Air Heater Manuals

User/Installation/Servicing

BMM Heaters Ltd

1 Copeland Court

Forest Grove

Middlesbrough

TS2 1RN

Tel:01642 240700

Fax:01642 240708

Sales@bmmheaters.co.uk

1

BMM HEATERS REFERENCES

Heater Models Description

BMG Horizontal Heater for ducted or AHU

applications suitable for natural gas.

BMVG Vertical heater for ducted or AHU applications

suitable for natural gas.

BMGVF Free standing nozzle head heater with force

draught gas burner.

BMGDF Free standing ducted heater with force draught

gas burner.

BMGF Horizontal ducted heater with force draught gas

burner.

BMGDD Downward discharge heater with force draught

gas burner.

2

CONTENTS PAGE

DESCRIPTION

Section 1: Introduction…………………………………………. 4

Section 2: Heater Safety………………………………………… 5

Section 3: Installers Responsibilities…………………………… 5

Section 4: Specifications………………………………………… 6

Section 5: Heater Installation & Clearances…………………... 7

Section 6: Air supply…………………………………………….. 9

Section 7: Overheat Protection Device…………………………. 10

Section 8: Flue System…………………………………………… 11

Section 9: Ventilation Requirements……………………………. 16

Section10: Gas Piping……………………………………………. 17

Section 11: Condensate Drains………………………………….. 19

Section 12: Electrical Connections……………………………… 19

Section 13: Heater Controls……………………………………... 21

Section 14: Commissioning……………………………………… 23

Section 15: Servicing…………………………………………….. 32

Section 16: Removal and Replacement of Parts……………….. 37

Section 17: Spare Parts………………………………………….. 39

Section 18: Troubleshooting…………………………………….. 40

Section 19: Users Manual………………………………………... 41

Model:

Serial Number:

3

Section 1: Introduction

The instructions refer to appliances designed to operate in the UK and

Ireland.

Appliances designed for other countries can be provided on request.

This appliance must be installed in accordance with the local and national

codes in force and used only in a sufficiently ventilated space, as specified in

these instructions.

Before installation, check that the local gas distribution systems, nature of gas

and pressure, and adjustment of the appliance are compatible.

Indirect Fired

The term ‘Indirect Fired’ indicates that the products of combustion are kept

isolated from the main supply air stream. The burner fires into a combustion

chamber, the resultant products of combustion are directed into a heat exchanger

and from there to an external flue, which discharges into the atmosphere.

Factory Test

All heaters produced by BMM Heaters Ltd will be subjected to various tests

before they are dispatched. Each heater is individual so the data will differ

between each unit. The relevant data can be found on the data plate attached to the

heater.

External Heaters

The construction of the unit will consist of double skin panels and be fully water

proof; the burner compartment will be adequately ventilated via two combustion

air grills.

Burner and Fuel

These appliances will be fitted with either a Force Induced Natural Gas Burner or

Pressure Jet Oil Burner.

Burner Type

BMM Heaters Ltd use two main manufacturers; Reillo or Weishaupt, which are

available for on/off, high/low or fully modulating appliances.

Oil Burners are available for on/off or high/low control.

4

Section 2: Heater Safety

The Installation of this appliance must be done by a registered installer/contractor

suitably qualified in the installation and service of gas fired heating equipment.

WARNING!

Improper installation, adjustment, alteration, service or maintenance can

result in death, injury or property damage. Read the installation, operation

and service manual thoroughly before installing or servicing this appliance.

Note:

To Installer: Please take the time to read and understand theses instructions prior

to any work servicing or installing this appliance.

Installers must leave a copy of this manual with the end user/owner.

To Owner: This manual must be kept in a safe place in order to provide necessary

information for service engineers at a later date.

Section 3: Installers Responsibilities

♦ To install the heater, as well as the gas and electrical supplies, in

accordance with applicable specifications and codes. BMM Heaters

recommends the installer contact a local Building Inspector, Fire Officer or

Insurance Company for guidance.

♦ To use the information given in the manual together with the local and

national codes to perform the installation.

♦ To install the heater in accordance with the Clearances to Combustibles of

this heater.

♦ To plan for the installation of supports, flues and air intakes.

♦ To provide access to burners for servicing.

♦ To provide the owner with a copy of this installation, commissioning,

operation and service manual.

♦ To never use heater as support for ladder.

♦ To ensure that there is sufficient ventilation in the area to comply with the

requirements of all relevant local and national codes.

