BMR Suspension TAS005 User Manual

TAS005 TORQUE ARM CONVERSION INSTALLATION INSTRUCTIONS

1970-1981 Camaro and Firebird – Ford 9” rear

Please take note before proceeding with this installation:

• This product may interfere with certain exhaust kits. Exhaust crossovers are not

compatible with this torque arm suspension. In some circumstances, it may be necessary

to fabricate a custom exhaust to insure adequate clearance.

• A service lift, while not necessary, is recommended for this installation.

TOOLS REQUIRED:

3/8” and ½” drive ratchets 9/16”, ¾”, 15/16” wrenches

3/8”, 9/16”, ¾”, 15/16” and 1-1/8” sockets Rubber mallet

Pry-bar Drill

3/8” Allen wrench Step bit or ½” and ¾” drill bits

Jack stands Hydraulic Jack

Grease gun with synthetic lube Torque wrench

Welder (optional) Plumb bob and tape measure

CROSS-MEMBER INSTALLATION:

1) Lift the vehicle and support

with stands under the rocker

panel pinch seams (Do not

place stands under the

subframe).

2) Remove the exhaust system.

3) Using a 15/16” socket,

remove the rear two body

mount bolts.

4) Remove the OE rubber body

mount bushings. They are

composed of an upper and

lower bushing that

“sandwich” the subframe

together in the middle.

NOTE: it may be necessary

to use a pry-bar to lower the

subframe enough to remove

these bushings.

5) Once the OE bushings have been removed, inspect the subframe for rust damage. This is

a common area susceptible to rust and if the mounting point is compromised, it needs to

be repaired before proceeding with the installation.

