Page 1

INSTALLATION INSTRUCTIONS

URINAL SCREENS, BENCHES & SHOWER SEATS

IMPORTANT:

Storage and Handling Information on last page.

Review these instructions thoroughly prior to

installation.

1033 Stainless Steel Edge

1043 High Pressure Laminate Edge

1083 Solid Phenolic

1183 Class A Solid Phenolic

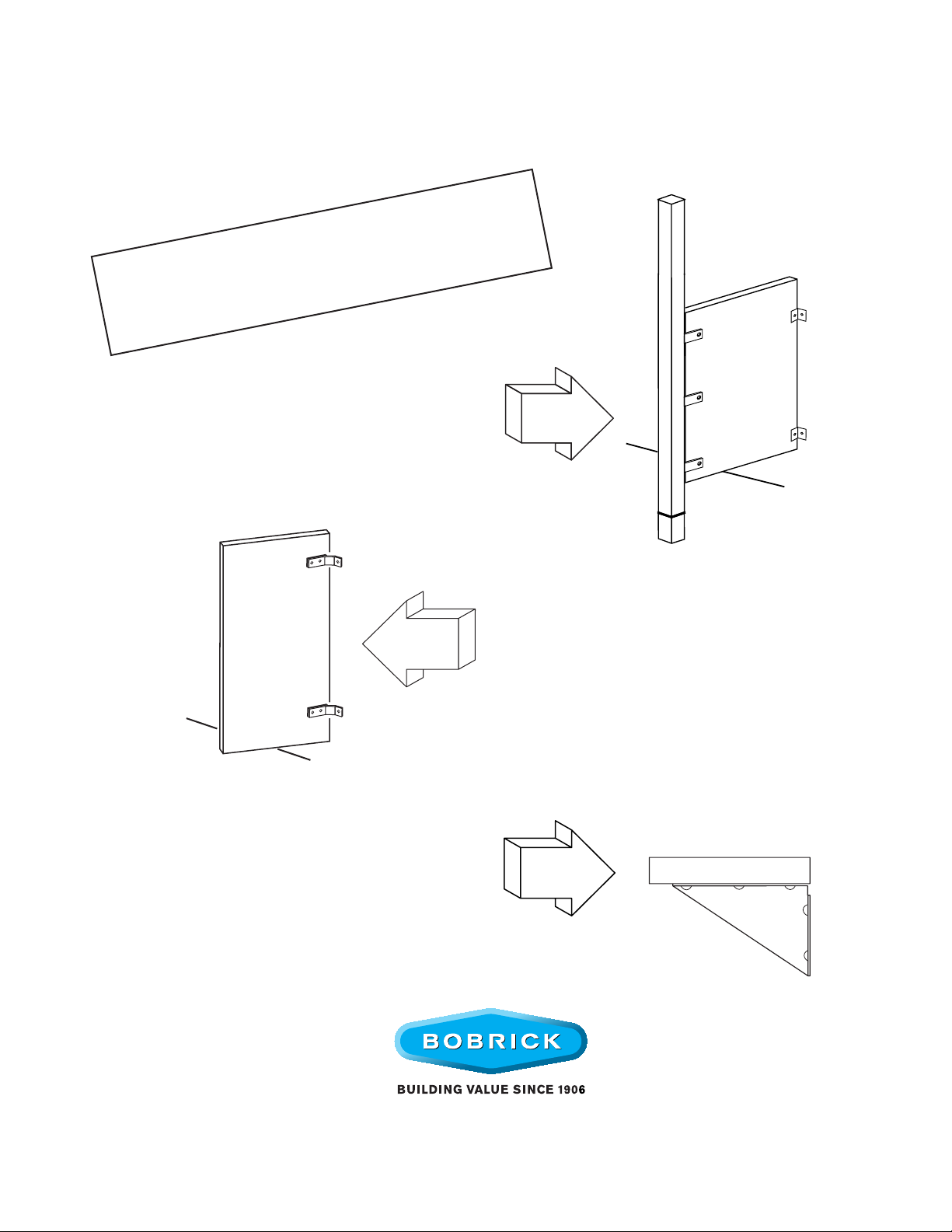

POST-TO

-CEILING

WALL

HUNG

1040 High Pressure Laminate

1080 Solid Phenolic

1180 Class A Solid Phenolic

1035 Stainless Steel Edge

1045 High Pressure Laminate Edge

1085 Solid Phenolic

1185 Class A Solid Phenolic

1545 Plastic Laminated Edge

1845 FRP

BENCHES &

SHOWER SEATS

Page 2

PREPARATION

BEFORE YOU BEGIN...