5

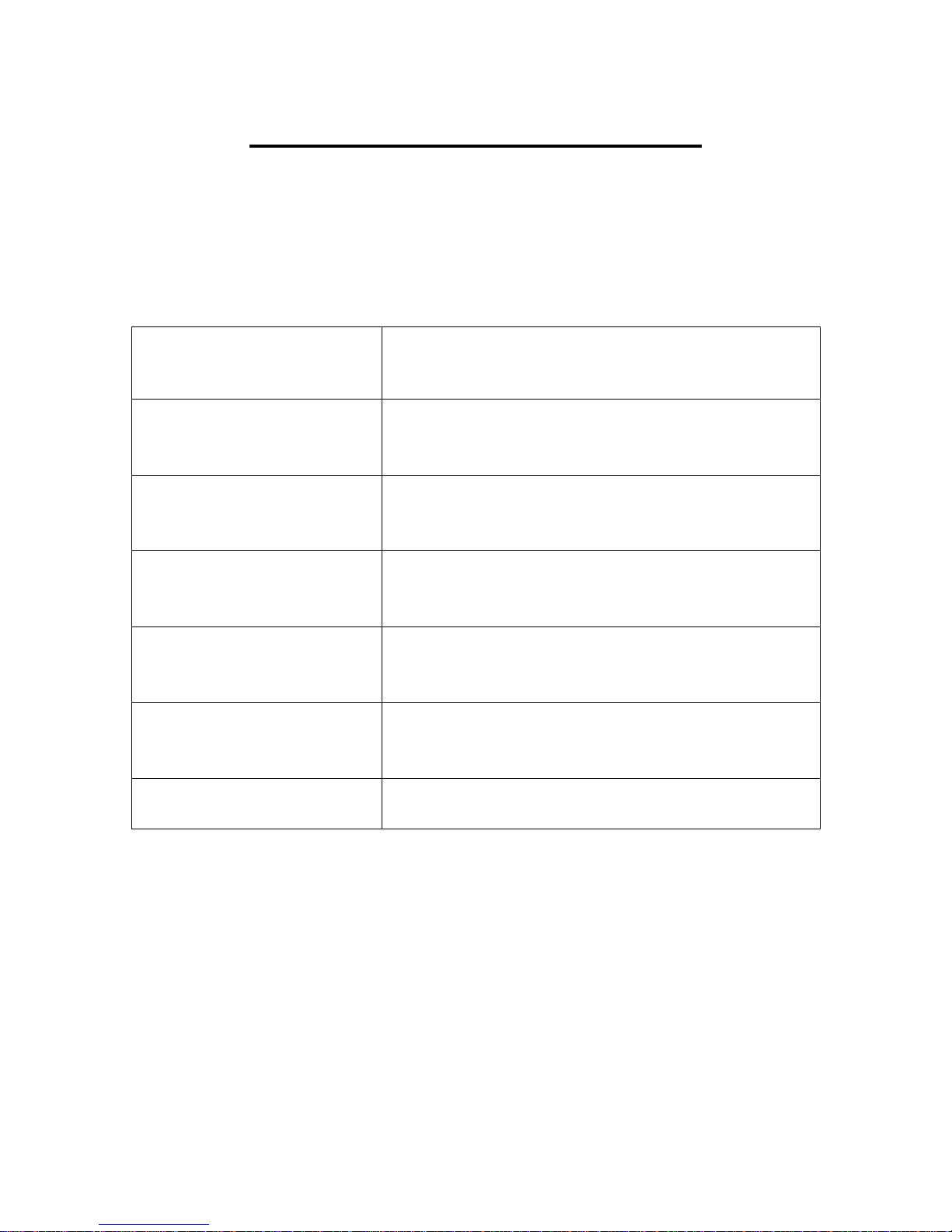

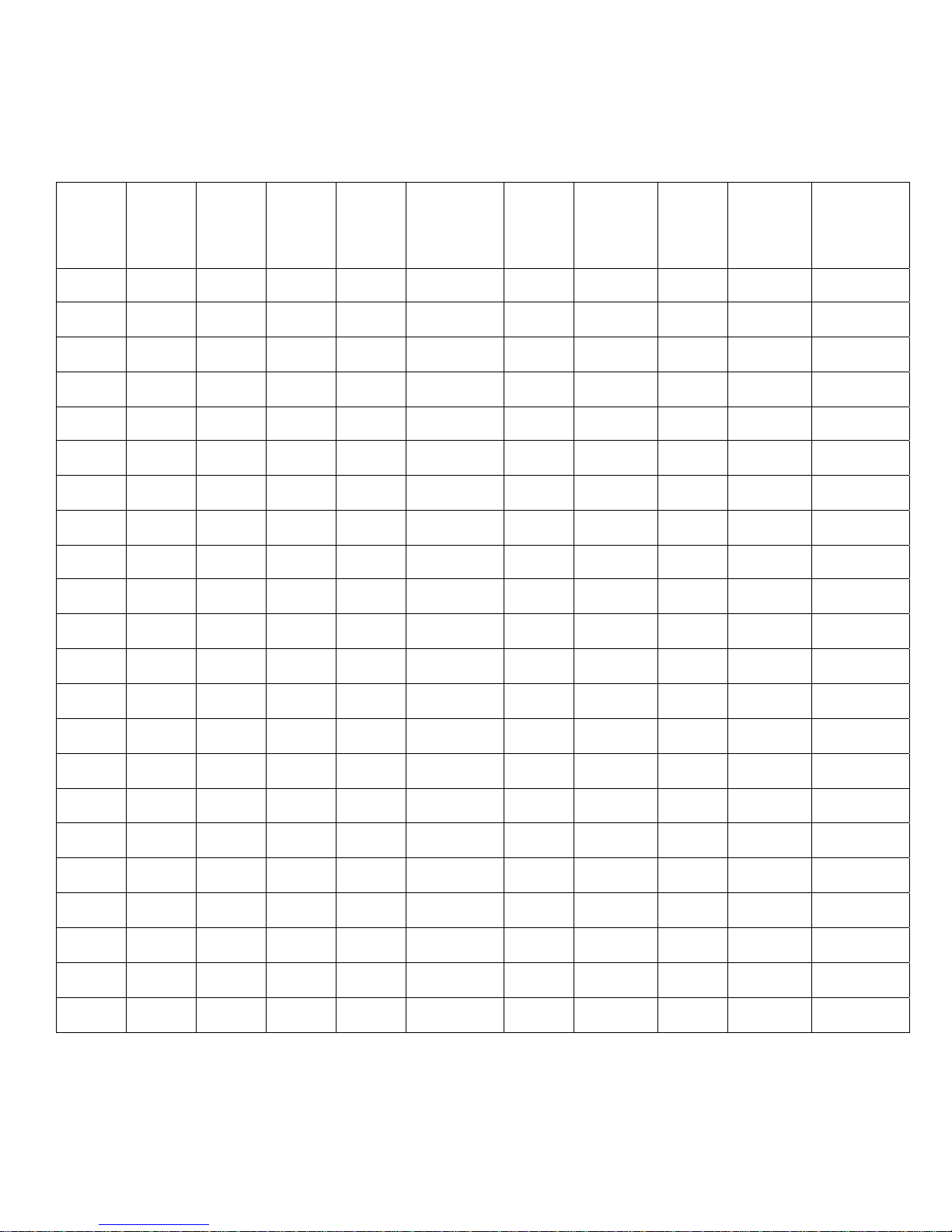

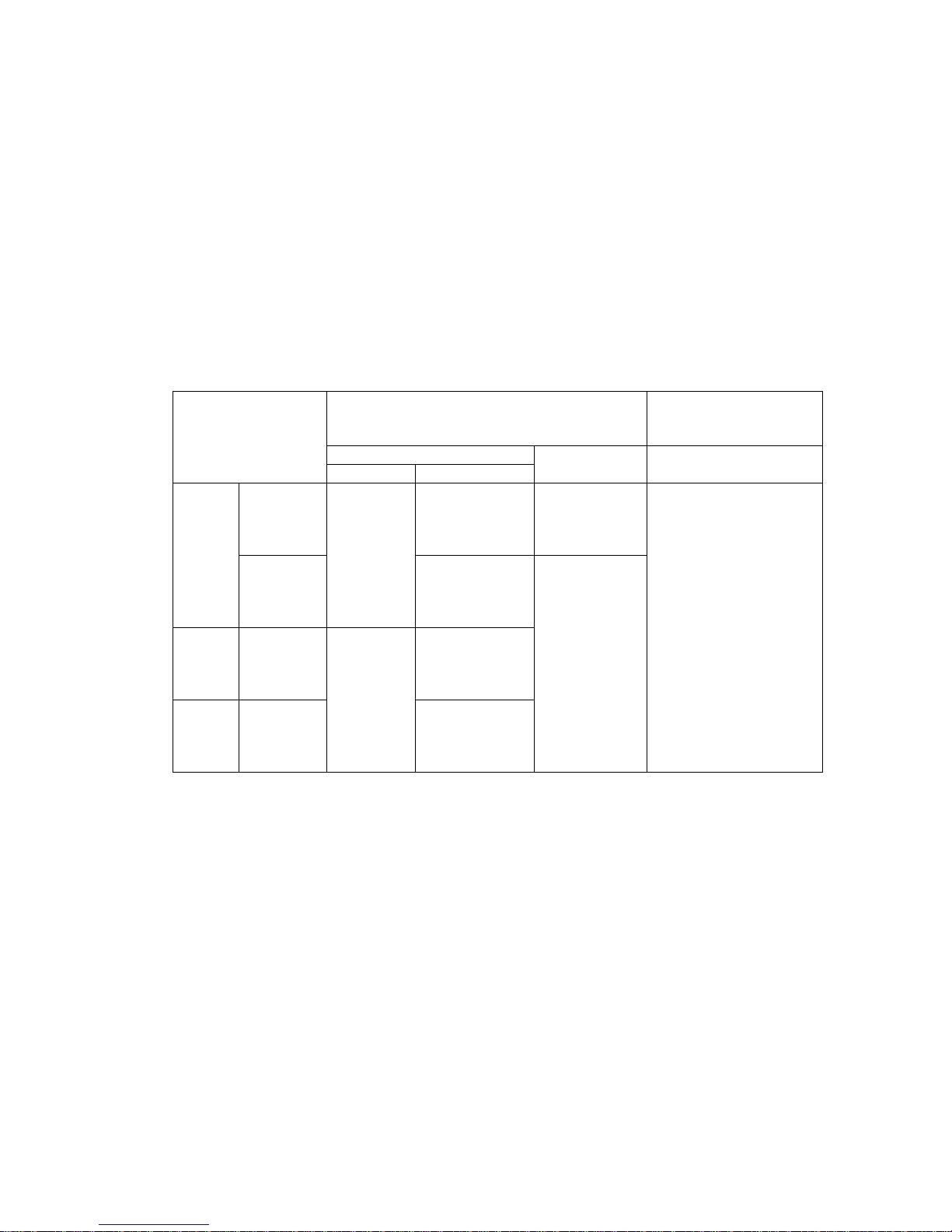

Section 4: General Technical Table 1

Model

12 .37 .75 15 12 0.36 1.5 154 150 75 66

15 .37 .75 19 15 0.432 1.8 154 150 75 66

18 .37 .75 23 18 0.44 2.2 154 150 75 66

23 .47 .75 30 23 0.7 2.9 154 150 75 66

30 .75 .75 38 30 0.94 3.9 154 150 75 66

44 .82 1.55 57 44 1.08 5.4 154 150 207 192

59 1.13 1.55 75 59 1.75 7.3 154 150 207 192

88 1.55 1.55 113 88 2.62 10.9 154 150 207 192

117 2.11 2.58 150 117 3.48 14.5 204 200 246 228

Min

Air

flow

m³/sec

Max

Air

flow

m³/sec

Heat

Input

kW

Heat

Output

kW

Max Start

Gas Rate

m³/hr

Gas

Flow

Rate

m³/hr

Flue

Spigot

Nominal

Ø mm

Flue

Size

Ø mm

Weights

External

Heater

Kg

Weights

Internal

Heater

Kg

147 2.58 2.58 188 147 4.18 17.4 204 200 246 228

176 3.19 5.17 225 176 5.23 21.8 204 200 420 384

205 3.75 5.17 263 205 6.1 25.4 254 250 420 384

235 4.23 5.17 300 235 6.98 29.1 254 250 420 384

264 4.75 5.17 338 264 7.85 32.7 254 250 420 384

293 5.17 5.17 376 293 8.71 36.3 254 250 420 384

352 6.23 6.23 451 352 10.32 43 304 300 1704 1364

440 8.46 10.34 537 440 13.08 54.5 304 300 1704 1364

513 9.40 10.34 658 513 15.24 63.5 304 300 1704 1364

586 10.34 10.34 752 586 17.42 72.6 354 350 1704 1364

733 13 16.53 939 733 19.34 80.6 406 400 2304 2160

880 15.35 16.53 1127 880 26.14 108.9 406 400 2304 2160

952 16.53 16.53 1221 952 28.32 118 406 400 2304 2160

Each appliance has been range rated; burner pressures can be found on the data

plate and the burner pressure once commissioned must be entered in the actual.

6

Section 5: Heater Installation

Before installation, check that the local distribution conditions, nature of gas

pressure and adjustment of the appliance are compatible.

The air heater must be installed in accordance with the rules in force and the

relevant requirements of any fire regulations or insurance company’s requirements

appertaining to the area in which the heater is located, particularly where special

risks are involved, such as areas where petrol vehicles are housed, where cellulose

spraying is carried out, in wood working departments etc.