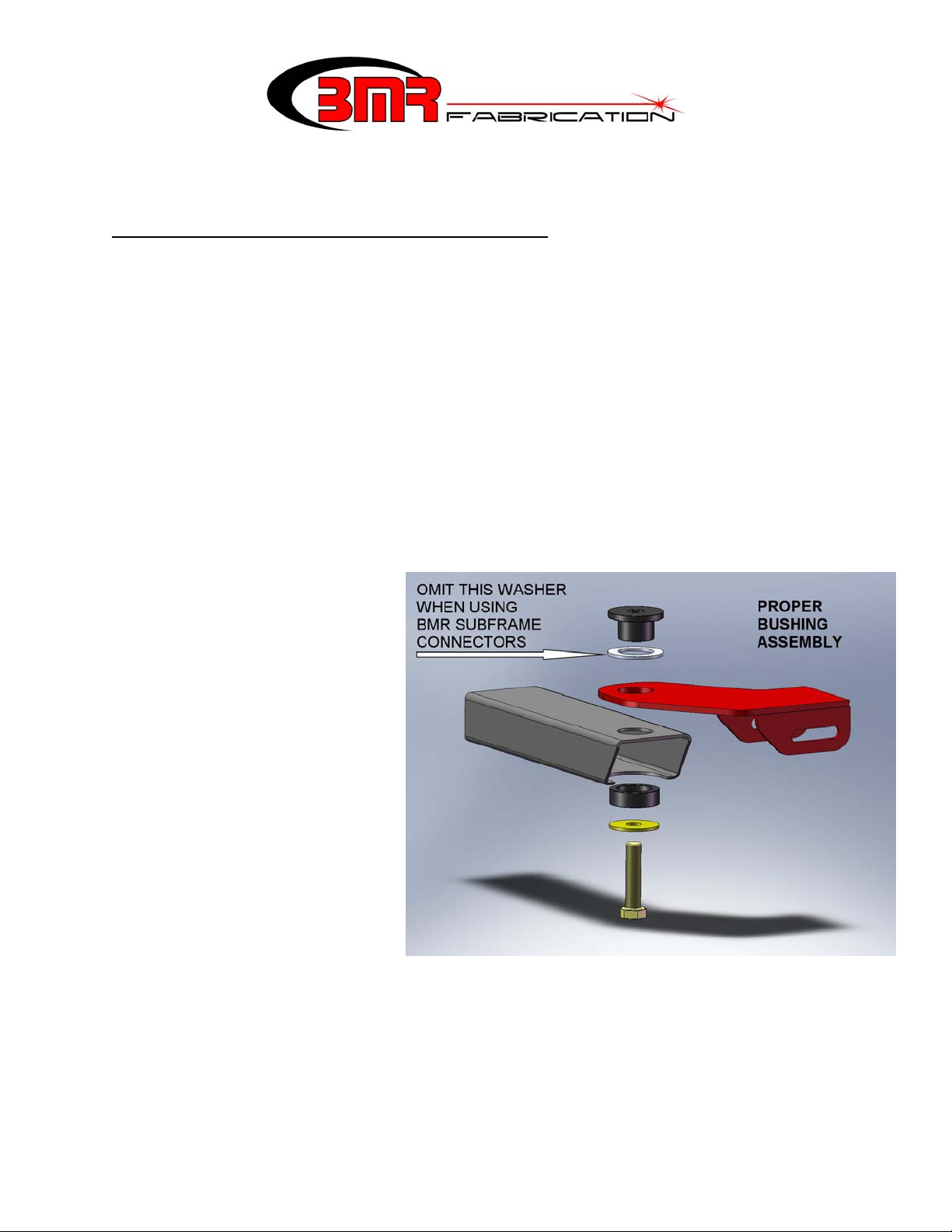

6) Begin with the driver’s side. Assemble the driver’s side frame mount, billet body mounts

and washer (if necessary) as shown in the image above. If you are using BMR subframe

connectors or any subframe connector that mounts around the body bushing, omit the

supplied aluminum spacer washer shown in the above image.

1

CROSS-MEMBER INSTALLATION (Cont.)

7) Thread the supplied bolt into the body and snug the bolt allowing the frame bracket to

rotate around the axis of the bushing.

8) Repeat steps 4-7 for the passenger side. At this stage both mounts should be installed and

you can mount the cross-member. Lift the cross-member into place and insert the

supplied ½” x 4.5” bolts, stainless washers, and nuts.

9) Tighten the body mount bolts to 150 ft/lbs.

10) Center the cross-member to the driveshaft then tighten the (4) cross-member bolts.

TORQUE ARM INSTALLATION:

