BMM Heaters BMG, BMGVF, BMGDF, BMGF, BMGDD User And Installation Manual

...

Air Heater Manuals

User/Installation/Servicing

BMM Heaters Ltd

1 Copeland Court

Forest Grove

Middlesbrough

TS2 1RN

Tel:01642 240700

Fax:01642 240708

Sales@bmmheaters.co.uk

1

BMM HEATERS REFERENCES

Heater Models Description

BMG Horizontal Heater for ducted or AHU

applications suitable for natural gas.

BMVG Vertical heater for ducted or AHU applications

suitable for natural gas.

BMGVF Free standing nozzle head heater with force

draught gas burner.

BMGDF Free standing ducted heater with force draught

gas burner.

BMGF Horizontal ducted heater with force draught gas

burner.

BMGDD Downward discharge heater with force draught

gas burner.

2

CONTENTS PAGE

DESCRIPTION

Section 1: Introduction…………………………………………. 4

Section 2: Heater Safety………………………………………… 5

Section 3: Installers Responsibilities…………………………… 5

Section 4: Specifications………………………………………… 6

Section 5: Heater Installation & Clearances…………………... 7

Section 6: Air supply…………………………………………….. 9

Section 7: Overheat Protection Device…………………………. 10

Section 8: Flue System…………………………………………… 11

Section 9: Ventilation Requirements……………………………. 16

Section10: Gas Piping……………………………………………. 17

Section 11: Condensate Drains………………………………….. 19

Section 12: Electrical Connections……………………………… 19

Section 13: Heater Controls……………………………………... 21

Section 14: Commissioning……………………………………… 23

Section 15: Servicing…………………………………………….. 32

Section 16: Removal and Replacement of Parts……………….. 37

Section 17: Spare Parts………………………………………….. 39

Section 18: Troubleshooting…………………………………….. 40

Section 19: Users Manual………………………………………... 41

Model:

Serial Number:

3

Section 1: Introduction

The instructions refer to appliances designed to operate in the UK and

Ireland.

Appliances designed for other countries can be provided on request.

This appliance must be installed in accordance with the local and national

codes in force and used only in a sufficiently ventilated space, as specified in

these instructions.

Before installation, check that the local gas distribution systems, nature of gas

and pressure, and adjustment of the appliance are compatible.

Indirect Fired

The term ‘Indirect Fired’ indicates that the products of combustion are kept

isolated from the main supply air stream. The burner fires into a combustion

chamber, the resultant products of combustion are directed into a heat exchanger

and from there to an external flue, which discharges into the atmosphere.

Factory Test

All heaters produced by BMM Heaters Ltd will be subjected to various tests

before they are dispatched. Each heater is individual so the data will differ

between each unit. The relevant data can be found on the data plate attached to the

heater.

External Heaters

The construction of the unit will consist of double skin panels and be fully water

proof; the burner compartment will be adequately ventilated via two combustion

air grills.

Burner and Fuel

These appliances will be fitted with either a Force Induced Natural Gas Burner or

Pressure Jet Oil Burner.

Burner Type

BMM Heaters Ltd use two main manufacturers; Reillo or Weishaupt, which are

available for on/off, high/low or fully modulating appliances.

Oil Burners are available for on/off or high/low control.

4

Section 2: Heater Safety

The Installation of this appliance must be done by a registered installer/contractor

suitably qualified in the installation and service of gas fired heating equipment.

WARNING!

Improper installation, adjustment, alteration, service or maintenance can

result in death, injury or property damage. Read the installation, operation

and service manual thoroughly before installing or servicing this appliance.

Note:

To Installer: Please take the time to read and understand theses instructions prior

to any work servicing or installing this appliance.

Installers must leave a copy of this manual with the end user/owner.

To Owner: This manual must be kept in a safe place in order to provide necessary

information for service engineers at a later date.

Section 3: Installers Responsibilities

♦ To install the heater, as well as the gas and electrical supplies, in

accordance with applicable specifications and codes. BMM Heaters

recommends the installer contact a local Building Inspector, Fire Officer or

Insurance Company for guidance.

♦ To use the information given in the manual together with the local and

national codes to perform the installation.

♦ To install the heater in accordance with the Clearances to Combustibles of

this heater.

♦ To plan for the installation of supports, flues and air intakes.

♦ To provide access to burners for servicing.

♦ To provide the owner with a copy of this installation, commissioning,

operation and service manual.

♦ To never use heater as support for ladder.

♦ To ensure that there is sufficient ventilation in the area to comply with the

requirements of all relevant local and national codes.

