BMR Suspension TAS010 User Manual

TORQUE ARM CONVERSION INSTALLATION INSTRUCTIONS

TAS010 - 1968-1974 Nova 10 BOLT

Please take note before proceeding with this installation:

• This product may interfere with certain exhaust kits. Exhaust crossovers are not

compatible with this torque arm suspension. In some circumstances, it may be necessary

to fabricate a custom exhaust for proper clearance.

• While not necessary, a heavy duty cast aluminum differential cover is recommended with

this kit. These covers are more structural in nature than the stamped steel OE unit and

will distribute the load across the differential, further strengthening the assembly.

TOOLS REQUIRED:

3/8” and ½” drive ratchets

½”, 5/8” deep, 9/16”, ¾” deep, 15/16” and 1-1/8” sockets

Pry-bar

3/8” Allen wrench

ADDITIONAL ITEMS REQUIRED:

RTV gasket silicone

Gear oil

CROSS-MEMBER

INSTALLATION:

1) Lift the vehicle and support

with stands under the rocker

panel pinch seams (Do not

place stands under the

subframe).

2) Remove the exhaust system.

3) Using a 15/16” socket,

remove the rear two body

mount bolts.

4) Remove the OE rubber body

mount bushings. They are

composed of an upper and

lower bushing that

“sandwich” the subframe

together in the middle. NOTE: a pry-bar may be necessary to get the subframe low

enough to remove these bushings.

5) Once the OE bushings have been removed, inspect the subframe for rust damage. This is

a common area susceptible to rust and if the mounting point is compromised, it needs to

be repaired before proceeding with the installation.

6) Begin with the driver’s side. Assemble the driver’s side frame mount, billet body mounts

and washer (if necessary) as shown in the image above. If you are using a subframe

connector that mounts around the body bushing, omit the supplied aluminum spacer

washer shown in Image 1 above.

1

CROSS-MEMBER INSTALLATION (Cont.)

7) Thread the supplied 5/8” bolt, washer and lock washer into the body and snug the bolt

just enough to allow the frame bracket to rotate around the axis of the bushing.

8) Repeat steps 4-7 for the passenger side. At this stage both mounts should be installed and

you can mount the cross-member. Lift the cross-member into place and insert the

supplied ½” x 4.5” bolts, (8) stainless washers, and nuts.

9) Tighten the body mount bolts to 150 ft/lbs.

10) Center the cross-member to the driveshaft then tighten the (4) cross-member bolts.

TORQUE ARM INSTALLATION INSTRUCTIONS:

1) Remove the differential drain plug or loosen the cover bolts to drain the gear oil from the

differential.

2) If it was not necessary to remove the cover previously, remove the 12 bolts from the

differential cover and remove the cover.

3) Using a gasket scraper, remove all

gasket material from the cover and the

differential.

4) Thread the four supplied 5/16” studs into

the differential at the four corners. All

studs should bottom out and should

thread in to the same depth. If not, run a

5/16-18 bottoming tap through the holes

in the differential.

5) Apply a thin bead of RTV Black or Grey

gasket silicone onto the differential

gasket mating surface. Install one of the

supplied gaskets.

6) Apply another thin bead of RTV on the exposed gasket surface. Position the BMR torque

arm mounting plate onto the rear end with the torque arm mounting points facing forward

as in Image 1 above.

2

TORQUE ARM INSTALLATION INSTRUCTIONS (Cont.)

7) Apply another thin bead of RTV onto the BMR torque arm mounting plate at the gasket

mating surface then install the other

supplied gasket.

8) Apply another thin bead of RTV onto the

exposed gasket surface then re-install the

differential cover.

9) Place one of the supplied 5/16” washers

and 5/16” poly-lock nuts onto each stud

and then insert the (6) 5/16” bolts and

washers into the remaining holes. Tighten

all twelve in a star shaped pattern. Snug

each one first then torque them to 20-25

ft/lbs.