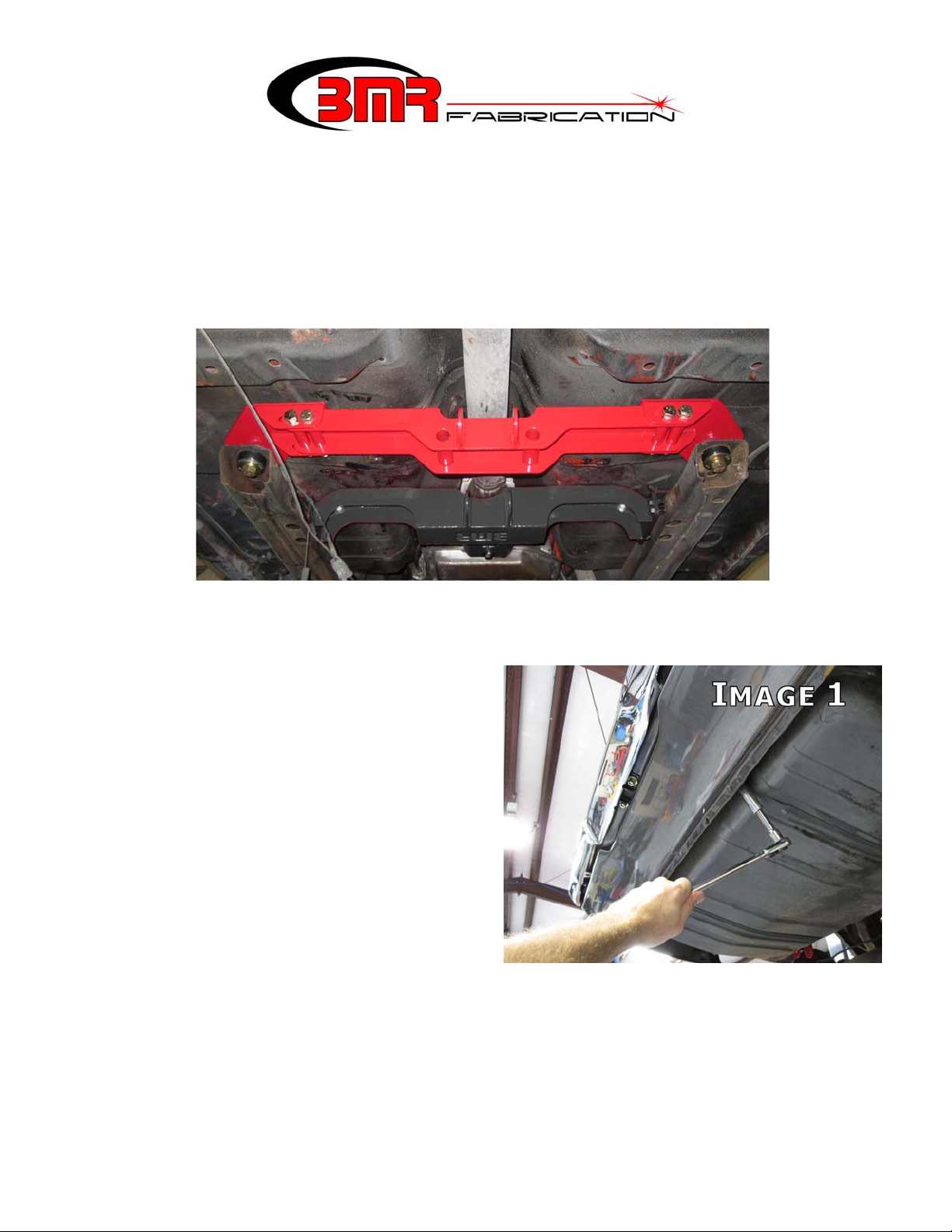

1. Lift vehicle and support with stands under

the frame, allowing the rear end to hang.

2. Remove the rear wheels/tires.

3. If the vehicle has exhaust installed,

remove it at this time.

4. Remove the rear shocks using a 9/16”

socket.

5. While not necessary, the installation is

simpler if the fuel tank is removed. If you

do not wish to remove the fuel tank, skip

steps 6-8 and proceed to step 9.

6. Drain the tank using a drill pump or

siphon.

7. Support the tank and then remove the two

mounting nuts using a 9/16” deep socket.

Pull the tank support straps down, allowing the tank to be lowered. (Image 1)

8. Lower the tank far enough to access the fuel lines and electrical connectors. Disconnect

and cap the fuel lines. Lower and remove the fuel tank.

2

(CONTINUED)

