete instructions on the preparation and use of the

system.

2.2 Description of the TCU 40/80 plus

The TCU 40/80

remote heat loads.

From distances up to 50 feet, the TCU 40/80

equipment. The coolant circulates through the TCU 40/80

then is transferred to the process equipment, and returns in a closed loop. The TCU 40/80

supply coolant at a temperature between -40 °C and +80 °C, selectable in 0.1 °C increments, with a

tolerance of ±1.0 °C.

2.3 Lockout Procedure

To prevent accidental or unauthorized starting of the TCU 40/80

power cord from the receptacle and install an appropriate lock-out device (Hubbell Small PlugoutÔ or

equivalent) on the end of the power cord.

plus is a single-channel temperature control unit engineered for temperature control of

plus).

plus can cool the heat load generated by the process

plus, where it is cooled or heated as required,

plus maintains

plus during maintenance, disconnect the

TCU 40/80 Temperature Control Unit 3

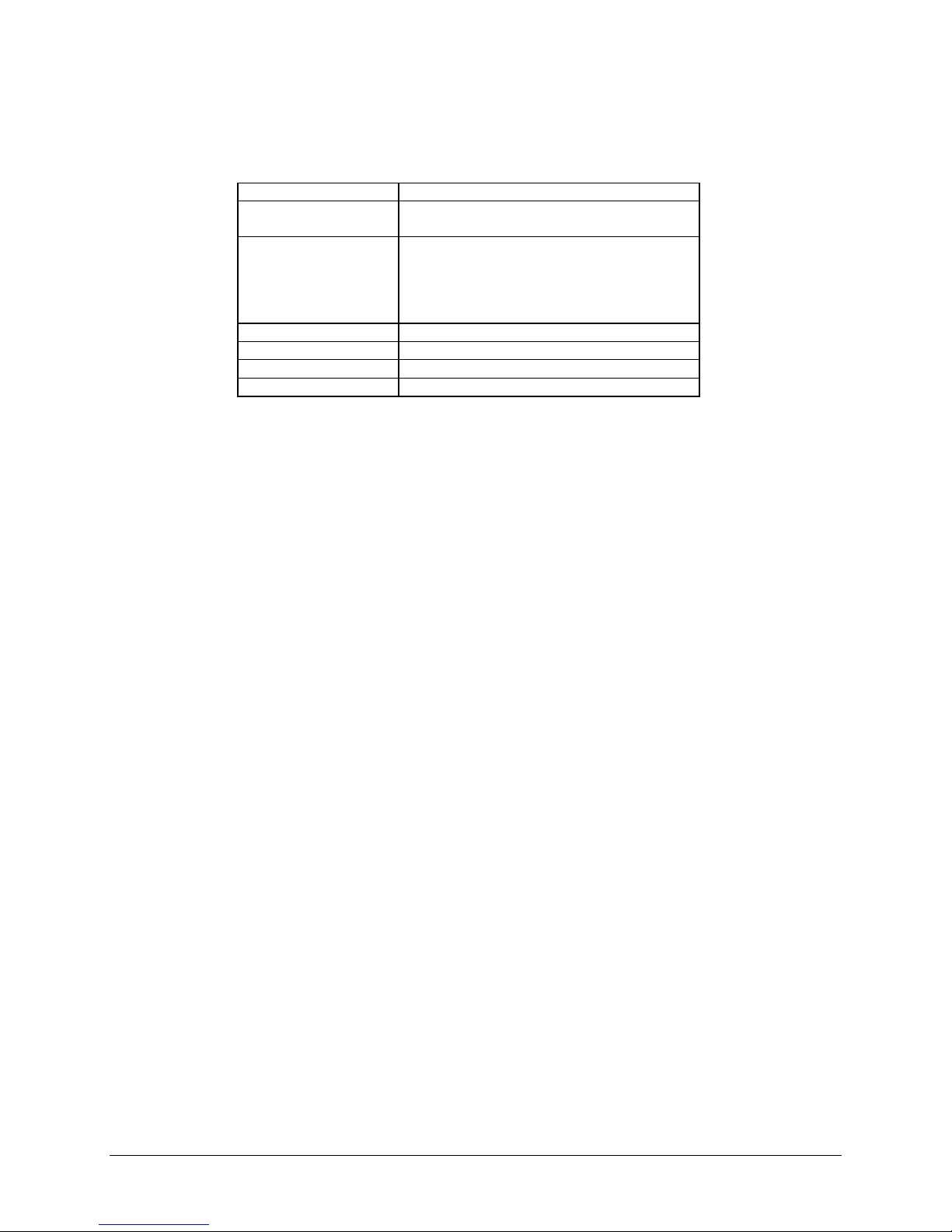

2.4 Safety Features

The safety features listed in Table are designed into the TCU 40/80

Component

EMERGENCY OFF

button (EMO)

Remote EMERGENCY

OFF

Drawer safety switch (LS1) Upon opening the drawer, shuts off power to major system

Pressure switch (PS1) Protects the refrigeration system against high discharge

plus.

Table 1 - Safety Features

Ref. Des. *

(PB1) Shuts off power to major system components.

(J72J2) Remote shut off of power to major system components.

components.

pressure. Interrupts operation at 300 psig.

Function

Condenser pressure relief

valve

Reservoir pressure relief

valve

Temperature switch (TS1)

Coolant flow switch (FS1) Protects the process equipment from inadequate coolant

Coolant float switch (LLS1) Protects against low level in the coolant reservoir by

Coolant float switch (LLS3) Protects against overfill of the coolant reservoir. Indication

Thermal overload (K3) Protects the pump motor from excess current.

Surge suppression VR1-4

Line phase monitor PMR1 Protects the equipment against incorrect wiring of the

(W2) Vents refrigerant to the atmosphere above 350 psig. Fail

safe for PS1, works even if there is no power applied to the

system.

(W1) Protects the reservoir from over-pressure.

Protects the process fluid from exceeding 99 °C

flow rates.

stopping the equipment.

on front and rear panels.

Protects the TCU 40/80

power line transients.

supply phases and low voltage burn-out.

plus against voltage surges and

Current sensor CSR1 Protects the compressor against abnormal conditions.

Secondary containment Captures fluids (internal to the TCU) in the event of a leak.

* See Figure 3 on page 10

4 TCU 40/80 plus Temperature Control Unit

3. Quick Start Procedure

This Quick Start procedure is for easy start

up and operation of an installed

working TCU 40/80 plus. If your TCU 40/80

plus is not installed, go to Installation,

Section 5 on page 17. Detailed operating

instructions are in Operation, Section 6 on

page 21. If at any time an alarm occurs,

press STOP and correct the fault indicated

by the display as directed in the

Troubleshooting Guide, Section 8 on page

43. Press RESET and START to continue

operation.

3.1 Power Up

Before applying power, verify that

all water and coolant lines are

connected to the system. The

handles on both coolant line valves

should be in the open position. For

the location of these connections,

refer to Figure 9 on page 19.

To power up the TCU 40/80 plus:

1. READY light should be on. If

the ready light is not on see

Powering Up the TCU 40/80

plus on page 21.

2. Press RESET. Verify that

front panel indicators are as

shown in the Reset column of

Table 2 on this page.

3. Press START. Verify that

front panel indicators are as

shown in the Start Condition

column of Table on this

page.

If in steps two or three any front

panel indicators do not match, refer

to the Troubleshooting Guide

Section 8 on page 43 for corrective

action.

4. Verify that the coolant

pressure gauge (located on the

front access panel) reads less

than 100 psig.

and fully

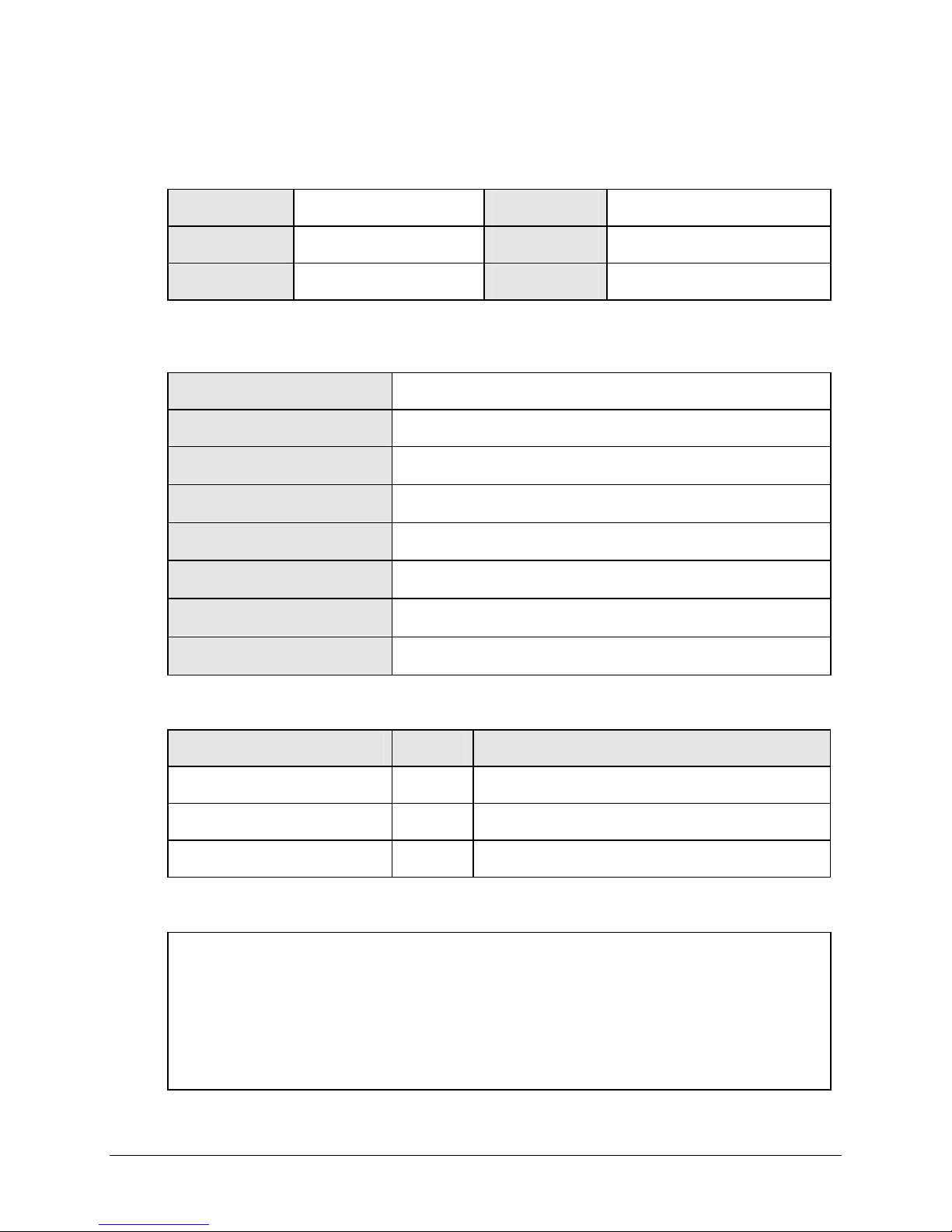

Table 2 - Front Panel Indicators

Indicator Reset

Condition

Power On Green Green

Reset White White

Facility Power Off Green

Facility Water Green Green

Circuit Breakers Green Green

Compressor Off Green

Temperature Green Green

Flow Off Green

Normal Level Green Green

Low Level Off Off

Remote RTD

(Optional)

Green

(if used)

Start

Condition

Green

(if used)

3.2 Setpoint Verification

Verify that the manual mode

setpoint value (SV1) displayed on

the temperature control is the value

desired. To change the Setpoint

value see Changing the Setpoint

Value (SV1) Section 6.3 on page

22.

Do not to exceed the normal

operating parameters. The system

is designed to operate from -40 °C

to +80 °C.