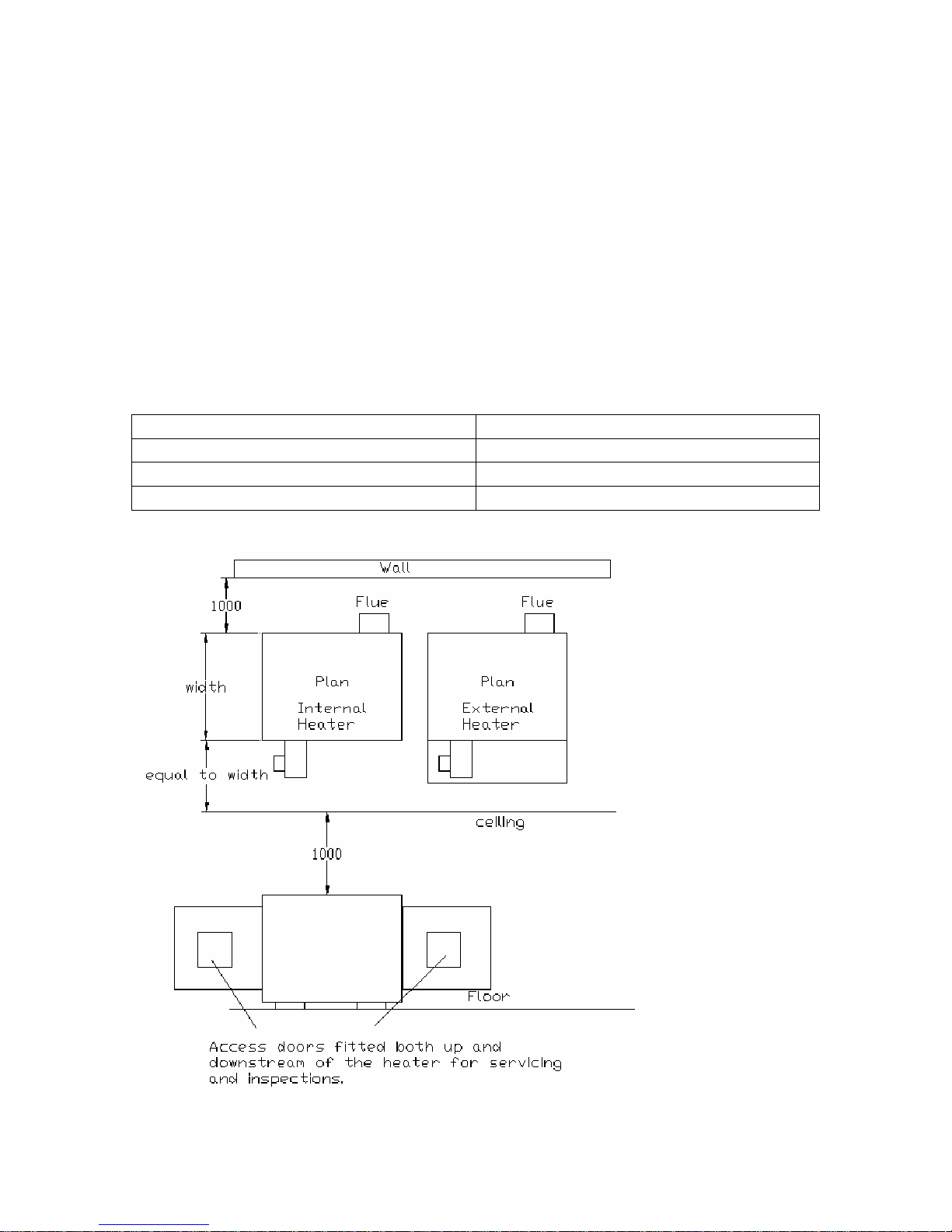

Clearances and Positioning:

The following clearances for installation and servicing must be observed.

To the front Equal to the depth of the heater.

To the rear 1.0m

To at least one side 1.0m

Above the heater 1.0m

Clearances fig.1

7

Clearances

A minimum of 500mm upstream and downstream must be allowed for, due to the

radiant heat. Filters must be fireproof, if fitted and a motor shield is required over

the main supply fan motor if directly in front of the heater.

When installing the heater, minimum clearance is required around the heater.

If the heater is to be fitted at a height, then the structure of the gantry must be

capable of the heaters weight (which can be found in section 4, table 1), also a safe

working platform and access must be allowed for; to enable easy and safe working

access.

Note: The front of the heater is the side on which the burner is fastened.

When designing a system, allowance must be made so equipment can be serviced

after installation and for the fitting of any spares, which may be required. The

BMG is designed to be installed within an Air Handling Unit or ductwork.

The appliance is designed to work in a maximum ambient temperature of 40°c.

The Air Heaters are mounted direct on the floor and do not need any fixing. The

base on which the heater is positioned should not be less than 150mm (6 inches)

thick and must be constructed of non-combustible material.

Any combustible material adjacent to the heater and the flue system must be

placed or shielded as to ensure that its temperature does not exceed 65ºC.

WARNING!

No air heater shall be installed where there is a foreseeable risk of flammable

particles, gases, vapours or corrosion inducing gases or vapours being drawn

into either the heated air stream or the air for combustion. In such cases

installation may only proceed if the air to be heated and the air for

combustion are ducted to the heater from an uncontaminated source,

preferably outside the building.

If this heater is to be suspended then weight in table 1 in section 4 must be taken

into account.

8

Section 6: Air Supply

Ductwork

All delivery and return air ducts, including air filters, jointing and any insulation

or lining must be constructed entirely of materials, which will not contribute to a

fire, are of adequate strength and dimensionally stable for the maximum internal

and external temperatures to which they are to be exposed during commissioning

and normal operation. In the selection of materials, account must be taken of the

working environment and the air temperatures which will result when the overheat

limit thermostat is being commissioned. Where inter-joint spaces are used as duct

routes, they should be suitably lined with fire-resisting material.

A full and unobstructed return air path to the air heater must be provided.

If the air heater is to be installed in a plant room, the return air and warm air

discharge arrangements must be such as to avoid interference with the operation of

the flue by the air circulation fan. The return air intake and the warm air outlet(s)

should therefore be fully ducted, in the plant room, to and from the heater,

respectively. The openings in the structure of the plant room through which the

ducting passes must be fire stopped.

In addition, where there is a risk of combustible material being placed close to the

warm air outlets, suitable barrier rails should be provided to prevent any

combustible material being within 900mm (3 ft) of the outlets.

Air flow

It is essential that the correct amount of air is provided through the heater and

should be evenly distributed when entering the heater. All pressure

calculations/resistances for air are ambient with the Heater in the ‘off’ position.

Adjustable by pass plates

BMG models fitted into larger cabinets for internal or external use should be fitted

with adjustable air balancing plates or a simple restriction damper. If the work is

not going to be carried out by BMM Heaters Ltd then we recommend that the

installer ensures that it can be altered to give guaranteed minimum equal air over

the combustion chamber/heat exchanger (see minimum and maximum air flow

volumes in section 4 table 1).

9

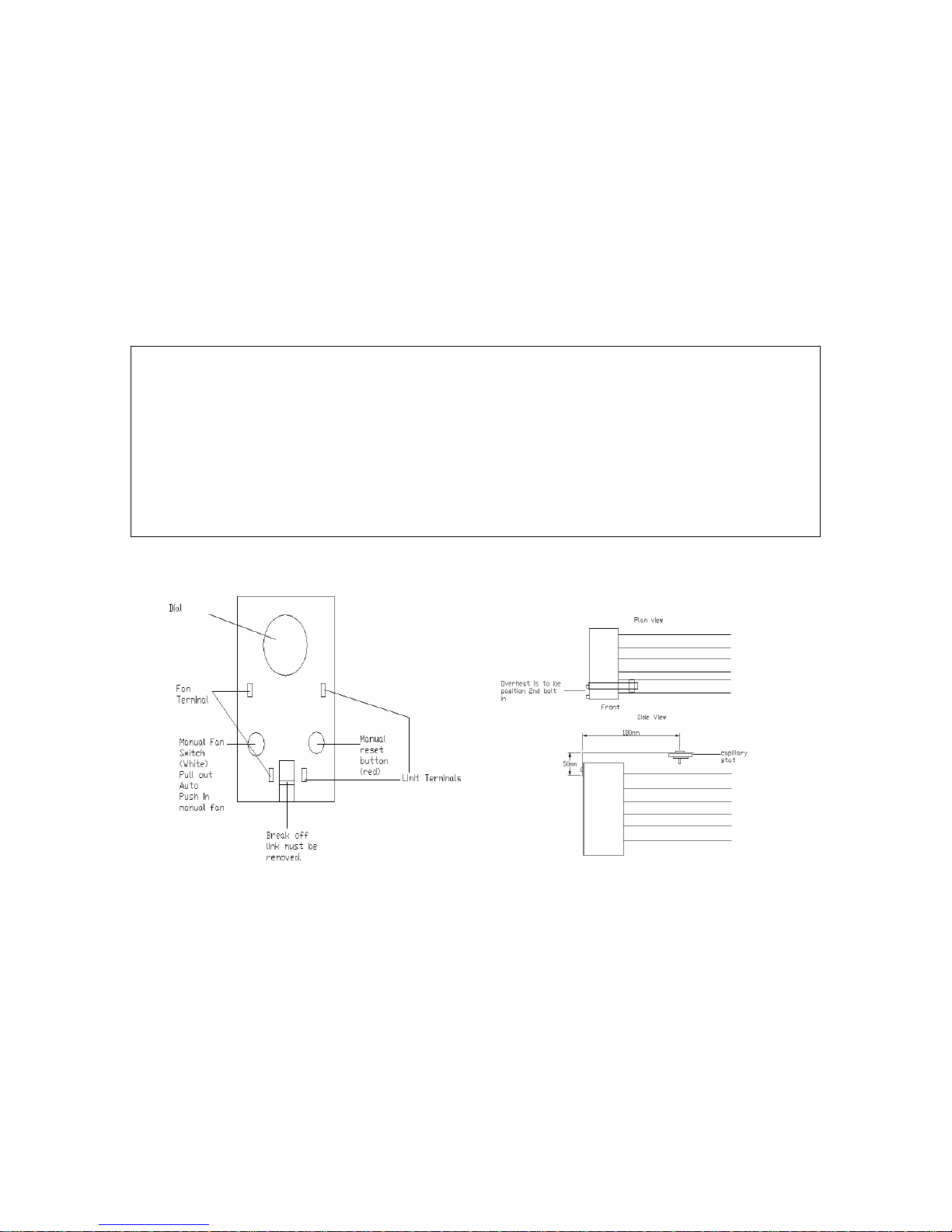

Section 7: Overheat Protection Device

Overheat protection is fitted in case the air flow falls below the minimum

necessary for safe operation of the heater, which may be caused by failure of the

supply fan motor or belt failure, dirty filters or inlet damper failure. If the air flow

falls too low, the high limit will trip out and will require manually resetting. If this

happens on a regular basis it must be investigated by a competent registered

engineer as this could cause serious damage to the heater.