These installation instructions cover wall hung urinal

screens, post-to-ceiling urinal screens, benches and

shower seats only.

For detailed instructions regarding installation of toilet

partitions, floor anchored urinal screens or ceiling hung

urinal screens please refer to one of the following:

1040-69

1080-69

1540-69

1080.67-69

1040.65-69

PRE-INSTALLATION.

A. Structural support in walls and floors is not furnished

by Bobrick. Confirm that adequate backing is present

in wall, ceiling and floors prior to installation.

B. This installation booklet must be used with the Bobrick

layout sheets.

C. You may verify hardware received by cross-referencing

the last page of the layout sheets against the box

contents.

RECOMMENDED TOOLS.

CAUTION: Be sure to use proper safety gear.

1. Chalk Line

2. Plumb-bob

3. Masking Tape (for laying out holes on

floors/walls/ceilings to be drilled)

4. Tape Measure and Pencils

5. Center Punch

6. Electric and/or Battery-Powered

Drill – 1/2" and 3/4" (13 and

19mm) Concrete Drill Bits

7. Drill Bits

1/16" to 1/4", numbered 1 to 60

metric 1.0 to 7.0mm

INSTALLATION STEPS.

1. Brackets and Screws......................................... Page 3

2. Post-to-Ceiling Urinal Screens .......................... Page 4

3. Wall Hung Urinal Screens ................................. Page 7

4. 1040 Series Benches ........................................ Page 8

5. 1080/1180 Series Shower Seats....................... Page 8

6. Finishing and Cleanup ...................................... Page 9

A. Organize components with

appropriate hardware.

8. Screwdrivers/Screwdriver Bits

flathead and phillips, #1, #2 and #3

9. Shims

10. Adjustable Supports

1-1/2" to 12" (40–105mm)

11. Level

12. Wrench – Adjustable or 9/16"

(14mm) open end (2 req'd.

for adjusting hex nuts on

anchors)

13. Allen Wrench – 5/64" (2mm)

(to install door latch)-Supplied

by Bobrick

Page 2

14. Hack Saw

15. Hammer

Form No. 1045-69 r5/21/14 © 2014 Bobrick Washroom Equipment, Inc. Printed in U.S.A.

Page 3

BRACKETS AND SCREWS

F-brackets

#1000353

Panel to Wall

#1000975

Panel to Wall 1080 Series

U-brackets

#1000356

Panel to Stile

#1000972

Panel to Stile 1080 Series

U-brackets

#1000357

1045 series

Base Plate

#1000157

SPC Hardware

#1002500

#12 x 3/4'' 1040 Bracket to Screen

#1000158 Front Plate

#1000159 Rear Plate

SPC Hardware

#1002499

#12 x 7/16" Bracket to Panel/

Bracket to Stile 1080 Series

Shoe

#1000050

#10-32 x 3/8'' Phillips

SPC Bracket to Post

#1002956

1085 series

Shoe Retainer

#1000103

SPC Hardware

#1000133

Acorn Nut - 10-32

Through-Bolt Urinal Screen

#1000134

#10-32 x 1-3/4'' (44mm) Phillips

Through-Bolt Urinal Screen 1040 Series

Form No. 1045-69 r5/21/14 © 2014 Bobrick Washroom Equipment, Inc. Printed in U.S.A.

#1002966

#10-32 x 1-1/4'' (38mm) Phillips

Screen - 1080 Series/Bench 1040

#1002495

#12 x 2" (50mm)

Wall Screws

Page 3

Page 4

5/8"

16mm

Finish Face of Wall

2-1/2''

65mm

3-1/2''

90mm

2-1/2''

65mm

Cut to

4-3/4''

120mm

Overall

2''

50mm

Min.

Finish Face of Ceiling

Drill 1/2'' (

12mm

) Hole in Ceiling.

Run Toggle Bolt through

Base Plate and Spacer, then

into Ceiling. Tighten securely.

Base Plate

Spacer

POST-TO-CEILING URINAL SCREENSSTEP 1

LAYOUT EXAMPLE.

A. Refer to Bobrick layout sheets for distance location on

screen depth.

B. From back wall, measure and mark the location of the

edge of the screen.

C. Centerline of floor anchor from edge of screen is 5/8"

(16mm).

D. Be sure, by plumb line, that floor and ceiling holes are

in line.

