Mod.BM43

COM

Vers.1.0

16/11/2005

Page 1 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

ULTRASONIC TRANSIT TIME FLOWMETER

TTFM100B-HH-NG

HAND-HELD TYPE

INSTRUCTION MANUAL – REV. 2.3.1

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 2 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

INTRODUCTION 5

1. WORKING PRINCIPLE 6

1.1 TYPICAL USE 7

1.2 DESCRIPTION 8

1.3 PACKING LIST 8

1.4 INTEGRATED REA L TIME CLOCK (RTC) 9

1.5 PRODCUT ID 9

1.6 TECHNICAL FEATURES 9

2. INSTALLATION AND OP ERATION 10

2.1 MEASURING POINT 10

2.2 REQUIRED CONDITIONS 11

2.3 A PRACTICAL EXAMPLE OF RAPID SETTINGS 12

2.3.1 FLUID AND PIPE’S FEATURES 12

2.3.2 DATA ENTRY 12

2.4 INSTRUCTIONS FOR CLAMP-ON SENSORS MOUNTING 17

2.5 TRANSDUCERS MOUNTING METHODS 25

2.5.1 “V” MOUNTING METHOD 27

2.5.2 “Z” MOUNTING METHOD 28

2.5.3 “W” and “N” MOUNTING METHODS 30

2.6 MOUNTING ANALYSIS 31

2.6.1 SIGNAL’S STREANGTH & QUALITY 31

2.6.2 TOTAL SPREADING TIME, TIME DIFFERENCE M93 32

2.6.3 RELATION BETWEEN CALCULATED AND MEASURED TRANSIT TIME

32

3. DISPLAY WINDOWS 33

3.1 FLOWRATE- TOTALIZERS MENU 33

3.2 INITIAL SETTINGS MENU 33

3.3 FLOWRATE UNITS MENU 34

3.4 OPTIONAL SETTING MENU 34

3.5 INPUTS/OUTPUTS MENU 34

3.6 DIAGNOSTICS MENU 35

3.7 OTHER DISPLAYS MENU 35

3.8 FLOWRATE- TOTALIZERS MENU ANALYSIS 36

3.9 INITIAL SETTING MENU ANALYSIS 39

3.10 FLOWRATE UNITS MENU ANALYSIS 46

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 3 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

3.11 INPUTS/OUTPUTS MENU NALYSIS 52

3.12 DIAGNOSTICS MENU ANALYSIS 61

3.13 OTHER DISPLAYS MENU ANALYSIS 62

4. DIAGNOSTICS AND PROBLEM SOLVING 64

4.1 AUTOTEST DURING SWITCHING ON AND POSSIBLE SOLUTIONS 64

4.2 ERROR CODES, CAUSES AND SOLUTIONS DURING FUNCTIONING 64

4.3 OTHER PROBLEMS & SOLUTIONS 65

5. COMMUNICATION WIT H A PC AND/ OR DATA LOGGING 66

5.1 REQUIRED HA RDWARE 66

5.2 COMPLETE PI-OUT OF DB9 M DOOR 66

5.3 DIRECT CONTROL – COMMUNICATION P ROTOCOL 67

5.4 USE OF THE PREFIX IN THE CONTROL 68

5.5 KEYPAD CODES 69

6. APPENDIX 70

6.1 SOUNS SPEEDS IN SOLIDS 70

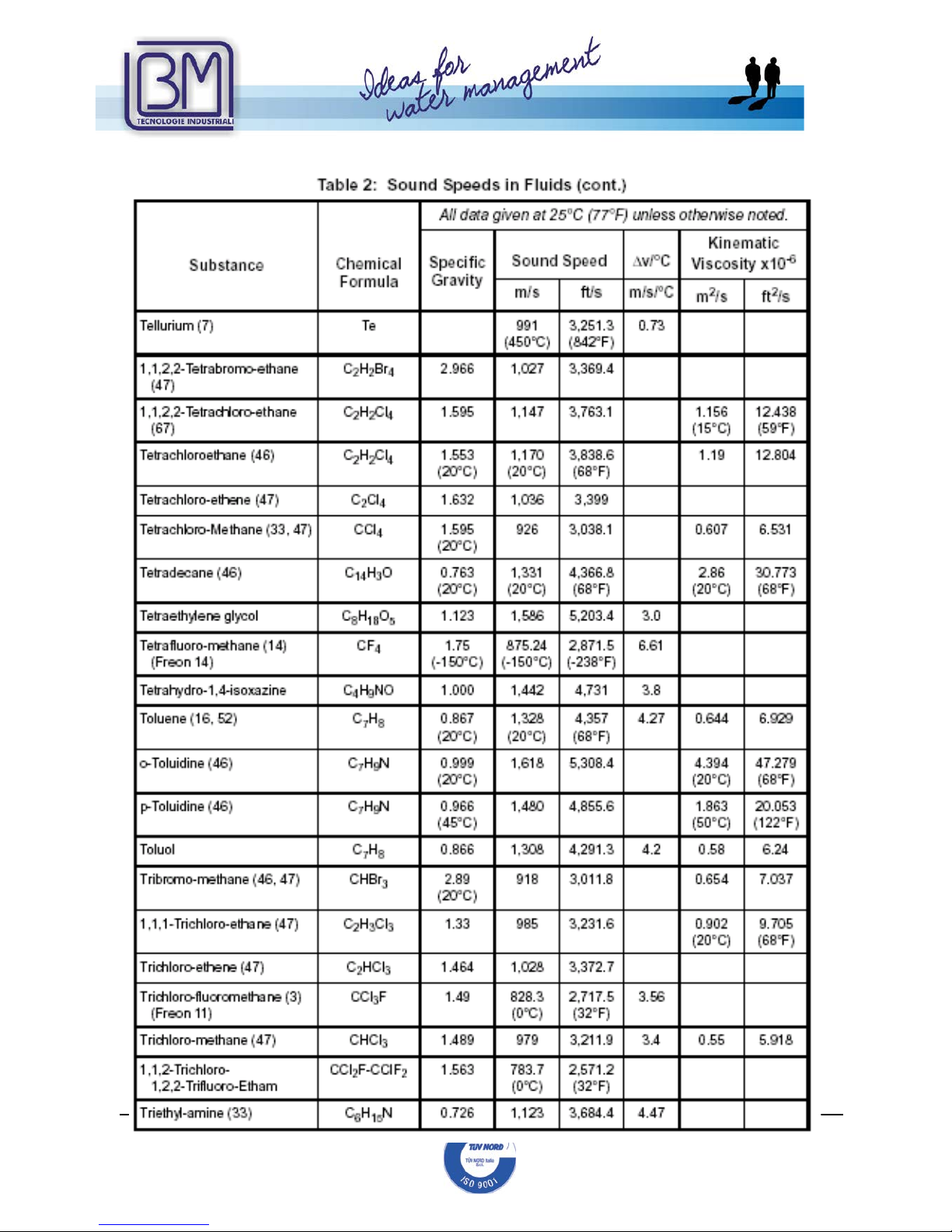

6.2 SOUND SPEEDS IN FLUIDS 72

6.3 SOUND SPEEDS IN WATER AT SELECTED TEMPERATURES 86

6.4 PIPE SIZE DATA 88

7. EC- DECLARATION OF CONFORMITY 93

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 4 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

IMPORTANT NOTICES:

1. EACH UNIT MUST BE CONNECTED TO ITS

OWN SENSORS.

THE SERIAL NUMBERS OF SENSORS AND

UNITS ARE WRITTEN IN THE ID LABELS

AND MUST CORRESPOND EACH OTHER.

2. THE DEVICE IS SUPPLIED WITH

UNCHARGED BATTERIES.

PLS CHARGE THE BATTERIES FOR 12

HOURS BEFORE USING THE DEVICE.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 5 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

INTRODUCTION

Thanks for buying an Ultrasonic Tr ansit Time Flowmeter TTFM100-NG series.

The device measures flowrate by calculati ng the spreading time of an ultrasonic wave in a

liquid, going upstream and downstream into a pipe. This flowmeter is mostly used to

measured the flowrate of homogeneous fluids , with a very little percentage of suspended

solids and possibly without gas bubbles.

Its peculiar installation makes this devic es suitable for measuring aggressive fluids ( acids,

basic and dissolvents) or very soiling fluids(oil and fuels).

The measuring system is composed of a c ouple of ultrasonic transducers acoust ically

coupled to the external pipe’s wall (it is also possible to use transducers in direct contact

with fluid to be measured) and a HOST unit elaborating the sent and received signals from

the transducers. The HOST unit has a DSP m icro processor, it gives signals to interfacing

with the process or the control system s.

The devices main features are:

• Clamp-on sensors: it is not necessary to stop the flow to install them.

• AC and DC supply: 230 VAC.

• The time difference during the measuring process could be 0.2 ns.

• RS232 output.