5

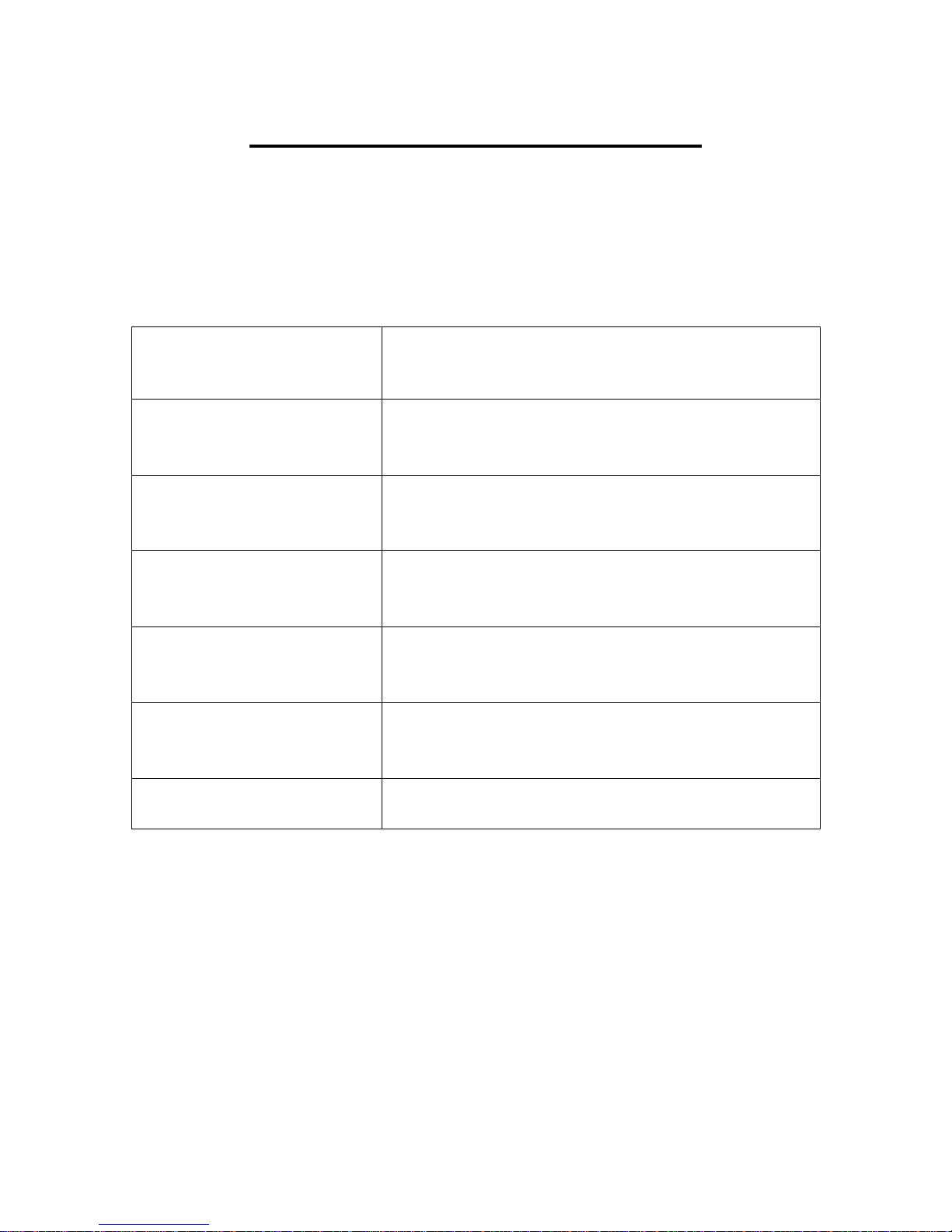

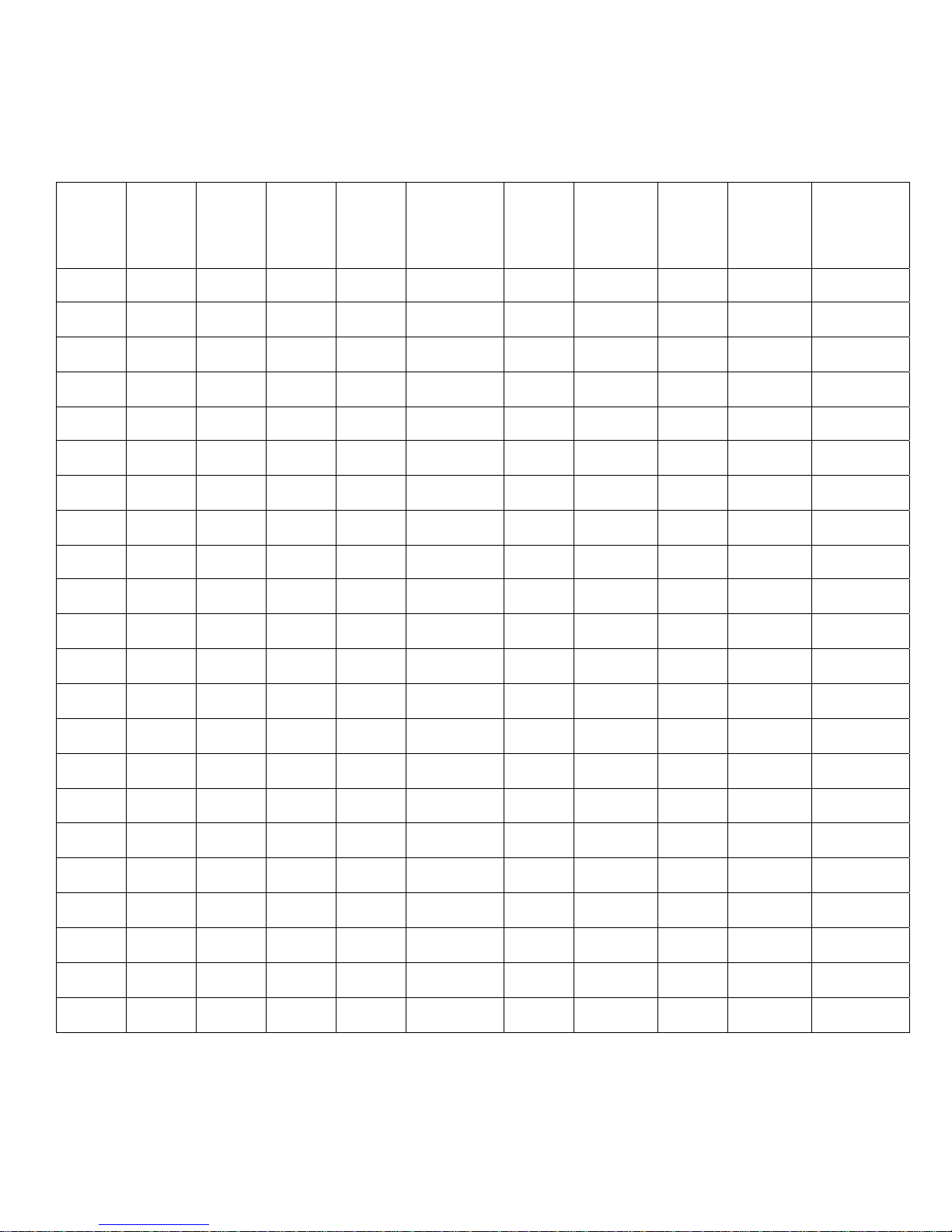

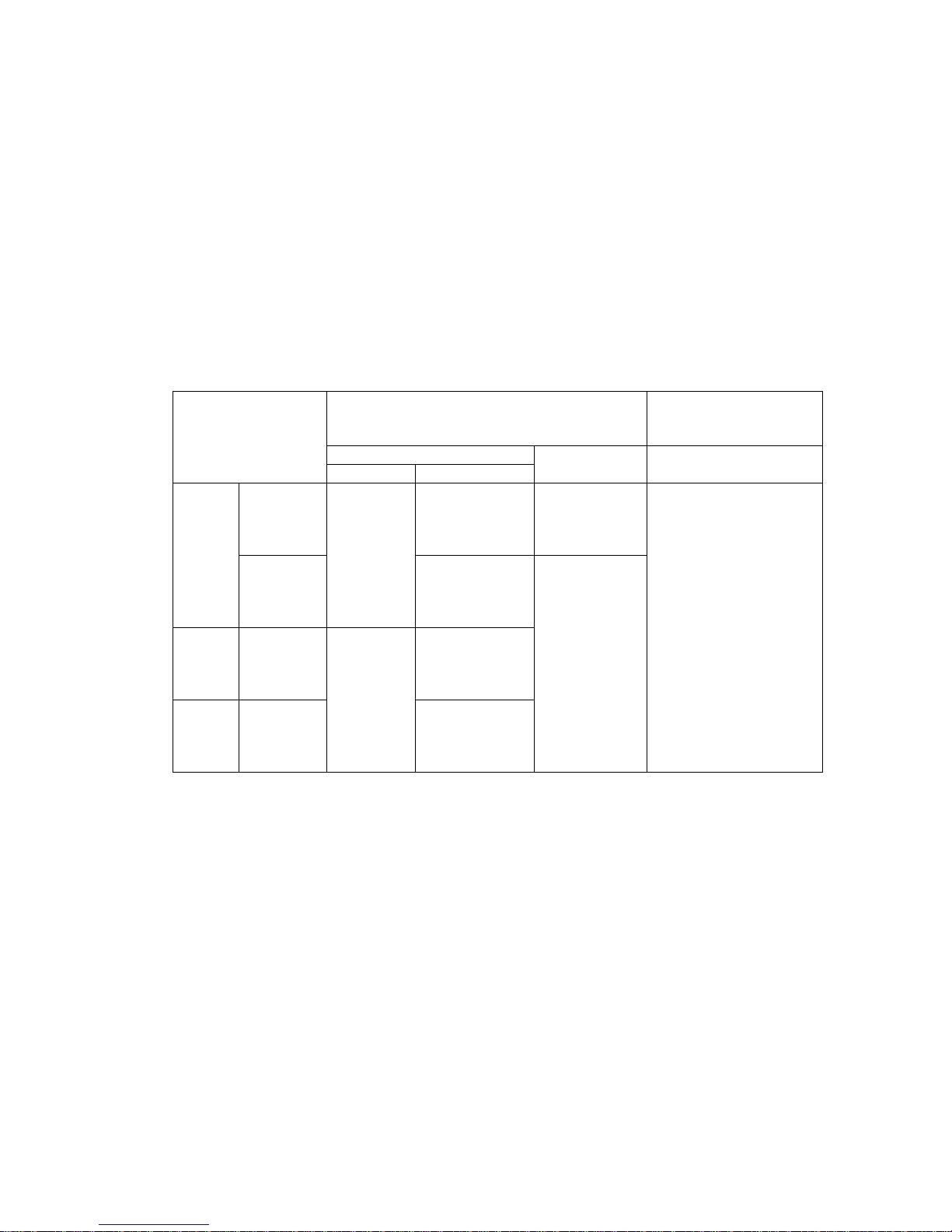

Section 4: General Technical Table 1

Model

12 .37 .75 15 12 0.36 1.5 154 150 75 66

15 .37 .75 19 15 0.432 1.8 154 150 75 66

18 .37 .75 23 18 0.44 2.2 154 150 75 66

23 .47 .75 30 23 0.7 2.9 154 150 75 66

30 .75 .75 38 30 0.94 3.9 154 150 75 66

44 .82 1.55 57 44 1.08 5.4 154 150 207 192

59 1.13 1.55 75 59 1.75 7.3 154 150 207 192

88 1.55 1.55 113 88 2.62 10.9 154 150 207 192

117 2.11 2.58 150 117 3.48 14.5 204 200 246 228

Min

Air

flow

m³/sec

Max

Air

flow

m³/sec

Heat

Input

kW

Heat

Output

kW

Max Start

Gas Rate

m³/hr

Gas

Flow

Rate

m³/hr

Flue

Spigot

Nominal

Ø mm

Flue