WARNING!

If the heater has a Honeywell combined thermostat installed then the jumper

link must be removed from the replacement thermostat.

Heat exchanger damage may be the result.

Failure to follow these instructions can result in death, injury, property

damage or product damage.

Honeywell overheat stat Fig 2 Overheat Position Fig 3

Ensure that the fan and limit settings are as follows:Fan On 35ºc

Fan Off 25 ºc

Limit 20 ºc above normal running temperature no greater than 100 ºc

10

Section 8: Flue System

The flue system must be made to the following specifications:

a) Mechanically robust.

b) Resistant to internal and external corrosion.

c) Non-combustible and durable under the conditions to which they are to be

subjected.

d) Stainless steel flue is recommended.

Design

When designing a flue system for the appliance the designer must take into

account the following points.

a) The flue gases exiting the appliance can be as great as 350 ºc and as low as

70 ºc on modulating burners.

b) Prevention of condensation within the flue and the management of drainage

from the flue; for example the use of twin wall flue will minimise the

condensation.

c) Flue must be a type acceptable to current standards.

d) Facilities should be made for the disconnection of the flue from the heater

to aid servicing and inspection.

e) This appliance does not require a draught diverter.

f) BMM Heaters recommend that a 90º Tee condensate piece is connected

directly onto the heater spigot, from this point the flue must then rise

vertically with no horizontal runs of flue pipe or 90º bends. If there is an

unavoidable obstruction then the use of 45º bends will be permitted.

(Please contact BMM Heaters if more that two 45º bends are used).

g) The flue should terminate in a freely exposed position and must be situated

as to prevent the products of combustion entering the building via any

opening.

h) A Flue terminal must be fitted.

i) The flue installation must be designed to the latest gas regulations and any

local environmental standards.

j) Where a flue passes through a combustible roof, ceiling or floor, the flue

pipe should be surrounded with a metal sleeve, the size of which should be

sufficient to provide a space not less than 25mm between the flue pipe and

the sleeve when positioned.

Note! Flue connection sizes can be found in section 4 table 1

11

Minimum and maximum flue heights

Internal: 600mm above the apex is the minimum height above the building if

within 1.5 metres of the surface, see drawings Figure 1 & 2.

Maximum height is no more than 25 metres, if this exceeded please

consult BMM Heaters or consideration should be given for a fan

assisted flue.

External: Minimum flue height is 1 metre above appliance roof.

Maximum height is no more than 25 metres, if this exceeded please

consult BMM Heaters or consideration should be given for a fan

assisted flue.

Flue terminal

A flue terminal (must be approved) needs to provide an extraction effect under

virtually all wind conditions, the free area of outlet openings should be at least

twice the nominal area of the flue. Outlet openings should be provided preferably

all round, or at least on opposite sides.

It is important for the terminal of an individual open flue system to be located so

that it is not likely to be subjected to wind pressures which could restrict or reverse

the flow of combustion products through the flue.

The ideal position is above the highest point on the roof. It is absolutely essential

that the terminal is positioned outside the building so that it is freely exposed to

any wind and is not shielded by any roof structure or object to such a degree that

they create undesirable pressure regions around the terminal.

12

Preferred positions are:

- At or above the ridge of a pitched roof by means of a roof terminal.

- Above the intersection with a pitched roof.

The pitch or angle of the roof will determine the required flue height from the base

of the terminal. See Table 2 below:

Table 2

RECOMMENDED LOCATIONS OF ROOF TERMINALS:

Location not within 1.5m of a vertical surface*

Type of roof

on the roof

Internal route

Pitch

Pitched

exceeding

45°

Flat With

Without

Pitch not

exceeding

45°

parapet

parapet

On ridge Not on ridge

At or

above roof

level (see

figure 4)

Not

applicable

1m above flue/

roof

intersection (see

figure 3)

600mm above

flue/roof

intersection (see

figure 4)

600mm above

flue roof

intersection (see

figure 6)+

250mm above

flue/roof

intersection (see

figure 10)

External route Internal route

See figure 3

The base of the

terminal to be

600mm above

the level of the

adjacent roof

edge (see

figures 1, 6

and 10)

Location within 1.5m of

a vertical surface* of a

structure on the roof

External route

The base of the terminal

to be 600mm above the

level of the top of the

structure (see figures 2,

5, 9 and 11)

*For example: a chimney stack dormer window; tank room; lift motor room;

parapet, etc.

+When the flue outlet is at a horizontal distance greater than 10 times the

height of the parapet or structure, the terminal outlet height need be only

250mm above the roof.

13

Not Less

m

than

1000 mm

Not less

than

600 mm

Not less

than

1000mm

Not greater than 45°

Fig 1. Pitched roof, not greater than 45°

Greater than 45°

Fig 3. Pitched roof, exceeding 45°

Not less than 600 mm

Dormer

window

Terminals must not be positioned

within 1.5m of the wall surface

Not less than

600 mm

Not less than

1000 mm

Not less than

600 mm

Fig 4. Pitch roof, internal route, pitch not

Fig 5. Pitch roof, chimney within

1.5 m from dormer window

measured horizontally

Less than

1500 m

Dormer

window

Fig 2. Pitched roof, within

1.5 m of a structure on roof

Termination

on ridge

Less than 45°

exceeding 45° and ridge termination

14

Not

Less

than

600mm

m

m

m

Not less than

600 m

Fig 6. Flat roof, with parapet

Structure

Not less

than

600 mm

h

2

Less than 10 h

Fig 7. Flat roof, envelope method

h

2

Structure

Greater than 10 h

Not less than

600 m

Fig 8. Flat roof, flue outlet more than 10 heights (h)

Less than

1500 m

Parapet

Fig 9. Flat roof, with flue close to parapet

Less

than

1500

mm

Parapet

2

2

away from all structures

Not less

than 600

mm

Greater than 1500 mm

250 mm

Greater than 10 h

Structure

Not less than

600 mm

Structure

1

Not less

than 600

Fig 10. Flat roof, with no parapet

Fig 11. Flat roof, with structure close

to flue outlet

Structure

h

h

Not less

than

250 mm

15

Section 9: Ventilation Requirements

Where the heater is to be installed in a plant room, the heater requires the plant room

housing to have permanent air vents communicating directly with the outside air, at a

high level and at a low level. Where communication with the outside air is possible

only by means of high level air vents, ducting down to floor level for the lower

vent(s) should be used. Air vents should have negligible resistance and must not be

sited in any position where they are likely to be easily blocked or flooded, or in any

position adjacent to an extraction system, which is carrying flammable vapour.

Grilles or louvers should be designed so that high velocity air streams do not occur

within the plant room.

The ventilation should be installed to in accordance with local and national codes.

Ventilation Requirements:

The space in which the heater is situated must be adequately ventilated, see below for

the minimum ventilation area at low and high levels.

Low Level:

540cm² plus 4.5cm² per kW after 60kw.

High Level:

270cm² plus 2.25cm² per kW after 60kw

16

Section 10: Gas Piping

All Gas Pipe-work to the appliance should be installed in accordance with

current regulations, local and national codes and must be connected with an

acceptable gas isolation valve and union, so that the burner maybe removed

to aid servicing and inspection of the burner.

Size and Connection

The following considerations are to be taken into account:

a) Pipe work smaller than the inlet gas connection should not be used.

b) The gas supply pipe is adequately sized to carry correct volume of gas from

the gas meter to the heater(s).

c) The heat input and gas flow rates for each heater can be found in section 4

table 1 to aid in the design of gas supply pipe work.

d) All gas pipe work and electrical connections must be adequately supported

and must not support any of the heaters weight or rely on the strength of the

burner gas pipe work.

e) Unless the heater is suspended or movement is apparent, the BMM Heater

must be connected with medium, heavy or copper pipe; otherwise the use

of an approved flexible connection between the isolating valve and the

heater can be used. We recommend that the flexi hose is one size bigger

than the heater connection to reduce any pressure loss.

The minimum inlet gas pressure for natural gas should be 20 mbar.

Please note: We require a minimum of 17.5mbar at the inlet when running and a

maximum of 75mbar, if this is exceeded then a governor must be fitted.

Important: The complete installation must be purged and tested for gas

soundness in accordance with local, national codes and a registered engineer.

17

Gas Connection Size

Model Weishaupt Burner Riello Burner

12

15

18

23

30

44

59

88

117

147

176

205

235

264

293

352

440

513

586

733

880

952

½" BSP ½" BSP

½" BSP ½" BSP

½" BSP ½" BSP

½" BSP ½" BSP

½" BSP ½" BSP

¾" BSP ½" BSP

¾" BSP ¾" BSP

¾" BSP ¾" BSP

1" BSP ¾" BSP

1" BSP ¾" BSP

1½" BSP 1" BSP

1½" BSP 1" BSP

1½" BSP 1¼" BSP

1½" BSP 1¼" BSP

1½" BSP 1¼" BSP

2" BSP 2" BSP

2" BSP 2" BSP

2" BSP 2" BSP

2" BSP 2" BSP

2" BSP 2" BSP

2" BSP 2" BSP

2" BSP 2" BSP

Further Information regarding pipe work to the burner can be found in the

burner manual attached to this document.

18

Section 11: Condensate Drains

On models where larger turndowns are required, there will be a 1” BSP

condensation drain, which must have a trap fitted and then pipe/drain

accordingly (by others). The condensate pipe work must not be installed

below 1” BSP.

WARNING!

Do not use plastic connections, as the temperature may be high at the

outlet to the drain. Copper pipe must not be used.

Important

Condensing heaters may be subject to local regulations with respect to the

discharge of condensate.

Section 12: Electrical Connections

All external wiring must be in accordance with current IEE Regulations and

local regulation which apply.