TCU 40/80 Temperature Control Unit 5

TCU 40/80 Temperature Control Unit 6

4. Product Description

4.1 Refrigeration and Coolant Circuits

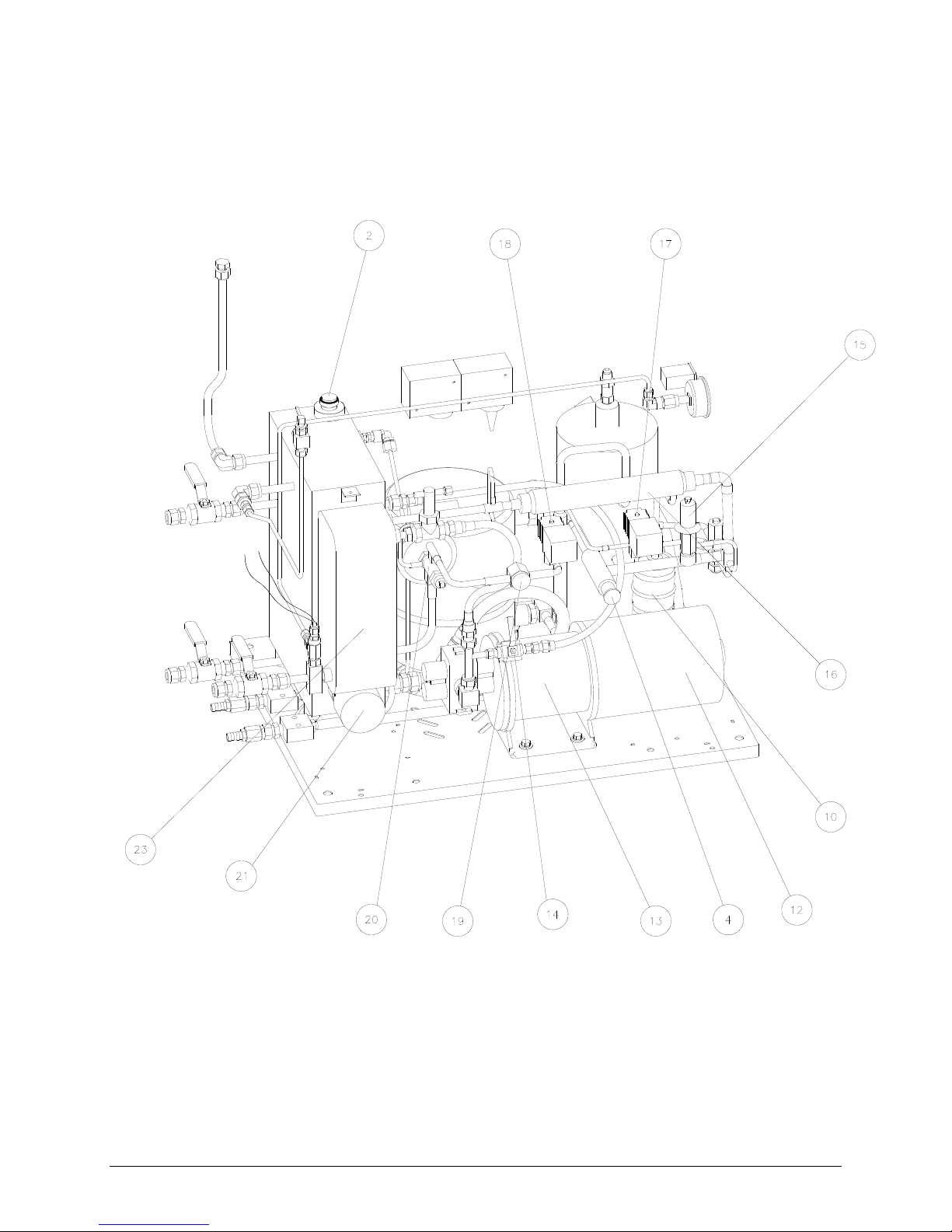

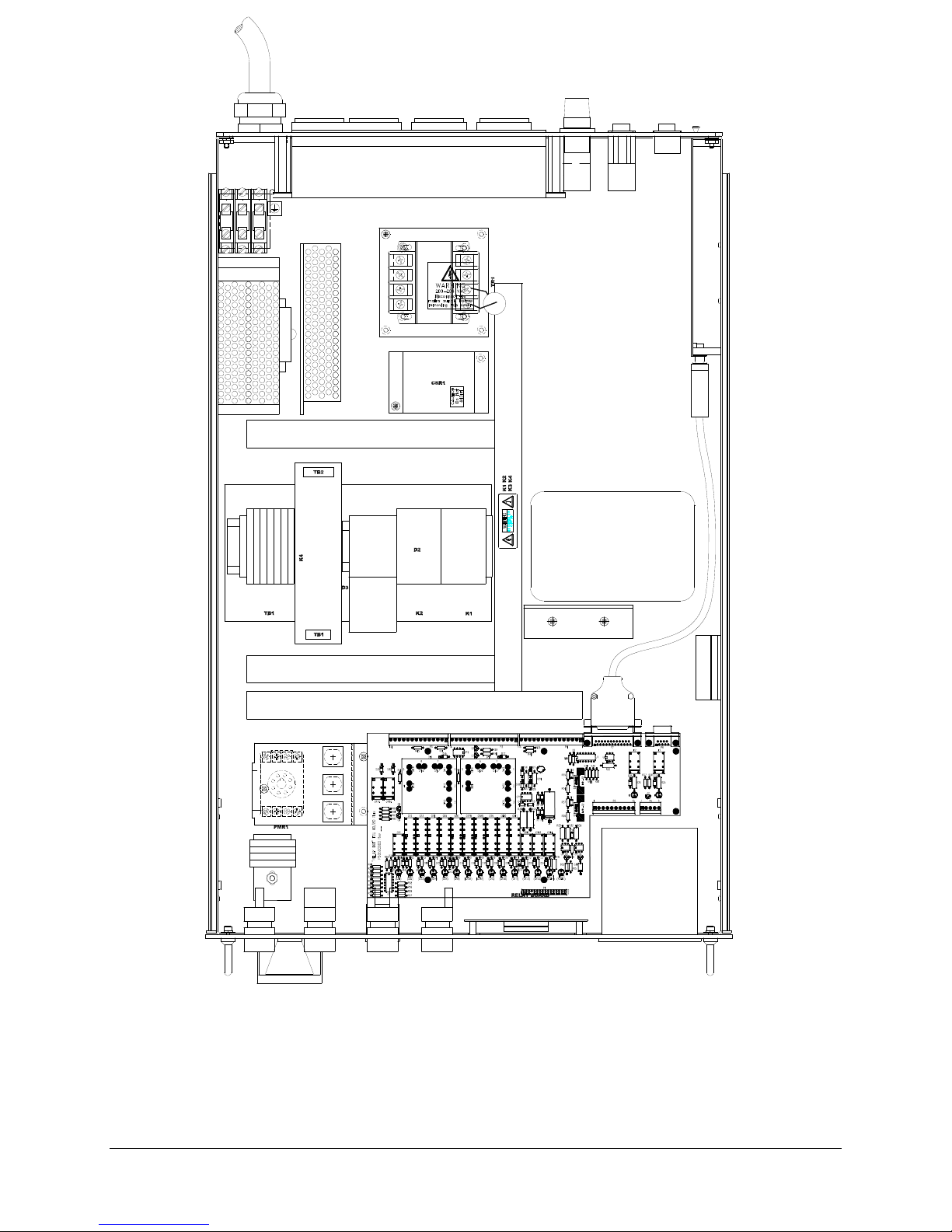

Figure 1, Figure 2, and Table 3 on page 80 describe the refrigeration and coolant components of the TCU

40/80 plus.

(G:\Technical Documents\MANUALS\W95900011- All)

6 TCU 40/80 plus Temperature Control Unit

Figure 1- Refrigeration and Coolant Components

Figure 2 - Refrigeration and Coolant Components

(G:\Technical Documents\MANUALS\W95900011- All)

TCU 40/80 Temperature Control Unit 7

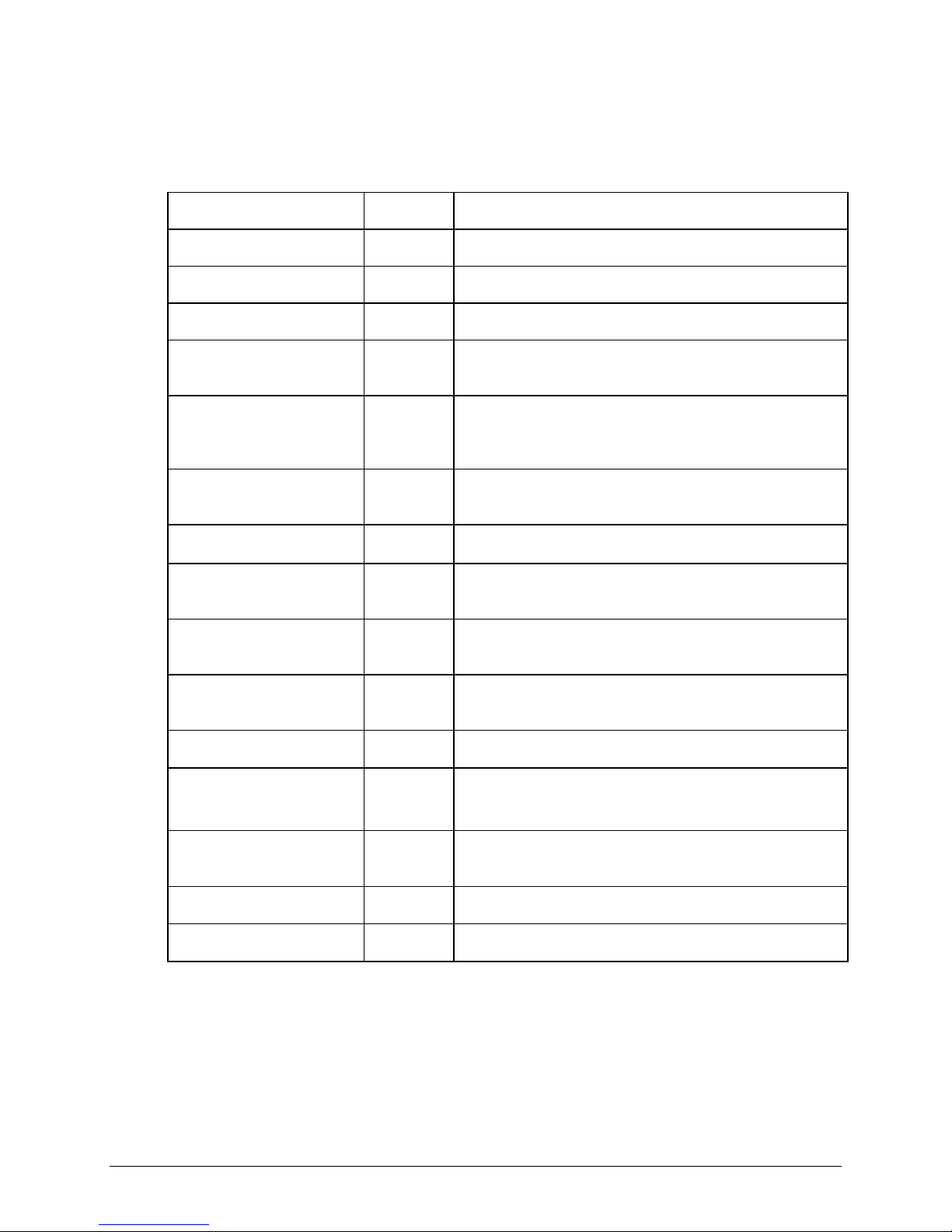

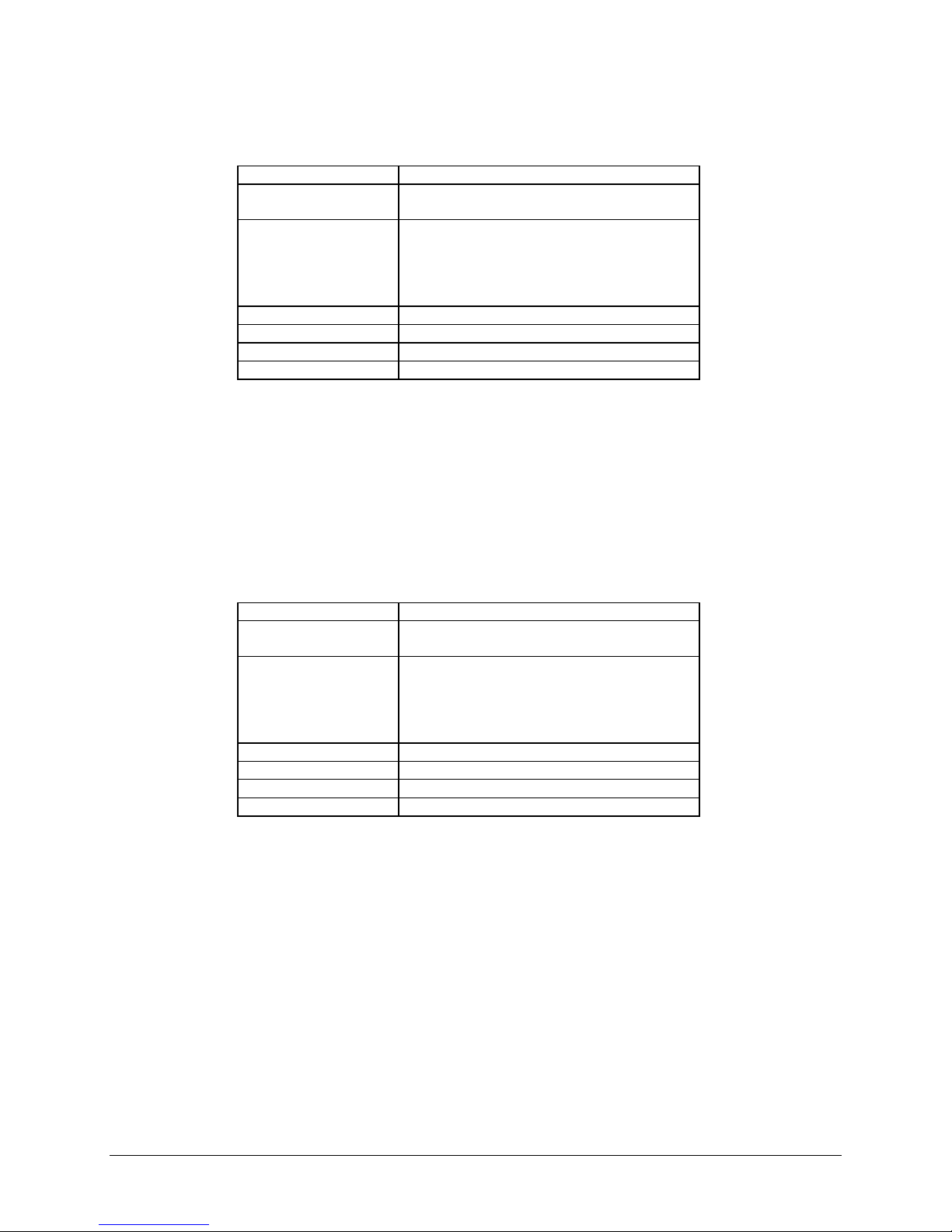

Table 3 - Refrigeration and Coolant Components

Item Component Name Function

1 Reservoir A holding tank for the Fluorinert coolant.

2 Level Switch Monitors the coolant level in the reservoir.

3 Compressor Compresses the refrigerant fluid.

4 Crankcase Regulator Protects the compressor against pressure overload.

5 Suction Service Valve Allows isolation at the compressor.

6 Discharge Service Valve Allows isolation at the compressor.

7 Temperature Switch High limit switch for reservoir heater.

8 Pressure Switch Limits maximum allowable discharge pressure.

9 Condenser Transfers heat from the compressed refrigerant to the facility water.

10 Filter Dryer Removes contaminants and moisture from the refrigerant.

11 Safety Cooling Valve Limits the discharge temperature.

12 Motor Drives the coolant pump.

13 Pump Circulates the Fluorinert coolant.

14 Bypass Valve Regulates coolant flow.

15 Hot Gas Bypass Valve Regulates cooling capacity.

16 Subcooler Further cools the refrigerant that is returning to the compressor.

17 Solenoid Valve SV2 Allows refrigerant to pass through the hot gas bypass valve, then to

the compressor suction line when energized.