Size

Ø mm

Weights

External

Heater

Kg

Weights

Internal

Heater

Kg

147 2.58 2.58 188 147 4.18 17.4 204 200 246 228

176 3.19 5.17 225 176 5.23 21.8 204 200 420 384

205 3.75 5.17 263 205 6.1 25.4 254 250 420 384

235 4.23 5.17 300 235 6.98 29.1 254 250 420 384

264 4.75 5.17 338 264 7.85 32.7 254 250 420 384

293 5.17 5.17 376 293 8.71 36.3 254 250 420 384

352 6.23 6.23 451 352 10.32 43 304 300 1704 1364

440 8.46 10.34 537 440 13.08 54.5 304 300 1704 1364

513 9.40 10.34 658 513 15.24 63.5 304 300 1704 1364

586 10.34 10.34 752 586 17.42 72.6 354 350 1704 1364

733 13 16.53 939 733 19.34 80.6 406 400 2304 2160

880 15.35 16.53 1127 880 26.14 108.9 406 400 2304 2160

952 16.53 16.53 1221 952 28.32 118 406 400 2304 2160

Each appliance has been range rated; burner pressures can be found on the data

plate and the burner pressure once commissioned must be entered in the actual.

6

Section 5: Heater Installation

Before installation, check that the local distribution conditions, nature of gas

pressure and adjustment of the appliance are compatible.

The air heater must be installed in accordance with the rules in force and the

relevant requirements of any fire regulations or insurance company’s requirements

appertaining to the area in which the heater is located, particularly where special

risks are involved, such as areas where petrol vehicles are housed, where cellulose

spraying is carried out, in wood working departments etc.