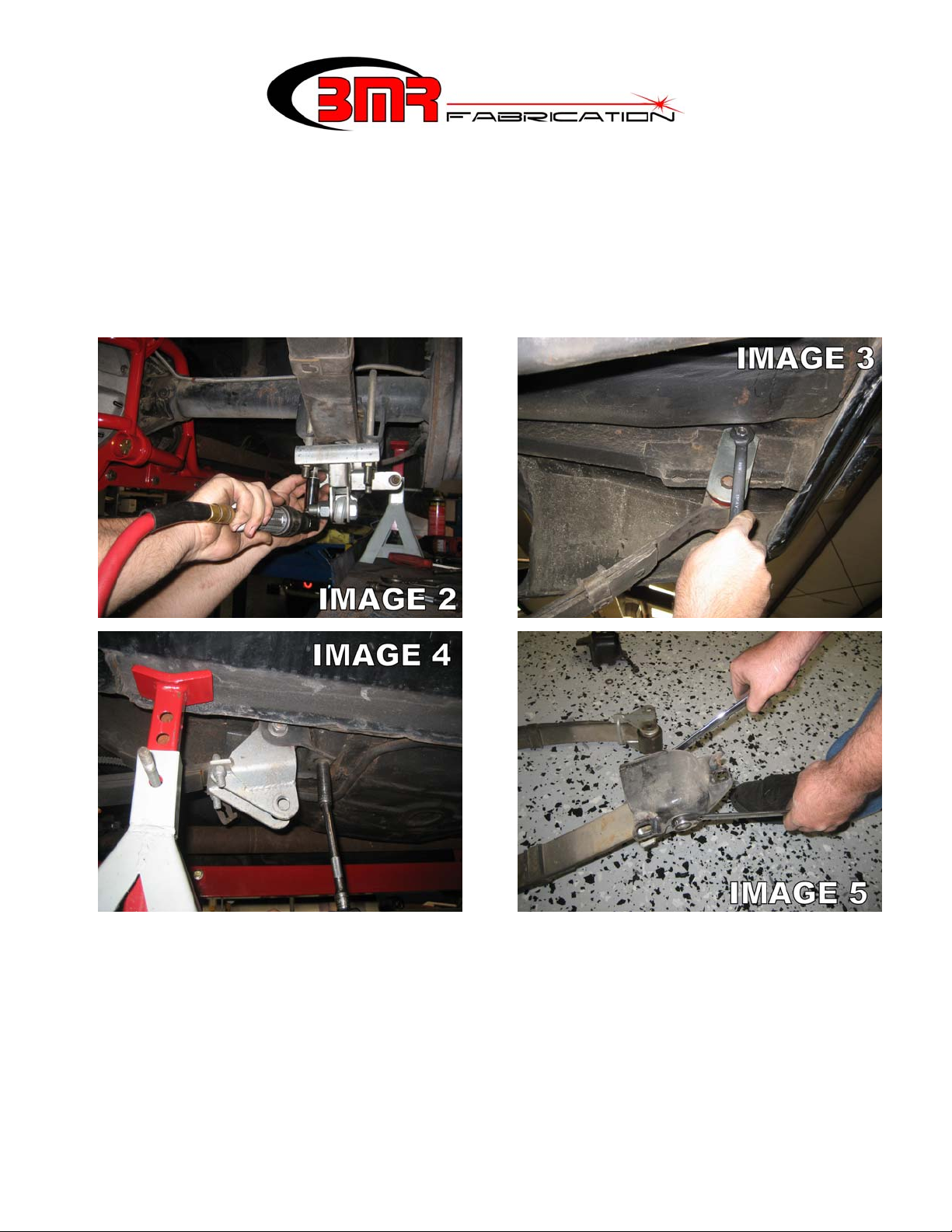

9. Support the rear end with jack stands.

10. Using a 3/4” socket, remove the leaf spring U-bolts on the rear end. (Image 2)

NOTE: the image shown has aftermarket traction bars installed. Leaf spring mounts

may appear slightly different in nature.

11. Using a 5/8” socket, loosen and remove the rear leaf spring shackle bolts. Loosen the

upper shackle bolt at the frame and remove the shackles. (Image 3)

12. Using a 9/16” socket, remove the (3) bolts on the front spring mount of each leaf spring.

(Image 4) NOTE: the image shown had aftermarket traction bars installed. Front leaf

spring eye may appear slightly different in nature.

13. Once all bolts are removed, remove the leaf springs.

14. Remove the rear end and set aside.

15. Loosen the bolts and remove the front spring pockets. (Image 5)

16. Install the BMR trailing arms into the leaf spring pockets as shown using the provided ½”

x 5” bolts. Thread a stainless washer under the nut then tighten to 80 ft/lbs. (Image 6)

17. Re-install the spring pockets with control arms into the body and leave bolts finger tight.

3

(CONTINUED)