• All the measures could be driven to the RS232 in order to save data into a PC o r a

serial printer.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 6 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

1. WORKING PRINCIPLE

When the ultrasonic wave spreads in a liquid, the flow will cause a changing in the

spreading time depending on downstream or upstream current.

The ultrasonic wave going towar ds the same directions of the flow increases the spreading

speed, while the ultrasonic w ave going towards th e opposite side of th e f l ow decreases the

spreading speed.

If the difference between the two spreading times is accurately measured, it would be

possible to calculate the flow speed (see the following picture).

The measures are taken by 2 sensors in direct contact wit h the pipe’s external surfac e.

The UP sensor (RED) is placed on the upper side of the pipe’s external surface, the DOWN

sensor (BLUE) is placed on the lower side of the pipe’s external su rface.

The sensors positions could look like a “Z” or like a “V” or a “W”, if the pipe has a small

diameter (in the previous sketch, the sensors are “Z” mounted).

The sensors are alternatively used to receive the ultrasonic pulses sent through the way

pipe - fluid - pipe.

The difference between the transmitted and received signals upstream and do wnstream is

calculated as follows:

(1) (2) (3)

Θ+

Θ

∗

=

VSINCo

COS

DM

Tup

Θ−

Θ

∗

=

VSINCo

COS

DM

Tdown

TdownTup

T

SIN

DM

V

*

*

2

* ∆

Θ

=

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 7 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Where:

M Spreading time

D Pipe’s internal diameter

Ө Transmission angle

Co Sound spread speed through the fluid in static conditions

Tup Positive spreading time

Tdown Negative spreading time

V Flow Velocity

The DT value is the difference of the spreading time into a homogenous fluid without gas

bubbles.

The equation (3) for calculating the average speed “V” could be used for all the typ es o f

fluids in ideal conditions. The fluid speed measuring is in fact conditioned by different

factors which make the precision decrease: for exa m ple the dumps on the pipe are internal

walls: they change the measuring principle of the transit time flow meter.

TTFM100 series has are a lot of solut ions trying to solve these problems, compensating the

temperature influence, the dumped internal walls and the asymmetry in the speed

distribution, in order to measure in critical conditions too.

It is possible to adjust the zero point of the devic e: if the fluid is in static conditions, this

operation makes the repeatabi li ty precision increase until reaching values near to 0.5%.

1.1 TYPICAL USE

• Water treatment, slurry and process water pumping;

• Oil and chemical industries;

• Hydro-electric, cooling, anti-fire stations;

• Extraction industries;

• Food, paper and pharmaceutical industries;

• Car industries;

• Flow balancing;

• Heat measuring in central systems.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 8 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

1.2 DESCRIPTION

Frontal View

Top View

Bottom View

1.3 PACKING LIST

• Portable ultrasonic tran sit ti me flow me te r 1 pc

• Serial cable DB9.F 1 pc

• Battery charger 12 VDC/ 0.5 A 1 pc

• Adaptor for serial connector/ battery charger 1 pc

•

Clamp-on sensors TS2 (small)* 2 pcs

•

Clamp-on sensors TM1 (medium) * 2 pcs

•

Clamp-on sensors TL1 (large) * 2 pcs

• Spiral cable, 5mt (optional 10 mt straight cable) 2 pcs

• Acoustic couplant (grease) 1 pc

• Sensors mounting kit 2 pcs

• EC certification 1 pc

• Instruction Manual 1 pc

* depending from the type of sensors ordered by the customer

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 9 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

1.4 INTEGRATED REAL TIME CLO CK (RTC)

The user’s setting s are saved into t h e device’s memory for at least 2100 years in case of

power failures. The device could be protected by a PASSWORD.

The RTC remains active until the batt ery discharge tension is 1.5 V.

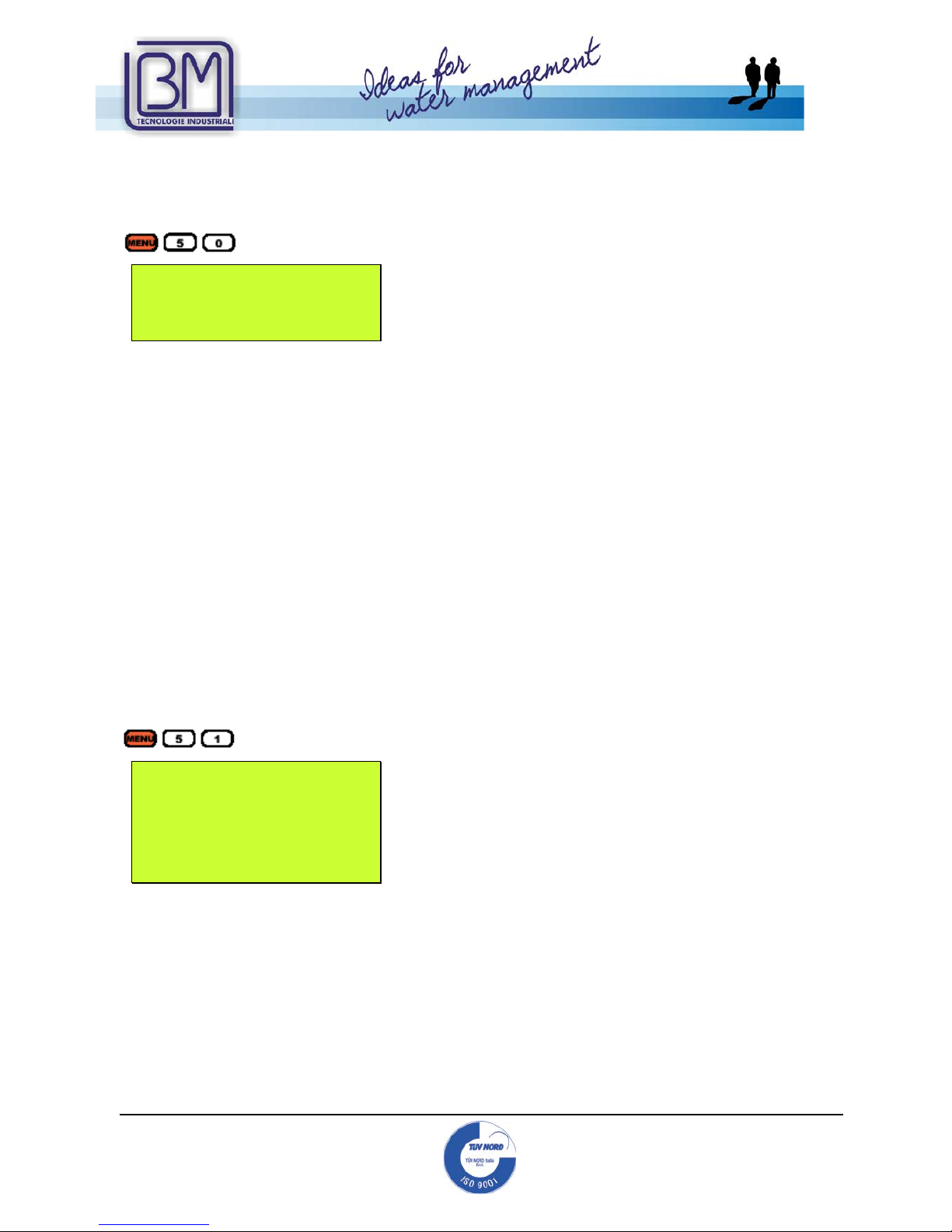

Ref. to menu M60 for resetting current d ate and time in the format: yy, mm, dd.

1.5 PRODUCT ID

Each device has a serial number, g enerated during its production. It could not be changed,

it should be used in case of repair and it could be displayed by menu M61.

1.6 TECHNICAL FEATURES

FEATURE

SPECIFICATION

Linearity

0.5%

Repeatability

0.2%

Accuracy

+/- 1% of the reading value > = 0.2 m/s

Response time

From 0 to 999 seconds , set by the user.

Speed

+/- 32 m/s

Pipes diameter

From DN20 to DN 6000

Eng. Units

Meters, Feet, Cub i c meters, Cubic feet, USA

Gallons, Imperial Gallons, USA Million

Gallons, set by the user.

Totalizers

7 digit for positive, negative and net

flowrate.

Measurable liquids All the liquids (virtually)

Safety Possible to set a password for blocking the

device.

Display

Graphic dislya4 lines, 16 characters.

Interface

RS232-C from 75 to 57 600 BPS.

Transducers

TS-2, TM-1, TL-1, or High temperature

sensors, at customers request.

Cable lengths From 2 x 5 m up to 2 x 500 m

Supply 3 x AAA Ni-MH batteries (included) for up

to 10 hours of continuous operation

Data logger

Internal data lo gger to save up to 2000

lines of data.

Manual totalizer 7 digit totalizaer for manual a cquisitions

and calibrations.