18 Solenoid Valve SV1 Allows refrigerant to pass to the TEV when energized.

19 Sight Glass Allows visual inspection of the refrigerant charge and presence of

moisture in the system.

20 TEV

Allows the refrigerant to expand from a liquid to a gas.

(Thermostatic

Expansion Valve)

21 Heater Raises the temperature of the coolant when the process requires

heating.

22 Flow Switch Monitors the flow rate.

23 Heat Exchanger Extracts heat from the coolant and transfers it to the refrigerant.

24 Pressure Relief Valve Discharges refrigerant from the system to the atmosphere in the event

of severe over-pressure condition.

8 TCU 40/80 plus Temperature Control Unit

Fill port

Vent

valve

Coolant

return

Heater

Drain valve

Coolant supply

Pressure

relief

valve

temperature

Bypass valve

Level switch

TS1

Temperature

switch

RTD

probe

Circulation

pump

Plate

heat

exchanger

FS1

TEV

bulb

Thermal

expansion

valve

Flow

switch

Subcooler

Main cooling

solenoid valve

SV1

Crankcase

pressure

regulator

Bypass

valve

Compressor

Service

valve

Hot gas

solenoid valve

SV2

Safety

cooling

TEV

Service

valve

TEV

bulb

Pressure

relief

valve

Filter

dryer

PS1

Pressure

switch

Water out

Condenser

Water in

4.2

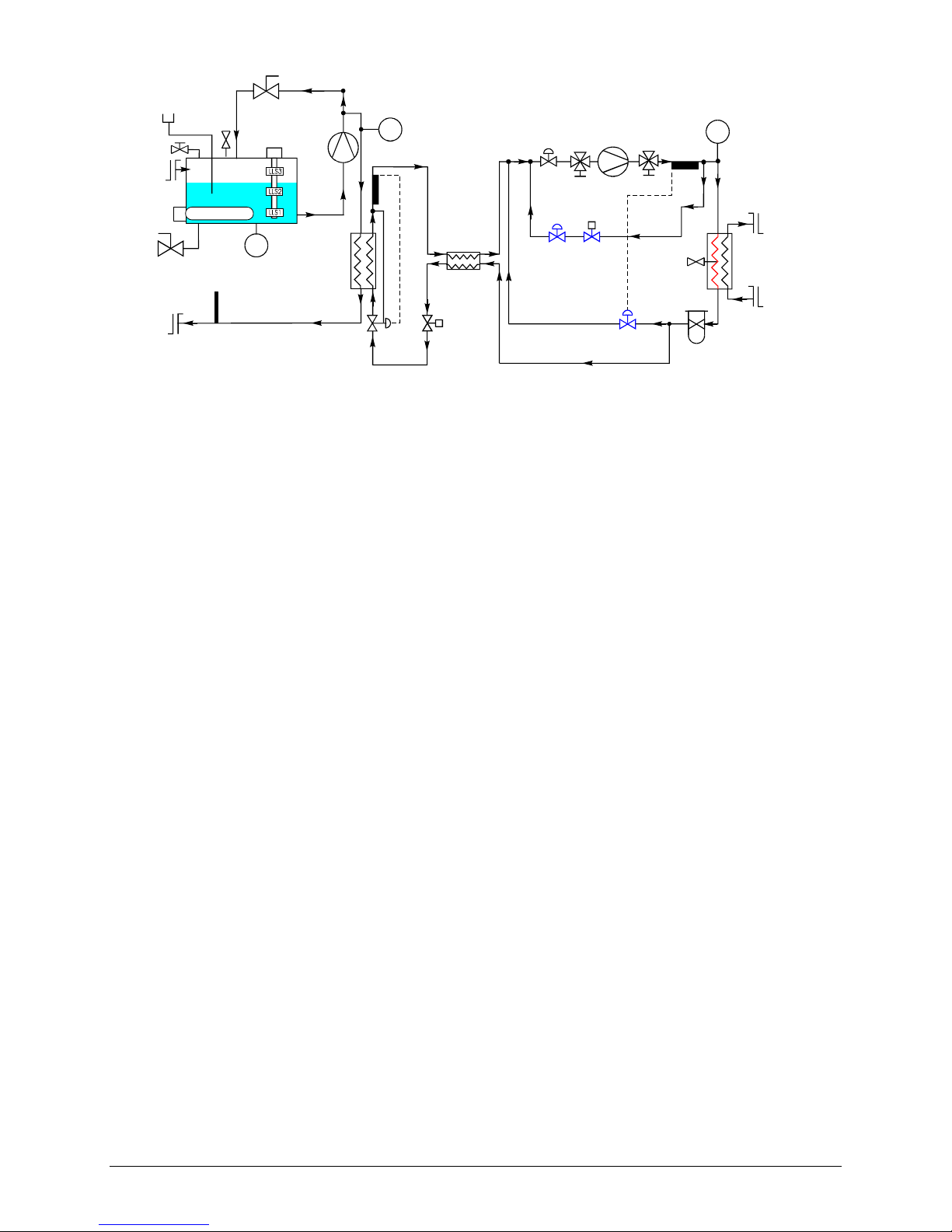

Figure 3 - Refrigeration and Coolant Circuits

(G:\Technical Documents\MANUALS\W95900011- All)

Refrigeration -

(See figure 3 above)

1. Refrigerant gas enters the compressor at low temperature and pressure. It leaves the compressor at high

pressure and temperature.

2. The gas passes into the condenser, where heat is removed by the external water supply, causing the gas

to condense into a liquid.

3. The cool liquid refrigerant exits the condenser and passes through a filter dryer that removes any

residual moisture or contaminants.

4.2.1 If Cooling Is Required:

1. Solenoid valve SV1 opens (coil energized), allowing the refrigerant to flow into the Thermostatic

Expansion Valve (TEV). The pressure drop across the TEV causes the refrigerant to change from

a liquid to a mixture of liquid and gas.

2. The liquid and gas mixture enters the heat exchanger where it becomes entirely a gas. The

process of expansion from a liquid to a gas reduces the temperature by absorbing energy.

3. The refrigerant leaving the heat exchanger returns to the compressor through the sub-cooler and a

crankcase pressure regulator. The sub-cooler further cools the refrigerant entering the TEV.

4.2.2 If Cooling Is Not Required:

1. Solenoid valve SV1 closes (coil de-energized).

2. Hot refrigerant from the compressor is passed through SV2 (coil energized) and a hot gas bypass

valve before returning to the compressor suction line. This bypassing allows the compressor to run

continuously.

3. Cooling, required to prevent the compressor from overheating, is provided by allowing some of

the liquid from the condenser to pass through the safety cooling automatic expansion valve into

the suction line, thus maintaining the discharge gas temperature below 99 °C.

TCU 40/80 Temperature Control Unit 9

4.3 Coolant Circuit

Coolant is pulled from the reservoir by the circulation pump and transferred to the heat exchanger where it

is cooled by the refrigeration system as required. It then flows to the process equipment by means of the

coolant supply hose. The coolant returns to the TCU 40/80 plus reservoir by means of the coolant return

hose. The coolant system requires 8 liters of coolant for the reservoir plus the volume of the circulation

lines and any other spaces filled with coolant that are attached to the TCU 40/80 plus. To increase the

coolant temperature, the reservoir uses an electrical resistance heater that is controlled by the temperature

controller. The heater must be fully submerged at all times, and if the coolant in the reservoir falls below

3.5 liters, a level switch causes the status alarm signal to automatically shut down the TCU 40/80 plus.

A three-float level switch, a thermostat, and a flow sensor provide coolant status signals to the TCU 40/80

plus control system.

4.4 Temperature Monitoring

A Resistance Temperature Device (RTD) monitors the temperature of the coolant leaving the TCU 40/80

plus and transmits this information to the temperature controller. The TCU 40/80 plus compares the output

of the RTD to the selected process temperature (SV1) and determines if the coolant needs to be cooled or

heated. The temperature controller then operates the main cooling solenoid valve or heater. The coolant

temperature at the supply port on the rear panel is measured by a local, internally connected RTD. If

sensing of process equipment temperature is needed, connect an RTD to J72J3 at the rear panel (See Figure

5 on page 13). For remote connection schematic details, see Figure 16 on page 56.

