Page 1

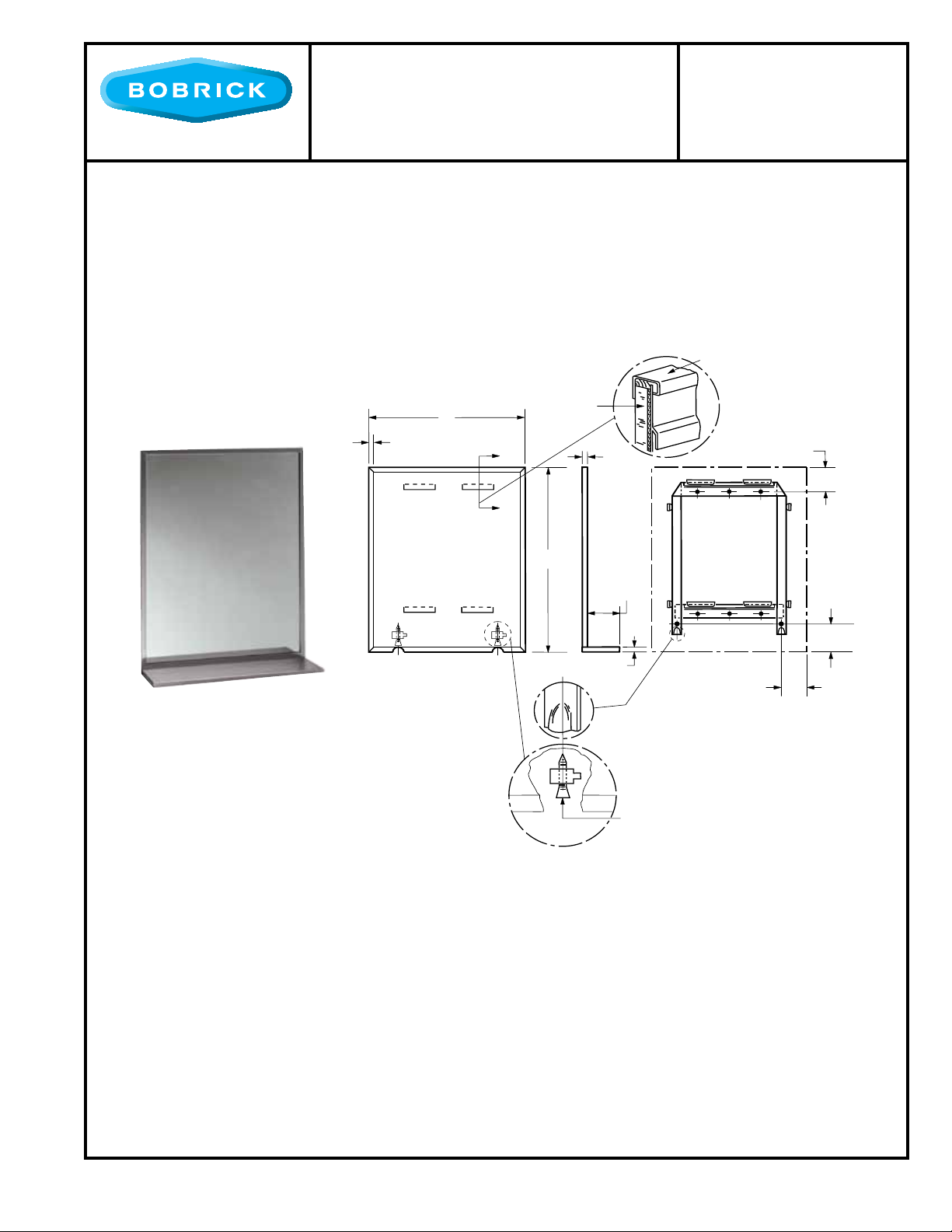

Wall Hanger

2-1/8'' to 2-3/4''

55 to 70mm

1-7/8''

45mm

S

2-1/16'' to 2-1/2''

50 to 65mm

Locking Screw

(Phillips-Head)

T

T

T

Back of Mirror

1/2''

13mm

H

3/8''

9.5mm

W

Frame

Mirror

S

S

5''

125mm

3/8''

10mm

Mirror WitH

B-1666

staiNless steel

cHaNNel fraMe

Technica l Dat a

special-order reflective surfaces

Specify Series Required:

B-1666 Series Polished Stainless Steel Mirror — 24" x 48" (61 x 122cm) maximum; 12" x 12" (30 x 30cm) minimum.

B-1668 Series Tempered Glass Mirror — 24" x 48" (61 x 122cm) maximum; 16" x 20" (41 x 51cm) minimum.

B-1669 Series Laminated Glass Mirror — 24" x 48" (61 x 122cm) maximum; 12" x 12" (30 x 30cm) minimum.

aNd sHelf

B-1668

B-1669

The illustrations and descriptions herein are applicable to production as of the date of this Technical Data Sheet. Revised 9/09 Printed in U.S.A.

The manufacturer reserves the right to, and does from time to time, make changes and improvements in designs and dimensions. © 2009 by Bobrick Washroom Equipment, Inc.