The method of connection to the mains electricity supply should allow

complete electrical isolation of the heater and the supply should serve the

heater only. The mains isolator should be provided adjacent to the heater in

an easily accessible position. The isolator must have contact separation of at

least 3 mm on all poles.

The electric and controls terminations are located on the front of the Heater

housed in an interface panel. All heaters are compatible for inter-facing with

building management systems and 0-10v DC is required as standard on

Modulating heaters.

All wiring and control cables must be ran in conduit and correct size glands

used etc.

All appliances must be earthed.

Each heater manufacture is individually made to suit the customer so a

dedicated circuit will be attached to this manual. BMM Heaters will also

attach a circuit within the interface panel.

19

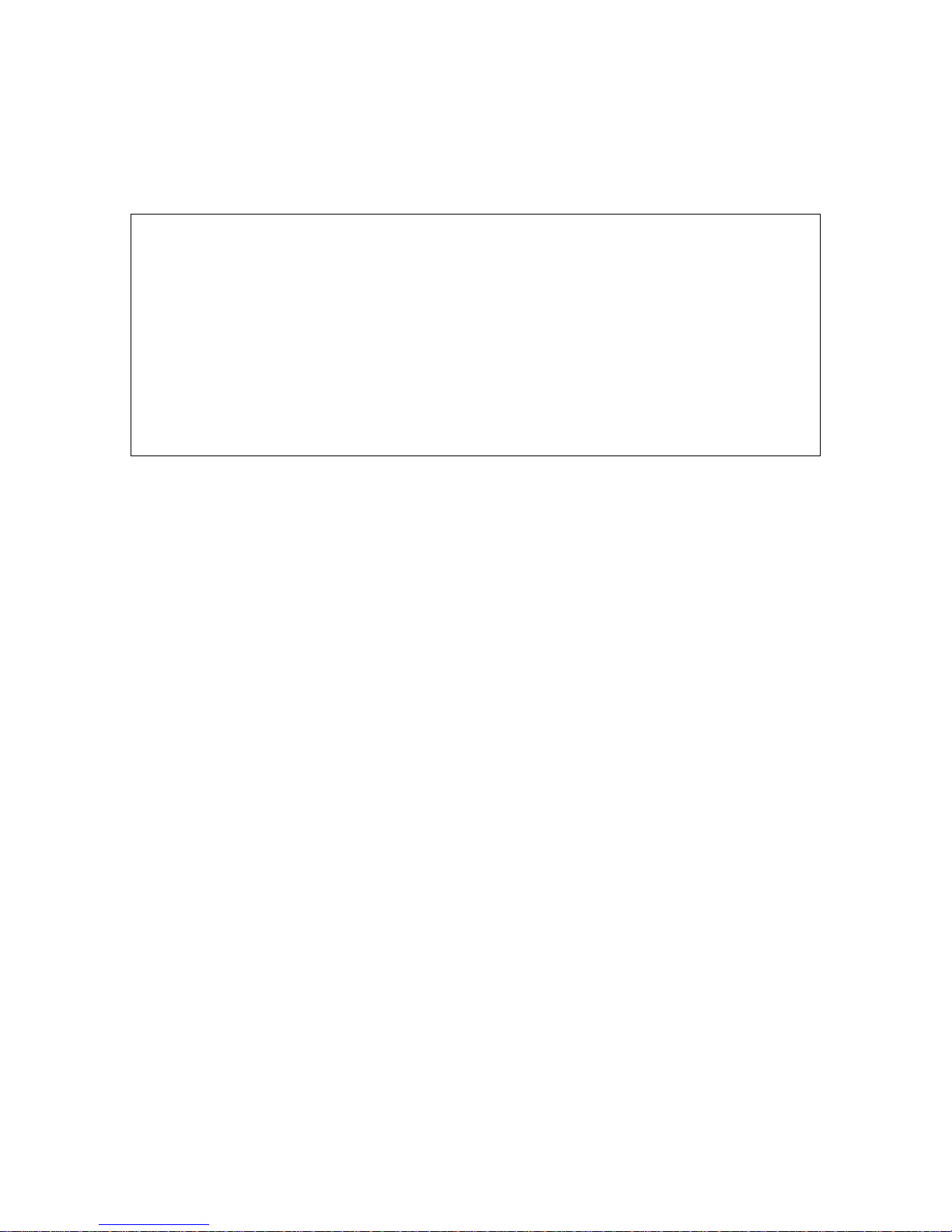

Table 3: Electrical Data

Model Motor size

Three phase

18 750w 550w 10 Amps 5 Amps 10 Amps

23 750w 550w 10 Amps 5 Amps 10 Amps

30 750w 550w 10 Amps 5 Amps 10 Amps

44 750w 550w 10 Amps 5 Amps 10 Amps

59 750w 550w 10 Amps 5 Amps 10 Amps

88 750w 750w 10 Amps 5 Amps 10 Amps

117 1.5kw N/A 15 Amps 5 Amps 15 Amps

147 2.2kw N/A 15 Amps 5 Amps 15 Amps

176 5.5kw N/A 20 Amps 5 Amps 30 Amps

205 5.5kw N/A 20 Amps 5 Amps 30 Amps

235 7.5kw N/A 30 Amps 5 Amps 30 Amps

293 7.5kw N/A 30 Amps 5 Amps 30 Amps

440 2 x 5.5kw N/A 30 Amps 5 Amps 30 Amps

513 2 x 7.5kw N/A 30 Amps 5 Amps 30 Amps

586 2 x 7.5kw N/A 30 Amps 5 Amps 30 Amps

733 Special Requirements On application - 880 Special Requirements On application - 952 Special Requirements On application - -

Motor size

Single phase

Motor rated

supply fuse

(Three phase)

Control Fuse Motor rated

supply fuse

(Single Phase)

Controls: BMM Heaters can supply controls for these heaters upon request.

Please confirm with us the type of controls prior to connecting to check

compatibility.

The Burner wiring diagrams can be found in the burner supplement provided with

this manual.

Note: All heaters have been electrically tested at BMM Heaters factory.

20

Section 13: Heater Controls

The heater can be used with most Building Management Systems.

2:1 Turndown Burner:

The heater interface panel connections:

(a). 240v & N supply

(b). T1 & T2 is the enable, T1 & T2 must break when up to a

temperature, all interlocks to be wired in series with T1 & T2. (The

burner must be interlocked with the supply fan).

(c). T6 - is 10v DC signal for modulation

(d). T7 - 24 volts AC supply for modulating, please note the 24 volts

transformer is in our panel, please advise if you are using external 24

volts.

(e) T8 - 0 volts

(f) T5 - 240v burner lockout indication if required.

Please supply 15 minutes supply fan over run on burner shutdown

If you require any further information or you have any special requirements

please do not hesitate to contact our Technical Department.

For ON/OFF Control Only, Omit sections C, D & E

21

4:1 Turndown Burner:

The heater interface panel connections:

(a). 240v & N supply

(a) T1 & T 2 is the enable, T1 & T2 must break when up to temperature, all

interlocks to be wired in series with T1 & T2. (The burner must be

interlocked with the supply fan).

(b) T6 – is 10v DC signal for modulation.

(d) T8 – 0 volts.

(e) T5 – 240v burner lockout indication if required.

Please supply 15 minutes supply fan over run on burner shutdown.

If you require any further information or you have any special requirements,

please do not hesitate to contact our Technical Department.

WARNING!

Electrical Shock Hazard

Use extreme caution while working on this appliance.

Failure to follow these instructions can result in death or electric shock.

Only competent engineer should carry out work on this appliance.

22

Section 14: Commissioning.

Commissioning ON/OFF

COMMISSIONING MUST BE CARRIED OUT BY A COMPETENT

REGISTERED ENGINEER (CORGI), ALSO TO BE USED WITH BURNER

COMMISSIONING DETAIL SEE BURNER INSERT.

1. Visually check full system to see if it is in accordance with our manual and to

current / CORGI legislation and IEE regulations and to this manual.

2. Check combustion air is adequate in plant room or surrounding area.

3. Check contractors electrical wiring is correct & terminated tight and fuse

ratings are correct.

4. Ensure that the gas pipe work is sized correctly and relative documents for

soundness & purging are available. It is the responsibility of the

commissioning engineer to check for soundness from the main inlet to

servicing stop tap on inlet of valve.

5. Ensure that the inlet gas pressure is no greater than 75mb static and no less

than 17.5mb running.

6. Make sure that all dampers are set and diffuser outlets are open to give correct

air flow and that the correct number of air by-pass blades have been removed

to by-pass the air in excess of our maximum amount of air through our heater,

which can be found in Section ‘Minimum and Maximum Air Volumes’ of this

Manual.

7. Check with the controls engineer that he has an interlock with the supply fan &

burner so that the burner can not run without the supply fan e.g. Air pressure

switch across supply fan in series with our Enable circuit between T1 & T2.

The controls must keep the supply fans running on for 15 minutes after burner

shut down, on a shut down condition. The terminals 1 & 2 are also used to wire

stats and time switches in series to switch the burner on and off.

8. Make sure that the stat, which is wired between terminals 1 & 2, is closed and

turn the main gas on to make the gas pressure switch and turn the

commissioning stop tap off. Switch the burner on, the burner should run

through its cycle and after the ignition spark goes out the burner should lockout

on flame failure on the burner control box.

23

9. Before opening the commissioning stop tap ensure that the burner air damper is

open. The main valve has to be disconnected and the pilot is to be left

connected, then open the commissioning tap and switch the burner on. The

burner should go through its sequence and fire but stay on. At this point in

time you have to check the start gas rate which should be no greater than 20%

of the total output. This is preset in the factory and should be checked.