4.5 Front Panel

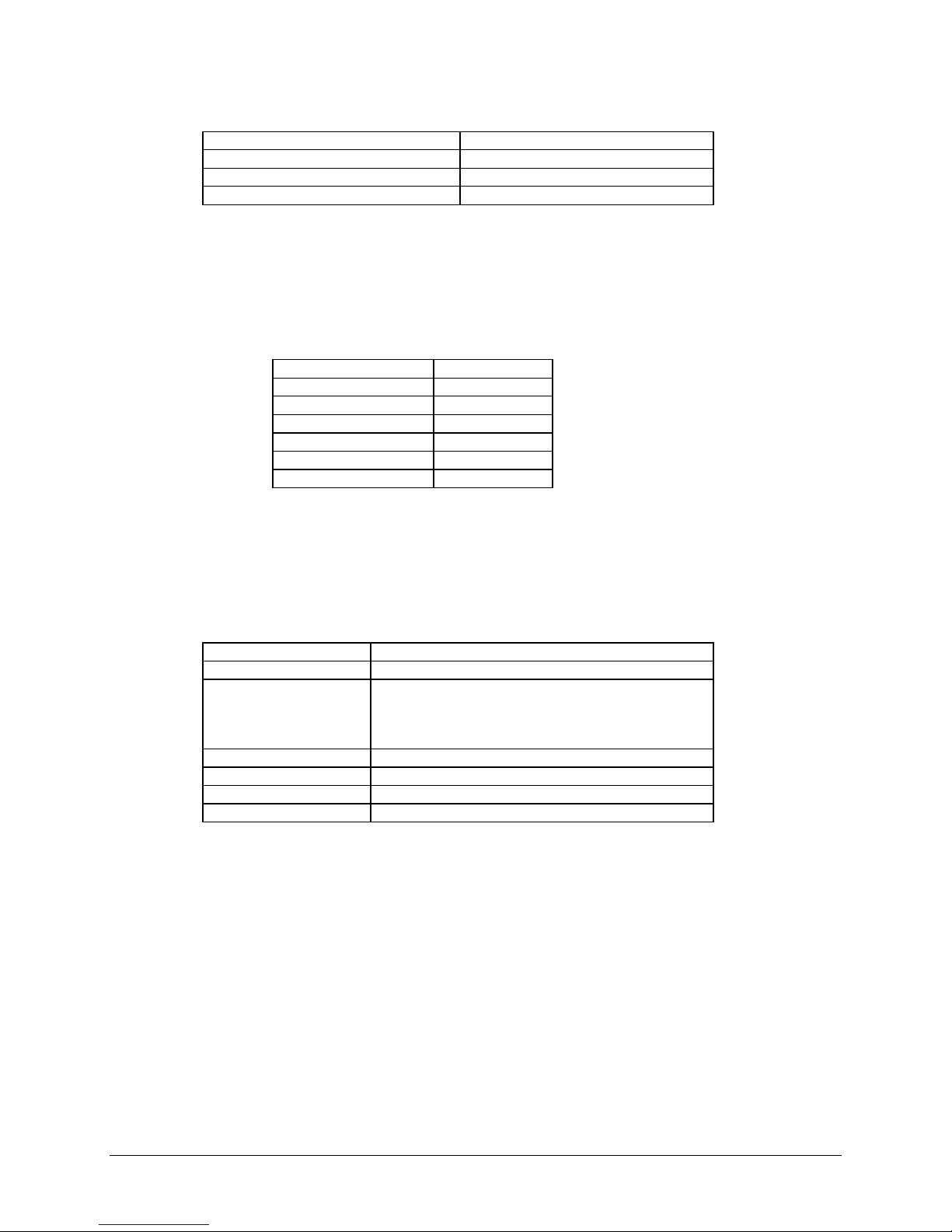

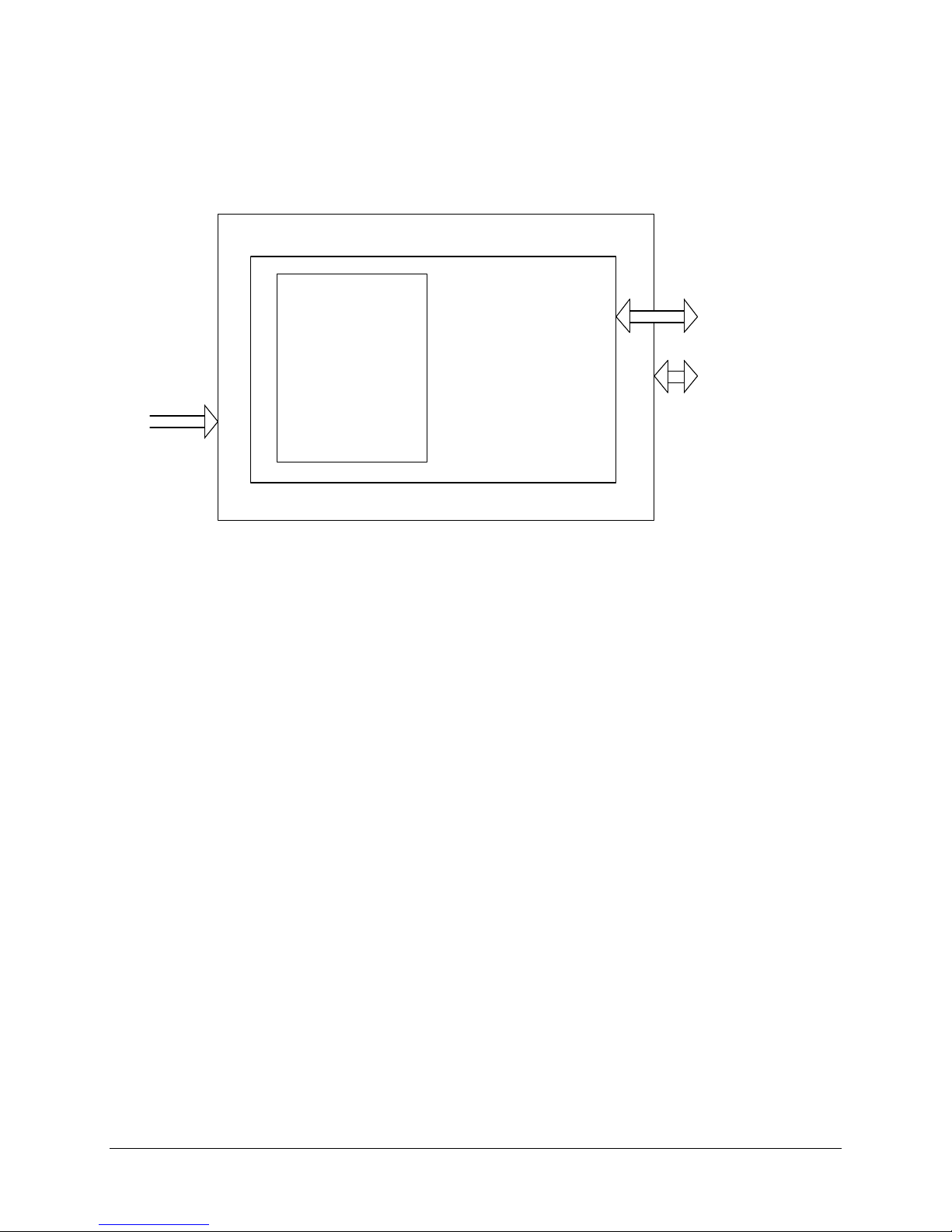

Figure 4 shows the Front Panel. Table 4, Table 5 and Table 6 identify its controls and indicators.

Figure 4 - Front Panel

(G:\Technical Documents\MANUALS\W95900011- All)

10 TCU 40/80 plus Temperature Control Unit

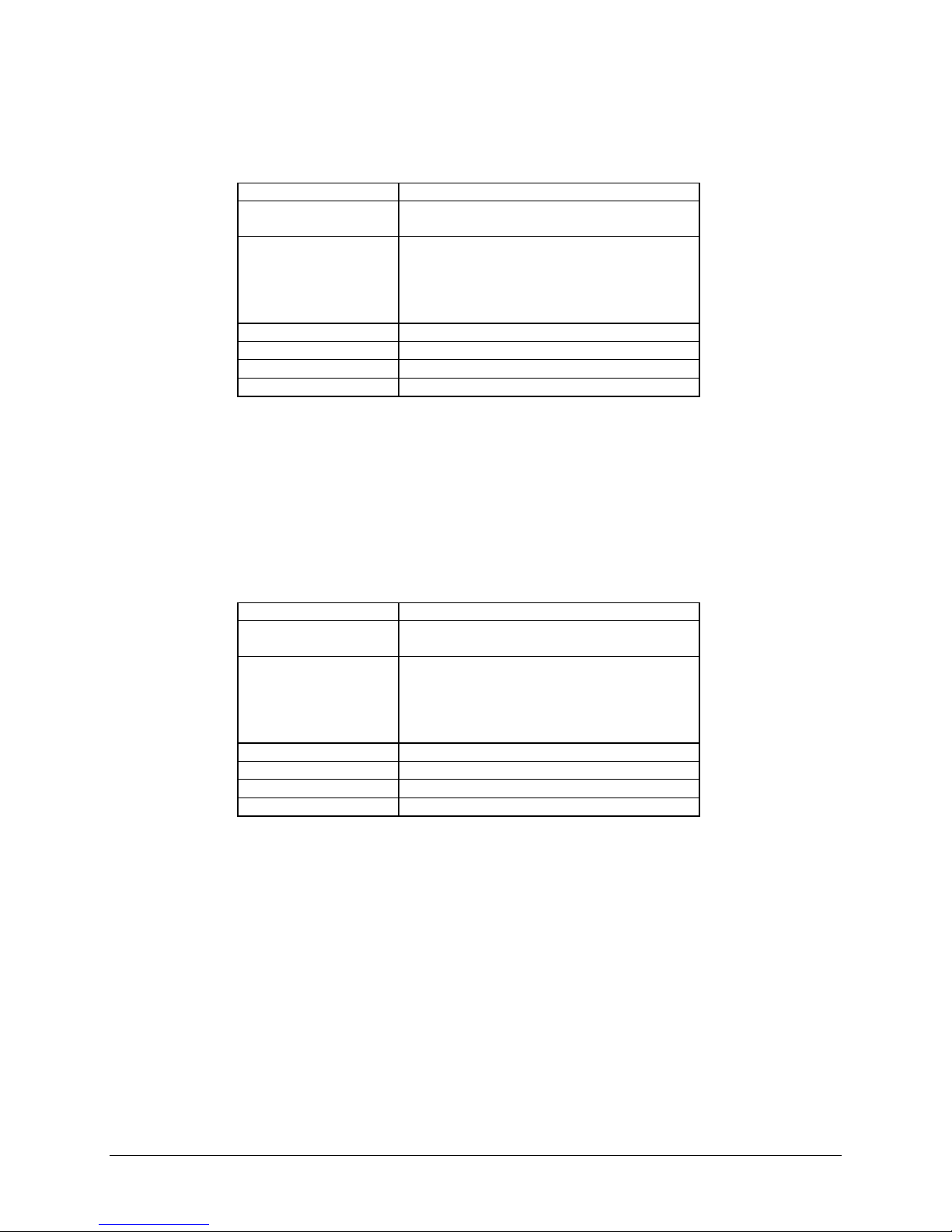

Table 4 - Front Panel Controls

Control Name Description

Power On Lights green when power is being supplied to the TCU 40/80 plus.

Reset Resets alarms and makes the TCU 40/80 plus ready to operate. The white light

indicates that the TCU 40/80 plus is ready to operate.

Emergency Off Removes power from all TCU 40/80 plus circuits except the EMERGENCY

OFF circuit. To shut off power, push EMERGENCY OFF (EMO). To reset,

rotate the EMERGENCY OFF button clockwise as shown on the switch.

Start/Stop Starts and stops the operation of the TCU 40/80 plus.

Alarm Emits a high pitched sound when there is a fault condition which has caused the

TCU 40/80 plus to stop operation.

Mute Silences the audible alarm.

Table 5 - Front Panel LED Indicators

LED Name Condition Description

Facility Power Green

Red

Facility Water

Green

Red

Circuit Breakers

Green

Red

Compressor Green

Red

Coolant Temperature Green

Red

Coolant Flow

Green

Red

Coolant Normal Level Green

Amber

Coolant Low Level Off

Amber

Red

Remote RTD

Off

Green

Power phases are normal.

Power phases are reversed or low line voltage.

Water pressure and flow are normal.

Water pressure or flow are not adequate. (See Specifications

Section 4.7 on page 14.

Rear panel circuit breakers 2, 3, and 4 are on.

One or more of these breakers is tripped or off.

Compressor is operating normally.

Compressor has stopped operating.

Coolant reservoir temperature is normal.

Coolant temperature is above the operating range.

Coolant flow is normal.

Coolant flow is not adequate.

Coolant level is normal .

Coolant level is over filled.

Coolant level is normal

Coolant level is low.

Coolant level is very low.

Remote RTD not connected.

Remote RTD temperature probe is in use.

Table 6 - Temperature Controller

Controls and

Description

Indicators

Process Value (PV) The present temperature of the coolant, as indicated by the internal RTD or the

remote RTD.

Setpoint Value (SP) The TCU 40/80 plus regulates to this temperature, as set by the operator.

Pushbuttons Used to program the controller.

Remote Mode Led

(AUX)

Indicates mode of operation:

Off indicates local operation.

On indicates remote operation.

TCU 40/80 Temperature Control Unit 11

4.6 Rear Panel **

Figure 5 shows the rear panel. Table 7 identifies the controls and indicators on the rear panel.

Figure 5 - Electrical Rear Panel

(G:\Technical Documents\MANUALS\W95900011- All)

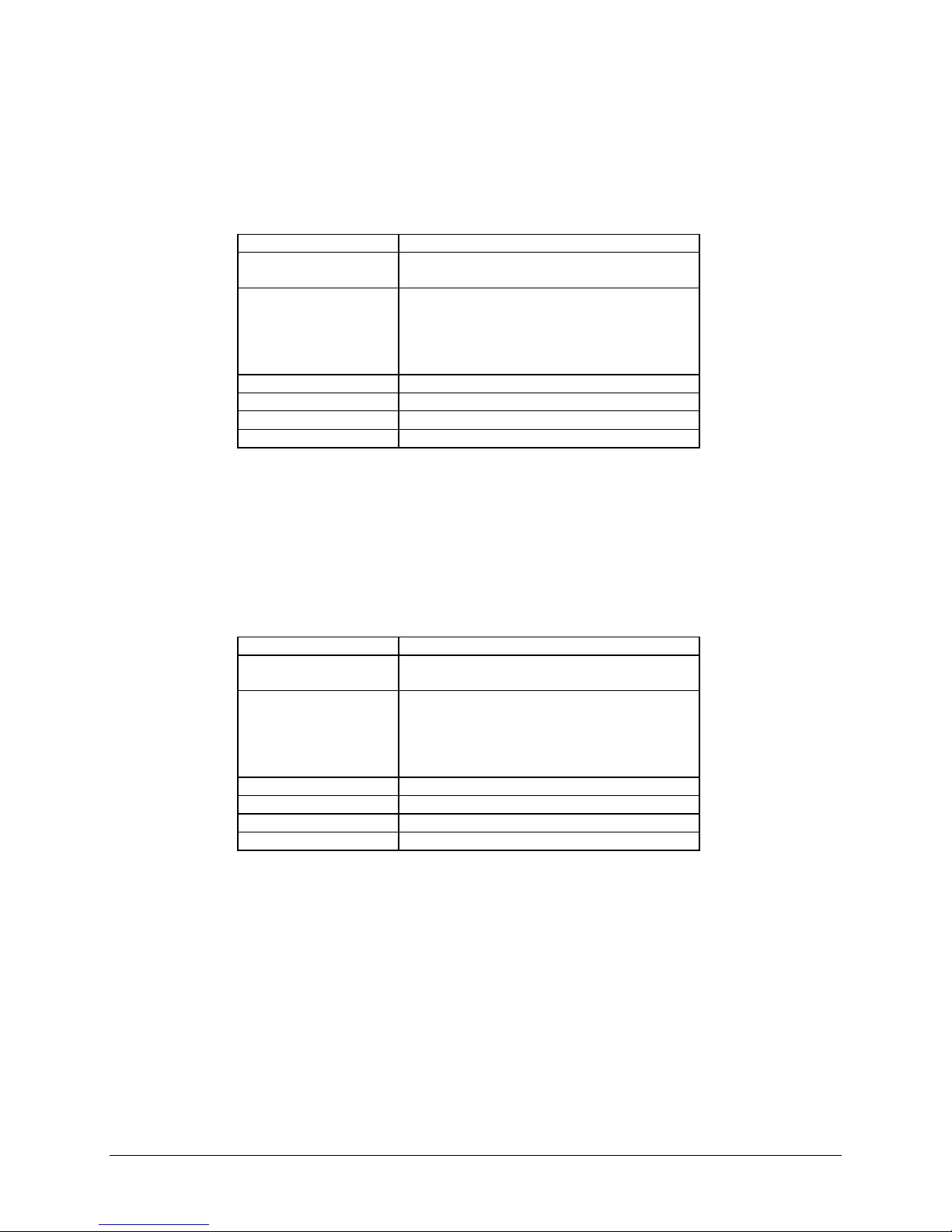

Table 7 - Description of Rear Panel Components and Indicators

Label Description

J72J3 Five-pin connector for remote RTD interface. See Figure 16 on page 56 for

pinouts.

CB7 24 VAC 1-pole, 2 Amp circuit breaker. Isolates the 24 VAC transformer. Normally on

(in).

CB8 24 VDC 1-pole, 2 Amp circuit breaker. Isolates the 24 VDC power supply output.

Normally on (in).

J72J2 Nine pin connector for remote EMERGENCY OFF, start-stop operation, and

remote setpoint operation enable. See Figure 16 on page 56 for pinouts.

CB4 Reservoir Heater 3-pole, 10 Amp circuit breaker. Normally on (up).

CB3 Circulation Pump 3-pole, 6 Amp circuit breaker. Normally on (up).

CB2 Compressor 3-pole, 16 Amp circuit breaker. Normally on (up).