Housing material

ABS

Housing dimensions

460 (L) x 400 (W) x 110 (H) mm

Total weight

4.5 kg batteries included

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 10 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

2. INSTALLATION AND OPERATION

The installation of TTFM-100-B-HH-NG series is quite simple. It is only necessary t o

determine the mounting point in the pipe and knowing some information about the pipe’s

dimension.

2.1 MEASURING POINT

It is very important to select the right measuring point. The fluid has to be a measurable

fluid and the pipe should be suitable for this measuring technology.

Do not hesitate to contact B.M. TECNOLOGIE INDUSTRIALI for any further clarification.

Please proceed as f ollows:

1) Select the measuring point on the pip e, in order to have a fluid free from

turbulences.

2) The distance of measurement point upstream is 10D, downstream is within 5D. If

there is valve upstream, it is suggested to increase the distance up to 30 D.

3) Actually, the device could be installed into pipes with lining, but it is suggested to

avoid it above all if the pipe is old or damaged. Pipes should be suitable to this

measuring technology in order to improve measure and precision.

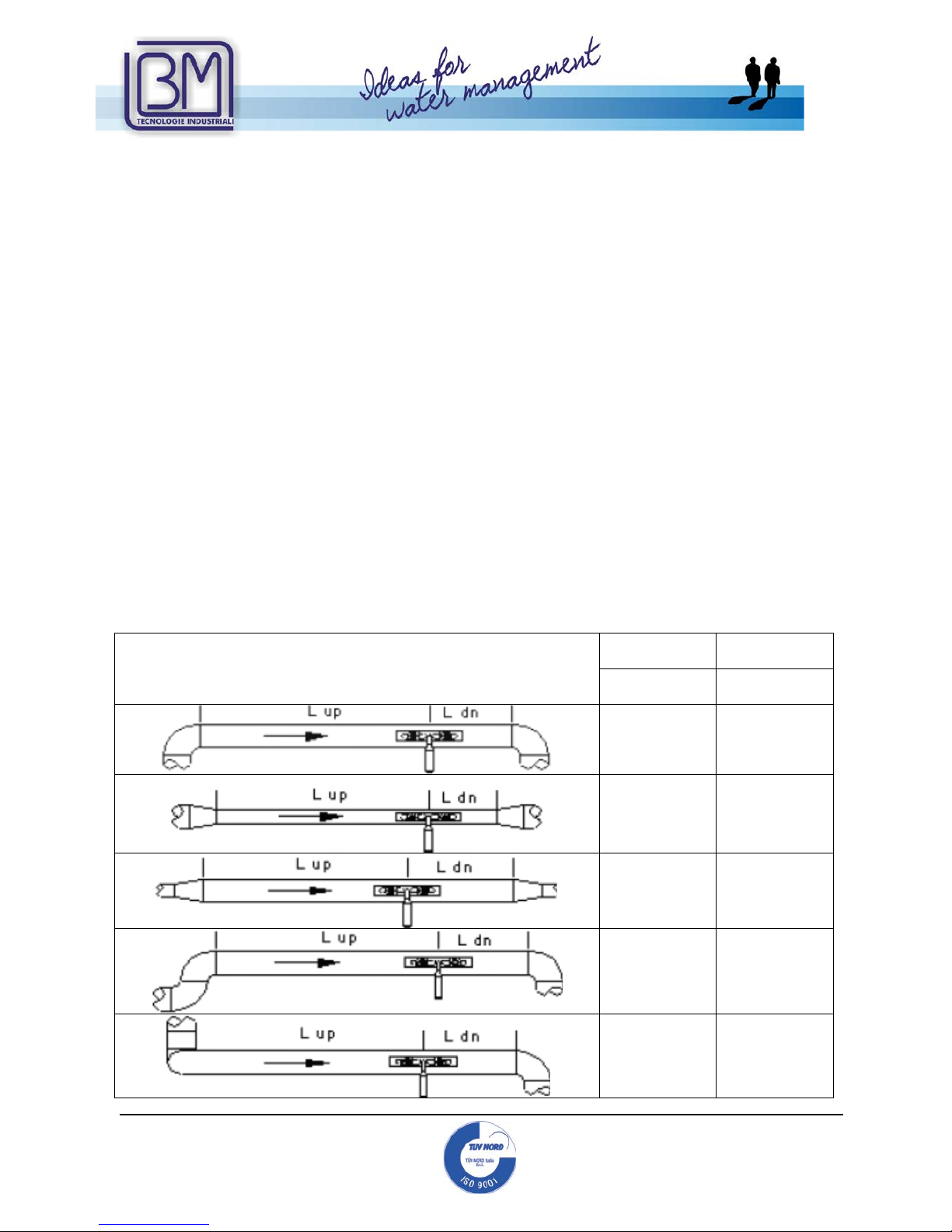

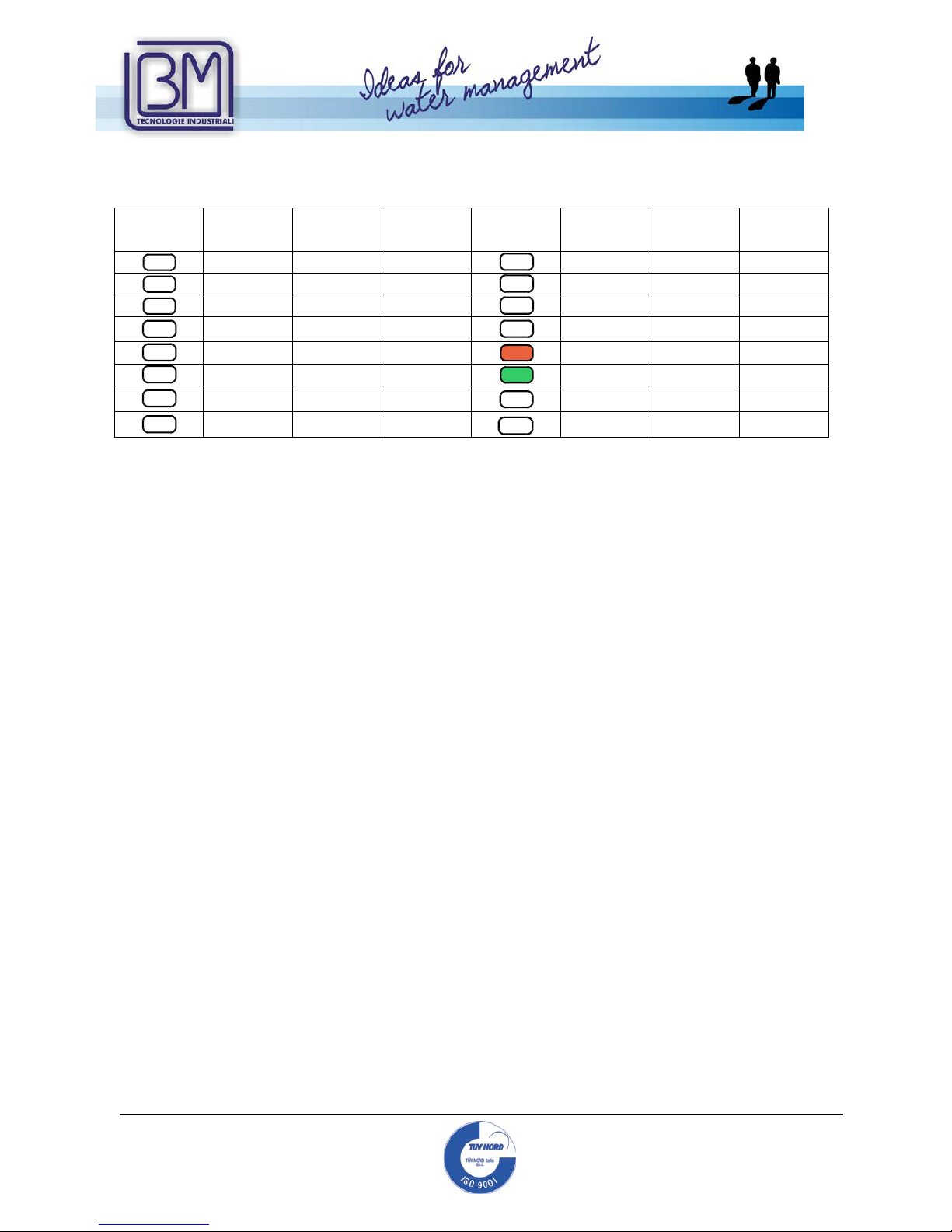

Possibile pipes configuration & possibile transducers position

Upstream

Dimensions

Downstream

Dimensions

L up x

Diameters

L dn x

Diameters

10D 5D

10D 5D

10D 5D

12D 5D

20D 5D

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 11 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

20D 5D

30D 5D

2.2 REQUIRED CONDITIONS

The more precise the below mentioned inform ation, the better accuracy and measure:

1) Pipe’s external diameter, without liner, if there is a liner.

2) Pipe’s internal diameter or thickness.

3) Pipe’s material or speed of sound through that material.

