Page 1

ConturaSeries

®

Technical Data

Patented

MATERIALS:

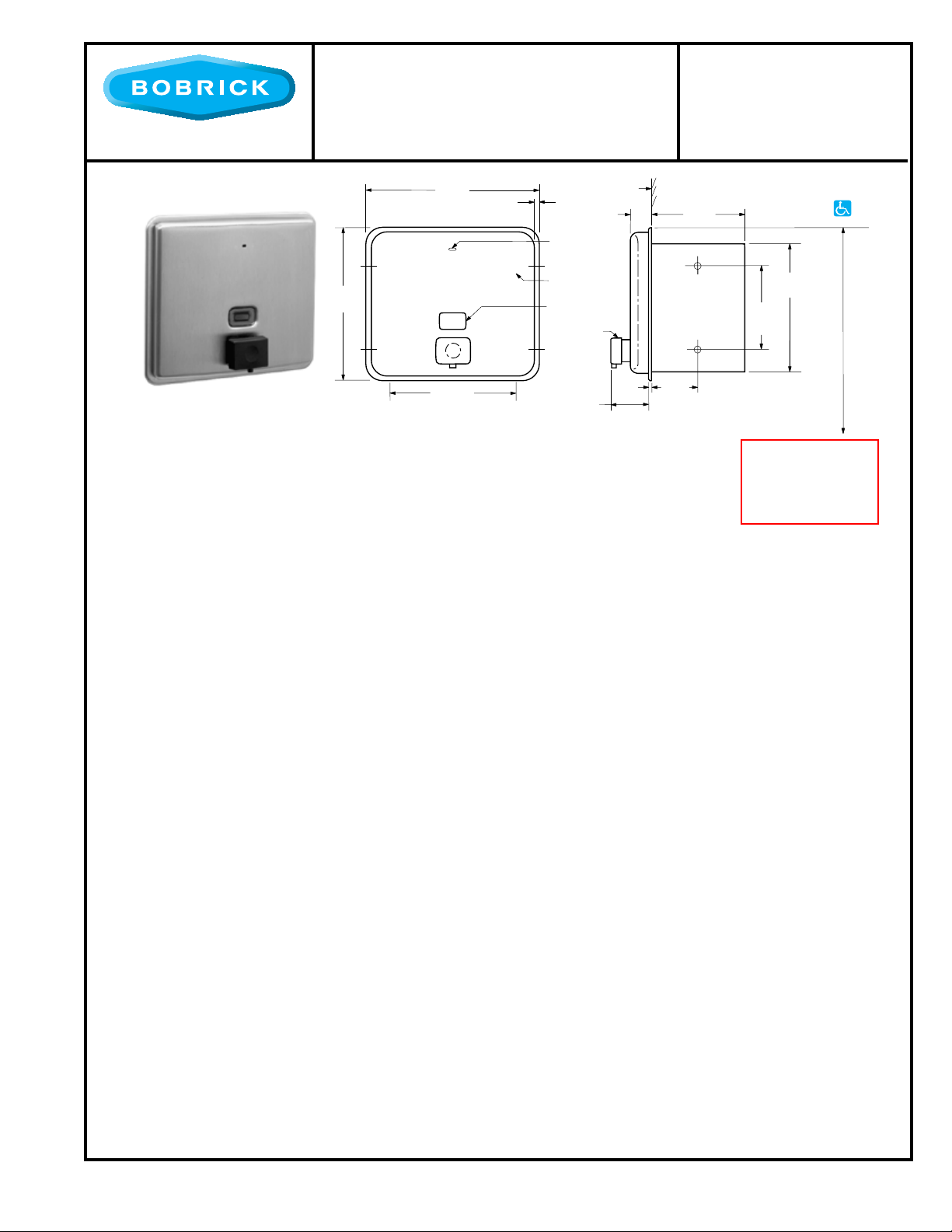

RECESSED SOAP

DISPENSER

7-1/4''

6-3/8''

160mm

185mm

S

S

5-3/4''

145mm

Recessed Cabinet

1/4''

6mm

Typ.

Finish Face of Wall

7/8''

22mm

Latch Release

S

Stainless Steel

Faceplate

Window

Push Button

Valve

S

1-1/2''

40mm

1/8''

3mm

1-7/8''

50mm

Typ.