CB1 Main Power 3-pole, 25 Amp circuit breaker. Normally on (up).

Normal/Overfill Normal, LED Green

Overfilled, LED Amber

Low/Fault Low, LED Amber

Fault, LED Red

200/208 VAC 3 PH

Mains input power connector.

50/60 Hz 30A

CB5-XFMR 2-pole, 0.5 Amp circuit breaker. Isolates the equipment transformer.

CB6-PSU 2-pole, 0.3 Amp circuit breaker. Isolates the power supply.

J72J1 37 pin D-subminiature connector, for setpoint value signal, process value

signal, and remote fail and warning signals.

See Figure 16 on page 56 for pinouts.

** Note: If LONWORKS/RS-485/RS-232 option is chosen, see specific chapter for modified rear panel

details.

12 TCU 40/80 plus Temperature Control Unit

4.7 Specifications

Parameter Conditions Specification

Temperature Ramp Coolant Short Circuit Conditions

Cooling capacity @ process

equipment

150 watt coolant line losses;

coolant water @ 15 °C

Heating Element 2800 Watts

System Flow

Process Temperature Range

Setpoint Resolution

Temperature Regulation

Facility Water Requirements

Process Coolant @ -40 °C

Process Coolant @-20 °C to +80

+25 °C to +80 °C

+25 °C to -30 °C

°C

@20 °C, 60 psig

+10 °C (-0° +2°) to

+26 °C (+0° -2°)

Elapsed Time: <25 Minutes

Elapsed Time: <15 Minutes

750 Watts

2400 Watts

3 gpm (11.36 l pm)

-40 °C to +80 °C

± 0.1 °C

± 1.0 °C Typical

3 to 6 gpm

(11.36 to 22.71 l pm)

Power Requirements

Ambient Operating Temperature

Weight

Dimensions

Altitude

Max. Relative Humidity

Transient Over-Voltage IEC 664, Installation Category II 2.5 kV

Pollution Degree IEC 664

Sound Pressure Level At a distance of 1meter. 65dB(A)

3-Phase Delta (Balanced Load),

4 Wire (3 Phases & Earth Gnd),

200 To 208 VAC, 50/60 Hz

Up to 31 °C

Above 31 °C Derate Linearly to 50% @ 40 °C

30 Amp Outlet

+10 °C to +40 °C

416 lbs. (190kg) Dry Weight

460 lbs. (210 kg) Wet Weight

832 lbs. (308 kg) Dry Weight

Dual Stacked

920 lbs. (420 kg) Wet Weight

Dual Stacked

22" wide x 30" deep x 35" high

(56 cm x 76 cm x 89 cm)

Up to 2000 Meters

(6562 ft.)

80%

2 Π

TCU 40/80 Temperature Control Unit 13

4.8 Dimensions

30.0

[762.0]

22.0

[558.8]

BOC ED WARD S

30.0

[762.0]

35.1

[892.3]

Figure 6 - TCU 40/80 (TCU 40/80

plus

) Dimensions

G:\Technical Documents\MANUALS\W95900011- All)

2

6

5

5

8

.

8

0

2

2

.

0

0

7

0

0

.

0

3

R

0

2

0

O

.

6

0

O

7

3

4

L

0

5

F

.

1

.

1

5

M

9

3

8

O

R

F

CENTER OF GRAVITY

SINGLE

DUAL STACKED

X Y Z

11.10 16.86 17.02

11.10 16.86 33.83

1

2

Z

Y

3

Figure 7 - TCU

40/80 (TCU 40/80

plus

) Dimensions

(G:\Technical Documents\MANUALS\W95900011- All)

14 TCU 40/80 plus Temperature Control Unit

5.4.3 Water

Connections to the water supply and return are made to either ½" brass barb fittings or ½"

compression fittings.

For bare hose connections (½" nominal ID):

1. Slip the hose over the barb fitting and tighten the hose clamp.

2. Turn on the water supply and check for leaks.

For connections using hose with tube adapters or tubing (½" nominal OD):

1. Remove the adapter coupled to the hose barb.

2. Insert the tube adapter or tubing with the appropriate ferrule and compression nut.

3. Tighten the compression nut, turn on the water supply, and check for leaks.

(G:\Technical Documents\MANUALS\W95900011- All)

5.4.4 Coolant

Note: If this TCU 40/80

coolant other than Fluorinert, contact process equipment supplier for retrofit instructions.

Connections to the coolant supply and return are made on the rear panel (See Figure 9 on page

19). The maximum distance between the process equipment and the TCU 40/80 plus is 50 feet

(100 feet total hose length).

1. Attach the hoses to the supply and return compression fittings. Follow the hose manufacturer

recommendations for appropriate adapters.

2. Insulate the hoses with closed cell insulation in order to minimize heat loss.

3. Tape and glue the insulated joints to avoid condensation and icing.

5.4.5 Remote Connections

Wiring details for remote connections are shown in Figure 16 on page 56. Remote connections

should not be run near or parallel to A.C. power lines or in the vicinity of equipment that generates

large electric fields.

Figure 10 - Water Connections

plus

is being installed on process equipment that has been used with a

18 TCU 40/80 plus Temperature Control Unit

5. Installation

5.1 Receiving and Unpacking

Do a complete visual inspection of the TCU 40/80 plus for any damage. Do not use the TCU 40/80 plus

if physical damage is evident. If there is any damage, notify your supplier and the carrier in writing

within three days; state the item number of the TCU 40/80 plus together with your order number and

supplier's invoice number. Retain all packing materials for inspection.

Caution

5.2 Location

Allow a space 46" wide x 54" deep for the TCU 40/80 plus cable and coolant connections. The TCU

40/80 plus should have at least two feet of clearance at the rear and one foot along the sides of the unit.

Be sure that the mounting surface can safely support the weight of the TCU 40/80 plus (460 lbs. evenly

distributed). The center of gravity is approximately the center of the refrigeration compartment.

When using a forklift to move the TCU 40/80 plus, position the forks from the side of the unit.

When using a forklift to move or position the TCU

40/80 plus, do not install the secondary containment

receptacle until the TCU 40/80 plus is in position.

Failure to follow these instructions may lead to

damage of the secondary containment receptacle

caused by the forks of the forklift.

Warning

A 3 ft. (1m) service length of the power cable is required to fully open the electrical drawer. Therefore,

do not install the TCU 40/80 plus further than 7 feet (2.1m) from the power source.

5.2.1 Securing the Unit

The four lockable casters of the TCU 40/80 plus swivel to provide maximum maneuverability.

Make sure that all four casters are turned inward and locked in position once the TCU 40/80 plus

is situated.

5.2.2 Installing the Secondary Containment Receptacle

The secondary containment receptacle slides into the base from the rear of the unit.

5.2.3 Floor Levelers

An optional floor leveler kit is available to compensate for uneven surfaces. See Table 15 on page

57 for ordering information.

The TCU 40/80 plus weighs 460 pounds (210 kg).

Failure to take proper care in moving or lifting these

units can result in serious bodily injury.

TCU 40/80 Temperature Control Unit 15

5.3 Stacking

The TCU 40/80 plus may be stacked two high. Be sure that the mounting surface can safely support the

weight of the two units (920 lbs., 420 kg). Be sure that the casters of the top unit are turned inwards,

but are not locked, until the top unit is fully seated.

5.3.1 Tie-Bolts

An optional tie-bolt kit is available for attaching stacked units. See Table 15 on page57 for

ordering information.

30.0

[762 .0 ]

41.0

[1041.1]

5.4 Facilities

The TCU 40/80 plus requires a water supply flow rate between 3 to 6 gallons per minute at a maximum

pressure of 100 psig, and an inlet temperature range of 10 °C to 26 °C. Power input is by a fused,

suitable isolating electrical outlet, 208 VAC, 50/60 Hz, 30 amp, 3-phase delta (balanced load), 3-wire

and earth. The required receptacle type is Hubbell P/N L21-30R2810-A, or equivalent.

5.4.1 50 Hz Installations

5.4.2 Water and Coolant Connections

Figure 8 - Stacked TCU 40/80 (TCU 40/80 plus) systems

(G:\Technical Documents\MANUALS\W95900011- All)

For 50 Hz installations, adjust the Phase Monitor Relay (PMR1). Open the electrical drawer by

loosening the two screws at the front. Locate PMR1 (reference Figure 13). Remove the

“CAUTION” label, and turn the dial to align with the “50” mark. Replace the “CAUTION” label

and close the drawer.

Figure 9 shows a rear view of the TCU 40/80 plus with its water and coolant connections.

16 TCU 40/80 plus Temperature Control Unit

(G:\Technical Documents\MANUALS\W95900011- All)

TCU 40/80 Temperature Control Unit 17

Figure 9 - System Rear View

5.4.3 Water

Connections to the water supply and return are made to either ½" brass barb fittings or ½"

compression fittings.

For bare hose connections (½" nominal ID):

1. Slip the hose over the barb fitting and tighten the hose clamp.

2. Turn on the water supply and check for leaks.

For connections using hose with tube adapters or tubing (½" nominal OD):

1. Remove the adapter coupled to the hose barb.

2. Insert the tube adapter or tubing with the appropriate ferrule and compression nut.

3. Tighten the compression nut, turn on the water supply, and check for leaks.

(G:\Technical Documents\MANUALS\W95900011- All)

5.4.4 Coolant

Note: If this TCU 40/80

coolant other than Fluorinert, contact process equipment supplier for retrofit instructions.

Connections to the coolant supply and return are made on the rear panel (See Figure 9 on page

19). The maximum distance between the process equipment and the TCU 40/80 plus is 50 feet

(100 feet total hose length).

1. Attach the hoses to the supply and return compression fittings. Follow the hose manufacturer

recommendations for appropriate adapters.

2. Insulate the hoses with closed cell insulation in order to minimize heat loss.

3. Tape and glue the insulated joints to avoid condensation and icing.

5.4.5 Remote Connections

Wiring details for remote connections are shown in Figure 16 on page 56. Remote connections

should not be run near or parallel to A.C. power lines or in the vicinity of equipment that generates

large electric fields.

Figure 10 - Water Connections

plus

is being installed on process equipment that has been used with a

18 TCU 40/80 plus Temperature Control Unit

6. Operation

6.1 Preparation

Verify that water and coolant connections are made at both ends that the drain valve is closed and the

coolant supply and return valves are open. Connect the remote interfaces if required.

1. To use an external RTD probe, attach it to connector J72J3. Refer to Figure 16 on page 60. Verify

that the plug J72J2 is installed.

2. Press the EMERGENCY OFF button on the front panel.

3. Plug the TCU 40/80 plus power cord into a fused, switchable, 30 amp, 3-phase, 208 VAC outlet.

4. Ensure that all circuit breakers on the rear panel are in the ON position. CB7 and CB8 are non switchable circuit breakers and will trip when there is a problem. They cannot be turned on or off,

but they are re-settable.

6.2 Powering up the TCU 40/80 plus

1. Verify that the POWER ON lamp on the front panel is illuminated.

2. Release the EMERGENCY OFF button.

Caution

3. Press the RESET button and verify the front panel indicators are as in the Reset Condition

column of Table .

Remote RTD (If Used) Green Green

4. Press MUTE to silence the alarm.

The TCU 40/80 plus is shipped without coolant. The coolant level alarm will sound and the front

panel Reservoir Coolant Low Level LED will be red indicating that the reservoir must be filled.

5. Fill the coolant reservoir using the procedure Filling the Reservoir on page 31.

6. Press the START button and verify the front panel indicators are as in the Start Condition column

of Table 8.

7. Use a halogen leak detector to check all supply and return line connections at both the TCU and

process equipment, around the pump head assembly, drain valve, heater, flow switch, vent line,

fill line, and reservoir pressure relief valve.

If the Facility Power LED

illuminates, the line voltage is low, or

the phase of the main power supply

is reversed.

Table 8 - Front Panel Power Up Indicator Conditions

Indicator Reset Condition Start Condition

Power On Green Green

Reset Off White

Facility Power Off Green

Facility Water Green Green

Circuit Breakers Green Green

Compressor Off Green

Temperature Green Green

Flow Off Green

Normal Level Off Green

Low Level Red Off

Adjust the line voltage, if it is low.

Correct the phases by swapping two

phases in the electrical outlet.

TCU 40/80 Temperature Control Unit 19

6.3 Changing the Setpoint Value (SV1)

The following instructions are for local temperature control only.

Caution

To change the temperature settings press page up or page down to either increase or decrease the

temperature. The red display “PV” indicates the process value. The green display “SP” indicates the current

setpoint.

Note: The temperature controller has been programmed to prevent the setpoint from exceeding the normal

operating range of the TCU 40/80

PID and other settings. Contact the process equipment supplier for access to these settings and other

information.

plus

Do not exceed the temperature

range of -40 °C to +80 °C.

This is the normal operating

range of the TCU 40/80 plus.

. The controller is also protected from unauthorized changes to the

PV

OUT 1

OUT 2

SP

OUT 3

OUT 4

AUXRESET

Figure 11 - Temperature Controller

(G:\Technical Documents\MANUALS\W95900011- All)

6.4 Temperature Controller PID Settings

BOC Edwards default settings are:

PID1 - Heating Value PID2 - Cooling Value Parameter

Pb1 14.0 Pb2 18.0 Proportional Band

Ar1 1.0 Ar2 4.5 Automatic Reset

rAt1 3.0 rAt2 4.0 Rate

db1 1.0 db2 1.0 Deadband

6.5 Remote Set-Point

To use the remote set point, wire the J72J2 mating connector as illustrated on page 56.

24vac must be applied to pins 3 and 4.