4) Internal liner: material and thickness or speed of sound through that material.

5) Fluid type or speed of sound through that fluid.

6) Transducers type.

7) Transducers mounting method (V, Z, N, W method).

In M25 menu it is possible to see the right mounting distance between the transducers.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 12 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

2.3 A PRACTICAL EXAMPLE OF RA PID SETTINGS

The following example shows an appli c ation with a DN 400 carbon steel pipe, no liner, with

“V” mounted sensors.

IMPORTANT NOTICE:

WHEN THE SET-UP IS COMPLETED, THE USER MUST GO BACK TO M EN U 26 AND

SELECT OPTION 1. SOLIDIFY SETTIN GS, AND THEN PRESS ENTER.

IN THIS WAY THE PARAMETERS WILL BE SAVED EVEN IF THE POWER SUPPLY

GOES OFF.

2.3.1 Fluid & pipe’s features

This is a zinc pipe, so its thickness is not a problem. It is also important to measure the

pipe’s circumference: it should b e 1286 mm. The pipe is PN10 and it will measure potable

water.

2.3.2

Data Entry

ATTENTION! The XXXXX values in the following windows are only examples.

The value could vary and must not be taken as representative.

Switch on the device and it will displ ay:

Ver.

XX.XX

S/N=XXXXXXXX

Then it will display, (it depends from the last switch off) for example:

Flow 0.0000 m3/h *I

No Signal Detected

The transducers are not installed and their mounting distance will be displayed only after

the set-up. Actually the device detect s no signals.

Press and the device will display:

Flow 0.0000 m3/h

*I

Window No. =

MENU

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 13 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Press and the device will display window no. 10.

Pipe Outer Perimeter

XXXX mm

Press and :

Pipe Outer Perimeter

1286 mm

If you press a wrong digit, press to correct.

Press and the device will display:

Pipe Outer Diameter

XXX.XXX mm

Press and the device will display:

Pipe Wall Thickness

X.X mm

Press , , + and the it will display:

Pipe Wall Thickness

6.5 mm

Press and the device will display:

Pipe Inner Diameter

396.347 mm

The device calculates the value based on the entered setti n gs.

It is possible to press again and the device will display the paramet ers it

calculated until now.

1

0

1

2

8

6

ENT

6

.

5

ENT

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 14 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Press and the device will display:

Pipe Material

[14

1. Stainless

Steel

The pipe material depends from the material of the pipe.

Press and “1” and is blinking.

Pipe Material [14

>1. Stainless Steel

Select the right material by using the

Pipe Material [14

>0. Carbon Steel

Press ENT and and the device will display:

Liner Material [16

0. None, No Liner

In this case, the pipe has no internal lini ng, so “0” is correct.

Press and the device will display:

Fluid Type [20

0. Water (General)

Press and the device will display:

Transducer Type [23

16. Clamp- on TM1

NOTE:

The standard sensors are Clamp-on TM1 type, for pip es fr om DN50 u p to

DN1000.

It is possible to ask for different sensors, depending from the application.

ENT

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 15 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Press and the device will display:

Transducer Mounting

0. V

Press and the device will display:

Transducer Spacing

385.268 mm

The displayed value id the sensors mounting distance, as shown in par. 2.2.

It is possible to install the transducers, as shown in the following par. 2.4.

Press and the device will display:

Default settings [26

1. Solidify settings

Press and the device will display:

Save / Load parameters

>>

Press to go through the parameters:

Save / Load parameters

>> To Browse

Or set up one of the 9 (0…8) preset configurations:

Save / Load parameters

>> Entry to LOAD

Press and the device will display:

Save / Load parameters

>> Entry to SAVE

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 16 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Press and the device will display:

Save / Load parameters

0: 409,347 mm, Carbon

This setting refers to the example configuration: DN400 carbon steel pipe.

Press and the device will display:

Save / Load parameters

Entry to SAVE

Press MENU, 1, ENT and the device will di sp l ay:

Flow 0.0000 m3/h *I

No Signal Detected

Now it is possible to install the transducers.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 17 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

2.4 INSTRUCTIONS FOR CLAMP-ON SENSORS INSTALLATION

If you ordered Clamp-on sensors type TTS100-TS2-NG, TTS100-M1-NG,

TTS100-L1-NG, TTS100-S1-NG-HT, TTS100-M1-NG-HT the following instructions are

very important for a correct installation of the sensors:

I. In order to install the sensors, check if the pipe has features which could affect the

measure, i.e. rust, dirt…

II. Measure the pipes’ diameter by using a callipers

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 18 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Or, if it is not possi ble to measure the diameter, please measure the pipe’s

circumference:

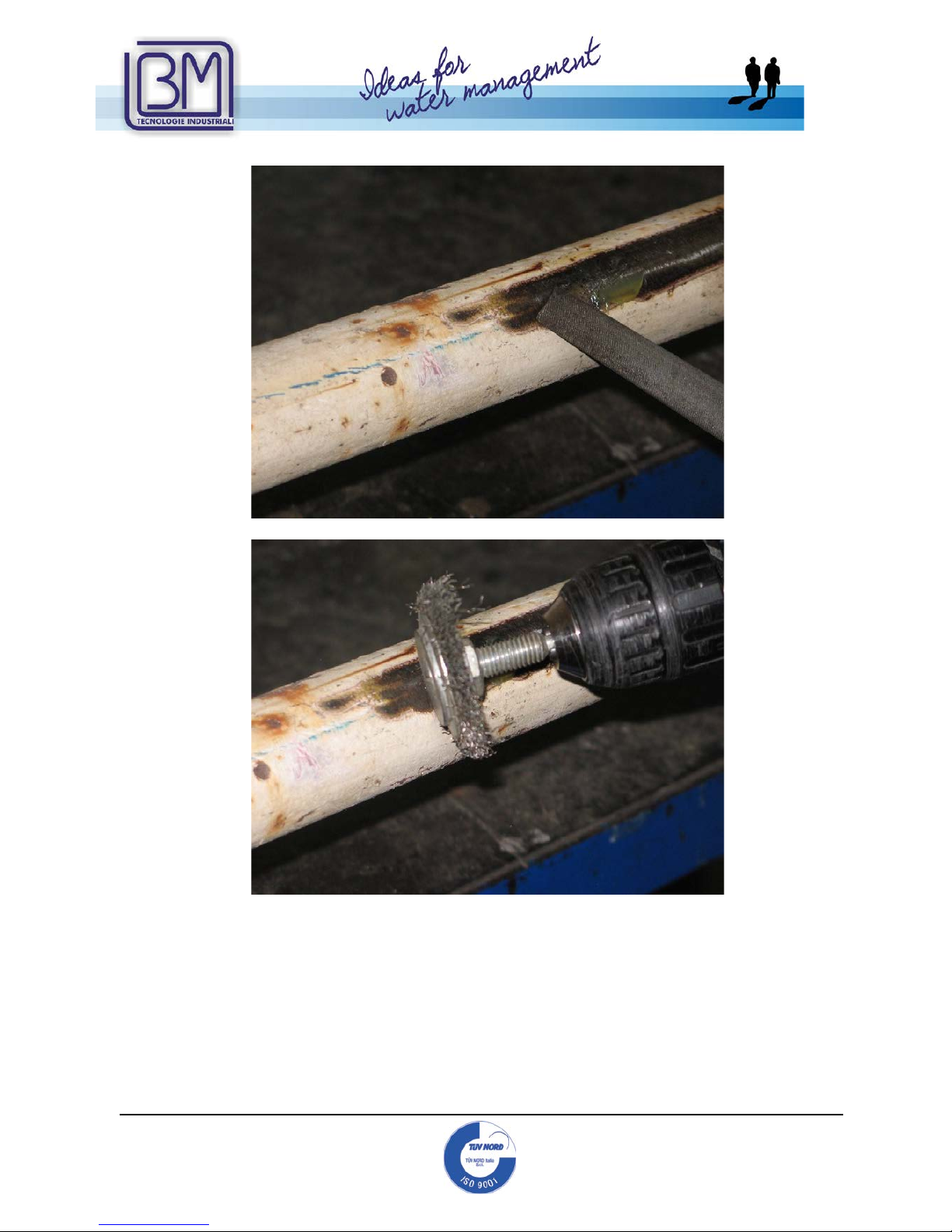

III. Clean the area where the sensors will be installed by using one of the following

tools:

Or

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 19 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Or

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 20 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

IV. The pipe section where the sensors will be installed should be completely clean:

V. Measure the pipe’s thickness.

This could be done by using our Thickness Gauge TT100-TM8812-NG

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 21 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Before placing and using the Thickness Gauge sensors, remember to use the

coupling grease:

Otherwise, the sensors could loo se the grip to the pipe.