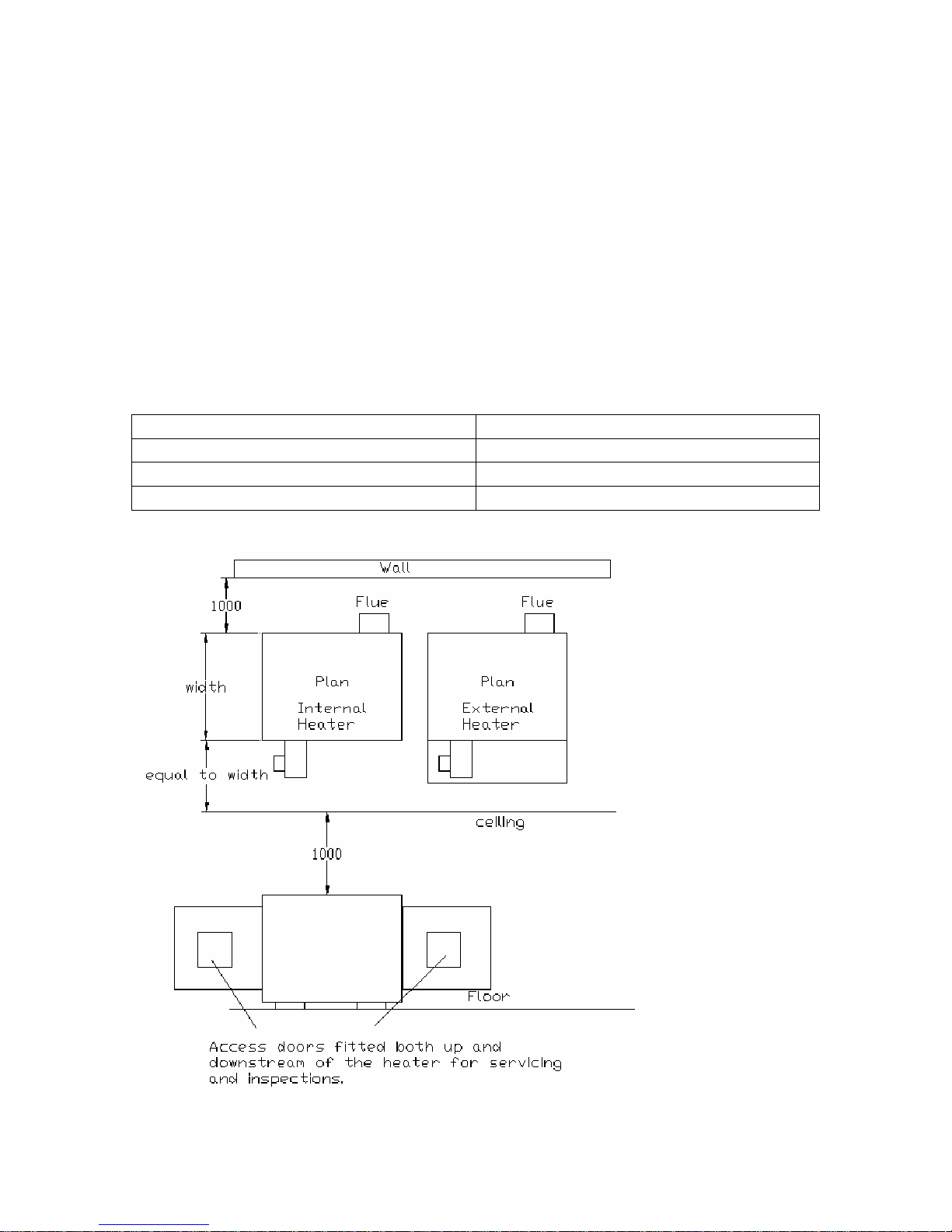

Clearances and Positioning:

The following clearances for installation and servicing must be observed.

To the front Equal to the depth of the heater.

To the rear 1.0m

To at least one side 1.0m

Above the heater 1.0m

Clearances fig.1

7

Clearances

A minimum of 500mm upstream and downstream must be allowed for, due to the

radiant heat. Filters must be fireproof, if fitted and a motor shield is required over

the main supply fan motor if directly in front of the heater.

When installing the heater, minimum clearance is required around the heater.

If the heater is to be fitted at a height, then the structure of the gantry must be

capable of the heaters weight (which can be found in section 4, table 1), also a safe

working platform and access must be allowed for; to enable easy and safe working

access.

Note: The front of the heater is the side on which the burner is fastened.

When designing a system, allowance must be made so equipment can be serviced

after installation and for the fitting of any spares, which may be required. The

BMG is designed to be installed within an Air Handling Unit or ductwork.

The appliance is designed to work in a maximum ambient temperature of 40°c.

The Air Heaters are mounted direct on the floor and do not need any fixing. The

base on which the heater is positioned should not be less than 150mm (6 inches)

thick and must be constructed of non-combustible material.

Any combustible material adjacent to the heater and the flue system must be

placed or shielded as to ensure that its temperature does not exceed 65ºC.

WARNING!

No air heater shall be installed where there is a foreseeable risk of flammable

particles, gases, vapours or corrosion inducing gases or vapours being drawn

into either the heated air stream or the air for combustion. In such cases

installation may only proceed if the air to be heated and the air for

combustion are ducted to the heater from an uncontaminated source,

preferably outside the building.