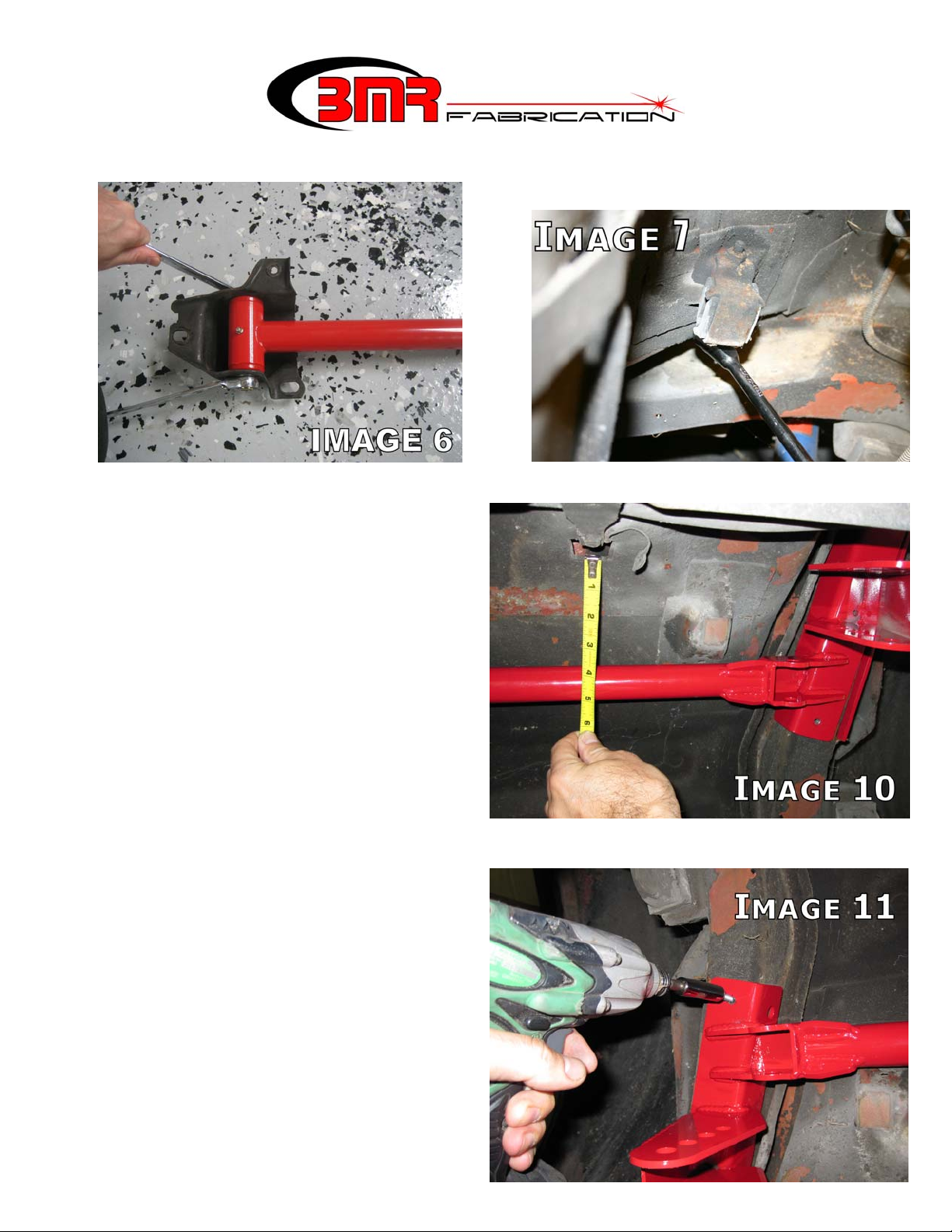

18. The next few steps involve installation of the shock cross-member. Begin by removing

the factory muffler hangers located

above the rear end. (Image 7).

19. NOTE: Images 8 and 9 have been

omitted due to updated design.

20. The cross-member can be welded or

bolted into place. Locating the shock

cross-member properly is important and,

while it can be performed by one person,

it is much easier with a helper. Have a

helper hold the shock cross-member up

into place on the frame rails. Slide the

cross-member as far forward as it will

allow.

21. Use the fuel tank strap mounting

positions as a reference point to locate

the cross-member properly front-to-back

and to insure that the cross-member is mounted square in the body. As shown in Image

10, measure the distance from the relief

in the trunk pan to the main cross tube of

the cross-member. Vehicle production

variance prevents a “one measurement

fits all” figure

but the measurements should fall

somewhere between 3-7/8” to 4 1/16” when viewing the tape measure

from directly below. Re-position the

cross-member until the reading from

each strap mount relief is equal and falls

within the range listed above.

4

Loading...

Loading...