VI. Enter the following values into device’s menus:

- pipe’s diameter (MENU 11) or pipe’ s circumference (MENU 10)

- pipe’s thickness (MENU 12)

- type of sensors to be used (MENU 23)

- Sensors mounting method (MENU 24)

The device will display the distance at which the sensors should be installed

(MENU 25).

Now it is possible to start the sensors install at i on.

Please remember to u se the coupling grease:

Otherwise, the sensor could loose grip to the pipe.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 22 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

VII. Sensors could be installed by using a fixing bra c ket:

Or by using our Rail Guide Mounting System RGMS-TS2-TM1-NG-FIX

(only with TS2 & TM1 sensors, pipes form DN15 to DN300).

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 23 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

VIII. Install the sensors according to the distance value the device displays in

MENU 25:

a) Installation of the clamp-on sensors wi th the fixing brackets:

Installation is completed:

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 24 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

b) Installation of the clamp-on sensors with our Rail Guide Mounting System

RGMS-TS2-TM1-NG-FIX (only with TS2 & TM1 sensors, pipes form DN15 t o DN300).

Installation is completed:

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 25 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

2.5 TRANSDUCER MOUNTING METHODS

The transducers mounting posit ions are related to the pipe diameter and to the type of

sensors. V and Z methods are the most common. By the way, V mounting is suggested.

The other mounting methods are N and W.

The letters V, Z, N, W stands for the number of signal crossings from one transducer to

another.

• Z= one crossing. Suitable for pipes > DN250 mm or smaller.

• V= two crossings. It is the easiest mounting method for DN600-800 pipes with TL-1

or TM-1 transducers.

• N= three crossings. Suitable for small pipes, DN100 or smaller, with TS-2

transducers. It similar to “Z” method, but for small pipes. In this case, the mounting

distance will be bigger.

• W= four crossings. Suitable for DN20 pipes with TS-2 transducers. It similar to “V”

method, but for small pipes. In this c ase, the mounting distance will be bigg er.

The following example shows the different m ounting solutions.

“Z” mounting method

“V” mounting method

“N” mounting method

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 26 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

“W” mounting method

“W” mounting method

V mounting method is the most commo n. It can be applied to almost all the applications: it

is the most simple and rapid one.

Z mounting method is suggested only if the signal strength, UP and DOWN (DN) is smaller

than 60 and Q valu e i s smaller than 60, see MENU “90”.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 27 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Strenth+Quality

[90

UP:54.4 DN:56.5

Q=45

2.5.1 “V” mounting method

The “V” method uses a bounce into the pipe and the ultrasonic wave goes through

more distance. The measuring principle is based on the difference of time and thro ugh

a “V” distance, the time needed is bigger a nd the precision higher. In case of ho r izontal

mounting, it is suggested to avoid m ounting the sensors on the top or on the bottom of

the pipe. Air bubbles on the top could stop the ultrasonic wave and the dump on the

bottom decrease and change the ultraso ni c entra nce angle. Refer to the picture below.

In case of vertical mounting, a void installing

the transducers on downward pipe walls,

even if they are under pressure. The pipes

with an external liner such as tar,

polyethylene, epoxy, should be cleaned

when in contact with the transducers.

A tube for acoustic coupling gel for sensor s

installation, is included in the supply. Use a

small quantity of coupling grease in or der to

improve acoustic the contact between the

sensor and the pip e’s external surface.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 28 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

2.5. 2 “Z ” mounting method

Press 1 while in menu 24 , if you want to choose “Z” mounting.

M24

Transducer Mounting

0. V-Method

=> 1. Z-Method

Press and the device will display:

M25

Transducer Spacing

152.771 mm

“Z” mounting method is more compli c ated than “V” mounting method: it is necessary to

create a band of foil as long as the pipe cir c um ferenc e and as wide as indicated i n MENU

25. Additionally, add a piece of paper to wrap the pipe.

Please refer to the picture below for finding the two lines needed to trace the exact half

point of the pipe.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 29 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Once the fascia is fixed on the pipe’s c i r c um ferenc e (with adhesive tape), it is possib le to

fix the sensors, as shown in the picture. If the pipe is horizontally mounted, it is suggested

to mount the sensors as shown in the next pictur e. If the pipe is vertically mounted, refer

to the instructions of “V” mounting metho d.

2.5.3 “W” & “N” Mounting Methods

These methods are suitable for small pipes, DN100 or less, wi th TS-2 transducers.

The signal path consists of four cro ssing s (for “W” method) and three crossings (for “ N”

method) inside t h e pipe. These methods are used to increase the transit time a n d

receiving time, otherwise the signal path in small pipes will be too short.

In “W” method, t h e sen sors are placed on the same side of the pipe at a definite distance,

in “N” method; they are placed on the opposite sides of the pipe, at a definite distance.

These methods are not very used because sm all sensors TS-2 could b e installed by using

“Z” method.

To choose “N” method, press 2 while in menu 24.

M24

Transducer Mounting

0. V-Method

1. Z -Method

=>2. N- Method

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 30 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Press and the device will display:

M25

Transducer Spacing

XXXXX mm

To choose “W” method, press 3 while in menu 24.

M24

Transducer Mounting

0. V-Method

1. Z -Method

2. N-Method

=> 3. W-Method

Press and the device will display:

M25

Transducer Spacing

XXXXX mm

Press and the device will display:

Save Paremeters [26

Select a room

by ENT UP DN

Save the configuration in one of the 18 rooms available (from 0 to 17) and press

Default Setting [26

>1. Solidify Setting

ENT

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 31 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

2.5.4

Mounting Analysis

After checking the strength of the received signal, the total spreading time, the time

difference and the rate of spreadi ng time, it is possible to confirm if the installation is

correct.

2.5.5

Signal s treng th and qual ity M90

Digit

The strength of signals is displayed by numbers from 00.0 to 99.9.

00.0 means no signal received, 99.9 means ma x sig nal. In normal working conditions, the

signal strength should be higher than 60.0.

The signal quality (Q) is displayed by numbers from 00.0 to 99.9. 00.0 m eans the signal is

the worst. 99.9 mean signal is the best. In normal working conditions, the signal quality

should be higher than 60.0.

During installation, please pay attention to signal strength and quality: they should be at

the maximum level.

M90 0.0000%

Strenth+Quality

S=000, 000 Q=00

Detect No Signal

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 32 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

2.5.6 To ta l spreading time, time difference M93

Digit

Total Time,Delta

Time

623,80uS, 242,12nS

The measurement method is based o n ti me difference, so the time and other disp layed

values can identify a correct install at i on. In normal operating conditions, t he time

difference should be smaller that ten p erc ent (10%). If the pipe diameter is small or the

speed is too low, the difference may be a l itt le higher. If the difference (and also flow and

speed) is too high, it means the signal quality is very bad. The reason may be: pipe’s

features, wrong installation o r wrong parameters setting.

2.5.7

Relation between calculated and measured transit time

To know if the sensors are well mounted, you should calcolate:

TIME – RATE = TOM * 100

TOS

In normal working conditions it should be 100 +/- 3%.

Digit

TOM/TOS*100

xxx,xx %

And eventually confirm the right mo unting method.

MENU

9

3

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 33 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

3. DISPLAY WINDOWS

This chapter will explain all the display wi ndows of TTFM100 Series and their contents.

The user can enter this menu by pressing

[*][*] represent the number of the window to be displayed .

The following list includes all the available windows.

3.1 FLOW RATE- TOTALIZERS MENU

00 All Totalizers

01 Main Display P OS Totalizer

02 Main Disp lay NEG Totalize r

03 Main Disp lay NET Totalizer

04 Date Time / Flow Rate + signal

05 Date Time / Signal Velocity

06 Received Shape of Signal

07 Battery Voltage / Battery remaining working time

08 System Error Code + Signal

0 9 Net Flow Today + Veloci ty

3.2 INITIAL SETTING MENU

10 Pipe Outer Perimeter

11 Pipe Outer Diameter

12 Pipe Wall Thickness

13 Pipe Inner Diameter

14 Pipe Material

(15 Pipe Sound Velocity)

if in menu 14 the user chose “other”

16 Liner Mate rial

(18 Liner Thickn ess)

if in menu 16 the user chose “other”

19 Inside ABS Thickness

20 Fluid Type

(21 Fluid Sound Velocity)

if in menu 20 the user chose “other”

(22 Fluid Viscosity)

if in menu 20 the user chose “other”

23 Trans ducer Ty pe

24 Transducer M ounting

25 Transducer Spacing

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 34 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

26 Save Parameters

27 Load Parameters

28 Poor Signal

29 Empty Pipe Set up

3.3 FLOW RATE UNITS MENU

30 Measurement Unit

31 Flow Rate Units

32 Totalize Units

33 Totalize Multiplier

34 NET Totalizer

35 POS Totalizer

36 NEG Totalizer

37 Totalizer Reset

38 Manual Totalizer

39 Language Selection

3.4 OPTIONAL SETTING MENU

40 Damping

41 Low Cutoff Value

42 Set Zero

43 Reset Zero

44 Manual Zero Point

45 Scale Factor

46 Network IDN

47 System Lock

(48 Keypad Lock Code)

if in the menu 47 the user chose YES

49 Communication Tester

3.5 INPUTS/ OUTPUTS MENU

50 Logger Option

51 Logger Setup

52 Data Direction

53 Buffer Viewer

54 AI5 Value Range

60 Date and Time

61 Software Version and Serial Number (ESN)

62 RS-232C Setup

67 FO Frequency Range

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 35 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