If this heater is to be suspended then weight in table 1 in section 4 must be taken

into account.

8

Section 6: Air Supply

Ductwork

All delivery and return air ducts, including air filters, jointing and any insulation

or lining must be constructed entirely of materials, which will not contribute to a

fire, are of adequate strength and dimensionally stable for the maximum internal

and external temperatures to which they are to be exposed during commissioning

and normal operation. In the selection of materials, account must be taken of the

working environment and the air temperatures which will result when the overheat

limit thermostat is being commissioned. Where inter-joint spaces are used as duct

routes, they should be suitably lined with fire-resisting material.

A full and unobstructed return air path to the air heater must be provided.

If the air heater is to be installed in a plant room, the return air and warm air

discharge arrangements must be such as to avoid interference with the operation of

the flue by the air circulation fan. The return air intake and the warm air outlet(s)

should therefore be fully ducted, in the plant room, to and from the heater,

respectively. The openings in the structure of the plant room through which the

ducting passes must be fire stopped.

In addition, where there is a risk of combustible material being placed close to the

warm air outlets, suitable barrier rails should be provided to prevent any

combustible material being within 900mm (3 ft) of the outlets.

Air flow

It is essential that the correct amount of air is provided through the heater and

should be evenly distributed when entering the heater. All pressure

calculations/resistances for air are ambient with the Heater in the ‘off’ position.

Adjustable by pass plates

BMG models fitted into larger cabinets for internal or external use should be fitted

with adjustable air balancing plates or a simple restriction damper. If the work is

not going to be carried out by BMM Heaters Ltd then we recommend that the

installer ensures that it can be altered to give guaranteed minimum equal air over

the combustion chamber/heat exchanger (see minimum and maximum air flow

volumes in section 4 table 1).