The AUX LED on the temperature controller will illuminate indicating remote setpoint enable mode as

soon as the mating connector is installed.

F

C

AUX

PAGE PAGE

20 TCU 40/80 plus Temperature Control Unit

6.6 Flow Rate Adjustment

Caution

The Fluorinert flow rate of the TCU 40/80 plus is factory set to provide approximately 3 gpm at

60 psig/20°C for a unit operating at 208vac/3-ph/60Hz. If the flow rate requires adjustment to

accommodate the process equipment suppliers’ recommendations, follow the steps below. The flow rate

may be measured using a flow meter external to the TCU 40/80 plus.

1. Open the left side access door.

2. Peel back the insulation covering the by-pass valve. Refer to Figure 1 on page 7.

3. The valve handle can be found in the plastic bag secured to the pump. Reduce the flow by turning the

valve stem clockwise. To increase the flow, turn the stem counter clockwise. The valve is a 1/4 turn

valve.

4. Once the required flow rate has been achieved, return the valve handle to the bag for future use, glue

the insulation back in place, and secure the access door.

Do not exceed coolant pressure of

100 psi.

Exceeding the coolant pressure

may result in damage to the

pump.

TCU 40/80 Temperature Control Unit 21

22 TCU 40/80 plus Temperature Control Unit

7. Maintenance

This section contains information that will allow you to safely keep your TCU 40/80 plus in working order.

It contains important Hazard Warnings, and a Preventive Maintenance Schedule on page 28.

7.1 Hazard Warnings

Warning

Warning

High Pressure

Maintenance to the electrical

system of the TCU40/80 should

be performed by qualified

personnel only.

The refrigeration units are sealed

and are not user serviceable.

Only trained and licensed

refrigeration personnel should

perform repairs on this

equipment.

All applicable EPA regulations

apply.

Water and the coolant are

pressurized within this equipment.

Water pressure will depend upon

utility supply, but usually is up to

60 psig. The coolant can be at

pressures up to 100 psig.

Refrigerant pressures can be up to

300 psig.

Do not open lines with pressure

present.

Toxic Gases

High Pressure

The coolant breaks down above

215 °C. If the coolant is allowed

to reach these temperatures; toxic

gasses may be discharged from

the unit.

Refer to the Appendix for

Material Safety Data Sheets for

the coolant and refrigerant used in

this system.

The reservoir may become

pressurized due to changes in

temperature.

Under no circumstances should

the reservoir pressure relief valve

be removed or capped off.

22 TCU 40/80 plus Temperature Control Unit

High

The refrigerant lines are at high

pressure.

Pressure

Under no circumstances should

Eye

Protection

Hand

Protection

the refrigerant pressure relief

valve be removed or capped off.

Leakage or failure of highpressure circuits may cause injury

or irritation of the eyes.

Eye protection should be worn

when working with fluid systems.

Hot or cold fluids and surfaces

can cause injury or irritation of

the hands.

Hand protection should be worn

when working with these fluid

systems.

Electric

Shock

Hot Surface

Ensure that all electrical power

has been removed and the main

circuit breaker has been turned off

prior to opening the electrical

drawer. The EMERGENCY OFF

circuit (EMO) does not

disconnect all power from the

electrical drawer.

Extreme caution must be

observed if performing

maintenance operations with the

drawer open.

Refrigeration and circulating fluid

lines can attain temperatures as

high as 110 °C.

Caution must be observed.

TCU 40/80 Temperature Control Unit 23

7.2 Hazards

Table 9 gives the classifications of electrical hazards. This number indicates the severity of the

hazard as defined by SEMI S2-93.

Table 9 - Electrical Hazards Classifications

Classification Description Comment

Type 1 Equipment is fully de-energized. None called out.

Type 2 Equipment is energized. Live circuits are covered or

insulated. Work is performed at a remote location to preclude

accidental shock.

Type 3 Equipment is energized. Live circuits are exposed and

accidental contact is possible. Potential exposures are less

than 30 volts RMS, 42.2 volts peak, 240 volt-amps, 20

Joules.

(See NFPA 79-14.3, IEC 204, UL 1950 & 1262, IEC 950.)

Type 4 Equipment is energized. Live circuits are exposed and

accidental contact is possible. Potential exposures are greater

than 30 volts RMS; 42.2 volts peak, 240 volt-amps, 20 Joules

or radio frequency (RF) is present.

Type 5 Equipment is energized and measurements and adjustments

require physical entry into the equipment, or equipment

configuration will not allow the use of clamp-on probes.

Called out as Type 2.

Called out as Type 3.

Called out as Type 4.

None called out.

7.3 Filling the Reservoir

Warning

When retrofitting a TCU 40/80

plus in place of a water/glycol

unit, the coolant lines must be

1. Open the vent port valve (See Figure 9 on page 19) to avoid air locks that may slow filling.

2. Remove the plug and fasten the funnel accessory to the ½" fill port located at the rear of the unit (See

Figure 9 on page 19).

3. Fill the reservoir with Fluorinert heat transfer fluid. The amount needed for a new installation is

approximately 44 pounds for the TCU and an additional amount for process lines (approximately 0.15

pounds/ft of 1/2” tube) and other external volumes.

4. Begin filling the reservoir until the Coolant Normal Level LED on the rear electrical panel turns green.

When the LED turns green, add approximately 4 liters more of fluid (approximately 17 pounds).

5. If this is a new installation, the lines to the tool are empty. If possible, start the TCU. The coolant will

leave the TCU to fill the lines and the level in the TCU reservoir will decrease. Observe the TCU to

determine if the Coolant Low Level LED on the rear panel turns amber. If so, add approximately 4

liters more fluid (approximately 17 pounds).

6. In the event of over-filling, the Coolant Normal LED will change from green to amber. Drain excess

fluid until the Coolant Normal Level LED turns green. Refer to Draining/Bleeding the Coolant

Reservoir, below.

flushed with nitrogen to remove

moisture prior to installation.

24 TCU 40/80 plus Temperature Control Unit

7.4 Draining/Bleeding the Coolant Reservoir

It may be necessary to drain the coolant reservoir for storage of the TCU 40/80 plus or due to

moisture contamination of the coolant.

It may be necessary to bleed the coolant reservoir to correct an overfill condition.

Note: The unit may continue running during this procedure.

Follow the procedure below whenever it becomes necessary to drain or bleed the system.

Extreme

Temperature

Hot or cold coolant may reach 40°C to +80°C during operation.

Hot or cold fluid can cause

burns.

1. Open the vent valve located at the top of the unit.

2. Place an appropriate container beneath the drain valve. The capacity of the container used

needs to be 10 liters plus the volume of the hoses and the volume of the process equipment.

3. Remove the cap fitting from the end of the drain valve.

4. Open the reservoir drain valve.

5. To correct an overfill condition,

a. Drain the reservoir until the Coolant Level Normal LED on the rear electrical panel turns

green. Close the reservoir drain and vent valves when the LED turns green.

b. To empty the reservoir, remove power to the TCU and allow the unit to drain until all

coolant has been removed.

6. Close the reservoir drain and vent valves.

7. For proper disposal of the coolant, follow the manufacturer recommendations.

Note: Uncontaminated Fluorinert may be reused. The Fluorinert should be stored in a compatible

and sealed container.

Coolant should be at ambient

temperature before handling.

7.5 Temperature Probe Calibration

The BOC Edwards Temperature Controller comes equipped with a factory calibrated internal ±10V

remote input/output option making calibration unnecessary.

7.6 Preventive Maintenance Schedule

Table 10 shows the maintenance required to keep the TCU 40/80 plus in good working order.

Failure to follow this schedule may result in degradation of system performance.

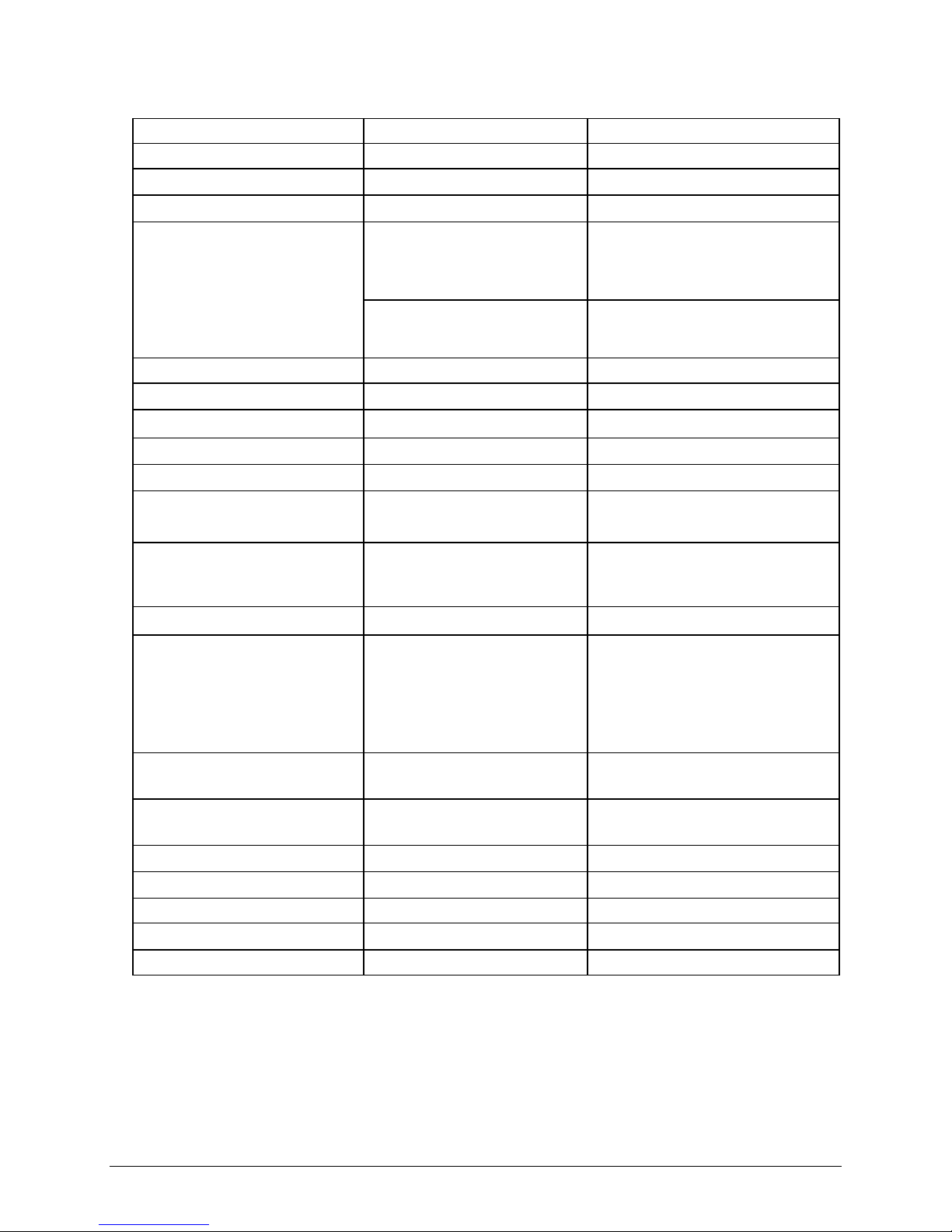

Table 10 - Preventive Maintenance Schedule

Frequency Operation Hazard

Verify system status

Check coolant level

Check lamps (Type 3)

Semi-annually Coolant leak check (Type 3)

Refrigeration leak check (Type 3)

Insulation repair (Type 3)

Water leak check (Type 3)

Replace solenoid coils SV1 and SV2 (Type 3)

Annually System check (Type 3)

Lamp replacement (Type 3)

Note: All maintenance should be recorded on the Preventative Maintenance Record label located

on the inside of the left-hand side access panel.

TCU 40/80 Temperature Control Unit 25

7.7 Semi-Annual Preventative Maintenance

Refer to the Troubleshooting section 8 on page43 when results for any of the following

checkpoints are not as expected.

7.7.1 Required Equipment

· 12” slotted screwdriver · Spare lamps (24 vac / 60 mA)

· 4” slotted screwdriver · Fluorinert

· Two 10” adjustable wrenches · Insulation Tape

· Halogen leak detector

7.7.2 Preparation

· Locate the two screws securing each of the side access panels and loosen to open doors.

· Listen for excessive or questionable noise or sounds coming from the pump assembly,

motor, compressor, or solenoid valves (SV1 and SV2).

7.7.3 Verify System Status

· Verify system status led indicators on the front electrical panel.

(See Table 8 on page 21.)

7.7.4 Refrigeration Leak Check

· Visually check for signs of compressor oil on the base, insulation, and on all refrigeration

Tube assembly.

· Using a halogen leak detector check around the discharge and suction service valves of

the compressor, and all accessible refrigeration tube assembly.

7.7.5 Fluorinert Leak Check

· Use a halogen leak detector to check all supply and return line connections at both the

TCU and process equipment, around the pump head assembly, drain valve, heater, flow

switch, vent line, fill line, and reservoir pressure relief valve.

7.7.6 Water Leak Check

· Visually check for signs of water leaks at all water line connections external to the TCU

and at the condenser connections inside the unit.

7.7.7 Insulation Repair

Note: If ice formation is excessive, it may be necessary to correct this condition before

insulation can be repaired.

· Visually inspect refrigeration and process fluid lines both inside the TCU cabinet and at

the supply and return line connections for signs of ice formation. Correct insulation as

necessary.

26 TCU 40/80 plus Temperature Control Unit

7.7.8 Lamp Check/Replacement

Electric

Shock

Caution

Visually verify that the POWER ON and RESET lamps are working. If either lamp needs

replacement and the proper authorization has been obtained:

1. Press STOP.

2. Turn off the main circuit breaker (CB1).

3. Disconnect power cord from mains power supply.

4. Locate the two securing screws on the front electrical panel and loosen. Open the electrical

drawer.