LEGEND: Obtain Dimension from Bobrick Layout Sheet.

Mounting holes to be drilled.

Top View

INSTALL ALL ANCHORSSTEP 2

FLOOR AND CEILING ANCHORS.

A. Drill 3/8" (9.5mm) diameter hole to depth shown. Remove all loose material from hole.

B. Insert anchor into drilled hole. Stud to be 2-1/2" (65mm) above floor.

C. Use 9/16" (14mm) wrench to tighten hex nut until anchor is expanded. Make sure shoe retainer is in proper position to

accept shoe. Angled ends to face front and rear of urinal screen.

D. Install second hex nut.

E. Place base plate over threaded rod.

NOTE: Wood-floor anchors are available upon request.

Fig. 2a: Detail of Floor Anchor.

Fig. 2b: Detail of Ceiling Anchor.

For tile or concrete floors

using filler sleeve

Page 4

For tile or concrete floors

without filler sleeve

Form No. 1045-69 r5/21/14 © 2014 Bobrick Washroom Equipment, Inc. Printed in U.S.A.

Page 5

46''

(1170mm)

18''

(455mm)

C

L

Panel

C

L

Threaded Rod

12''

(305mm)

18''

(455mm)

46''

(1170mm)

Set panel on support(s)

and in brackets.

Do Not Fasten

STEP 3

POST-TO-CEILING URINAL SCREENS

Fig. 3a: Layout Walls and Install Brackets.

A. Using the wall brackets as templates, measure and

mark the location of all mounting holes, according to

dimensions shown in illustrations (Fig. 3a, 3b, 3c).

B. Use #19 (.166) drill bit for 2" (50mm) deep pilot holes

into adequate wall backing.

C. Secure wall brackets with #1002495 screws.

Fig. 3b: Put Screen in Place.

Form No. 1045-69 r5/21/14 © 2014 Bobrick Washroom Equipment, Inc. Printed in U.S.A.

Page 5

Page 6

23''

(535mm)

23''

(535mm)

16-3/8''

(416mm)

Upper

Nut

Trim End with Label

12''

(305mm)

STEP 3

POST-TO-CEILING URINAL SCREENS

Fig. 3c: Install Post

A. Post is furnished in 10' -0" (305cm) lengths. Post is to

be field cut on end with label attached.

Follow instructions on label to cut post to your job

conditions.

B. Fasten three brackets with No. 10 x 3/8" (10mm)

screws.

Be sure short end of post is towards floor to assure

proper mounting of panel to brackets.

C. Place post over floor base plate. Be sure brackets are

on panel side. Turn upper nut raising post to engage

on ceiling base plate.

Caution: Use care when raising post to prevent

damage to ceiling.

Fig. 3d: Attach Panel

D. Install shoe with No. 6 x 1/4" (6mm) screws. Screws to

be on panel side of post. Be sure to engage retainer at

floor.

Position panel so that it contacts the heads of the

screws that attach the brackets to the post. Drill No. 19

holes x 3/4" (19mm) deep. Fasten panel to brackets

on post with #1002499 screws for 1/2" (12mm) panels

and #1002500 for 1" (25mm) panels. Make sure that

post is plumb and straight. Drill pilot holes and fasten

wall brackets to panel.

Page 6

Form No. 1045-69 r5/21/14 © 2014 Bobrick Washroom Equipment, Inc. Printed in U.S.A.

Page 7

STEP 1

WALL HUNG URINAL SCREENS

Fig. a: Layout Walls and Install Brackets.

36''

(915mm)

21''

(535mm)

C

L

Panel

42''

(1070mm)

15''

(381mm)

C

Panel

L

For 42" (107cm) High Screens For 48" (122cm) High Screens

A. Using the wall brackets as templates, measure and mark the location of all mounting holes, according to

dimensions shown in illustrations (Fig. a, b).

B. Use #19 (.166) drill bit for 2" (50mm) deep pilot holes into adequate wall backing.

C. Secure wall brackets with #12 x 2" screws.

Fig. b: Put Screen in Place.

Set panel on support(s)

and in brackets.

36''

(915mm)

21''

(535mm)

18''

(455mm)

For 42" (107cm) High Screens For 48" (122cm) High Screens

A. Position panel so that it contacts the heads of the screws that attach the brackets to the wall.

B. Using brackets as templates, drill #19 through the panel.

42''

(1070mm)

15''

(381mm)

12''

(305mm)

Set panel on support(s)

and in brackets.