9

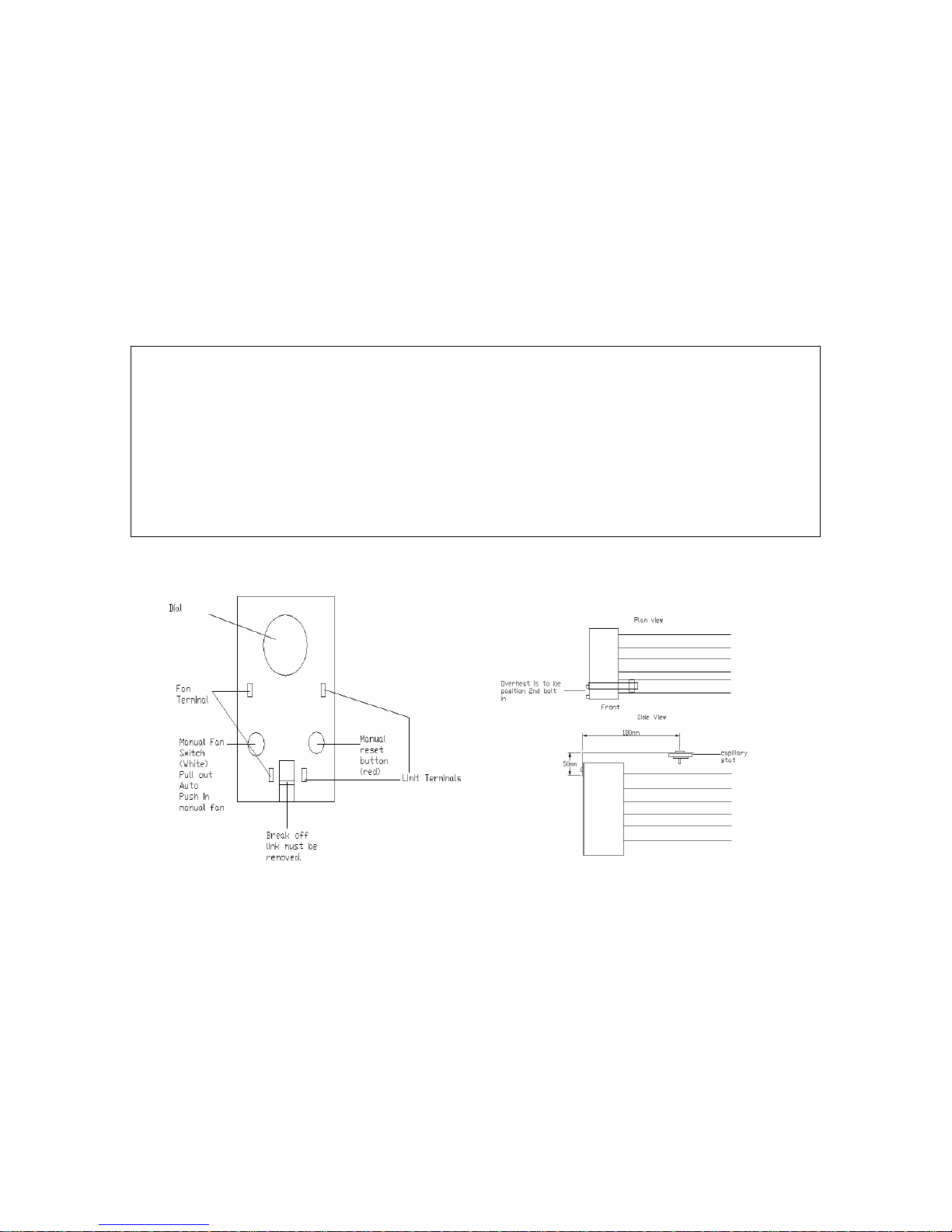

Section 7: Overheat Protection Device

Overheat protection is fitted in case the air flow falls below the minimum

necessary for safe operation of the heater, which may be caused by failure of the

supply fan motor or belt failure, dirty filters or inlet damper failure. If the air flow

falls too low, the high limit will trip out and will require manually resetting. If this

happens on a regular basis it must be investigated by a competent registered

engineer as this could cause serious damage to the heater.

WARNING!

If the heater has a Honeywell combined thermostat installed then the jumper

link must be removed from the replacement thermostat.

Heat exchanger damage may be the result.

Failure to follow these instructions can result in death, injury, property

damage or product damage.

Honeywell overheat stat Fig 2 Overheat Position Fig 3

Ensure that the fan and limit settings are as follows:Fan On 35ºc

Fan Off 25 ºc

Limit 20 ºc above normal running temperature no greater than 100 ºc

10

Section 8: Flue System

The flue system must be made to the following specifications:

a) Mechanically robust.

b) Resistant to internal and external corrosion.

c) Non-combustible and durable under the conditions to which they are to be

subjected.

d) Stainless steel flue is recommended.

Design

When designing a flue system for the appliance the designer must take into

account the following points.

a) The flue gases exiting the appliance can be as great as 350 ºc and as low as

70 ºc on modulating burners.

b) Prevention of condensation within the flue and the management of drainage

from the flue; for example the use of twin wall flue will minimise the

condensation.

c) Flue must be a type acceptable to current standards.

d) Facilities should be made for the disconnection of the flue from the heater

to aid servicing and inspection.

e) This appliance does not require a draught diverter.

f) BMM Heaters recommend that a 90º Tee condensate piece is connected

directly onto the heater spigot, from this point the flue must then rise

vertically with no horizontal runs of flue pipe or 90º bends. If there is an

unavoidable obstruction then the use of 45º bends will be permitted.

(Please contact BMM Heaters if more that two 45º bends are used).

g) The flue should terminate in a freely exposed position and must be situated

as to prevent the products of combustion entering the building via any

opening.

h) A Flue terminal must be fitted.

i) The flue installation must be designed to the latest gas regulations and any

local environmental standards.

j) Where a flue passes through a combustible roof, ceiling or floor, the flue

pipe should be surrounded with a metal sleeve, the size of which should be

sufficient to provide a space not less than 25mm between the flue pipe and

the sleeve when positioned.

Note! Flue connection sizes can be found in section 4 table 1

11

Minimum and maximum flue heights

Internal: 600mm above the apex is the minimum height above the building if

within 1.5 metres of the surface, see drawings Figure 1 & 2.

Maximum height is no more than 25 metres, if this exceeded please

consult BMM Heaters or consideration should be given for a fan

assisted flue.

External: Minimum flue height is 1 metre above appliance roof.

Maximum height is no more than 25 metres, if this exceeded please

consult BMM Heaters or consideration should be given for a fan

assisted flue.

Flue terminal

A flue terminal (must be approved) needs to provide an extraction effect under

virtually all wind conditions, the free area of outlet openings should be at least

twice the nominal area of the flue. Outlet openings should be provided preferably

all round, or at least on opposite sides.

It is important for the terminal of an individual open flue system to be located so

that it is not likely to be subjected to wind pressures which could restrict or reverse

the flow of combustion products through the flue.

The ideal position is above the highest point on the roof. It is absolutely essential

that the terminal is positioned outside the building so that it is freely exposed to

any wind and is not shielded by any roof structure or object to such a degree that

they create undesirable pressure regions around the terminal.

12

Preferred positions are:

- At or above the ridge of a pitched roof by means of a roof terminal.

- Above the intersection with a pitched roof.