10. When satisfied with the pilot pressure, switch the burner off and reconnect the

main valve, turn the main gas valve and turn the gas valve throttle to minimum

and switch the burner back on. Now the burner should fire and go to full fire,

then set the head pressure in accordance to the rating plate. The governor must

be throttled down until it takes control of the head pressure and left there. The

main gas valve throttle can be locked in to position when the gas head pressure

is set. When you are satisfied with the gas settings then the CPI switch requires

setting, on the SKP valves they are integral, which are factory set. For further

information please see burner insert in this manual.

11. Carry out full emission checks with a flue gas analyser. The parameters are to

be set as specified in this manual by the adjustment of the burner air damper,

which, when satisfied must be locked off securely.

12. The high and low air pressure switch must be set after the damper has been

locked off. The low air pressure switch is set by turning it up until it locks out

and moving it back 1.2mb on the pressure switch then setting the high air

pressure switch to 1.2mb above the lockout pressure.

13. The low gas pressure switch will be pre-set in the factory to 10mb.

14. You are then required to check the strength of the flame sensing device by

removing the link on the burner which connects the flame probe to the control

box and put your multi-meter in series, which should give you a reading in uA.

The signal strength should be a least 70uA for U.V. and 6uA on flame

rectification.

15. After running the unit for a period of one hour you will be able to get a running

temperature from the fan limit side of the stat. When you have this you must

set the over heat to 20°c above the running temperature. The supply fans

should be shut down once, when the burner is running, to try the overheat

protection device and the fans must be switched on as soon as it locks out on

over heat.

24

16. All gas nipples are to be replaced and checked for tightness and checked with

leak detection fluid.

17. A leak detection test is to be done with leak detection fluid and electronic leak

detector on the gas train while the burner is running, to see if there are any

leaks in the burner gas train and a soundness test is to be done on all gas work.

18. Finally make a full record of combustion data on commissioning sheet

provided; a copy is to be presented to the customer and to BMM Heaters on

completion of work. The commissioning sheet should include the following:-

(a) Model and serial numbers.

(b) Heater running temperature and over heat settings.

(c) Full thermal input.

(d) Governor pressure settings (pilot for start gas and main for full fire).

(e) Gas flow rates for full fire.

(f) Burner damper setting and pressure switch settings.

(g) Flame signal strength on full fire.

(h) Exhaust gas O², CO², CO and temperature.

19. After setting all air pressure switches and valves etc, you must mark the

position or lock off if possible.

Please note BMM Heaters provide a full commissioning service if required. Also if

you require further information call BMM Heaters technical department.

TYPICAL FLUE GAS READINGS

O² - 4% to 5%

CO² - 9.5% to 10%

CO – up to 100 PPM (Typical approx 20 PPM)

Flue Stack Temperature – Up to 330°c Nett

25

Commissioning High/Low

COMMISSIONING MUST BE CARRIED OUT BY A COMPETENT

REGISTERED ENGINEER (CORGI), ALSO TO BE USED WITH

BURNER COMMISSIONING DETAIL SEE BURNER INSERT.

1. Visually check full system to see if it is in accordance with our manual

and to current/CORGI legislation and IEE regulations and to this

manual.

2. Check combustion air is adequate in plant room or surrounding area.

3. Check contractors electrical wiring is correct & terminated tight and fuse

ratings are correct.

4. Ensure that the gas pipe work is sized correctly and relative documents

for soundness and purging are available. It is the responsibility of the

commissioning engineer to check for soundness from the main inlet to

servicing stop tap on inlet of valve.

5. Ensure that the inlet gas pressure is no greater than 75mb static and no

less than 17.5mb running.

6. Make sure that all dampers are set and diffuser outlets are open to give

correct air flow and that the correct number of air bypass blades have

been removed to bypass the air in excess of our maximum amount of air

through our heater, which can be found in the section ‘Minimum and

Maximum Air Volumes’ in this Manual.

7. Check with the controls engineer that he has an interlock with the supply

fan and burner so that the burner can not run without the supply fan e.g.

air pressure switch across supply fan in series with our enable circuit

between 1 & 2. The controls engineer must keep the supply fans

running on for 15 minutes after burner shutdown, on a shutdown

condition. The terminals 1 & 2 are also used to wire stats and time

switched in series to switch the burner on and off. Terminals 6 & 7 are

required for high/low operation and is fixed air turndown, when the

circuit is made it is high and when it is broken it is low.

26

8. Make sure that the stat, which is wired between terminals 1 & 2 is closed

and turn main gas on to make the gas pressure switch and turn the

commissioning stop tap off. Switch the burner on, the burner should run

through its cycle and after the ignition spark goes out, the burner should

lockout on flame failure on the control box.

9. Before opening the commissioning stop tap ensure that the burner air

damper is open. The main valve has to be disconnected and the pilot is

to be left connected, then open the commissioning tap and switch the

burner on. The burner should go through its sequence and fire but stay

on. At this point in time you have to check the start gas rate which

should be no greater than 20% of the total output. This is preset in the

factory and should be checked.

10. When satisfied with the pilot pressure, switch the burner off and

reconnect the main valve, turn the main gas valve and turn the gas valve

throttle to minimum and switch the burner back on and make the

high/low circuit. Now the burner should fire and go to full fire, then set

the head pressure in accordance to the rating plate, now break the circuit

between 6 & 7 so that the valve goes to low fire and set it in accordance

to the rating plate pressure. The governor must be throttled down until it

takes control of the head pressure and left there. The main gas valve

throttle can be locked in to position when the gas head pressure is set.

When you are satisfied with the gas settings then the CPI switch requires

setting on the SKP valves, they are integral, which are factory set. For

further information please see burner insert in this manual.

11. Carry out full emissions check with a flue gas analyser. The parameters

are to be set as specified in this manual by the adjustment of the burner

air damper, which, when satisfied must be locked off securely. Then the

burner requires setting 50% turndown, which can be done by breaking

the circuit between 6 & 7, when you break this circuit you must check

the emissions are okay. They will be approximately 10% to 11% O² on

low fire and CO emissions should be below 100 PPM. Note the air

damper is not altered between high and low, it is set on high.

12. The high and low air pressure switch must be set after the damper has

been locked off. The low air pressure switch is set by turning it up until

it locks out and moving it back 1.2mb on the pressure switch then setting

the high air pressure switch to 1.2mb above the lockout pressure.

13. The low gas pressure switch will be pre-set in the factory to 10mb.

27

14. You are then required to check the strength of the flame sensing device

by removing the link on the burner, which connects the flame probe to

the control box and put your multi-meter in series, which should give

you a reading in uA. The signal strength should be a least 70uA for U.V.

and 6uA on flame rectification.

15. After running the unit for a period of one hour you will be able to get a

running temperature from the fan limit side of the stat. When you have

this you must set the over heat to 20°C above the running temperature.

The supply fans should be shut down once, when the burner is running

to try the overheat device and the fans must be switched on as soon as it

locks out on overheat.

16. All gas nipples are to be replaced and checked for tightness and checked

with leak detection fluid.

17. A leak detection test is to be done with leak detection fluid and

electronic leak detector on the gas train while the burner is running to

see if there are any leaks in the burner gas train and a soundness test is to

be done on all gas work.

18. Finally make a full record of combustion data on commissioning sheet

provided; a copy is to be presented to the customer and to BMM Heaters

on completion of work. The commissioning sheet should include the

following:

(a) Model and Serial Numbers.

(b) Heater running temperature and overheat settings.

(c) Full thermal input.

(d) Governor pressure setting (pilot for start gas and main for full fire).

(e) Gas flow rates for full fire.

(f) Burner damper setting and pressure switch settings.

(g) Flame signal strength on full fire.

(h) Exhaust gas O², CO², CO and temperature.

After setting all air pressure switches and valves etc, you must mark the

position or lock off if possible.

TYPICAL FLUE GAS READINGS

O² - 4% to 5%

CO² - 9.5% to 10%

CO – up to 100 PPM (Typical approx 20 PPM)

Flue Stack Temperature – Up to 330°c Nett

28

Commissioning High Turndown

COMMISSIONING MUST BE CARRIED OUT BY A COMPETENT

REGISTERED ENGINEER (CORGI), ALSO TO BE USED WITH

BURNER COMMISSIONING DETAIL SEE BURNER INSERT.

1. Visually check full system to see if it is in accordance with our manual

and to current/CORGI legislation and IEE regulations and to this

manual.

2. Check combustion air is adequate in plant room or surrounding area.

3. Check contractors electrical wiring is correct and terminated tight and

fuse ratings are correct.

4. Ensure that the gas pipe work is sized correctly and relative documents

for soundness and purging are available. It is the responsibility of the

commissioning engineer to check for soundness from the main inlet to

servicing stop tap on inlet of valve.

5. Ensure that the inlet pressure is no greater than 75mb static and no less

than 17.5mb running.

6. Make sure that all dampers are set and diffuser outlets are open to give

correct air flow and the correct number of air bypass blades have been

removed to bypass the air in excess of our maximum amount of air

through our heater, which can be found in the section ‘Minimum and

Maximum Air Volumes’ in this Manual.

7. Check with the controls engineer that he has an interlock with the supply

fan and burner so that the burner can not run without the supply fan eg

air pressure switch across supply fan in series with our enable circuit

between 1 & 2. The controls engineer must keep the supply fans running

on for 15 minutes after burner shutdown, on a shutdown condition. The

terminals 1 & 2 are also used to wire stats and time switches in series to

switch the burner on and off. The unit also requires a 0-10v DC signal

from the controls to modulate the burner from 100% to 25%.

29

8. Make sure that the stat, which is wired between terminals 1 & 2, is

closed and turn the man gas on to make the gas pressure switch and turn

the commissioning stop tap off. Switch the burner on, the burner should

run through its cycle and after the ignition spark goes out the burner

should lockout on flame failure on the burner control box.