10) Mount the torque arm to the differential

mounting plate using one of the supplied

½” x 3.25” bolts. Place a stainless washer

under the nut and temporarily thread it

finger tight. (See Image 2)

11) Insert the front telescoping bushing into

the torque arm with the grease fitting

pointing downward.

12) Lift the front of the torque arm up until the

bushing hole lines up with the mount on

the torque arm cross-member. Insert the

supplied ½” x 4” bolt, nut and stainless

washer. Tighten to 90 ft/lbs. (Image 3)

13) Using either a 5/8” or ¾” deep socket,

slightly loosen the leaf spring mounts on

the rear end. They should be loose enough

to allow the rear end to rotate slightly.

14) Position one of the support braces up

against the torque arm as shown in Image

5. Place a lock washer over two of the

supplied ¾” x 2” bolts and thread them

into the support brace, through the BMR

differential mounting plate. Leave the

bolts loose.

3

TORQUE ARM INSTALLATION INSTRUCTIONS (Cont.)

15) Repeat step 18 for the other side.

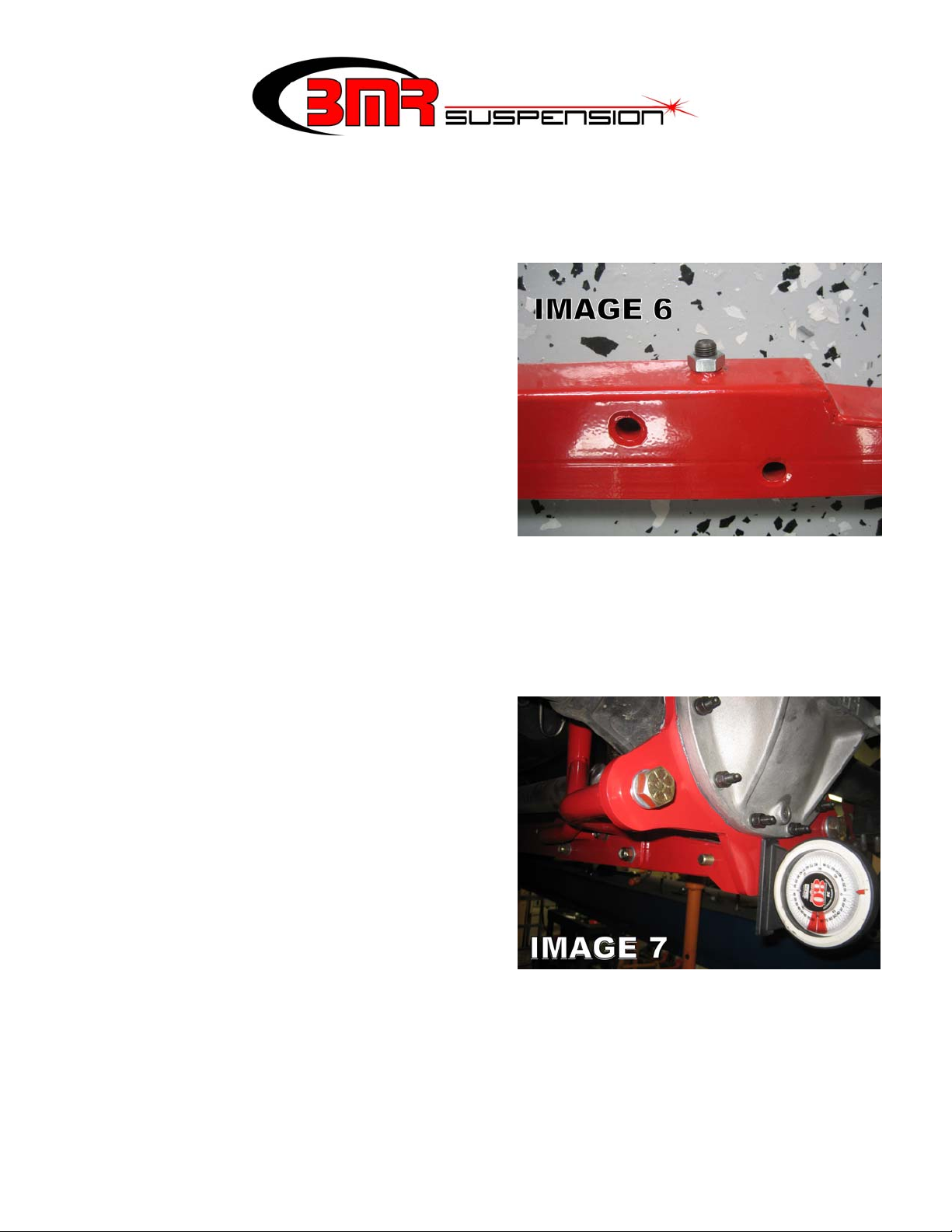

16) Loosen the jack screw from the bottom side of the torque arm using a 3/8” Allen

wrench.(Image 6) Loosen it as far as

possible to provide clearance between the

rear end and the torque arm. This will be

adjusted in a later step.

17) Place washers over the supplied ½” x 3.25”

bolts and insert them into the four holes on

the torque arm. It is typical for these holes

not to align properly and is necessary to use

a pry-bar to pivot the rear end until all four

bolts slide through. NOTE: this step is

somewhat difficult and it may seem that the

parts do not fit together however all

assemblies are pre-fit and tested before

shipping to insure proper fitment.

18) Once all four bolts are through the assembly, place another washer and a nut on each one

and finger-tighten them.

19) Using a 1-1/8” socket, tighten the four ¾” bolts on the rear of the differential mounting

plate to 100 ft/lbs.

20) The following step involves setting the driveline angle. While this process is actually

very simple, it is difficult to explain so we have provided detailed instructions and

examples below. Driveline angle is the difference between the pinion angle and the

