BMR Suspension SB042 User Manual

SB042 INSTALLATION INSTRUCTIONS

REQUIRED TOOLS:

Jack and jack stands

13mm, 15mm, 18mm, 19mm, 9/16”, ¾” sockets and wrenches

5/16” Allen wrench

Pry bar

INSTALLATION:

1. Lift vehicle and safely support with stands

under the frame. It may also help the

installation to position the jack under the rear

end and lift it slightly to remove some of the

load off the control arm bolts.

2. If working on jack stands, remove both rear

wheels/tires to gain better access to the work

area. NOTE: the installation pictured was done

on a 2-post service lift and the wheels/tires

were left installed throughout the installation

process.

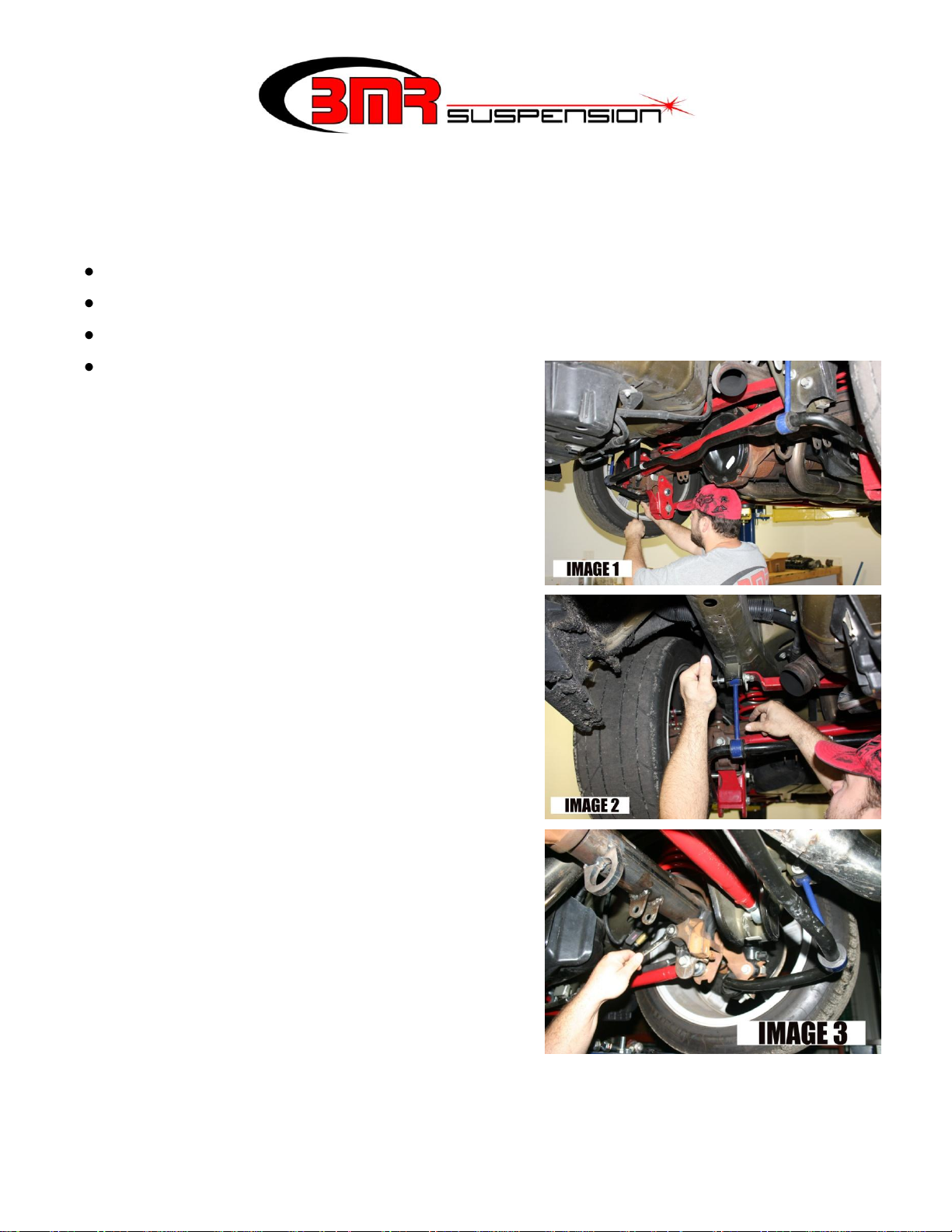

3. Using a 13mm socket, un-bolt the outer sway

bar mounting bushings as shown in IMAGE 1.

4. Using a 15mm socket, un-bolt the sway bar

end links as shown in IMAGE 2.

5. Remove the factory sway bar.

6. Starting with the drivers’ side of the car,

remove the control arm bolt at the axle using

an 18mm wrench or socket.

7. Directly above the control arm bolt is the axle

damper weight that must also be removed for this installation. Remove it using a 15mm

socket or wrench as shown in IMAGE 3.

1

SB042 INSTALLATION INSTRUCTIONS

CONTINUED

8. Install the BMR mounting bracket as shown in

IMAGES 4. If you have BMR CAB005Control

Arm Relocation brackets already installed on

your vehicle, you can simply bolt the bracket in

place using the hardware that was provided

with your Control Arm Relocation brackets

(See images on final page of instructions). If

you do not have BMR Control Arm Relocation

brackets installed on your vehicle, bolt the

BMR sway bar bracket to your axle using the

supplied 12mm x 30mm bolt, washer, and

spacer as shown in IMAGE 4.

9. Once the bracket is installed, tighten the

control arm bolt to 129 ft/lbs. and the damper

bolt to 45 ft/lbs.

10. Proceed to the passenger

side and install the BMR

supplied bracket as

shown in IMAGE 5. This

side does not require a

spacer. Tighten to 129

ft/lbs.

11. Using the provided 1”

Energy Suspension

bushings, connect the

BMR end links to the BMR sway bar as shown in IMAGE 6. Use the provided 3/8” Allen

bolts, nuts, and washers for this connection.

2

Loading...

Loading...