68 Low FO Flow Rate

69 High FO Flow Rate

70 LCD Backlight Option

71 LCD Contrast

72 Working Timer

73 Alarm #1 Low Value

74 Alarm #1 High Value

75 Alarm #2 Low Value

76 Alarm #2 High Value

77 Buzzer Setup

78 OCT Output Setup

82 Date Totalizer

85 Auto Power Off

86 Auto Control Enabled

87 Power selection

88 RCV Window start

89 RCV Window end

3.6 DIAGNOSTICS MENU

90 Single Strength and Quality

91 TOM / TOS*100

92 Fluid Sound Velocity

93 Total Time and Delta Time

94 Reynolds Numbe r and Factor

3.7 OTHER DISPLAYS MENU

From menu 94 onwards, by pressing

It is possible to display some additional information

M+ 0 Power ON/OFF Time

M+ 1 Total Working Time

M+ 2 Last Power Off

M+ 3 Last Flow Rate

M+ 4 ON/OFF Times

M+ 5 Calculator

M+ 6 Velocity change

M+ 7 Protocol Select

M+ 8 Receive Shape

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 36 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

3.8 FLOW RATE- TOTALIZERS MENU ANALYSIS

Digit

and the device will display

POS +4879 m3

NEG -336 m3

NET +4543 m3

S=000, 000 Q=00

I

This a display window. The measuring units should be set up in menu M31 a nd M32.

NET is the net totalizer, result of adding the positive totalizer POS to the negative totalizer

NEG.

Digit

and the device will display

POS +4879 m3

Flow 123.00 l/s

Vel 0.5678 m/s

S=679, 681 Q=56R

This a display window. The measuring units should be set up in menu M31 and M32.

Digit

and the device will display

NEG -336 m3

Flow 123.00 l/s

Vel 0.5678 m/s

S=679, 681 Q=56R

This a display window. The measuring units should be set up in menu M3. The POS value

refers to the positive totalizer.

Digit

and the device will display

NET +4543 m3

Flow 123.00 l/s

Vel 0.5678 m/s

S=679, 681 Q=56R

This a display window. The measuring units should be set up in menu M31 a nd M36. The

NEG value refers to the negative totalizer.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 37 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Digit

and the device will display

Date 06-11-12

Time 09:54:00

Flow 123.00 l/s

S=679, 681 Q=56R

This window displays date and tim e in the following format yy-mm-dd; hh-mm-ss, and the

current flow rate.

Date and time should be set up in m enu M 60.

Digit

and the device will display

Date 06-11-12

Time 09:54:00

Vel 0.5678 m/s

S=679, 681 Q=56R

This window displays date and tim e in the following format yy-mm-dd; hh-mm-ss, and the

current speed.

Date and time should be set up in menu M60.

Digit

and the device will display

RCV

SHP___________

This window displays shape of the signal received by the transducers

Digit

and the device will display

Battery Voltage

3.5679 V

Battery Worktime

00:45:34

This window displays the battery features and status.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 38 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Digit

and the device will display

Error Code

-----------------------R

System Normal

S=679, 681 Q=56R

This window displays the error codes. Please refer to the list of complete error codes at

page 65.

Digit

and the device will display

Net Flow Today

134 m3

Vel 0.5678 m/s

S=679, 681 Q=56R

This window displays the net daily flow rate.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 39 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

3.9 INITIAL SETTING MENU ANALYSIS

Digit

and the device will display

M10

Outer Perimeter

1286 mm

This window is used to set up the p i pe’s perimeter, if known or measurable.

Digit

and the device will display

M11

Outer Diameter

409.347 mm

This window is used to set up the external pipe’s diameter. When the pipe’s external

perimeter diameter is set up, the exter n al pip’s diameter is automatically setup too.

Digit

and the device will display

M12

Wall Thickness

6.5 mm

This window is used to set up the p i pe’s thickness. It is also possible to pass over this

menu and go to the menu M13, used to set up the internal pipe’s diameter.

Digit

and the device will display

M13

Inner Diameter

396,347 mm

This window is used to set up the net pipe’s internal diameter.

Digit

and the device will display

M14

Pipe Material

0.Carbon Steel

This window is used to set up the pipe’s material.

Press ENTER to activate the material selection.

Use the arrow keys to scroll among the list:

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 40 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

0 Carbon Steel

1 Stainless Steel

2 Cast Iron

3 Ductile Iron

4 Copper

5 PVC

6 Aluminium

7 Asbestos

8 Fibreglass

9 Other*

*If option 9 is chosen, the sound speed set up is mandatory, see the APPENDIX,

from page 70.

This window will de displayed only i f i n M14 the user chose “9. OTHER”

Digit

and the device will display

M15

Pipe Sound Vel

xxxx m/s

Set up the speed of sound through the pipe material, referring to the construction material

of the pipe.

For information about the sound speed through other types of materials that

are not included in the list, please refer to the tables starting at page 70.

Digit

and the device will display

M16

Liner Material

0.No Liner

This window is used to set up the liner’ s m aterial.

Press ENTER to activate the material selection.

Use the arrow keys to scroll among the list :

0 NO Liner

1 Tar Epoxy

2 Rubber

3 Mortar

4 Polypropylene

5 Polystyrol

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 41 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

6 Polystryene

7 Polyester

8 Polyethylene

9 Ebonite

10 Teflon

11 Other*

*If option 11 is chosen, the sound speed s et up is mandatory, see the

APPENDIX, f rom page 70.

This Menu will activate only if in M16 the user chose “11. OTHER”

Digit

and the device will display

M17

Liner Sound Velocity

xxxx m/s

Set up the spreading time of sound through the constructi on material of the liner.

For information about the sound speed through other types of materials that

are not included in the list, please refer to the tables starting at page 70.

This Menu will activate only if in M16 the user chose “11. OTHER”

Digit

and the device will display

M18

Liner Thickness

0 mm

Set up the internal liner thickness.

Digit

and the device will display

Inside ABS Thickness

[18

0

mm

This menu is not used, please ignore it.

MENU

1

9

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 42 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Digit

and the device will display

M20

Fluid Type

0 Water

This window is used to set up the measuring flow type.

Press ENT to enable the fluid selection and use the arrow keys to scroll the list:

0 Water

1 Sea Water

2 Kerosene

3 Gasoline

4 Fuel Oil

5 Crude Oil

6 Propane (-45°C)

7 Butane (0°C)

8 Other

9 Diesel Oil

10 Castor Oil

11 Peanut Oil

12 Gasoline #90

13 Gasoline #93

14 Alcohol

15 Water (+125°C)

Press ENT to confirm.

This Menu will activate only if in M20 the user chose “8. OTHER”

Digit

and the device will display

M21

Fluid Sound Velocity

1482.8 m/s

Enter speed of sound through the fluid to be measured.

For information about the sound speed through other types of materials that

are not included in the list, please refer to the tables starting at page 70.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 43 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

This menu will activate only if in M20 the user chose “8. OTHER”

Digit

and the device will display

M22

Fluid Viscosity

1.0038 cST

Enter the viscosity of the fluid to be measured.

Digit

and the device will display

Transducer Type

[23

0. Clamp-on TM-1

This window is used to set up the type of transducers.

Press ENT to enable the transducers type selection and use the arrow keys to scroll the

list:

0. Standard M

1. Plug-in type A

2. Clamp-on TM-1 *

3. User Type

4. Standard B

5. Plug-in Type B45

6. Standard L

7. Clamp-on TS-2 *

8. Standard M1

9. Plug-in Type C

10. Standard HS

11. Standard HM

12. Standard S1

13. PI-Pipe

14. Standard L1

15.Clamp-on TL-1 *

* OUR STANDARD CLAMP-ON SENSORS

Press ENT to confirm the type of tra nsducers.

Selection No. 3 “USER TYPE” allows the user to install types of sensors not included in the

list. In this case, it is necessary to enter some more information about the technical

features of the new type of sensors:

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 44 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

1. wedge degree of u l tr asonic impulse.

Pi-PipeParameter

Wedge Degree

45 deg

2. speed of sound.

Pi-PipeParameter

Wedge Sound Velocity

2720 m/s

3. distance from crystal to sensor wedge.

Pi-PipeParameter

Wedge Distance

32 mm

4. delay of ultrasonic signal.

Pi-PipeParameter

Wedge Time Delay

5.18 uS

Digit

and the device will display

M24

Txducer Mounting

0. V -Method

This window is used to set up the mounting method of the transducers.