The pitch or angle of the roof will determine the required flue height from the base

of the terminal. See Table 2 below:

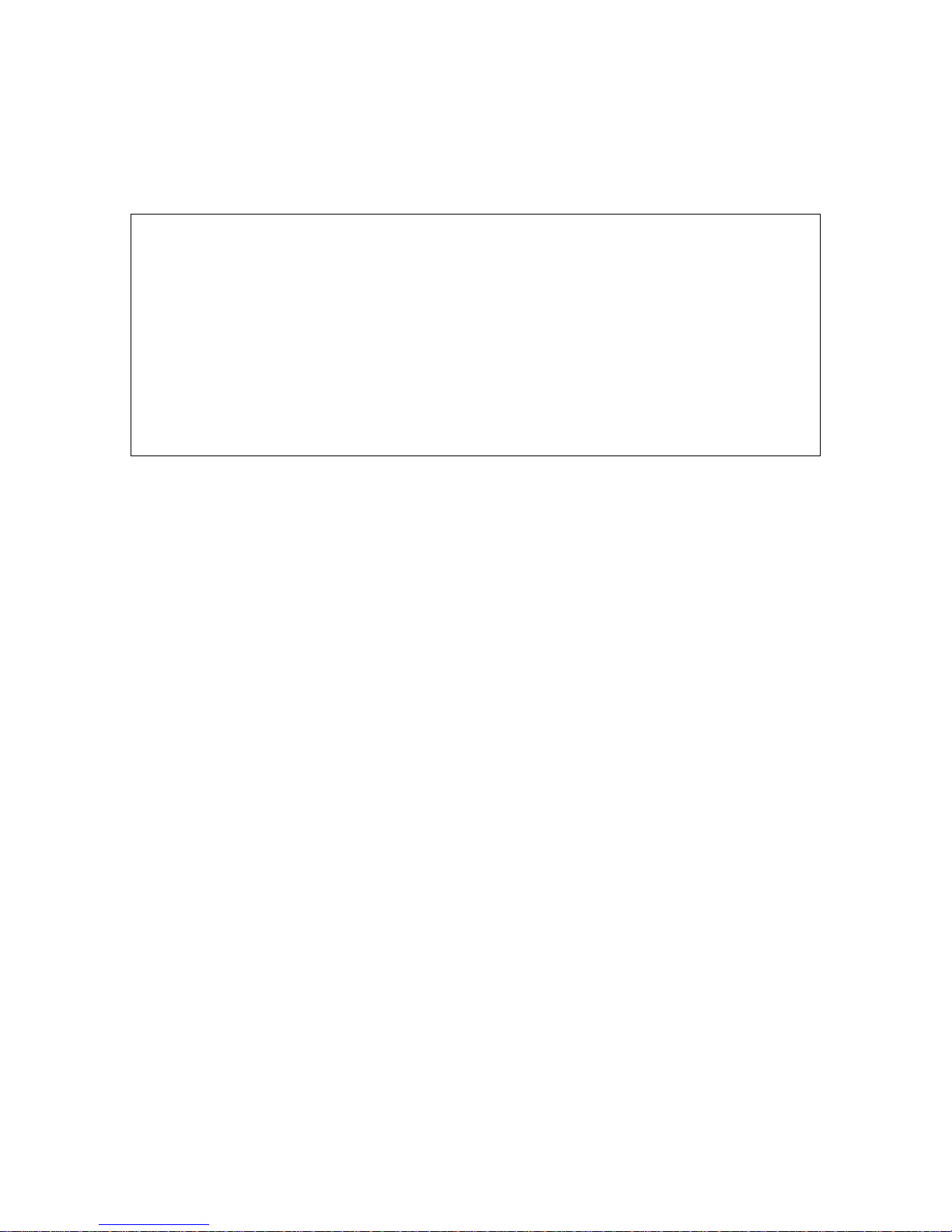

Table 2

RECOMMENDED LOCATIONS OF ROOF TERMINALS:

Location not within 1.5m of a vertical surface*

Type of roof

on the roof

Internal route

Pitch

Pitched

exceeding

45°

Flat With

Without

Pitch not

exceeding

45°

parapet

parapet

On ridge Not on ridge

At or

above roof

level (see

figure 4)

Not

applicable

1m above flue/

roof

intersection (see

figure 3)

600mm above

flue/roof

intersection (see

figure 4)

600mm above

flue roof

intersection (see

figure 6)+

250mm above

flue/roof

intersection (see

figure 10)

External route Internal route

See figure 3

The base of the

terminal to be

600mm above

the level of the

adjacent roof

edge (see

figures 1, 6

and 10)

Location within 1.5m of

a vertical surface* of a

structure on the roof

External route

The base of the terminal

to be 600mm above the

level of the top of the

structure (see figures 2,

5, 9 and 11)

*For example: a chimney stack dormer window; tank room; lift motor room;

parapet, etc.

+When the flue outlet is at a horizontal distance greater than 10 times the

height of the parapet or structure, the terminal outlet height need be only

250mm above the roof.

13

Loading...

Loading...