5. If replacing the POWER ON lamp, locate contactor block (LP1) on the backside of the front

electrical panel. If replacing the RESET lamp, locate contactor block (PB1) on the backside of

the front electrical panel.

6. Pry up the metal retaining ring attached to the coupling plate. Remove the contact block

assembly.

7. Replace the defective lamp.

8. Reinstall the contact block assembly by snapping it back onto the front element.

9. Close the electrical drawer and tighten securing screws.

10. Reconnect main power and turn on the main circuit breaker (CB1). The POWER ON lamp

should be illuminated.

11. Press RESET. The lamp should illuminate. Press START to reactivate the TCU.

Ensure all electrical power has

been removed and the main

circuit breaker has been turned

off due to the presence of high

voltage or current.

Should a lamp require

replacement, notify the

appropriate personnel that an

EMO condition will occur.

Failure to follow these

instructions may result in the

shutdown of the process tool

and associated equipment.

(G:\Technical Documents\MANUALS\W95900011- All)

TCU 40/80 Temperature Control Unit 27

Figure 12 - Lamp Replacement

7.8 Annual Preventative Maintenance

Refer to the Troubleshooting section 8 on page47 when results for any of the following checkpoints are not

as expected.

7.8.1 Required Equipment

· 12” slotted screwdriver · Miniature diagonal cutters

· 4” slotted screwdriver · Halogen leak detector

· 7” slotted screwdriver · 3\8” open-ended wrench

· 8” Phillips screwdriver · 1\4” open-ended wrench

· Two 10” adjustable wrenches · Wire crimpers - Insulated terminal

· Wire strippers (14 AWG) · Digital multimeter (DMM)

· Two test clips w/12” leads · Remote RTD connector plug (J72J3)

7.8.2 Required Supplies

· Preventative Maintenance Kit (P60153005)

· Fluorinert

· Insulation Tape

7.8.3 Solenoid Valve Coil Replacement

Electric

Shock

Caution

1. Press STOP. Turn off the main circuit breaker (CB1).

2. Disconnect the power cord from the mains power supply.

3. Locate the main cooling solenoid valve (SV1) from the left side access door.

4. Remove the junction box attachment screw. Slide off the junction box cover.

5. Back off the strain relief-retaining nut.

6. Unfasten the ground screw. Cut off the wire butt splices (ensuring that the wire labels remain

attached to the base assembly) and pull the wires through the junction box.

7. Remove the solenoid valve coil lock nut. Lift off the spacer cup. Separate the coil from the

solenoid valve body by gently pulling up on the coil.

8. Remove replacement solenoid valve coil from packaging.

9. Remove the junction box.

10. Note the location of the conduit hole on the coil removed and remove the appropriate “knock-

out” on the replacement coil.

11. Gently slip the replacement coil onto enclosing tube of solenoid valve body.

12. Pull the base assembly wiring through conduit hole and slip on the strain relief-retaining nut.

13. Attach the ground wire to coil.

Ensure all electrical power has

been removed and the main

circuit breaker has been turned

off due to the presence of high

voltage or current.

Should a solenoid valve coil

require replacement, notify the

appropriate personnel that an

EMO condition will occur.

Failure to follow these

instructions may result in the

shutdown of the process tool and

associated equipment.

28 TCU 40/80 plus Temperature Control Unit

14. Strip the ends of all wires on base assembly and solenoid valve coils.

15. Attach wires and secure mating connections per figure 13 below.

16. Tighten the strain relief-retaining nut.

17. Install the original junction box cover and fasten attachment screw.

18. Install the spacer cup.

19. Install and tighten the lock nut.

20. Verify the coil junction box is labeled SV1.

21. Repeat the procedure for Hot Gas Bypass solenoid valve coil (SV2).

22. Discard the old solenoid coils.

23. Perform the System Check procedure.

RED WIRE

WHITE WIRE

Junction Box Cover

P43018200

P43018300

Ground Screw

Retaining Nut

Lock Nut

Spacer Cup

(G:\Technical Documents\MANUALS\W95900011- All)

TCU 40/80 Temperature Control Unit 29

Figure 13 - Solenoid Coil Replacement

7.8.4 System Check

Component Settings

Motor Overload Setting (K3) 3.5 amps

Current Sensing Relay Setting (CSR) 25 amps

Thermostat Setting (TS1) 210°F (Differential set at 10°F)

High Pressure Switch Setting (PS1) 300 psig. (Differential set at 40 psig)

Power-Up Conditions

· Power cord connected to mains power supply.

· All circuit breakers on.

· EMO released.

· Drawer interlock switch in maintenance position.

· Host connector J72J2 installed (Pins 5 & 6 shorted).

Indicator Condition

Relays All off

LED All off

Power On

Reset Off

PMR Green

Current Sensing Relay Off

Note: REMOTE RTD is optional. LED will be green if used.

Reset Button

1. Press RESET.

2. Verify contactor K1 engages.

3. Verify LED indicator on PMR is green.

Indicator Condition

Relays CR1, CR4, & CR12 on all others off

LED Facility Water, Circuit Breakers, Coolant

Temperature, Coolant Normal Level, Green

Facility Power, Compressor, Coolant Flow, Coolant

Low Level, Remote RTD, Off

Power On

Reset On

PMR Green

Current Sensing Relay Off

Note: REMOTE RTD is optional. LED will be green if used.

30 TCU 40/80 plus Temperature Control Unit

Temperature Controller

1. All control parameters and selections procedures for the temperature controller are

accomplished through simple MENU selections. These MENU selections are organized

into PAGES. On each page you will find a specific set of related functions. The PAGES

setup structure is as follows: diSP PAGE, Ctrl PAGE, inPt PAGE, ScAL PAGE, Out1

PAGE and Out2 PAGE.

To select a PAGE:

Press and hold the RESET key, while pressing the or keys. The upper display of

the temperature controller will increment or decrement through the PAGEs, and PAGE

will be displayed in the lower display.

To select a MENU:

After reaching the correct page, press reset to move through MENUs. The alpha cue for

the MENU will appear on the upper display and the current value will appear in the lower

display.

To change a MENU value:

After the MENU is selected and displayed, use the and keys to change the value.

2. To enter the SetUp Mode, press the controller RESET key and hold it for about 3

seconds. The controller will display LocH XXX where XXX is the security code. The

security code number should be 458. If not, press either the or keys until the

display reads 458. This is the first menu in the Ctrl PAGE.

3. Verify that the menu settings for the Ctrl PAGE are as follows:

PID1 - Heating Value PID2 - Cooling Value Parameter

Pb1 14.0 Pb2 18.0 Proportional Band

Ar1 1.0 Ar2 4.5 Automatic Reset

rAt1 3.0 rAt2 4.0 Rate

db1 1.0 db2 1.0 Deadband

OFst = 0.0 FL = On Orng = 0.0 LooP = OFF Auto = 4 rrAt = OFF Cont = HtCl

CooL = PID2 rSP = On Enti = rSP Au = none Aout = Proc rSEn = OFF

4. Select the next page, which is the InPT PAGE. Verify that the menu settings for the InPt

PAGE are as follows:

SEnS = rtdt unit = °C CoFF = .0 SPLL = -40.0 SPUL = 80.0

5. Select the next page, which is the ScAL PAGE. Verify that the menu settings for the

ScAL PAGE are as follows:

DP = 1 AinL = -50.0 AinH = 100.0 AotL = -100.0 AotH = 100.0 rSPL = -100.0

rSPH = 100.0

6. Select the next page, which is the Out1 PAGE. Verify that the menu settings for the

Out1 PAGE are as follows:

Cyc1 = 16 OL1 = 100.0 HoFF = .0

7. Select the next page, which is the Out2 PAGE. Verify that the menu settings for the

Out2 PAGE are as follows:

Cyc2 = 16 OL2 = 100.0 CoFF = .0

8. Press START.

To return to Operating Mode, press and hold the RESET key for more than 3 seconds.

The controller will automatically return to operating mode after 10 minutes of no pushbutton activity.

9. Press START.

TCU 40/80 Temperature Control Unit 31

EMO Circuit

Do not perform the EMO

Warning

circuit check while the TCU is

on-line with the process tool.

Failure to follow these

instructions will lead to the

shutdown of the process tool

and other associated equipment.

1. Press the EMO button and check that the following occur.

· READY lamp goes out.

· All front panel LED indicators go out.

· Temperature controller shuts off.

· K1 contactor opens.

2. Release the EMO button and press RESET. Perform the following:

· Remove rear panel connector J72J2. The READY lamp should go out. Contactor K1

should open, the temperature controller and the front panel LED indicators should go

out. Replace J72J2 connector and press RESET.

3. Press in the interlock switch then release it. The READY lamp should go out. Contactor

K1 should open, the temperature controller and the front panel LED indicators should go

out. Place the drawer interlock switch in the maintenance position.

· Press RESET

· Press START

PMR

1. On the PMR rotate the adjustment knob completely clockwise.

2. Verify the unit shuts down, LED 1 (Facility Power) illuminates red, and that the alarm

sounds.

3. Press MUTE.

Indicator Condition

Relays CR1, CR4, CR11, CR12, CR13

On all others, Off

LED Facility Water, Circuit Breakers, Coolant

Temperature, Coolant Normal Level, Green

Compressor, Coolant Flow, Coolant Low Level,

Remote RTD, Off

Facility Power, Red

Power On

Reset Off

PMR Red

Current Sensing Relay Off

Note: REMOTE RTD is optional. LED will be green if used.

4. Return the PMR adjustment control to the original position.

5. Press RESET then START

32 TCU 40/80 plus Temperature Control Unit

Current Sensing Relay

1. Set CSR1 to 50 amps. The indicator LED on CSR1 should go from green to red.

2. After a 5 second time delay, verify that the unit shuts down, COMPRESSOR illuminates

red and the alarm sounds.

3. Press MUTE.

Indicator Condition

Relays CR1, CR4, CR8, CR11, CR12, CR13

On all others, Off

LED Facility Water, Circuit Breakers, Coolant

Temperature, Coolant Normal Level, Green

Facility Power, Coolant Flow, Coolant Low Level,

Remote RTD, Off

Compressor, Red

Power On

Reset Off

PMR Green

Current Sensing Relay Off

Note: REMOTE RTD is optional. LED will be green if used.

4. Reset CSR1 to 25 amps.

5. Press RESET.

6. Press START.

Circuit Breaker

1. Power off CB4. The TCU will shut down, alarm will sound and CIRCUIT BREAKER LED

should be red.

2. Press MUTE.

3. Power on CB4, press START.

4. Repeat steps 1 through 3 for CB3 and CB2.

Indicator Condition

Relays CR4, CR11, CR12, CR13

On all others, Off

LED Facility Water, Coolant Temperature, Coolant

Normal Level, Green

Facility Power, Compressor, Coolant Flow,

Coolant Low Level, Remote RTD, Off

Circuit Breakers, Red

Power On

Reset Off

PMR Green

Current Sensing Relay Off

Note: REMOTE RTD is optional. LED will be green if used.

TCU 40/80 Temperature Control Unit 33

Water Supply

1. Open TCU right side panel and remove PS1 cover. Using a flat head screwdriver, lift up PS1

tab. The TCU will shut down, alarm will sound, and FACILITY WATER LED should

illuminate red.

2. Press MUTE.

Indicator Condition

Relays CR1, CR2, CR4, CR11, CR12, CR13

On all others, Off

LED Circuit Breakers, Coolant Temperature, Coolant

Normal Level, Green

Facility Power, Compressor, Coolant Flow,

Coolant Low Level, Remote RTD, Off

Facility Water, Red

Power On

Reset Off

PMR Green

Current Sensing Relay Off

Note: REMOTE RTD is optional. LED will be green if used.

3. Reinstall PS1 cover.

4. Press RESET.

5. Press START.

Reservoir Over-Temperature

1. Open TCU right side panel and remove TS1 cover. Using a flat head screwdriver, lift up TS1

tab. The TCU will shut down, alarm will sound and COOLANT TEMPERATURE LED

should be red.

2. Press MUTE.

Indicator Condition

Relays CR1, CR4, CR6, CR11, CR12, CR13

On all others, Off

LED Facility Water, Circuit Breakers, Coolant

Normal Level, Green

Facility Power, Compressor, Coolant Flow,

Coolant Low Level, Remote RTD, Off

Coolant Temperature, Red

Power On

Reset Off

PMR Green

Current Sensing Relay Off

Note: REMOTE RTD is optional. LED will be green if used.

3. Reinstall TS1 cover.

4. Press RESET.

5. Press START.

34 TCU 40/80 plus Temperature Control Unit

Coolant Flow

1. Shut off coolant supply valve. After 5 second delay, the TCU will shut down, alarm will

sound and COOLANT FLOW LED should be red.

2. Press MUTE.

Indicator Condition

Relays CR1, CR4, CR7, CR11, CR12, CR13

On all others, Off

LED Facility Water, Circuit Breakers, Coolant

Temperature, Coolant Normal Level, Green

Facility Power, Compressor, Coolant Low

Level, Remote RTD, Off

Coolant Flow, Red

Power On

Reset Off

PMR Green

Current Sensing Relay Off

Note: REMOTE RTD is optional. LED will be green if used.

3. Open coolant supply valve.

4. Press RESET

5. Press START

Compressor

1. Remove wire #60 from CSR1. After 5 second delay, the TCU will shut down, alarm will

sound and COMPRESSOR LED will be red.