B-4063

3-7/8''

100mm

S

5-3/8''

135mm

3-1/2''

90mm

Typ.

S

S

Rough Wall Opening

5-7/8" (150mm) wide

5-1/2" (140mm) high

4" (102mm) minimum

recessed depth

Cabinet — 18-8 S, type-304, heavy-gauge stainless steel. All-welded construction.

Flange — 18-8 S, type-304, heavy-gauge stainless steel with satin finish. Drawn, one-piece, seamless construction. Radius on corners and

return edges complement corners and edges of faceplate.

49" 1245mm

For Universal / Barrier-Free Design

Recommended Mounting Height Off Floor

Faceplate — 18-8 S, type-304, 20-gauge (1.0mm) stainless steel with satin finish. Drawn, one-piece, seamless construction. Front of faceplate

has same degree of arc as other Bobrick ConturaSeries washroom accessories. Radius on corners and edges of faceplate complement other

ConturaSeries accessories. Equipped with a plastic soap refill-indicator window and concealed locking device opened with a special key

provided. Two stainless steel angle brackets are spot-welded to back of faceplate for securing plastic container.

Soap Container — Molded plastic. Large opening equipped with plastic cover. Capacity: 50-fl oz (1.5-L).

Valve — Black molded plastic push button and spout. Soap head-holding mushroom valve. Stainless steel spring. U-packing seal and duckbills.

Antibacterial-soap-resistant plastic cylinder.

OPERATION:

Corrosion-resistant valve dispenses commercially marketed all-purpose hand soaps. Valve operates with one hand, without tight grasping,

pinching, or twisting of the wrist, and with less than 5 pounds of force (22.2 N) to comply with barrier-free accessibility guidelines (including

ADAAG in U.S.A.). Window indicates when refill is required. Faceplate unlocks with key provided and pulls out for filling container. Large

opening in container provides fast, easy filling. Faceplate/container assembly can be removed for cleaning.

INSTALLATION:

Provide framed rough wall opening 5-7/8" wide x 5-1/2" high (150 x 140mm). Minimum recessed depth required from finish face of wall is 4"

(102mm). Allow clearance for construction features that may protr ude into rough wall opening from opposite wall. Coordinate with mechanical

engineer to avoid pipes, vents, and conduits. Mount unit in rough wall opening with shims between framing and cabinet at all points indicated

by an S, then secure unit with #8 x 1-1/4" (4.2 x 32mm) sheet-metal screws (not furnished).

Note: Place unit as close to top of deck of lavatory as plumbing vent code will permit and with bottom of door high enough to clear fixture trim.

SPECIFICATION:

Recessed soap dispenser shall be type-304 stain less steel with all-welded construction; exposed sur faces shall have satin finish. Corrosionresistant valve shall dispense commercially marketed all-purpose hand soaps. Valve shall be operable with one hand and with less than 5

pounds of force (22.2 N) to comply with barrier-free accessibility guidelines (including ADAAG in U.S.A.). Front of soap dispenser faceplate

shall have same degree of arc and match other Bobrick ConturaSeries accessories in the washroom. Radius on corners and edges of flange

and faceplate shall complement other Bobrick ConturaSeries washroom accessories. Flange shall be drawn, one-piece, seamless construction.

Soap dispenser faceplate shall be drawn, 20-gauge (1.0mm), one-piece, seamless construction; equipped with an soap refill-indicator window

and concealed locking device opened with special key provided; and shall pull out for filling and cleaning the covered molded plastic soap

container attached to back. Soap container shall have a capacity of 50-fl oz (1.5-L). Manufacturer's service and par ts manual shall be provided

to the building owner/manager upon request.

Recessed Soap Dispenser For Antibacterial Soaps shall be Model B-4063 of Bobrick Washroom Equipment, Inc., Clifton Park,

New York; Jackson, Tennessee; Los Angeles, California; Bobrick Washroom Equipment Company, Scarborough, Ontario;

Bobrick Washroom Equipment Pty. Ltd., Australia; and Bobrick Washroom Equipment Limited, United Kingdom.

The illustrations and descriptions herein are applicable to production as of the date of this Technical Data Sheet. Revised 5/06 Series G Printed in U.S.A.

The manufacturer reserves the right to, and does from time to time, make changes and improvements in designs and dimensions. © 2006 by Bobrick Washroom Equipment, Inc.

Loading...

Loading...