Designer's Notes:

1. Special-order only.

2. Maximum shelf length is 24" (61cm).

3. All Bobrick framed mirror/shelf models are manufactured to overall width and height dimensions including shelf.

EXAMPLE: A 24" x 36" (61 x 91cm) mirror will be furnished 24" x 36" (61 x 91cm) outside-of-frame to outside-of-frame

including shelf.

4. To specify sizes use Series Number followed by width then height in inches. EXAMPLE: B-1666 2024.

5. Bobrick framed mirror/shelf models are manufactured to a tolerance ±1/8" (3.2mm).

6. For sufficient space to lift mirror onto wall hanger(s), provide 2-7/8" (75mm) minimum clearance above center line of

mounting screw holes.

7. Provide 1" (25mm) minimum clearance at bottom of mirror for engaging locking screws and 1" (25mm) clearance on each

side.

continued . . .

Page 2

Materials:

Frame — Type 430 stainless steel, 1/2" x 1/2" x 1/2" (13 x 13 x 13mm) channel with bright polished finish. One-piece frame

with 90°

mitered corners. Galvanized steel back with formed edges for additional strength has integral horizontal hanging

brackets located near top. Concealed Phillips-head locking screws securely fasten mirror to wall hanger(s).

Shelf — 18-8 S, type 304, 22-gauge (0.8mm) stainless steel with satin finish. 3/8" (10mm) return edges on front and sides

with front edge hemmed for additional safety. Shelf is welded to mirror frame and reinforced by concealed 16-gauge (1.6mm)

stainless steel brackets. No exposed rivet-heads, screws, or fasteners of any type appear on frame or shelf.

Mirror — (B-1666 Series) Stretcher leveled stainless steel with reflective, highly polished strip finish. Tempered

masonite backing.

(B-1668 Series) No. 1 quality, 1/4" (6mm) tempered select float glass: selected for silvering and electrolytically

copper-plated by the galvanic process.

(B-1669 Series) 1/4" (6mm) thick. Two pieces of 1/8" (3mm) select float glass: selected for silvering, laminated

with 0.003'' (0.08mm) thick clear vinyl in the center, and electrolytically copper-plated by the galvanic process.

Note: These reflective surfaces resist breakage and provide a measure of safety from broken glass, but dif fer in

color and reflective quality from standard glass mirrors.

Corners are protected by friction-absorbing filler strips. Backs of all glass mirrors are protected by full-size,

shock-absorbing, water-resistant, nonabrasive, 3/16" (5mm) thick polyethylene padding.

Concealed Wall Hanger(s) — 20-gauge (0.9mm) x 15/16" (24mm) galvanized steel.

Designer's Note: Mirrors larger than 24" (61cm) high are supplied with wall hanger(s) that include lower support brace, welded

construction, to form rigid rectangle.

iNstallatioN:

Mount wall hanger(s) on wall with screws, (not furnished), at points indicated by an S. For plaster or dr y wall construction, provide concealed backing to comply with local building codes, then secure wall hanger(s) with screws (not furnished). For other

wall surfaces, provide fiber plugs or expansion shields for use with screws (not furnished), or provide 1/8" (3mm) toggle bolts

or expansion bolts. Hang mirror on wall hanger(s). Lock mirror to wall hanger(s) by tightening Phillips-head locking screws

that are concealed in bottom of frame at points indicated by a T.

specificatioN:

Mirror shall have a one-piece type 430 stainless steel channel frame, 1/2" x 1/2" x 1/2" (13 x 13 x 13mm), with 90° mitered

corners; all exposed surfaces shall have bright polished finish. Shelf shall be type-304, 22-gauge (0.8mm) stainless steel with

satin finish and shall have 3/8" (10mm) return edges on front and sides with front return edge hemmed. Shelf shall be welded

to mirror frame and reinforced by concealed stainless steel brackets. No rivet-heads, screws, or fasteners of any type shall be

exposed on frame or shelf. Mirror shall be __________________________ (inser t one: polished stainless steel, tempered glass,

or laminated glass). Corners shall be protected by friction-absorbing filler strips. Backs of all glass mirrors shall be protected

by full-size, shock-absorbing, water-resis tant, nonabrasive, 3/16" (5mm) thick polyethylene padding. Galvanized steel back shall

have integral horizontal hanging brackets located near top for mounting on conceal wall hanger(s). Mirror shall be secured to

wall hanger(s) with concealed Phillips-head locking screws located in bottom of frame.

Framed Mirror With Shelf shall be Model _______________ (insert model number) of Bobrick Washroom

Equipment, Inc., Clifton Park, New York; Jackson, Tennessee; Los Angeles, California; Bobrick Washroom

Equipment Company, Scarborough, Ontario; Bobrick Washroom Equipment Pty. Ltd., Australia; and Bobrick

Washroom Equipment Limited, United Kingdom.

The illustrations and descriptions herein are applicable to production as of the date of this Technical Data Sheet. B-1666 Revised 9/09 Printed in U.S.A.

The manufacturer reserves the right to, and does from time to time, make changes and improvements in designs and dimensions. © 2009 by Bobrick Washroom Equipment, Inc.

Loading...

Loading...