9. Open the commissioning tap and switch the burner on. The burner will

start on full air and the pilot will only open. When the pilot has

established then the pilot will go out and switch to the gas air ratio valve

the output of the burner will then be decided on the 0-10v dc signal.

When commissioning we would advise that you modulate the burner by

moving the low setting up to the same as the maximum setting and

unplug the 0-10v dc signal, then you can just turn the low speed down or

up to modulate burner. We would advise that you set the highest point

of the burner to the head pressure on the rating plate and adjust the air on

the inverter by high speed setting to get the correct combustion readings

of about between 0²: 4.0 & 5.0. After setting the top end then set the

bottom end of the burner by turning the low speed down. The burner fan

should slow down and the output should decrease, now set the burner to

the low head pressure and adjust the low setting to match the air for

combustion, the readings should be the same. For further information

see insert or inverter manual for inverter setting in this manual.

10. Now plug the burner 0-10v dc back in and connect the 0-10v dc signal

back in. Now try the modulation, 0v dc will be 25% of the burner output

and 10v dc will be 100% burner output. Please note, you must check

emissions right throughout the range 0-10v and make sure gas and air

match each other. The emissions should be approx the same throughout.

11. The high and low air pressure switch must be set on low speed. The low

air pressure switch is set by turning it up until it locks out and moving it

back 1.2mb on the pressure switch, then setting the high air pressure

switch to 1.2mb above the lockout pressure.

12. The low gas pressure switch will be preset in the factory to 10mb.

13. You are then required to check the strength of the flame sensing device

by removing the link on the burner which connects the flame probe to

the control box and put your multi-meter in series, which should give

you a reading in uA. The signal strength should be at least 70uA for

U.V. and 6uA on flame rectification.

30

14. After running the unit for a period of one hour you will be able to get a

running temperature off the fan limit side of the stat. When you have

this you must set the overheat to 20°C above the running temperature.

The supply fans should be shut down once, when the burner is running

to try the overheat protection device and the fans must switched on as

soon as it locks out on overheat.

15. All gas nipples are to be replaced and checked for tightness and checked

with leak detection fluid.

16. A leak detection test is to be done with leak detection fluid and

electronic leak detector on the gas train while the burner is running to

see if there are any leaks in the burner gas train and a soundness test is to

be done on all gas work.

17. Finally make a full record of combustion data on commissioning sheet

provided; a copy is to be presented to the customer and to BMM Heaters

on completion of work. The commissioning sheet should include the

following:-

(a) Model and serial number.

(b) Heater running temperature and overheat settings.

(c) Full thermal input.

(d) Governor pressure settings (pilot for start gas and main for full fire).

(e) Gas flow rates for full fire.

(f) Burner damper setting and pressure switch settings.

(g) Flame signal strength on full fire.

(h) Exhaust gas O², CO², CO and temperature.

18. After setting all air pressure switches and valves etc., you must mark the

position or lock off if possible.

Please note, BMM Heaters provide a full commissioning service if required.

Also if you require further information call BMM Heaters technical

department.

TYPICAL FLUE GAS READINGS

O² - 4% to 5%

CO² - 9.5% to 10%

CO – up to 100 PPM (Typical approx 20 PPM)

Flue Stack Temperature – Up to 330°c Nett

31

Section 15: Servicing

INSTRUCTION FOR THE HEAT HEATER

PLEASE NOTE SERVICING MUST ONLY BE CARRIED OUT

BY A COMPETENT REGISTERED ENGINEER (CORGI)

BEFORE CARRYING OUT ANY WORK ON THE UNIT SEE

THAT THE ISOLATING SWITCH IS IN THE ‘OFF’ POSITION

AND THE GAS SUPPLY IS SHUT OFF.

BMM HEATERS ONLY RECOMMEND THE USE OF PARTS

SUPPLIED OR RECOMMENDED BY OURSELVES.

INFORMATION IS FOR GUIDANCE OF QUALIFIED

SERVICE ENGINEERS ONLY

Note: We recommend that the Heater is fully serviced every year and

recommissioned. If the flue gas passages in the heat exchanger, the

combustion chamber, or in the flue chamber are blocked, the Heater can

overheat causing the unit to shut down on the overheat thermostat.

To clean the Heat exchanger:

The heat exchanger must be cleaned from the front and rear of the appliance

after first removing the following items:

(a) The burner assembly

Burner Removal (With gas and electrical supply isolated):

1. Disconnect the electrical supply to the burner by removing the multi-pin

plug from the socket on the Heater interface panel.

2. Disconnect gas valve plugs.

3. Unscrew gas union assembly at inlet to gas train and at entry into burner

mounting flange and remove gas train assembly.

4. Remove four fixing screws holding burner to heater front and lift

away burner.

32

5. Fully service burner and replace electrodes, if required

(a) The fan limit thermostat

(b) The front outer case panel

(c) Remove and support flue

(d) Remove Rear panel

(e) The heat exchanger cover plate, front and rear.

(f) Brush any deposits from all of the flue ways using a brush. Also brush down

the heat exchanger tubes.

(g) Remove any soot from the bottom of the combustion chamber with a vacuum

cleaner.

(h) Inspect soundness of combustion chamber/heat exchanger.

(i) Replace all items in reverse order.

NOTE: Fit new gasket or seal to gas exchanger box, cleaning door where

necessary.

Note: Regarding External Heaters

If the heater is housed within an Air Handling Unit, there will be sufficient room

to allow servicing. Servicing as per our standard internal procedures.

Please note in extreme weather conditions, always ensure any electrical

connections etc are protected and do not allow water onto them.

If stand alone external heater, there will be a door, which is hinged up over to

allow protection to the engineer from weather conditions; an illustration of the

external heater can be found in section 5 Fig 1.

Wet Conditions

If it is found that the area in which the heater is installed has become

wet/flooded, the heater must be electrically isolated immediately and an

investigation to find out if any water has penetrated into the heater controls. If so,

ensure they are dried out properly before re-installing the electric supply.

33

Burner Maintenance:

Refer to the Burner Supplement supplied with the heater.

Servicing Heat Exchanger:

Heat Exchanger of multi-tube construction with removable access clean out doors

at either end. Access plates are secured by brass nuts, sandwiching glass wool

webbing type gasket material between the heat exchanger flange and the access

doors. When removing the doors it is important to inspect the gasket material and

replace if necessary.

It is important that the tubes should be inspected and swept out if necessary,

replacing Gasket Material – the material is of glass wool webbing 25mm x 3mm

thick in strip form. The method of securing it is to have strips overlapping, and to

cut through both surfaces with a sharp knife to give an exact join. Self adhesive

webbing is easier to secure (available from BMM Heaters).

Recommended intervals:

Weekly check:

Check that there are no apparent leaks.

Clean air filters if fitted, if of the washable type, or replace where necessary.

Quarterly check:

As weekly check, and also:

Check the tension of the main fan belt(s).

Check the flue for condensation.

Remove the Burner Inner Assembly – clean and replace.

Annual Inspection:

Clean heat exchanger surface.

Inspect and align fan and motor pulleys. Check the tightness of the motor

bolts.

Adjust fan belts for tension.

Inspect and adjust electrical connections.

Check all wiring and tube connections.

Remove the burner inner assembly – clean and replace.

Start the Heater and check CO readings, stack temperature efficiency and

CO level.

Check the combustion air supply and check the smoke reading.

34

Overheat/Limit control:

The limit control provides protection for the heater, should the temperature rise

above a safe level. If an overheat condition occurs, the limit control will shut down

the burner and hold it off until the manual reset button is pressed.

NOTE:

If the limit requires re-setting more than once after first re-set, then a

competent engineer must be called to investigate further.

Fan setting - 35°c ON (If required)

- 25°c OFF

High Limit - 20°c above normal running temperature no greater than 100°c

Important: When integrated with building management system, the fan will be

operated via their controls and all interlocks must be fitted to ensure the burner

cannot start until the supply fan is running. On burner shutdown the supply fan

overrun will continue running for 10 – 15 minutes to dissipate residual heat.

Fan Assembly:

Inspect the fan blades to see they are not damaged and that there is no excessive

building up of deposits that could give an imbalance via access panel on the side

of the heater. If necessary clean the fan blades.

The main fan bearings are permanently sealed and do not require lubrication.

Check belts for signs of wear and replace if required.

Gas control valves maintenance:

No regular maintenance is required on these devices. Please refer to section 16 for

removal or replacement of parts.

WARNING!

Replace faulty gas valve with genuine BMM Heater replacement part; failure

to do so could result in death, injury and damage to property.

Note! Check all gas pipes and joints to ensure there are no cracks or gas leaks.

Any cracks in the pipe work or joint must be repaired.

35

Fan control:

The burner should start its safety sequence and then fire up. When the heater

achieves 35°c the supply fan will cut in and your heater is up and running. When

the space is up to temperature the burner will stop and the supply fans will run on

until the fan control reaches 25°c and then the supply fan will shut down. The

heater will then switch on and off as required via the day thermostat and time

clock. If your heater fails to start, check burner lockout and high limit resets as

referred to in fault findings, if any further investigation is required or the heater

repeatedly locks out then a Corgi registered engineer must be called to investigate

further.

Please Note:

You must not electrically isolate the heater when in full fire, always

wait until the burner stops and the supply fan over runs to dissipate the heat before

electrically isolating.

For summer ventilation switch on/off switch to off and set fan switch from auto to

manual.

Cleaning Of Heater:

The heater can be cleaned externally using a damp cloth with a light detergent.

Please note: this is on the outer panel only, away from all of the electrics. No

substance can be used that will cause harm to the surface of the metal, or remove

paint etc.