C. Fasten panel to brackets with #10-32 x 1-1/4'' (#10-32 x 1-3/4'' 1040 only) screw and #10-32 acorn nut.

Form No. 1045-69 r5/21/14 © 2014 Bobrick Washroom Equipment, Inc. Printed in U.S.A.

Page 7

Page 8

''D''

Finish Face of Floor

Sheet Metal

Screws

3/4''

19mm

Masonry Wall

Bracket

Sheet Metal Screws

2''

50mm

''D''

Finish Face of Floor

Panel

Bracket

Plain

Washers

Phenolic Shower Seat

12''

305mm

STEP 1

BENCH/SHOWER SEAT INSTALLATIONS

Fig. 1a: Bench 1040 Series

A. Mark holes on one side of bench using mounting

brackets as templates. Mounting holes to be 3"

maximum from each end of seat.

B. Drill #19 (.166) x 3/4" (19mm) deep holes in seat.

Caution: Do Not Drill Through.

C. Attach brackets with #1002500 screws.

D. Support bench so that height of bench complies with

local building codes. Bench must be level with the floor

in all directions and mounting brackets must be flat

against the wall.

E. Using brackets as templates mark and drill #19

(4.2mm) into wall 2" deep.

F. Attach brackets to wall with #1002495 screws.

G. Test and examine bench and fasteners and brackets to

make sure there are no loose parts.

Fig. 1b: Shower Seat 1080/1180 Series

(Panel Installation)

Page 8

Form No. 1045-69 r5/21/14 © 2014 Bobrick Washroom Equipment, Inc. Printed in U.S.A.

A. Mark holes on one side of shower seat using mounting

brackets as templates. Mounting holes to be 3" max.

from each end of seat.

B. Drill #19 x 7/16" (5.5 x 11mm) deep holes in seat.

Caution: Do Not Drill Through.

C. Attach brackets with #1002499 screws.

D. Support seat so that height of seat complies with local

building codes. Seat must be level with the floor in all

directions and mounting brackets must be flat against

the panel.

E. Using brackets as templates mark and drill #10

(4.8mm) holes through panels.

F. Attach brackets to panel with #10-32 x 1-1/4" machine

screws, hex nuts and washers.

G. Test and examine seat, fasteners and brackets to

make sure there are no loose parts.

Page 9

Finish Face of Floor

Phenolic Shower Seat

Masonry Wall

Bracket

''D''

STEP 1

BENCH/SHOWER SEAT INSTALLATIONS

Fig. 1c: Shower Seat 1080/1180 Series

A. Mark holes on one side of shower seat using mounting

brackets as templates. Mounting holes to be 3"

maximum from each end of seat.

B. Drill #19 x 3/8" deep holes in seat. Caution: Do Not

Drill Through.

C. Attach brackets with #1002499 screws.

D. Support seat so that height of seat complies with local

building codes. Seat must be level with the floor in all

directions and mounting brackets must be flat against

the panel.

E. Using brackets as templates mark and drill #19

(4.2mm) into wall 2" (50mm) deep.

F. Attach brackets to wall with #1002495 screws.

G. Test and examine seat and fasteners and brackets to

make sure there are no loose parts.

FINISHING AND CLEANUP

A. Remove any exposed labels from the components.

B. Clean surfaces as needed. CAUTION: Do not use cleaners containing acid on Bobrick toilet compartments.

For example, tile cleaners containing acid may attack the stainless steel hardware.

For Bobrick recommendations, refer to Bobrick Advisory Bulletins Nos. TB-21 and TB-60.

Form No. 1045-69 r5/21/14 © 2014 Bobrick Washroom Equipment, Inc. Printed in U.S.A.

Page 9

Page 10

In the United States: BOBRICK WASHROOM EQUIPMENT, INC.

200 Commerce Drive, Clifton Park, NY 12065-1350, Telephone: (518) 877-7444 • FAX: 518-877-5029

11611 Hart Street, North Hollywood, CA 91605-5882: (818) 982-9070 • FAX: 818-503-1102

or email Bobrickcustomerservice@bobrick.com

In Canada: BOBRICK WASHROOM EQUIPMENT COMPANY

45 Rolark Drive, Scarborough, Ontario M1R 3B1 • FAX: (877) 423-8555

1045-69

16954 00910

7

Form No. 1045-69 r5/21/14 © 2014 Bobrick Washroom Equipment, Inc. Printed in U.S.A.

4

Loading...

Loading...