driveshaft angle. Zero degrees means there

is no angle and the pinion and driveshaft are

straight as viewed from the side. If the

angle is negative, the driveshaft and the

rear-end will form a “V”. If it is positive,

the driveshaft and rear-end will form an

“upside down ^”. For street driving this

angle should be between 0 and -3 degrees to

promote long u-joint life.

Begin by placing the supplied angle finder

on the rear BMR mounting plate as shown

in Image 7 and record the reading. Take

your reading from the drivers’ side of the

car. Since the rear cover is 90 degrees perpendicular to the pinion, this angle represents

the angle of the pinion gear minus 90 degrees. Now place the angle finder on the

driveshaft (Image 8) and record the reading from the drivers’ side of the car. This angle

represents the driveshaft angle. The goal angle to reach is a 2 degree difference between

the two recorded angles. For example, our test car used for these instructions had the

following readings:

4

TORQUE ARM INSTALLATION INSTRUCTIONS (Cont.)

The rear angle on the differential

mounting plate was 88 degrees. You

need to subtract 90 degrees from this to

get your pinion angle, resulting in -2.

The driveshaft angle just happened to be

at 0 degrees. The difference between

these two angles is -2, right where we

want to be. If your resulting angle is

anywhere between 0 and -3, it is an

acceptable angle. To adjust this angle

you can use the jack screw located at the

back of the torque arm to raise or lower

the pinion simply by turning the screw

(refer back to Image 6). The screw will

turn against the rear end, pushing it upward. If the angle is off excessively, use a pry-bar

to rotate the rear end until the angle is close enough to use the jack screw.

21) Once the driveline angle is set, tighten all 5 cross-bolts to 90 ft/lbs.

22) Make sure the jack screw is touching the differential housing and then tighten the jam-nut

located on the jack screw.

23) Re-tighten the leaf spring bolts.

24) Fill the differential with gear lube.

25) Grease both of the front grease fittings with a silicone or other synthetic based lube.

5

Loading...

Loading...