Please Note: You must not use water on unpainted galvanised finished surfaces.

36

Section 16: Removal and Replacement Parts

Note! Please refer also to the burner supplement supplied with this Manual.

Multi-Block gas valve

1. Isolate electric and gas.

2. Remove Din Plugs by using a terminal screwdriver to undo locking screw.

3. Undo valve flanges with 13mm spanner (up to 500 model), 17mm spanner

(above 500 model). Lift out valve assembly.

4. Replace and re-assemble in reverse order, taking care that the O rings are in

position.

5. Check for gas soundness and recommission heater.

Fan and limit stat

1. Isolate electric supply.

2. Remove outer casing and disconnect wires. The wires are held in by spring

terminals which will release by pushing a small screwdriver into the slot next

to the wiring termination.

3. Remove fixing screws, which secure stat to front of panel, carefully withdraw

stat from heater and remove casing.

4. Re-assemble in reverse order and check settings, adjust if required to fan on

35°, fan off 25°, high limit 90°.

Supply Fan

1. Isolate electric supply.

2. Remove front lower access panel.

3. To remove fan belt, slacken both adjustment bolts on motor plate by turning

anti-clockwise.

4. Remove rear panels (opposite side to burner).

5. Undo x 4 bolts and remove shelf assembly.

6. Undo x 4 bolts on the fan assembly and then the fan can be withdrawn.

7. Re-assemble as reverse.

37

Main Supply fan

1. Isolate electric supply.

2. Remove front lower access panel.

3. To remove fan belt, slacken both adjustment bolts on motor plate by turning

anti-clockwise.

4. Disconnect fan motor electrics.

5. Remove motor on motor plate and undo x 4 bolts, Note, you will require x 4

locking nuts on replacement.

6. Re-assemble in reverse order.

7. Re-tighten the supply fan belt until 12mm movement is obtained.

8. Check fan rotation is correct.

Recommend Tools to be used.

a) Spanner 10mm, 13mm and 17mm

b) Screwdriver – Terminal, medium flat blade and philips medium

c) Stillsons – 14” and 18”

d) Allen keys – standard metric set, 1.5mm – 10mm

e) Side cutters/pliers

f) Multi-meter

g) Manometer

h) Flue – brush 3” head for exchanger tubes

38

Section 17: Spare Parts

Spares List:

Item Part No.

Fan and Limit Control JTL 13A or Honeywell

Spark Electrode 101

Flame Probe 102

Please refer to gas burner supplement supplied with this manual.

All components can be purchased from BMM Heaters.

WARNING

Only use parts recommended by BMM Heaters or other wise stated in this

manual.

You must first contact BMM Heaters if you want to use alternative parts.

39

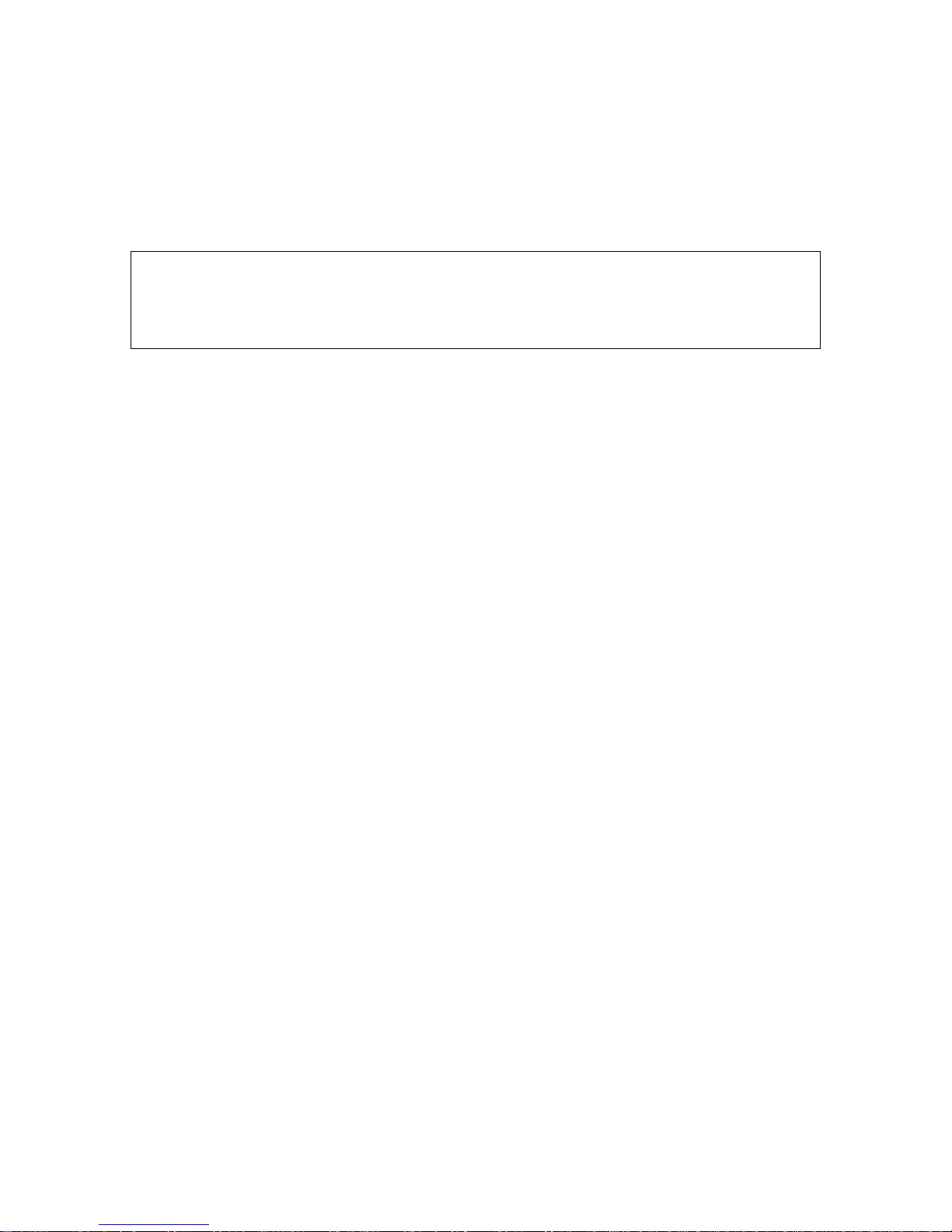

Section 18: Troubleshooting

Note!

Please refer to burner supplement supplied with this manual where more

specific troubleshooting will be found.

Fault Cause Check

Burner Lockout Burner fault, check sector

lockout occurred on

Refer to burner

supplement finding chart

controls box

Overheat trip Dirty filters, low supply

air

Filters, supply fan belts,

damper operations

Burner held off No enable signal Check BMS/Controls

back via T1 & T2 in

heater interface panel

Main fan runs

continuously

Electrical Summer/Winter switch

set to summer(Manual)

Fan thermostat set to low

Fault Fan/Limit stat

Main fan Fails to run Electrical Fan Motor faulty

Fan/Limit stat faulty

Contactor faulty

Motor on overload

40

Section 19: Users Instructions

WARNING!

If you smell gas:

1. Open all windows and door.

2. DO NOT try to light any appliance.

3. DO NOT use electrical switches.

4. DO NOT use any telephone in your building.

5. Leave the building.

6. Immediately call your local gas supplier after leaving the building; follow

the gas supplier’s instructions

7. If you cannot reach your gas supplier, call the fire department

USERS INSTRUCTIONS

Once the controls have been fully installed and proved with the Heater (all

interlocks proved etc), the supply air has been balanced and only when the Heater

has been fully commissioned by a qualified registered engineer (Corgi), you are

now able to use your Heater safely.

Easy Lighting and Shutting Off Instructions

Burner Start up

1. Ensure Burner and Heater On/Off Switch is on.

2. Fan switch is in auto position. If the heater is controlled via a BMS then the

supply fan should be running before the burner can start.

3. Make sure the time clock and thermostats are calling for heat or that the

BMS is giving enable signal to terminals 1 & 2 in our interface panel.

Burner Shut down

1. Ensure Burner and Heater On/Off Switch is off.

2. Fan switch is in auto position. The fans should run on for at least 10 min or

till the fan limit is below 25ºc to cool heat exchanger.

3. Make sure the time clock and thermostats are not calling for heat or that the

BMS is not giving enable signal to terminals 1 & 2 in our interface panel.

41

WARNING!

In Emergency only! Use electrical isolator and the gas isolation valve to isolate

the appliance.

Do not use electrical isolator to switch this appliance off in normal use, as the fan

is required to run on to cool the heat exchanger failure to do so will cause damage

to this appliance.

Simple Fault Finding

Some possible reasons for the heater not operating are:

1. Gas supply not turned ON.

2. Electrical Supply not turned ON.

3. The time and/or Thermostats may not be ON.

4. The Limit stat may have operated due to an interruption of electrical supply

or fault with the distribution fan.

WARNING!

If the limit thermostats persistently operate, there is a fault which must be

investigated by a qualified engineer registered with corgi. This Heater should

not be electrically isolated during normal operation; doing so without a fan

run on for 10 min will cause serious damage to the heater.

Simple Fault Finding (burner faults)

If the burner fails to ignition for any reason, it will go to lockout. This will be

indicated by the red light on the burner or digitally shown on a display screen.

Press in and release the lockout reset button; call a registered engineer if this does

not rectify the problem.

Lockout should not occur during normal operation of the heater and indicates there

is a fault condition which must be corrected.

WARNING!

Do not store or use petrol or other flammable vapours and liquids in the

vicinity of this or any other appliance.

Some objects will catch fire or explode when placed close to the heater.

Failure to follow these instructions can result in death, injury or property

damage.

42

Loading...

Loading...