2. Press MUTE.

Indicator Condition

Relays CR1, CR4, CR8, CR11, CR12, CR13

On all others, Off

LED Facility Water, Circuit Breakers, Coolant

Temperature, Coolant Normal Level, Green

Facility Power, Coolant Flow, Coolant Low

Level, Remote RTD, Off

Compressor, Red

Power On

Reset Off

PMR Green

Current Sensing Relay Off

Note: REMOTE RTD is optional. LED will be green if used.

3. Reinstall wire #60 to N.O. contact of CSR1.

4. Press RESET.

5. Press START.

TCU 40/80 Temperature Control Unit 35

Circulation Pump

1. Adjust overload trip on K3 to the minimum setting. Within three minutes the overload will

trip. After a five second time delay, the TCU will shut down, the alarm will sound and the

COOLANT FLOW LED should illuminate red.

2. Press MUTE.

Indicator Condition

Relays CR1, CR4, CR7, CR11, CR12, CR13

On all others off

LED Facility Water, Circuit Breakers, Coolant

Temperature, Coolant Normal Level, Green

Facility Power, Compressor, Coolant Low

Level, Remote RTD, Off

Coolant Flow, Red

Power On

Reset Off

PMR Green

Current Sensing Relay Off

Note: REMOTE RTD is optional. LED will be green if used.

3. Reset overload trip to 3.5 amps.

4. Press RESET

5. Press START

Reservoir Overfill

1. Short wire #23 (TB1) to wire #63 (Relay board J3-4). COOLANT NORMAL LEVEL LED

will go from green to amber.

Indicator Condition

Relays CR1, CR4, CR5, CR10

On CR12, Off

LED Facility Power, Facility Water, Circuit

Breakers, Compressor, Coolant Temperature,

Coolant Flow, Coolant Normal Level, Green

Coolant Low Level, Remote RTD, Off

Coolant Normal Level, Amber

Power On

Reset On

PMR Green

Current Sensing Relay Green

Note: REMOTE RTD is optional. LED will be green if used.

36 TCU 40/80 plus Temperature Control Unit

Remote Start/Stop

1. Remove jumper from terminal strip (TB1). The TCU will shut down.

2. Press RESET.

3. Press START.

Remote Temperature Probe

1. Install connector J72J3 and verify REMOTE RTD illuminates green.

Indicator Condition

Relays CR1, CR4, CR9, CR10, CR12

On all others, Off

LED Facility Power, Facility Water, Circuit

Breakers, Compressor, Coolant Temperature,

Coolant Flow, Coolant Normal Level,

Remote RTD, Green

Coolant Low Level, Off

Power On

Reset On

PMR Green

Current Sensing Relay Green

2. Remove connector J72J3.

Cooling

1. Change the temperature controller set point to -40°C.

2. Verify CR15 on the relay board illuminates.

3. Verify main solenoid valve (SV1) has opened by confirming that the sight glass has filled

with refrigerant.

4. Verify OUT 2 LED on the temperature controller is on.

Indicator Condition

Relays CR1, CR4, CR10, CR12, CR15

On all others, Off

LED Facility Power, Facility Water, Circuit

Breakers, Compressor, Coolant Temperature,

Coolant Flow, Coolant Normal Level,

Remote RTD, Green

Coolant Low Level, Remote RTD, Off

Power On

Reset On

PMR Green

Current Sensing Relay Green

Note: REMOTE RTD is optional. LED will be green if used.

TCU 40/80 Temperature Control Unit 37

Heating

1. Change the temperature controller set point to 80°C.

2. Verify contactor K4 pulls in.

3. Verify CR15 goes out. Verify OUT 1 on the temperature controller is on and OUT 2 is off.

4. Verify hot gas bypass solenoid (SV2) is energized.

Indicator Condition

Relays CR1, CR4, CR10, CR12

On all others, Off

LED Facility Power, Facility Water, Circuit

Breakers, Compressor, Coolant Temperature,

Coolant Flow, Coolant Normal Level,

Remote RTD, Green

Coolant Low Level, Remote RTD, Off

Power On

Reset On

PMR Green

Current sensing relay Green

Note: REMOTE RTD is optional. LED will be green if used.

Process Value Setting

1. Set the temperature controller to the proper process set value.

2. Verify all the host interface connections are mated properly.

38 TCU 40/80 plus Temperature Control Unit

7.9 Preventive Maintenance Checklist

Record Date:

Customer Name:

Checked By:

System Status

Timer Hours:

Coolant Pressure:

Process Temperature:

Fluorinert Type:

Quantity Of Fluorinert Added:

Operation Mode:

Utilities Water Temperature:

Leak Check Results:

Parts Replaced

Actions / Concerns

FC8270 FC77

Remote Local

Pass

Quantity Cause / Reason

Serial No:

Line / Area:

Tool Name:

Hours

psig

°C

lbs.

°C

Fail

Other:

Liters

Remarks:

TCU 40/80 Temperature Control Unit 39

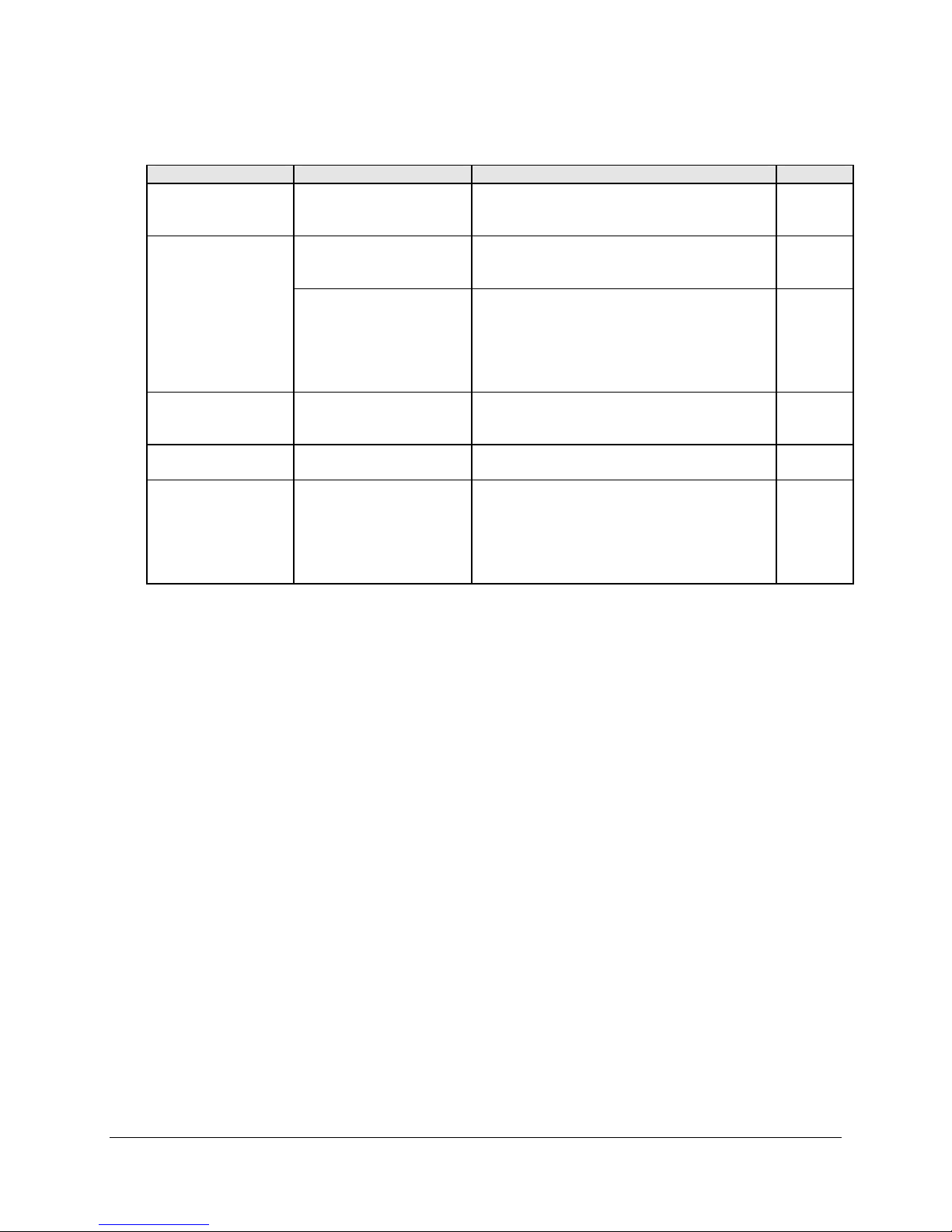

8. Troubleshooting

Table 11, Table 12, Table 13 and Table 14 identify fault conditions that may encounter with the TCU 40/80

plus. For additional assistance contact the BOC Edwards Service Department.

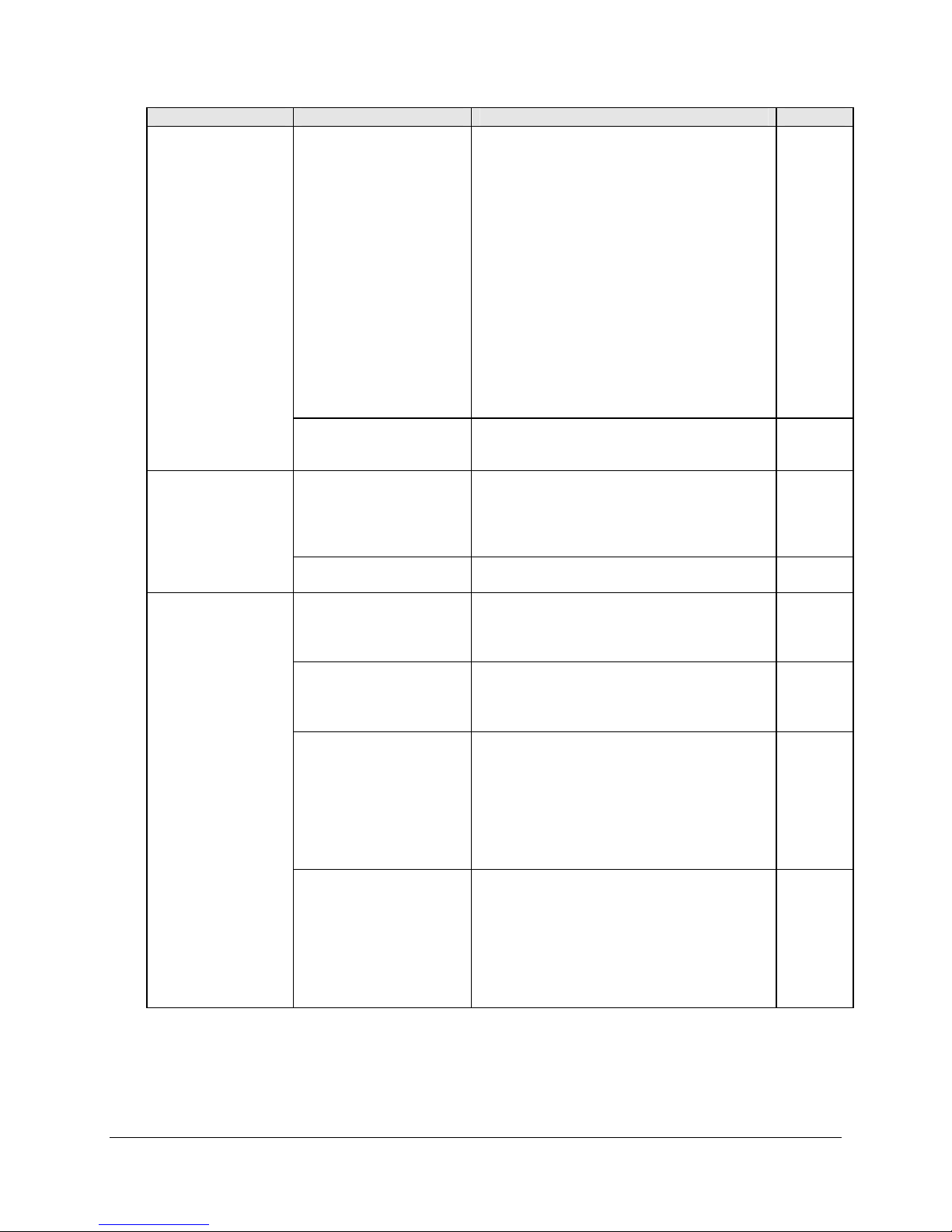

Table 11 - Faults Identified By Front Panel Lamps

Indicator Possible Causes Action Hazard

POWER ON lamp

is not

illuminated.

The main power circuit

POWER ON lamp

The transformer isolating

The transformer isolating

One of the following

No power to the TCU

40/80 plus.

breaker (CB1) is off.

requires replacement.

circuit breaker CB5 may

be off.

circuit breaker CB7 may

be tripped.

circuit breakers may not

be functional:

· main power circuit

breaker (CB1)

· transformer isolating

circuit breaker CB5

· transformer isolating

circuit breaker CB7

Verify that the power cord is plugged in.

Verify that outlet's circuit breaker is on.

Verify that the outlet’s EMO is not activated.

Verify that the main power circuit breaker

(CB1) is on.

Verify that the POWER ON lamp assembly

is receiving 24 VAC. To do this, opening of

the electrical drawer is necessary. This will

activate the drawer interlock switch and shut

the TCU 40/80 plus down.

Notify the tool operator prior to opening the

electrical drawer.

Check to see that 24 VAC is present across

the lamp assembly terminal block (LP1),

terminals X1 and X2. If 24 VAC is present,

then replace the POWER ON lamp. (EHVI

part no. P23247900).

Refer to the “Lamp Check/Replacement”

Section 7.7.8 page 30.

Verify that the transformer isolating circuit

breaker CB5 is on.

Verify that the transformer isolating circuit