1

COIL-OVER CONVERSION KIT INSTALLATION

CCK002 – 1964-1972 A-BODY

NOTE: Do not use bushing-type coil-overs with this setup, use only bearing-type coil-overs with ½” ID bearings.

INSTALLATION:

1. Safely support the vehicle. Remove the upper and lower A-arms and remaining front suspension to gain access to

the upper A-arm mount.

2. Using a cut-off wheel or plasma cutter, cut off the upper shock mount as shown in IMAGE 1 and 2. The

removed portion should look similar to the piece shown in IMAGE 3.

3. Smooth the remaining weld and contour the upper A-arm bracket using a sanding disc. The frame should appear

similar to IMAGE 4 when finished.

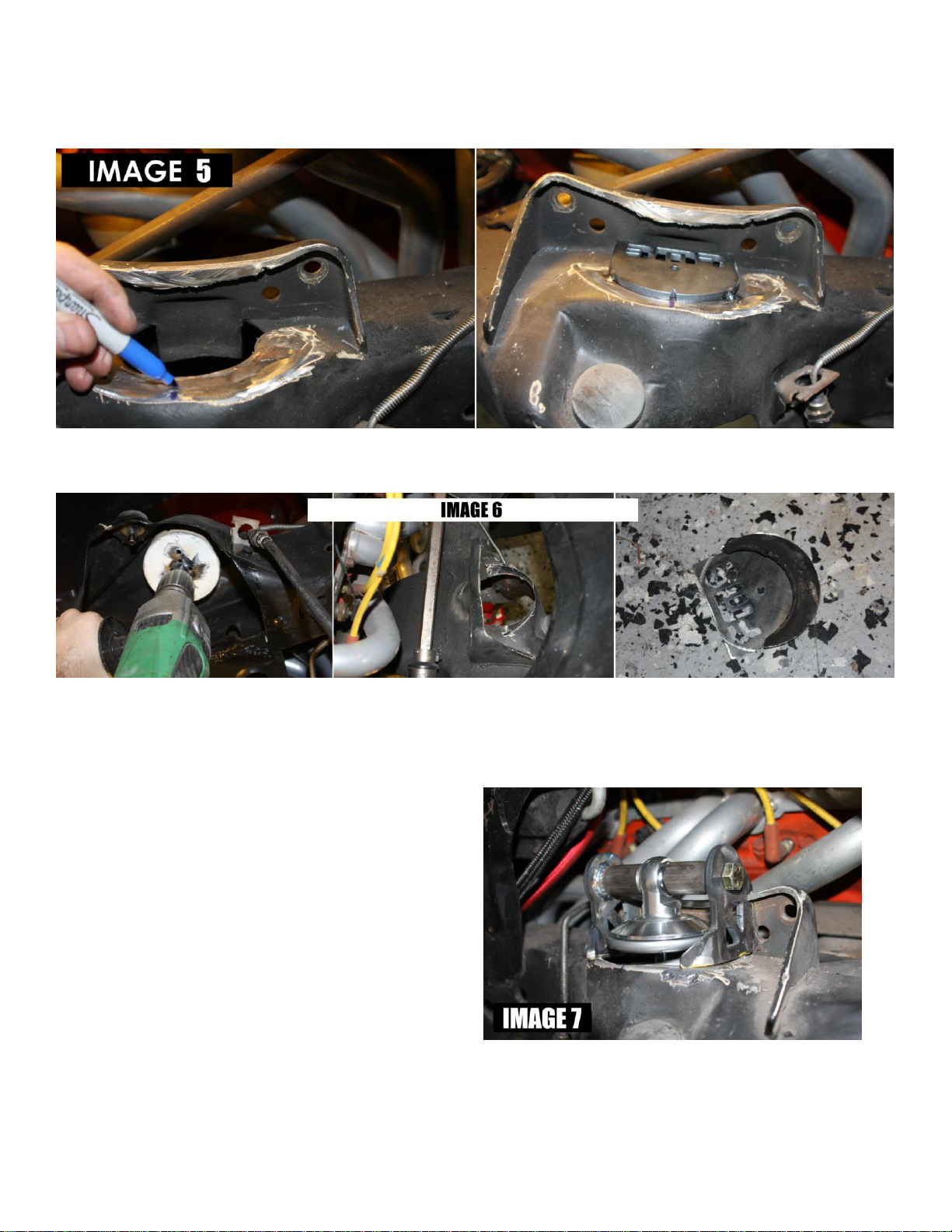

4. Once the upper shock mount is removed, it will expose a hole in the frame that extends into the spring pocket.

Find the center of the hole with a tape measure then mark it as shown in IMAGE 5 on the following page.

5. As shown in IMAGE 5, lay the drill template into the spring pocket and line up the relief in the template with the

previous mark.

6. Weld the drill template into place with 2-3 tack welds.

CONTINUED

2

COIL-OVER CONVERSION KIT INSTALLATION

CCK002 – 1964-1972 A-BODY

7. Chuck a 4” bi-metallic hole saw into a drill and cut out the top of the frame using the drill template to locate the

hole saw. The finished cut should look similar to IMAGE 6. De-bur the opening.

8. Properly positioning the upper shock perch requires an assembled coil-over and lower A-arm. In the images

shown below, we used a Viking coil-over with a lower shock T-bar. This allows the shock to bolt to the lower Aarm without any modifications. Most coil-over shocks can be ordered this way or you can buy T-bar adapters

from quality coil-over manufacturers such as AFCO, QA1, and Viking.

NOTE: Most coil-overs will have an upper mount that is somewhere between 1”- 1.5” wide. Your BMR coilover brackets will easily accommodate this range.

9. Bolt the lower A-arm in place then bolt the BMR

coil-over brackets to the upper mount of your coilover as shown in IMAGE 7. Position the coil-over

assembly into the frame and mount to the lower Aarm. Insure that the coil-over is centered in the

hole then position the coil-over brackets until they

fit with minimal weld gap as shown in IMAGE 7.

(NOTE: frame contours and OE welds vary slightly

and may require trimming of the bracket to get the

best fit. Also, varying widths of different brand

coil-overs will position the brackets differently,

requiring slight trimming to compensate.

10. Once the assembly is properly positioned and

centered in the opening, tack-weld the brackets into place.

CONTINUED

Loading...

Loading...