Press ENT to enable the transducers type selection and use the arrow keys to scr oll the

list:

0. V Method

1. Z Method

2. N Method (small pipes)

3. W Method (small pipe)

Press ENT to confirm the type of tra nsducers.

Digit

and the device will display

M25

Transducer Spacing

385.268 mm

This window informs about the mo unting distance of the transducers. See. Par. 2.4-2.5.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 45 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Digit

and the device will display

M26

Save Parameters

Select a room

by ENT UP DN

This windows allows the user to save the configuration. It is possible to save up to 18

configurations (from 0 to 17).

Digit

and the device will display

M27

Load Parameters

Select a room

by ENT UP DN

This window is used to upload one of t he 18 saved configurations. Press ENT and t hen use

the arrow keys to scroll among the configurations. Press ENT to select the desired one.

Digit

and the device will display

M28

Holding Poor Signal

YES

This window is used to set up the d evic e in order to maintain the last readi ng as valid in

case of temporary loss of signal. If NO is selected, output signal could be modified.

Digit

and the device will display

M29

Empty Pipe Setup

0

This window is used to set up a m i n threshold. Below that threshold the device considers

the pipe as empty. Set up a value among 30 and 40 in order t o be sure the device does

not measure when the pipe is empty.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 46 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

3.10 FLOW RATE UNITS MENU ANALYSIS

Digit

and it will display

M30

Measurement Units

Metric

This window is used to set up the measuring system:

0. metric

1. English

Press ENT and then use the arrow keys to choose the measuring system. Confirm with

ENT.

Digit

and the it will display

M31

Flow Rate Units

m3/h

This window is used to set up the measuring flow rate units. Press ENT and then use the

arrow keys to select the measuring unit am ong:

0. Cubic Meters

1. Litres

2. USA Gallons

3. Imperial Gallons

4. USA Million Gallons

5. Cubic Feet (cf)

6. USA Barrels

7. Imperial Barrels

8. Oil Barrels (ob)

Press ENT to confirm the selection and it will display:

M31

Cubic Meters (m3)

:: /hour

/day

Use the arrow keys to select the time units to w hich the current flow rate should refer:

/hour

/day

/min

/sec

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 47 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Press ENT to confirm the selection.

Digit

and the it will display

M32

Totalizer Units

Cubic Meters

This window is used to set up totalizing flow rate units, please refer to menu M 31 f or what

concerns Volumetric units and their setting.

Factory settings are in m3.

Press ENT and then use the arrow keys to select t he measuring unit among:

0. Cubic Meters

1. Litres

2. USA Gallons

3. Imperial Gallons

4. USA Million Gallons

5. Cubic Feet (ct)

6. USA Barrels

7. Imperial Barrels

8. Oil Barrels (ob)

Digit

and the it will display

M33

Totalizer Multiplier

X1

This window is used to set up the multiplying factor for totalization, in order to avoid

reaching the max. counting in a shor t time.

Press ENT and then use the arrow keys to select among:

0. X 0.001 (1E-3)

1. X 0.01

2. X 0.1

3. X1

4. X10

5. X100

6. X1000

7. X10000 (1E+4)

Press ENT to confirm.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 48 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Digit

and the it will display

M34

NET Totalizer

ON

This window is used to enabl e the net totalizer, between positive and negative totalizers.

Factory setting is ON.

Press ENT and then use the arrow keys to select ON or OFF. Press ENT to confirm.

Digit

and the it will display

M35

POS Totalizer

ON

This windows is used to enable the positive totalizer. Factory setting is ON.

Press ENT and then use the arrow keys to select ON or OFF. Press ENT to confirm.

Digit

and the it will display

M36

NEG Totalizer

ON

This windows is used to enable the negative totalizer. Factory setting is ON.

Press ENT and then use the arrow keys to select ON or OFF. Press ENT to confirm.

Digit

and the it will display

M37

Totalizer Reset?

Selection

This window is used to enable the comp lete or selective reset of internal co unters.

Press ENT and then use the arrow keys to select NO or YES. If YES is cho sen , please select

among:

None

All

NET TOtalizer

POS Totalizet

NEG Totalizer

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 49 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Press ENT to confirm the selection and the device will display:

M37

Select Totalizer

Reset Finished

Digit

and the it will display

M38

Manual Totalizer

ENT When Ready

This window is used to enable the totalizer backlog. Press ENT to enable the backlog (ON),

press ENT again to disable the backlog (OFF).

Digit

and the it will display

M39

Language

English

This window is used to select the device’s d i splay language.

Press ENT and then use th e arrow keys to select the language. Press ENT to confirm.

Digit

and the it will display

M40

Damping

15 sec

This window allows the user to change the value of damping, the seconds needed to

display the analog signals and the output signals. The standard value i s between 15 and

30 seconds, the setting range goes from 0 to 99 seconds.

Digit

and the it will display

M41

Low Flow Cutoff Val.

0.03 m/s

This window allows the user to set up the speed threshold. Below that level, the device w i ll

display 0 flow rate and the totaliza tion is stopped.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 50 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Digit

and the it will display

M42

Set Zero

Press ENT to go

This windows is used to enable the flow rate zero procedure with a static fluid . The flow

into the pipe must be completely sta tic. The zero procedure has beneficial effects b oth in

low and high flow rate.

Press ENT and the device will display an indicator going right to “0”. it will be possible t o

delete the zero setting by using the next menu 43.

Warning!!!

If the flow rate is different from 0, the displayed current flow rate will be 0.

Digit

and the it will display

M43

Reset Zero

NO

This window is used to delete the zero procedure of the previ ous menu M42. press ENT

and then use the arrow keys to display NO or YES, to disable or enable the deleting

function.

Digit

and the it will display

M44

Manual ZeroPoint

0 m3/h

This window is used for setting an offset value to be added or detracted (it depends from

the setting polarity) to the current flow rat e. Usually, i f the user knows very well the

current flow rate, this function permit s to correct the displayed value.

Press ENT and then the arrow keys in order to have a negative offset value, followed by

the valued to be added or detracted. Press ENT again to confirm.

Digit

and the it will display

M45

Scale Factor

1

This window is used to set up the scale factor value. This value will affect the measure in

order to correct the displayed value.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 51 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Digit

and the it will display

M46

Network IDN

88

This window is used to set up the ID value of the net.

The values could b e set among 0 and 65535 excep t for 13(0DH enter), 10(0AH enter),

42(2AH*), 38(26H&), 65535.

The ID value is used during the setting operations to identify the device in a devices

network.

Digit

and the it will display

M47

System Lock

**** Unlocked ****

This windows is used to set up a password to block the system from unauthorized access.

It is composed of a number from 1 up to 4 digits.

Digit

and the it will display

M49

Comm Tester

This window is used to display the co m m uni cation test with a remote device by serial port.

MENU

4

9

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 52 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

3.11 INPUTS/ OUTPUTS MEN U ANALYSIS

Digit

and the it will display

M50

Logger Option

ON

This window is used to enable the data l ogging by using an external logger.

Press ENT and then use the arrow keys to enable or disable the p arameter to be log ged.

If ON is chosen, it will be possible to choose among:

1. Date Time ON / OFF

2. System Status ON / O FF

3. Current Window ON / OFF

4. Flow Rate ON / OFF

5. Velocity ON / OFF

6. NET Totalizer ON / OFF

7. POS Totalizer ON / OFF

8. NEG Totalizer ON / OFF

9. Signal Strength ON / OFF

10. Working Timer ON / OFF

11. Flow Today ON / OFF

Press ENT and then use the arrow keys to select the desired parameter to be

enable/disabled.

Digit

and the it will display

M51 Logger Setup

Start Time 00:00:00

Interval 00:00:00

Go On Time

00:00:00

This window is used to set up the data logging time. It should be set to go on until a

definite time set by the u ser.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 53 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Digit

and the it will display

M52

Data Direction

0.To RS-232

This window is used to set the direction of the data the device is log ging. It is possible to

select an ption among:

0. To RS232

1. To Buffer

2. Buffer=>RS232

3. Clear Buffer

Select the option and confirm with ENT .

Digit

and the it will display

M53

Buffer Viewer

Press ENT to go

This window is related to the editing of the internal buffer’s da ta.

Menus from M54 to M59 are not used. They will be implemented in the next

software versions.

Digit

and the device will display

M60

Date YY–MM–DD

Time HH:MM:SS

This window is used to set up date and time. Press ENT and digit: year, month, day of the

month, hour, minute and seconds. Pr ess ENT again to confirm. If during the set-up the

user makes a mistake, or if it is necessary to change a value, press the key until you

reach the desired digit and the digit the right number.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 54 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Digit

and the device will display

M61

Ver 8.38x32

ESN=06080262H

This window displays the software version and the serial number of the device (ESN). Due

to continuous software updating, the software versions could be different.

Digit

and the device will display

M62

RS-232C Setup

Baudrate:=19200,

Parity: None

This window is used to set up the communication parameters of the serial por t. Press ENT

and then use the arrow keys to select among:

Baud Rate:

115200

57600

38400

14400

28800

19200

9600

4800

3600

2400

1200

600

300

150

110

75

Press ENT to confirm the selected option and then select the parity type among:

None

Even

Odd

Press ENT to confirm the selection and exit the setting.

The other parameters are factory set up: 8 bit data, 1 bit stop and flow control Xon/Xoff.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 55 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Menus from M63 to M66 are not used. They will be implemented in the next

software versions.

Digit

and the device will display

M67

FO Frequency Range

0 – 9999

This window is used to set up the frequence output in the field 0-9999 Hz, proportionally

to the measured flow rate:

Press ENT and then the ↓ key. the device will display:

M68

Low FO Flow Rate

0 m3/h

Digit the starting range value and press ENT, then press the ↓ key and the device will

display:

M69

High FO Flow Rate

150

m3/h

Digit the ending range value and press t he ↓ key. The setting is finished.

Digit

and the device will display

M70

LCD Backlight

This window is used to set up the d i sp l ay backlight mode.

Digit

and the device will display

M71

LCD Contrast

8

This window is used to set up th e display contrast. Press ENT and the use th e arrow keys

to select a value from 0 up to 31. Press ENT agai n to confir m the selection.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 56 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Digit

and the device will display

M72

Working Timer

34:54:32

This window displays the device working time. Press ENT and then use the arrow keys to

delete the device working time. Press ENT to confirm the selection.

Digit

and the device will display

M73

Alarm #1 Low Value

0 m3/h

This window is used to set up the min. flow rate threshold for alarm 1. press ENT, digit the

flow rate value and press ENT again.

Digit

and the device will display

M74

Alarm #1 High Value

500 3/h

This window is used to set up the max. flow rate threshold for alarm 1. press ENT, digit

the flow rate value and press ENT again.

Digit

and the device will display

M75

Alarm #2 Low Value

0 m3/h

This window is used to set up the min. flow rate threshold for alarm 2. press ENT, digit the

flow rate value and press ENT again.

Digit

and the device will display

M76

Alarm #2 High Value

500 3/h

This window is used to set up the max. flow rate threshold for alarm 1. press ENT, digit

the flow rate value and press ENT again.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 57 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Digit

and the device will display

M77

BUZZER Setup

16. Not Using

This window is used to set up up the buzzer. Press ENT and then use the arrow keys to

select among:

No signal

Poor signal

Not ready

Reverse flow

A.O. Over 100%

F.O. Over 120%

Alarm #1

Alarm #2

Batch control

POS Int Pulse

NEG Int Pulse

NET Int Pulse

No function

ON/OFF via RS232

Fluid changed

Key stroke ON

Not using

Press ENT again to confirm the selection.

Digit

and the device will display

M78

OCT Output Setup

13. FO

This window is used to set up the open collector function (OCT). Press ENT and then use

the arrow keys to select among these options:

No signal

Poor signal

Not ready

Reverse flow

A.O. Over 100%

F.O. Over 120%

Alarm #1

Alarm #2

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 58 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Batch control

POS Int Pulse

NEG Int Pulse

NET Int Pulse

Energy Pulse

FO

FO via RS232C

ON/OFF via RS232

Fluid changed

Not using

Press ENT again to confirm the selection.

Menus from M79 to M81 are not used. They will be implemented in the next

software versions.

Digit

and the device will display

M82

Date Totalizer

View by Day

This window is used to set up the time for logging the flow rate volume. Press ENT and

then use the arrow keys to select one option among the following:

View by Day

View by Month

View by Year

Press ENT again to confirm the selection and activate the displaying of the fo ll owing:

No. 00

Date 06-11-12

Status ---------R

3456.95 m3

The first line display the logging “ 00” dated 11th of August 2006, other info r m ation are

related to the current errors, the other line displays the flow rate on the 11th of August

2006 at 23:59:59. p ress the ↑ key to scroll the other 63 logg ings. Press ENT to exit this

display.

Menus M83 and M84 are not used. They will be implemented in the next

software versions.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 59 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Digit

and the device will display

M85

Auto Power Off

Enable

Disable

This menu allows the user to enable or disable the automatic power off.

Select between the t wo options and press ENT to confirm.

WARNING!!!

THE FOLLOWING MENU 86, 87, 88, 89 ARE FOR EXPERT USERS

ONLY.

B.M. TECNOLOGIE INDUSTRIALI SUGGESTS NOT TO CHANGE THEM.

PLS LEAVE THE FOLLOWING MENUS AS DEFAULT SET.

Digit

and the device will display

M86

Auto CNTR Enable

YES

This menu allows the user to select between automatic or user defined status.

Automatic is the default status. User defined status is used to define peculiar

conditions in which the contro l parameters set by the customer are activated.

We suggest not to change this menu. Leave it as factory default.

If needed, select between the two optio n s and press ENT to confi rm.

Digit

and the device will display

M87

Power Selection

This menu allows the user to select how many p ulses wil l be sent out to activate the

transducers. The selection could be done among 1…10 pulses. Default setting: 10 pulses.

We suggest not to change this menu. Leave it as factory default.

If needed, select between the options and press ENT to confirm.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 60 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

Menus M88 and M89 will be operative only if in menu M86, the user selected NO

(not default setting).

As we recommend not to change M86 settings, the following menus will not be

used.

Digit

and the device will display

M88

RCV Window Start

80

This menu allows the user to enter the sta r ting time of the receiving signal window.

Signals arriving before the starting time will be neglected by the device.

We suggest not to change this menu. Leave it as factory default.

If needed, select between the option s and press ENT to confirm.

Digit

and the device will display

M89

RCV Window End

125

This menu allows the user to enter the ending time of the receiving signal window. Signals

arriving after the ending time will be neglected by the device.

We suggest not to change this menu. Leave it as factory default.

If needed, select between the option s and press ENT to confirm.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 61 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

3.12 DIAGNOSTICS MENU ANALYSIS

Digit

and the device will display

M90 0.0000%

Strenth+Quality

S=xxx, xxx Q=xx

Detect No Signal

This window displays the strength a nd the quality of the signal with numbers from 00.0 to

99.9.

00.0 means that there is no signal, 99.9 means that the signal is at its max. value.

In normal working conditions the streng th signal should be around 60.0.

During installation, quality and strength have to be at their max. values.

Digit

and the device will display

M91

TOM/TOS*100

100,25 %

This window displays the relationship between the transit time and the measured tim e. In

normal working conditions, it should be 100 +/- 3%. Bigger differences indicate an error in

mounting or the setting of wrong parameters.

Digit

and the device will display

M92

Fluid Sound Velocity

1482.56 m/s

This window displays the speed of sound through the fluid. In normal wor king conditions,

the value should be similar to the one indicated in menu M21. big difference indicate an

error during the sensors mounting or an error in the setting of M21.

Digit

and the device will display

M93

Total,Delta Time

623,80uS

242,12nS

This window displays the tota l transit time and the UP-DOWN difference between transit

times. The values give info r m ation about the installation. In normal working conditions the

difference is less than 10%.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 62 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

If the pipe diameter is small or the fluid velocity is very low, the difference might be a little

bigger. If the difference, the flow rate and the speed are too big, they indicate a very bad

signal. The causes could be: pipe’s features, wrong mounting, wrong parameter setting.

Digit

and the device will display

M94

Reynold Number

12234.6 0.92435

This window displays the calculated Reynold’s number. It indicates the moving mode inside

the pipe.

Menus from M95 to M99 are not used. They will be implemented in the next

software versions.

3.13 OTHER DISPLAYS MENU ANALYSIS

Digit

and the device will display

M+0

ON/OFF Time

ENT When Ready

It is possible to see the last time the device has been switched ON/OFF.

Press ENT and then use the arrow keys to di splay the sequence of 64 ev en ts (from 00 up

to 63) of switching on and switching off.

Press the ↓ key to display:

M+1

Total Work Hours

35:34:45

Press the ↓ key to display:

M+2

Last Power Off Time

Date 06-08-12

Time 09:34:26

Press the ↓ key to display:

M+3

Last Flow Rate

0 m3/h

Press the ↓ key to display:

MENU

9

5

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 63 of

95

B.M. Tecnologie Industriali

Via Praimbole 13

35010 LIMENA (PD)

VAT No. IT02459940280

Tel. +39 (0) 49 884.16.51

Fax +39 (0) 49 884.16.54

E-Mail bm@bmtecnologie.it

Web www.bmtecnologie.it

M+4

ON/OFF Times

132

Press the ↓ key to display:

Calculator

Input X=

0

It is used as a calculator, setting X value, and then Y value. Press ENT to calculate.

Press the ↓ key to display:

M+6

Velocity Change

1 m/s